Automatic loading and unloading device for railway goods traffic

A technology of railway freight transportation and automatic equipment, which is applied in the directions of transportation and packaging, loading/unloading, lifting devices, etc. It can solve the problems of large workload, low efficiency, and affecting the loading efficiency of stations, so as to improve loading efficiency and benefits , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

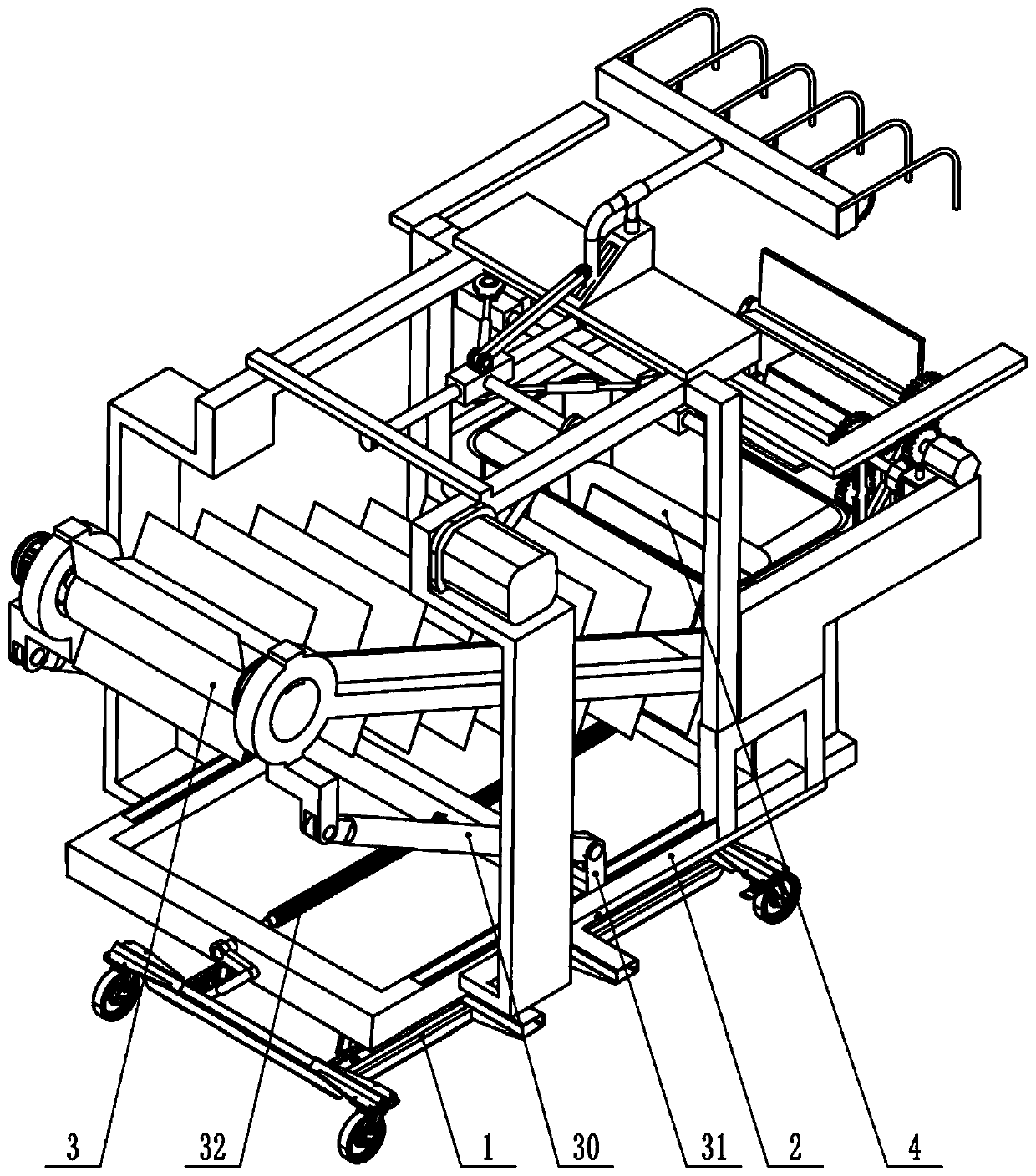

