Electron beam processing system capable of realizing multiple electron beam center wire feeding

An electron beam processing and electron beam technology, applied in the field of electron beam processing systems with multi-electron beam center wire feeding, can solve the problems of economic loss, inability to cut the wire material, unable to accurately control the amount of wire material entering, etc., to prevent leakage , The effect of improving processing efficiency and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

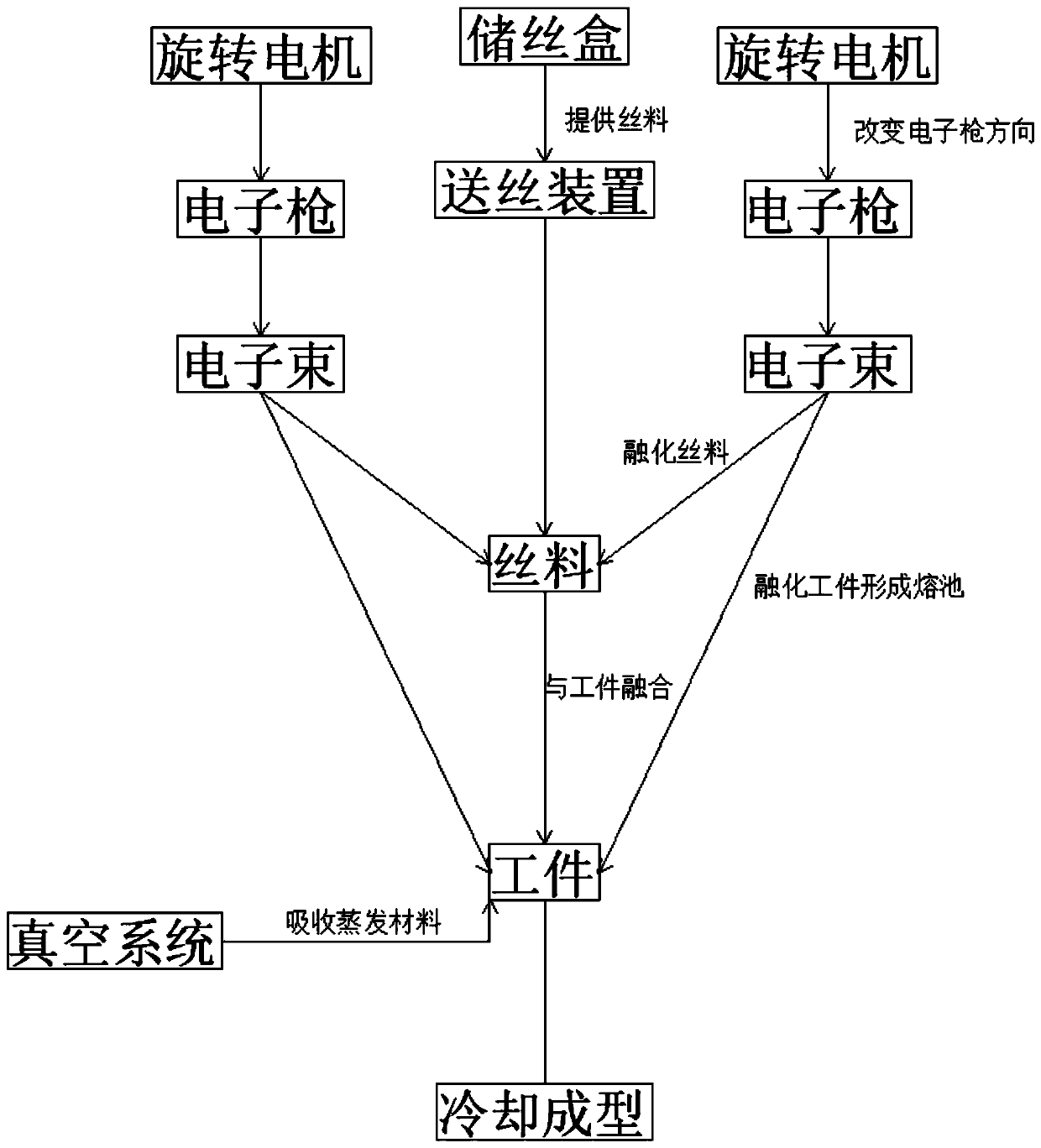

Method used

Image

Examples

Embodiment 1

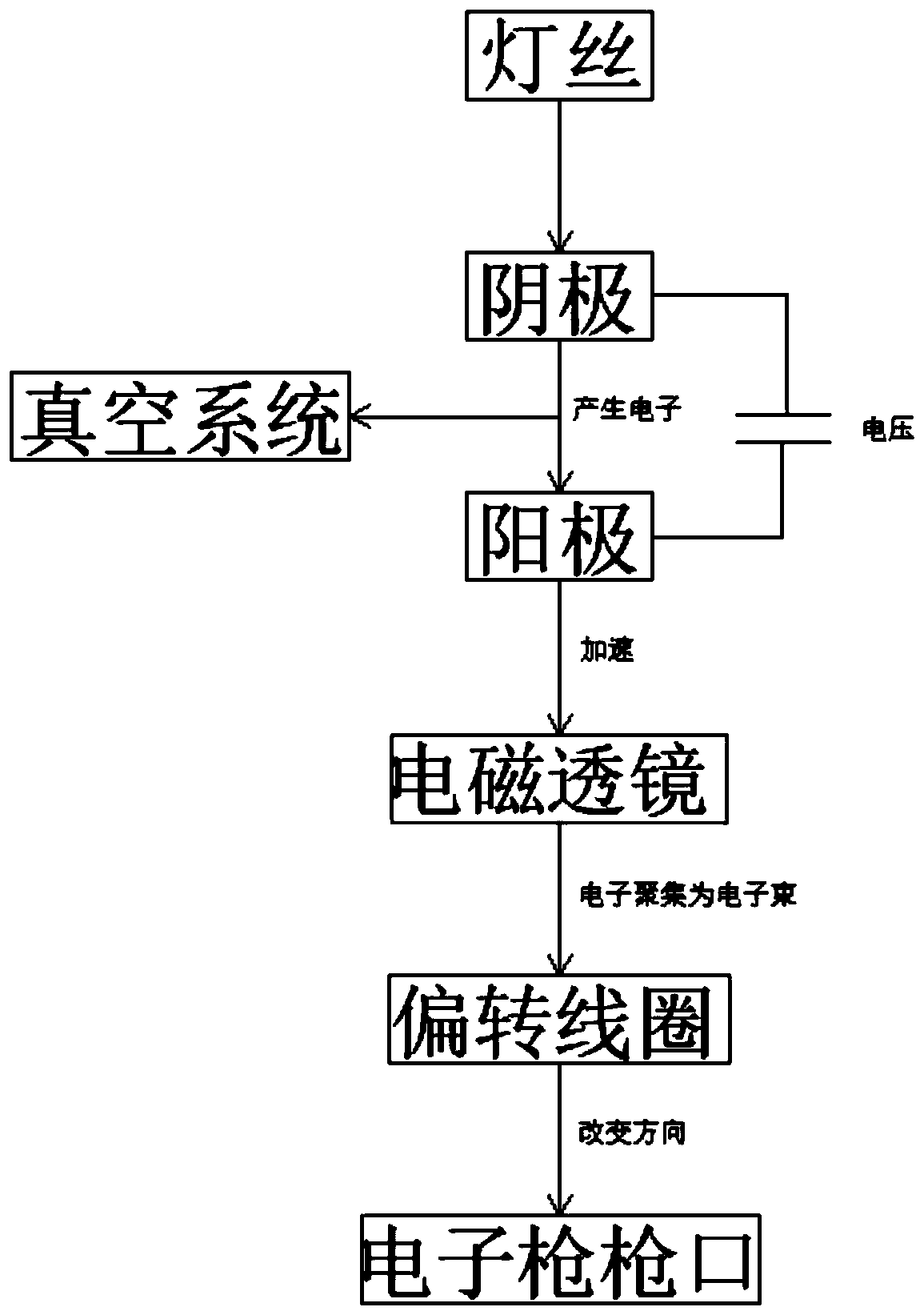

[0039] As a preferred embodiment of the present invention: a filament is provided on the top of the electron gun, a cathode is connected to the bottom end of the filament, an anode is arranged directly below the cathode, and one side of the cathode is connected to the vacuum system set, the An electromagnetic lens is provided directly below the anode, a deflection coil is provided directly below the electromagnetic lens, and the bottom end of the deflection coil is connected to the muzzle of an electron gun;

[0040] After the filament is energized and heated, a large number of thermal electrons are generated on the surface. Under the action of the high-voltage electric field between the anode and the cathode, the thermal electrons accelerate to move toward the anode at a high speed, and enter the battery lens. The axial magnetic field generated by the electromagnetic lens and the electron beam The centerline is parallel, and the radial magnetic field is perpendicular to the ce...

Embodiment 2

[0042] As a preferred embodiment of the present invention: the material of the filament is made of tungsten wire, a high voltage is connected to the outside of the cathode and the anode, and the pressure of the high voltage is 50,000 volts to 150,000 volts. There are two groups of electromagnetic lenses, two groups of deflection coils, and each group of deflection coils is perpendicular to each other;

[0043] By changing the voltage between the cathode and the anode, the moving speed of the electrons can be changed, thereby changing the strength of the electron beam. The deflection coil can change the deflection angle of the electron beam within a certain range, thereby changing the processing position.

