Patents

Literature

34results about How to "No downtime for maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

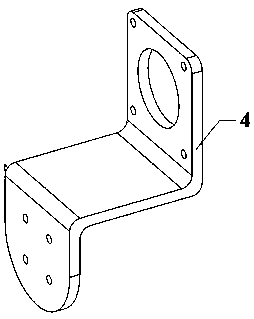

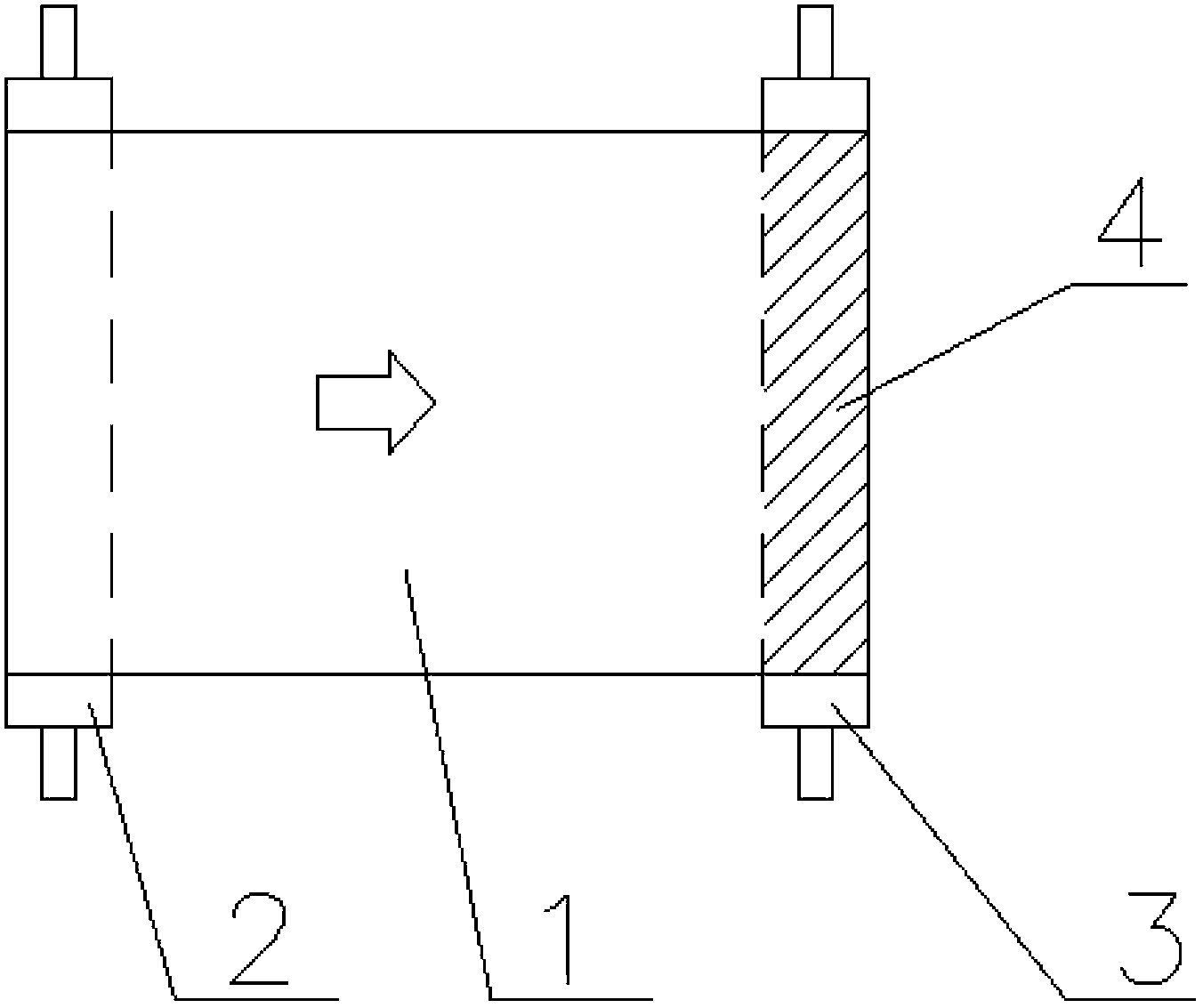

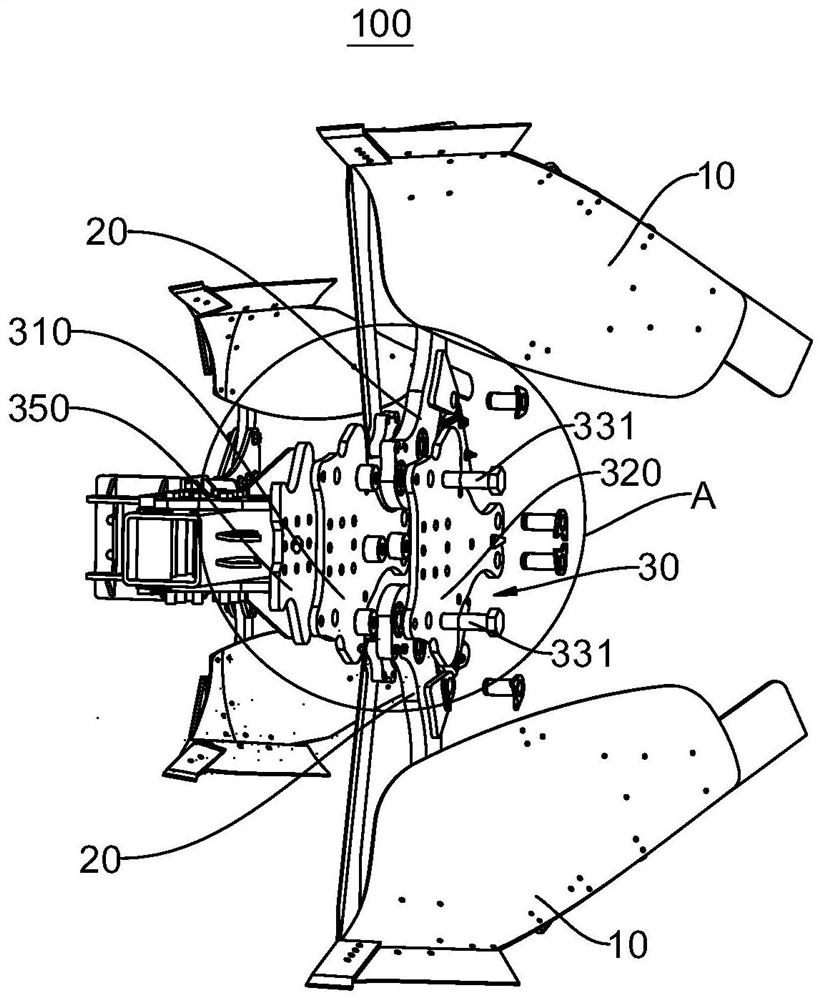

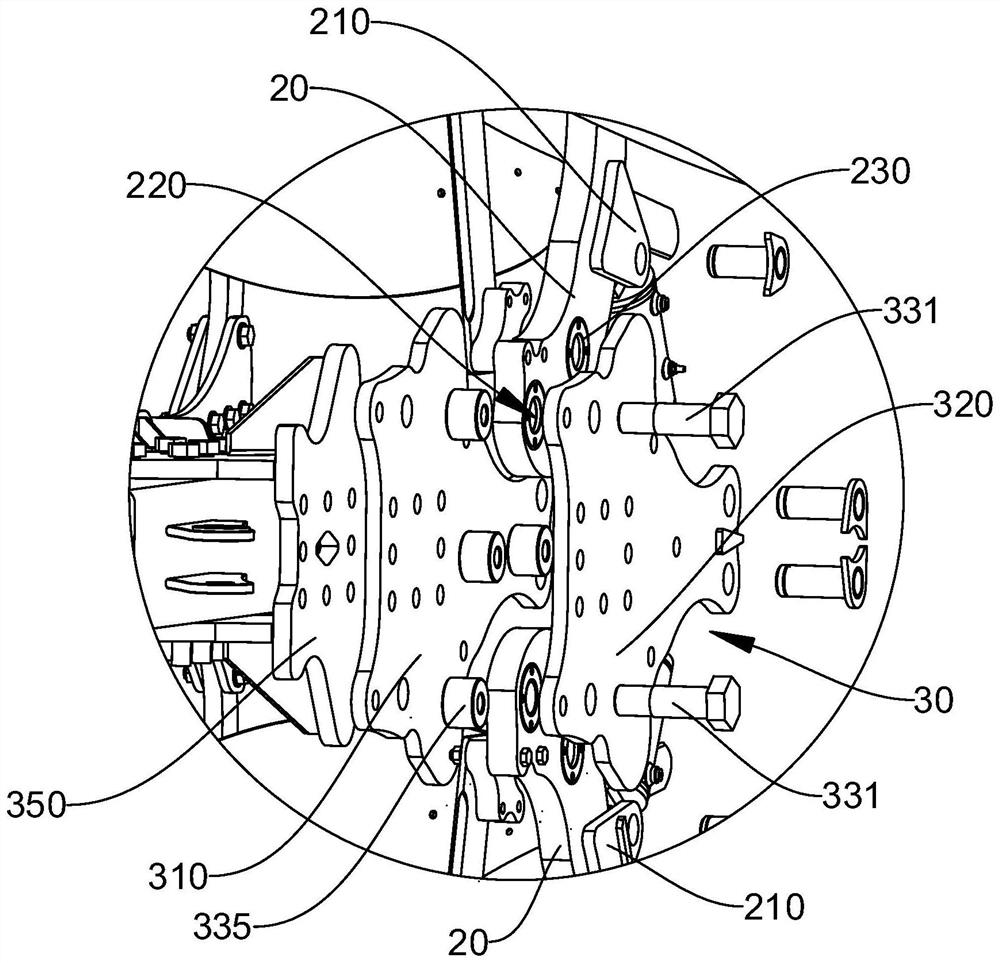

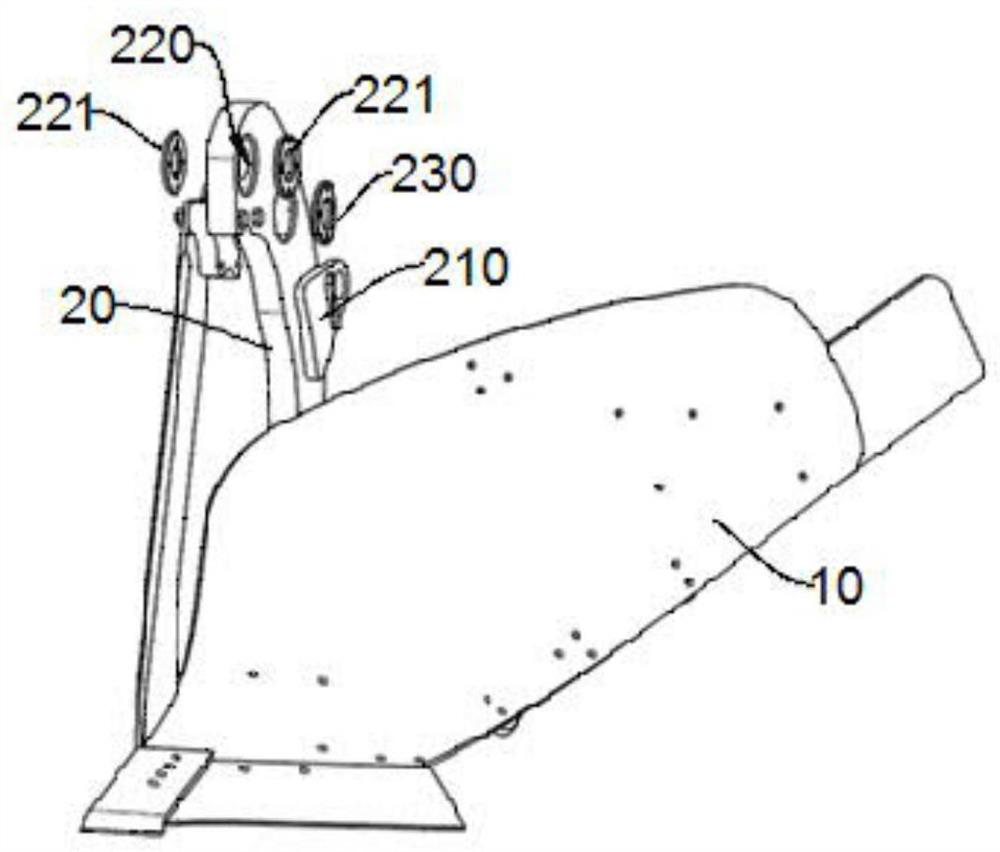

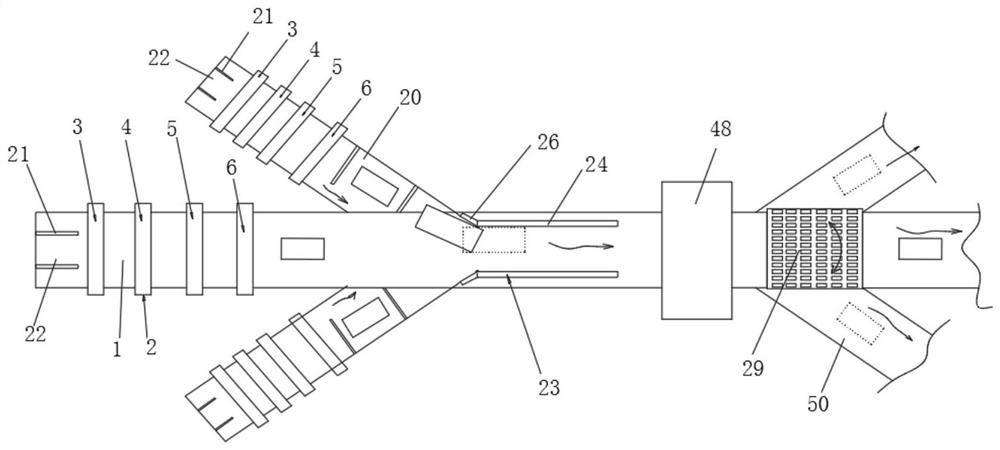

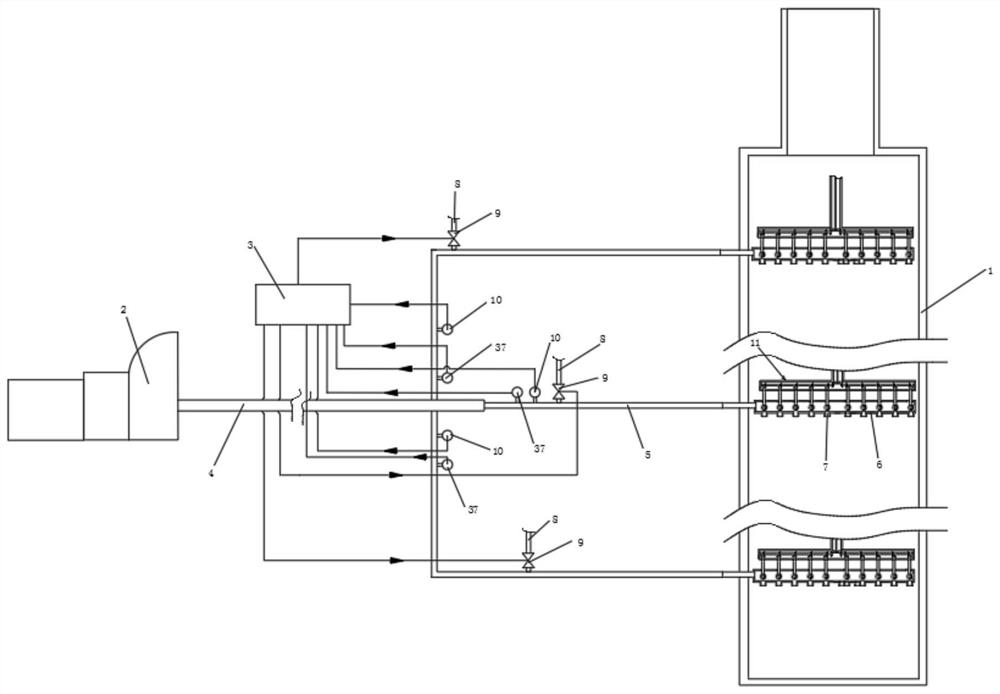

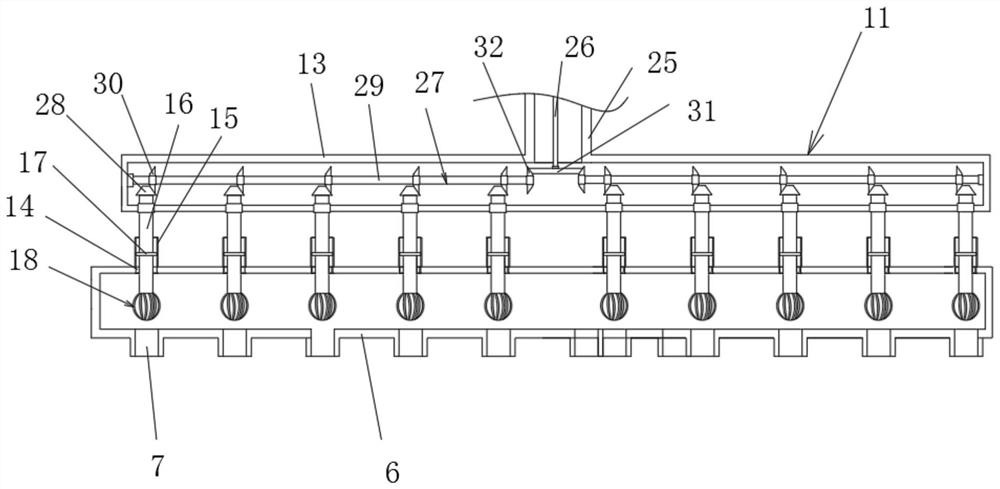

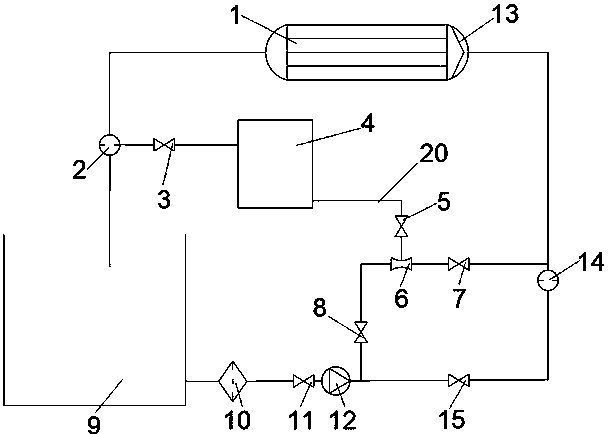

Jet assembly, multi-burner gasifier and feeding system thereof

InactiveCN106635172AEasy to useExtended stayGasification apparatus detailsGranular/pulverulent flues gasificationSpray nozzleEngineering

