Preparation method of high-solid content catalytic cracking catalyst

A catalytic cracking, high solid content technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of complex process and high preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

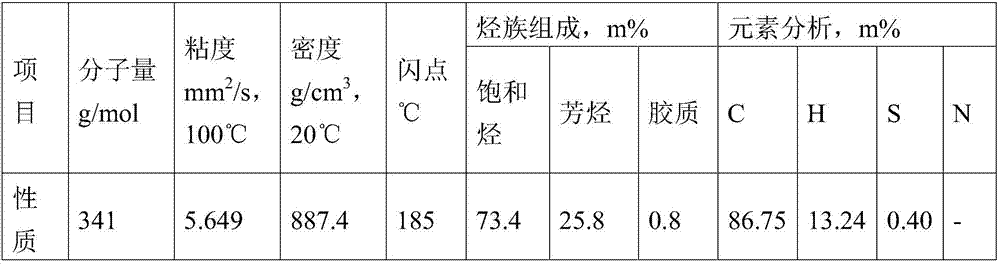

Image

Examples

Embodiment 1

[0034] Add 2540 grams of deionized water, 800 grams of aluminum sol, 1656 grams of pseudoboehmite in the reaction kettle, add 187 grams of ammonium chloride reagent after beating for 10 minutes, stir for 15 minutes, let stand for 24 hours, then stir, add 138 60 grams of concentrated phosphoric acid, stirred for 30 minutes, then added 60 grams of concentrated phosphoric acid, stirred for 10 minutes, added 1652 grams of kaolin, stirred for 15 minutes, then added 784 grams of REY molecular sieve, 60 grams of ZSM-5 molecular sieve and 600 grams of USY molecular sieve, and stirred evenly , spray-dried, and the obtained catalyst particles were calcined at 500° C. for 30 minutes, then added 8 times of deionized water, stirred evenly, filtered and dried to obtain the FCC catalyst prepared by the method of the present invention, which was recorded as A1.

[0035] The solid content of the catalyst A1 spray slurry was 48%, the slurry viscosity was 4338 centipoise, the wear index of the ob...

Embodiment 2

[0037] Add 1530 grams of deionized water, 635 grams of aluminum sol, and 882 grams of pseudoboehmite in the reaction kettle, add 3612 grams of lanthanum chloride heptahydrate reagent after beating for 10 minutes, stir for 25 minutes, let stand for 20 hours, then stir, Add 185 grams of boric acid, stir for 20 minutes, add 30 milliliters of rare earth chloride, 30 grams of phosphoric acid, 668 grams of kaolin, stir for 10 minutes, then add 678 grams of REY molecular sieves, 40 grams of ZSM-5 molecular sieves and 369 grams of USY molecular sieves, and stir evenly , spray-dried, and the obtained catalyst particles were calcined at 500° C. for 30 minutes, then added 5 times of deionized water, stirred evenly, filtered and dried to obtain the FCC catalyst prepared by the method of the present invention, and recorded as A2.

[0038] The solid content of the catalyst A2 spray slurry was 51%, the slurry viscosity was 4567 centipoise, the wear index of the obtained catalyst was 1.4%, and...

Embodiment 3

[0040] Add 2530 grams of deionized water, 779 grams of aluminum sol, and 1082 grams of pseudoboehmite in the reaction kettle, add 2307 grams of magnesium nitrate hexahydrate reagent after beating for 10 minutes, stir for 15 minutes, let stand for 13 hours, and then add 1000 grams of Stir silicic acid for 20 minutes, add 78 grams of boric acid, stir for 30 minutes, then add 1240 grams of silicic acid and stir for 20 minutes, add 737 grams of REY molecular sieve, 35 grams of ZSM-5 molecular sieve and 296 grams of USY molecular sieve, stir for 10 minutes, add 752 grams of Kaolin, stirred evenly, spray-dried, the obtained catalyst particles were roasted at 500°C for 30 minutes, then added 8 times deionized water, stirred evenly, filtered and dried to obtain the FCC catalyst prepared by the method of the present invention, which was recorded as A3.

[0041] The solid content of the catalyst A3 spray slurry was 57%, the slurry viscosity was 4039 centipoise, the wear index of the obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com