Patents

Literature

35results about How to "Instantaneous gear ratio constant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

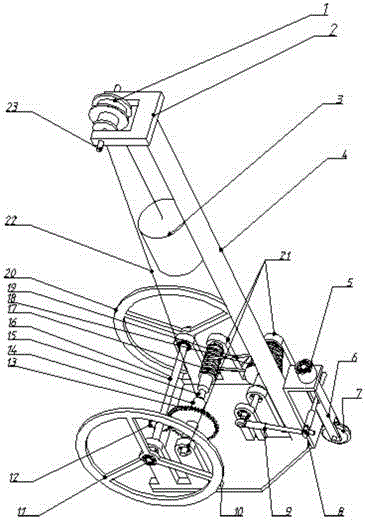

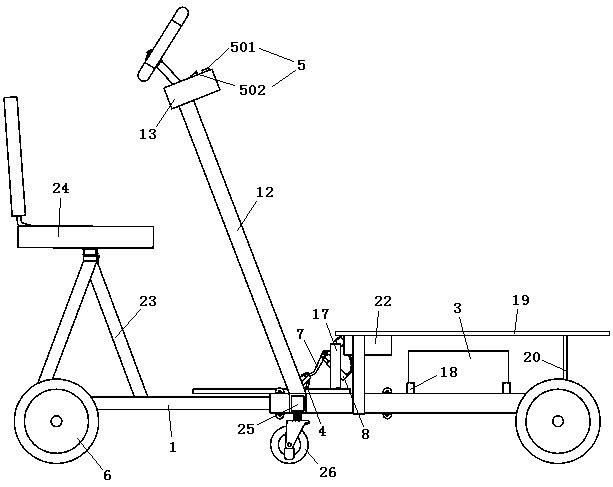

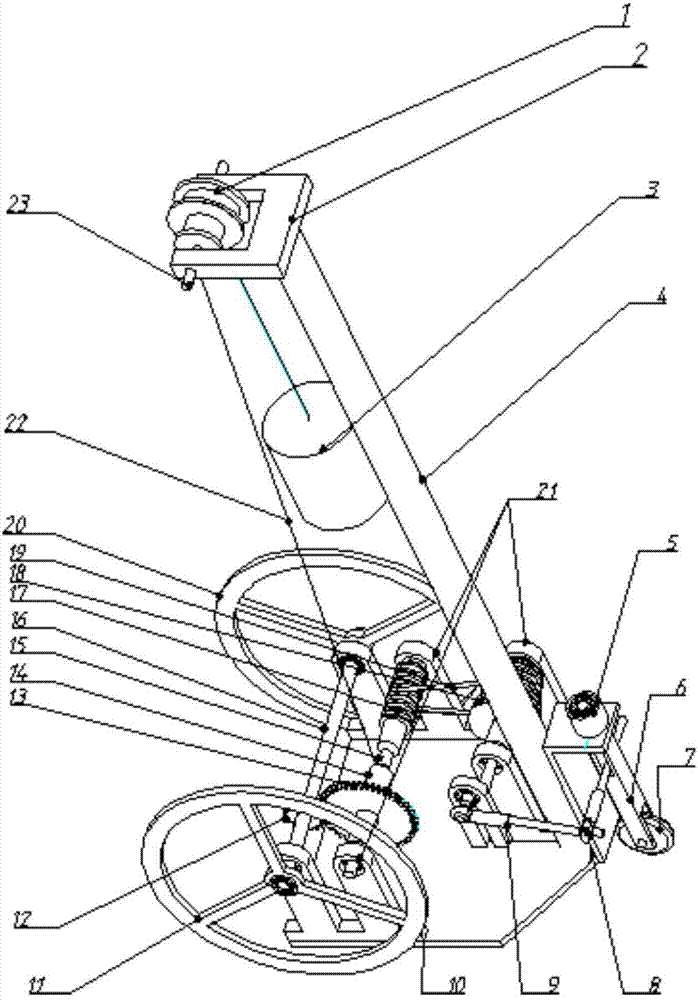

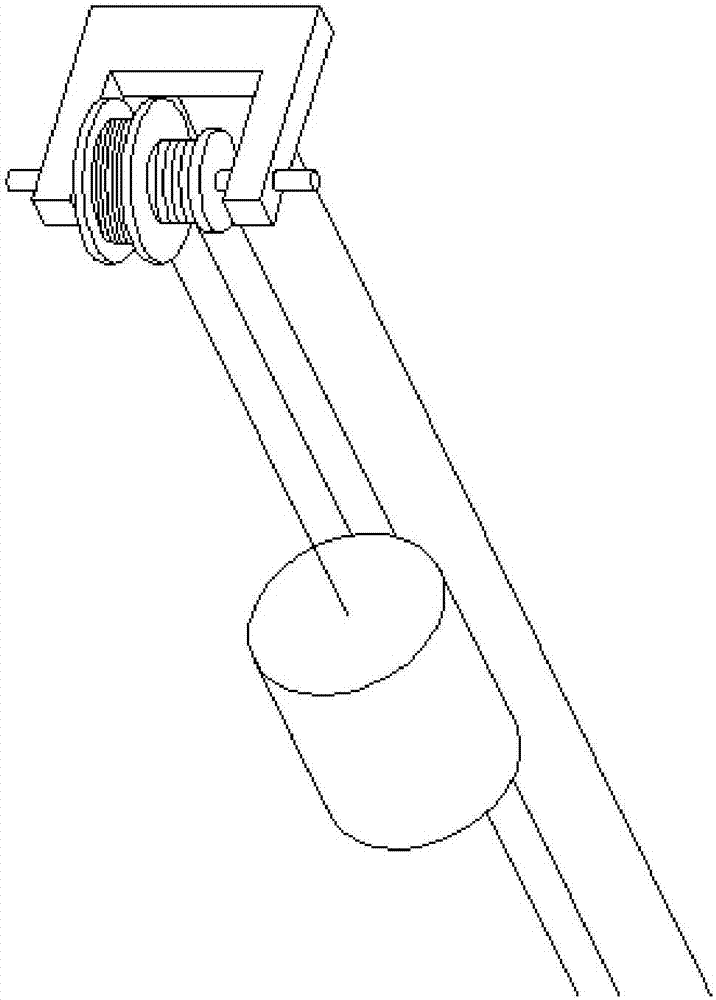

Obstacle-crossing carbon-free trolley running in S-shaped mode

ActiveCN104998419AReduce weightAccurately Control Range of MotionToy gearsToy vehiclesDrive wheelBobbin

