Plough share assembly, turnover plow, plough share assembly overload protection control method and tractor

A control method and overload protection technology, which is applied to the plowshare assembly, the overload protection control method of the plowshare assembly, and the field of tractors and flip plows, can solve problems such as downtime maintenance, plowshare assembly damage, impact, etc., to avoid damage and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

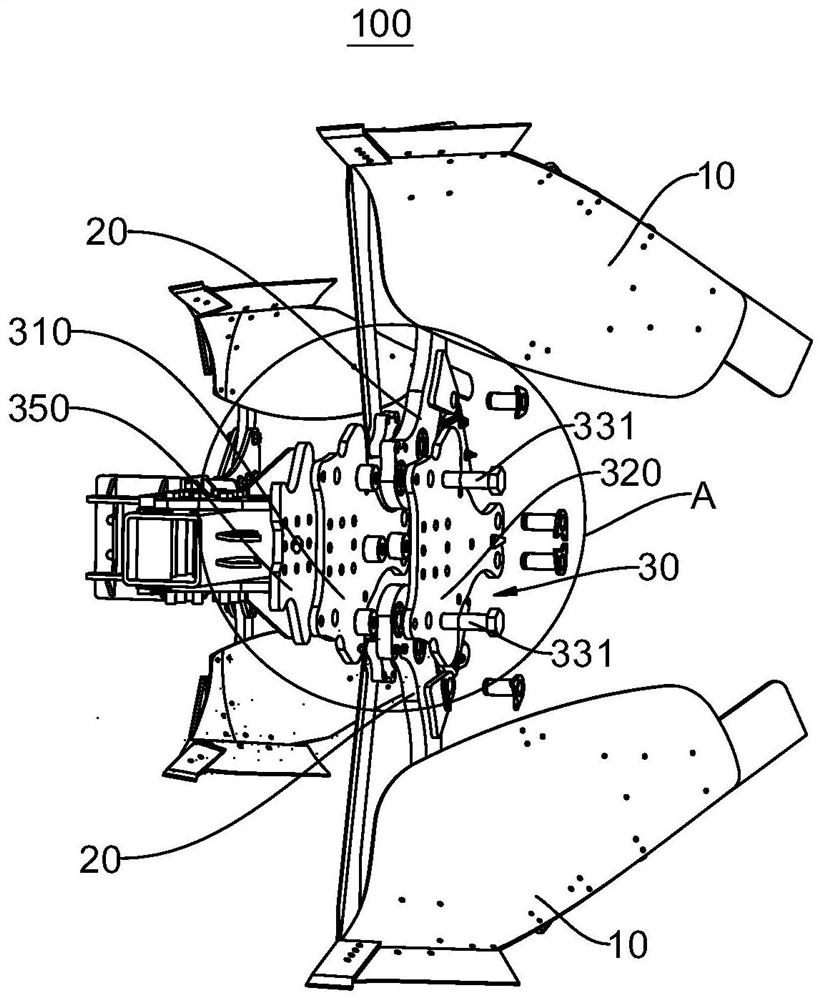

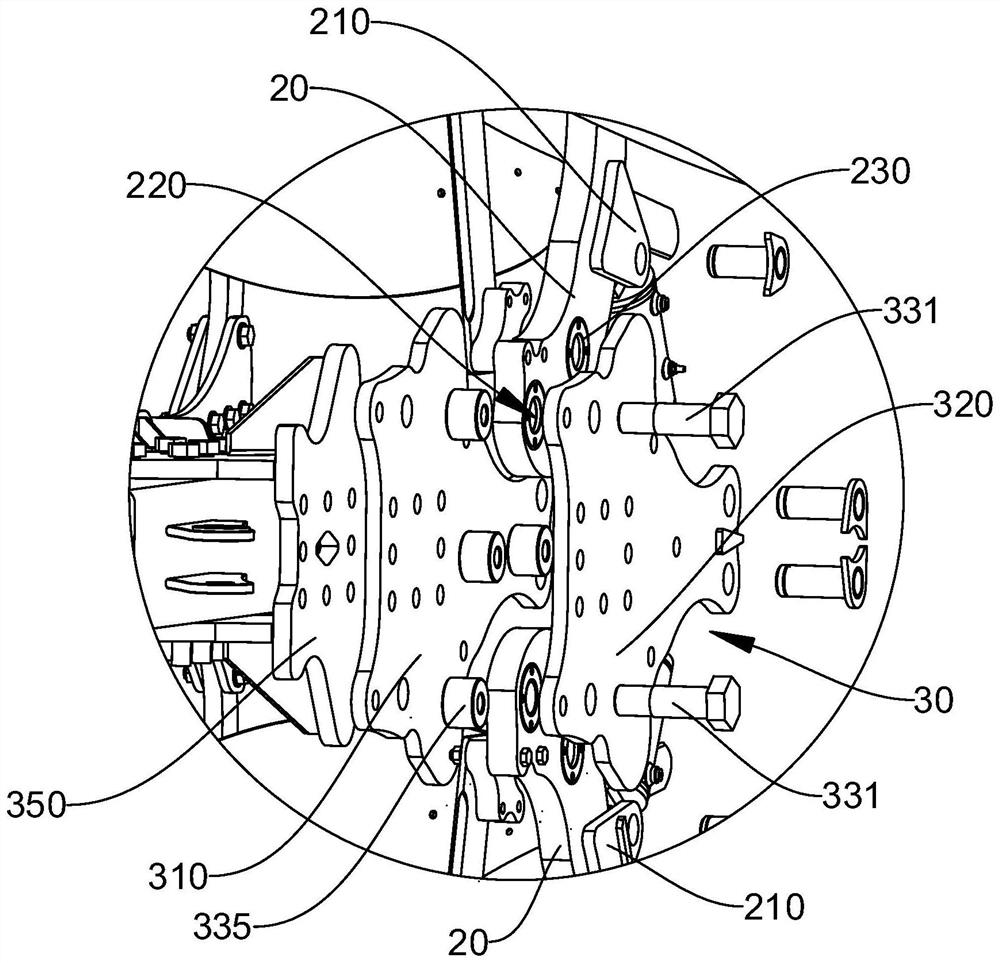

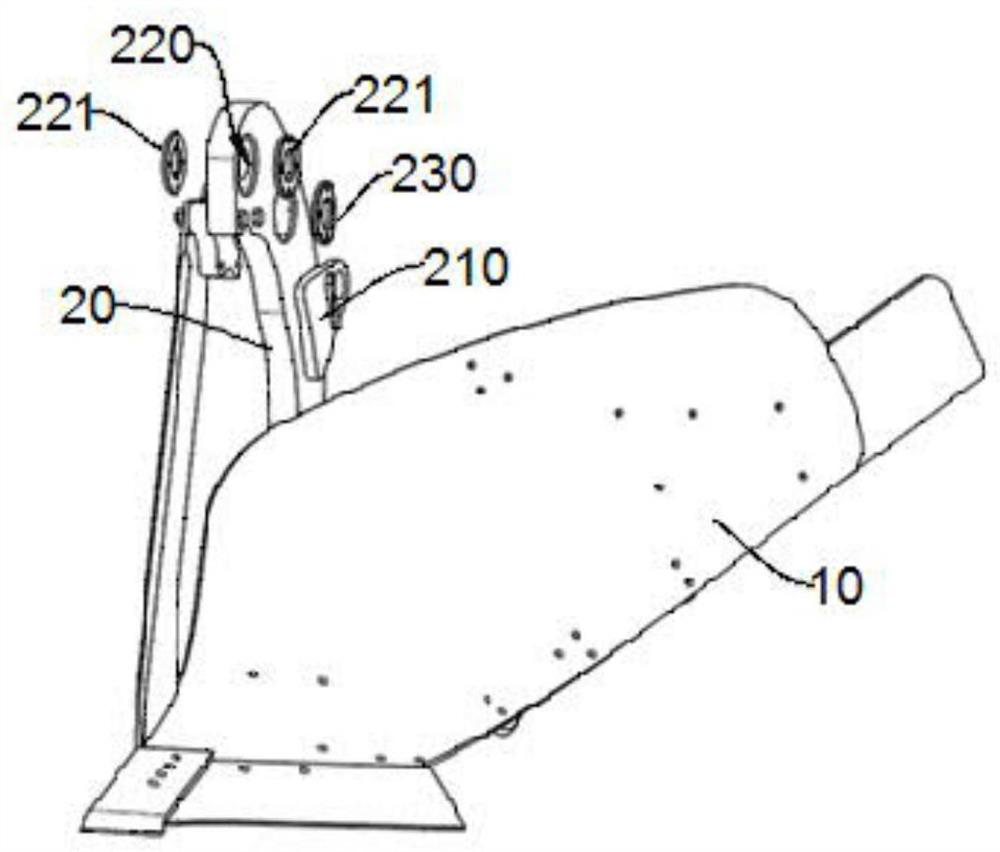

[0048] Please refer to Figure 1 to Figure 4, the present embodiment provides a plowshare assembly 100, including a plowshare 10, a plow column 20, a mounting seat 30 and a buffer cylinder 40, the plowshare 10 is fixedly connected to the plow column 20, and the plow column 20 is rotatably connected to the mounting seat 30, One end of the buffer oil cylinder 40 is connected to the plow column 20 , and the other end is connected to the mounting seat 30 . The plow column 20 can rotate relative to the mounting seat 30 under the action of external force to compress the buffer oil cylinder 40 . Since the plow column 20 is rotationally connected to the mounting seat 30, when the plowshare 10 encounters an obstacle, the plow column 20 is forced to rotate relative to the mounting seat 30, thereby compressing the buffer cylinder 40, and passing the resistance and impact generated by the obstacle through the buffer cylinder 40 absorption, thereby realizing the overload protection of part...

no. 2 example

[0057] An embodiment of the present invention provides a reversible plow, including the above-mentioned plowshare assembly 100. If the reversible plow encounters an obstacle during the digging operation, the buffer cylinder 40 on the plowshare assembly 100 can absorb the resistance from the obstacle, thereby The damage to the plowshare assembly 100 is avoided, and there is no need to shut down the plow for maintenance, which improves the working efficiency of the turning plow.

[0058] Please refer to Figure 5 , the present invention provides an overload protection control method for the plowshare assembly 100, which can be applied to a tractor, and the tractor is used to mount the above-mentioned reversible plow to drive the reversible plow to perform operations. The tractor includes a controller, and the control method includes:

[0059] S10: receiving the overload signal of the buffer cylinder 40;

[0060] S20: Control the tractor to stop according to the overload signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com