Cooling device of alumina decomposition pond

A cooling device, alumina technology, applied in the direction of alumina/hydroxide, etc., can solve problems such as abnormal production and operation, frequent disassembly and maintenance, easy blockage of plate heat exchanger equipment, etc., to achieve high energy-saving benefits and application value , Long service life, no material clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

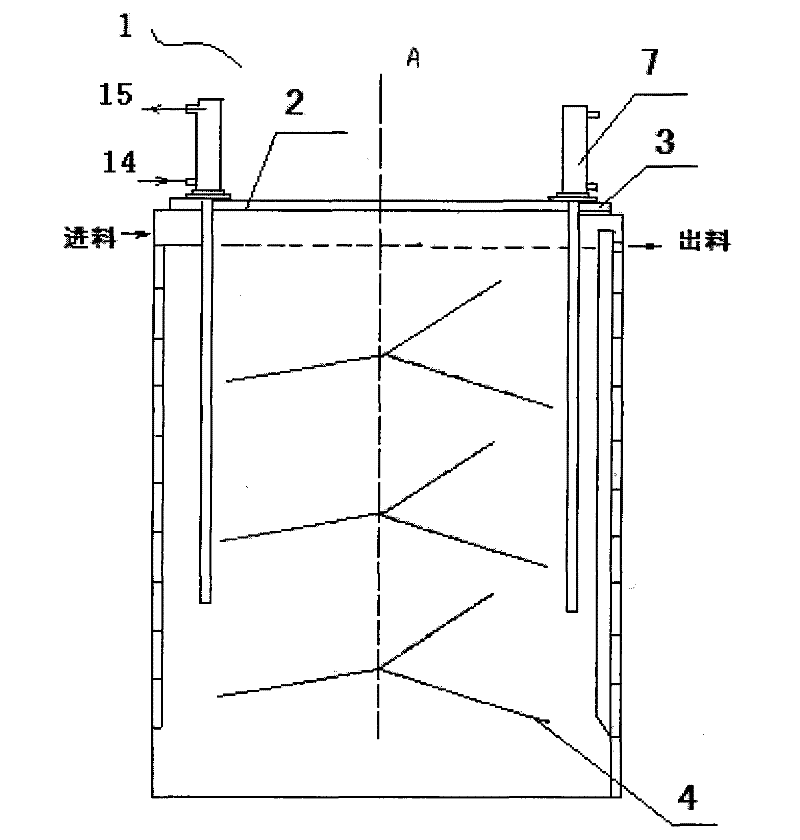

[0019] figure 1 It is a structural schematic diagram of the cooling device of the alumina decomposition tank of the present invention.

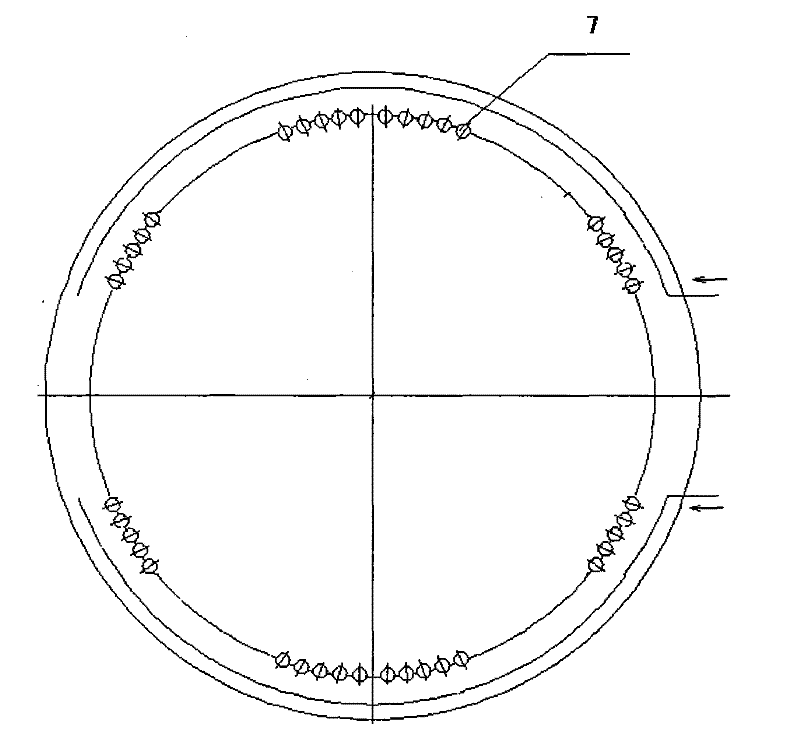

[0020] refer to figure 1 As shown, a cooling device for an alumina decomposition tank, the specifications are as follows: The diameter of the decomposition tank 1 is 14000mm, and the top area is 153.86M 2 , The top plate 2 of the decomposition tank and the heat pipe 7 are installed in a detachable manner, which is convenient for installation and maintenance to replace a single heat pipe. The stirring blade 4 in the decomposition tank has a diameter of 9000 mm, and the outer diameter of the blade has a circumferential distance of 24000 mm from the inner wall of the decomposition tank.

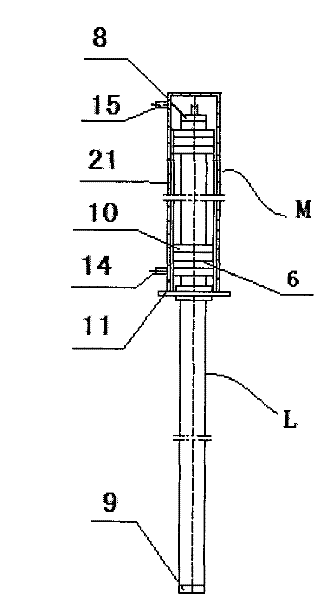

[0021] figure 2 Schematic diagram of the structure of the heat pipe, refer to figure 2 As shown, the heat pipe is provided with an upper head 8 for sealing, a lower head 9, a high-frequency welding spiral fin 6 with a flow guide groove 10 for increasing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com