Injection molding machine convenient to demold and capable of preventing adhesion

An anti-adhesion and injection molding machine technology, applied in the field of injection molding machines, can solve problems such as damage to injection molding machines and injection molding products, and that the injection molding machine cannot be quickly demolded, so as to facilitate the demoulding work and speed up the demoulding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

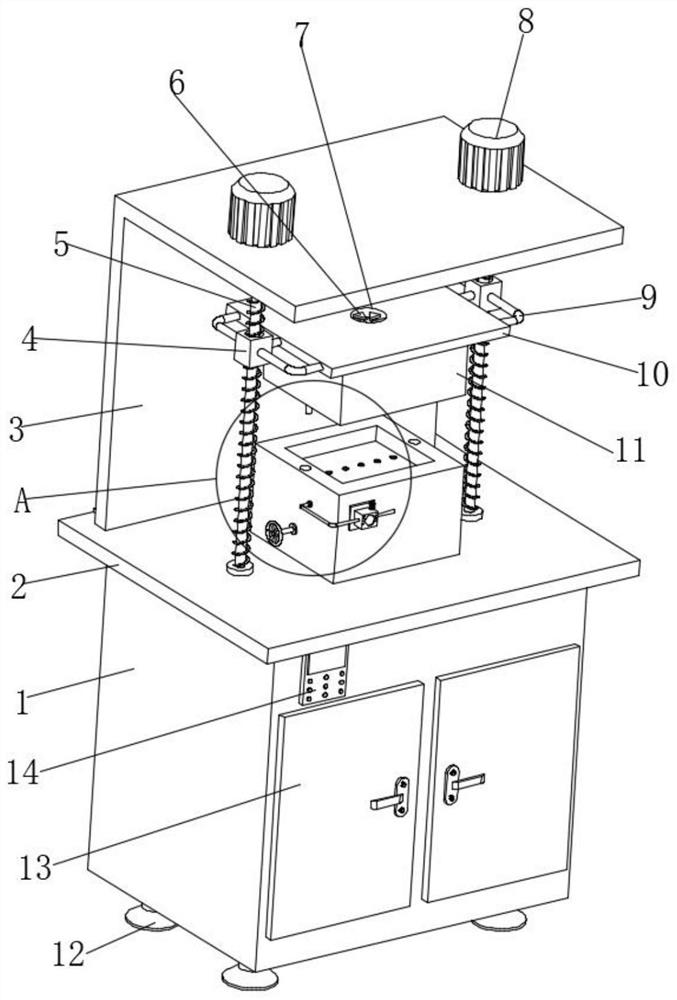

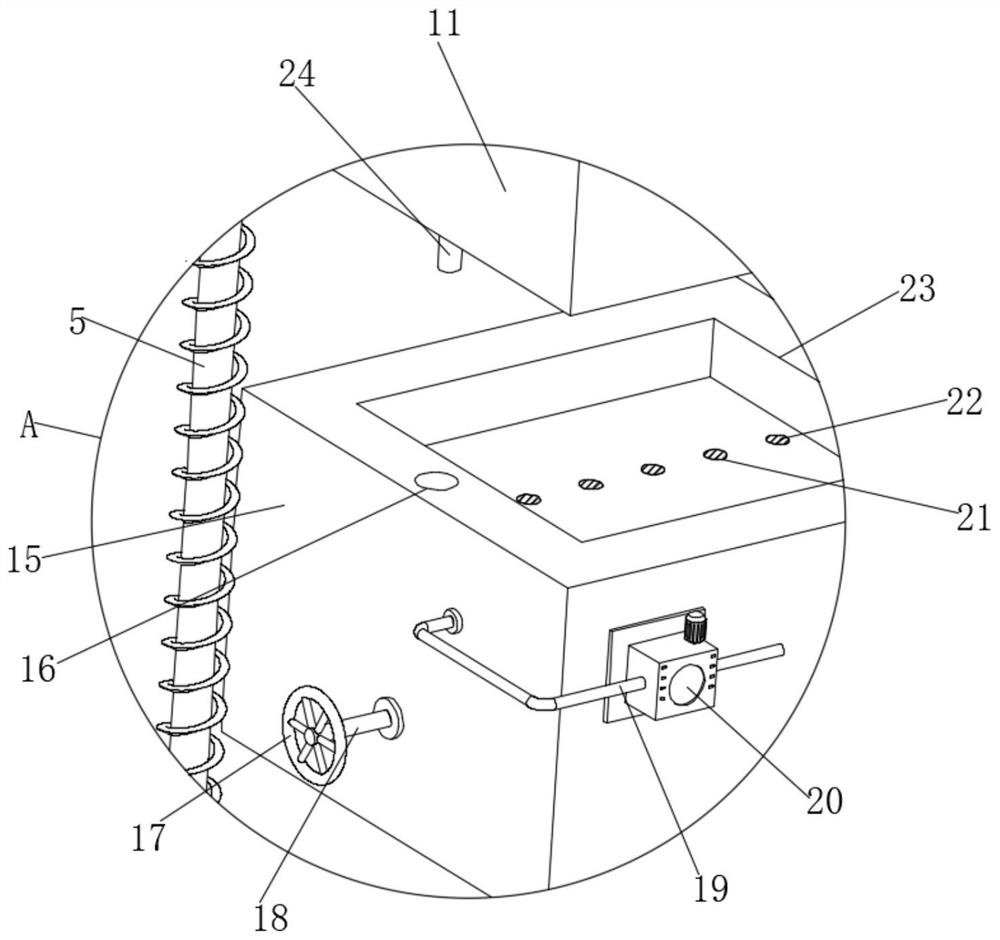

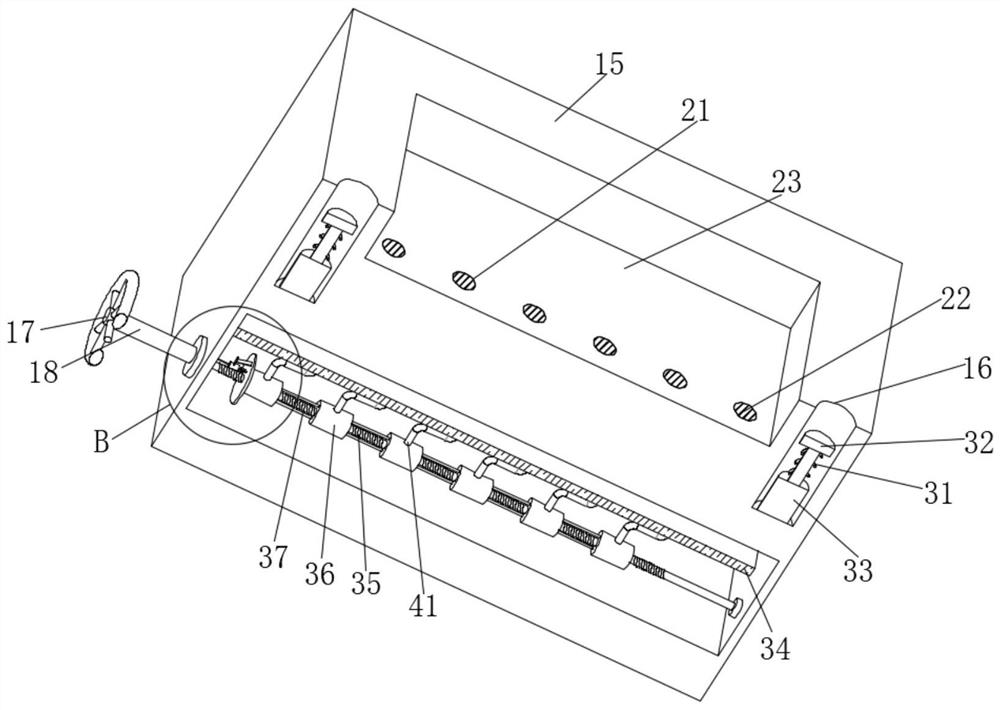

[0031] refer to Figure 1-6 , an injection molding machine for easy demoulding and anti-adhesion, comprising a table body 1, a base 12, a box door 13 and a control panel 14, the top of the table body 1 is fixedly connected with a top plate 2, and the top of the top plate 2 is fixedly connected with a baffle plate 3, The top of the baffle plate 3 is fixedly connected with a motor 8, and one end of the output shaft of the motor 8 is fixedly connected with a first threaded screw rod 5, and the peripheral outer wall of the first threaded screw rod 5 is sleeved with a first threaded sleeve 4, and the first threaded sleeve Both sides of the cylinder 4 are fixedly connected with a fixing frame 9, and one end of the fixing frame 9 away from the first threaded sleeve 4 is fixedly connected with a mounting plate 10, and the bottom of the mounting plate 10 is fixedly connected with an upper mold body 11, and the top of the table body 1 is set There is a lower mold body 15, and one side o...

Embodiment 2

[0035] refer to Figure 7 Compared with Embodiment 1, this example also includes a deflector 30 fixedly connected to the outer wall of the heating column 27. The cross section of the deflector 30 is fan-shaped. Since the cross section of the deflector 30 is fan-shaped, when the injection molding material When it falls into the top of the deflector 30, it can drive the heating column 27 to rotate rapidly. During the rotation of the heating column 27, it can drive the steel needle 29 to evenly defoam the injection molding material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com