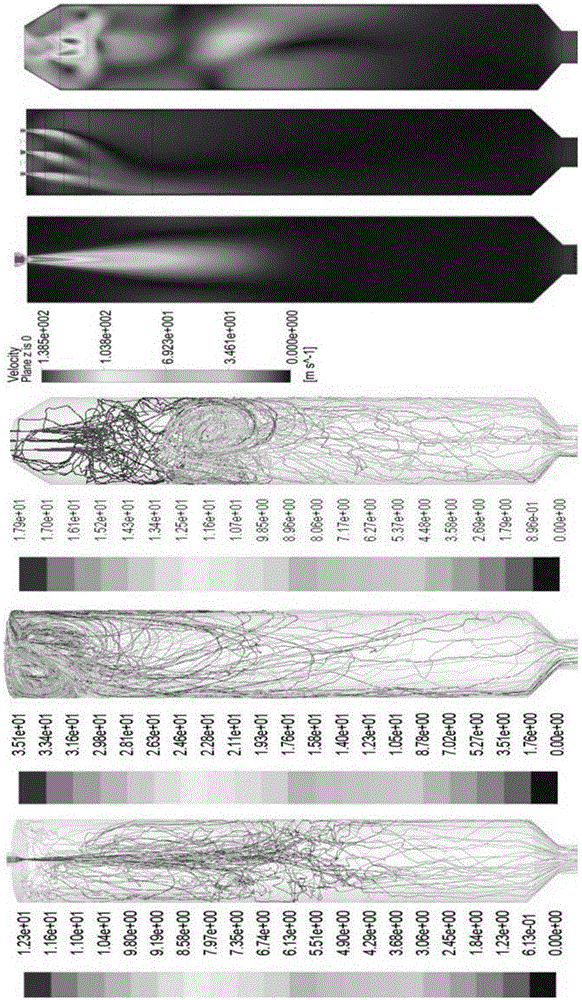

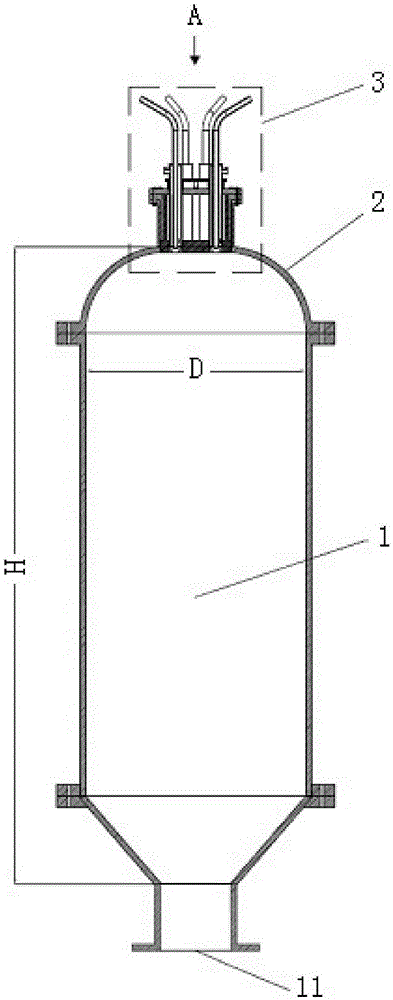

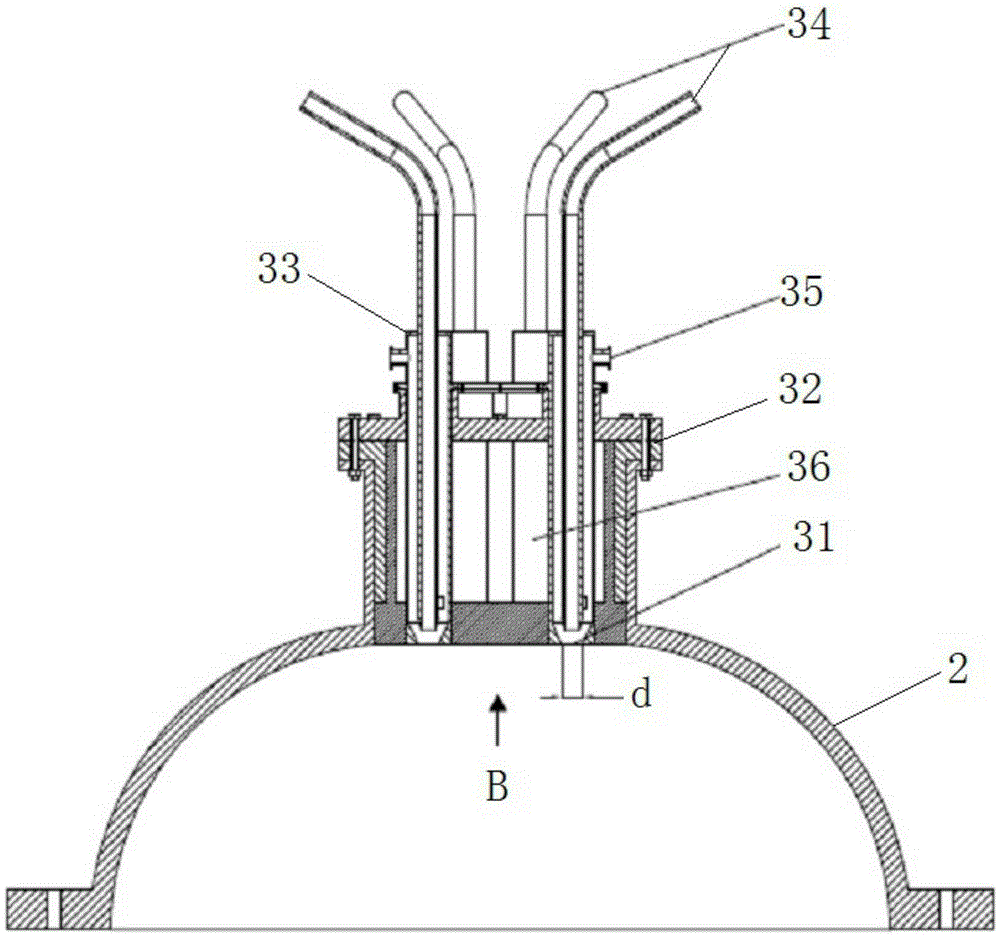

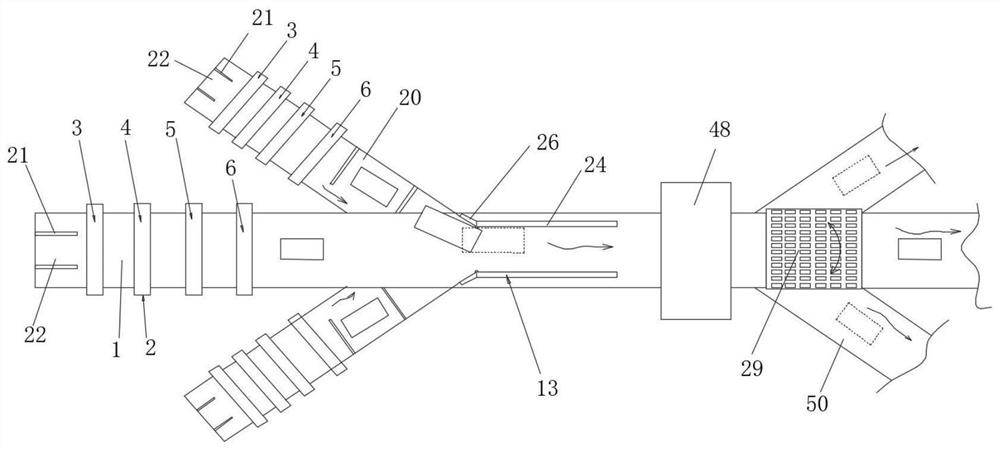

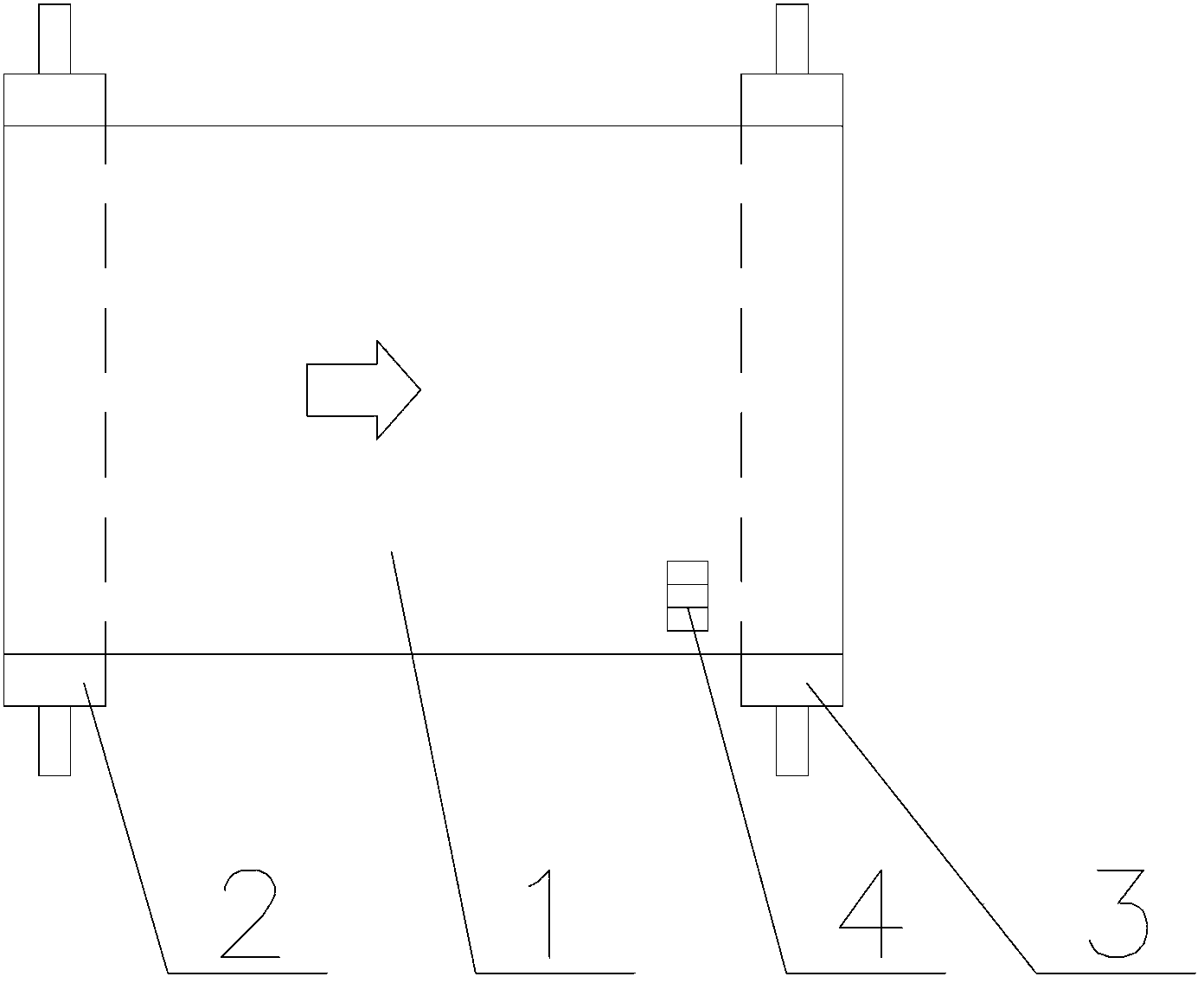

The invention discloses a jet assembly, a multi-burner gasifier and a feeding system thereof. The gasifier comprises a gasifier body (1) and a body top seal head (2). The jet assembly (3) comprises a burner table (32) mounted on the body top seal head, more than two burner units are mounted on the burner table, burner openings (31) of the burner units are annularly distributed and circumferentially spaced, and the jet directions of the burner openings are vertically downward or obliquely downward but not collected at one point. A pulverized coal or coal slurry conveying device (4) can respectively and independently convey pulverized coal or coal slurry for each burner or each group of burners, so that stable and symmetric flow field distribution can be achieved while mass transfer efficiency is improved by the multiple burners, standing time of particles in a furnace chamber is prolonged, and mixing effects of the particles and gasifying agents are enhanced. The feeding system avoids the shortcomings of non-uniform distribution, easiness in blockage and difficulty in detachment and maintenance by independent or grouped independent pulverized coal supply of the burners.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

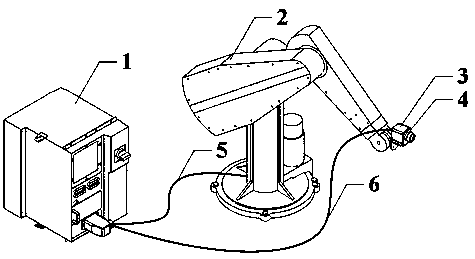

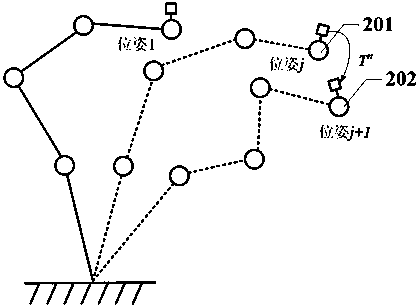

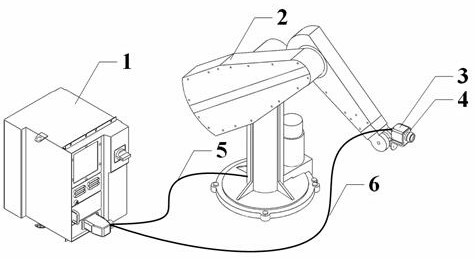

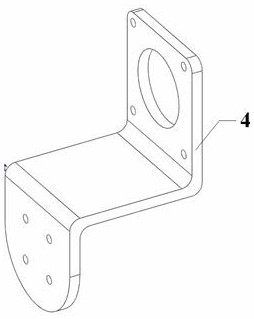

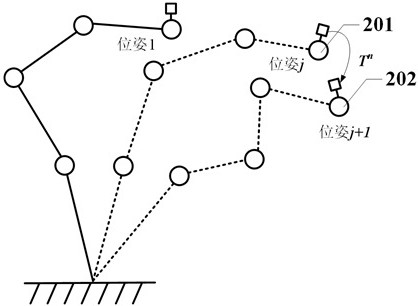

Industrial robot geometric parameter identification method based on transformation matrix error model

ActiveCN109465829AImprove end positioning accuracyImprove efficiencyProgramme-controlled manipulatorProduction lineControl signal

The invention relates to an industrial robot geometric parameter identification method based on a transformation matrix error model, wherein the industrial robot structure comprises a robot control cabinet, an industrial robot, a smart industrial camera, a camera mount, a control signal communication cable and a transmission signal communication cable. The industrial robot geometric parameter identification method first establishes the transformation matrix error model of the industrial robot, and secondly, obtains the tail end pose nominal transformation matrix of the industrial robot and thetail end pose actual transformation matrix of the industrial robot, finally, obtains a geometric parameter error by substituting the nominal transformation matrix and the actual transformation matrixinto the transformation matrix error model, and inputs the geometric parameter error into the robot control cabinet to adjust the positioning accuracy of the tail end of the industrial robot. This method eliminates the need for expensive external measuring equipment and eliminates the need for additional calibration to increase the efficiency, productivity and automation of industrial lines.

Owner:NANJING INST OF TECH

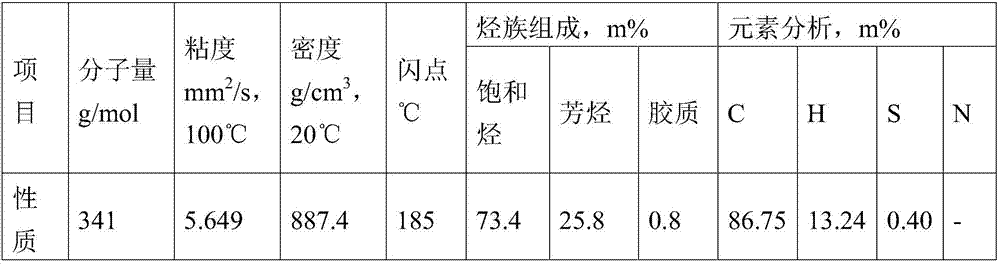

Preparation method of high-solid content catalytic cracking catalyst

ActiveCN107303502AModerate viscosityReduce the speed of peptizationMolecular sieve catalystsMolecular sieveSlurry

The invention provides a preparation method of a high-solid content catalytic cracking catalyst. The method comprises the following steps: (1) mixing pseudo-boehmite, a binder and water and stirring evenly; (2) adding a soluble salt of which an anion is selected from Cl<->, NO3<->, ClO4<->, CH3COO<-> or HCOO<->, stirring evenly and standing; (3) adding an acid to the slurry obtained in the step (2), stirring and adding the acid in multiple times; and (4) adding a molecular sieve and the clay to the slurry obtained in the step (3), pulping and mixing evenly to prepare catalyst slurry, carrying out spray drying, solidification roasting, water adding and stirring, filtering and drying to prepare the high-solid content FCC catalyst. In the process of preparing the high-solid content catalyst by adopting the preparation method, the peptization speed is controllable and the mobility of the slurry is good; and heating and warming are not needed in the peptization process and a hydrochloric acid is replaced with other acids in the acidifying peptization process, so that the damage of a hydrochloric acid gas to the molecular sieve in the catalyst roasting process is avoided and the activity of the catalyst is improved.

Owner:PETROCHINA CO LTD

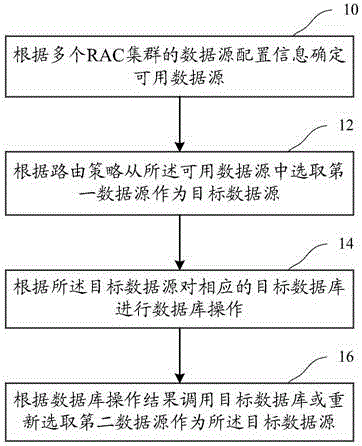

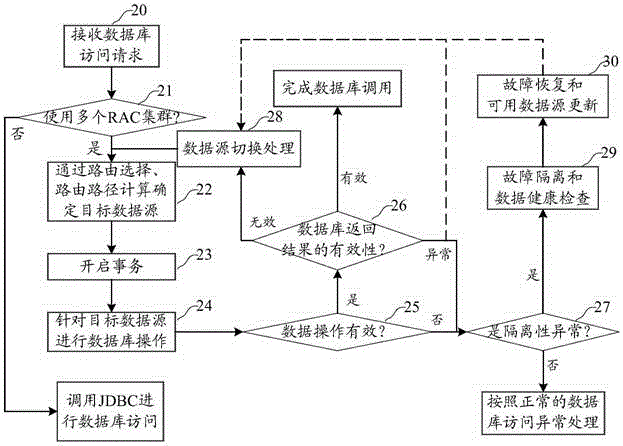

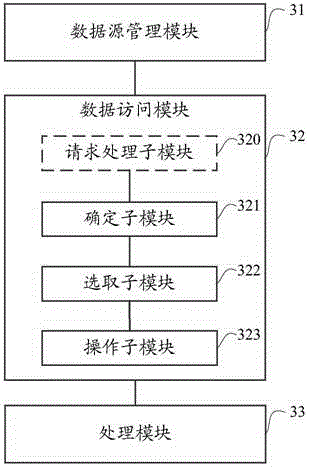

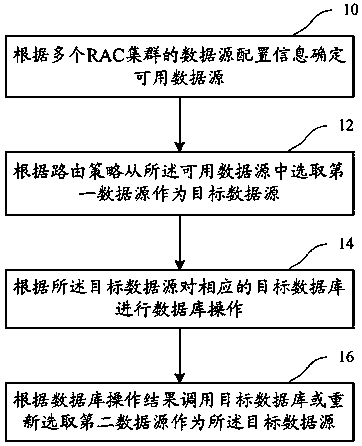

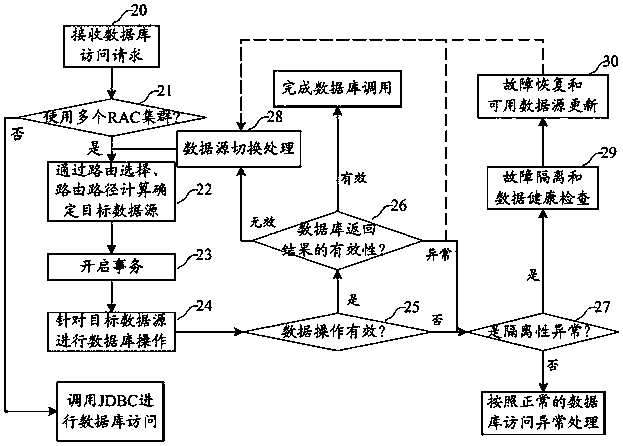

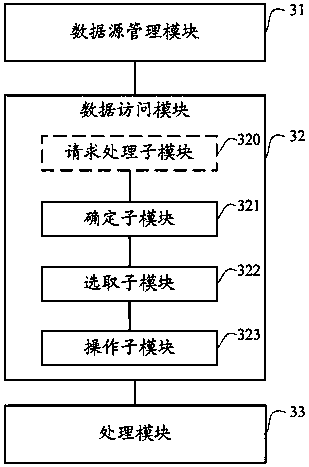

Multi-RAC cluster system and data access method and device

ActiveCN106095571AShort switching timeNo TPS jitterResource allocationDatabase management systemsAccess methodDowntime

The invention discloses a multi-RAC cluster system and a data access method and device. The data access method comprises the following steps: determining available data sources according to the data source configuration information of a plurality of RAC clusters; choosing the first data source as a target data source from the available data sources according to a routing policy; according to the target data source, operating a corresponding target database; and calling the target database according to the database operating result or re-choosing the second data source as the target data source. By the multi-RAC cluster system and the data access method and device, new RAC clusters can be flexibly and dynamically added, and halt and maintenance are not required; transparency switching between failed RAC clusters and normal RAC clusters can be realized, the switching time is short, and TPS shaking or failed businesses hardly exists; and the RAC clusters are in equivalent relationship, when in downtime of any one RAC cluster, automatic migration of businesses (such as transaction) can be realized and service to the outside is not affected.

