Distribution device suitable for rail transmission and control method thereof

A control method and track technology, applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve problems such as sorting inconvenience, and achieve the effect of strong control and increased intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

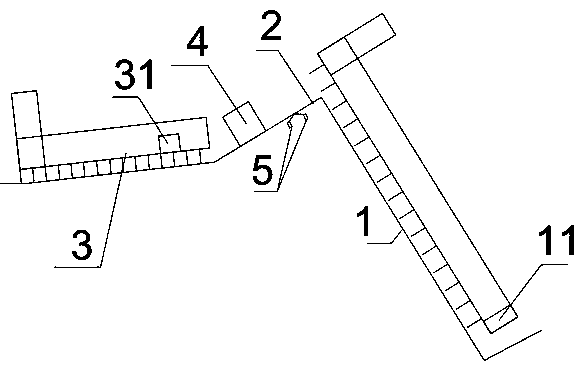

[0049] Example 1, such as figure 1 and Figure 5 As shown, there are three sections of tracks, which are starting track 1, temporary track 2 and transmission track 3 respectively. The direction of travel of the track is in figure 1 Middle is conveying from right to left. The vehicle arrives at the starting track 1 first, and the starting track 1 is provided with a separate motor to make its own track run, thereby driving the vehicle placed on it to move. In this embodiment, the starting track 1 is a lifting track designed for uphill. When there is no carrier, the starting track 1 does not run, and when the carrier is put into the starting track 1, it will be sensed by the starting sensor 11 on it. The starting sensor 11 can be a photoelectric sensor in the prior art. After sensing the carrier, the control system controls the starting track 1 to move forward, and the carrier enters the temporary track 2 from the starting track 1 .

[0050] Suspension track 2 is arranged ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com