Rotary pushing type feeding device

A technology of feeding device and pushing mechanism, which is applied in the direction of packaging, conveyors, conveyor objects, etc., can solve problems such as low work efficiency, falling below the conveyor belt, and uneven material quality, so as to improve work efficiency and prevent falling , the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

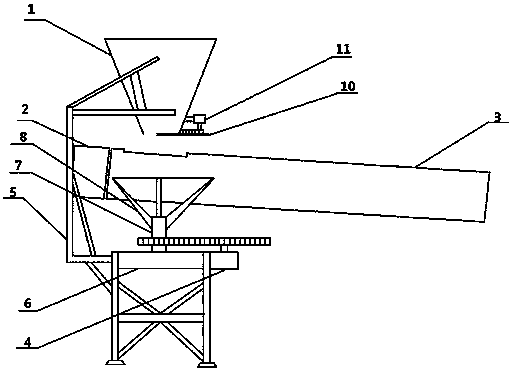

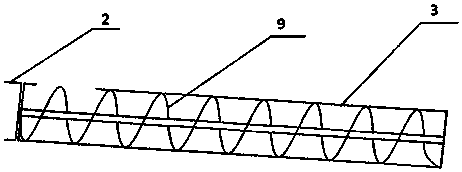

[0020] A kind of rotatable pushing type feeding device, comprises hopper 1, pushing mechanism, transport pipe 3, rotating mechanism, motor and fixed frame 5; Described rotating mechanism comprises rotating motor 4; Described rotating motor 4 is arranged on fixed On the frame 5; the hopper 1 is arranged on the fixed frame 5; the frame is provided with a bearing; the inner ring of the bearing is provided with a rotating shaft 7; the rotating motor 4 and the rotating shaft 7 pass through the gear connection; the transport pipe 3 is arranged on the fixed frame 5; the rotating shaft 7 and the transport pipe 3 are connected through the support rod 8; the push mechanism includes a push motor 2; the push motor 2 is arranged on the transport On the tube 3; the said push motor 2 is provided with a screw push shaft 9.

[0021] A feeding opening is arranged above the transport pipe 3 .

Embodiment 2

[0023] A kind of rotatable pushing type feeding device, comprises hopper 1, pushing mechanism, transport pipe 3, rotating mechanism, motor and fixed frame 5; Described rotating mechanism comprises rotating motor 4; Described rotating motor 4 is arranged on fixed On the frame 5; the hopper 1 is arranged on the fixed frame 5; the frame is provided with a bearing; the inner ring of the bearing is provided with a rotating shaft 7; the rotating motor 4 and the rotating shaft 7 pass through the gear connection; the transport pipe 3 is arranged on the fixed frame 5; the rotating shaft 7 and the transport pipe 3 are connected through the support rod 8; the push mechanism includes a push motor 2; the push motor 2 is arranged on the transport On the tube 3; the said push motor 2 is provided with a screw push shaft 9.

[0024] The transport pipe 3 is placed obliquely.

Embodiment 3

[0026] A kind of rotatable pushing type feeding device, comprises hopper 1, pushing mechanism, transport pipe 3, rotating mechanism, motor and fixed frame 5; Described rotating mechanism comprises rotating motor 4; Described rotating motor 4 is arranged on fixed On the frame 5; the hopper 1 is arranged on the fixed frame 5; the frame is provided with a bearing; the inner ring of the bearing is provided with a rotating shaft 7; the rotating motor 4 and the rotating shaft 7 pass through the gear connection; the transport pipe 3 is arranged on the fixed frame 5; the rotating shaft 7 and the transport pipe 3 are connected through the support rod 8; the push mechanism includes a push motor 2; the push motor 2 is arranged on the transport On the tube 3; the said push motor 2 is provided with a screw push shaft 9.

[0027] A movable baffle 10 is arranged under the hopper 1; a movable motor 11 is arranged on the hopper 1; the movable motor 11 is connected with the movable baffle 10 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com