Multi-head scale full-automatic packaging production line

A technology of fully automatic packaging and fully automatic packaging machine, which is applied in the directions of packaging, transportation and packaging, and types of packaging items, can solve the problems of low efficiency and high labor cost, and achieve the effect of improving production efficiency and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

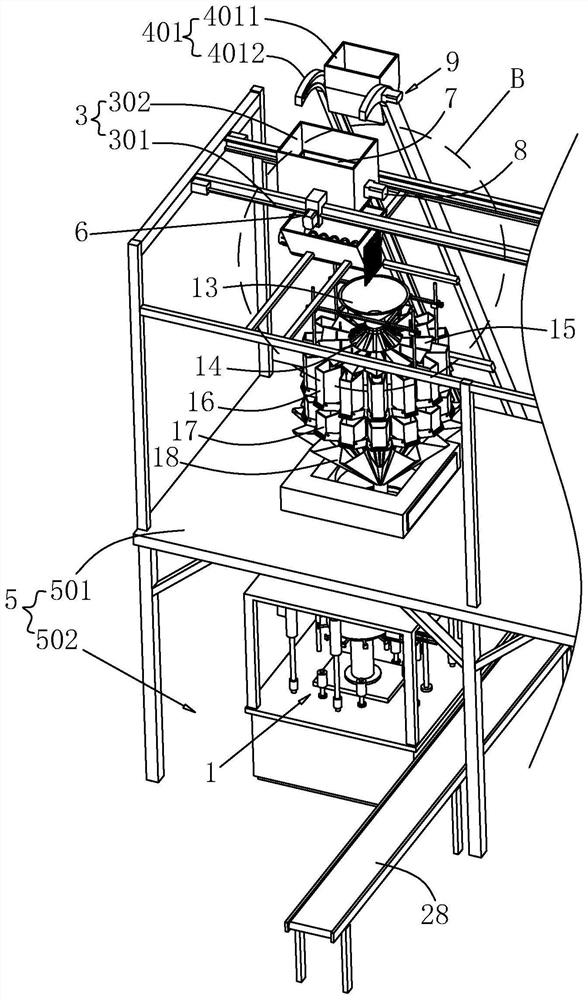

[0040] The following is attached Figure 1-4 The application is described in further detail.

