Gas-liquid-solid separation control valve and portable chemical oxygen producer using the same

A control valve and solid separation technology, which is applied in the direction of valve devices, oxygen-generating respiratory protection devices, life-saving equipment, etc., can solve the problems of inability to carry oxygen cylinders, hidden dangers of safety, inconvenience for users, etc., and achieve light weight and airtightness Good, portable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

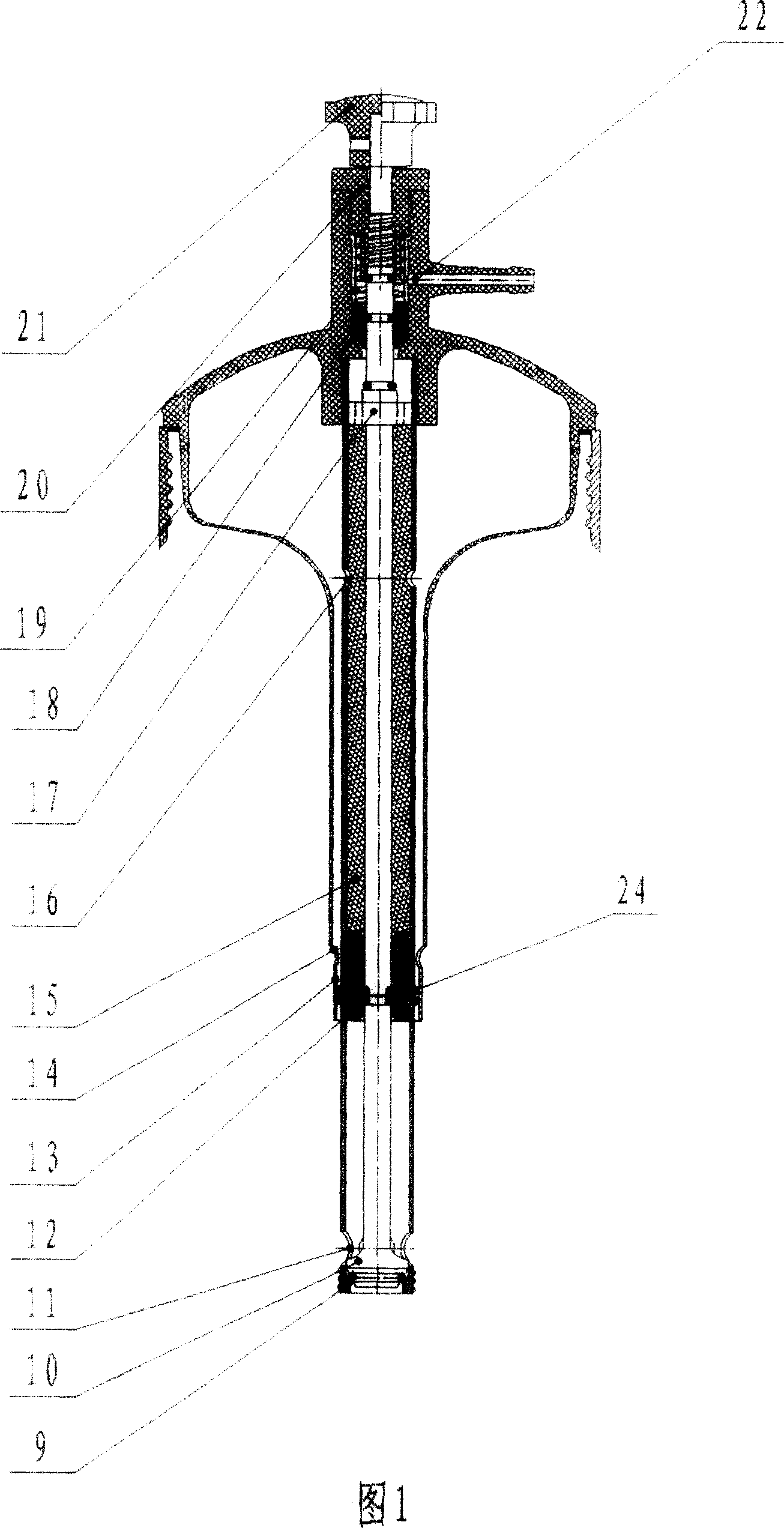

[0014] Embodiment 1, this is an embodiment of the gas-liquid-solid separation control valve involved in the first technical solution of the present invention, and its structural schematic diagram refers to FIG. 1 . As can be seen from Figure 1, the gas, liquid and solid separation control valve is mainly composed of a valve body 3, a valve stem 17, a water valve core 10, a valve core sleeve 9 sleeved on the water valve core, a valve stem guide pipe 13, Located at the lower end of the valve stem guide pipe 13 and the water inlet hole 11 on the wall corresponding to the water valve core, the water vapor isolation sealing sleeve 12, and the air intake hole 14 located on the valve stem guide pipe wall; located on the upper part of the valve stem guide pipe 13 The filter air inlet 16 on the wall, the microporous filter membrane 15 between the valve stem 17 corresponding to the upper part of the filter inlet hole and the valve stem guide pipe 13, and the microporous filter membrane 1...

