High-precision aluminum profile bending mechanism

A bending mechanism and aluminum profile technology, which is applied to metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of reducing the service life of the bending mechanism, affecting the bending accuracy, and easily damaging the aluminum profiles, so as to improve the transmission Stability and transmission accuracy, easy demoulding work, and the effect of improving bending quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

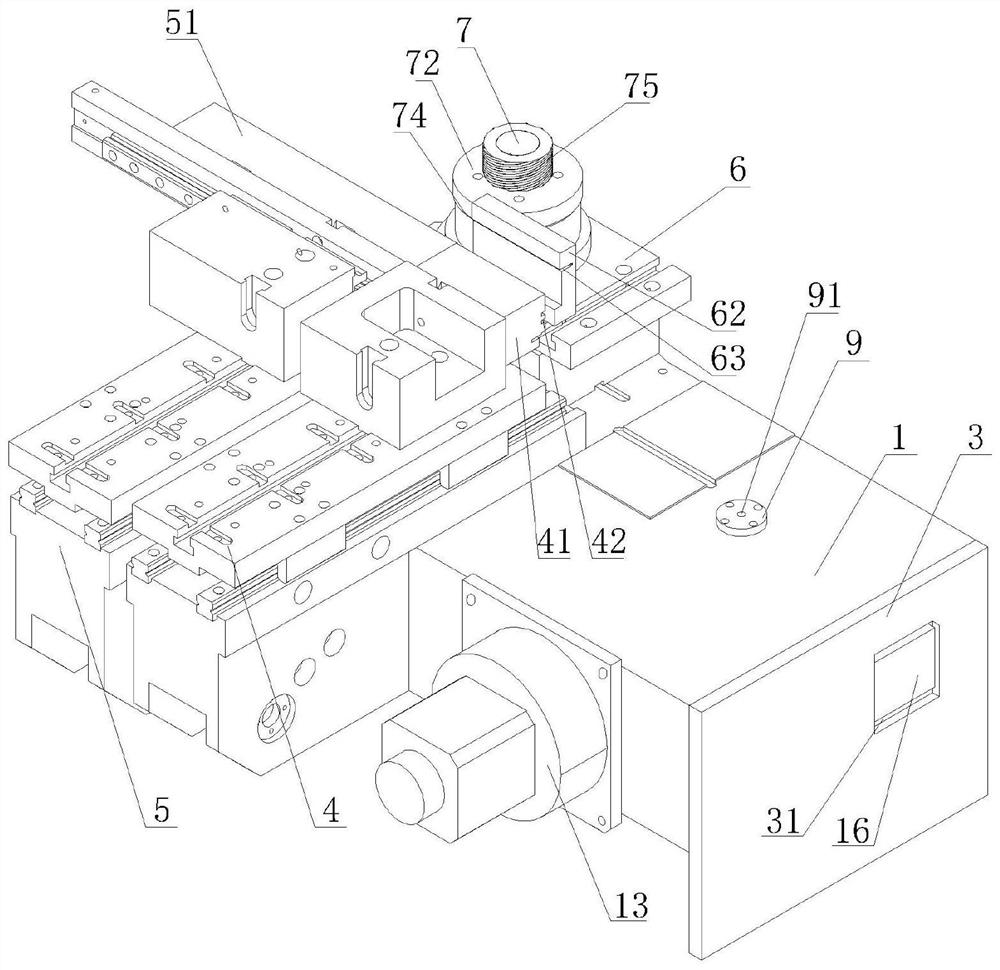

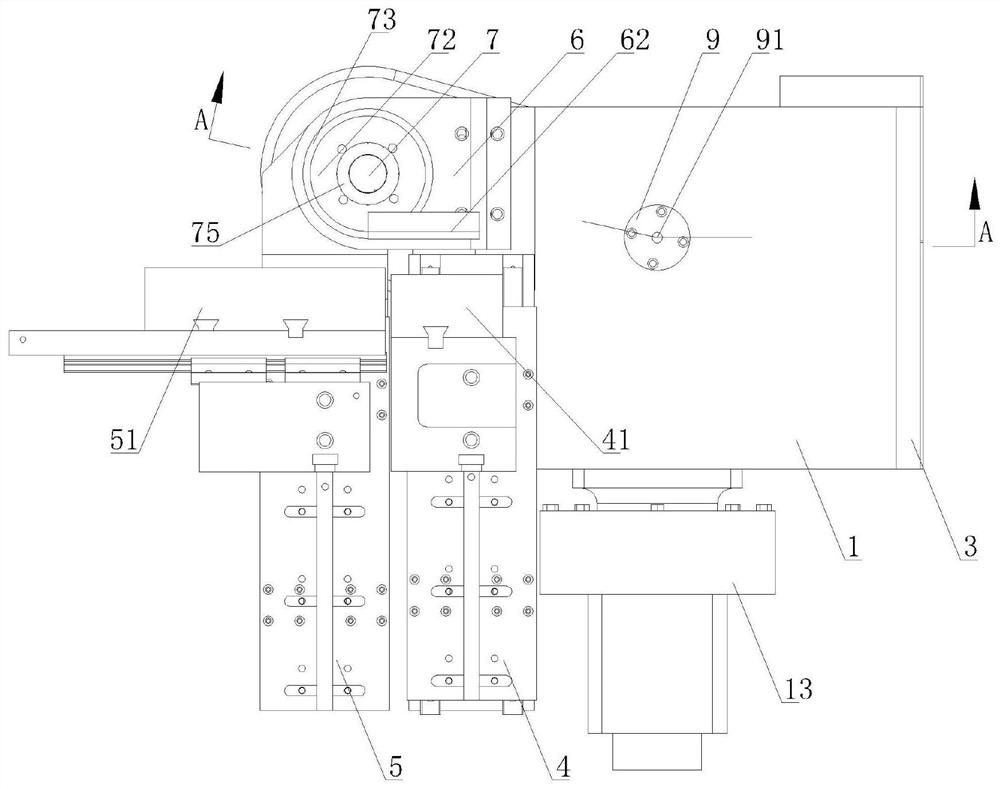

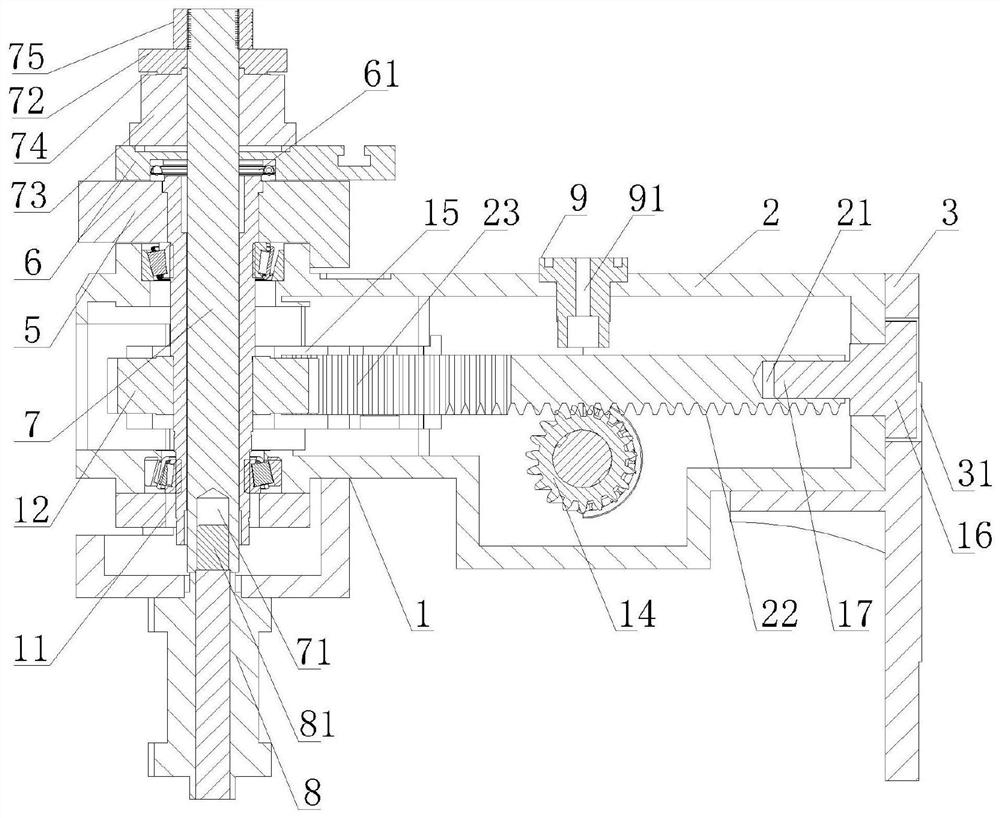

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

[0018] Such as figure 1 , figure 2 , image 3 As shown, the high-precision aluminum profile bending mechanism described in the present invention includes: a frame 1, on which a main shaft tube 11 capable of rotating in the frame 1 is arranged, and the lower end of the main shaft tube 11 is keyed to a The first gear 12 is provided with a servo motor 13 on the frame 1 on the right side of the main shaft tube 12, and the output shaft of the servo motor 13 is keyed with a second gear 14, and is positioned on the frame 1 above the second gear 14. A rack plate 2 is provided for sliding in the middle, and the connection structure between the rack plate 2 and the frame 1 is as follows: a chute cavity 15 is provided at the left end of the frame 1, and the left end of the rack plate 2 extends into the chute cavity 15 and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com