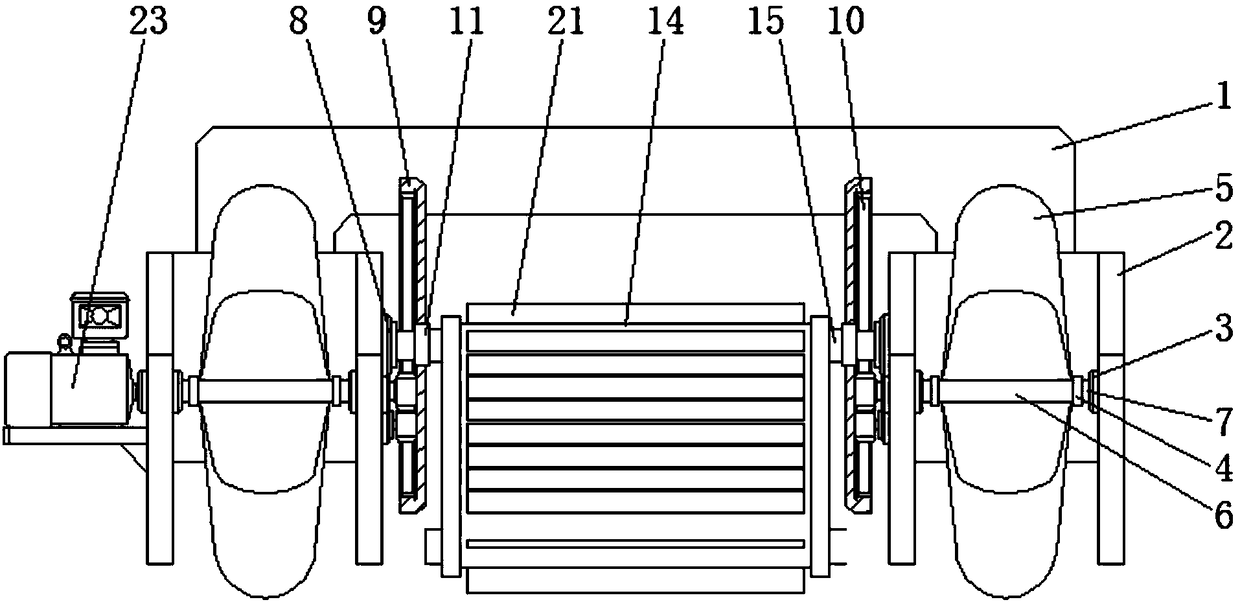

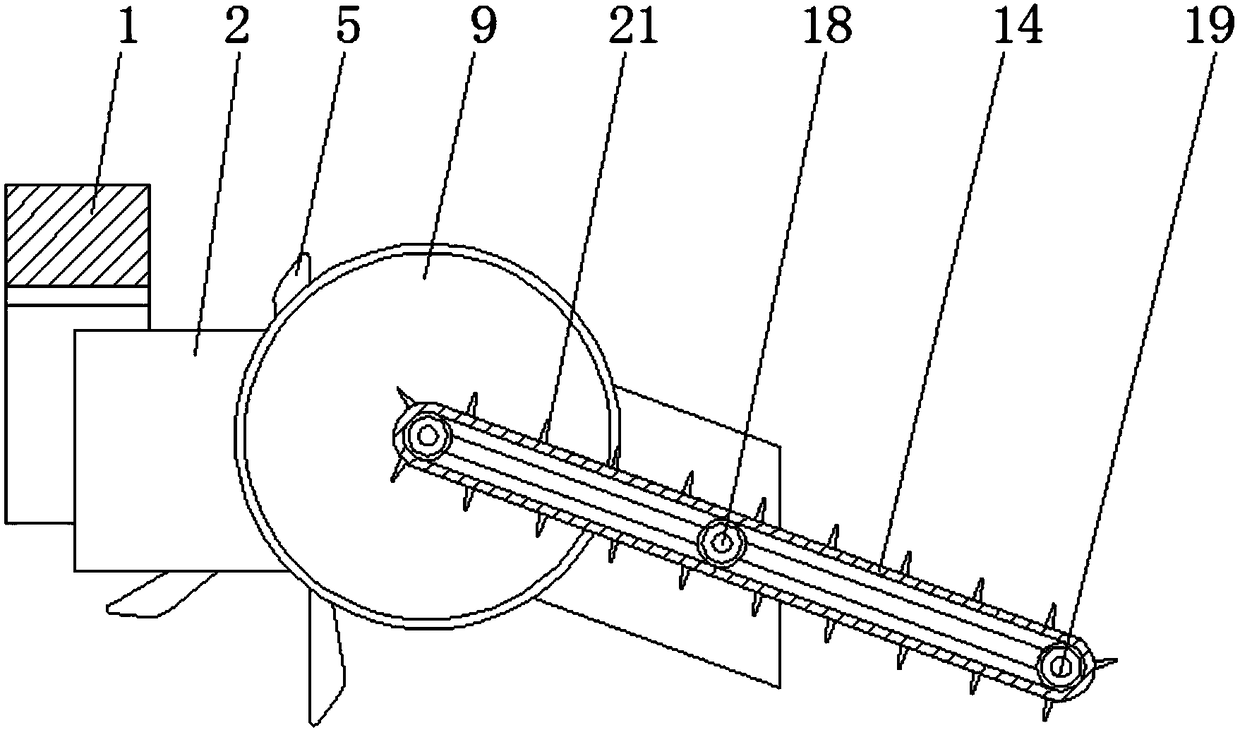

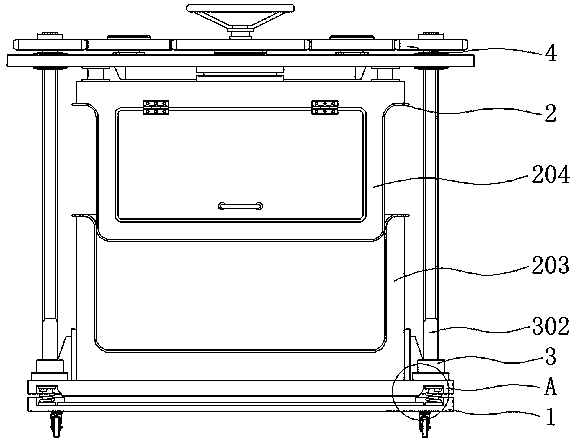

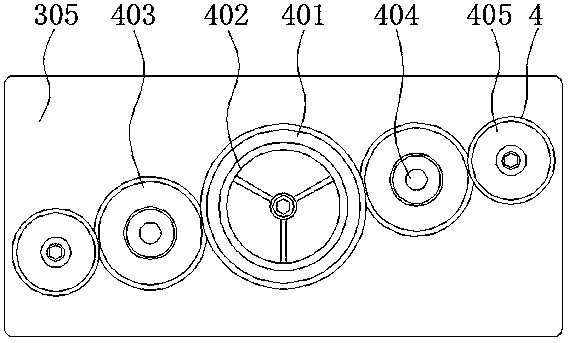

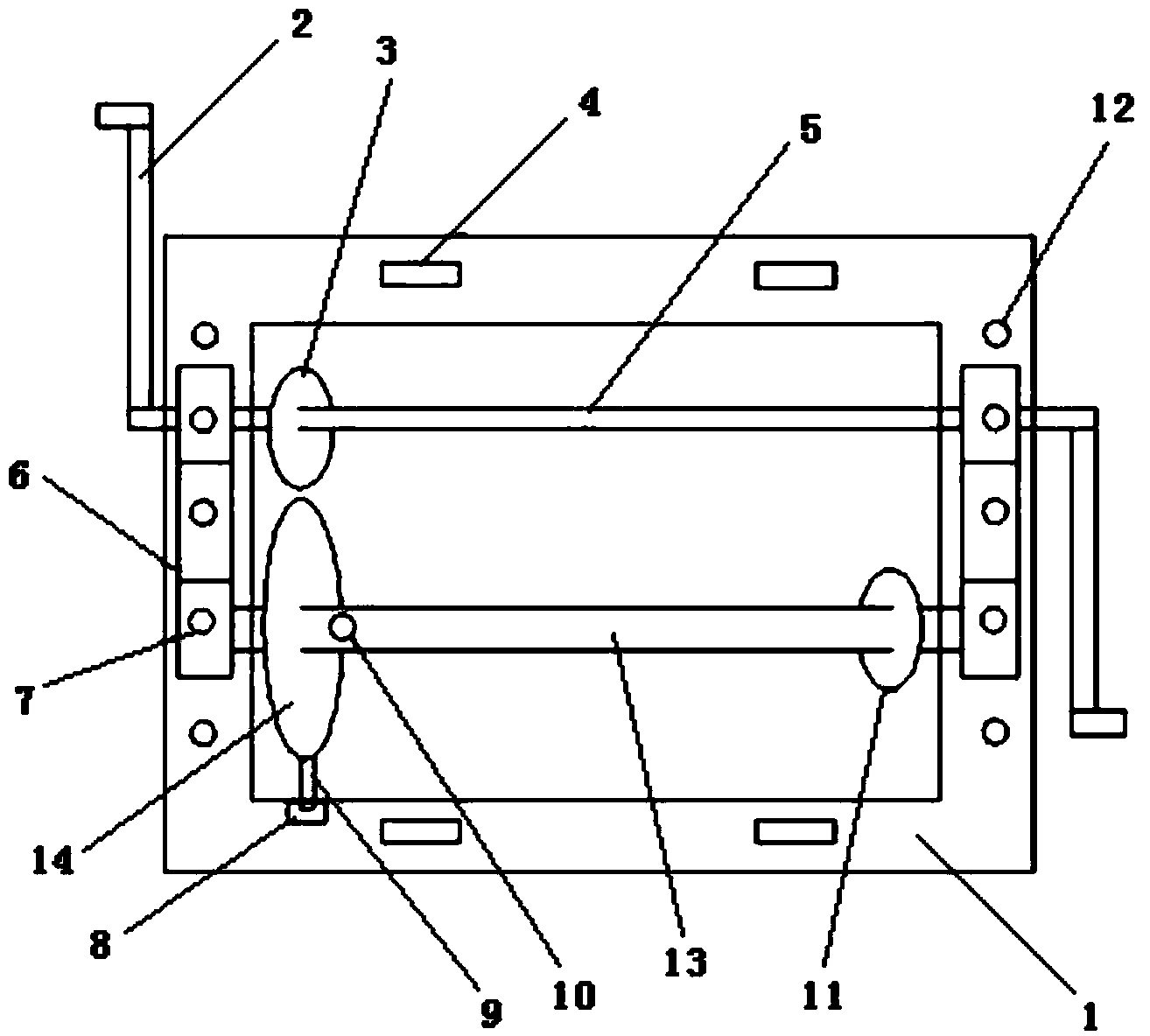

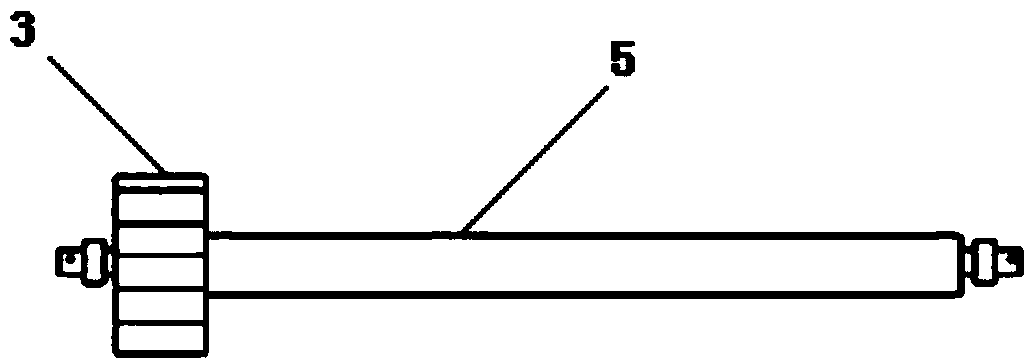

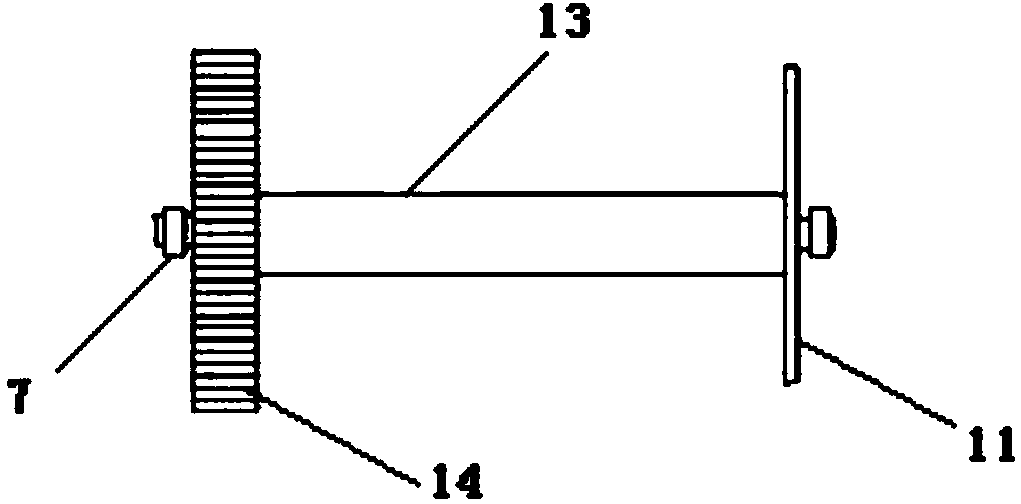

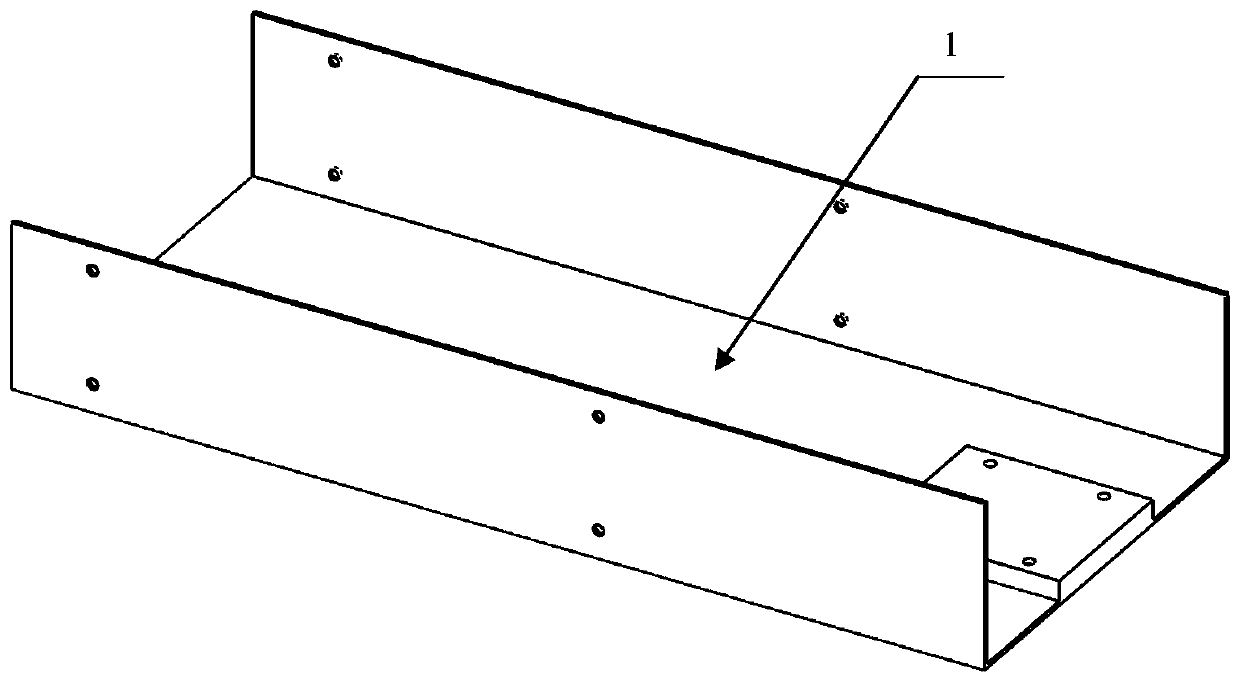

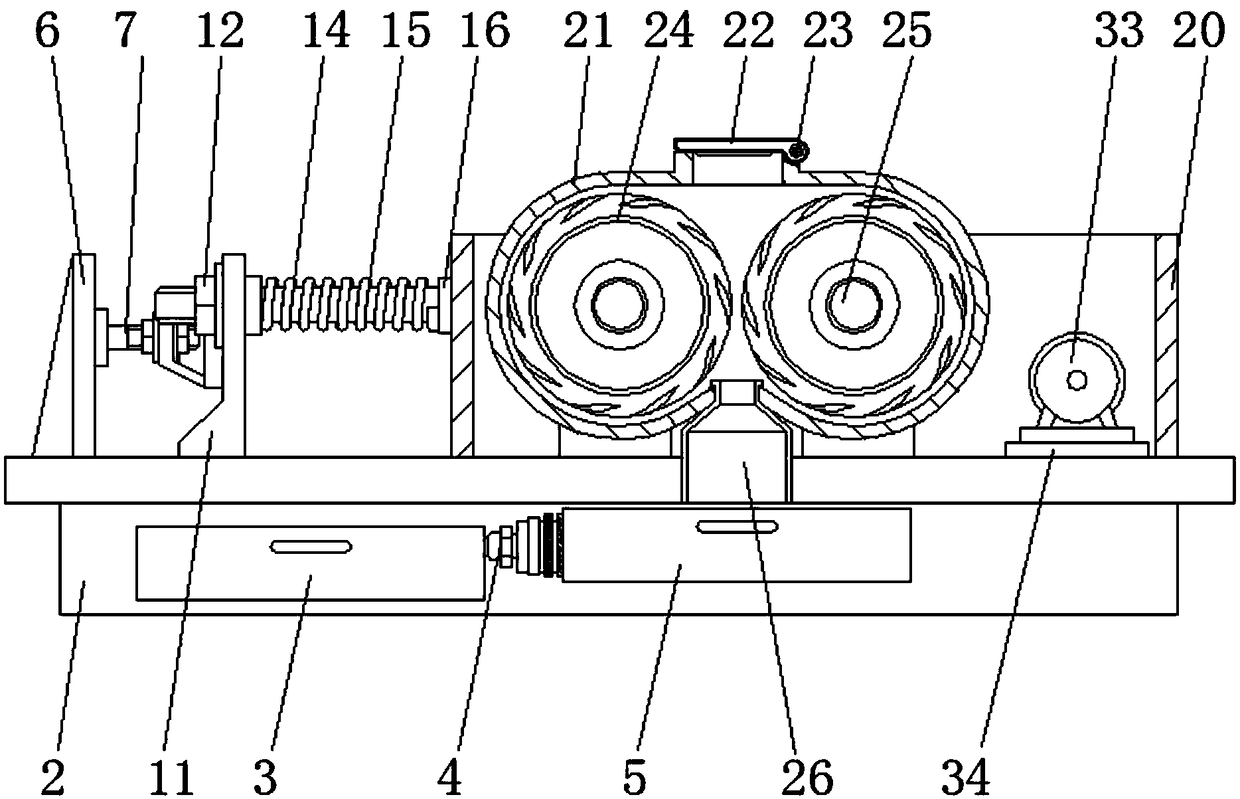

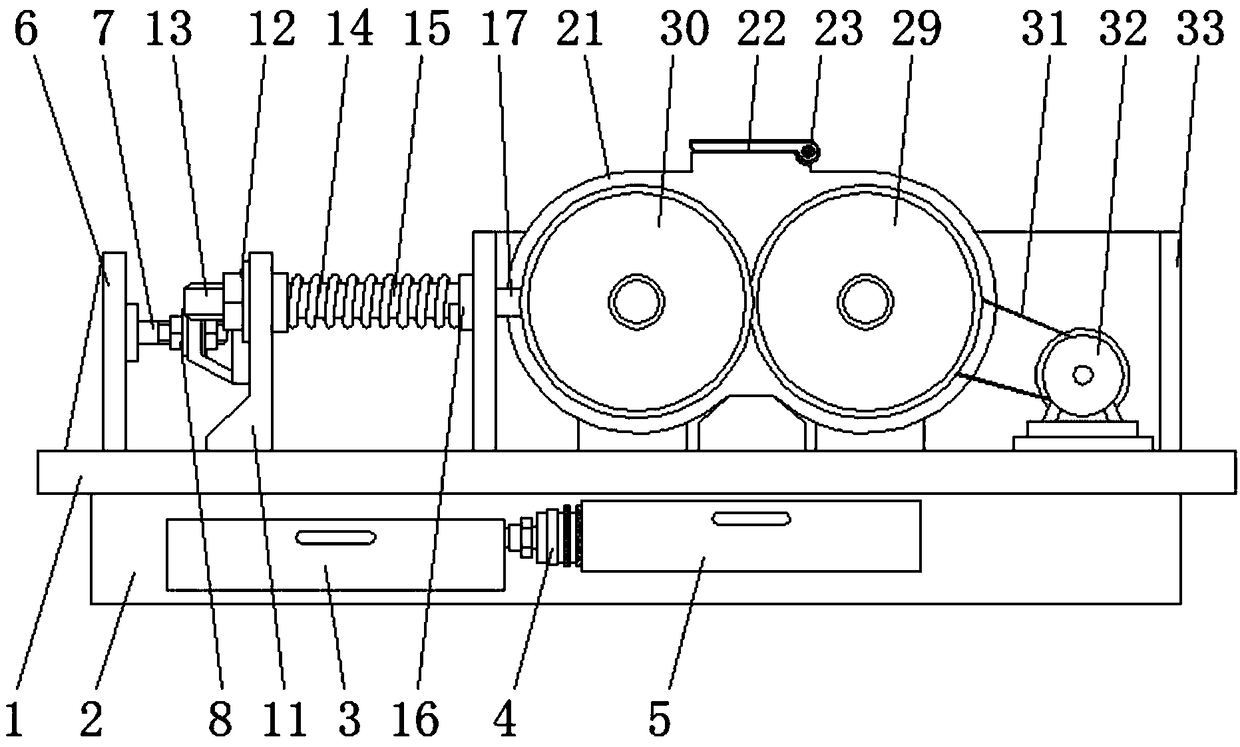

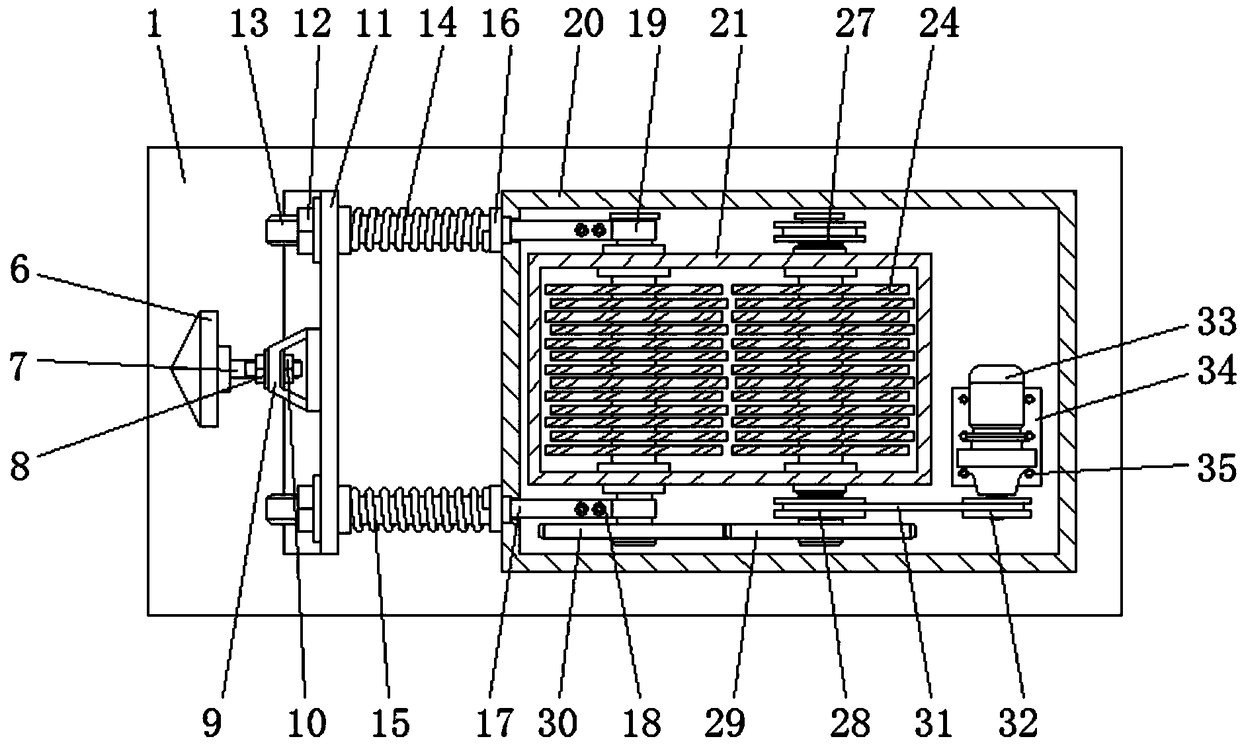

The invention relates to an obstacle-crossing carbon-free trolley running in an S-shaped mode. A wire wheel support 3 and a secondary fixed pulley 1 are mounted on a potential energy support 4 through a wire wheel shaft 14. A front wheel 7 is mounted on a front wheel support 6 through a front wheel steering shaft. A driving wheel 20, a driven wheel 11 and a pinion 12 are mounted on a driving shaft 16. A bull gear 13 and a small belt pulley 17 are mounted on a bobbin 14. A large belt pulley 18 is mounted on a shaft connected to a crank connecting rod 9. The pinion 12 is engaged with the bull gear 13. The small belt pulley 17 is connected to the larger belt pulley 18 through a belt 19. One end of a rope 22 is connected to a potential energy block 2, the rope 22 bypasses the secondary fixed pulley 1 and is wound in a wire winding groove 15, and the other end of the rope 22 is positioned through a wire hole in the secondary fixed pulley 1. According to the invention, the potential energy generated by the falling of the potential energy block is converted into the kinetic energy of the trolley, the trolley can periodically avoid obstacles from a long distance based on a preset track and through gear engaging and belt transmission, and the trolley is simple in structure and convenient to use.

Owner:CHANGZHOU UNIV

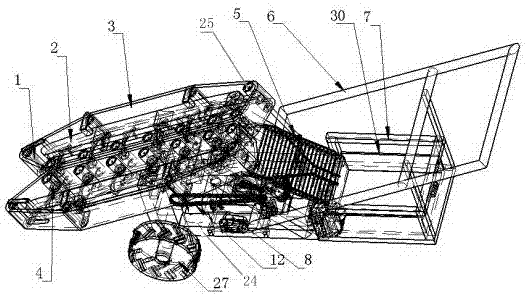

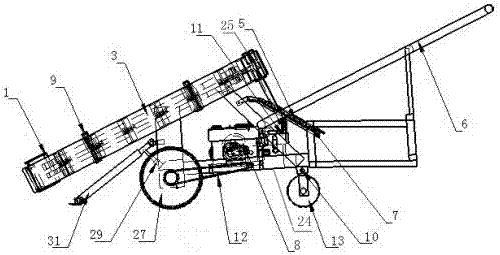

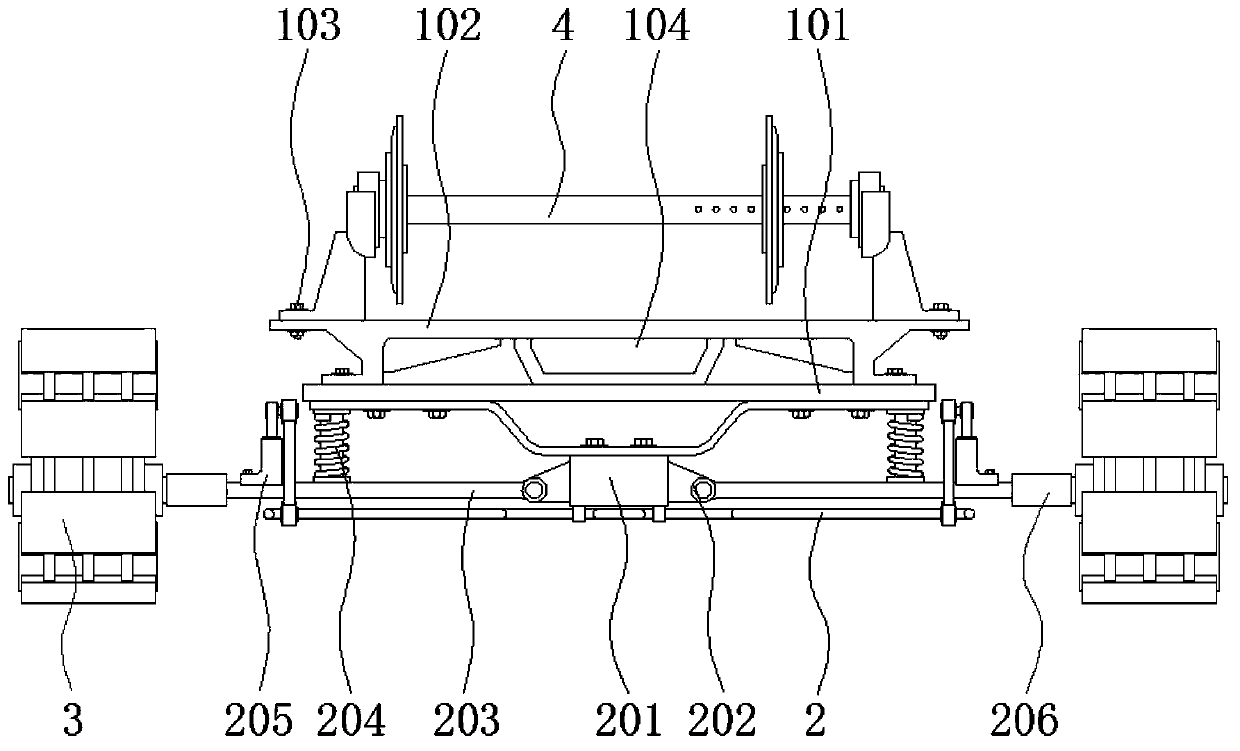

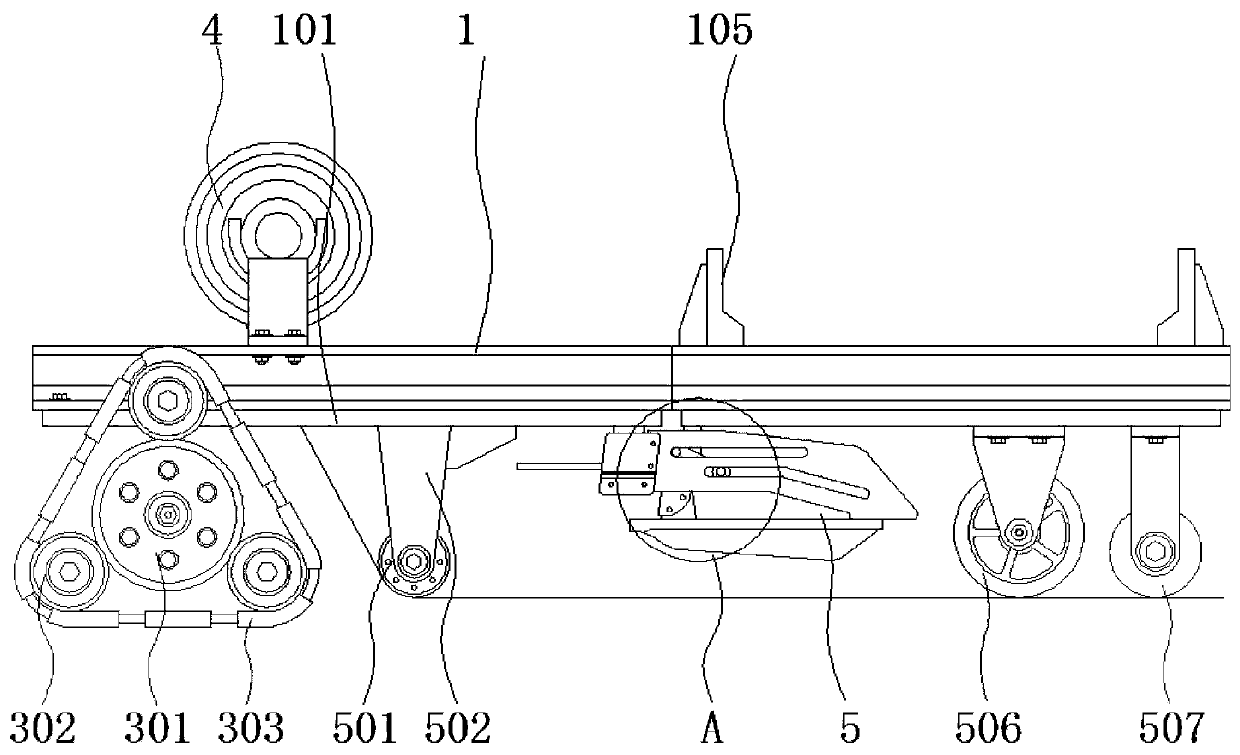

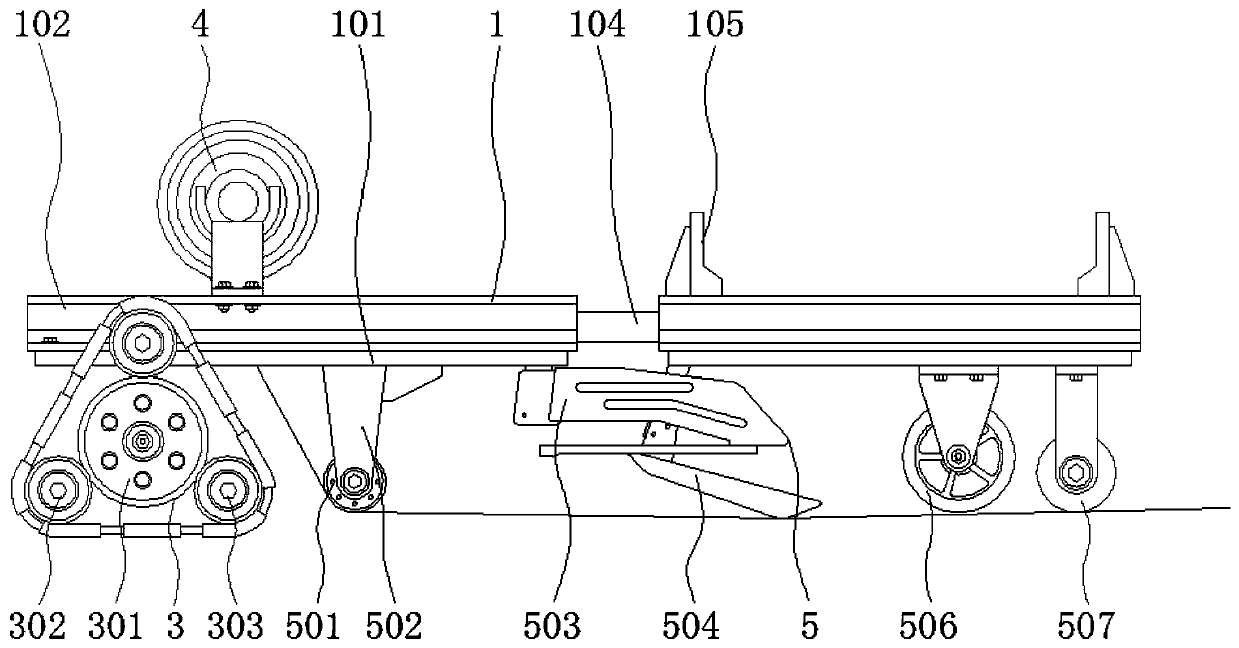

Line-aligning celery harvester and use method thereof

PendingCN107455076AGuaranteed clampingSo as not to damageHarvestersFood treatmentDrive wheelAgricultural engineering

The invention relates to a line-aligning celery harvester which comprises a rack, a power device, a transmission device, a driving device, a root cutting device, a clamping conveyor, a collecting device and a handle. The power device is connected with the driving device and the clamping conveyor through the transmission device and provides power for the driving device and the clamping conveyor; the clamping conveyor comprises two conveying frames fixed side by side in front of the rack and driving wheels respectively arranged behind the conveying frames; each conveying frame is provided with a guide wheel at the front end, the guide wheel and the driving wheel on the same conveying frame are wounded with one conveying belt, and a row of tension devices capable of rotating along a mounting point under the action of force is mounted on each conveying frame; the guide wheel, the conveying belt and the tension device enclose to form a conveying channel with the width gradually decreased from front to back. By the arrangement, damage rate of celery is low, and the harvested celery can be automatically aligned.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

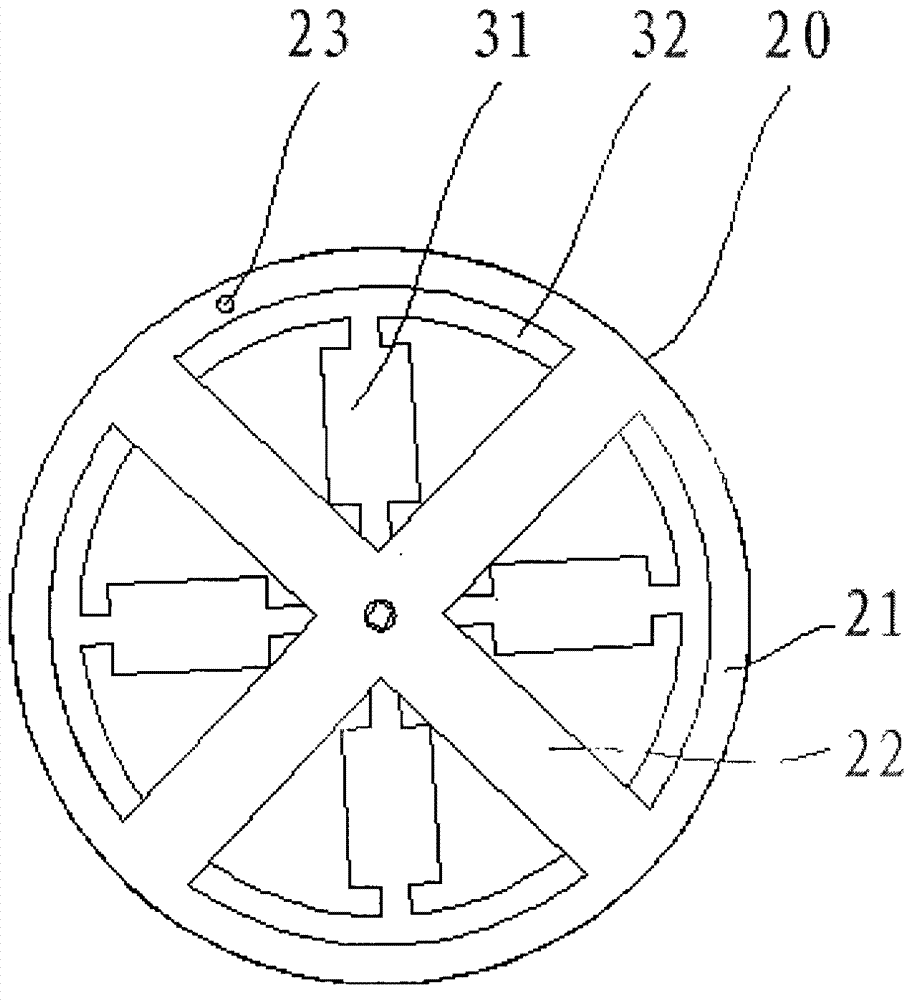

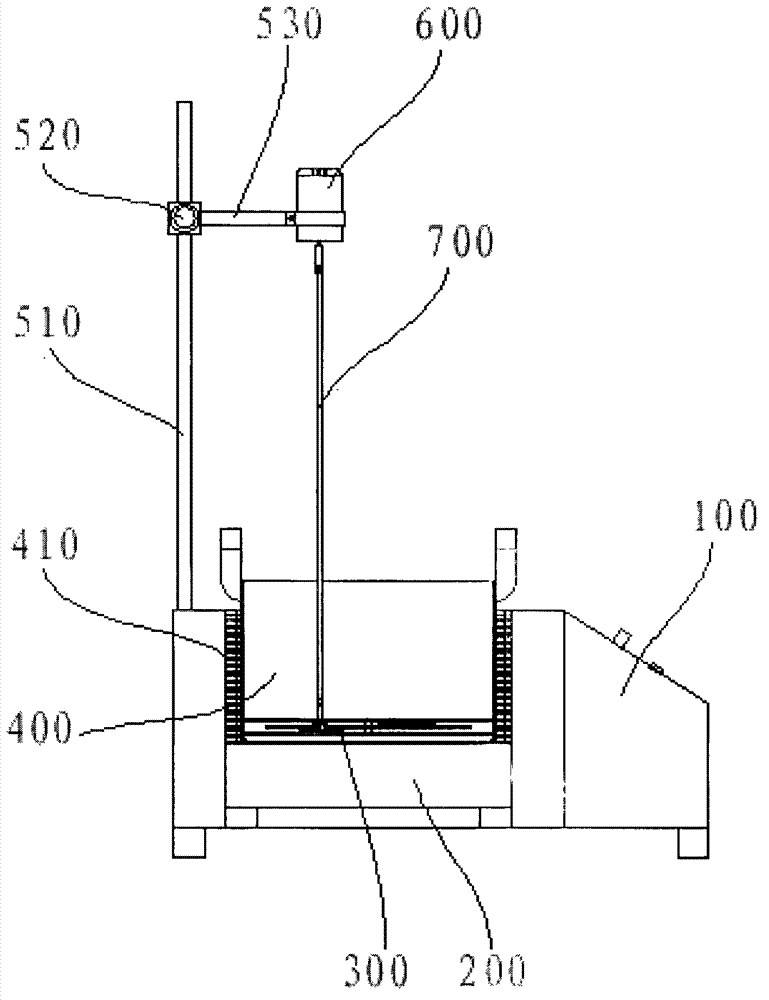

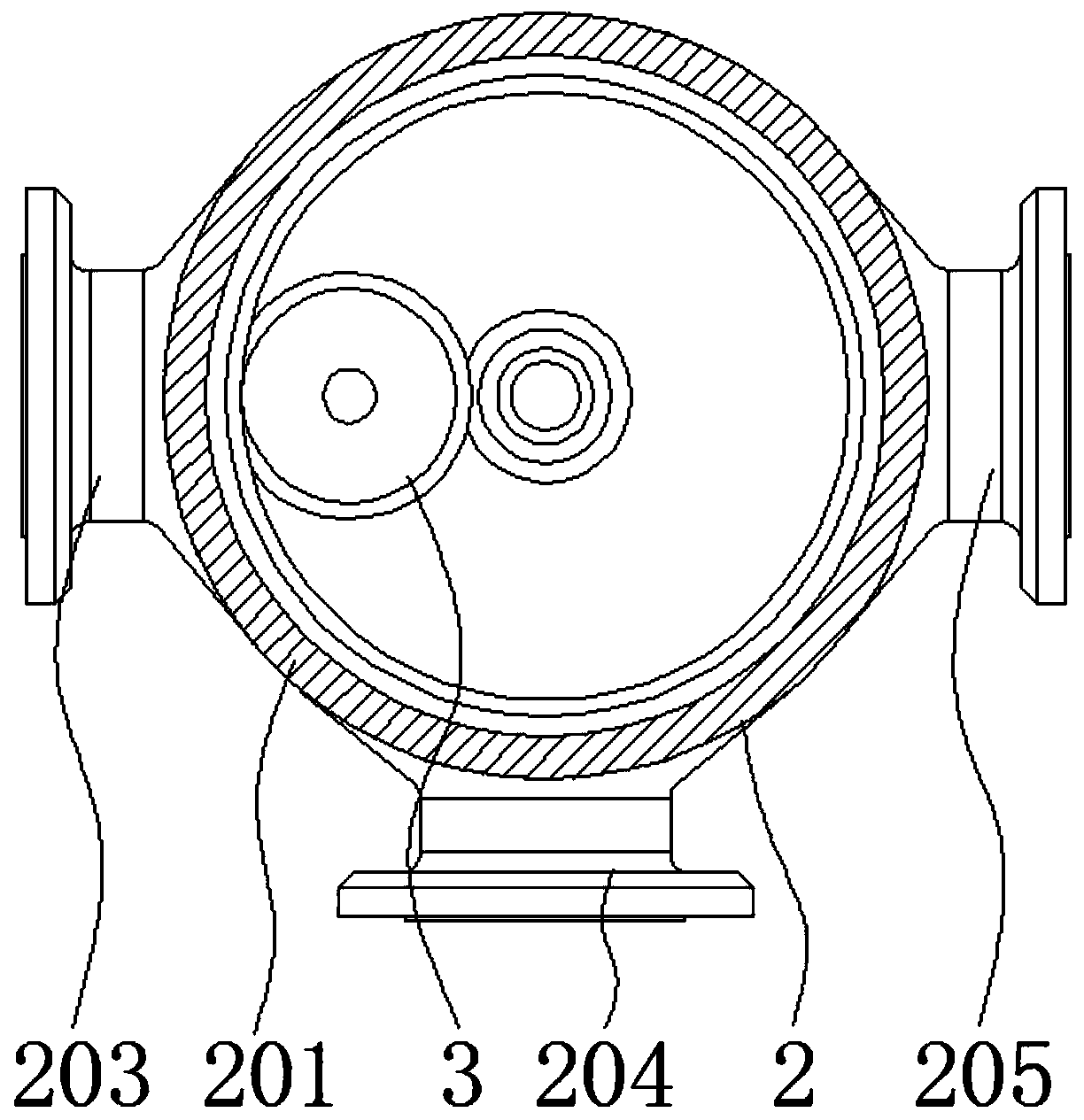

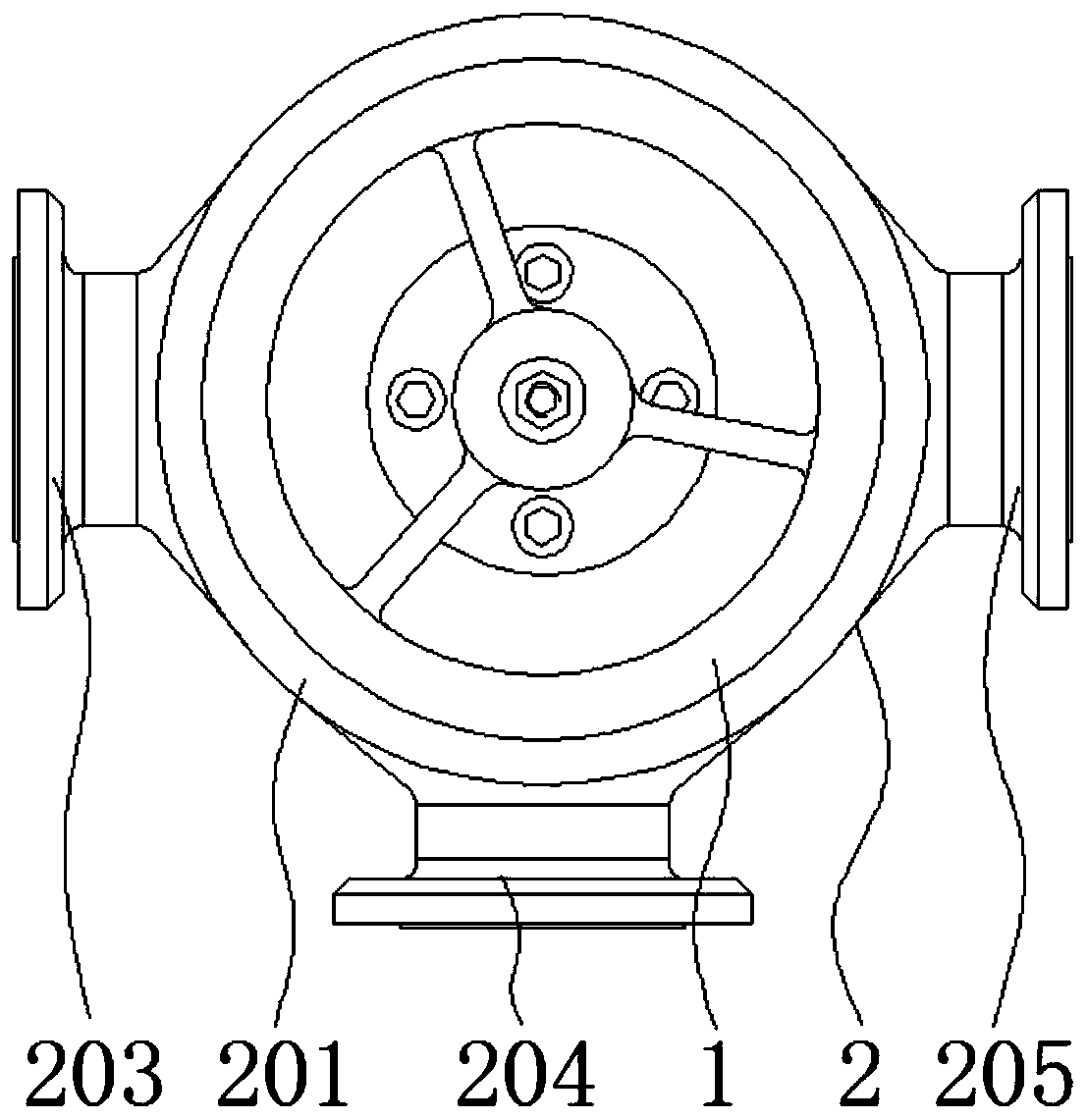

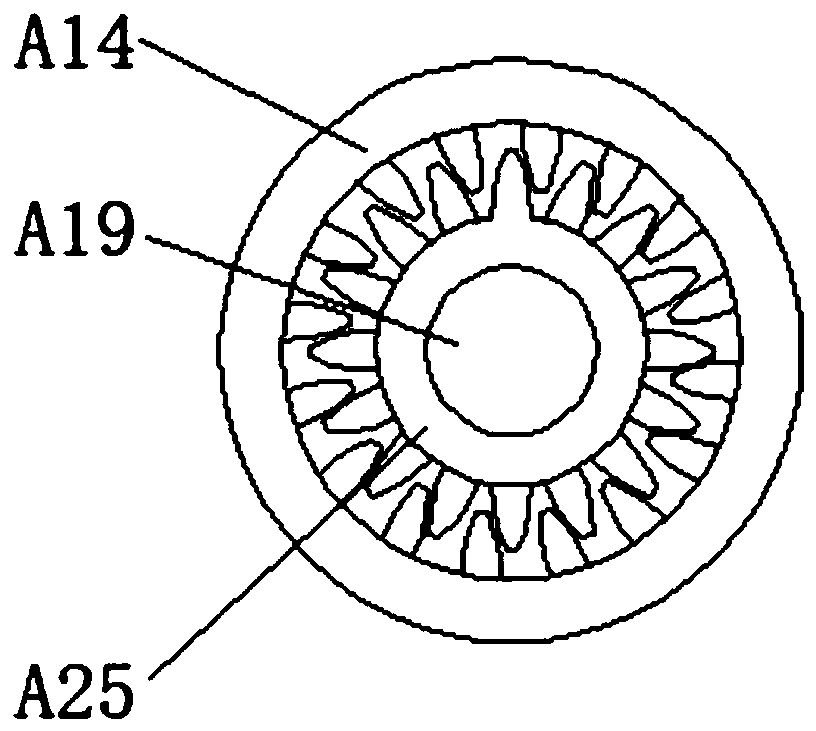

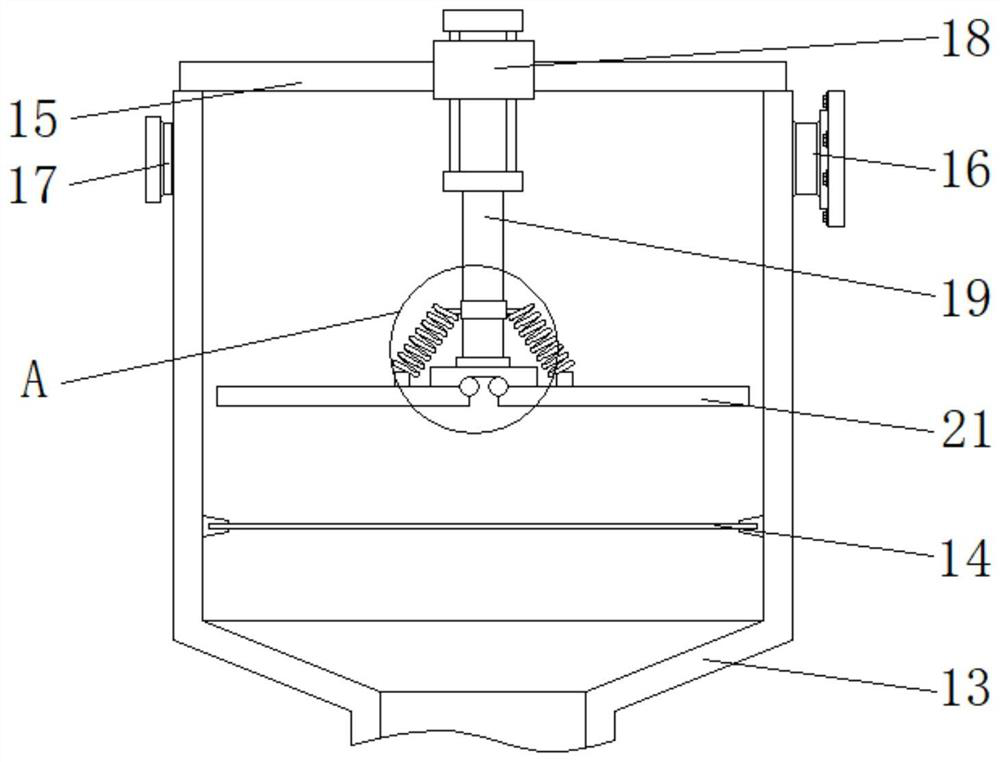

Stirring paddle and automatic temperature control stirrer using same

InactiveCN102806044AInstantaneous gear ratio constantImprove stabilityRotary stirring mixersMixer accessoriesTemperature controlReliable transmission