Owner:CHINA CONSTRUCTION BANK

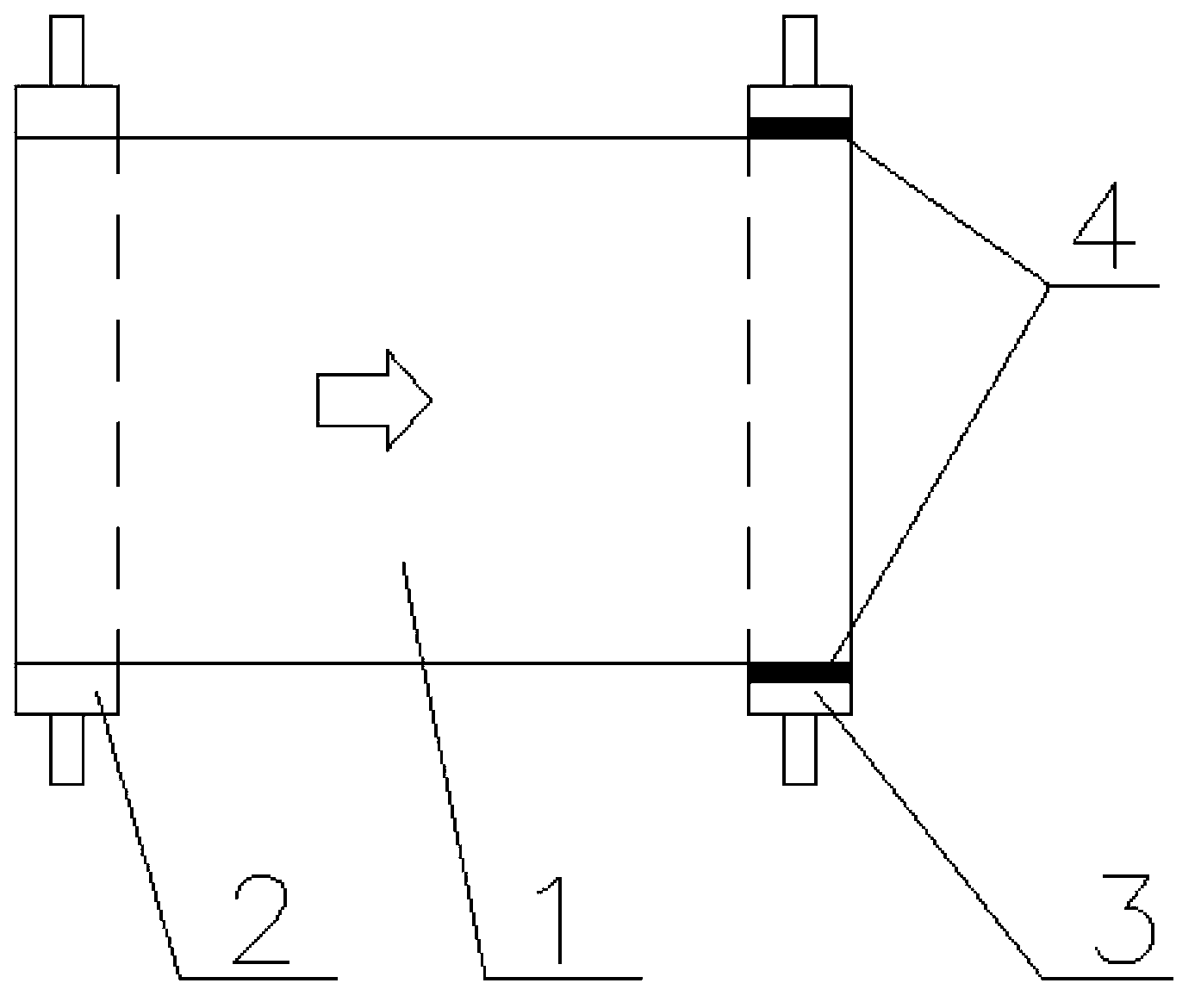

Guide belt correcting device of rotary screen printing machine

InactiveCN103832064AEasy to detectSimple structureScreen printersPrinting press partsScreen printingEngineering

The invention discloses a guide belt correcting device of a rotary screen printing machine. The guide belt correcting device comprises a guide belt, a tension roller, a driving roller, a correcting motor, a camera and a controller. The guide belt is tensioned on the tension roller and the driving roller and transmitted by the driving roller. A coloring coating is arranged on the outer surface of the driving roller or the outer surface of the tension roller. The widths of the portions, protruding out of the two sides of the guide belt, of the coloring coating serve as standard widths in the normal running process. The camera collects images on the portions, protruding out of the two sides of the guide belt, of the coloring coating in real time. The controller obtains widths of the portions, actually protruding out of the two sides of the guide belt, of the coloring coating according to the images collected in real time, determines whether the guide belt deflects or not, and obtains control instructions. The correcting motor corrects the driving roller according to the control instructions. According to the guide belt correcting device of the rotary screen printing machine, by collecting the images on the coloring coating, whether the guide belt deflects or not and which direction the guide belt deflects in can be quite easily determined through comparison, and detection of deflection of the guide belt is quite easy.

Owner:WUJIANG LIQUN TEXTILE

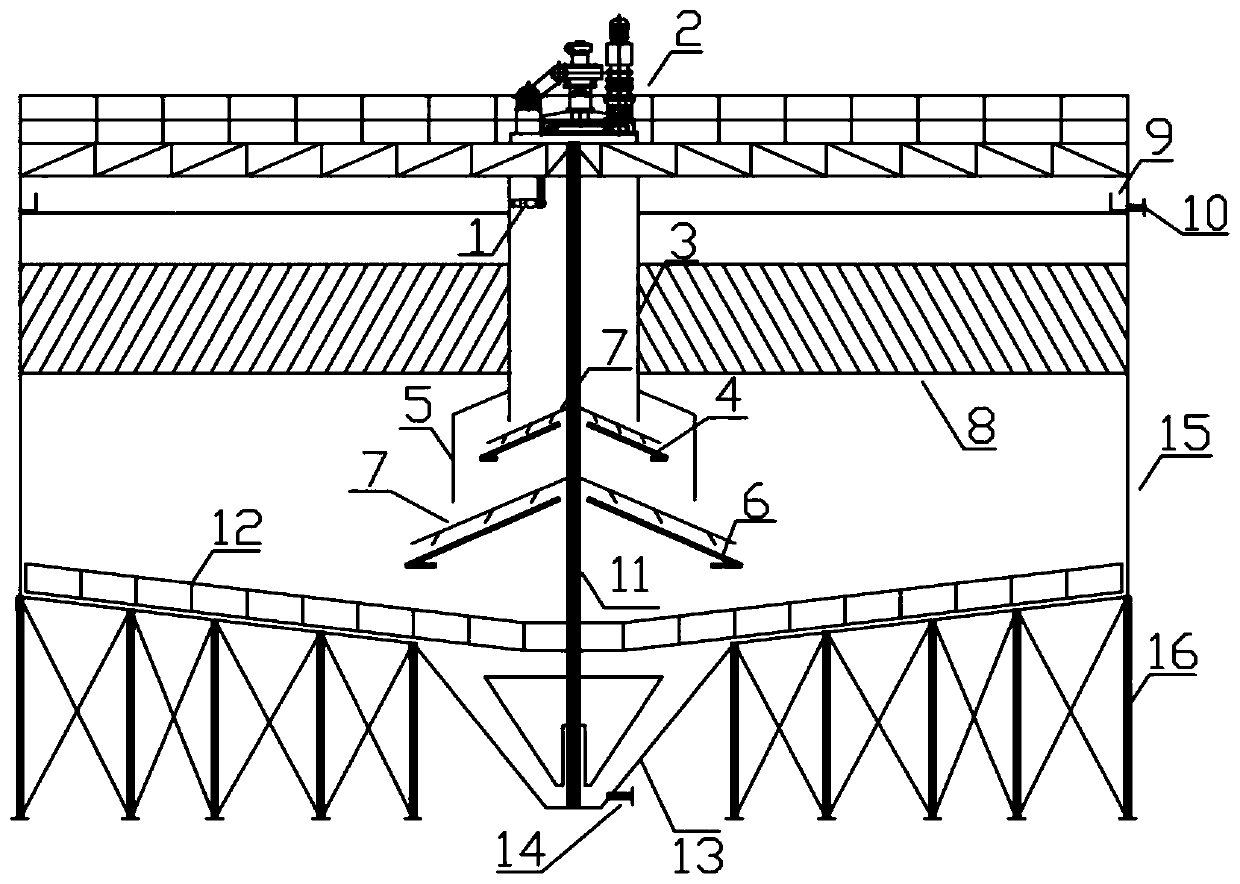

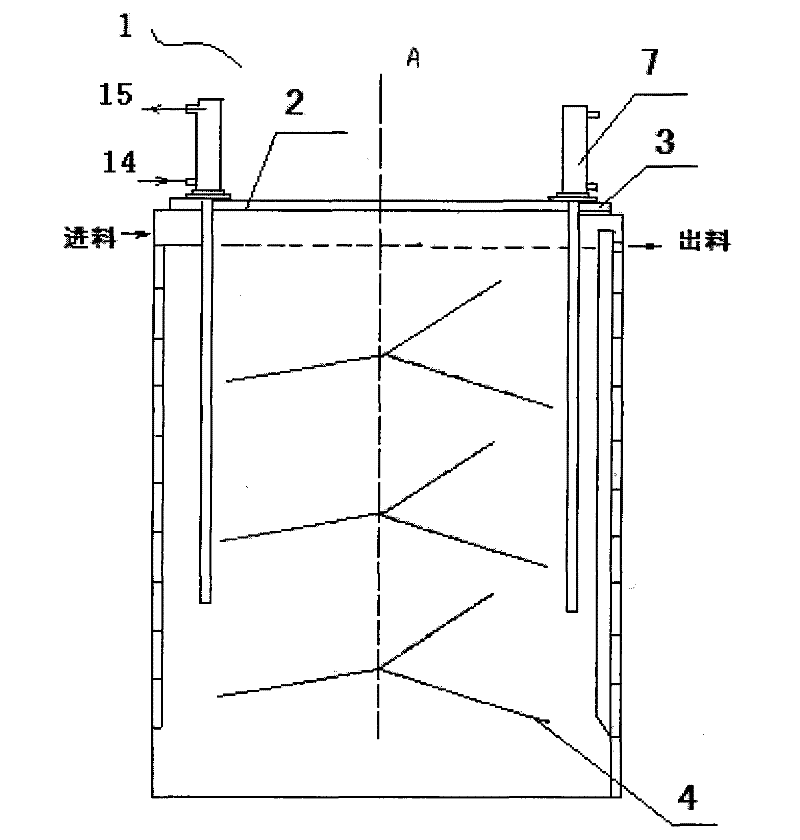

High-efficiency solid-liquid clarification and separation device

PendingCN111450581AReduce processing sizeReduce effluxSettling tanks feed/dischargeWater/sewage treatment by flocculation/precipitationSludgeEngineering

The invention discloses a high-efficiency solid-liquid clarification and separation device. The device comprises a bottom bracket, a cylinder body, a flow guide device, an inclined plate, a mud scraping mechanism and a speed reducer, wherein the cylinder body is mounted on the bottom bracket, the speed reducer is arranged on the cylinder body, the flow guide device comprises a flow guide barrel and a reflecting plate, the reflecting plate is arranged below the flow guide barrel, the top of a first-stage flow guide barrel is communicated with a sewage / grey water inlet, the top of a second-stageflow guide barrel is connected to the outer side of a lower end opening of a first-stage flow guide barrel, and auxiliary scraping arms are arranged on the upper surface of a first-stage reflecting plate and the upper surface of a second-stage reflecting plate respectively, a slag / sludge concentration hopper is arranged at the bottom of the cylinder body, a scraping arm is arranged on a bottom plate of the cylinder body, and the scraping arm and auxiliary scraping arms jointly form the sludge scraping mechanism. According to the invention, the specific surface area is increased, the treatmentload is increased, the diffusion flow is enhanced by the flow guide reflection device, the water distribution is more uniform, the flow velocity is more stable, the liquid medicine is more fully mixed, and the clarification and separation efficiency is greatly improved.

Owner:宜兴市荣盛达环保有限公司

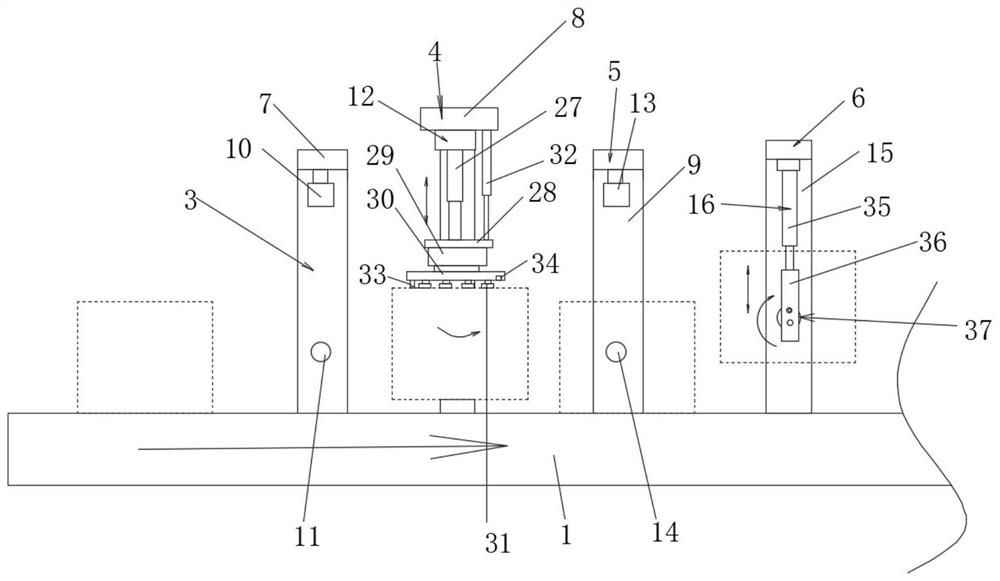

Logistics transportation sorting device for coping with emergency situations

ActiveCN112845111ASimplify work intensityConvenient sorting workSortingLogistics managementVisual recognition

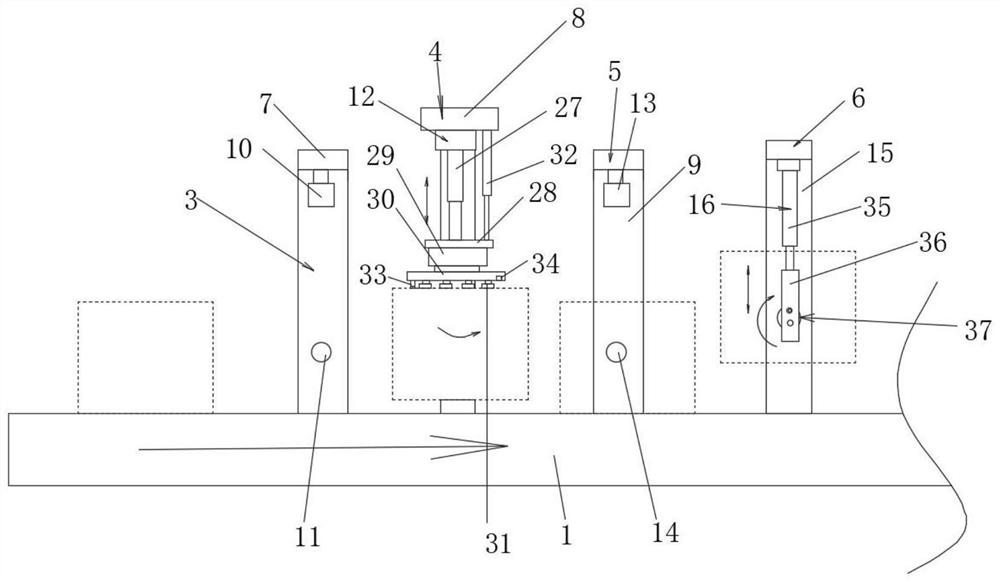

The invention discloses a logistics transportation sorting device coping with emergency situations. The logistics transportation sorting device comprises a main conveying belt, a packaging box position correcting mechanism is arranged on the main conveying belt, the packaging box position correcting mechanism comprises a first position visual identification mechanism, a first logistics packaging box flanging mechanism, a second position visual identification mechanism and a second logistics packaging box flanging mechanism, wherein one side of an output end of the main conveying belt is provided with a visual detection mechanism used for scanning and identifying logistics labels, the tail end of the main conveying belt is provided with balance wheel logistics sorting machines, and a plurality of material receiving conveying belts in butt joint with the balance wheel logistics sorting machines are correspondingly arranged at the tail ends of the balance wheel logistics sorting machines. According to the logistics transportation sorting device, the situation that all the side faces, pasted with the logistics labels, of material packaging boxes can be recognized by a visual detection mechanism to read logistics information on the logistics labels after being corrected through the packaging box position correcting mechanism, so that the logistics sorting efficiency is improved.

