Centrifugal compressor

A centrifugal compressor and impeller technology, applied in mechanical equipment, non-variable pumps, machines/engines, etc., can solve the problem that the compression process cannot always maintain a saturated state, the compressor inlet and compressor outlet cannot be guaranteed, and the compression performance is safe Poor reliability and other problems, to achieve the effect of convenient oil supply pipeline, high degree of automation, and low compression cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

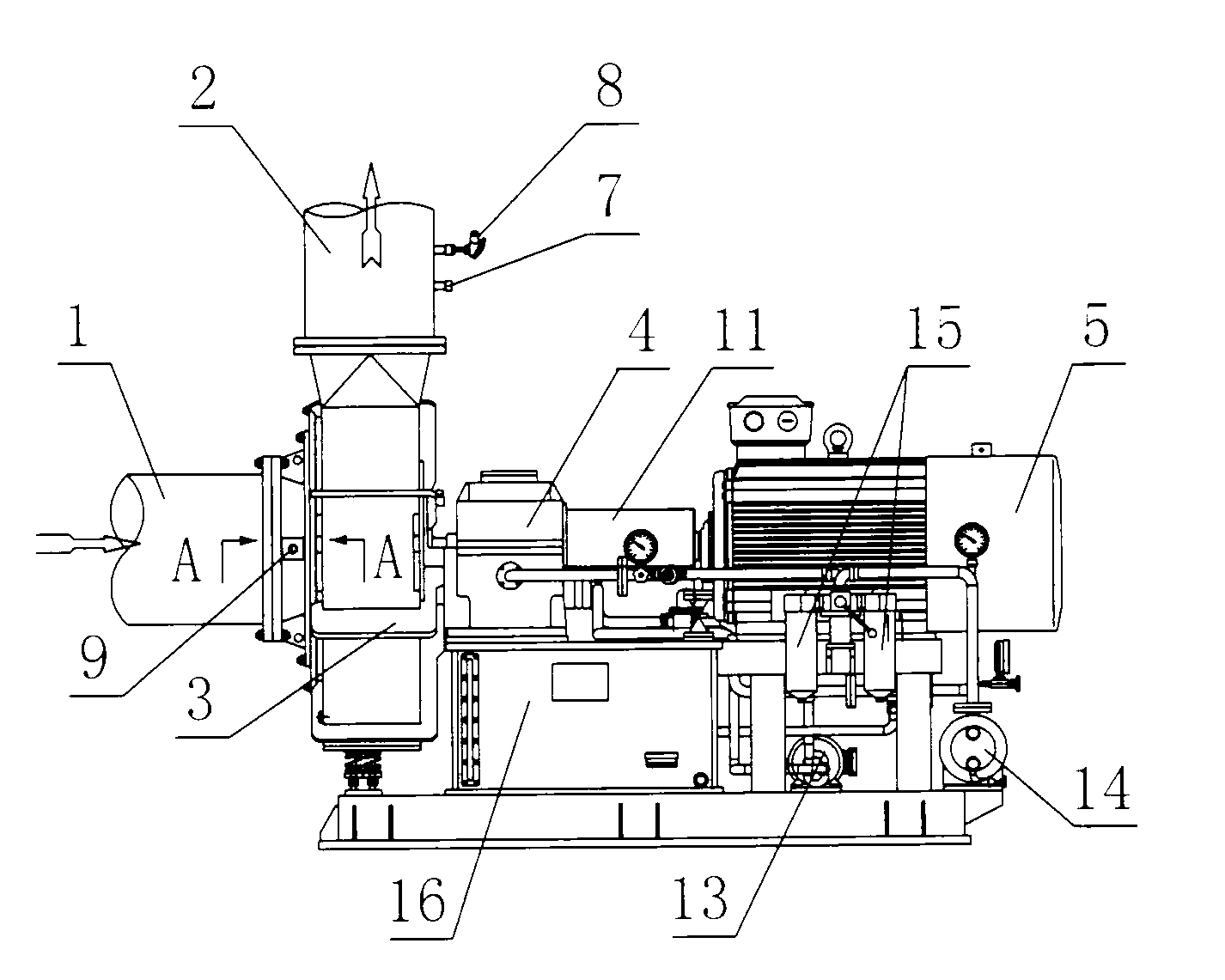