Embodiment 3

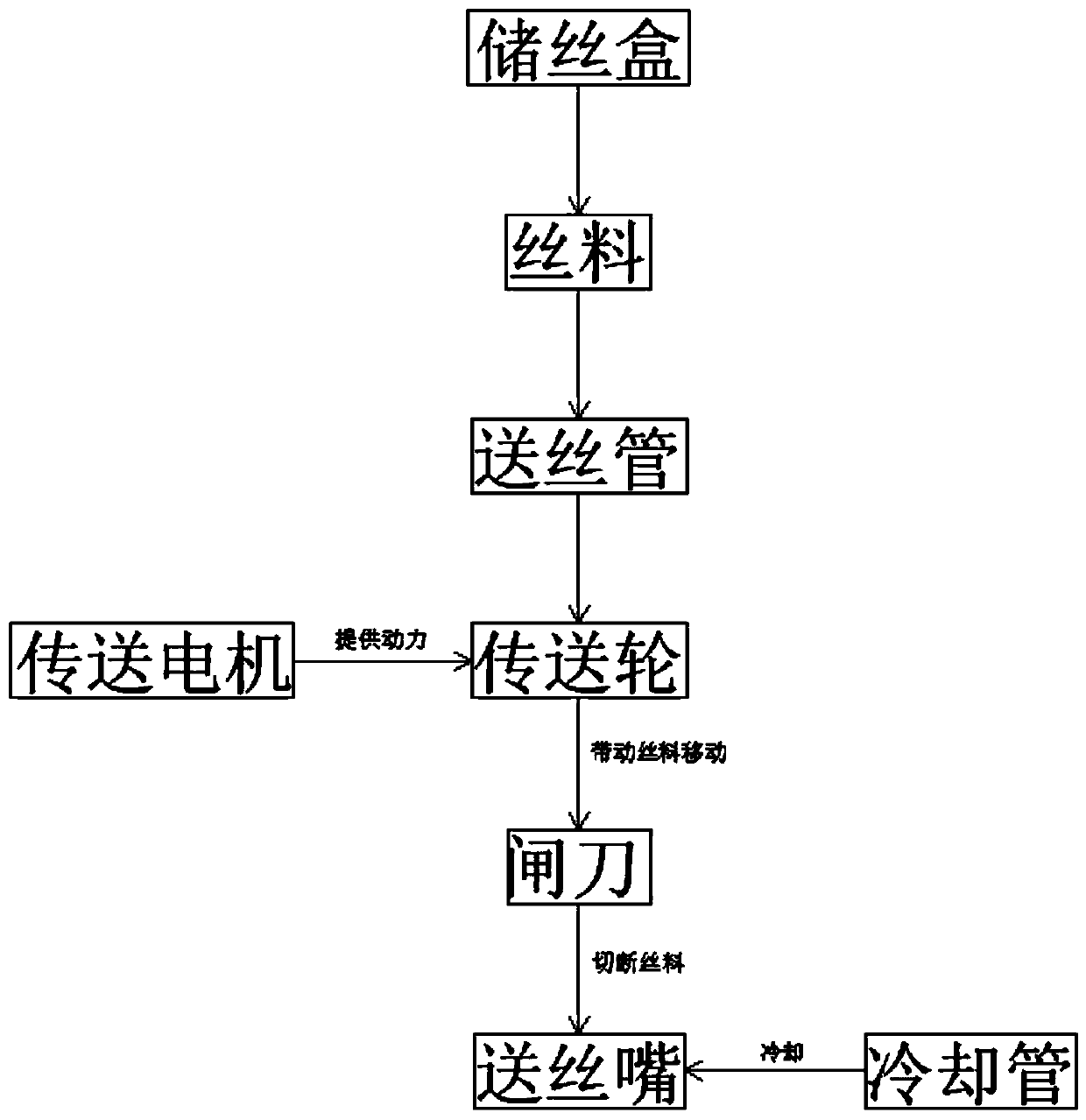

[0045]As a preferred embodiment of the present invention: a wire feeding tube is provided at the top of the feeding device, the wire material enters into the wire feeding tube through the wire storage box, a transmission motor is installed on one side of the wire feeding tube, and the transmission motor runs through the The wire feeding pipe extends to the inside of the wire feeding pipe and is connected with a transmission wheel. The inside of the wire feeding pipe is located directly below the transmission wheel with a knife knife, and the bottom end of the wire feeding pipe is provided with a wire feeding nozzle. The wire feed nozzle is located above the workpiece, and a cooling pipe is arranged on the outside of the wire feed nozzle;

[0046] The transmission wheel can control the movement of the wire, thereby controlling the amount of feed during processing and improving the accuracy of processing. The knife can cut the wire so that the wire will not stick to the product w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com