Owner:NANJING INST OF RAILWAY TECH

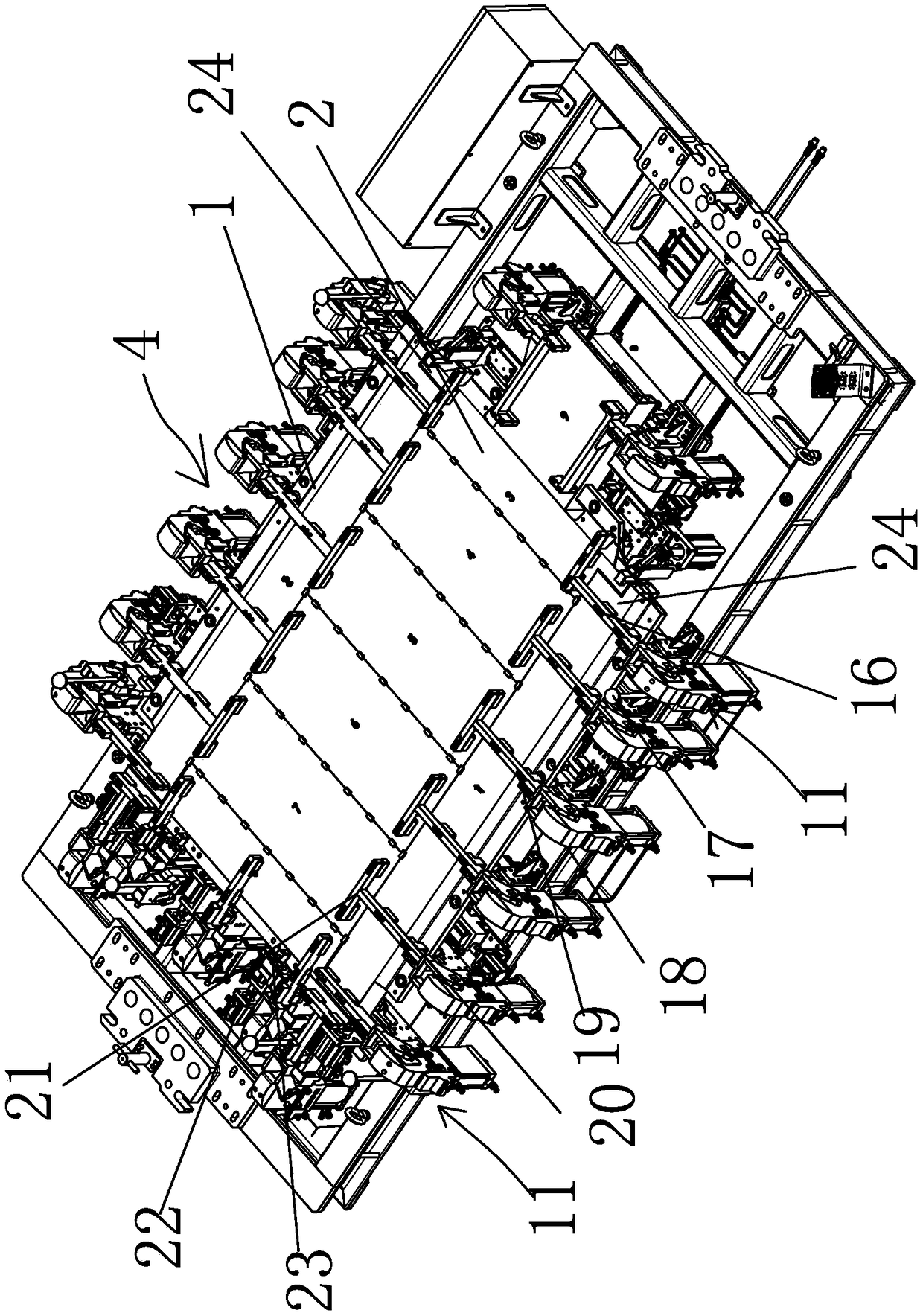

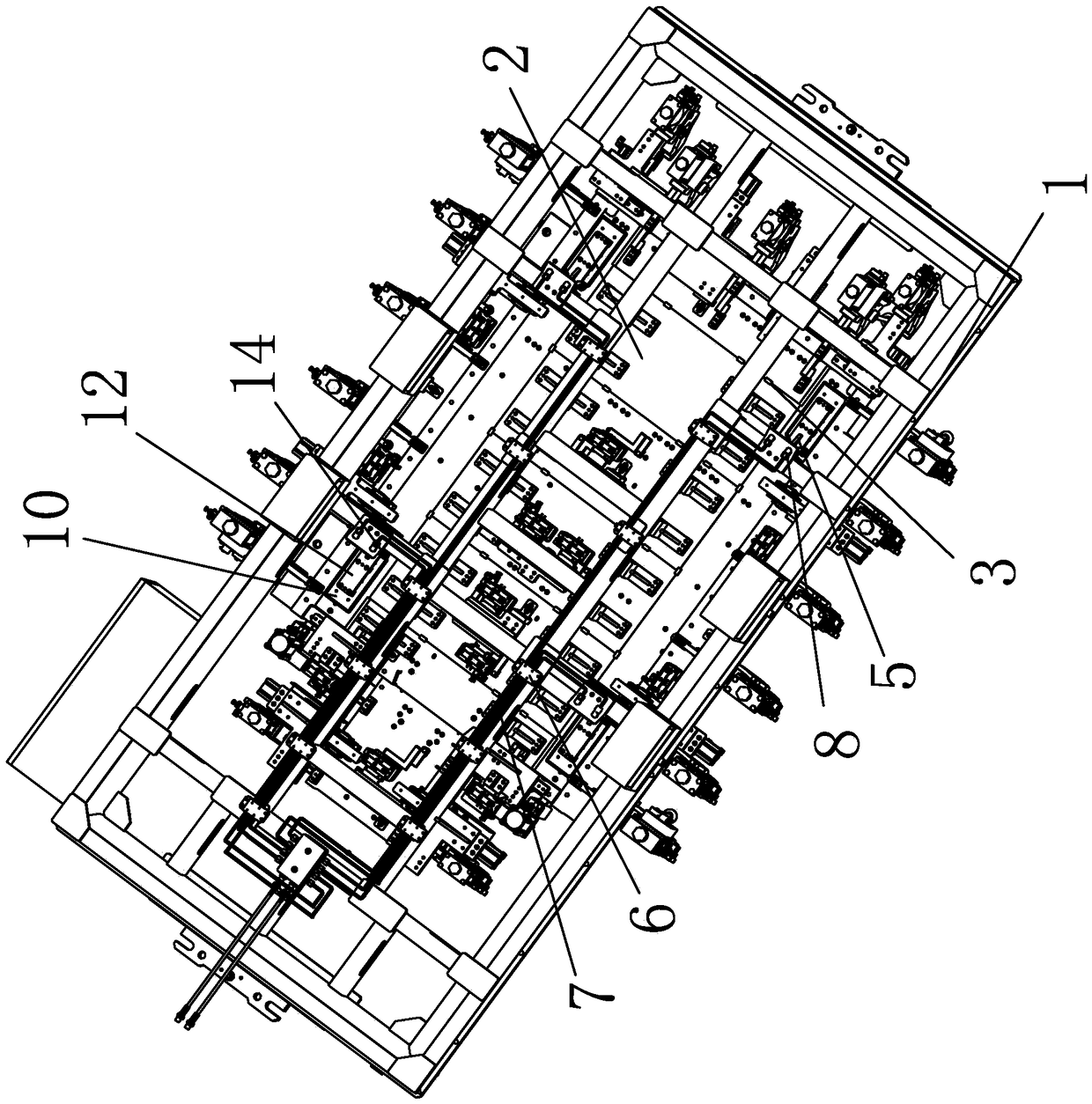

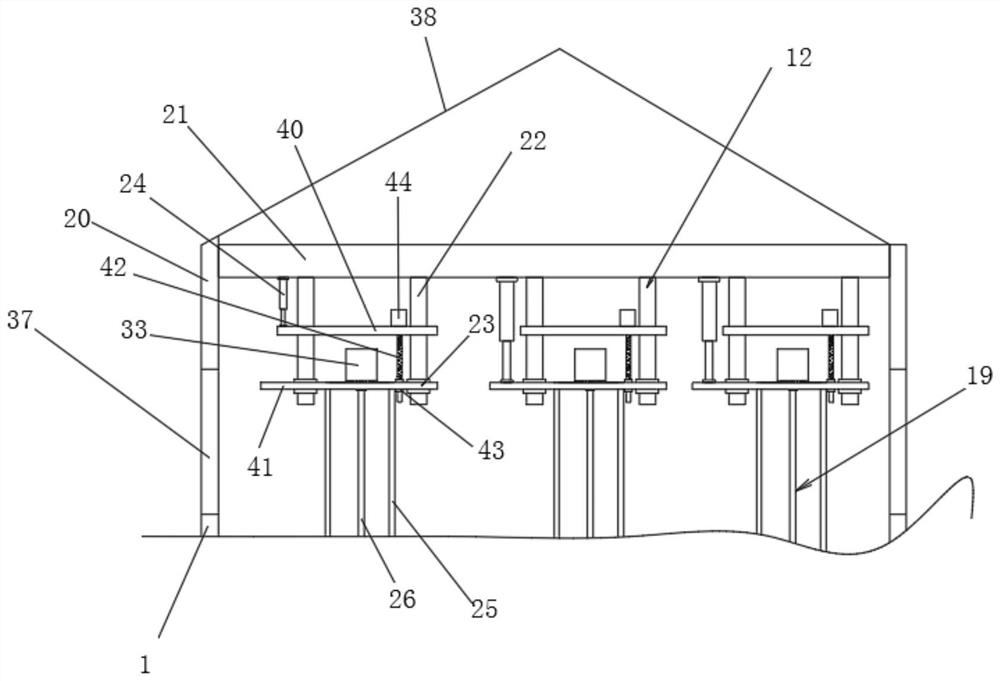

Aluminum alloy CMT arc welding rotary table jig

PendingCN109382571AEliminate post-weld distortionGuarantee the quality of weld beadWelding/cutting auxillary devicesAuxillary welding devicesProduction lineThermal deformation

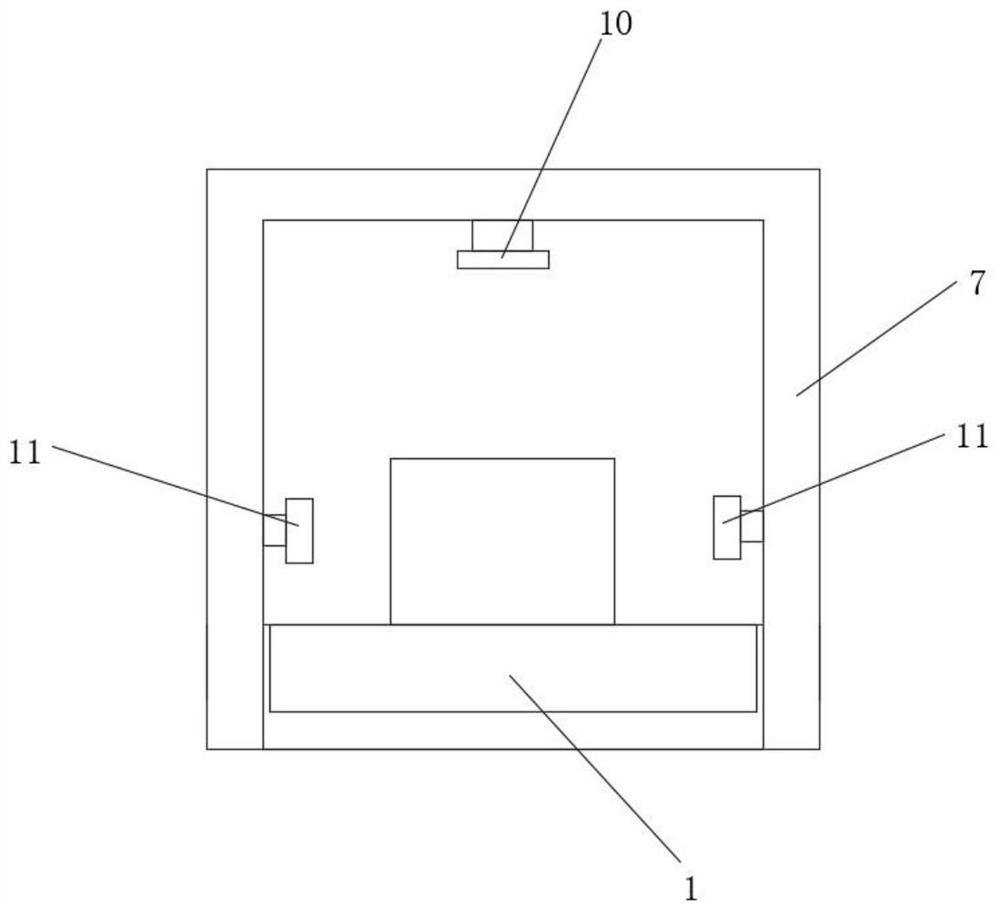

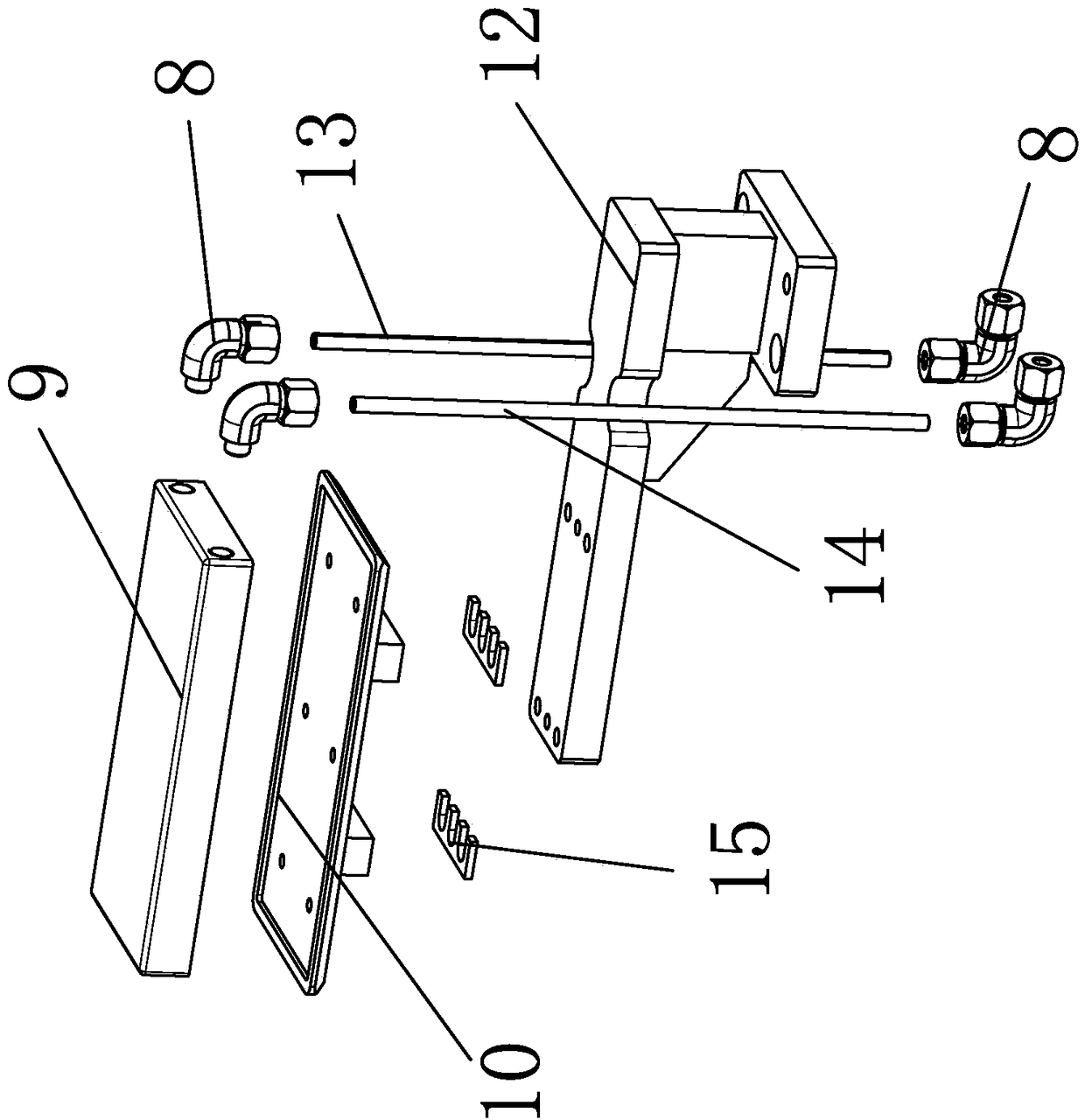

The invention belongs to the technical field of welding devices for automobile parts, and provides an aluminum alloy CMT arc welding rotary table jig. The aluminum alloy CMT arc welding rotary table jig comprises a jig body, the jig body is provided with a plurality of aluminum alloy frame plates, and the aluminum alloy frame plates are mutually spliced to form a storage battery box aluminum alloyproduct. Arc welding passes are arranged at the positions where the four corners of the aluminum alloy frame plates are connected, a plurality of press pliers mechanisms are arranged around the jig body, and supporting surface water cooling plate mechanisms are arranged beside the arc welding passes corresponding to the four corners of the jig body. The aluminum alloy CMT arc welding rotary tablejig has the advantages that postwelding deformation of a product is eliminated, the quality of welding seams and the welding passes in the welding process is ensured, continuous production of a jig production line is ensured, the process of post-welding deformation correction or repair is omitted, the inspection process is simplified, thermal deformation of a welded product is reduced or eliminated, a positioning mechanism of the jig is protected from being eroded by heat, and the situation that due to damage of the positioning mechanism, the production line needs to be stopped and maintainedcan be avoided.

Owner:NINGBO MINTH AUTOMOTIVE PARTS RES&DEV CO LTD

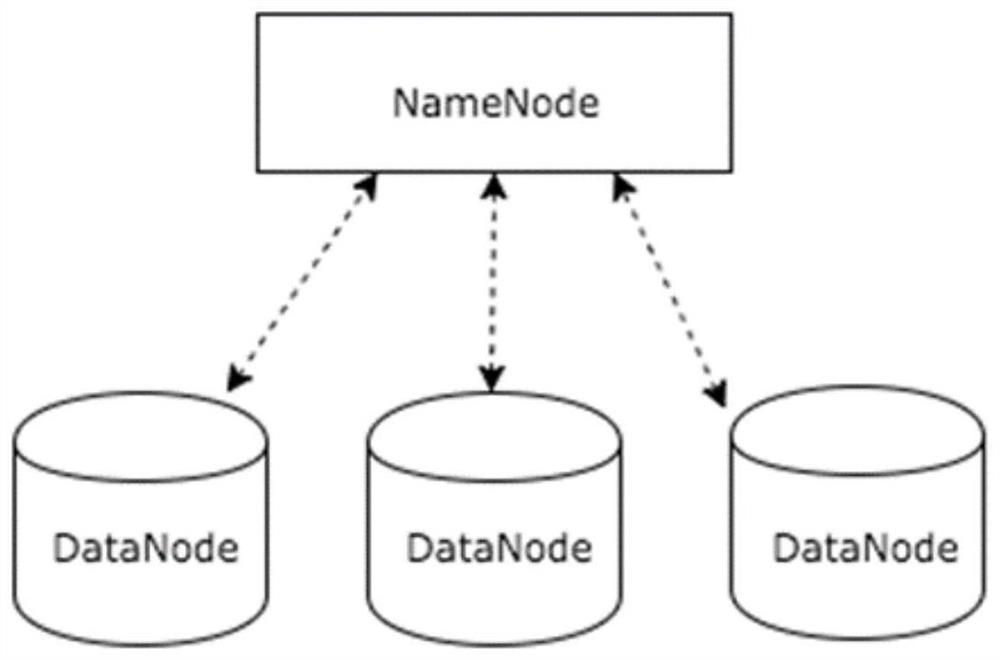

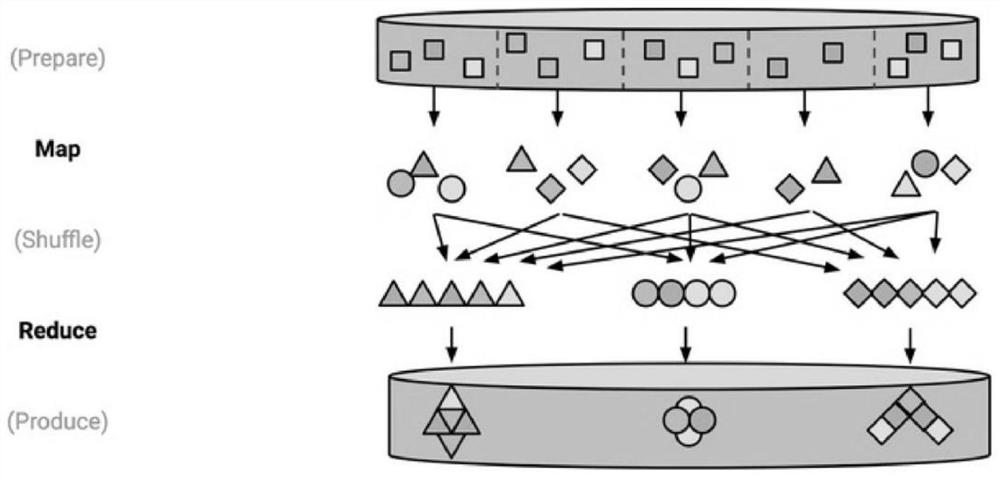

Decentralized distributed data processing system

PendingCN112380288AImprove reliabilityDoes not affect normal workProgram initiation/switchingResource allocationData processing systemDistributed computing

The invention provides a decentralized distributed data processing system, and the system comprises a system construction and maintenance module, wherein a hash ring is partitioned by using a consistent hash algorithm, each partition is occupied by a key value, the key value range is 0-2160, and each node Node is mapped to a key value bit in the hash ring; a task scheduling module which is used for carrying out hash operation on the to-be-processed data to generate a corresponding hash identification value by utilizing a consistent hash algorithm when the to-be-processed data enters the system, and mapping the hash identification value to a key value bit in a hash ring; and a data processing module which is used for monitoring the to-be-processed data mapped to the interval section from the current node to the adjacent upstream node in real time, and receiving, processing and storing the to-be-processed data. According to the system, a previous master-slave distributed framework is abandoned, and a p2p decentralized distributed framework is adopted, so that the high reliability of the whole distributed operation is guaranteed.

