Method and device for fast preparing white activated rice hull ash

A technology of rice husk gray and white, applied to the removal of solid waste, silicon dioxide, silicon oxide, etc., can solve the problem that the quality cannot reach high-performance concrete, and avoid excessive heat dissipation, white color, and loss little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

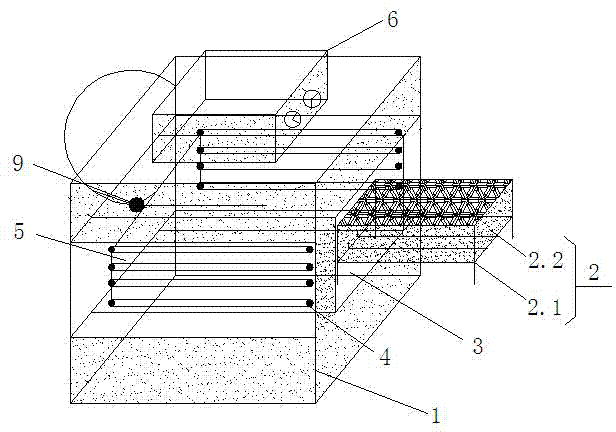

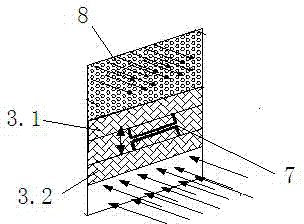

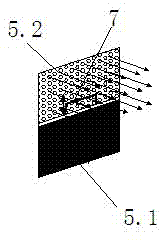

[0034] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

[0035] The method for rapidly manufacturing white active rice husk ash of the present invention, the method is carried out as follows:

[0036] (1) Carry out dilute acid pretreatment (hydrochloric acid, nitric acid) to the rice husk, the mass ratio of water to acid of the pretreatment liquid is 5~15:1, and the pretreatment time is 2~24 hours;

[0037] (2) The rice husk after dilute acid pretreatment needs to be washed with clean water for several times, generally 2 to 3 times, and the impurities in the rice husk are removed;

[0038] (3) Put the cleaned rice husk directly into the incineration basket, and place it in a pre-set 600°C furnace for incineration. Before putting the rice husk into the furnace, open th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com