A sorting device for logistics transportation in response to emergencies

An emergency, sorting device technology, applied in sorting and other directions, can solve the problems of reduced response capacity, poor sorting effect, low efficiency, etc., to achieve the effect of increasing sorting speed and simplifying work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

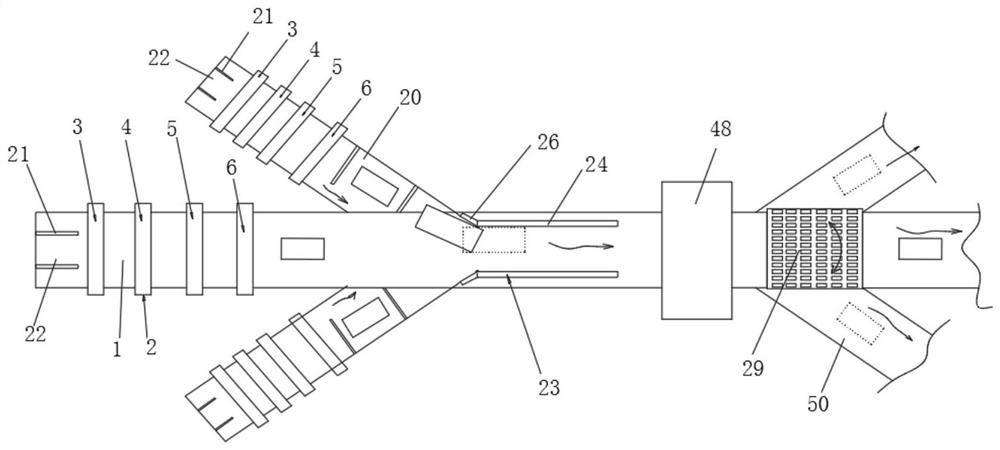

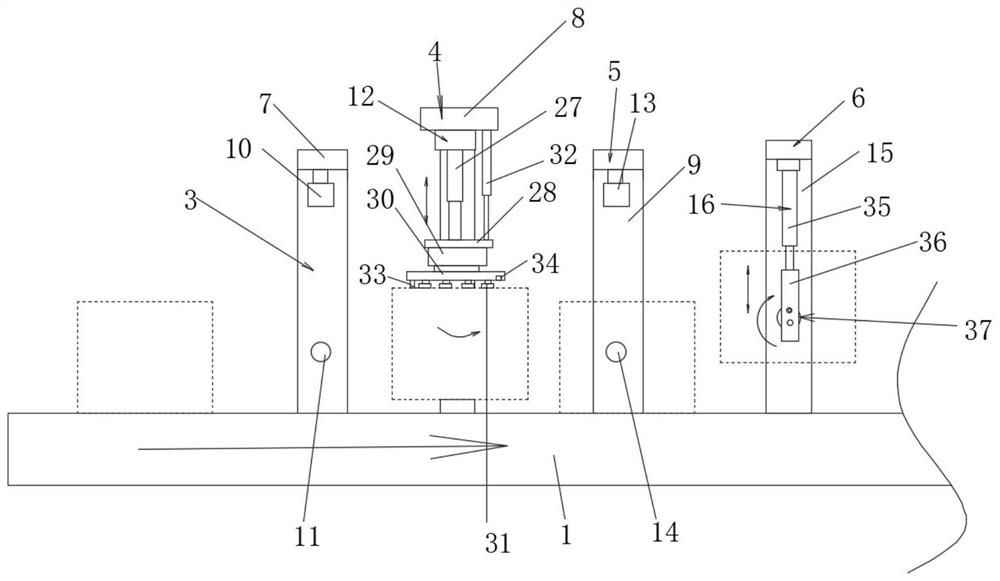

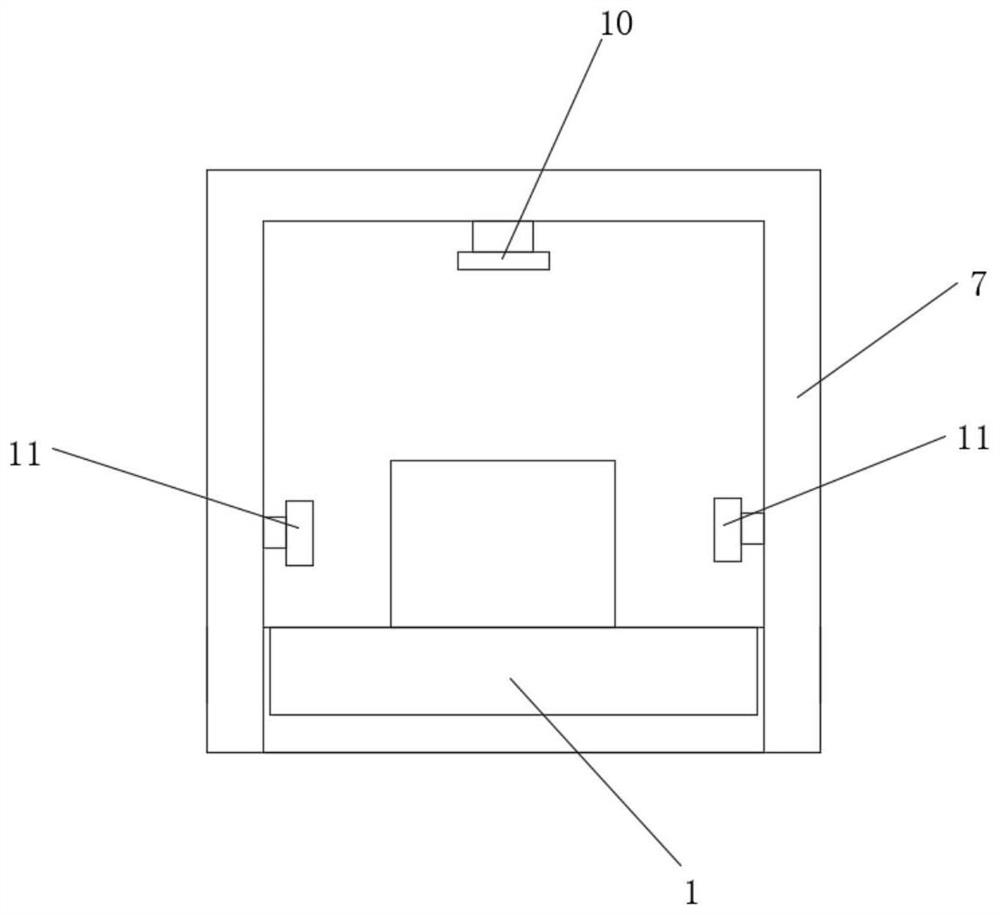

[0036] Example: as Figure 1-8As shown in the figure, a sorting device for logistics transportation in response to emergencies of the present invention includes a main conveyor belt 1, and the main conveyor belt 1 is provided with a packing box position correction mechanism 2, and the packing box position correction mechanism 2 includes a The first position visual recognition mechanism 3, the first logistics packaging box flanging mechanism 4, the second position visual identification mechanism 5 and the second logistics packaging box flanging mechanism 6 are set in sequence in the order of conveyance. One side of the output end is provided with a visual detection mechanism 48 for scanning and recognizing the logistics labels, and the end of the main conveyor belt 1 is provided with a balance wheel logistics sorter 49, and the ends of the balance wheel logistics sorter 49 correspond to each other. A receiving conveyor belt 50 is provided for docking with a plurality of counter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com