Owner:林亮

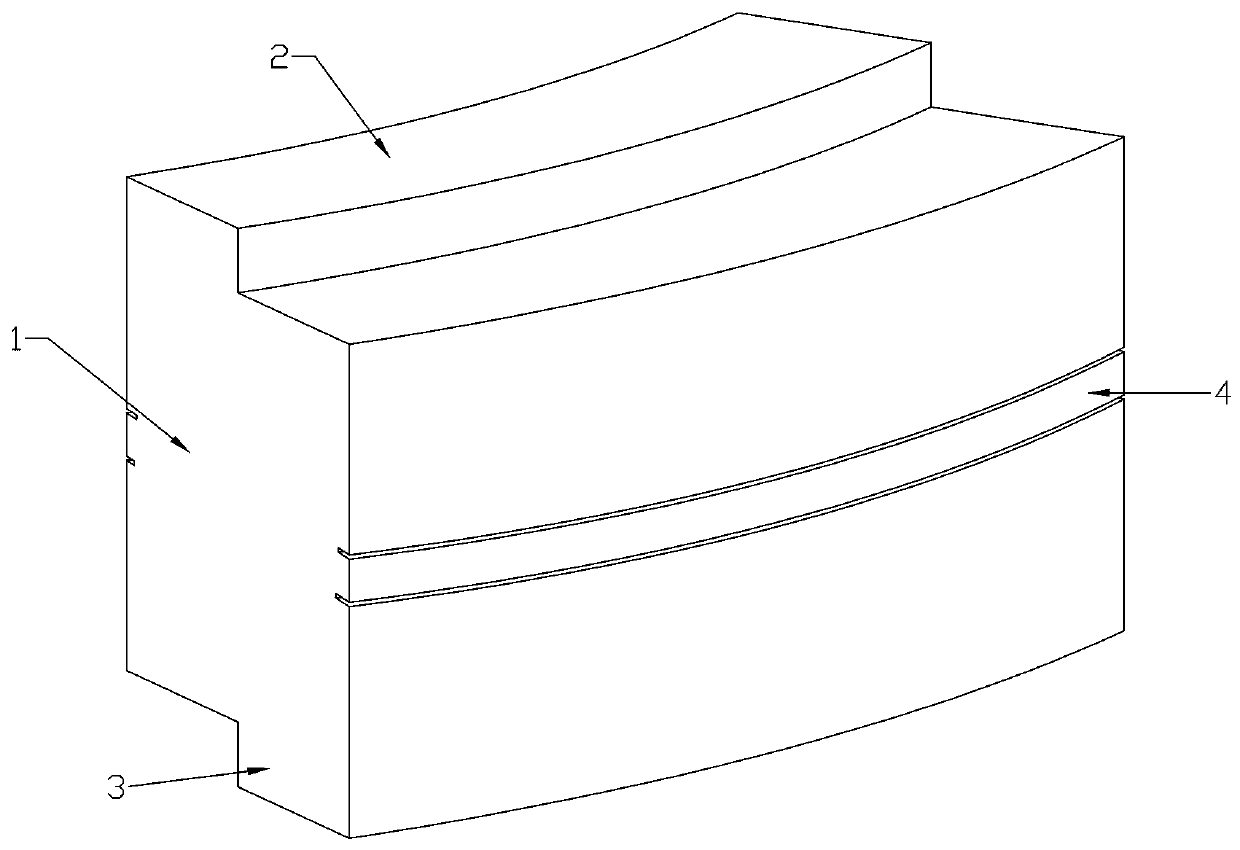

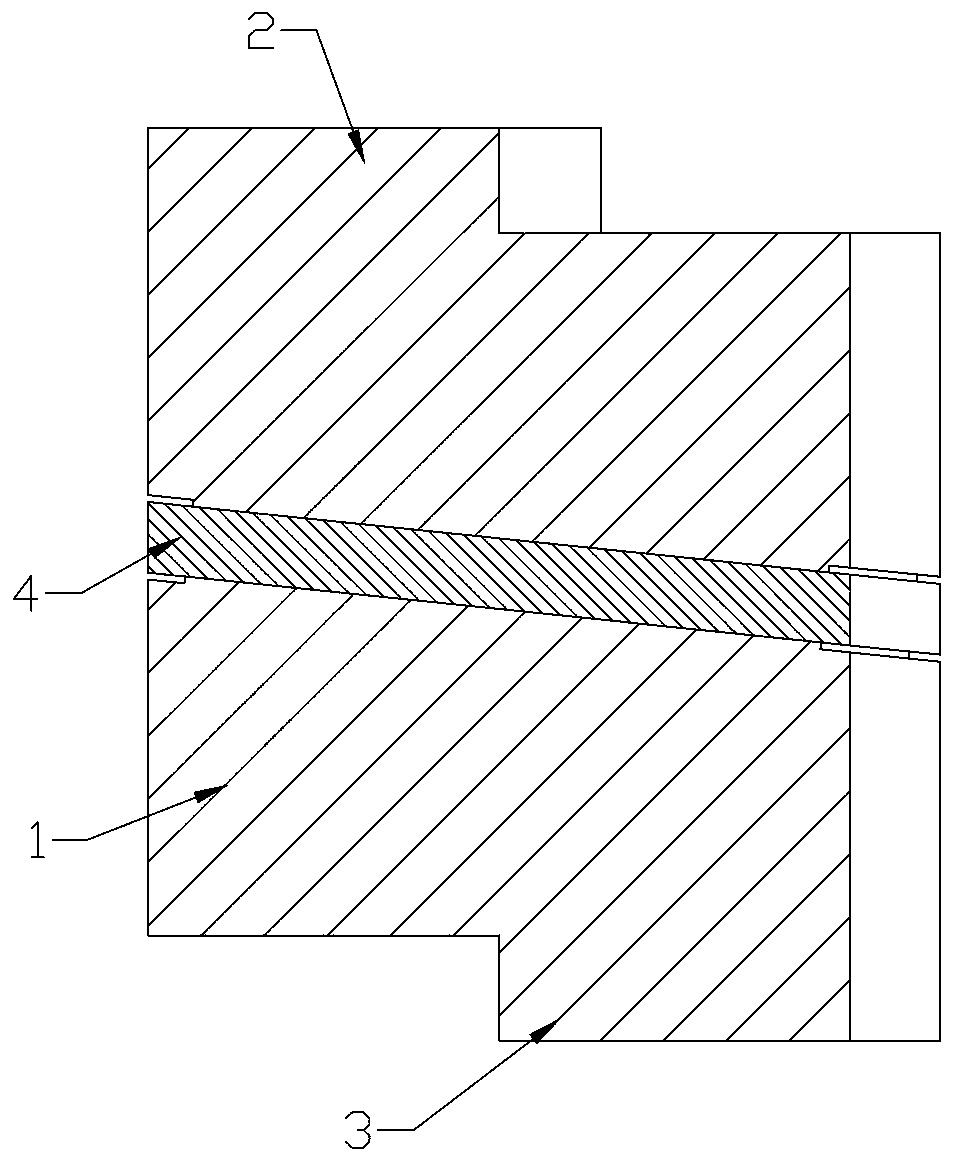

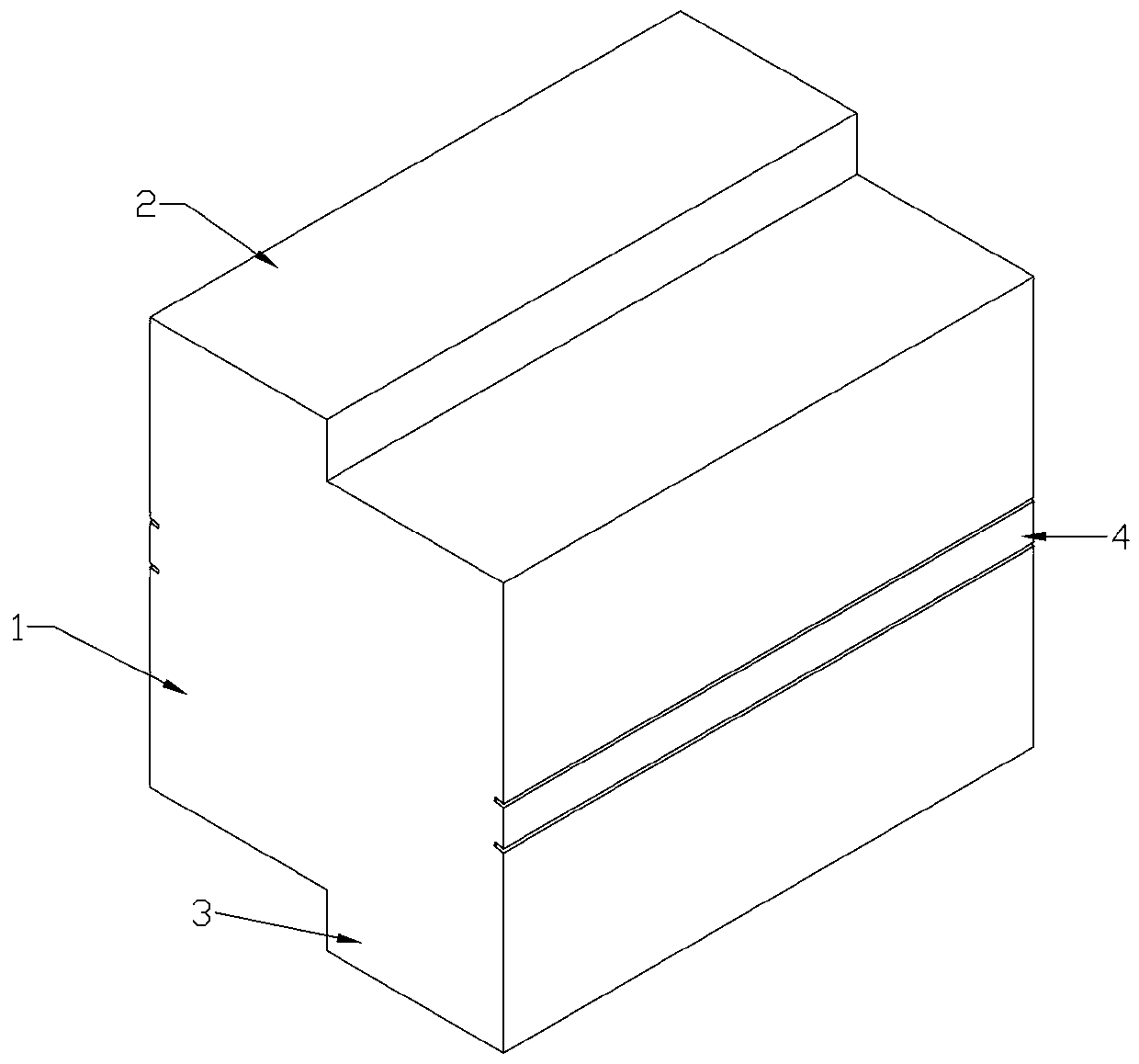

Acid-corrosion-resistant high-strength combined block for furnace lining of circulating fluidized bed boiler

InactiveCN111116218AIt is not easy to solve the constructionSolve the cracks in the brick jointsCasings/liningsCarbide siliconFluidized bed

The invention relates to an acid-corrosion-resistant high-strength combined block for a furnace lining of a circulating fluidized bed boiler, and effectively solves the problems of difficulty in sintering, poor acid corrosion resistance and wear resistance, easiness in cracking, difficulty in construction, easiness in cracking at brickwork joints and difficulty in maintenance after cracking in theuse process of a conventional castable for a furnace lining of a circulating fluidized bed boiler. The combined block comprises the main components: 30-50 parts of compact aluminum oxide, 5-10 partsof kyanite, 10-20 parts of flint clay, 5-8 parts of activated alpha alumina micro powder, 3-5 parts of zirconite powder, 5-10 parts of silicon carbide powder, 3-5 parts of silicon nitride powder, 2-5parts of pure calcium aluminate cement, 1 part of wear-resistant steel fibers, 0.5-1 part of a special additive B and phosphate as a binding additive. According to the invention, combined bricks are combined and buckled, and dismounting blocks and inlaying bodies are arranged, so that the problems that the lining of the existing fluidized bed boiler is difficult to construct, cracks are easily generated at brick joints, and the lining is difficult to maintain after cracking are effectively solved, the cost is low, and the practicability is strong.

Owner:巩义市瑞东耐火材料有限公司

Guiding belt deviation rectifying device of circular screen printer

InactiveCN103832067AEasy to detectSimple structureScreen printersPrinting press partsEngineeringPrinting press

Owner:WUJIANG LIQUN TEXTILE

A kind of preparation method of high solid content catalytic cracking catalyst

ActiveCN107303502BModerate viscosityReduce the speed of peptizationMolecular sieve catalystsMolecular sievePtru catalyst

Owner:PETROCHINA CO LTD

Production process of pre-molten material for continuous crystallizer protecting slag

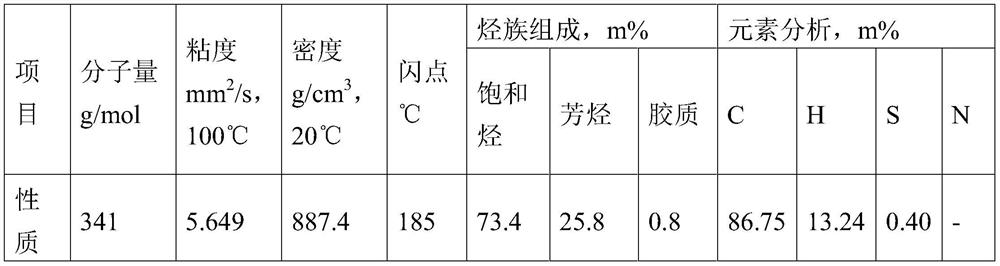

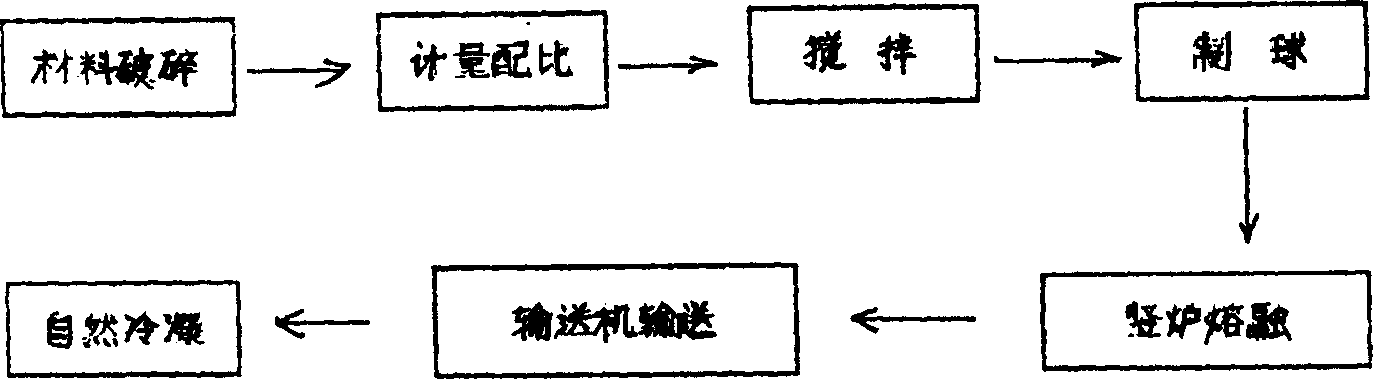

InactiveCN1133518CSmall cell uniformityStable physical and chemical propertiesProcess efficiency improvementChemical compositionSlag

The pressure-molten material accounts for 60-85% of protecting slag. It is produced through the process of material crushing to 5 mm below size, mixing with loess and water in a cylinder stirrer, pressing in a briquette making machine into hollow block with certain mechanical strength, melting together with coke inside a furnace, spraying water to cool in a conveyer to form solid block and cooling naturally. The said process makes the pressure-molten material homogeneous in component, alkality, smelting point, etc. and has high yield and low cost.