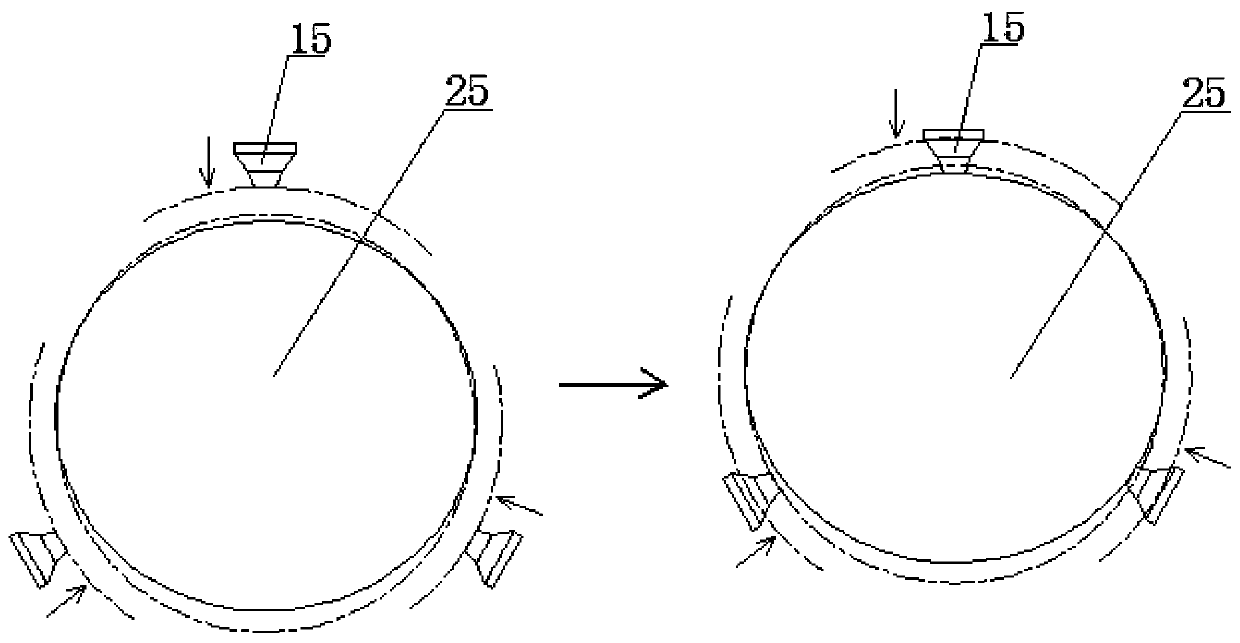

The invention discloses a stirring paddle and an automatic temperature control stirrer using same. The stirring paddle comprises a stirring shaft, a paddle group and a paddle group fixing frame, wherein the paddle group fixing frame is fixed together with the middle part of the paddle group; and the stirring shaft runs through the edge of the paddle group fixing frame to be connected with the paddle group through a gear transmission mode. The paddle group fixing frame comprises an upper hollow-out fixed plate and a lower hollow-out fixed plate, which are the same as each other; and the paddle group is fixed between the upper fixed plate and the lower fixed plate. Through the adoption of gear transmission connection, constant instantaneous transmission ratio can be guaranteed, high stability is achieved and accurate and reliable transmission is achieved. As the stirring shaft is biased from the center, the stirring paddle disclosed by the invention is beneficial for containers to accommodate heated materials and convenient for operators to do relevant operations so as to eliminate safety problems. The automatic temperature control stirrer using the stirring paddle has an automatic stirring function, so that the temperature of a heating medium is uniform and heat transfer speed is increased, so that uniformity of heat conducted to the heated materials is guaranteed.

Owner:SHENZHEN POLYTECHNIC

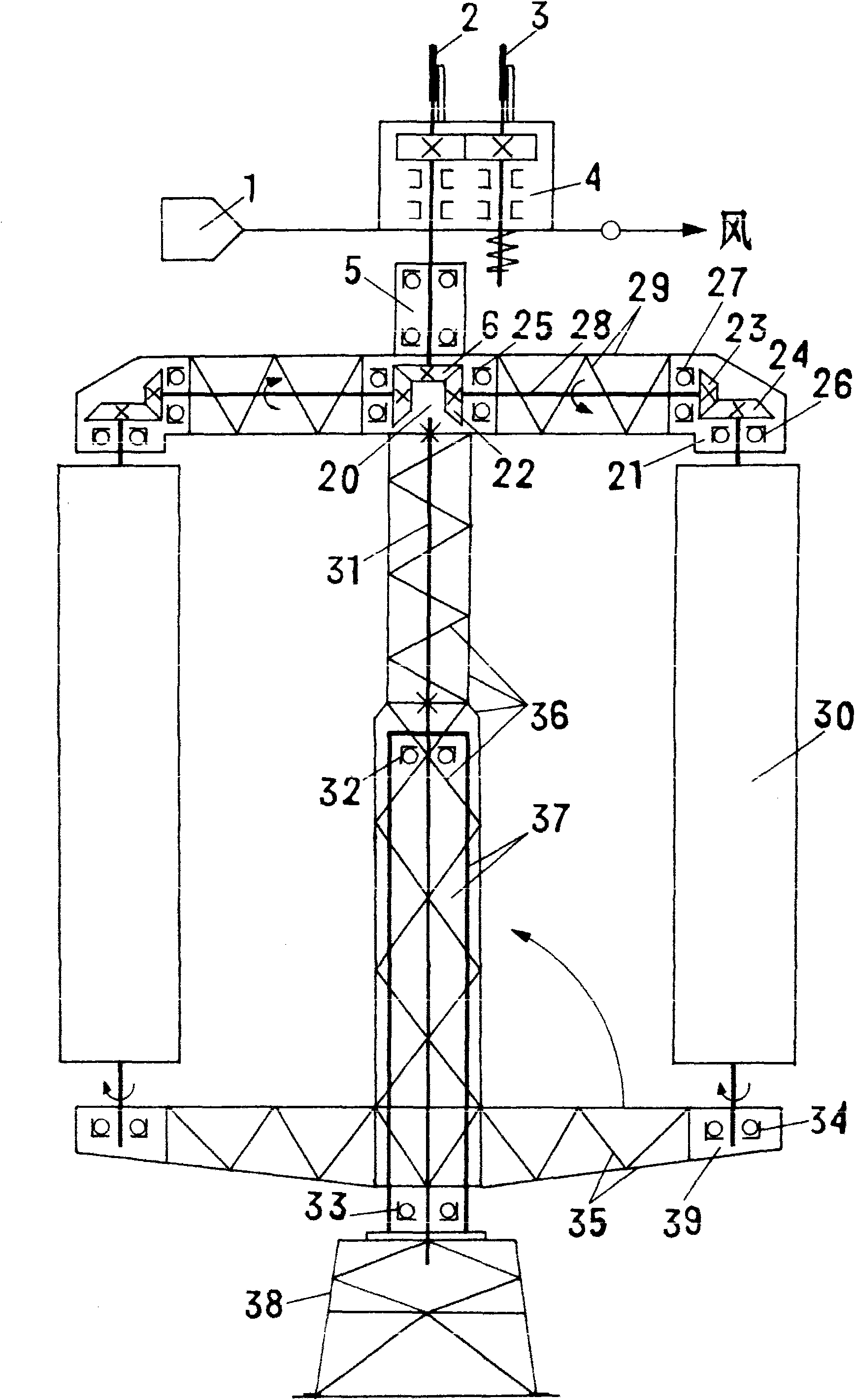

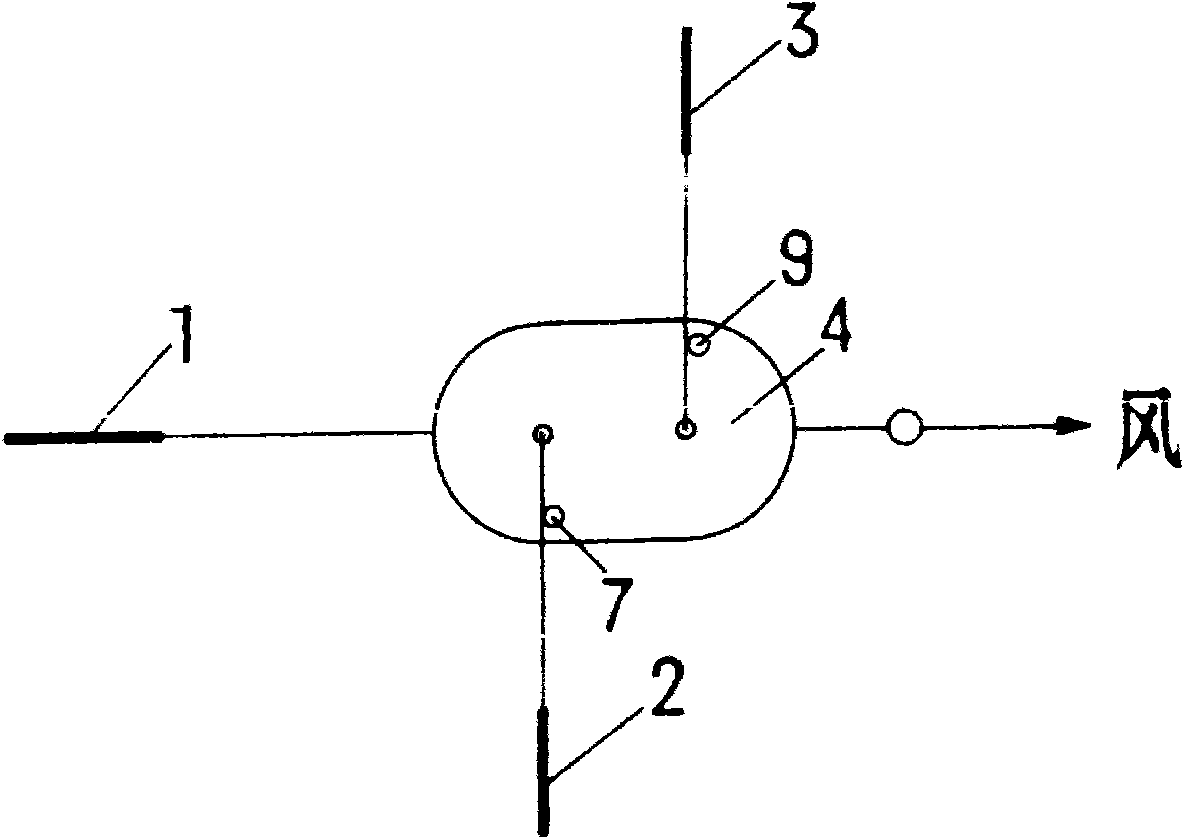

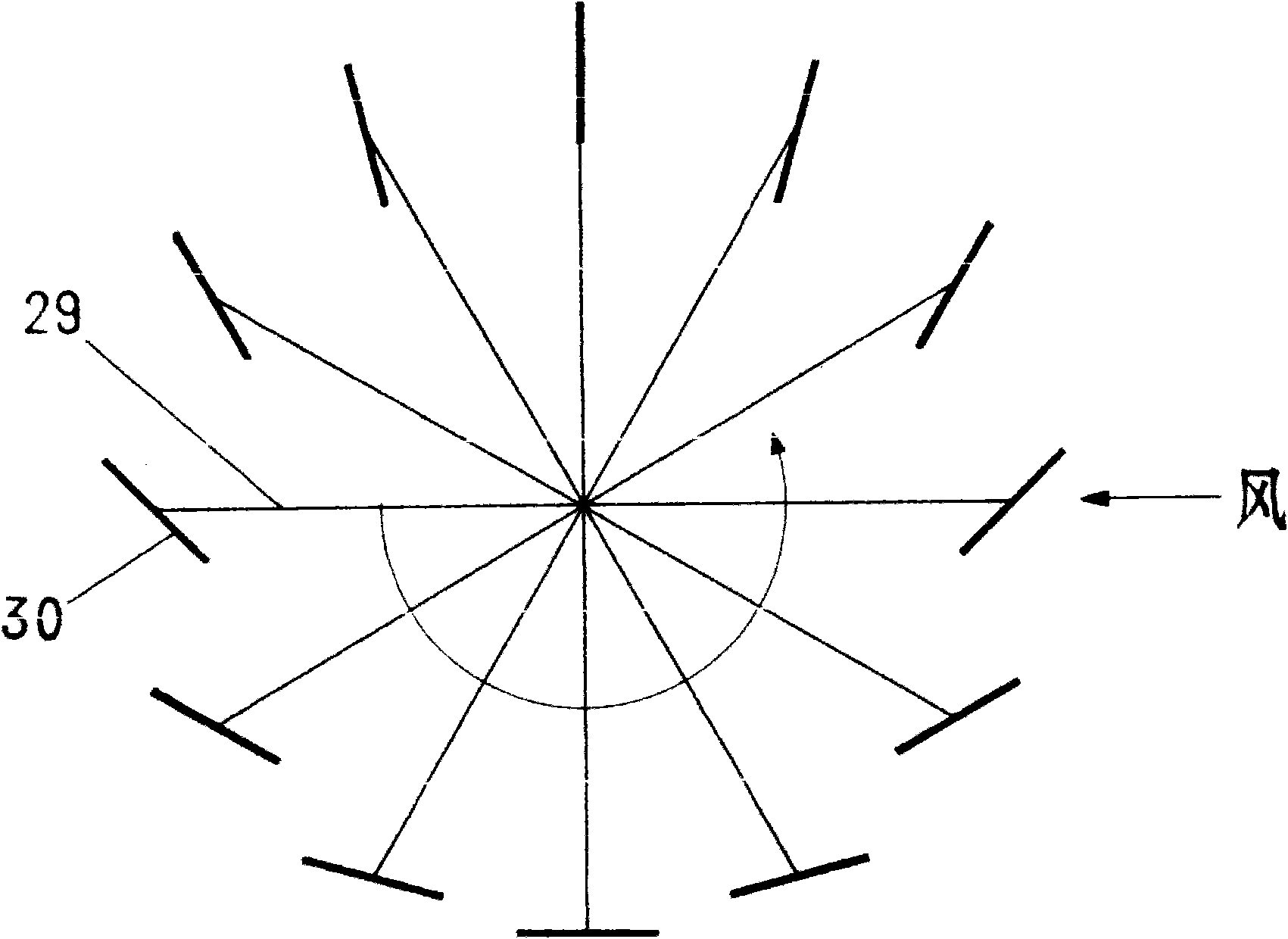

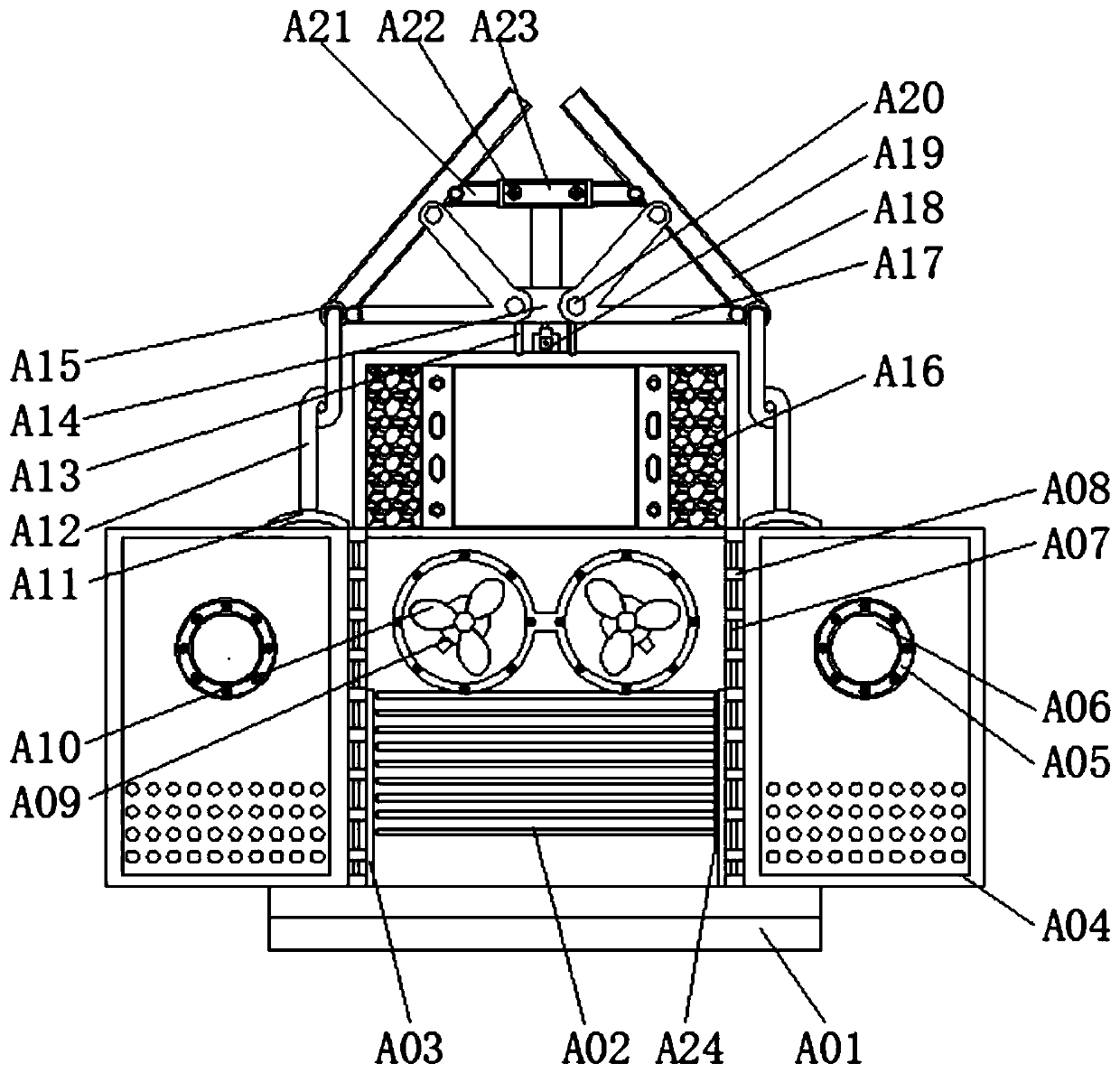

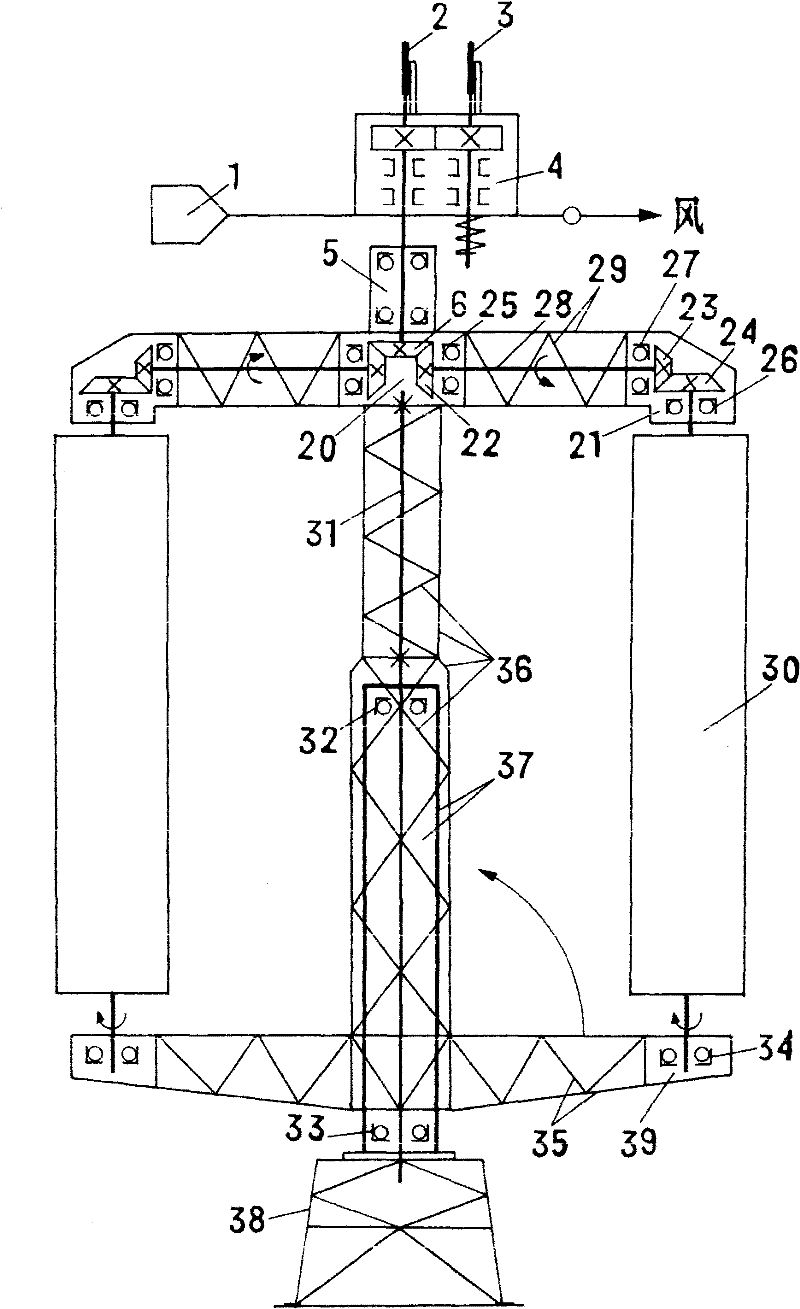

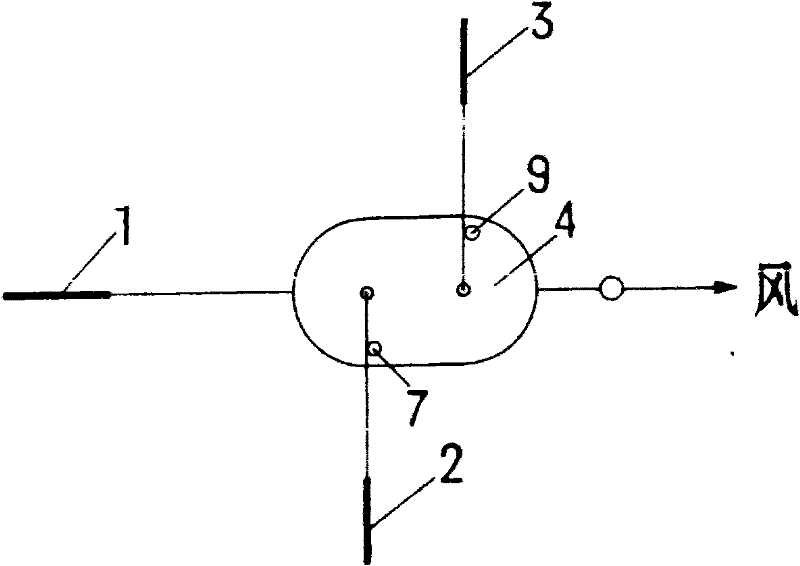

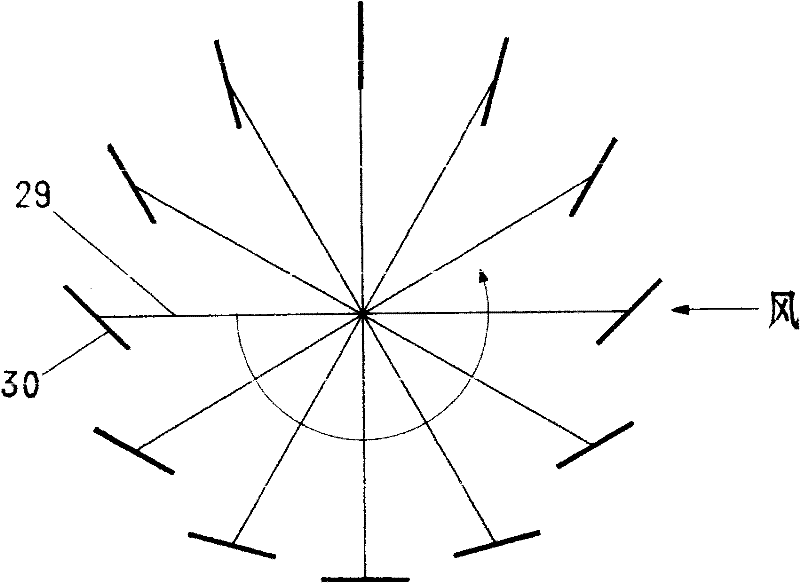

Vertical axis wind turbine with blade angle varying along with wind direction and wind velocity