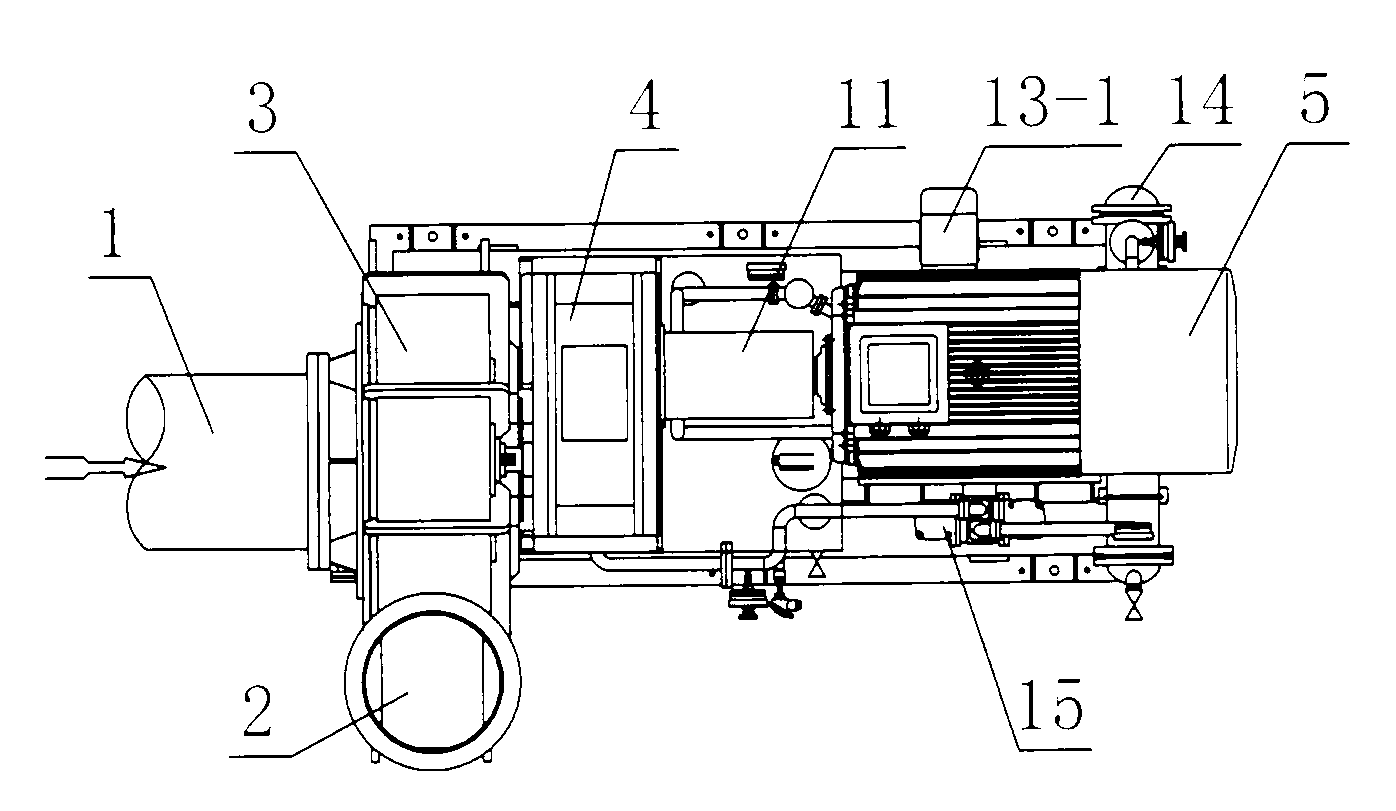

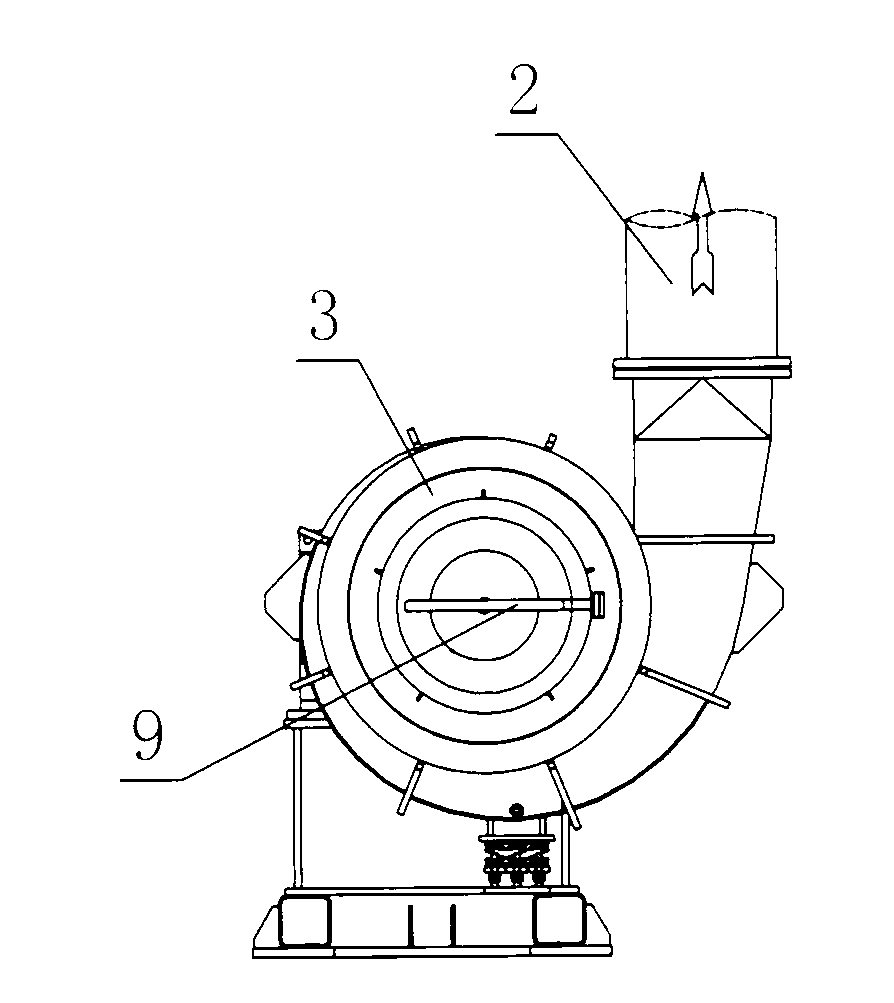

[0033] like Figure 1 ~ Figure 3 as well as Figure 5 As shown, a centrifugal compressor includes a volute 3 connected to the inlet pipe 1 and the outlet pipe 2, and also includes an impeller 10 and a motor 5, and the impeller 10 is placed in the volute 3, as known in the prior art : The motor 5 can be directly connected with the impeller 10, that is, the power output end of the motor 5 is connected with the impeller 10.

[0034] In order to improve the compression efficiency of the compressor, the following technical measures are taken: the water spray pipe 9 containing the shower head 901 is added, the water spray pipe 9 is arranged on the air inlet pipe 1, or the water spray pipe 9 is arranged on the volute 3, and the water spray The nozzle 901 of the pipe 9 faces the inner cavity of the volute 3 , that is, the nozzle 901 faces the impeller 10 .

[0035] In this way, the water spray pipe 9 sprays water into the volute 3 through the spray nozzle 901, so as to ensure that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com