Owner:HENAN LONGCHENG GROUP CO LTD

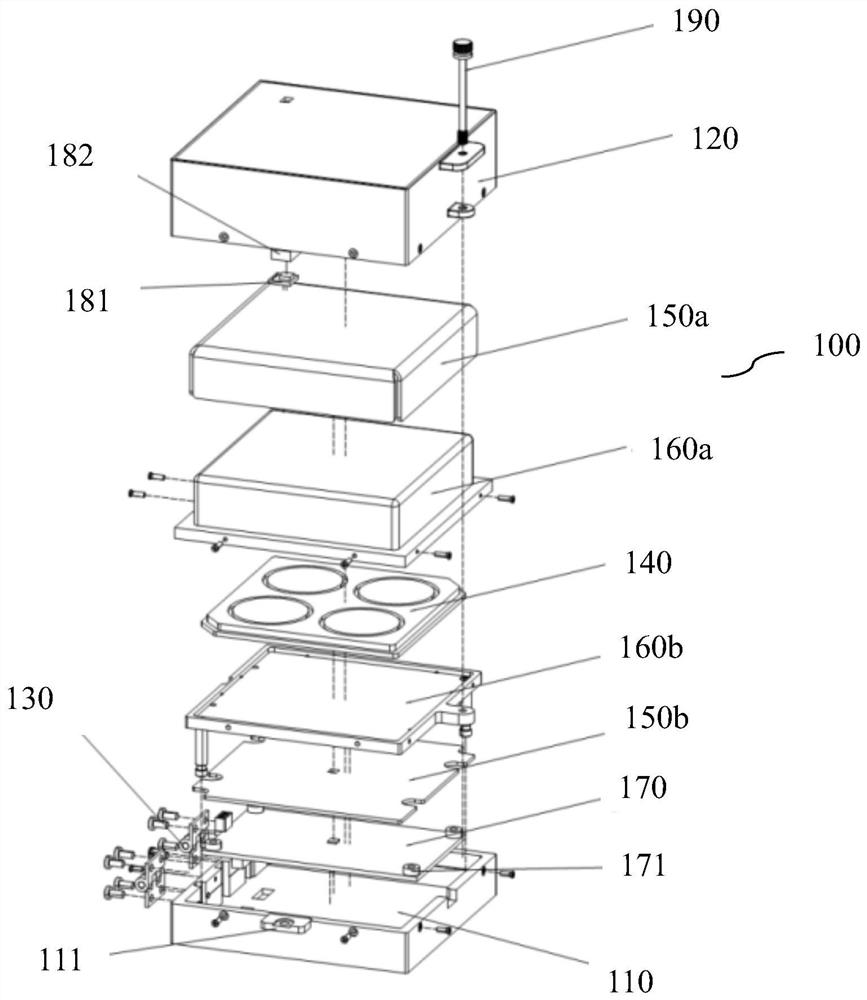

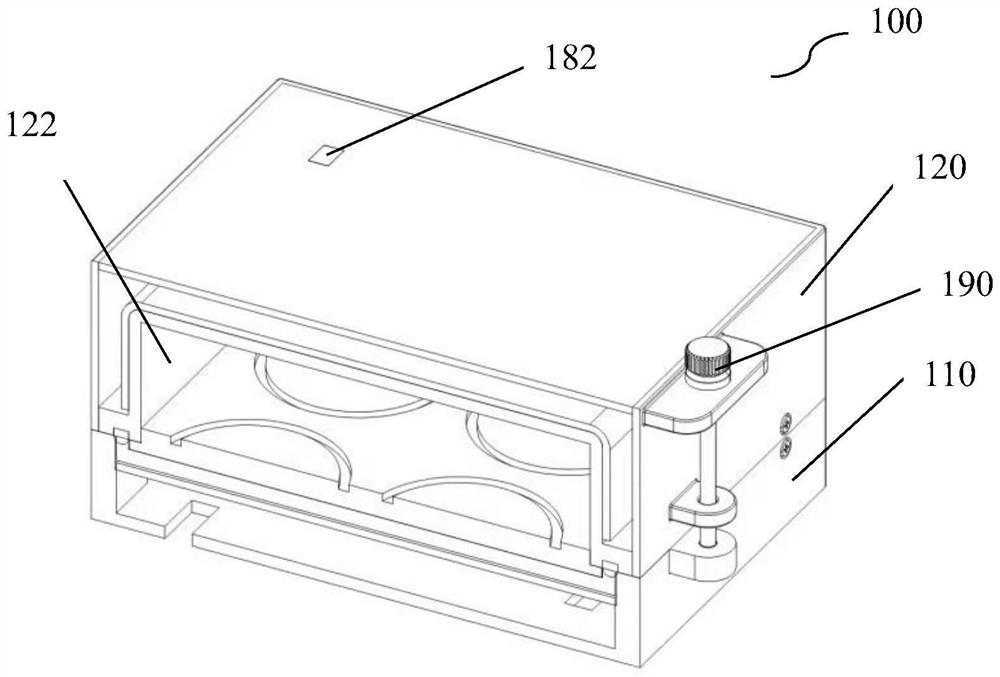

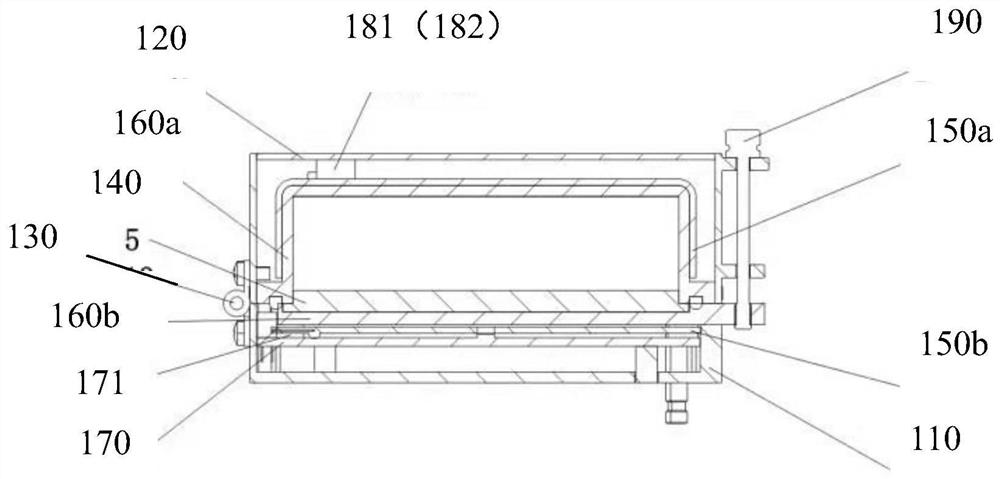

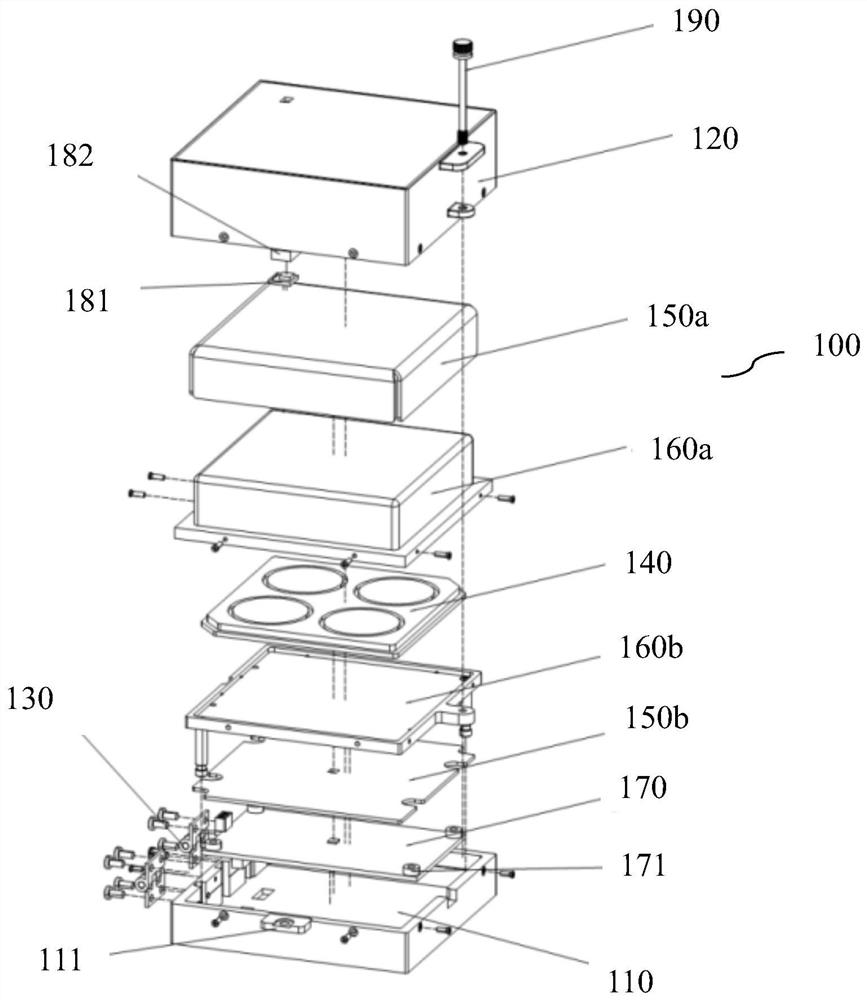

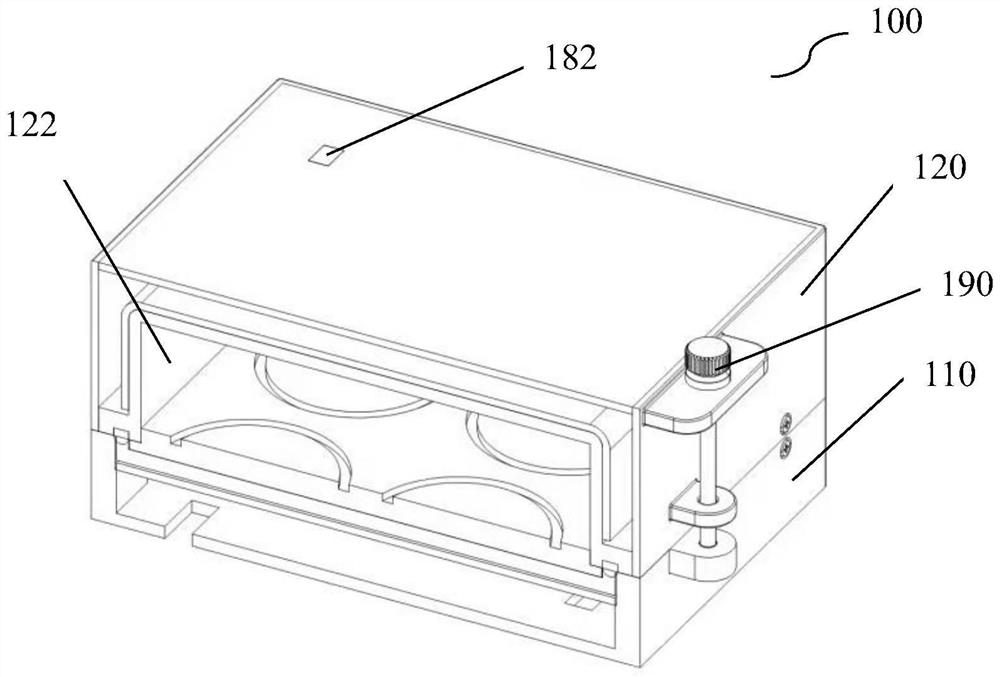

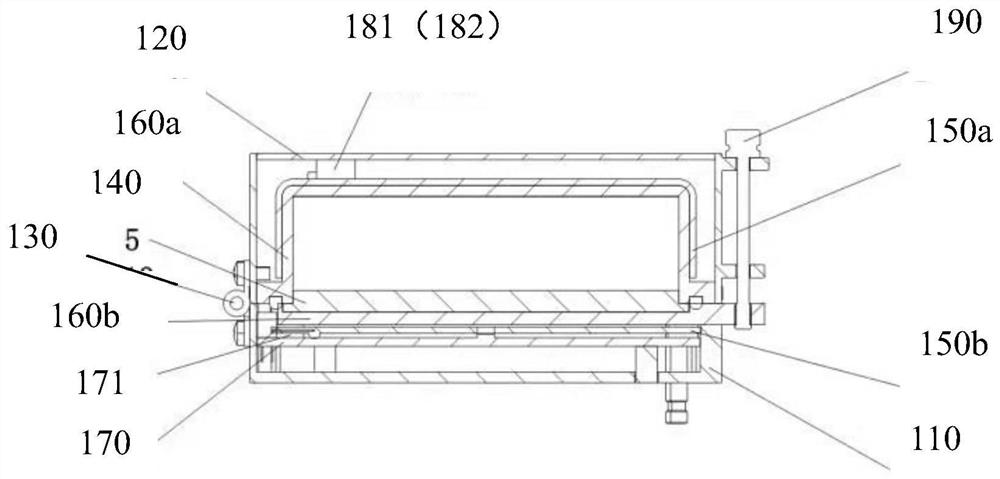

Cell culture compartment unit

InactiveCN113699041AImprove the cultivation effectAvoid overall overheatingBioreactor/fermenter combinationsBiological substance pretreatmentsPetri dishEngineering

The present application relates to a cell culture compartment unit, comprising: a lower shell and an upper shell forming vessel shapes corresponding to each other; a hinge which is arranged between the corresponding side walls of the lower shell and the upper shell so as to form hinge connection of the upper shell relative to the lower shell; a culture dish supporting plate which is accommodated in the lower shell and comprises at least one culture dish accommodating hole; a first electric heating sheet which is arranged in the upper shell; a second electric heating sheet which is arranged in the lower shell and is positioned between the culture dish supporting plate and the bottom surface of the lower shell; a first heat conducting plate which is arranged in the upper shell and located on the side, away from the top face of the upper shell, of the first heating sheet; a second heat conducting plate which is arranged in the lower shell and is positioned between the second electric heating sheet and a culture dish bracket; and a mixed gas distributor which is used for uniformly distributing mixed gas for the culture dish so as to create an atmosphere of a preset simulated living body environment. When the upper shell and the lower shell are buckled, the side walls of the upper shell and the lower shell are opposite to each other and are sealed through airtight seal.

Owner:华艾博越(上海)生物医疗科技有限公司

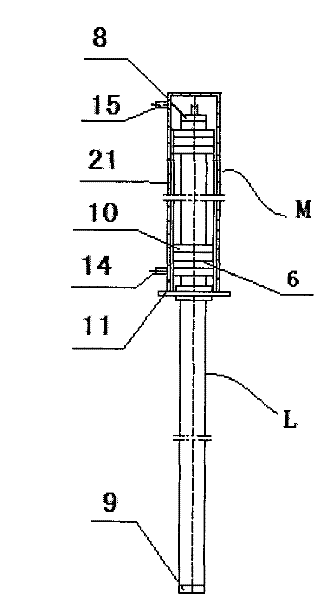

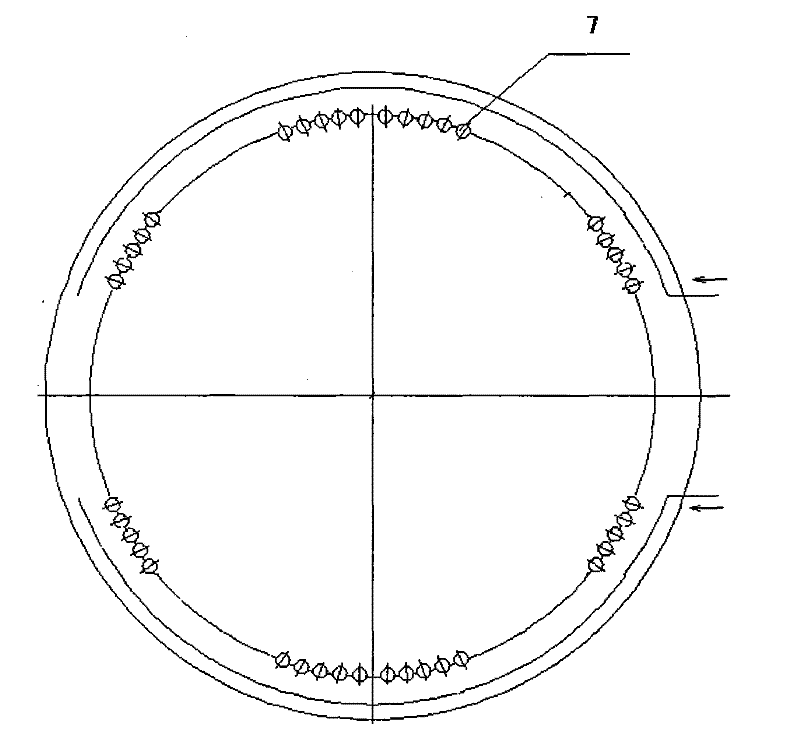

Cooling device of alumina decomposition pond

The invention relates to a cooling device of an alumina decomposition pond, which comprises a decomposition pond and a stirrer arranged in the decomposition pond. The cooling device is characterized in that a heat pipe is arranged at the top of the decomposition pond and extends into the decomposition pond through a hole reserved on a top plate of the decomposition pond, wherein a heated section L of the heat pipe is inserted into fluid of the decomposition pond for absorbing heat, and the heat is continuously conducted into a cooling section M through a working medium in the heat pipe; a spiral cooling water guide channel is welded between an external sleeve of the cooling section of the heat pipe and the heat pipe, circular cooling water enters the spiral cooling water guide channel through the cooling section and flows out from the top of the external sleeve of the heat pipe through the guide channel for carrying out heat exchange, thereby the aim of fluid cooling in the decomposition pond is achieved. The invention is convenient to install and reliable in operation, has no power consumption during the operation of the heat pipe, no material plugging and has long service life; the maintenance and the replacement are convenient as the single heat pipe works independently, and the maintenance off production is unnecessary.

Owner:南京科臣节能设备有限公司

Guiding belt deviation rectifying device of circular screen printer

InactiveCN103832065AEasy to detectSimple structureScreen printersPrinting press partsEngineeringPrinting press

The invention discloses a guiding belt deviation rectifying device of a circular screen printer. The guiding belt deviation rectifying device comprises a guiding belt, a tension roller, a driving roller, a deviation rectifying motor, a camera and a controller. The guiding belt is arranged on the tension roller and the driving roller in a tensioning mode and carries out transmission through the driving roller. A coloring coating layer with the same width as the guiding belt is arranged on the outer surface of the driving roller. During normal operation, the guiding belt completes covers the color coating layer. The camera collects images of the two side ends of the guiding belt on the driving roller in real time. The controller determines whether the coloring coating layer protrudes out of the guiding belt according to the images collected in real time, whether the guiding belt deviates is determined, a control order is obtained, and the control order is sent to the deviation rectifying motor. The deviation rectifying motor carries out deviation rectifying on the driving roller according to the control order. According to the guiding belt deviation rectifying device of the circular screen printer, the images of the coloring coating layer are collected, whether the guiding belt deviates can be easily know by comparing, the direction of deviating can be easily known by comparing, and detecting of guiding belt deviation is very easy.

Owner:WUJIANG LIQUN TEXTILE

Multi-rac cluster system, data access method and device

ActiveCN106095571BFlexibleFlexible and dynamic increaseResource allocationDatabase management systemsAccess methodDowntime

Owner:CHINA CONSTRUCTION BANK

An identification method of geometric parameters of industrial robots based on transformation matrix error model

ActiveCN109465829BImprove end positioning accuracyImprove efficiencyProgramme-controlled manipulatorProduction lineControl signal

The invention is an identification method of geometric parameters of an industrial robot based on a transformation matrix error model, wherein the structure of the industrial robot includes a robot control cabinet, an industrial robot, an intelligent industrial camera, a camera mounting frame, a control signal communication cable and a transmission signal communication cable. The geometric parameter identification method of industrial robots first establishes the transformation matrix error model of industrial robots, and then obtains the nominal transformation matrix of the end pose of the industrial robot and the actual transformation matrix of the end pose of the industrial robot. Finally, the nominal transformation matrix and the actual transformation matrix The matrix is brought into the transformation matrix error model to obtain the geometric parameter error, and the geometric parameter error is input into the robot control cabinet to adjust the positioning accuracy of the end of the industrial robot. This method does not require expensive external measuring equipment and does not require additional calibration, and can be used to improve the efficiency, production capacity and automation of industrial production lines.

Owner:NANJING INST OF TECH

Plough share assembly, turnover plow, plough share assembly overload protection control method and tractor

ActiveCN114097315AImprove work efficiencyAvoid damagePloughsAgricultural scienceAgricultural engineering

The embodiment of the invention provides a plough share assembly, a turnover plow, a plough share assembly overload protection control method and a tractor, and relates to the technical field of agricultural machinery. The plough share assembly comprises a plough share, a plough column, a mounting seat and a buffer oil cylinder, the plough share is fixedly connected with the plough column, the plough column is rotatably connected to the mounting seat, one end of the buffer oil cylinder is connected with the plough column, the other end of the buffer oil cylinder is connected with the mounting seat, and the plough column can rotate relative to the mounting seat under the action of external force to compress the buffer oil cylinder. By arranging the buffer oil cylinder, overload protection can be achieved after the plough share assembly encounters an obstacle, parts are prevented from being damaged, shutdown maintenance is not needed, and the operation efficiency of the tractor is improved.