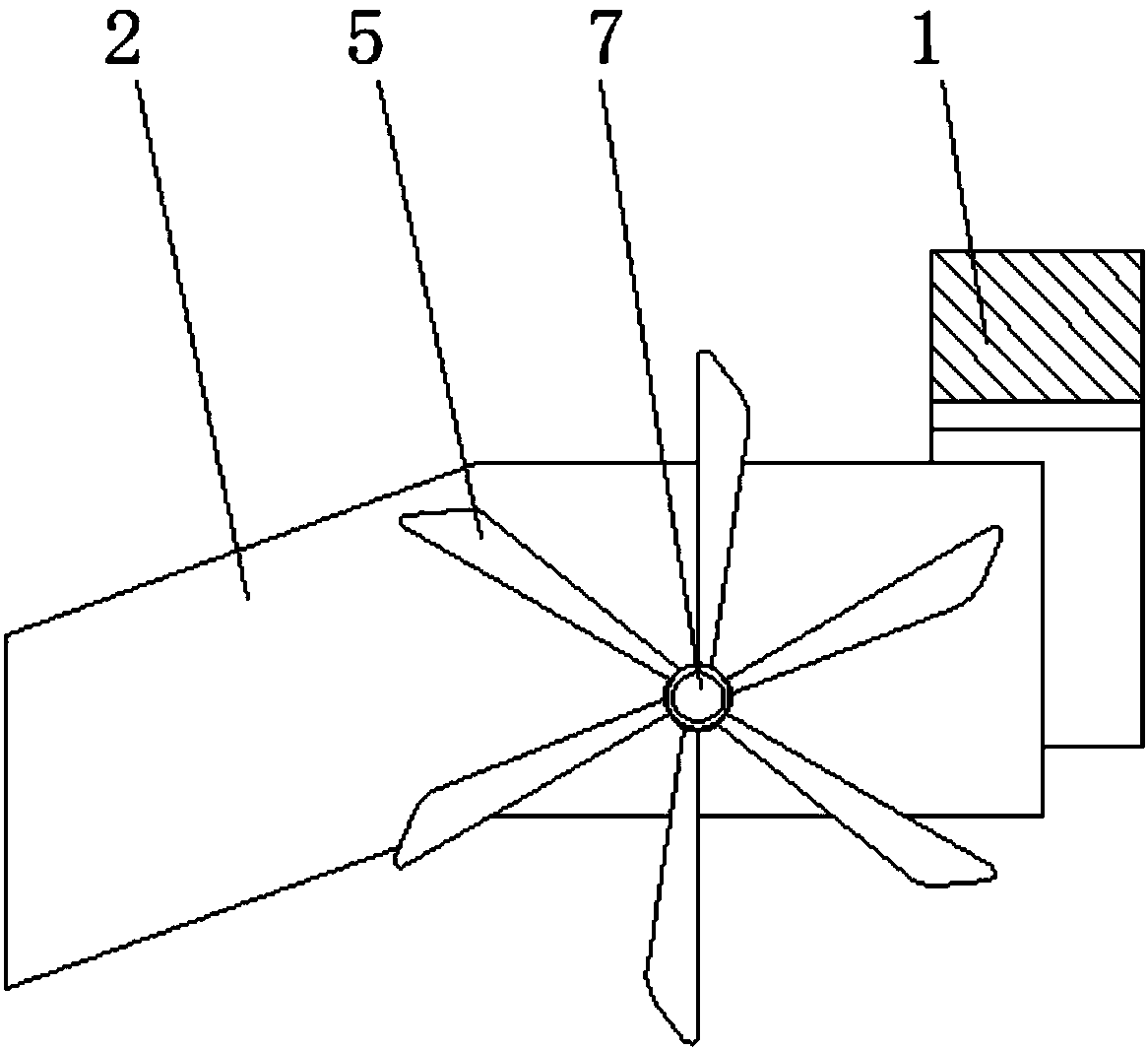

InactiveCN101956653AReduce manufacturing costReduce power generation costsWind motor controlRenewable energy generationDrive shaftControl system

The invention relates to a vertical axis wind turbine with a blade angle varying along with wind direction and wind velocity, which comprises a control system, a planetary gearbox, a fixed axis gearbox, a transmission shaft, a main support, an upper cantilever beam, a lower cantilever beam, a bearing pedestal, a bearing, blades, a vertical axis, a tower and the like, wherein the vertical axis is connected with the tower through the bearing and the bearing pedestal; the main support is sleeved outside the vertical axis and the bearing pedestal, so that the middle part of the main support is connected with the middle part of the vertical axis, and the top end of the main support and the head of the vertical axis are connected with the bottom of the planetary gearbox; the control system is connected with the top of the planetary gearbox through the bearing pedestal; the root part and the end part of the upper cantilever beam are respectively connected with the side face of the planetary gearbox and the side face of the fixed axis gearbox, and the root part and the end part of the lower cantilever beam are respectively connected with the lower end of the main support and the bearing pedestal; both ends of the transmission shaft are respectively connected with the planetary gearbox and the fixed axis gearbox; and the blades are respectively connected with the fixed axis gearbox and the bearing pedestal so that output power maintains near the rated power value.

Owner:孙世杰

Salvaged object transferring device

InactiveCN108517852AIncrease power durabilityReduce electrical safety hazardsWater cleaningFixed bearingElectricity

The invention discloses a salvaged object transferring device which comprises a main body cross beam, a shaft sleeve, a transferring conveyor belt and a conveying shaft. A supporting clamping plate isconnected to the lower portion of the left end of the main body cross beam, and a fixing bearing seat is arranged in the supporting clamping plate. A limiting ring is arranged on the right side of the fixing bearing seat, and a power shaft is arranged in the shaft sleeve. A connecting seat is arranged on the right side of the supporting clamping plate, and a built-in gear is arranged in the leftend of a braking disc. A driving gear and a transmission gear are arranged in the built-in gear. According to the salvaged object transferring device, compared with an existing common transferring device, under the premise that the using effect of equipment is ensured, internal structures are reduced as far as possible, the whole device is simpler in structure, operating is easier, original electric braking is abandoned, power is provided for the whole equipment through hydraulic power, energy is saved while electricity utilization potential safety hazards are reduced, and using demands of people are effectively met.

Owner:QINGDAO HUANGHAI UNIV

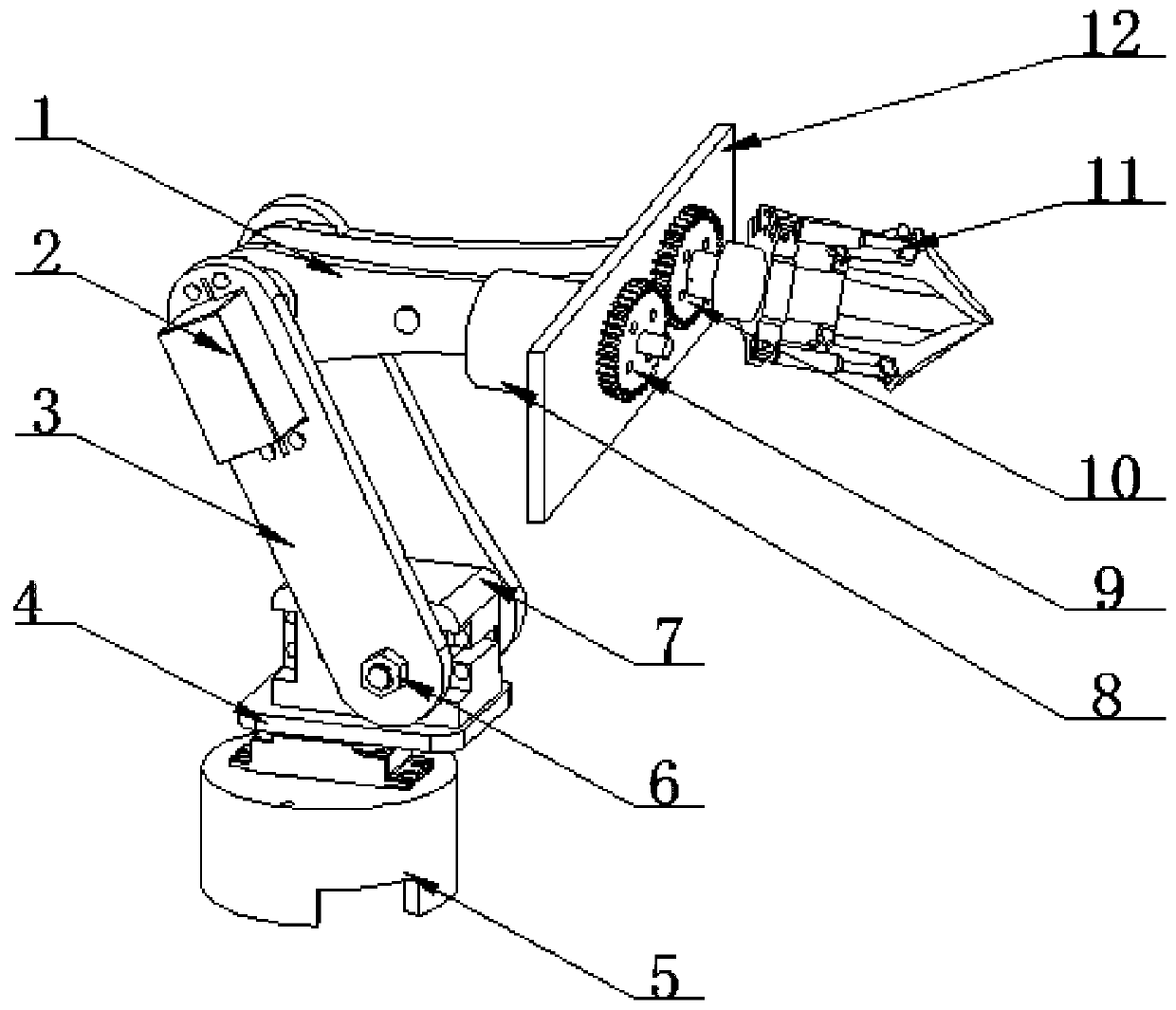

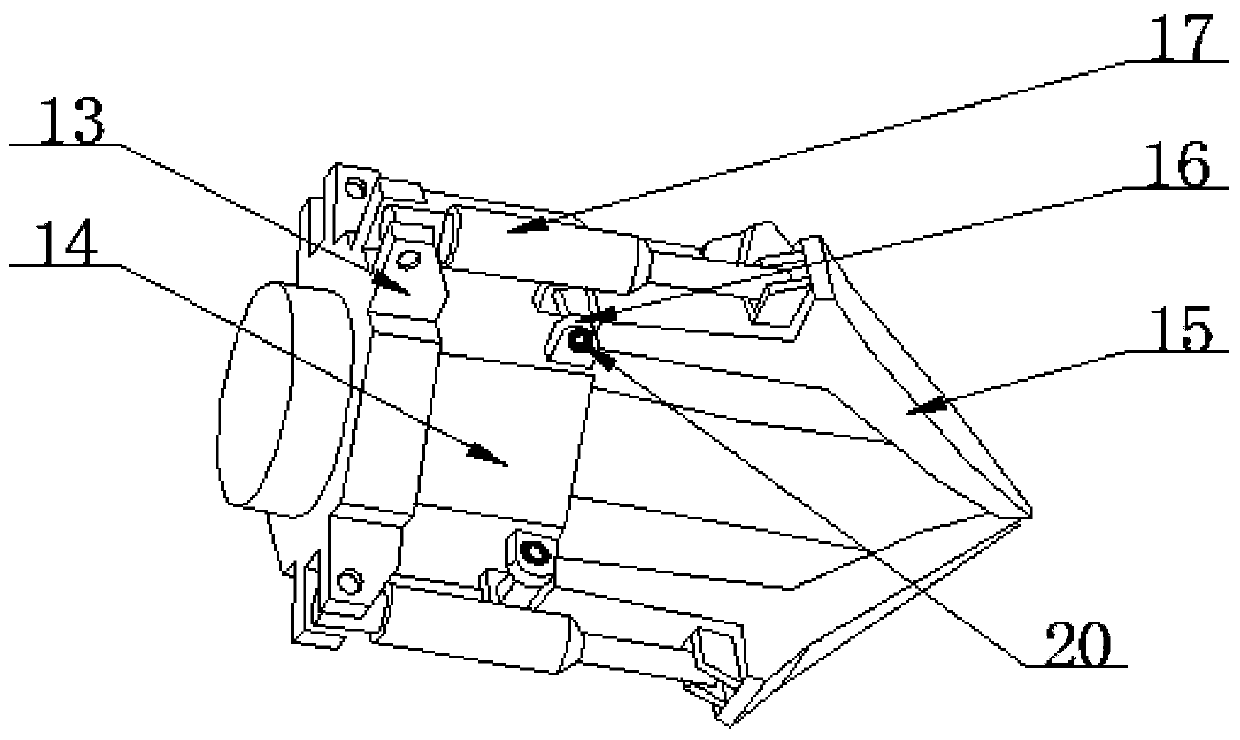

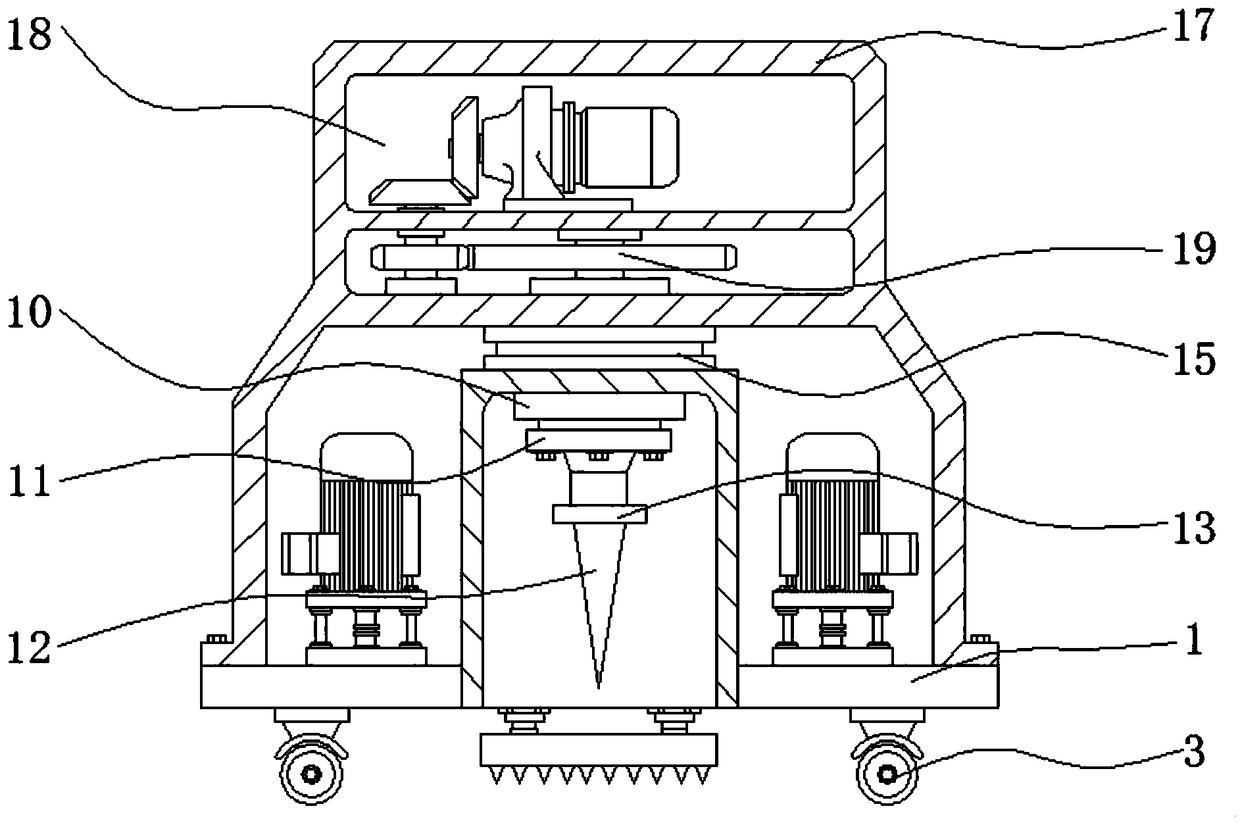

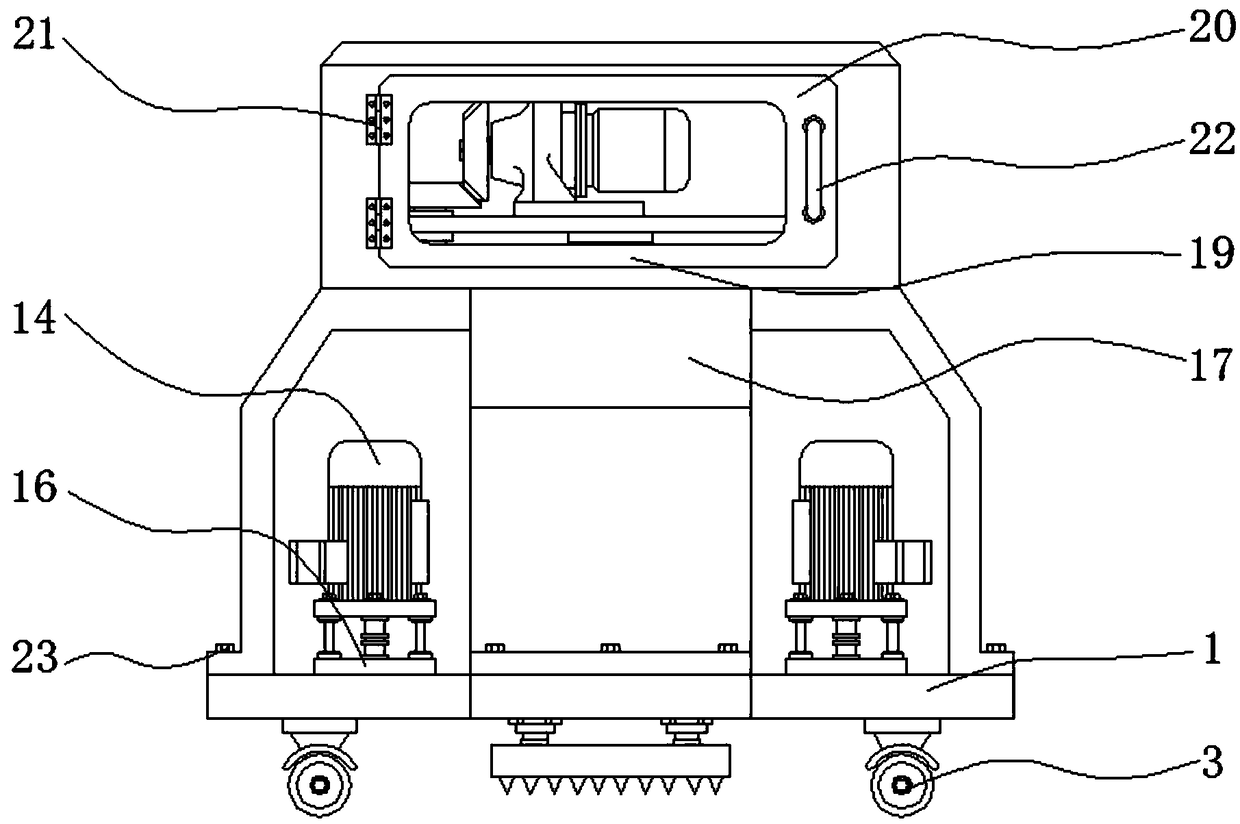

Rotary mechanical hand for machining

The invention relates to the field of mechanical hands, in particular to a rotary mechanical hand for machining. Pressure sensors can be prevented from being adopted, and the problem is solved that pressure sensors at grabbing positions are damaged under great friction, collision and extrusion; when an angle detecting assembly detects the actions of a control cylinder at some time and the rotatingangle of the angle detecting assembly during detecting is smaller than a set threshold, a controller controls the cylinder to stop actions or continue to inject set gas into a cylinder body of the cylinder and then stop actions, required clamping force is kept, it is ensured that all claws can make contact with and clamp a workpiece, the grabbing capacity and grabbing stability of the mechanicalhand are effectively improved, and the grabbing precision is improved; the control mode is simple, it can be ensured that all the claws grab the workpiece with the force as identically or similarly aspossible, it is ensured that all the claws can make contact with and clamp the workpiece, the workpiece grabbing efficiency is improved, and the stress uniformity of al the claws can be ensured.