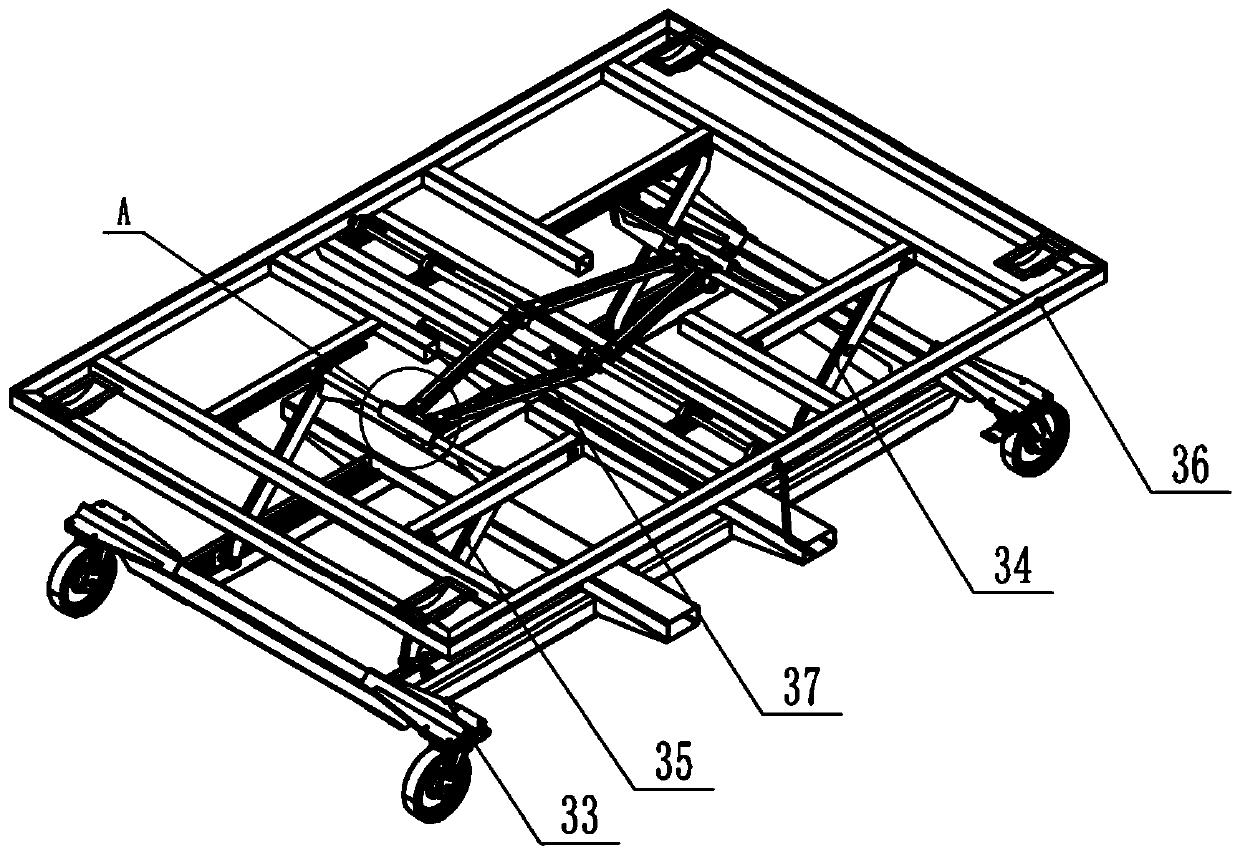

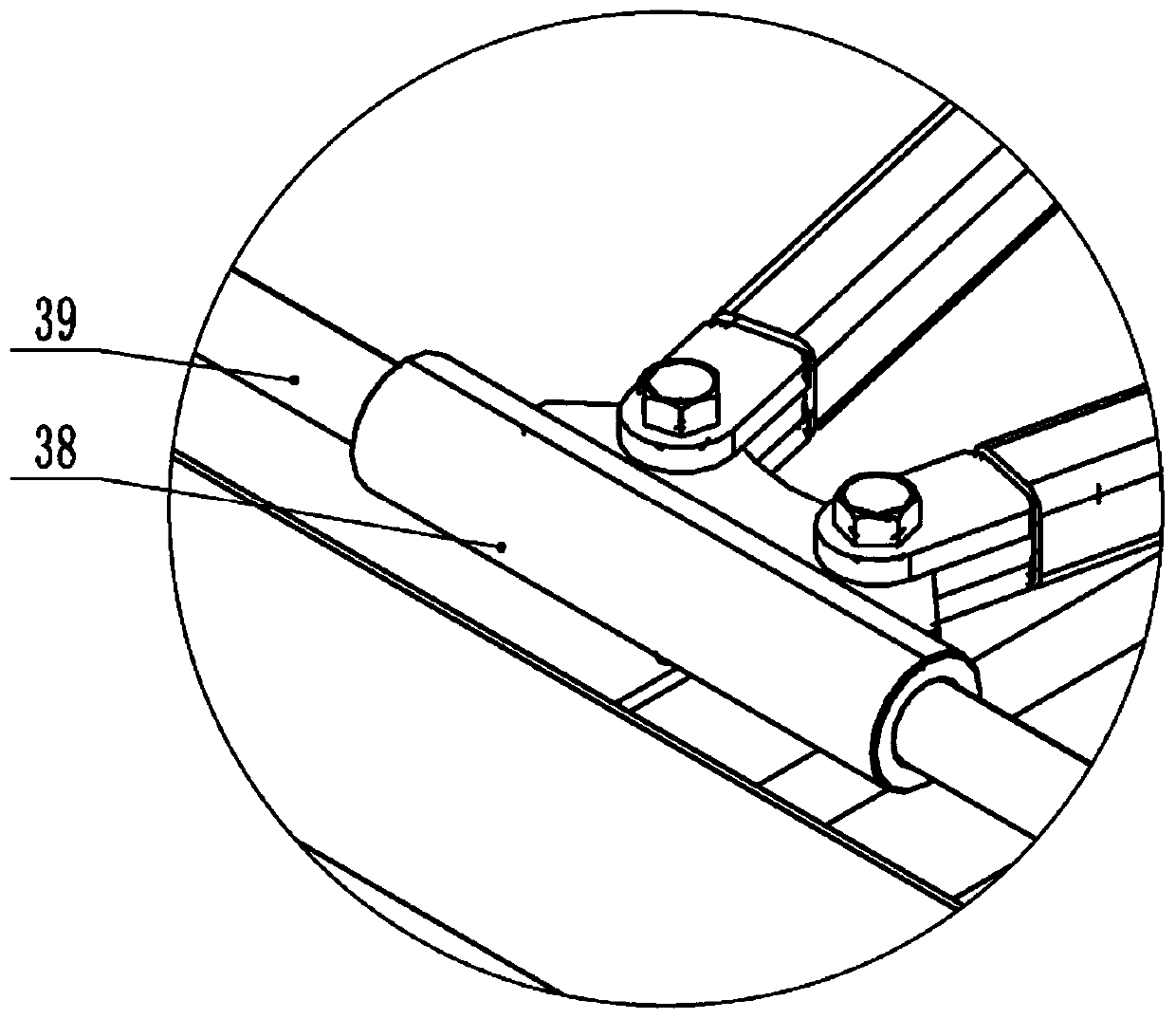

[0024] The present invention is described in further detail now in conjunction with accompanying drawing. The accompanying drawings are simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the components related to the present invention.

[0025] refer to Figure 1-8 As shown, the present invention includes a lifting platform 1, a load-bearing frame 2 is fixedly connected to the lifting platform 1, a conveying device 3 with an adjustable angle is provided on the load-bearing frame 2, and a collecting hopper is arranged above the conveying device 3 4. The collecting hopper 4 is fixed on the front end of the load-bearing frame 2, and the load-bearing frame 2 is provided with a driving block 5 that can slide back and forth horizontally, and the driving block 5 is above the collecting hopper 4, and the driving block 5 The upper hinge is provided with a first adjustment rod 6, a second adjustment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com