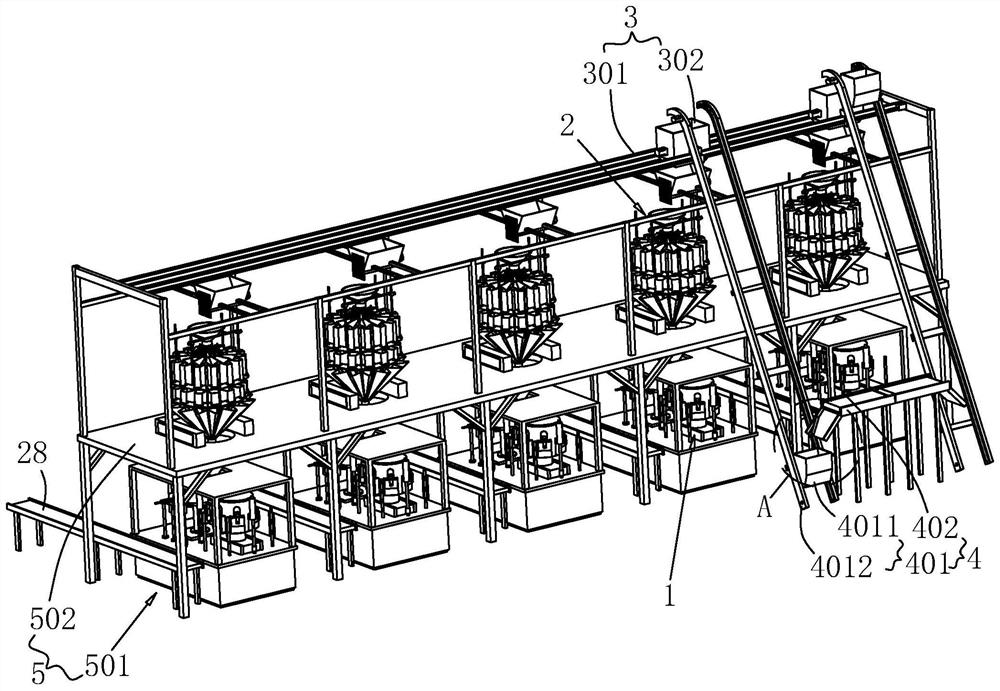

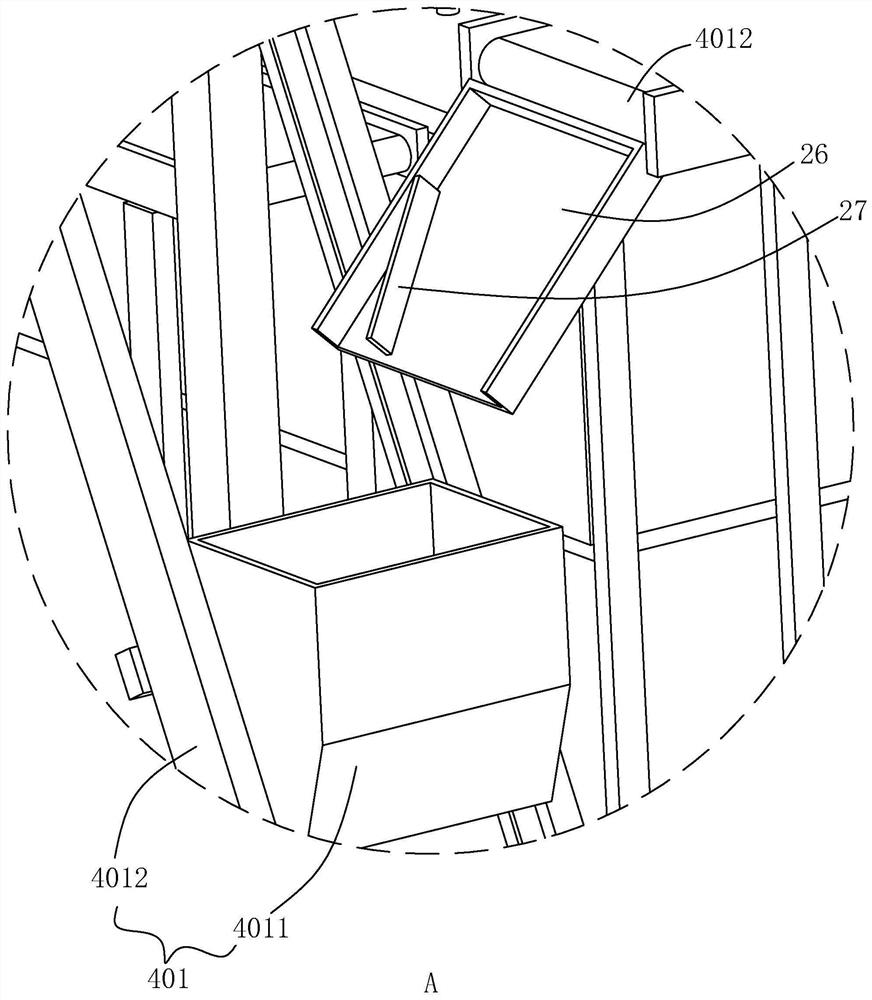

[0041] The embodiment of the application discloses a multi-head weigher fully automatic packaging production line. refer to figure 1 , Multi-head scale 2 automatic packaging production line includes automatic packaging machine 1, multi-head scale 2, material distribution conveying system 3, feeding conveying system 4 and frame 5. The frame 5 includes a first platform 501 and a second platform 502 arranged from bottom to top, and the second platform 502 is welded above the first platform 501 through struts. Five fully automatic packaging machines 1 are installed side by side on the first platform 501 at equidistant intervals along the length direction of the first platform 501. In this embodiment, the fully automatic packaging machines 1 are bag-feeding fully automatic packaging machines 1 for The vermicelli after quantitative weighing is vacuumized and packed. A multi-head scale ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com