Owner:GUILIN UNIV OF AEROSPACE TECH

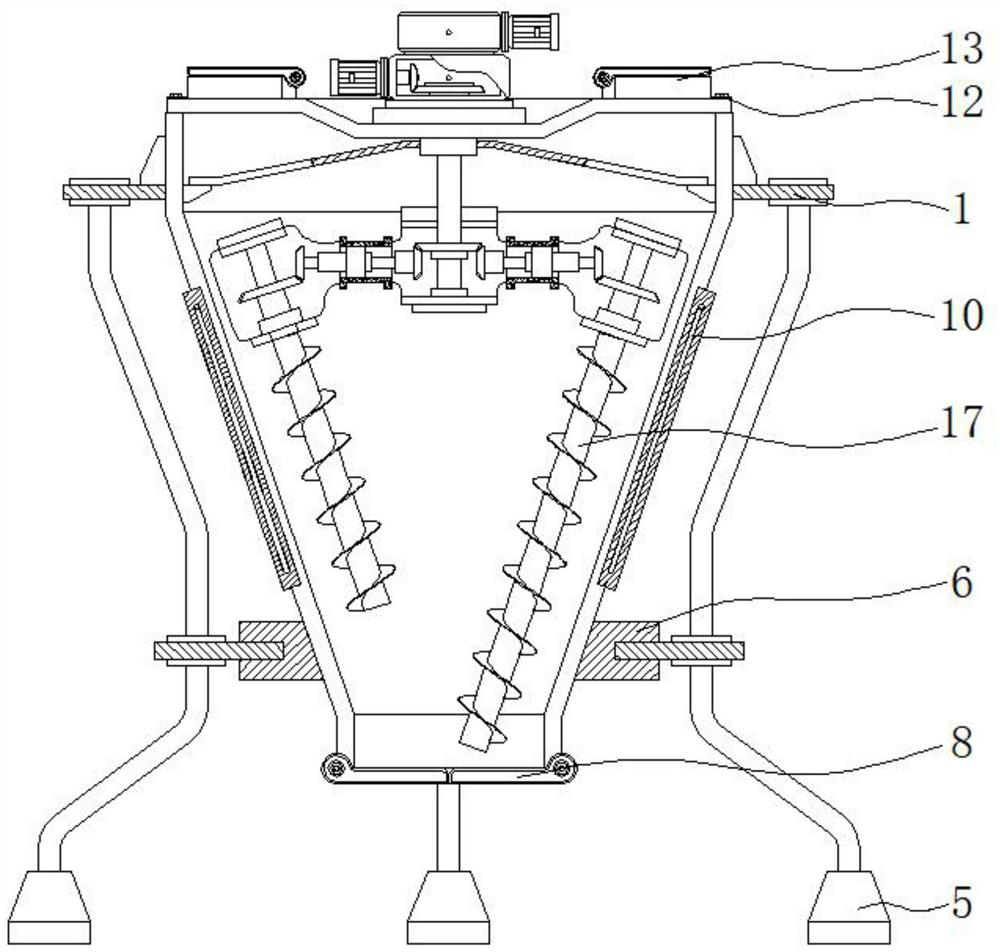

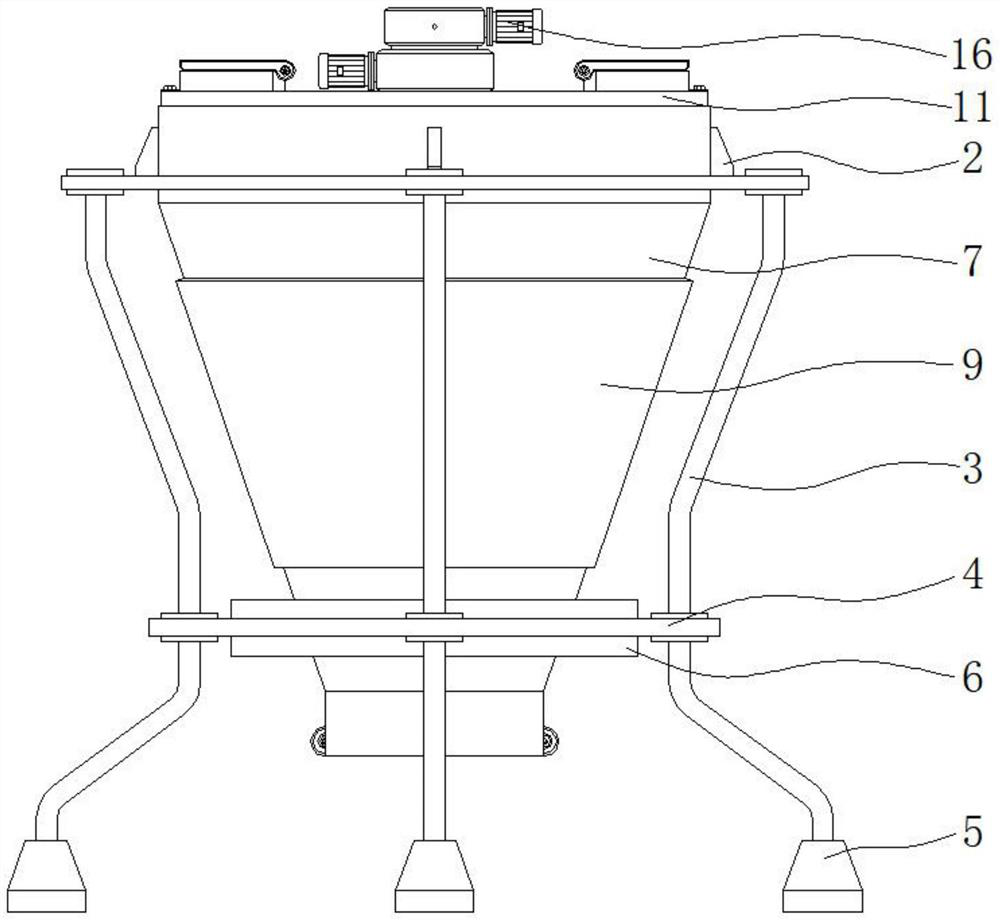

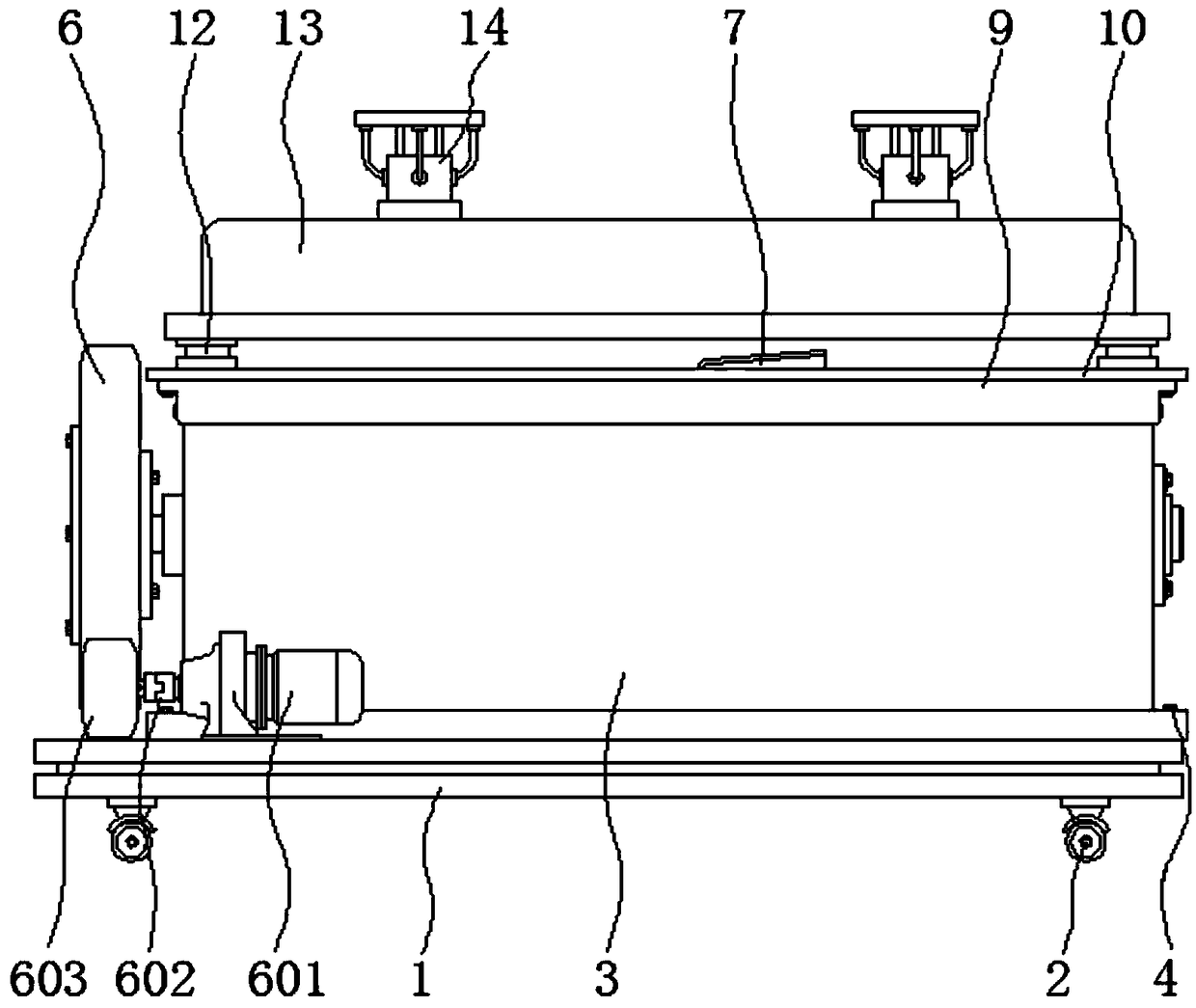

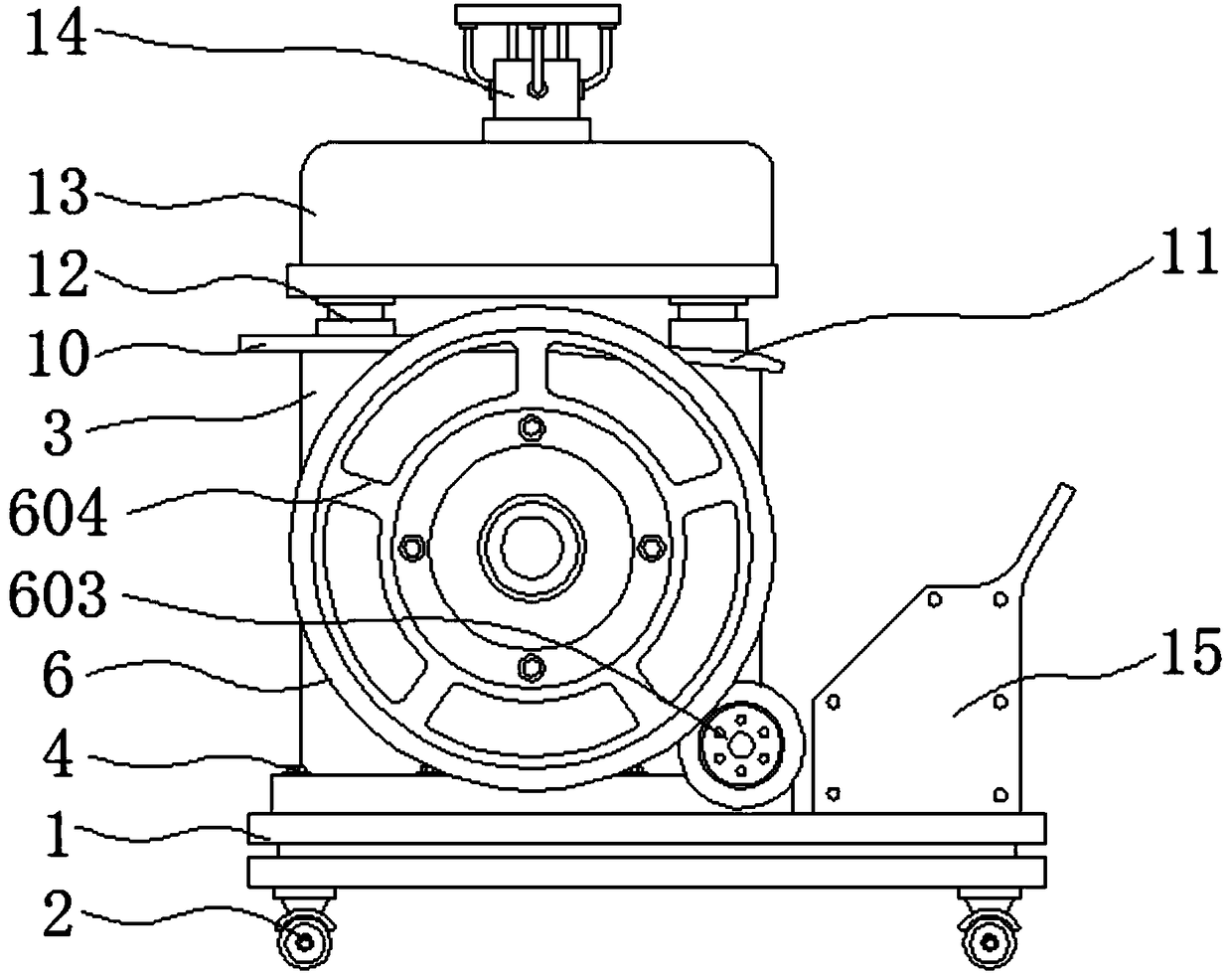

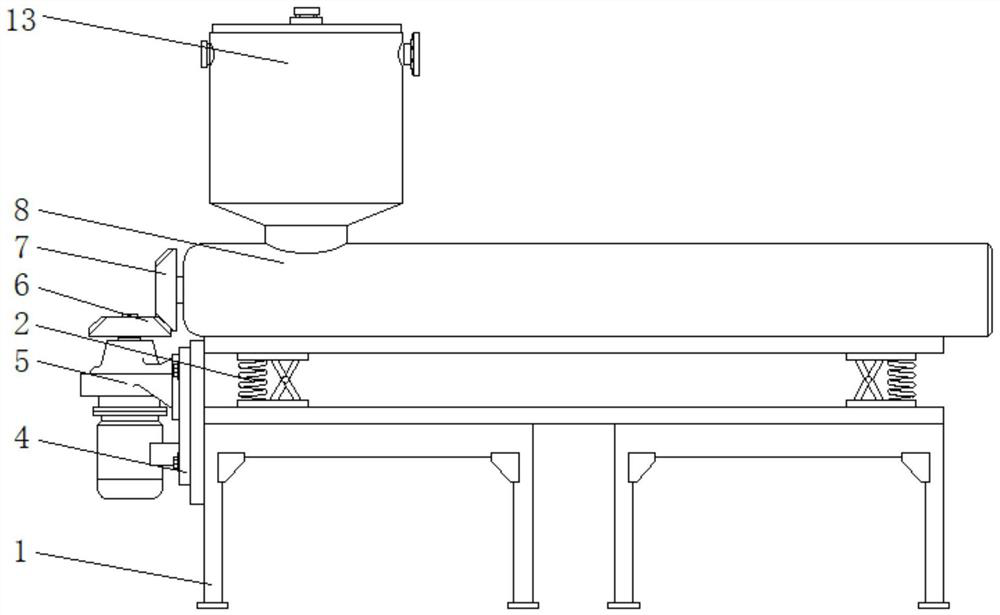

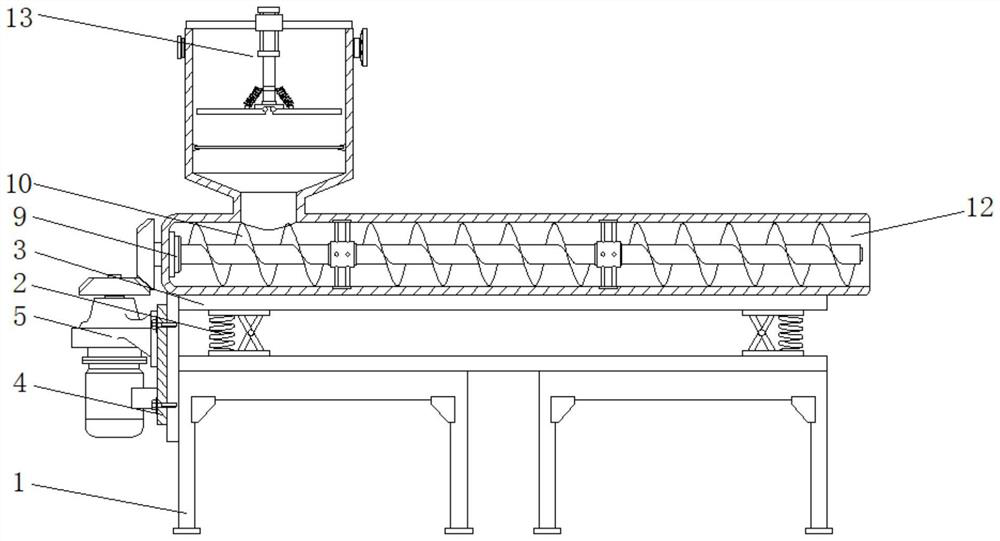

Mixing and stirring device for feed additive production

InactiveCN111617663AImprove pressure bearing capacityGuaranteed stabilityFeeding-stuffRotary stirring mixersProcess engineeringFeed additive

The invention discloses a mixing and stirring device for feed additive production, and relates to the technical field of feed additive mixing equipment, in particularly to the mixing and stirring device for feed additive production. The mixing and stirring device for feed additive production comprises a supporting ring and a sealing cover, a supporting block is arranged above the supporting ring,a positioning plate is arranged in the middle of a supporting column, a connecting ring is arranged in the middle of the positioning plate, a discharging port is formed in the lower end of a main bodyshell, an electric heating wire is arranged in a heating layer, and fixing screws are installed at the left end and the right end of the sealing cover. A rotary shaft drives a sealing shell, a main shaft and an auxiliary shaft to rotate, so that materials in the main body shell are stirred, and the mixing and stirring device adopts an inclined double-shaft structure, so that the mixing and stirring device has a larger stirring range, the materials are stirred more comprehensively in a larger range, and the working efficiency of the mixing and stirring device in use is indirectly improved.

Owner:ANHUI HUANGHUAI VETERINARY MEDICINE

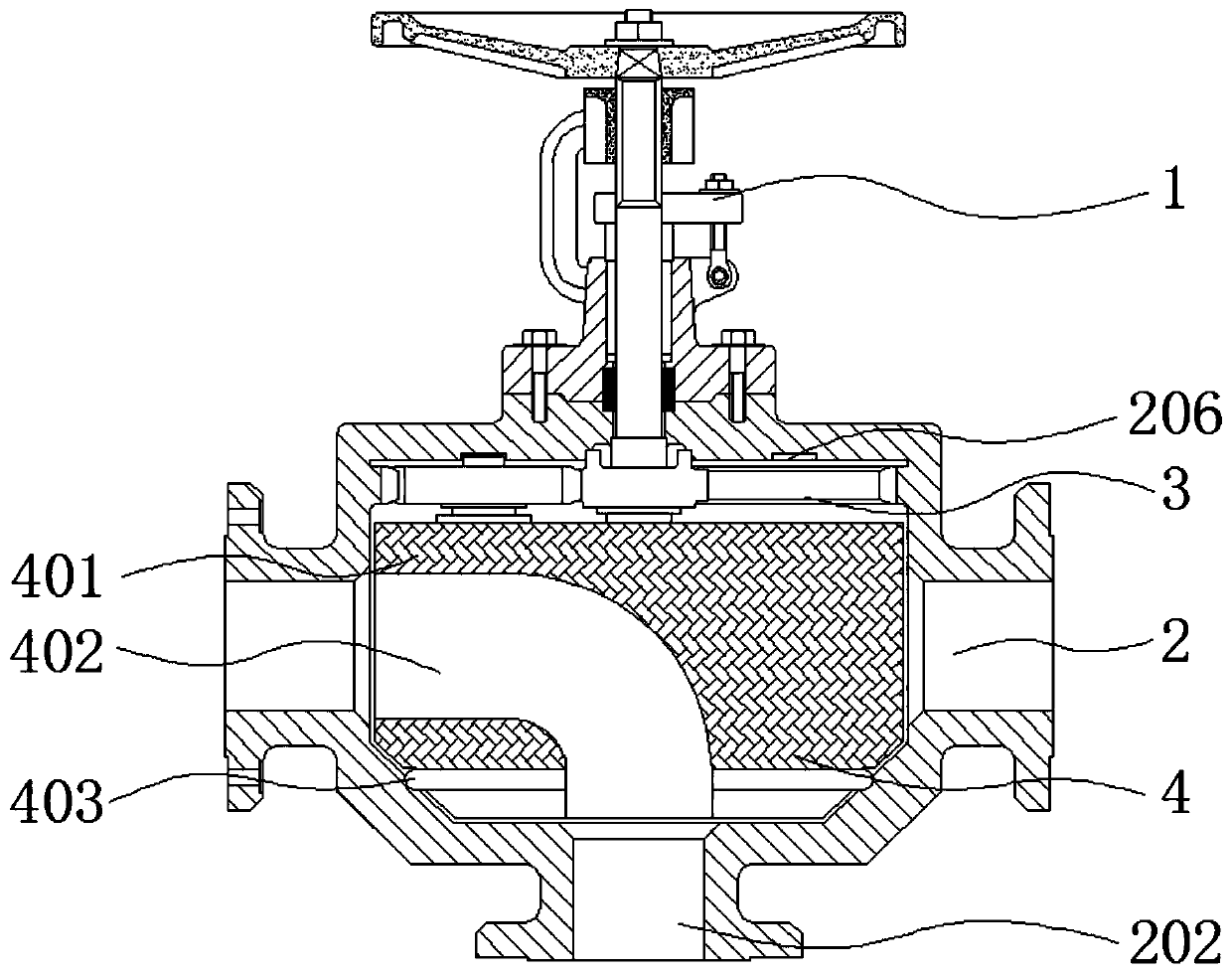

Valve capable of changing gas flow direction

InactiveCN110094549AChange flow directionReduce layingOperating means/releasing devices for valvesMultiple way valvesEngineeringAirflow

Owner:陈卫

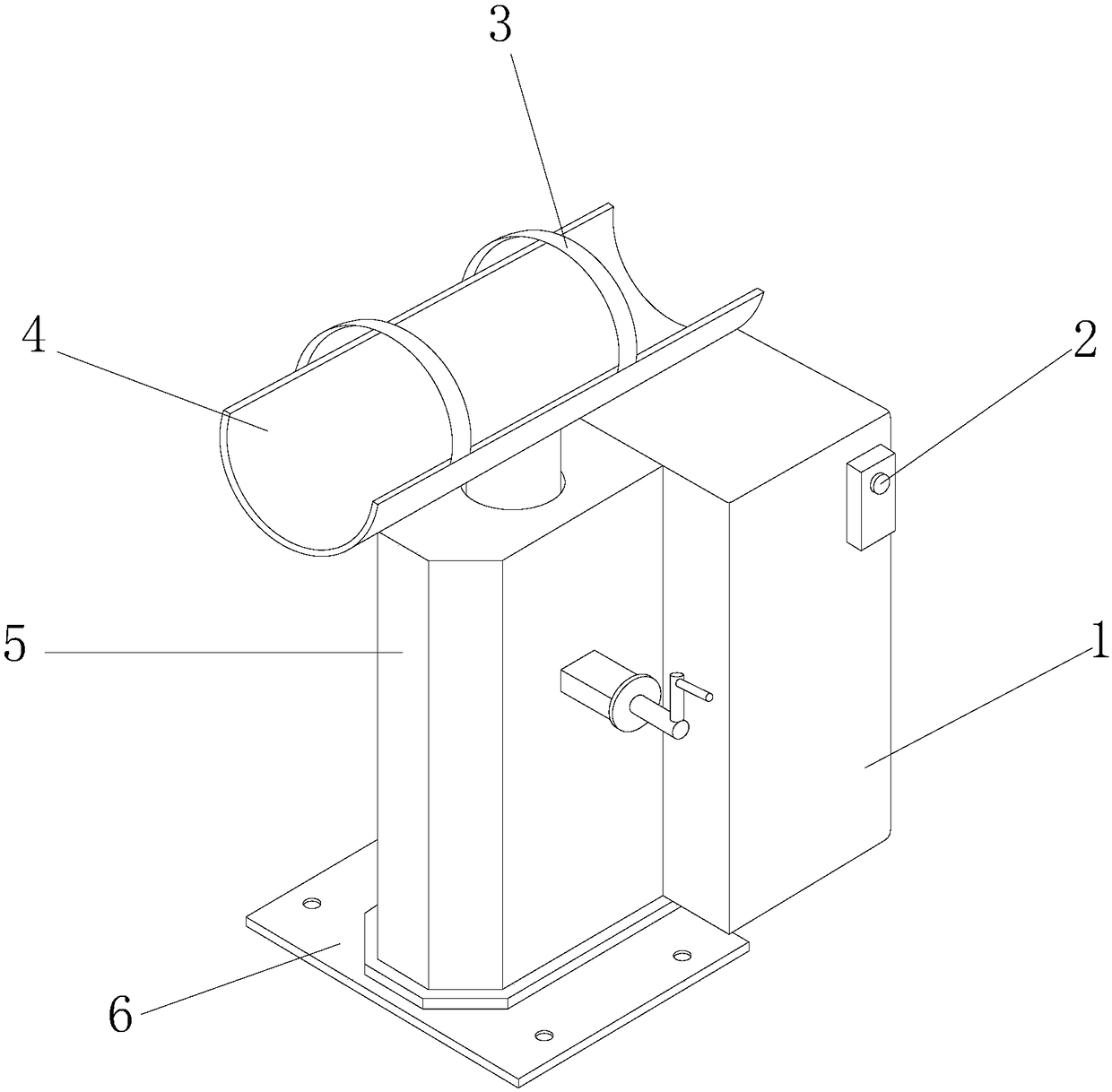

Rotary turning device for oil pipeline processing

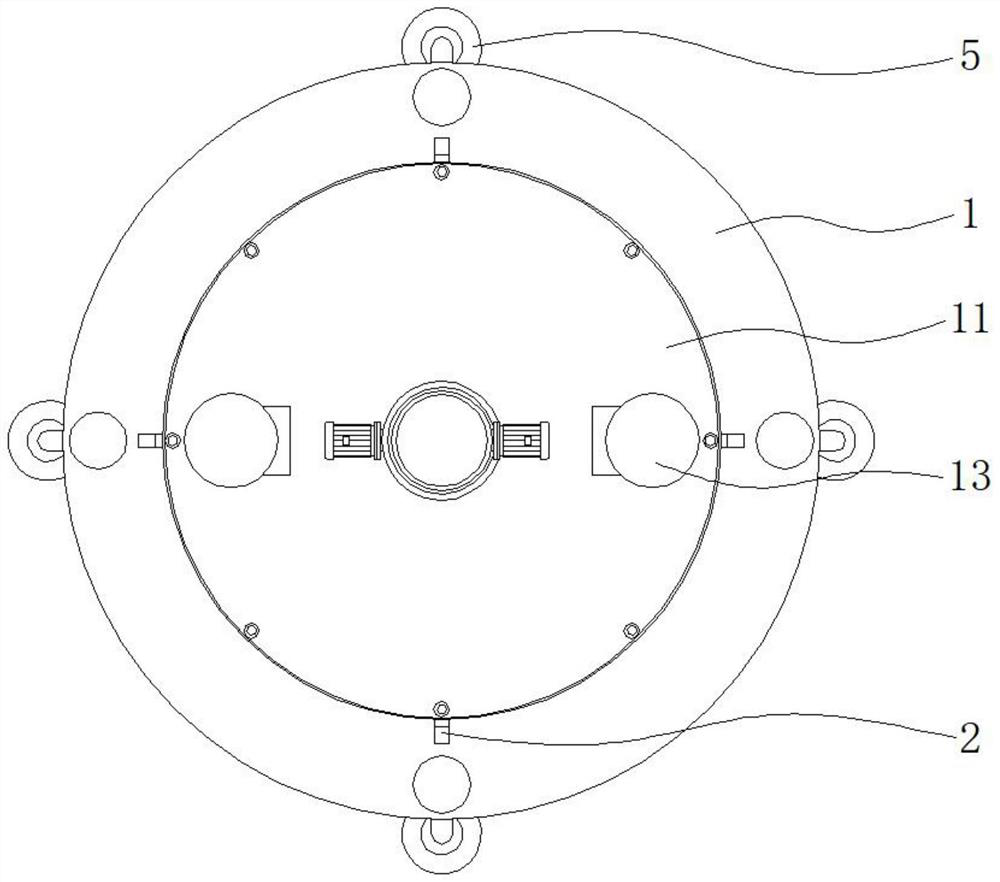

InactiveCN108557730AFast stability controlEasy to controlLifting devicesHoisting equipmentsInterference fitPower switching

The invention discloses a rotary turning device for oil pipeline processing. The device structurally comprises a power supply cabinet, a power switch, pipeline adjustable fixing sleeves, a pipeline supporting base, a rotary turning device and a fixed baseplate. The pipeline supporting base is arranged above the rotary turning device and is in interference fit with the rotary turning device, and the two pipeline adjustable fixing sleeves are uniformly arranged on the pipeline supporting base at an interval and are in clearance fit with the pipeline supporting base; an oil pipeline is placed inthe pipeline supporting base and tightly locked on the pipeline supporting base by means of the pipeline adjustable fixing sleeves, the direction of the pipeline can be adjusted on site through the rotary turning device, and the consumed time is short. The turning speed is high, the pipeline can quickly enter a next step for processing, improvement of the efficiency of continuous production of thepipeline is facilitated, only one worker is needed in the turning process, the operation is simple, and the risk during turning of the pipeline is reduced.

Owner:郑逸凡

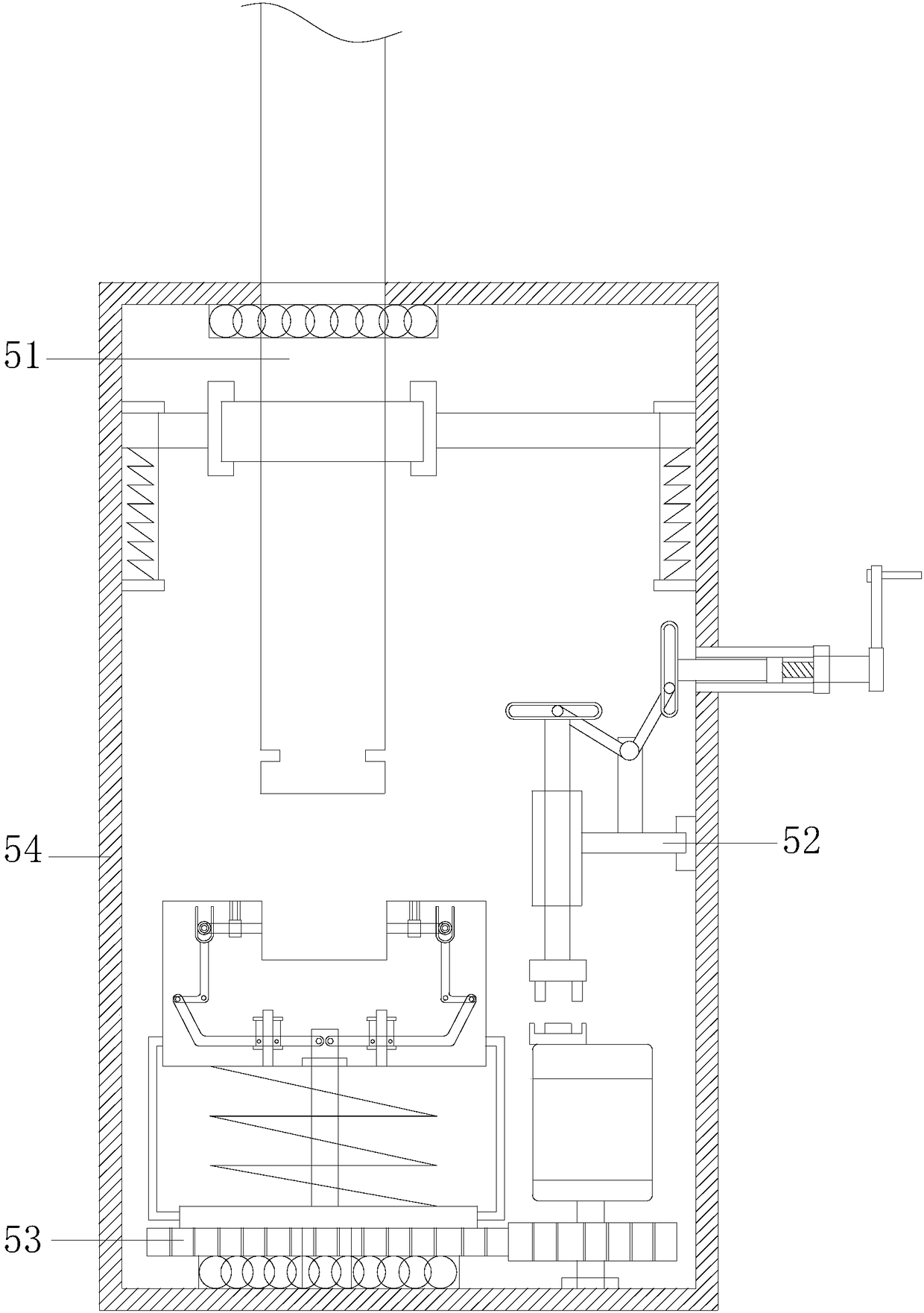

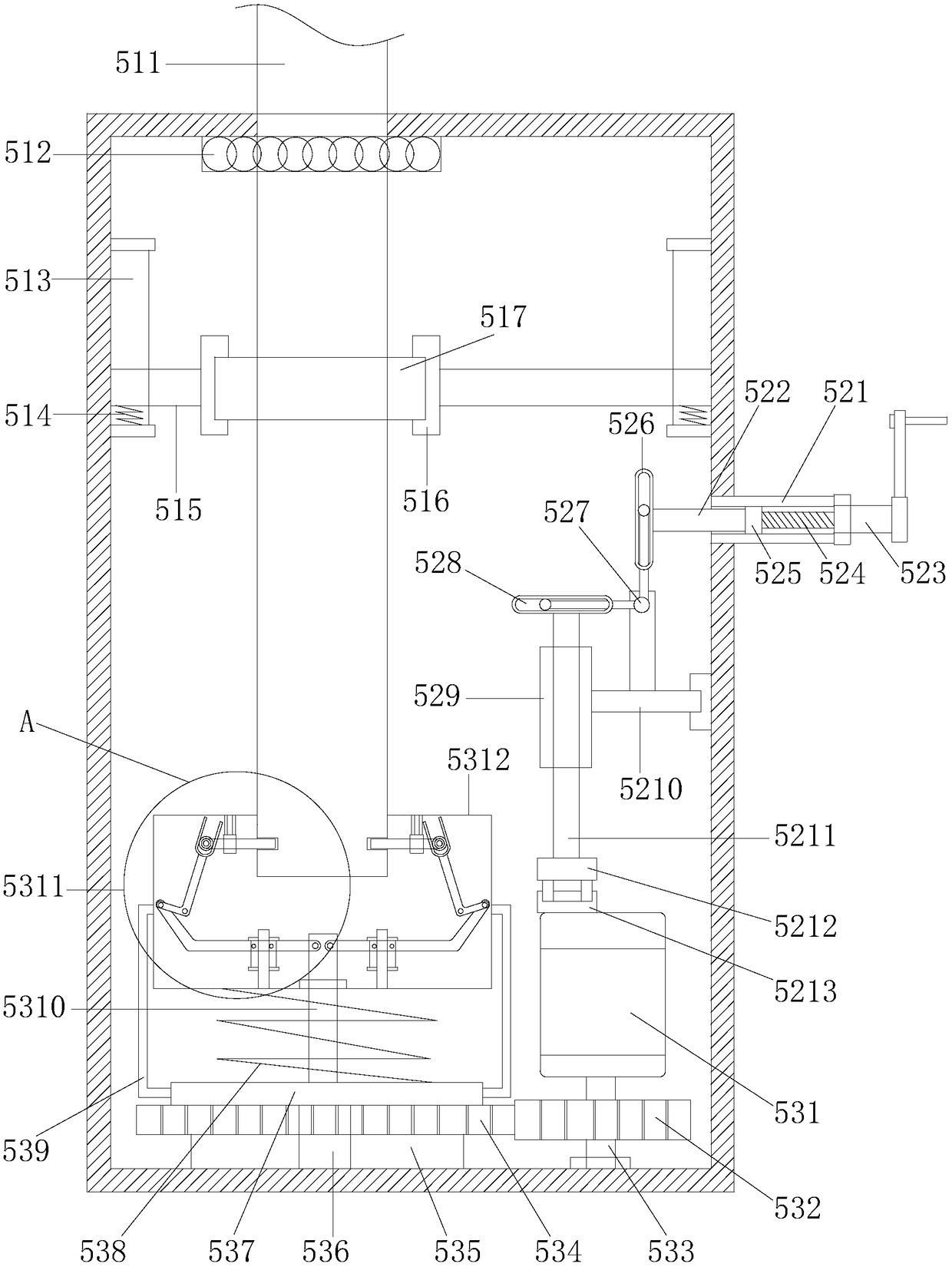

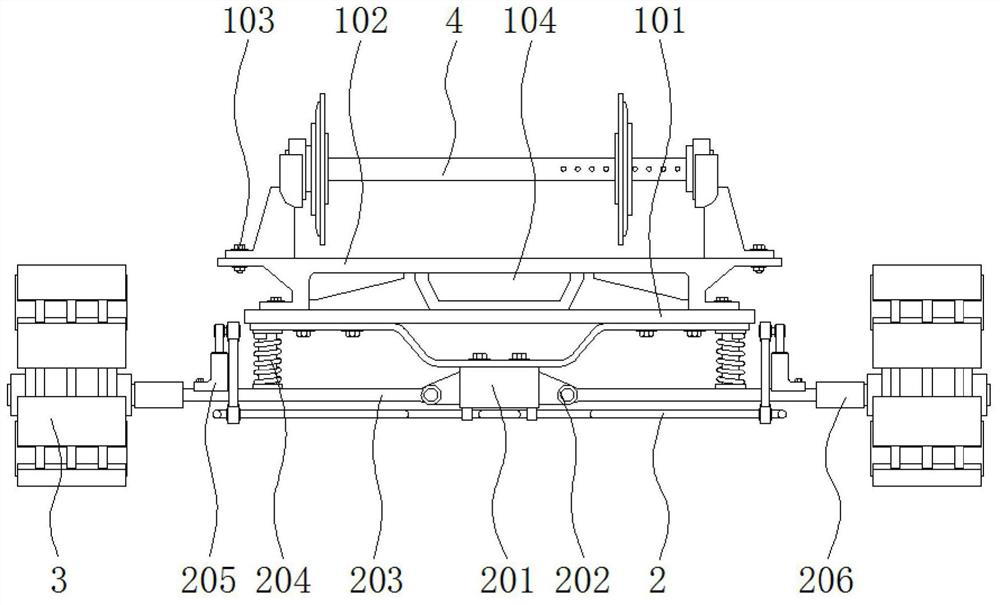

Air tightness test equipment facilitating internal part cleaning for railway track health maintenance

