Method for control PH value of nickel powder electrolyte

An electrolyte and nickel powder technology, which is applied in the field of controlling the pH value of nickel powder electrolyte, can solve the problems of worsening working conditions, easy hardening of the cathode, and increased consumption of liquid ammonia, so as to eliminate a large number of bubbles and improve the operating environment. The effect of easy installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

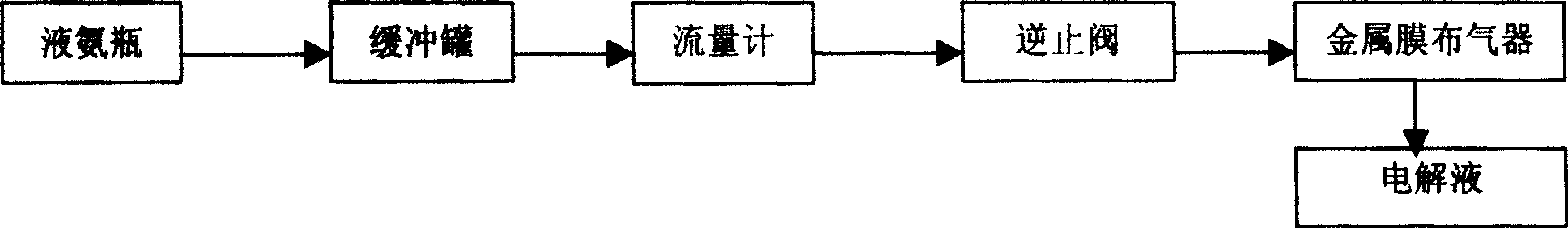

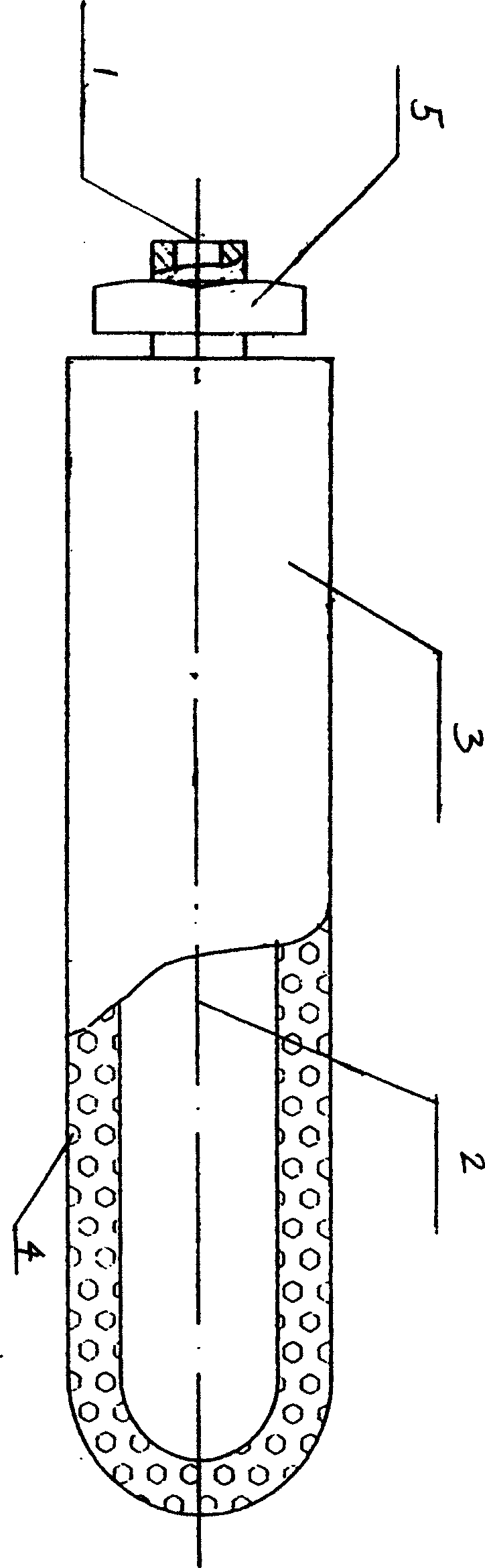

[0011] A method for controlling the pH value of the nickel powder electrolyte, which uses liquid ammonia as a regulator to control the pH value of the electrolyte. Membrane gas distributor and enter the electrolyte to control the pH value. The structure of the metal film air distributor used is a metal film shell with an air inlet 1 at one end, a hollow ammonia cavity 2 , and a shell 3 with metal micropores 4 .

[0012] The specific use and operation are as follows: First, tie up the hose between the check valve and the metal membrane filter to prevent the passage of gas; after connecting the various pipelines, use bottled nitrogen to check for leaks at the joints of the pipelines, valves, etc. ; The specific operation for leak detection is as follows: install a nitrogen pressure reducing valve at the outlet of the nitrogen cylinder, open the nitrogen cylinder valve, slowly open the nitrogen pressure reducing valve, so that the pressure is controlled at 0.2-0.3Mpa, and use soa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com