Embodiment 2

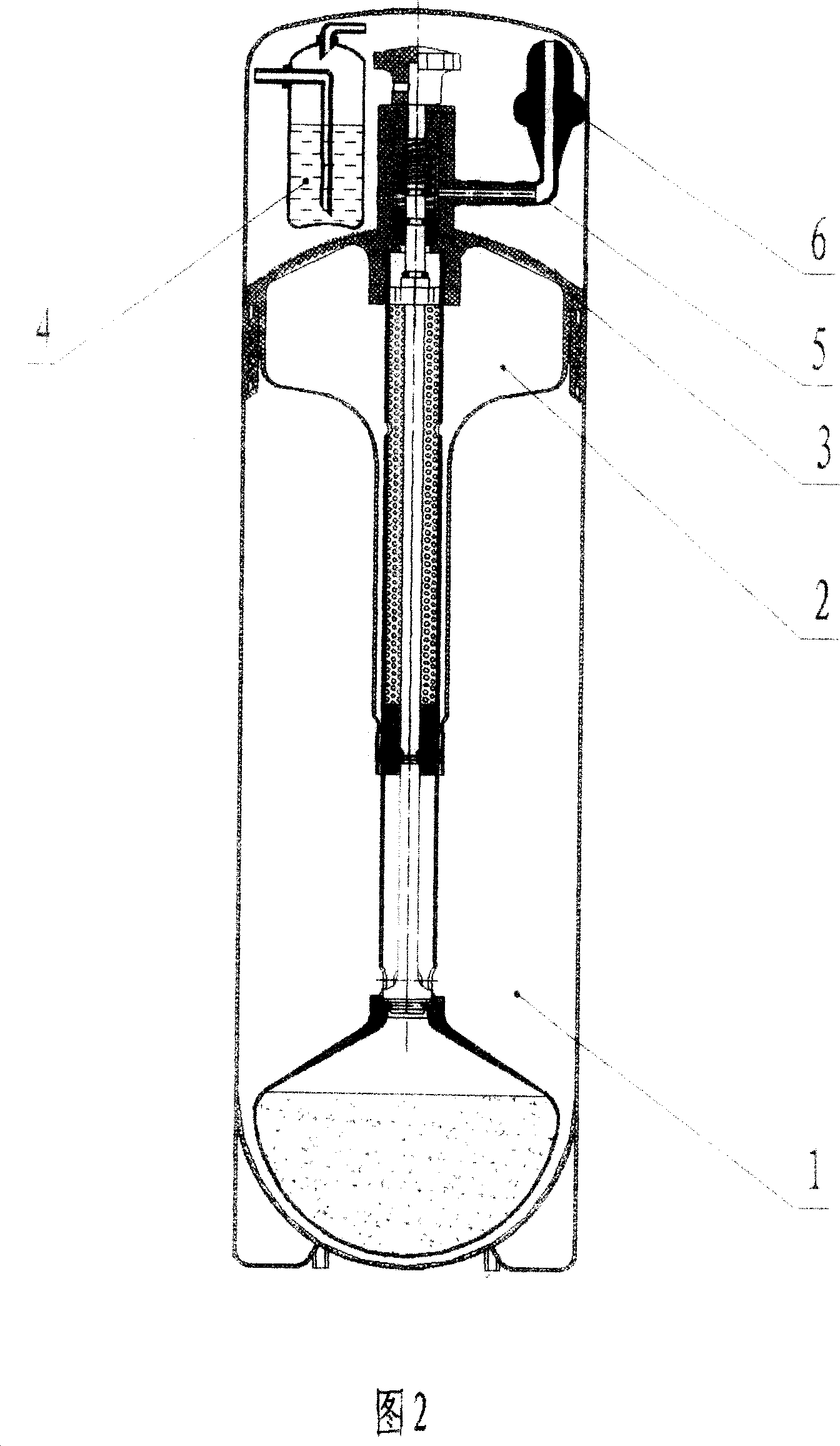

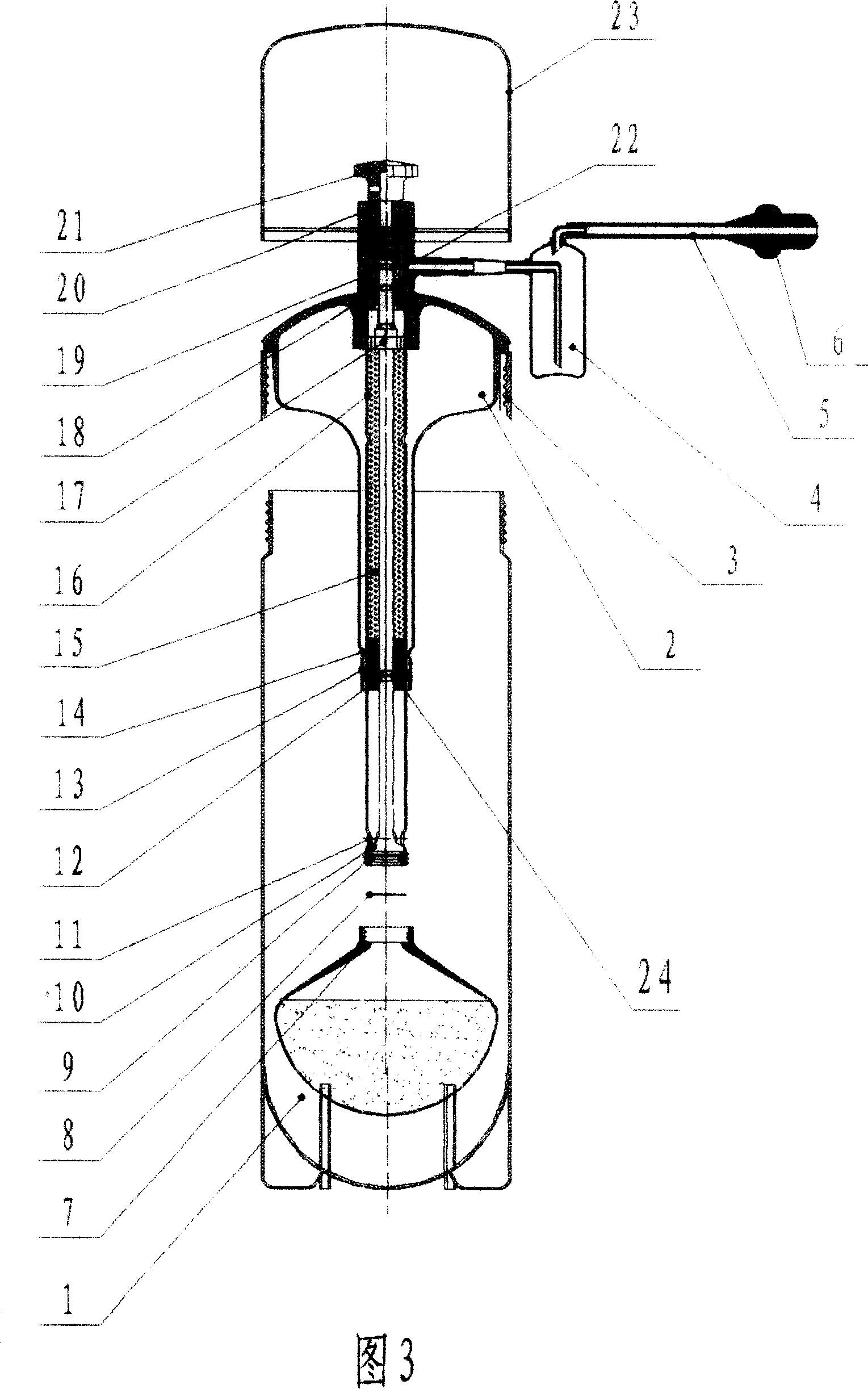

[0017] Embodiment 2, this is an embodiment of the portable chemical oxygen generator described in the second technical solution, refer to Fig. 2 and Fig. 3 . Fig. 2 is a schematic structural diagram of a portable chemical oxygen generator in a non-practical state, and Fig. 3 is a schematic diagram of an exploded structure of a portable chemical oxygen generator. It can be seen from these two drawings that all the oxygen generators are connected by threaded connection. It consists of an oxygen chamber 1, a preparation box 7 fixed therein, a humidification filter 4, an oxygen inhalation catheter 5, an oxygen inhalation nasal plug 6, a cover 23 and a gas, liquid and solid separation control valve. The mouth of the preparation box is connected with the lower end of the valve stem guide pipe of the gas, liquid, and solid separation control valve in a threaded manner, and the upper end of the oxygen generating chamber 1 is fixedly connected with the inner wall of the valve correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com