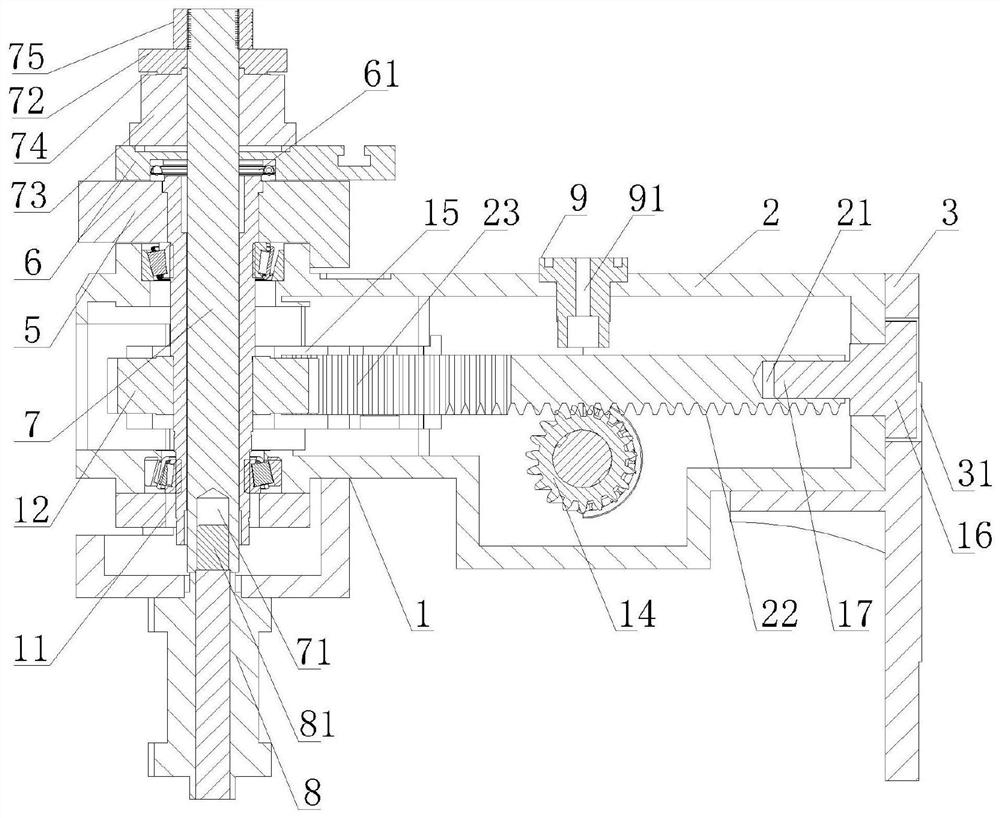

InactiveCN110763401AAvoid rigid frictionGuaranteed stabilityFluid-tightness measurement using fluid/vacuumGear wheelAir tightness

The invention discloses air tightness test equipment facilitating internal part cleaning for railway track health maintenance, relates to the technical field of railway track test equipment, and in particular relates to the air tightness test equipment facilitating internal part cleaning for railway track health maintenance. The air tightness test equipment facilitating internal part cleaning forrailway track health maintenance comprises a support base and a power control mechanism; a main body shell is arranged over the support base; the power control mechanism is arranged over the main bodyshell; the power control mechanism comprises a power gear, a rotating wheel, transmission gears, rotating shafts, control gears and threaded sleeves; both the left and right sides of the power gear are each provided with the transmission gear; and the control gears are arranged at one sides, away from the power gear, of the transmission gears. According to the air tightness test equipment facilitating internal part cleaning for railway track health maintenance in the invention, the use performance of the whole device is greatly improved while the structure is increased; the improved equipmentis relatively simple and convenient when in use; with the help of gear meshing transmission, opening and closing of the device are realized; and use requirements of people are effectively satisfied.

Owner:DONGGUAN UNIV OF TECH

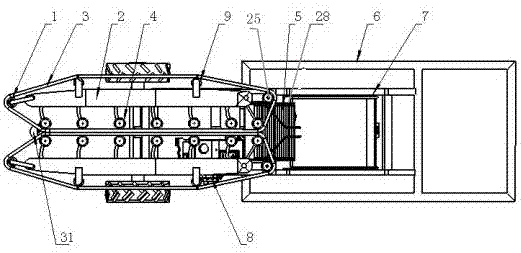

Axis part diameter high precision rapid measuring device

InactiveCN100562706CRealize measurementMovement is light and flexibleUsing optical meansGratingMeasurement device

The high-precision and fast measuring device for the diameter of shaft parts is characterized by a pair of left-end movable bayonet and right-end movable bayonet that can slide toward each other along the diameter direction of the measured shaft to form a bayonet-type probe. Between the moving bayonets, a grating measuring device for measuring the relative sliding distance between the left end moving bayonet and the right end moving bayonet is installed. The grating measuring device is composed of a grating ruler and a grating head. The moving direction is set in parallel and is fixedly connected with the right-end movable bayonet, and the grating head arranged opposite is fixedly connected with the left-end movable bayonet. The invention can realize fast and accurate measurement of the diameter of shaft parts, and can directly display the measurement results on the computer screen to realize the functions of data storage and transmission; it can also calculate the shaft parts by processing and analyzing the measurement data Data information such as cylindricity and conicity.

Owner:HEFEI UNIV OF TECH

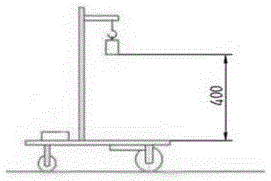

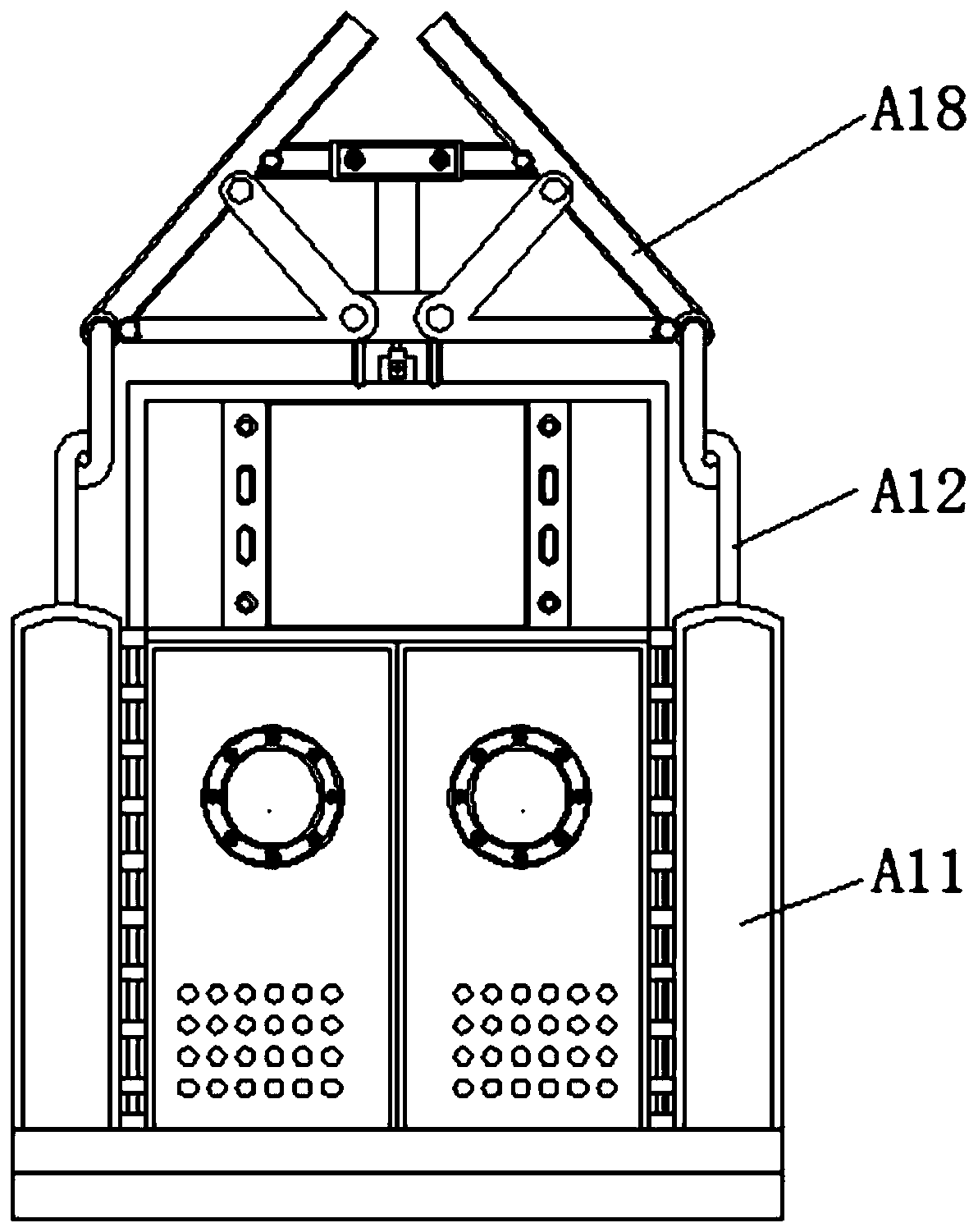

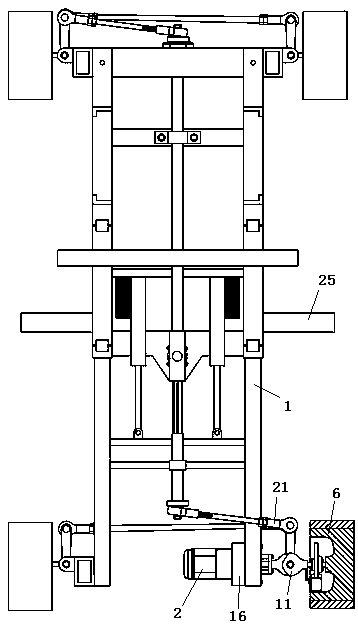

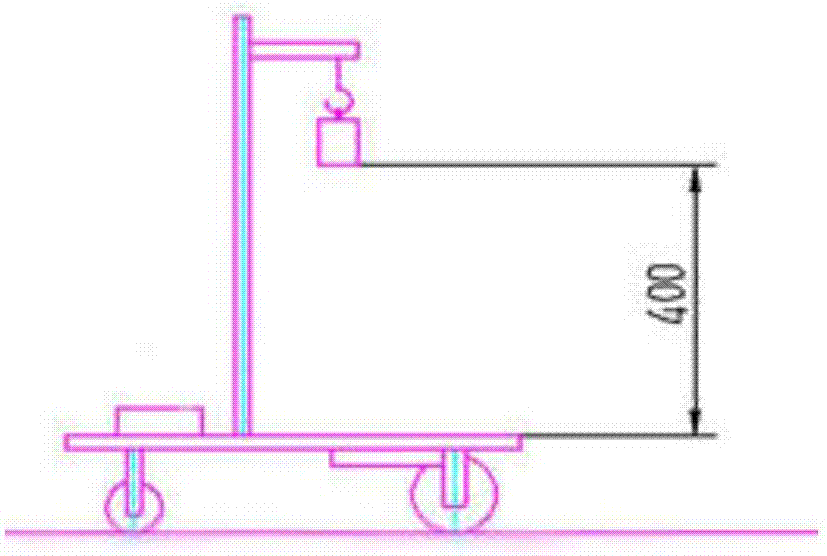

Manual gear type column switch hoisting device and application thereof

InactiveCN104340899ASave time at workImprove work efficiencyWinding mechanismsSwitchgearWork periodDrive shaft

The invention relates to a manual gear type column switch hoisting device and application of the manual gear type column switch hoisting device. The hoisting device comprises a main body, a transmission device and a fixing device, wherein the transmission device comprises a first transmission shaft and a second transmission shaft; gears which are meshed with each other for transmission are respectively arranged on the first transmission shaft and the second transmission shaft; the two ends of the first transmission shaft and the second transmission shaft are arranged on a three-dimensional framework; the two ends of the first transmission shaft are respectively fixedly connected with a shaking handle; a steel wire rope is arranged on the second transmission shaft. When the hoisting device is used, the main body is fixed on an electric pole by utilizing a hoop, the steel wire rope penetrates through fixed pulleys on a cross arm at the top of the electric pole and is used for tying switch equipment, and then a worker shakes the handle to hoist the switch equipment. Compared with the traditional hoisting mode, the hoisting device has the advantages that the operators are reduced, the operation time is shortened, the working efficiency is improved, and the operation cost is reduced.

Owner:国网山东省电力公司聊城供电公司

Waterproof charging pile for new energy automobile

PendingCN111216579AReduce entryReduce the impactPhotovoltaic supportsCharging stationsNew energyStructural engineering

The invention discloses a waterproof charging pile for a new energy automobile. The waterproof charging pile comprises a main body shell, a hose and a vertical rod, a cross arm is mounted on the rightside of the main body shell, a pin rod is arranged in the cross arm, the main body shell is in pin connection with the cross arm through the pin rod, a door is fixed on the right side of the cross arm; the cross arm and the door leaf are welded, a clamping piece is arranged in the door leaf, glass is arranged in the clamping piece, the glass is in threaded connection with the door leaf through the clamping piece, a blade is installed at the rear end of the vertical rod, the vertical rod is located in the main body shell, and an inner sliding groove is formed on the left side of the blade. Through the arrangement of the main body shell, the pin rod, the cross arm and the door leaf, the door leaf can rotate along the exterior of the pin rod through the cross arm, an installation space for reducing dust entering and preventing external water from interfering with work of the charging pile is formed between the door leaf and the main body shell, and the influence of the external environment on internal components of the charging pile is reduced.

Owner:耿东勇 +2

Safe driving system of driving and pushing dual-purpose electric shopping cart

PendingCN111016999AOptimize structure layoutCompact structureHand cart accessoriesVehicle frameElectric machinery

The invention discloses a safe driving system of a driving and pushing dual-purpose electric shopping cart. The safe driving system comprises a driving system and a braking system, wherein the drivingsystem comprises a speed reducing device, and a motor, a controller, a power supply, a foot-operated speed regulator and a switch assembly which are connected through wires; the controller, the powersupply and the foot-operated speed regulator are arranged on a frame; the motor is in driving connection with a speed reducer; the speed reducer is fixedly connected to the frame through bolts; the power output end of the speed reducer is in driving connection with one rear wheel; the rear wheel is connected with the frame through a steering knuckle; the other three wheels are rotatably connectedto the frame through wheel shafts; the braking system comprises a brake pedal, a brake pump assembly, a brake disc and a caliper; the brake pedal is connected with the frame through a bolt; and the brake pump assembly is fixedly connected to the frame. The motor, the speed reducer and a half shaft are in coaxial transmission, structural arrangement of the shopping cart is facilitated, and it is guaranteed that the shopping cart is compact in structure and small in size.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

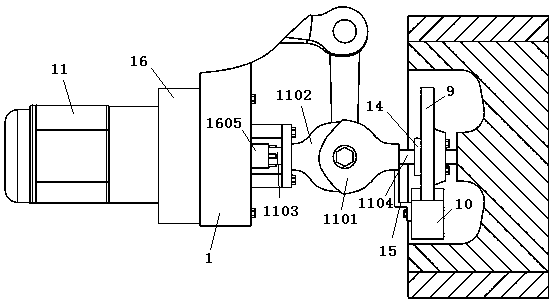

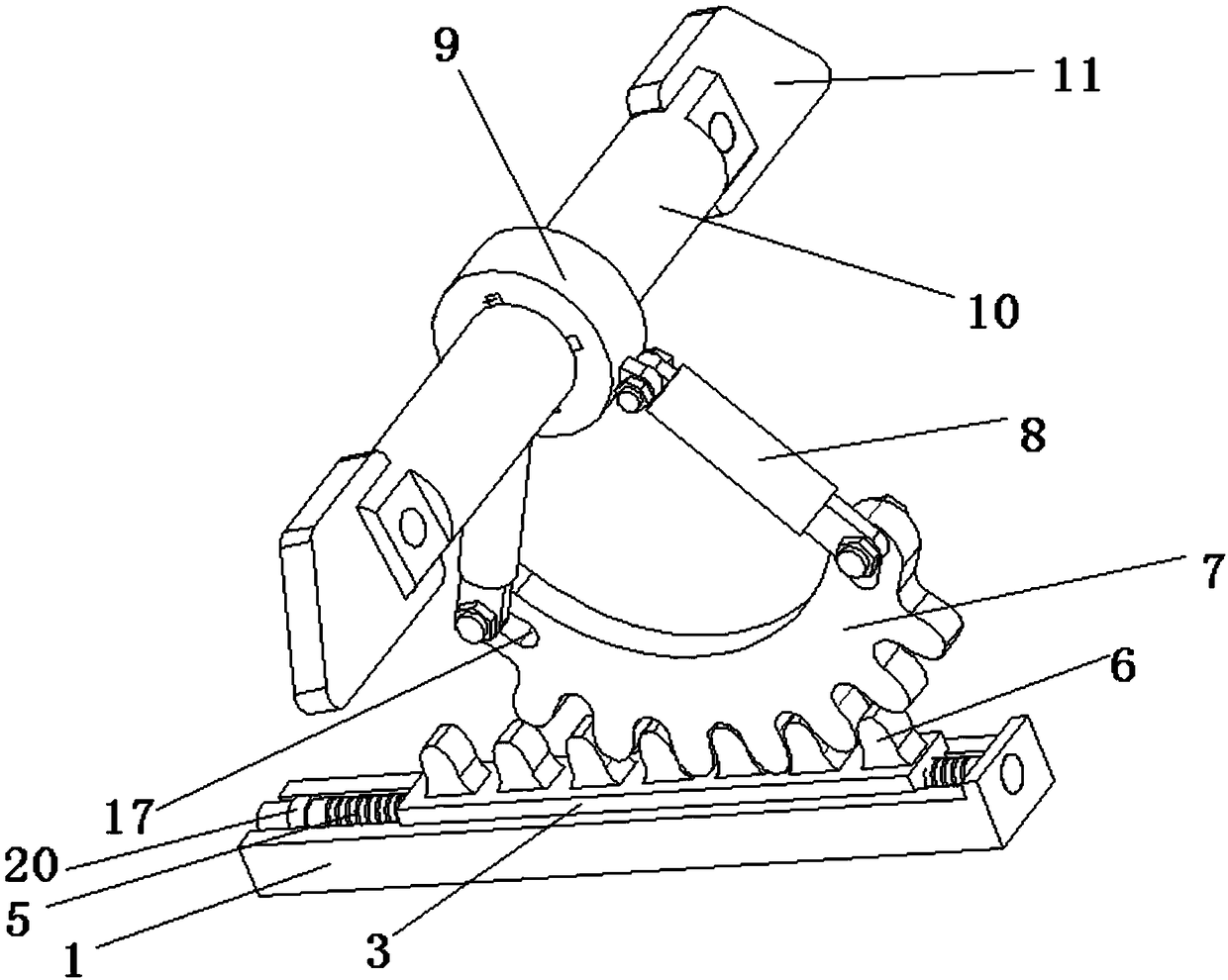

Vehicle automatic anti-glare visor based on light sensitive resistor and gear transmission

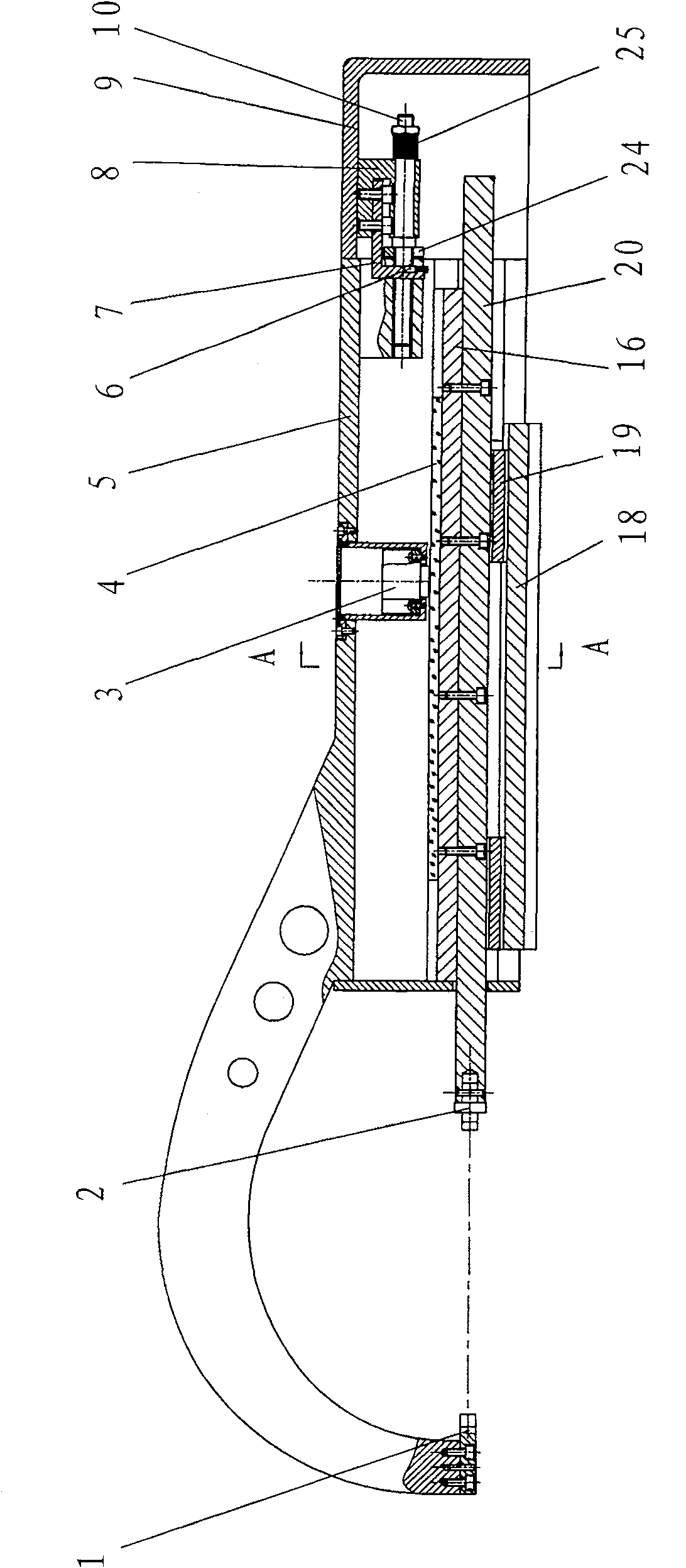

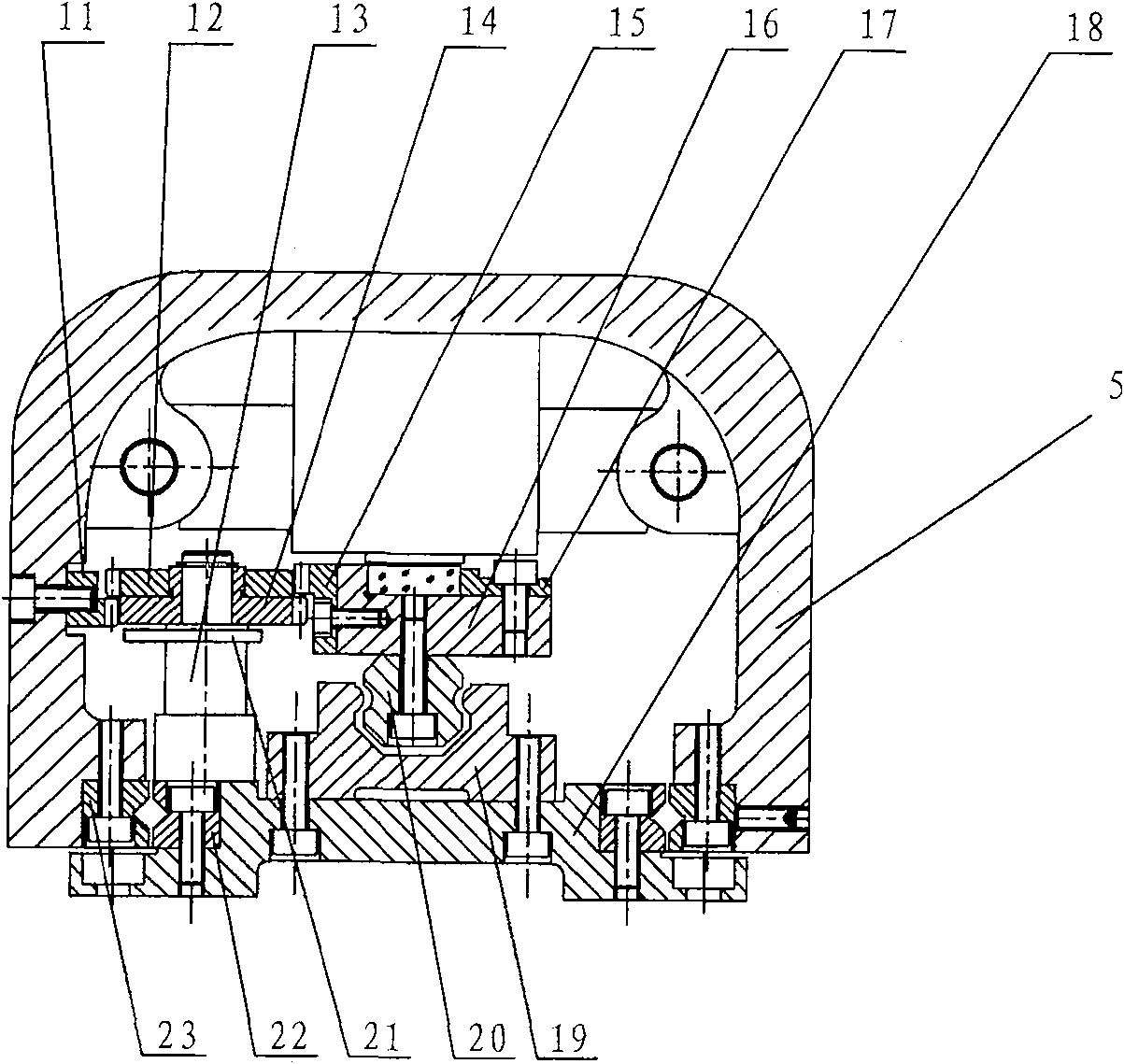

PendingCN110053460AImprove driving safetyInstantaneous gear ratio constantAntiglare equipmentDaylightVisor

The invention discloses a vehicle automatic anti-glare visor based on a light sensitive resistor and gear transmission. The problem of adjustment of the vehicle automatic anti-glare visor based on thelight sensitive resistor and gear transmission according to sunlight intensity is solved. The vehicle automatic anti-glare visor based on the light sensitive resistor and gear transmission is mainlycomposed of a motor (1), a motor gear (2), a rotary shaft support seat (3), a rotary shaft gear (4), the visor (5), a rotary shaft (6), a micro switch support seat (7), a reverse micro switch (8), a base (9), a motor support seat (10), the light sensitive resistor (11), a light sensitive resistor relay module (12), a motor controller (13), a stabilized voltage supply (14), a foreward micro switch(15) and a rocker switch (16). The light sensitive resistor (11) is connected with the light sensitive resistor relay module (12). The vehicle automatic anti-glare visor with the simple structure andthe reliable performance and based on the light sensitive resistor and gear transmission is provided.