Owner:广东皓耘科技有限公司

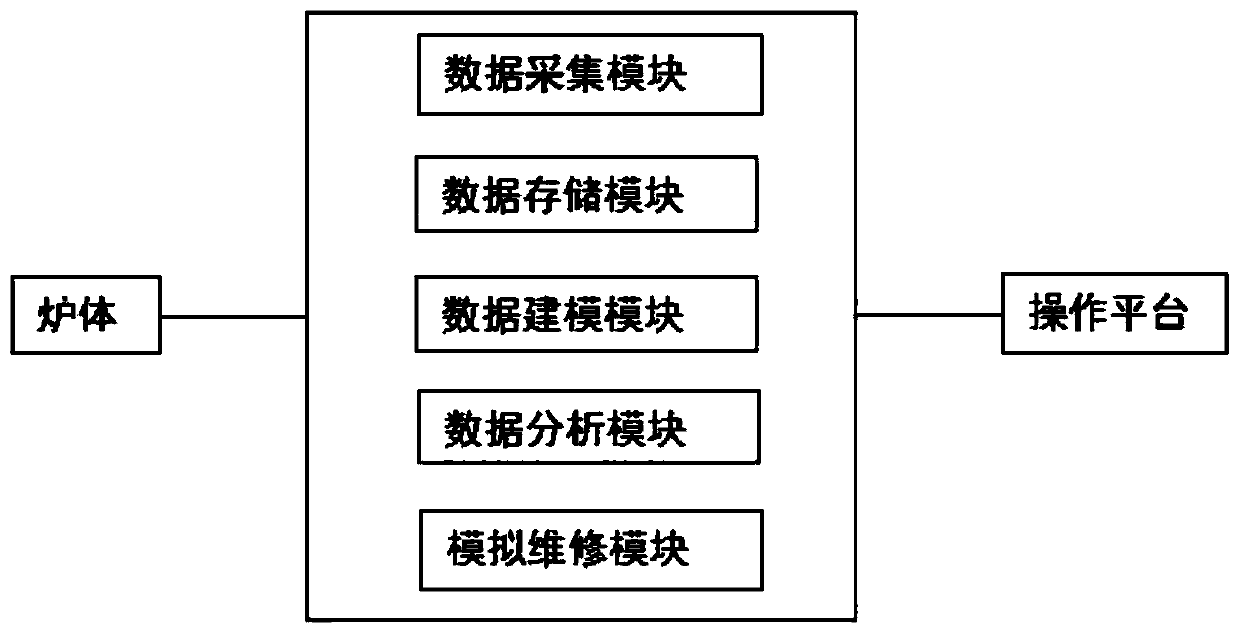

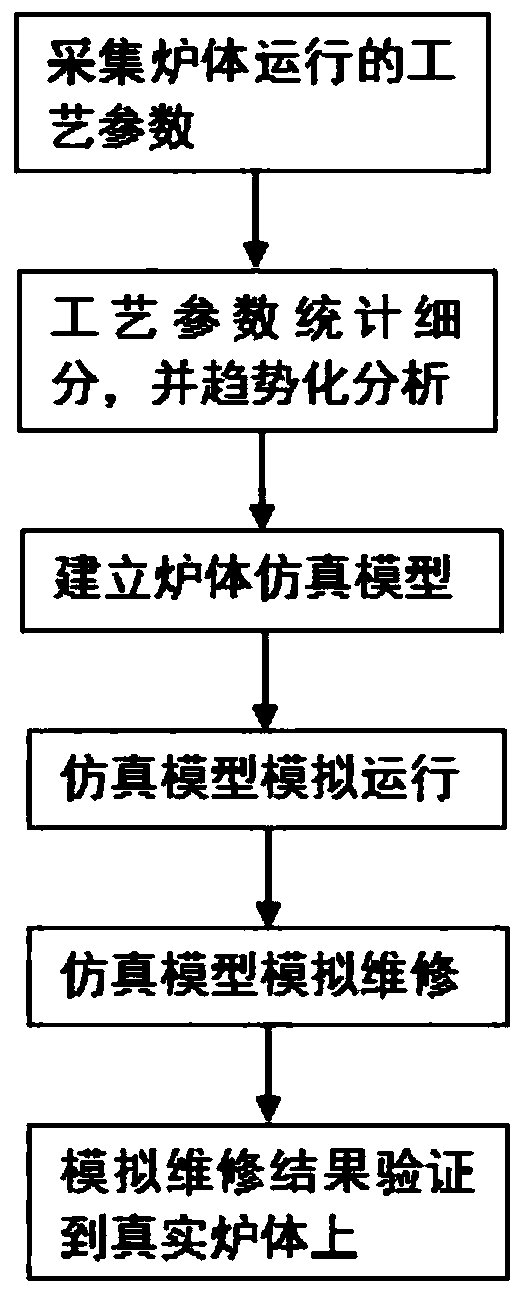

System and method for controlling furnace body process based on big data analysis

InactiveCN110059359ANo downtime for maintenanceImprove yieldDesign optimisation/simulationSpecial data processing applicationsData modelingSimulation

The invention discloses a furnace body process control system and method based on big data analysis. The system comprises a data acquisition module, a data storage module, a data modeling module, a model analysis module and a simulation maintenance module. Based on a big data analysis method, simulation model simulation is carried out on all process parameters of operation of a real furnace body,and then a simulation model simulation result is applied to the real furnace body. Overhaul and maintenance are time-saving and labor-saving, productivity is improved, and production is optimized.

Owner:江苏东方国信工业互联网有限公司

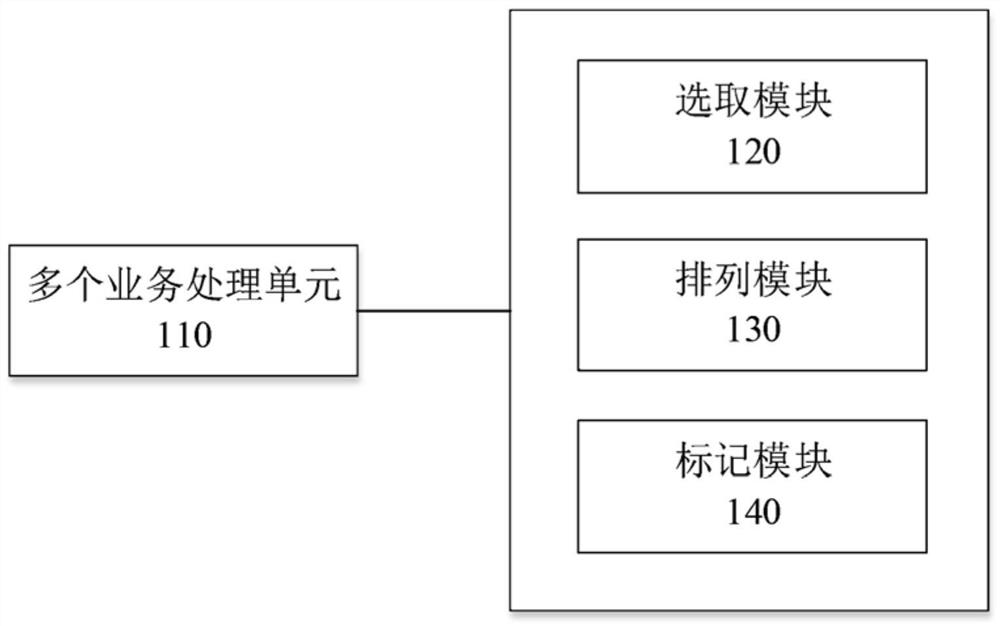

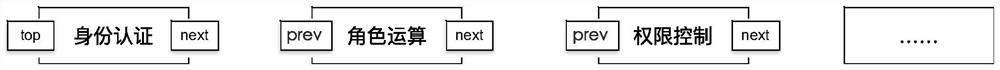

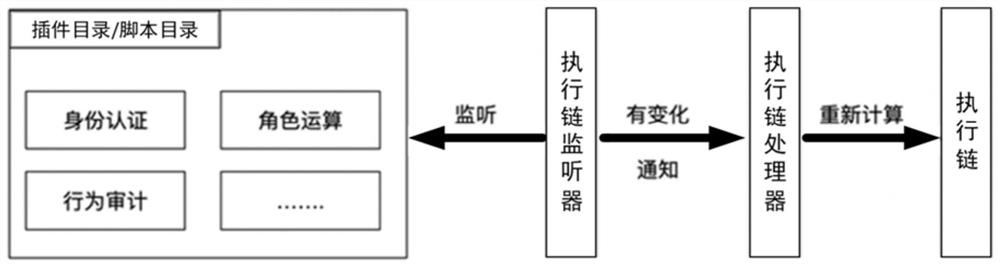

Multi-source fusion identity authentication system and method

InactiveCN112738045ARealize customized functionsRealize dynamic adjustmentDigital data authenticationProgram loading/initiatingSoftware engineeringProcessing element

The invention discloses a multi-source fusion identity authentication system and method. The multi-source fusion identity authentication system comprises a plurality of service processing units, and further comprises a selection module, an arrangement module and a marking module, wherein the selection module is used for selecting each service processing unit matched with the current service from the plurality of service processing units; the arrangement module is used for arranging the selected service processing units into a service processing unit chain according to an execution sequence; and the marking module is used for marking the sequence of the business processing units in the business processing unit chain on the arranged business processing units. According to the multi-source fusion identity authentication system and the method, each service processing unit processes own service and performs own functions and responsibilities clearly, and each node of the chain type identity authentication process can adjust the execution sequence or tailor according to the requirements of the service, so that dynamic adjustment is realized.

Owner:3CLEAR SCI & TECH CO LTD

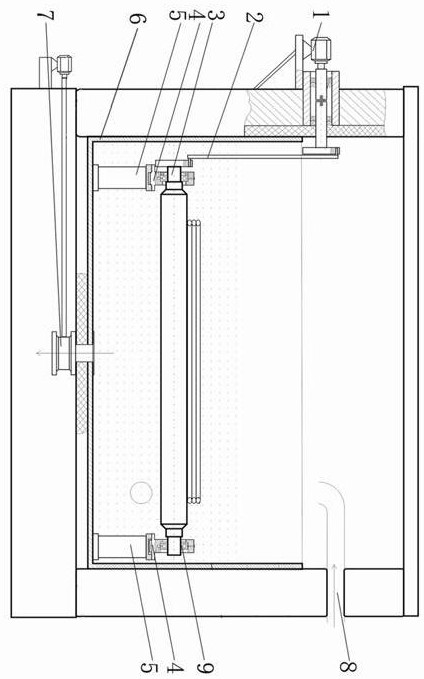

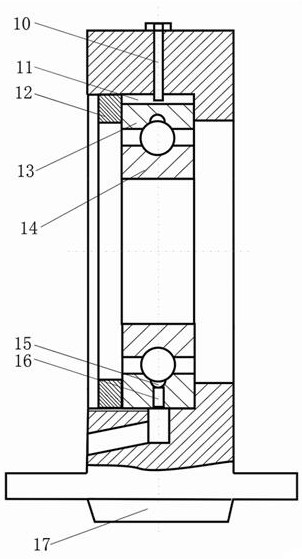

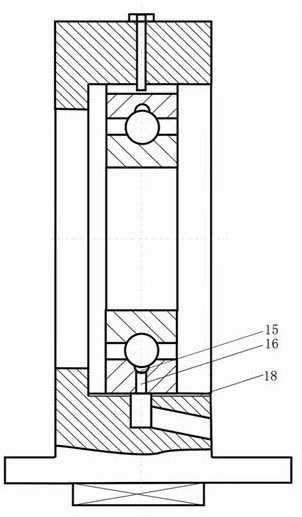

In-groove roller bed full-immersion type salt bath heat treatment device

PendingCN113684352AGuaranteed uptimeEvenly heatedHeat treatment process controlQuenching agentsElectric machineMolten salt

The invention relates to an in-groove roller bed full-immersion type salt bath heat treatment device. The in-groove roller bed full-immersion type salt bath heat treatment device comprises a salt bath groove, supports and a motor, a plurality of conveying rollers are arranged in the salt bath groove, and a continuous conveying roller way is formed through the conveying rollers; the two ends of each conveying roller are installed in the salt bath groove through the supports, the motor is installed outside the salt bath groove, and a transmission mechanism is arranged between the motor and the conveying rollers. According to the in-groove roller bed full-immersion type salt bath heat treatment device, a support and a conveying roller can be wholly immersed below the molten salt liquid level of the salt bath groove, so that all parts are heated uniformly, thermal deformation is kept consistent, and the in-groove roller bed full-immersion type salt bath heat treatment device can normally operate in high-temperature molten salt.

Owner:东营恒基石油科技有限公司

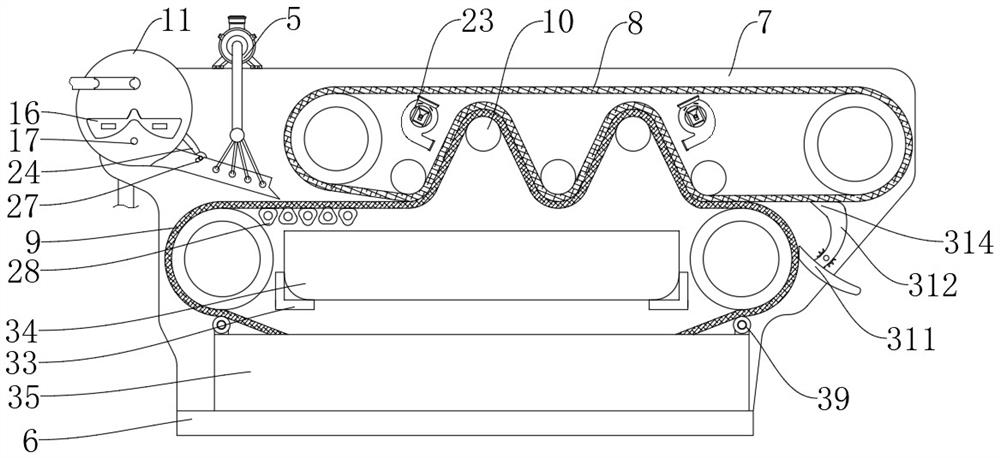

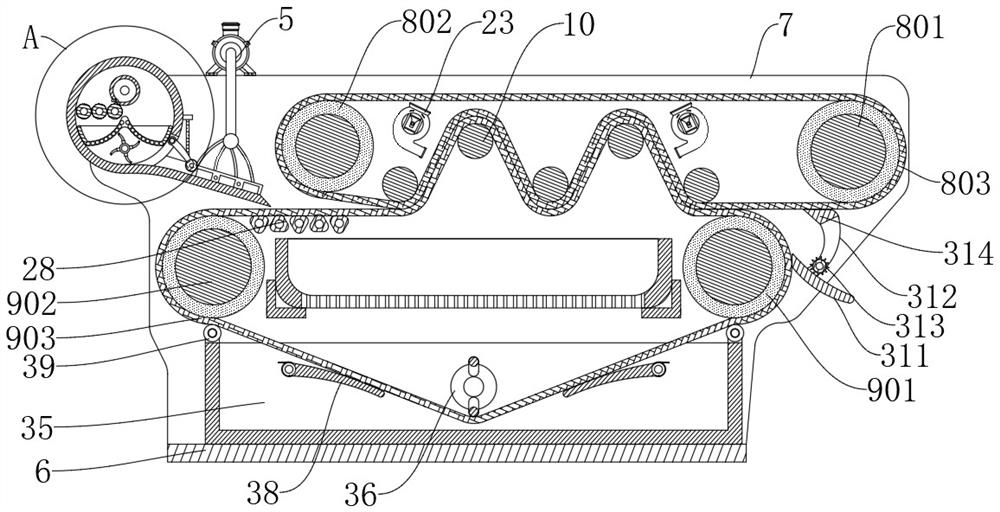

A kind of environmental protection sludge treatment equipment for water conservancy projects

ActiveCN112194330BFilter evenlyImprove processing efficiencySludge treatmentMoving filtering element filtersSludgeBelt filter

The invention discloses an environmental protection sludge treatment equipment for water conservancy projects, which comprises a belt filter press body, a reaction stirring tower is arranged on one side of the belt filter press body, and a mud pump is arranged at the bottom of the reaction stirring tower , one side of the mud pump is provided with a clean water tank, the top of the belt filter press body is provided with a water pump, and one side of the water pump is provided with a distributing device. In the present invention, the impurities in the sludge are broken and intercepted by the crushing roller row and the filter frame, and are homogeneously dispersed by the distributing roller and then smoothed by the pressing plate, gathered and transported to the top of the second conveying pressing belt, and made under the action of the shaking device It is paved inside the distribution trough, the first press belt and the second press belt cooperate with the compacted mud to squeeze out the water, cooperate with the hot air blower to improve the sludge treatment efficiency, reduce the adhesion of impurities, and scrape the material after extruding the mud cake Scraping and crushing mud cake, the device has high working efficiency, can ensure the uniform pressure filtration of sludge, squeeze out water to the greatest extent, and reduce the loss of the device.

Owner:陈峰

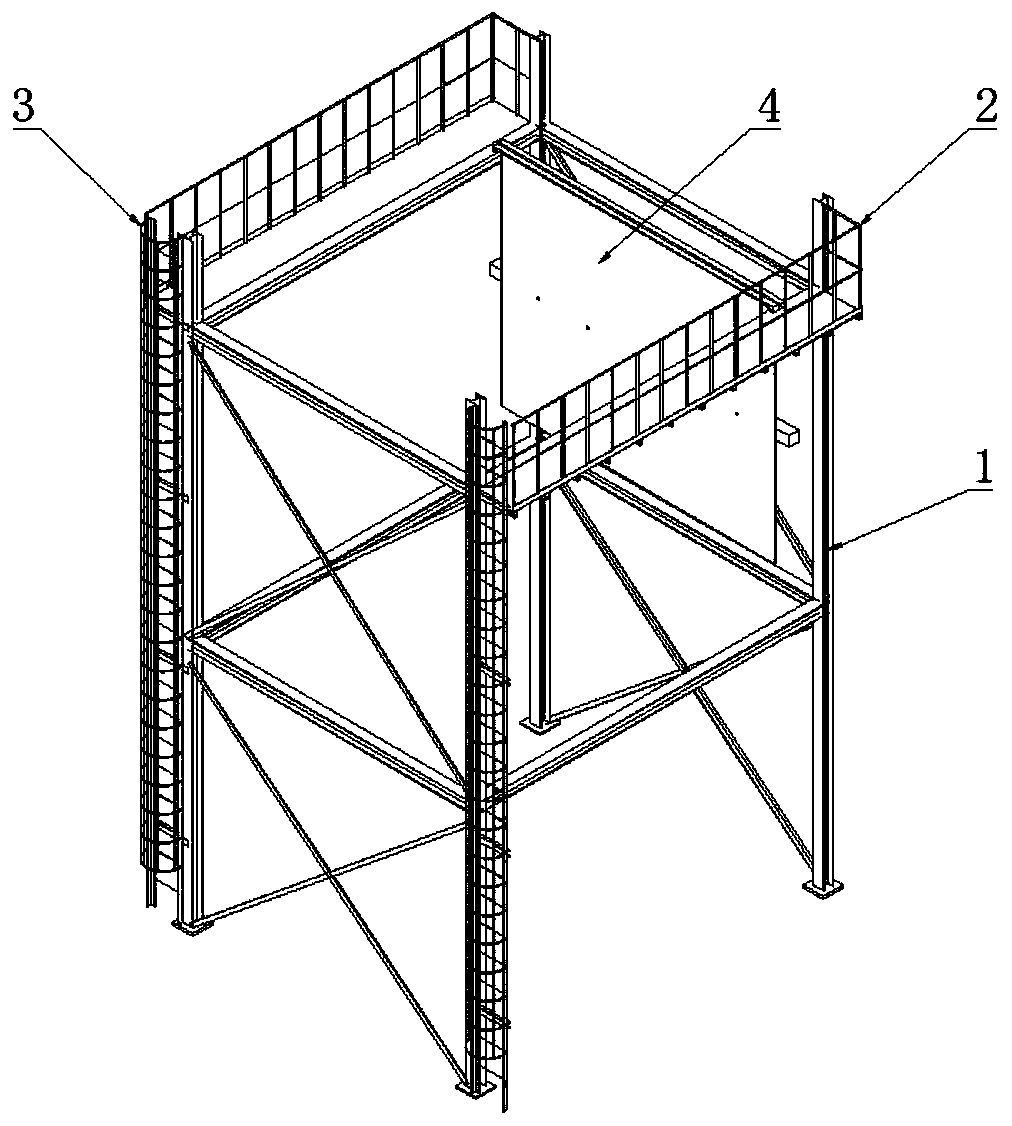

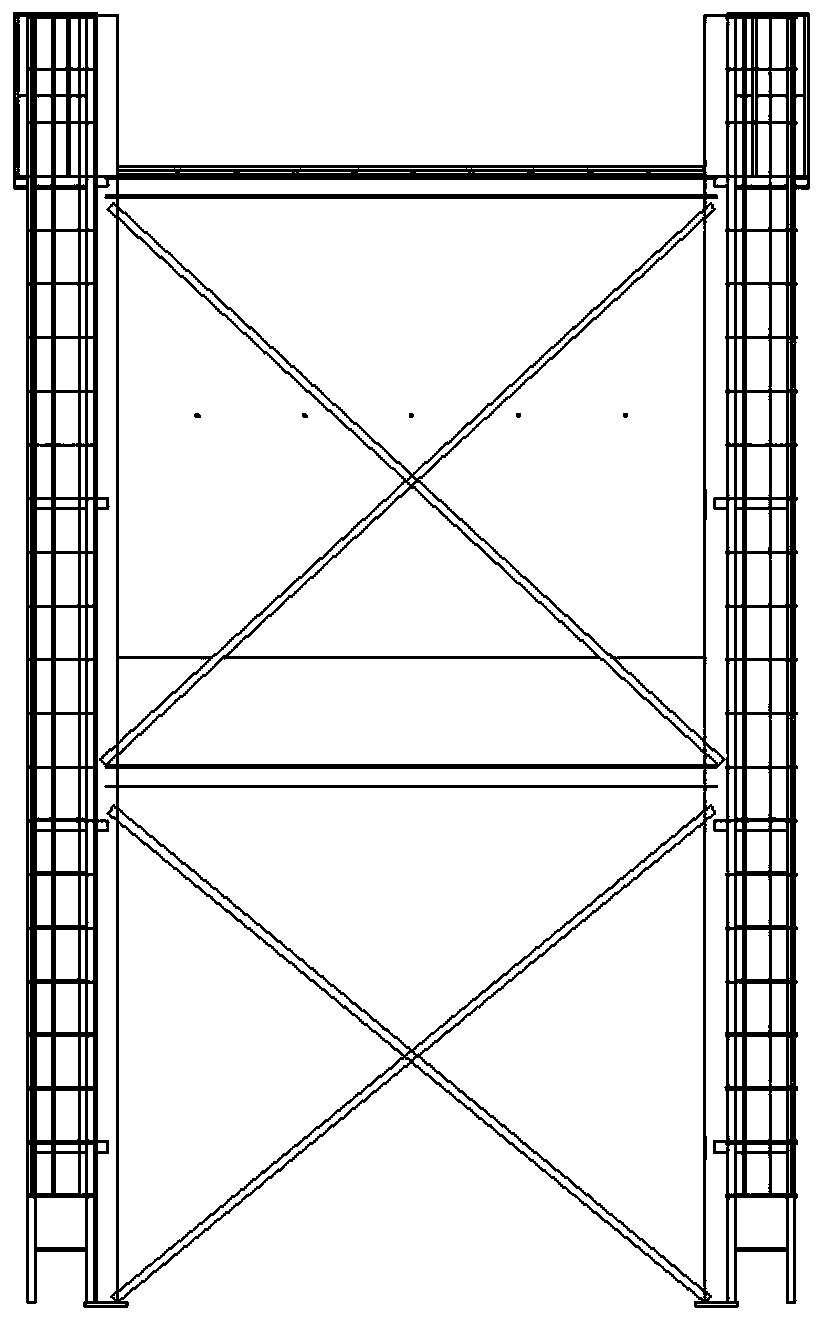

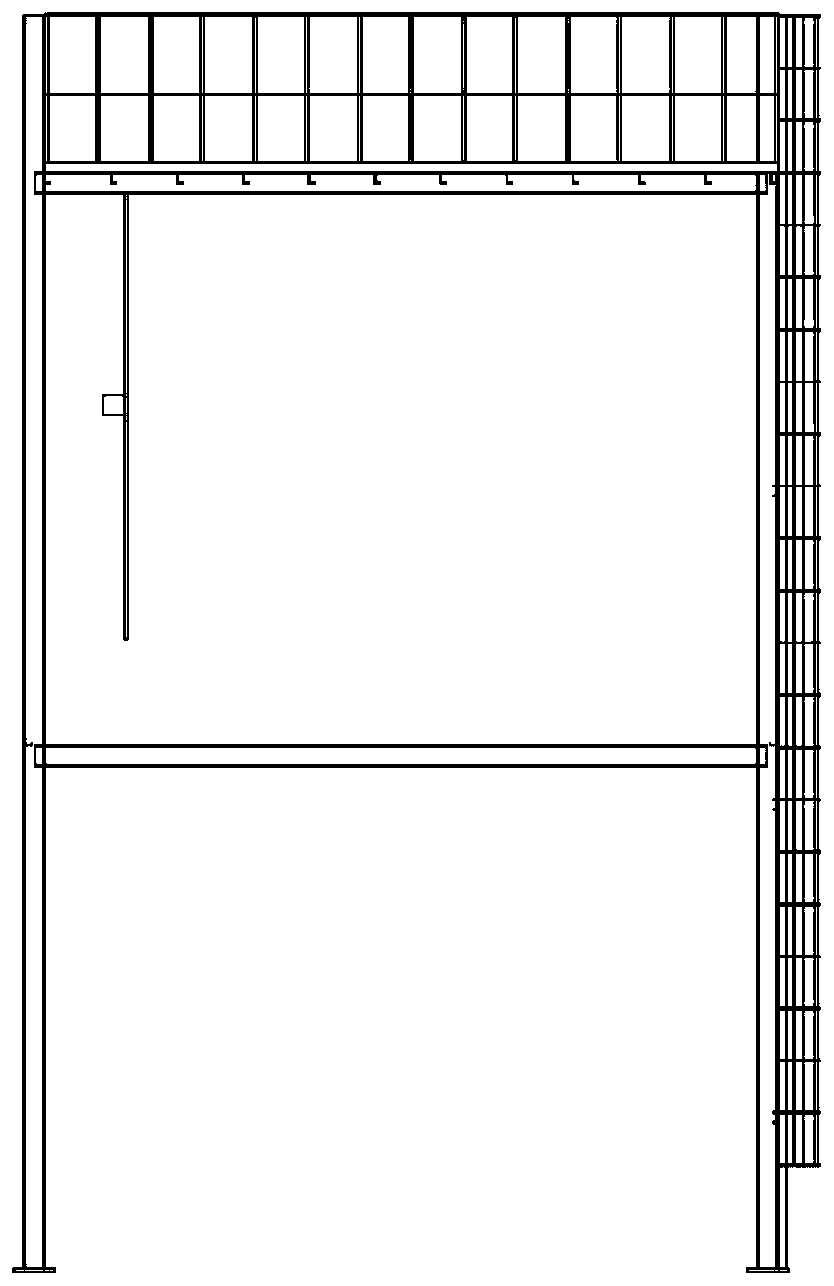

Storage tool for anode rows of tank type electric dust remover and use method

PendingCN111251267AShorten production downtimeNo downtime for maintenanceWork tools storageDust controlProcess engineering

The invention provides a storage tool for anode rows of a tank type electric dust remover. The storage tool comprises a component module and an operation module, wherein the component module is used for placing the anode rows, and the operation module is connected with the component module and used for assisting in placing the anode rows. The invention also provides a use method of the storage tool for the anode rows of the tank type electric dust remover. According to the storage tool for the anode rows of the tank type electric dust remover, the operation module and the component module which are mutually independent are arranged and respectively used for assisting and placing the anode rows, the functions of the operation module and the component module are cooperatively matched, and the operation module and the component module can be assembled, adjusted and stored in advance, so that the shutdown maintenance time is not occupied, and the on-site maintenance period is saved; and the storage tool can be recycled, so that not only is the environmental requirement met, but also the production downtime of the tank type electric dust remover is reduced, and the dust removal efficiency and the production stability are improved.

Owner:MCC TIANGONG GROUP

A sorting device for logistics transportation in response to emergencies

ActiveCN112845111BSimplify work intensityConvenient sorting workSortingLogistics managementVisual inspection

The invention discloses a sorting device for logistics transportation for responding to emergencies, comprising a main conveyor belt on which a packing box position correcting mechanism is arranged, and the packing box position correcting mechanism comprises the following steps in the order of conveying. The first position visual identification mechanism, the first logistics packaging box flanging mechanism, the second position visual identification mechanism and the second logistics packaging box flanging mechanism are provided, and one side of the output end of the main conveyor belt is provided with a logistics label. In the visual inspection mechanism for scanning and identification, the end of the main conveyor belt is provided with a balance wheel logistics sorter, and the ends of the balance wheel logistics sorter are respectively provided with a plurality of connectors for docking the balance wheel logistics sorter. material conveyor belt. The invention ensures that no matter which side the material packing box is affixed with the logistics label, after being corrected by the packing box position correction mechanism, it can be identified by the visual inspection mechanism to read the logistics information on the logistics label, thereby improving the logistics sorting efficiency.

Owner:NANJING INST OF RAILWAY TECH

Abrasion-resistant, anti-drag and damaged surface repair agent for metal and preparation method thereof

ActiveCN102719301BImprove wear resistanceConditions to reduce or control wearAdditivesLanthanum fluorideBoron nitride

The invention belongs to the field of repair agents for surface of metal and in particular relates to an abrasion-resistant, anti-drag and damaged surface repair agent for metal and a preparation method thereof. The repair agent includes, by mass, 2-40% of abrasion-resistant repair powder, 45-95% of lubricating oil and 3-20% of random polyether, and a hexahydric composite emulsifier can also be added, wherein the abrasion-resistant repair powder comprises, by mass, 5-35% of organic molybdenum, 20-60% of lanthanum fluoride, 2-28% of nickel powder, 5-30% of silicon dioxide powder and 3-15% of boron nitride powder. The preparation method includes grinding the lubricating oil, the abrasion-resistant repair powder and the random polyether according to the ratio after even mixing, adding the hexahydric composite emulsifier, and evenly mixing to obtain the repair agent. According to the repair agent, abrasion due to friction can be reduced, the repair function of damaged surfaces is provided, using accuracy and reliability of equipment can be improved, energy and electricity can be saved, and the service life of the equipment can be prolonged.

Owner:兴友新材料科技(山东)有限公司

Control system for cell incubator

ActiveCN113699042BImprove the cultivation effectAvoid overall overheatingBioreactor/fermenter combinationsBiological substance pretreatmentsControl systemControl engineering

The present application relates to a control system for a cell incubator, comprising: a first CPU and a second CPU, which are electrically connected to the cell incubator through a serial bus, and receive and output signals from and to the cell incubator, which are mutually The same, the two are connected in parallel and run alternately with each other; the first isolated driver IC is isolated from the first CPU signal, and the two are connected to each other through a serial bus; the second isolated driver IC is isolated from the second CPU signal, the two connected to each other through a serial bus; and a cabin control unit, respectively connected to the first isolation driver IC and the second isolation driver IC through the serial bus, including a PID control unit, a heater drive circuit, a thermistor, red, green, and blue LED control circuit, gate control switch. The heating plate adopts PWM modulation to control the heating temperature, and the temperature is collected by PT1000 to realize the temperature closed-loop PID control. The control system of the cell incubator according to the present application can be used for dual-machine fault-tolerant control of various cell incubators.

Owner:华艾博越(上海)生物医疗科技有限公司

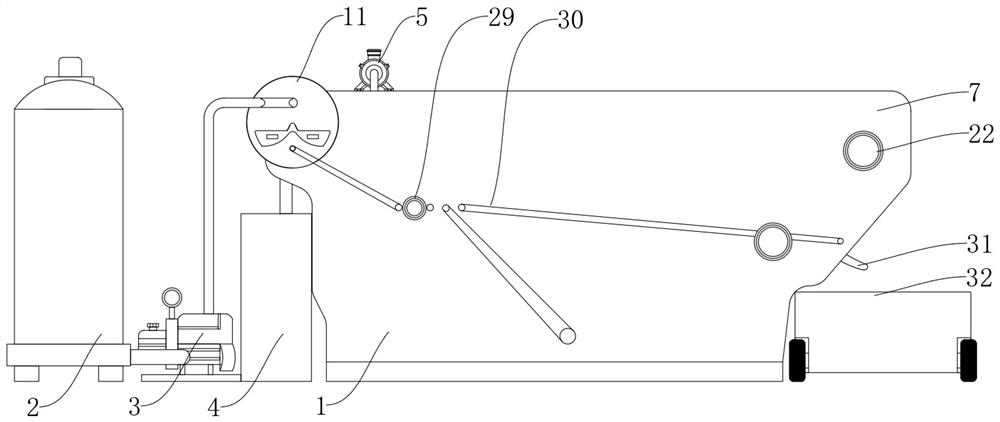

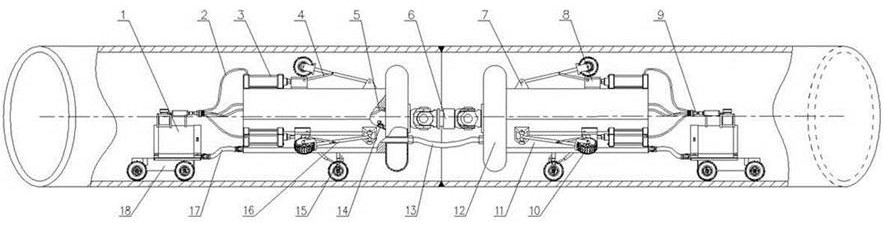

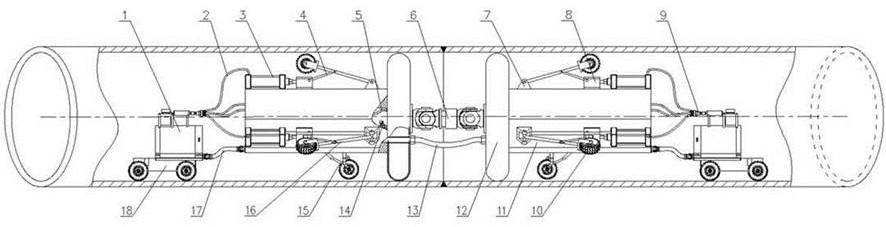

Airflow preventing device used for oil-gas pipeline welding

InactiveCN112228689ARealize working under pressureRealize remote controlWelding/cutting auxillary devicesPipe elementsLine tubingUniversal joint

The invention relates to an airflow preventing device used for oil-gas pipeline welding. The airflow preventing device is mainly composed of an inflating device, an air cylinder inflating pipeline, anair cylinder, a sliding supporting shaft, an air bag inflating pipeline, a universal joint, a fixed hinged support, a sliding hinged support, a multi-way joint, a centering wheel, a box body, an airbag, a ventilating hose, an air bag air escape valve, a load-bearing wheel, a fixed supporting shaft, a traction hinge and a tractor, the structure of the airflow preventing device is symmetrical about the universal joint, the inflating device is installed on the tractor and inflates the air cylinder through the air cylinder inflating pipeline and inflates the air bag through the air bag inflatingpipeline, the air cylinder, the sliding supporting shaft, the fixed hinged support, the sliding hinged support, the centering wheel and the fixed supporting shaft are all installed on the box body, the sliding hinged support slides under the action of the air cylinder through the sliding groove in the box body, so that the fixed supporting shaft is driven to be opened, and the centering wheel acts on the pipelines to achieve the centering effect. The airflow preventing device used for oil-gas pipeline welding can be used for realizing under-pressure maintenance of the in-service pipelines with cracks and other problems which occur.

Owner:SOUTHWEST PETROLEUM UNIV

Automatic purging system for carbon black flue gas desulfurization oxidation air pipeline

PendingCN114191976AEliminate false positivesReduce appearance effectGas treatmentDispersed particle separationEnvironmental engineeringControl valves

The invention discloses a carbon black flue gas desulfurization oxidation air pipeline automatic purging system, which comprises a desulfurization tower, an oxidation fan and a PLC controller, the air outlet end of the oxidation fan is connected with an oxidation air main pipe, the desulfurization tower is provided with an oxidation air branch pipe entering the desulfurization tower from top to bottom, the inner end of the oxidation air branch pipe is provided with an air outlet pipe, and the air outlet pipe is connected with the PLC controller. A plurality of downward air outlet nozzles are arranged in the air outlet pipe, a water inlet pipe communicated with each oxidation air branch pipe is arranged at the front end of each oxidation air branch pipe, an electromagnetic control valve is arranged on each water inlet pipe, and a flow meter corresponding to the interior of each oxidation air branch pipe is further arranged at the front end of each oxidation air branch pipe; and an electric cleaning mechanism for cleaning the air outlet nozzles on each air outlet pipe is arranged on the desulfurizing tower. The air outlet nozzle can be cleaned without shutdown, smoothness of an oxidation air pipeline of a desulfurization system is guaranteed, and efficient and stable operation of the desulfurization system is guaranteed.

Owner:CHAOYANG BLACK CAT WUXINGQI CARBON BLACK CO LTD

Dynamic ice cold storage deicing system and method

PendingCN110307681AAvoid increased energy consumptionWorks wellLighting and heating apparatusIce productionIce storageChiller

The invention relates to a dynamic ice cold storage deicing system. The dynamic ice cold storage deicing system comprises an ice storage tank, an ice crystal filter, a first valve, a circulating pumpand a supercooler which are arranged in sequence. Two supercooler inlet branches are arranged between the circulating pump and the supercooler. One supercooler inlet branch is provided with a second valve and a filter screen. The other supercooler inlet branch is provided with a third valve, a laval pipe and a fourth valve. An outlet pipe of the supercooler is connected with a ball collection tankthrough a deicing ball removing interceptor. An electric filter screen is arranged in the deicing ball interceptor. A fifth valve is arranged on an outlet pipe of a cooler. The ball collection tank is internally provided with deicing balls. A deicing ball outlet pipe of the ball collection tank is connected with the laval pipe through a sixth valve. The dynamic ice cold storage deicing system eliminates ice blockage in the manner that deicing balls circulate and flow in a pipe of the supercooler. The dynamic ice cold storage deicing system has the advantages that the system is simple in structure and reliable in operation and has no influence on cold storage energy consumption; and the deicing system and an ice storage system can operate simultaneously.

Owner:江苏双良低碳产业技术研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com