Owner:JILIN UNIV

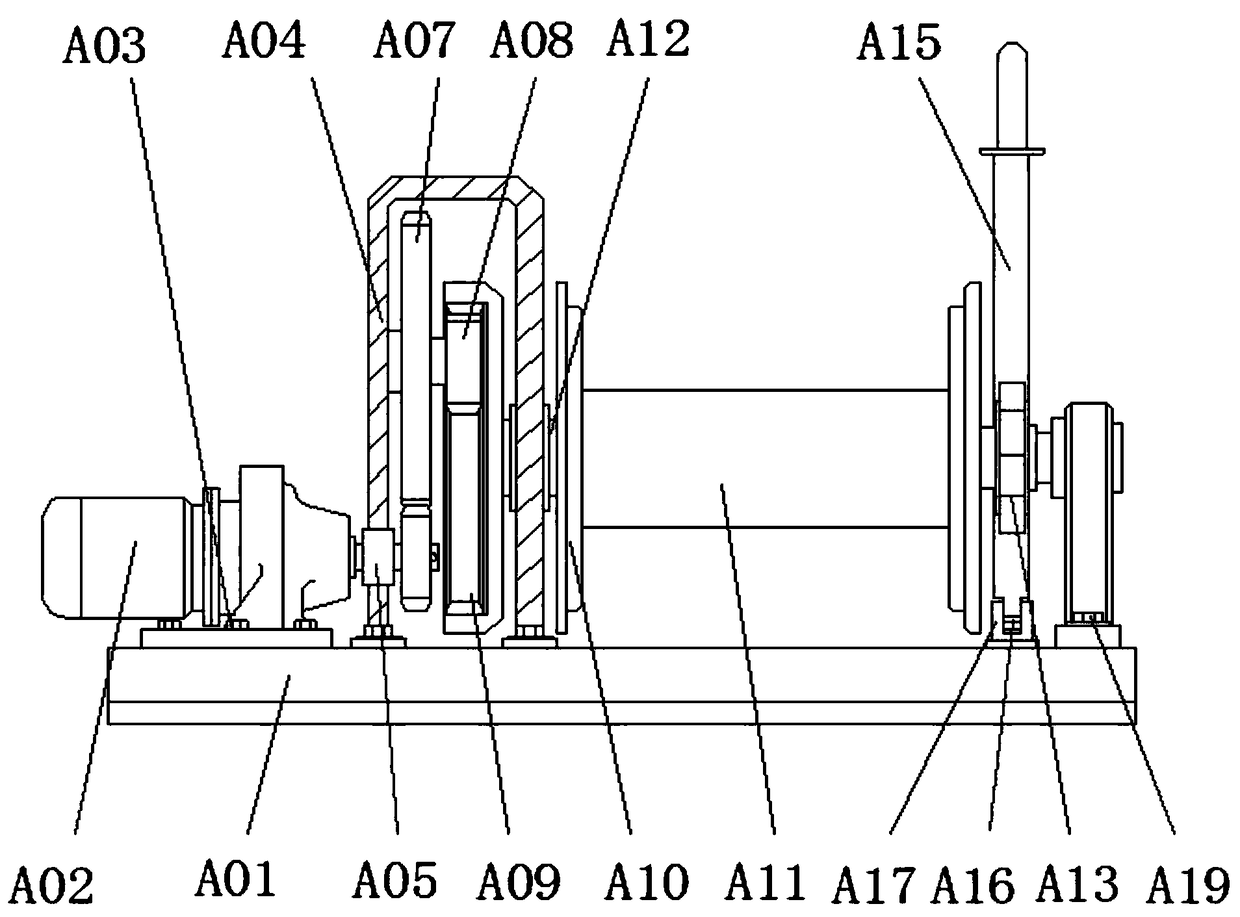

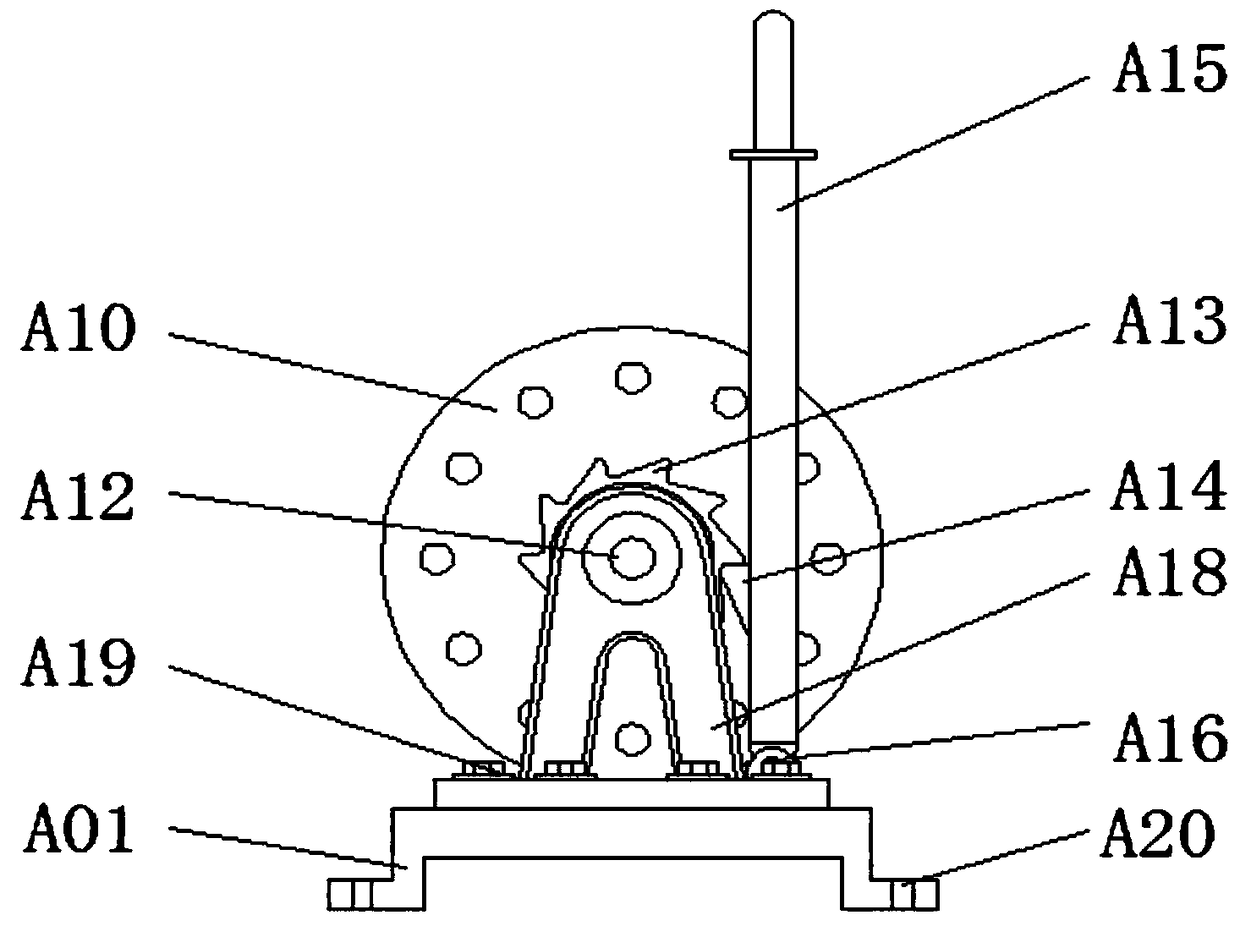

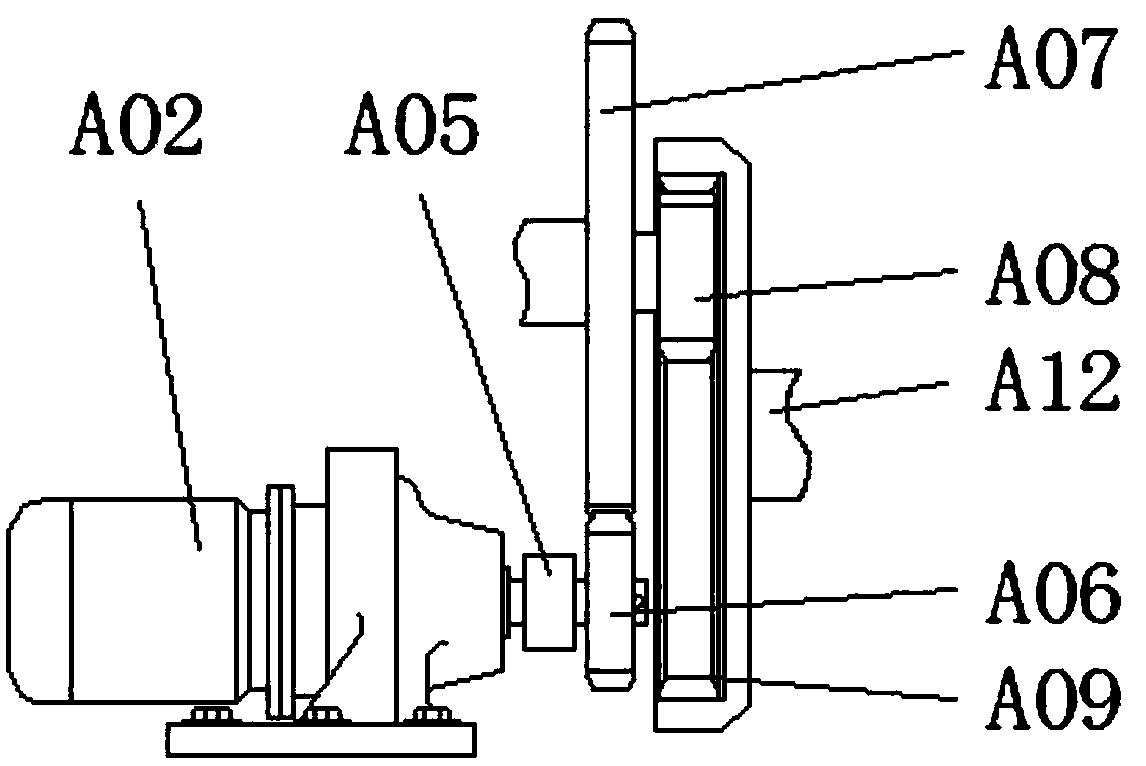

A transmission mechanism for a crawler implement

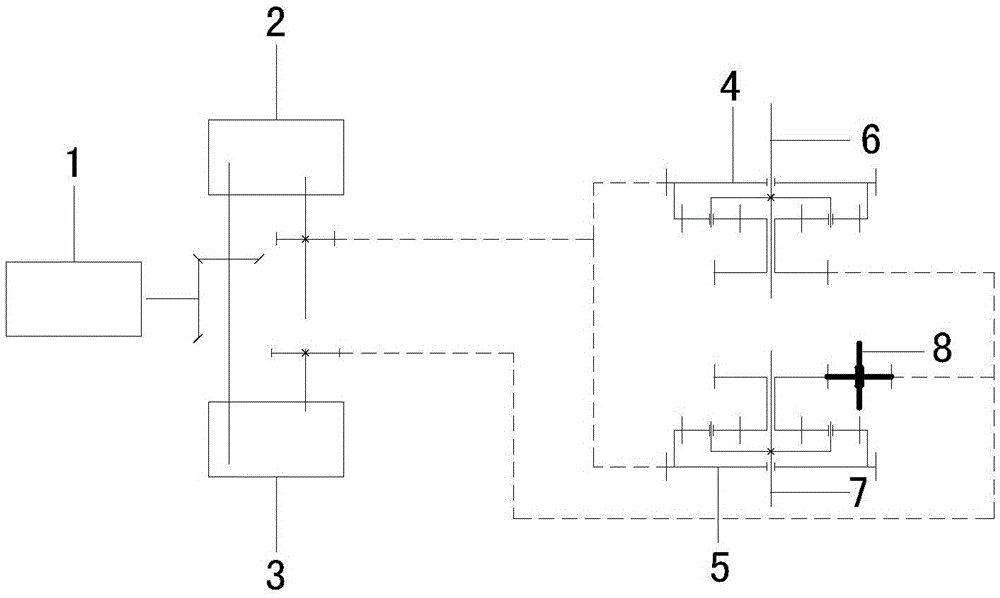

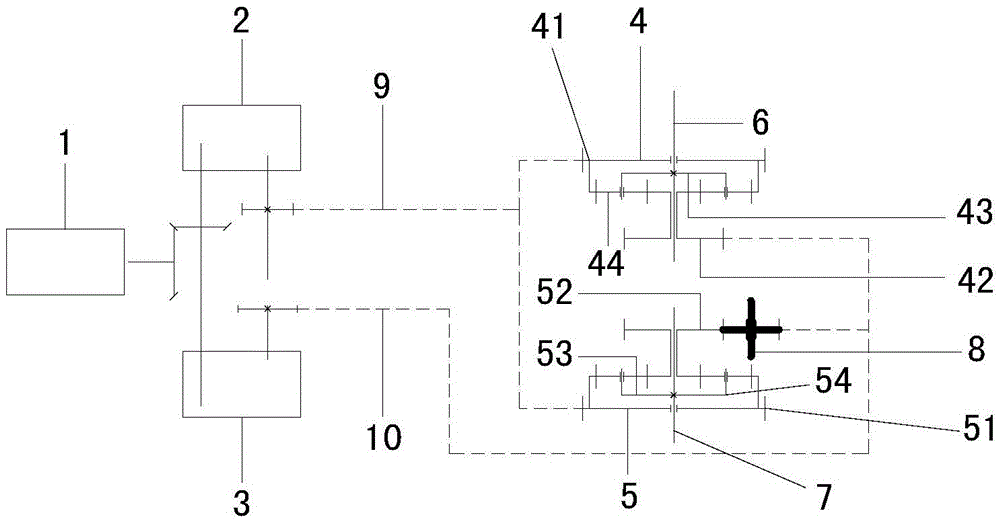

ActiveCN104964019BReliable driveReliable steeringGearing controlFluid gearingsTransmission systemInput device

The invention provides a transmission mechanism of a crawler-type machine. The transmission mechanism of the crawler-type machine comprises a power input device, a first hydrostatic transmission system, a second hydrostatic transmission system, a first planetary transmission mechanism, a second planetary transmission mechanism, a first power output device, a second power output device and a reversing device, wherein the first hydrostatic transmission system and the second hydrostatic transmission system are connected with the power input device, the first planetary transmission mechanism and the second planetary transmission mechanism are in transmission connection with the first hydrostatic transmission system and the second hydrostatic transmission system, the first power output device is connected with the first planetary transmission mechanism, the second power output device is connected with the second planetary transmission mechanism, and the reversing device is connected with the first planetary transmission mechanism or the second planetary transmission mechanism. According to the transmission mechanism of the crawler-type machine, high precision equipment is not needed for controlling the power output quantity of the two sides of the machine, and the cost is greatly reduced; meanwhile, due to the fact that the mechanical transmission efficiency usually can reach over 90%, waste of energy is avoided. Therefore, by means of the transmission mechanism of the crawler-type machine, the problems that in the prior art, the cost of the transmission mechanism is high, and the efficiency is low can be solved.

Owner:HUNAN NONGYOU MACHINERY GRP

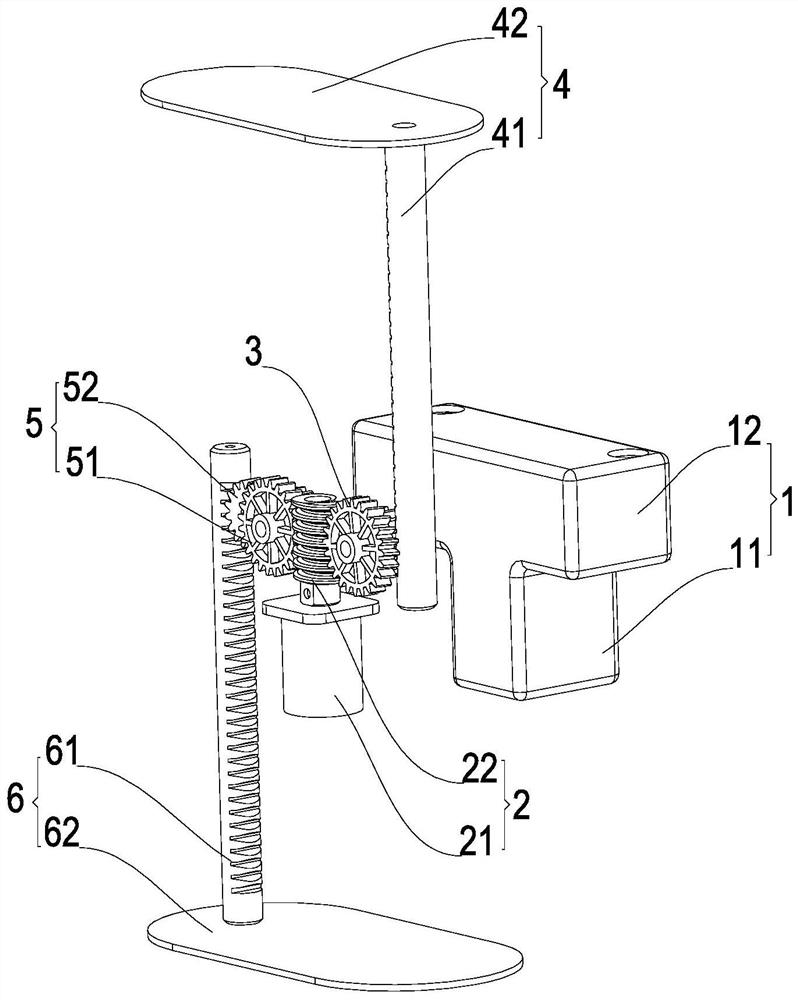

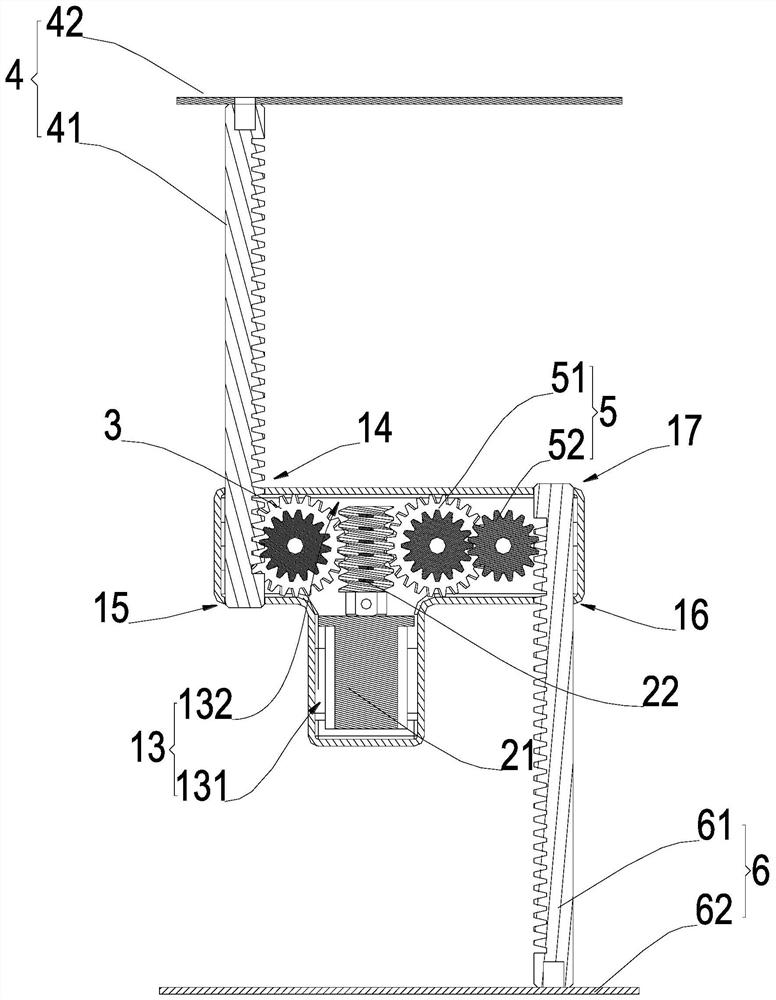

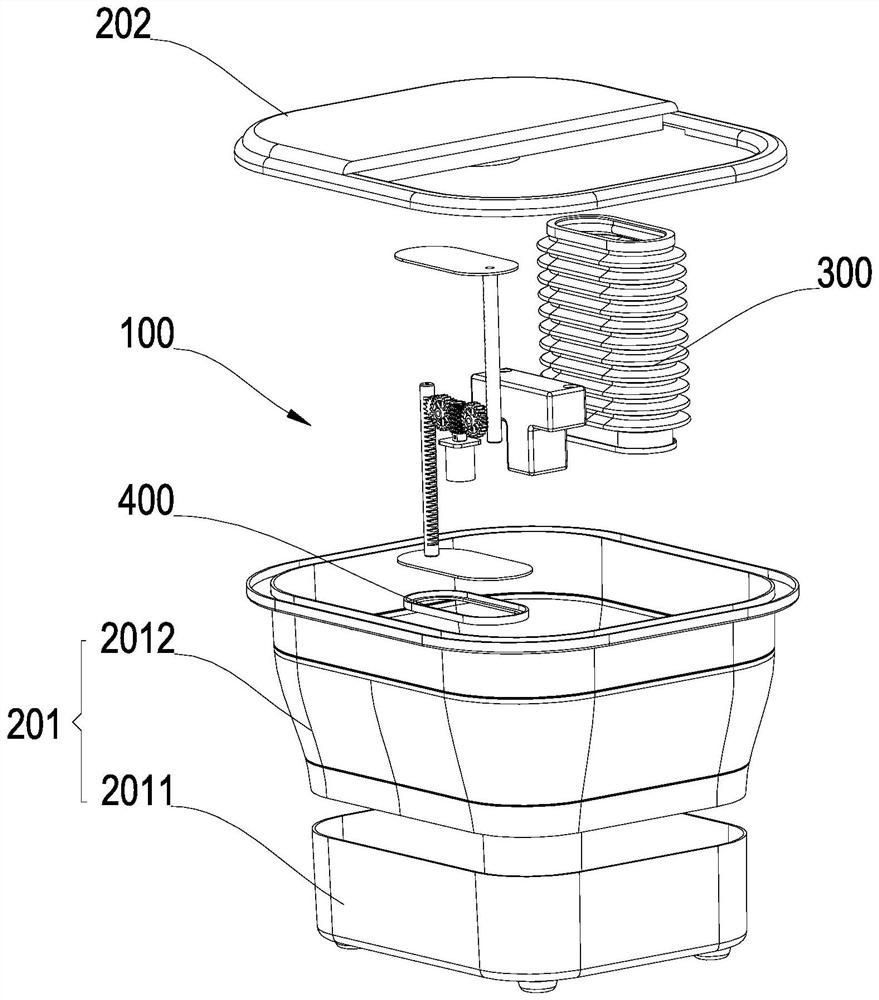

Lifting device and foot massage electric appliance

InactiveCN114557878AEasy to useImprove wear resistanceBathing devicesVehicular energy storagePhysical medicine and rehabilitationMassage

The invention relates to a lifting device and a massage electric appliance. The lifting device comprises a mounting shell; the driving device is arranged on the mounting shell; the first transmission part is arranged on the mounting shell; the first lifting assembly is arranged on the mounting shell, and when the first transmission part moves, the first lifting assembly can be driven to move in the first direction away from the mounting shell or move in the direction close to the mounting shell; the second transmission part is arranged on the mounting shell, and the driving device is used for driving the second transmission part and the first transmission part to move; and the second lifting assembly is arranged on the mounting shell, when the second transmission part moves, the second lifting assembly can be driven to move in the second direction away from the mounting shell or move in the direction close to the mounting shell, and the second direction is opposite to the first direction.

Owner:佛山市星曼信息科技有限公司

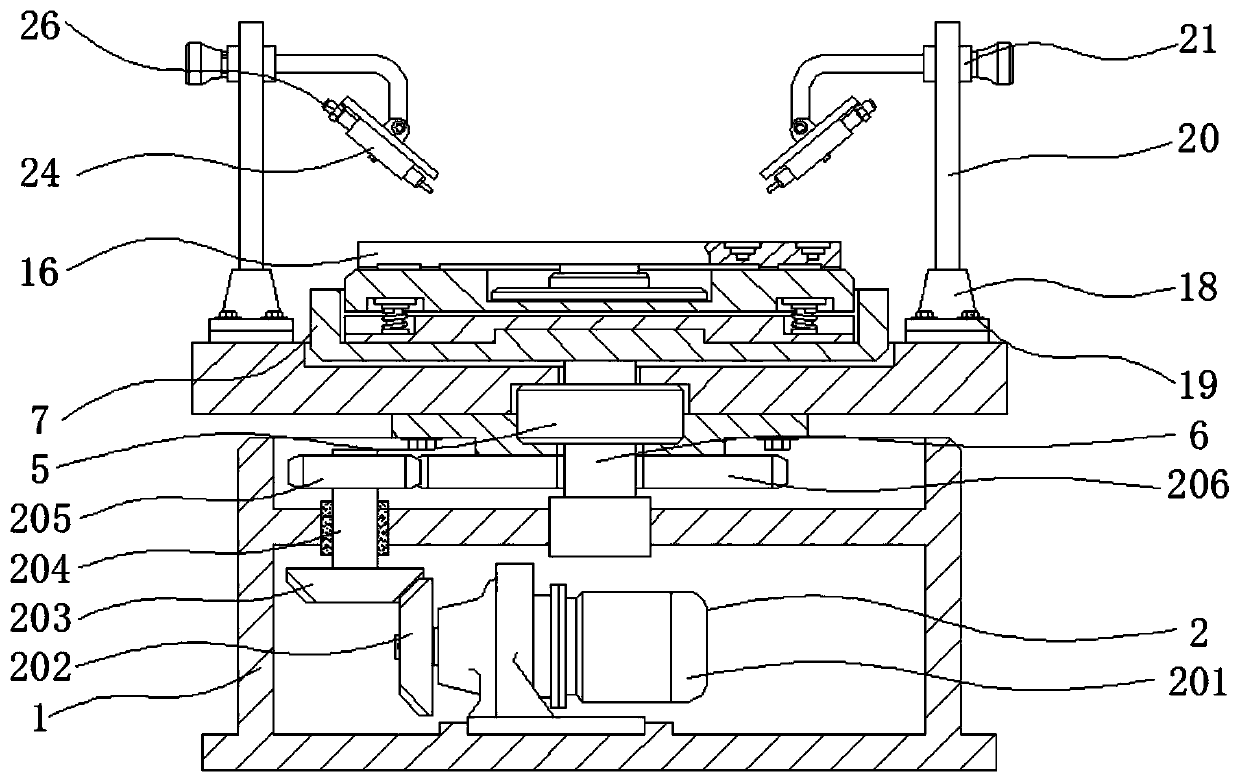

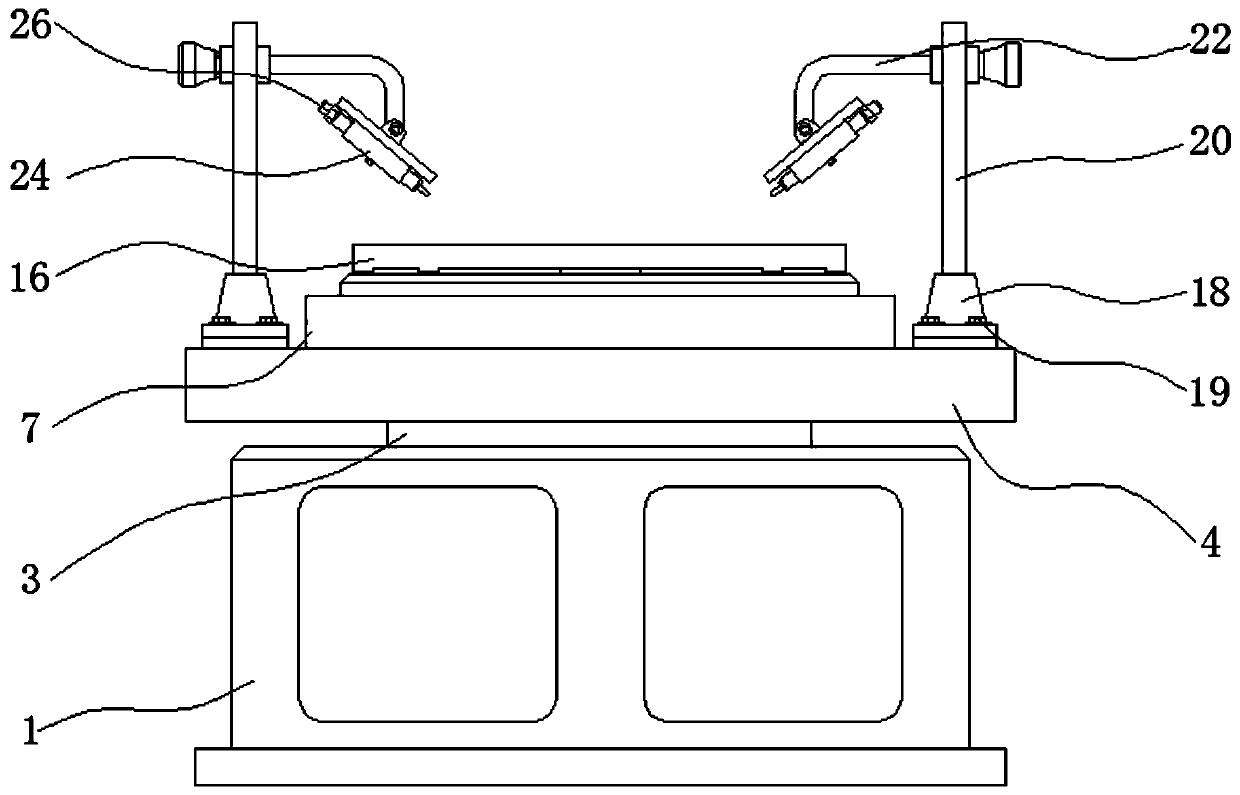

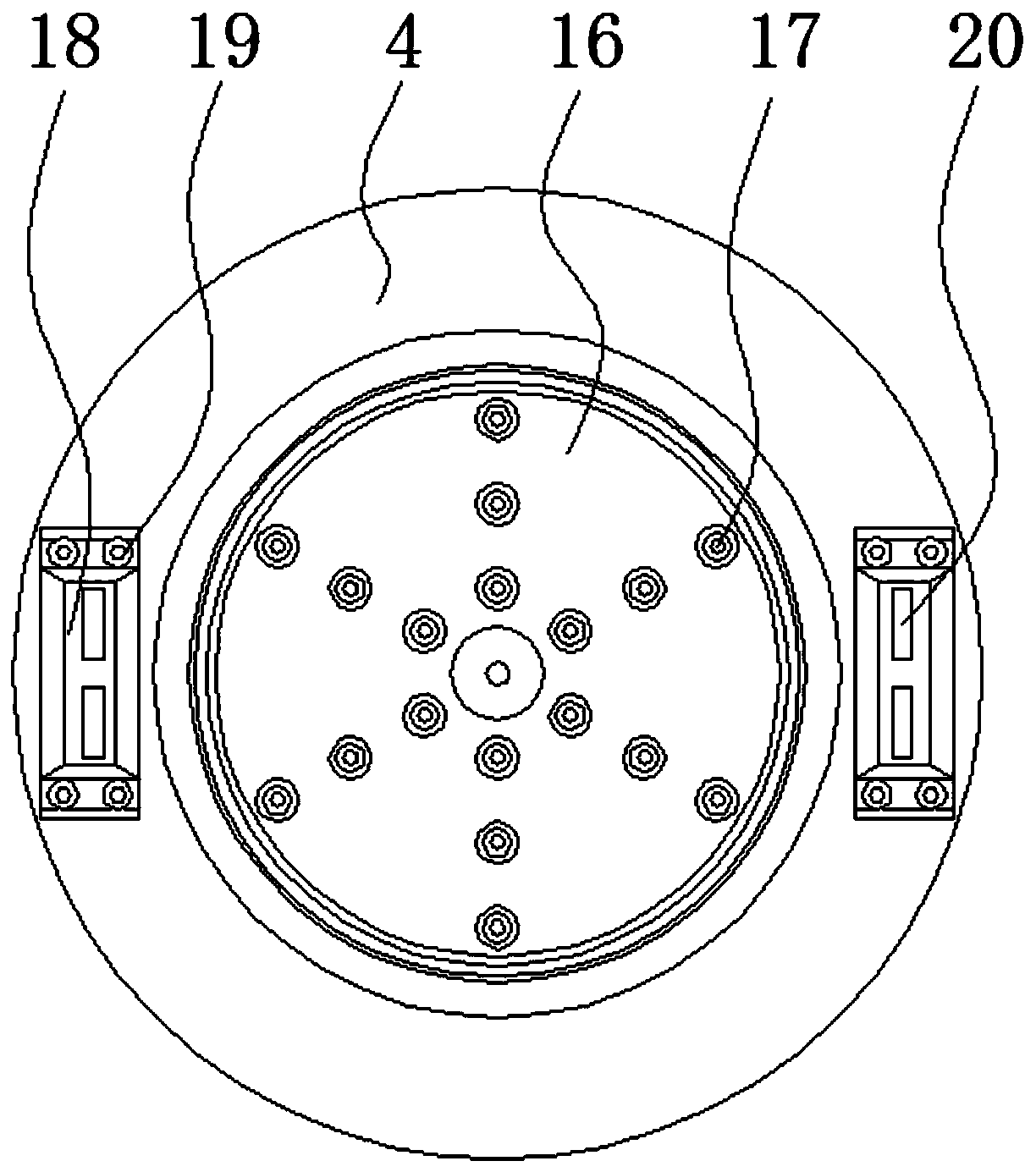

A rotatable omni-directional electroplating device for electronic components

InactiveCN109082699BImprove transfer efficiencyImprove reliabilityElectrodesFixed bearingElectronic component

The invention discloses a rotatable omni-directional electroplating device for electronic elements. The rotatable omni-directional electroplating device includes a main body frame, pressure-bearing springs and an electric rotary table, the main body frame is internally provided with a power output device, and the upper portion of the main body frame is provided with a supporting base; an operationplatform is arranged on the upper portion of the supporting base, and a fixed bearing is arranged inside the operation platform; and the fixed bearing is internally provided with a bearing column, the upper portion of the bearing column is connected with an outer surround, the lower end of a built-in base is internally provided with a positioning block, and the upper end of a moving rotary tableis internally provided with a positioning socket. According to the rotatable omni-directional electroplating device for the electronic elements, compared with existing ordinary electroplating devices,the use performance of the rotatable omni-directional electroplating device is greatly improved while increasing the structure, the improved rotatable omni-directional electroplating device has a better and more comprehensive electroplating capability and a bidirectional staggered rotation capability, the machining efficiency of the electronic elements is indirectly improved, and the use demandsof people is effectively met.

Owner:中国人民解放军海军航空大学青岛校区 +1

Vertical axis wind turbine with blade angle varying along with wind direction and wind velocity

InactiveCN101956653BReduce manufacturing costReduce power generation costsWind motor controlRenewable energy generationDrive shaftControl system

The invention relates to a vertical axis wind turbine with a blade angle varying along with wind direction and wind velocity, which comprises a control system, a planetary gearbox, a fixed axis gearbox, a transmission shaft, a main support, an upper cantilever beam, a lower cantilever beam, a bearing pedestal, a bearing, blades, a vertical axis, a tower and the like, wherein the vertical axis is connected with the tower through the bearing and the bearing pedestal; the main support is sleeved outside the vertical axis and the bearing pedestal, so that the middle part of the main support is connected with the middle part of the vertical axis, and the top end of the main support and the head of the vertical axis are connected with the bottom of the planetary gearbox; the control system is connected with the top of the planetary gearbox through the bearing pedestal; the root part and the end part of the upper cantilever beam are respectively connected with the side face of the planetary gearbox and the side face of the fixed axis gearbox, and the root part and the end part of the lower cantilever beam are respectively connected with the lower end of the main support and the bearing pedestal; both ends of the transmission shaft are respectively connected with the planetary gearbox and the fixed axis gearbox; and the blades are respectively connected with the fixed axis gearbox andthe bearing pedestal so that output power maintains near the rated power value.

Owner:孙世杰

Plate shearing machine with alarm equipment convenient for collecting raw material

InactiveCN109352061ASimple structureEasy to useShearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention discloses a plate shearing machine with alarm equipment convenient for collecting the raw material, relates to the technical field of shearing machines, in particular to the plate shearing machine with alarm equipment convenient for collecting the raw material. The plate shearing machine comprises a composite base, a connecting seat and a top protective cover, wherein a universal wheel is mounted below the composite base; a main body shell is arranged above the composite base; connecting screws are mounted in the lower end of the main body shell; a horizontal guiding mechanism isarranged in the main body shell; and the universal wheel and the main body shell are connected with the external surface of the composite base through the connecting screws. The plate shearing machine greatly improves the service performance of the entire device while additionally arranging the structure, the improved plate shearing machine is more stable during the using process and adopts gearengagement transmission, so that the plate shearing machine has higher instantaneous starting speed, avoids the overload phenomenon and effectively meets the using demand of a user.

Owner:GUIZHOU RUIHANG INTELLIGENT TECH CO LTD

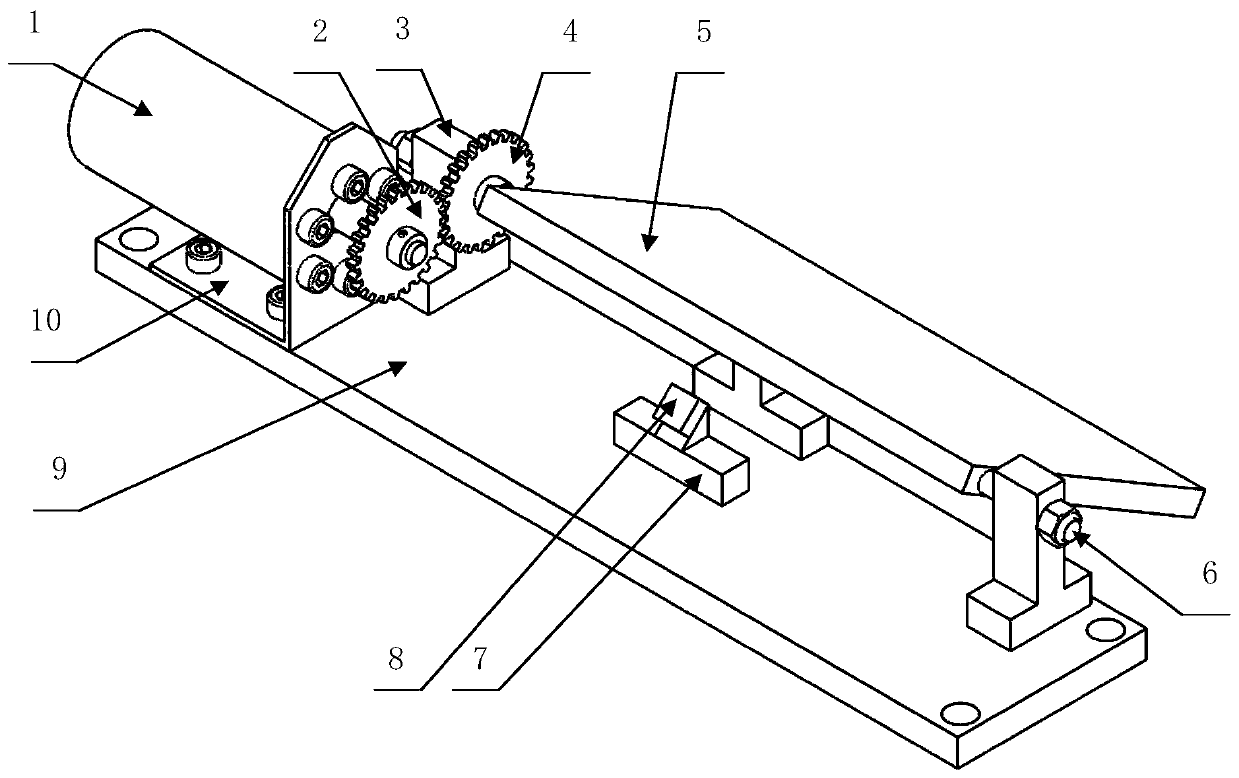

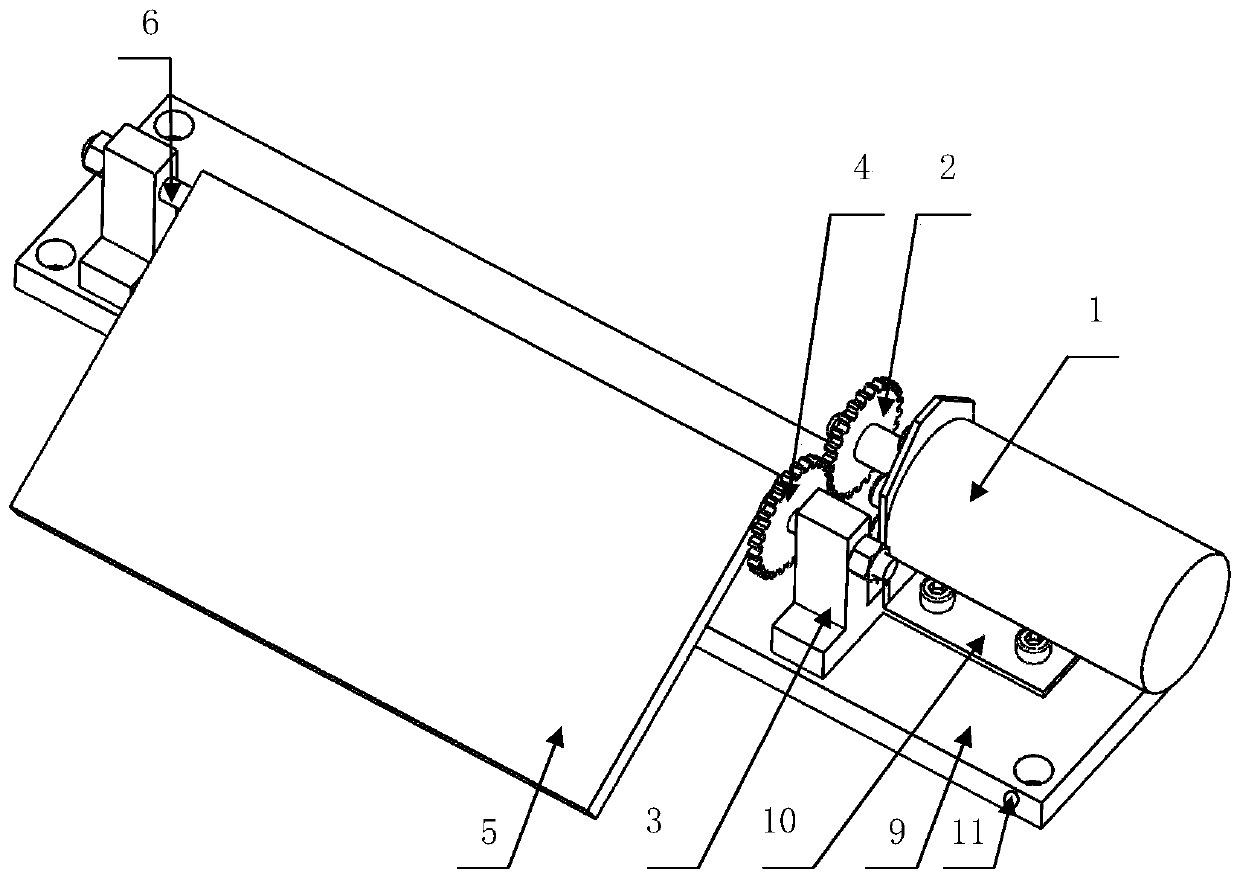

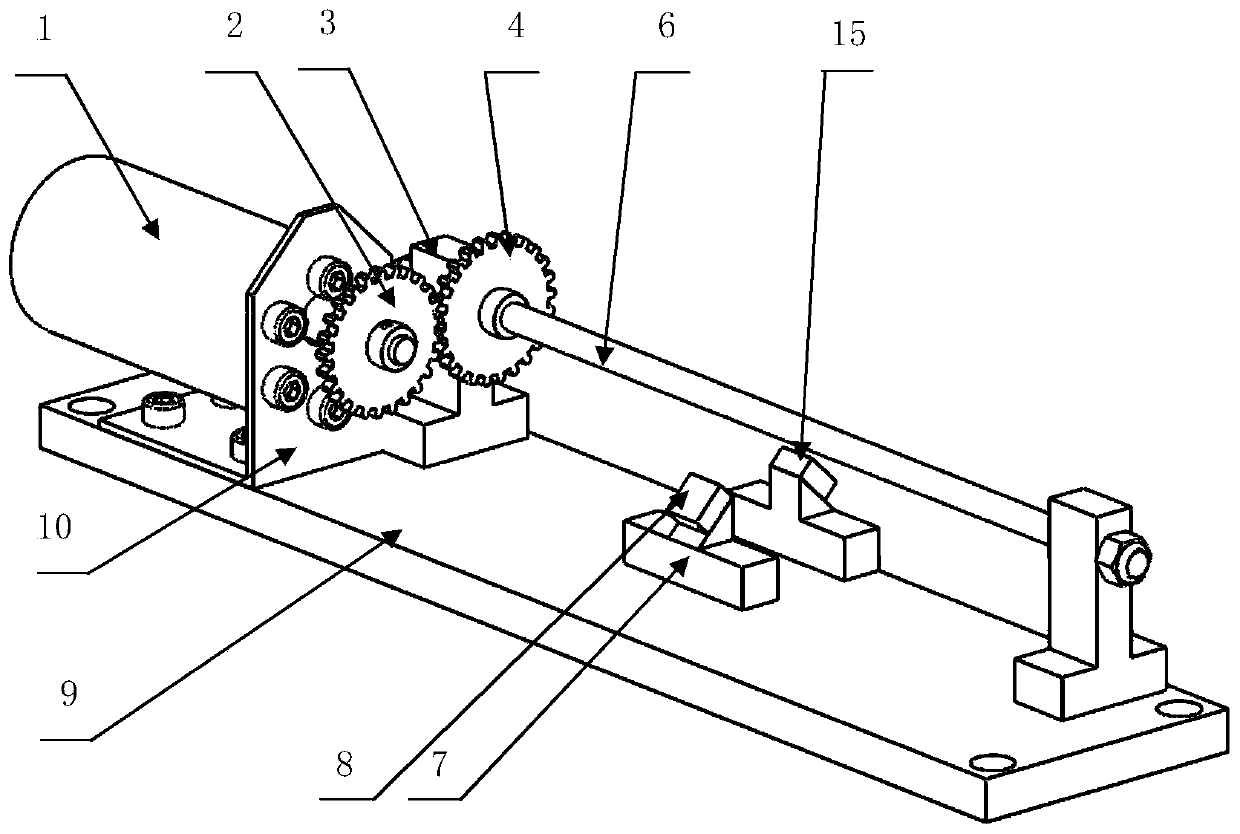

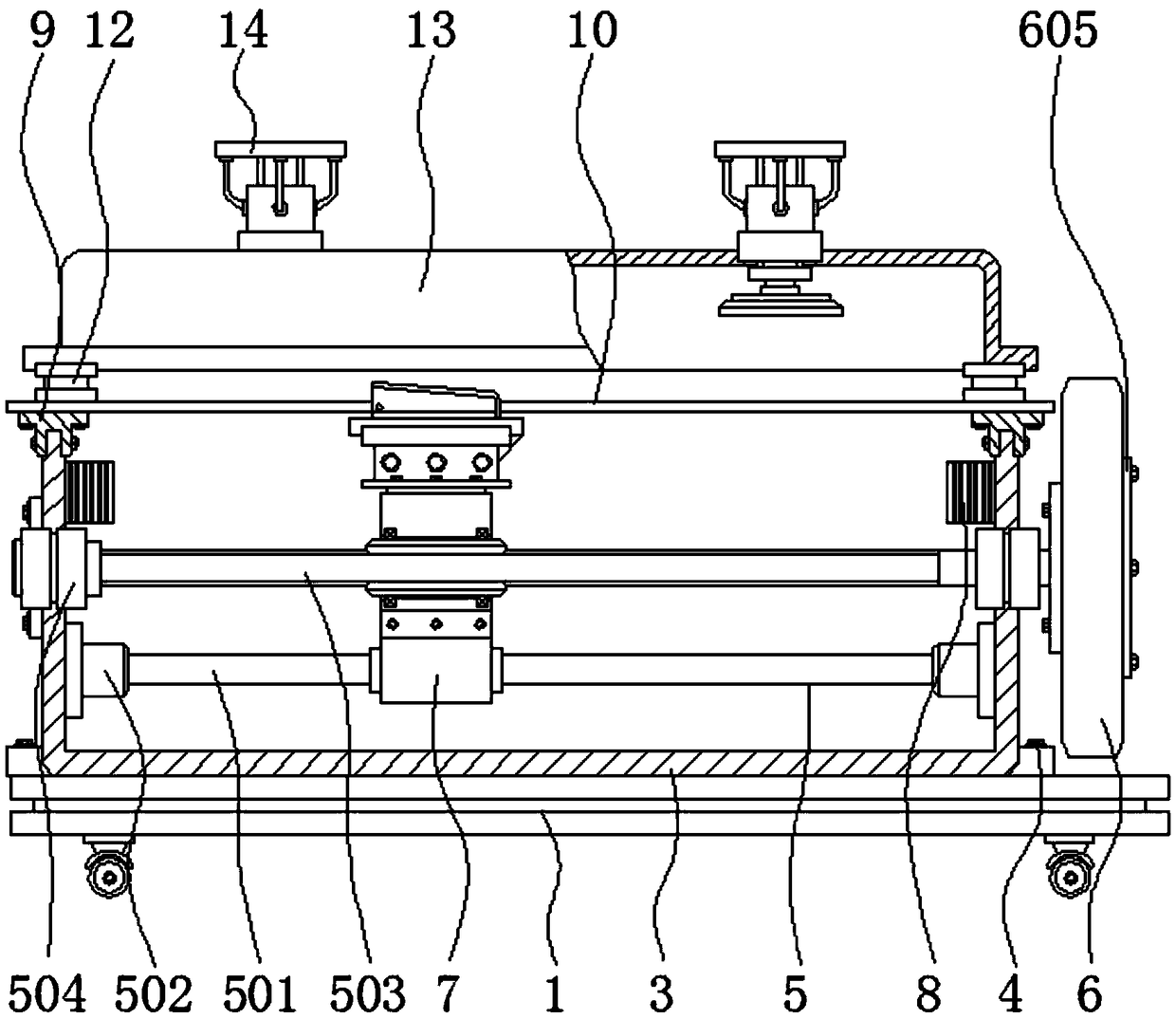

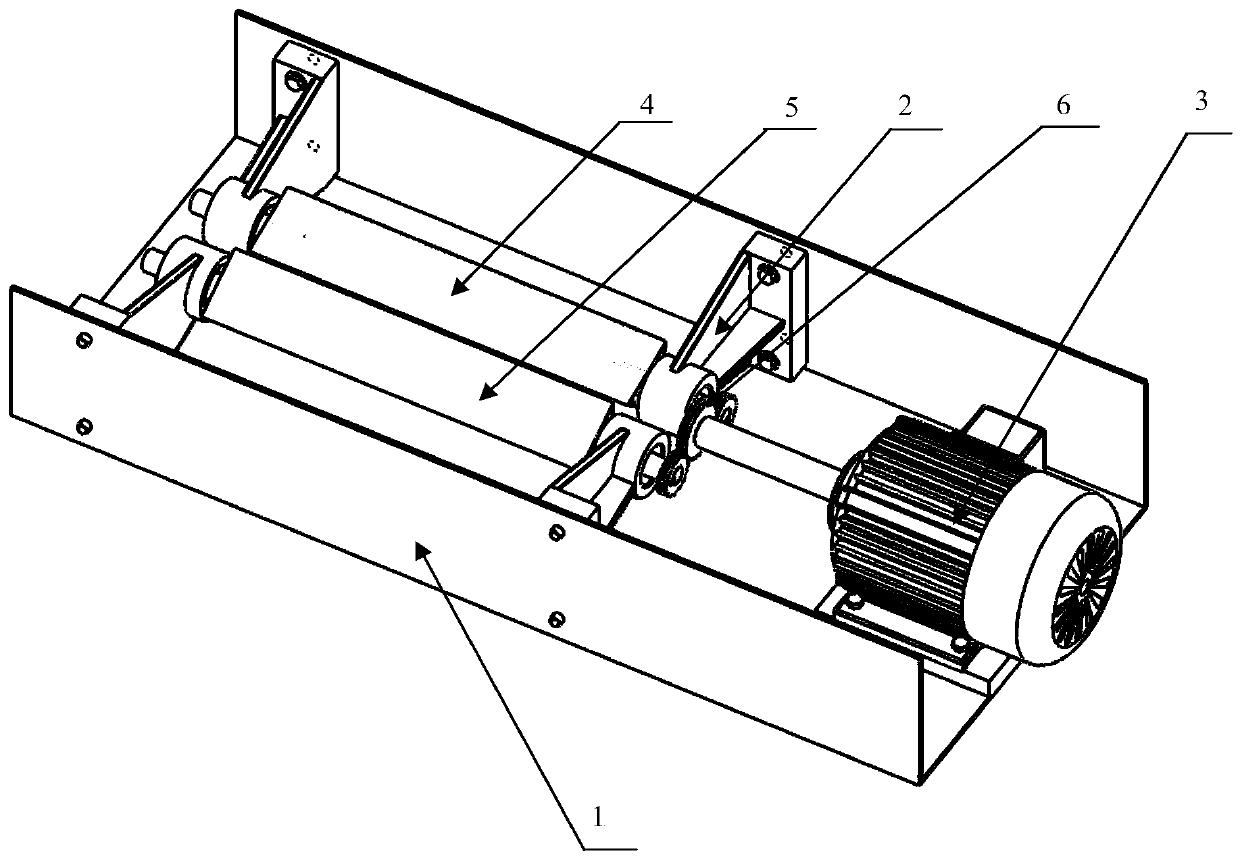

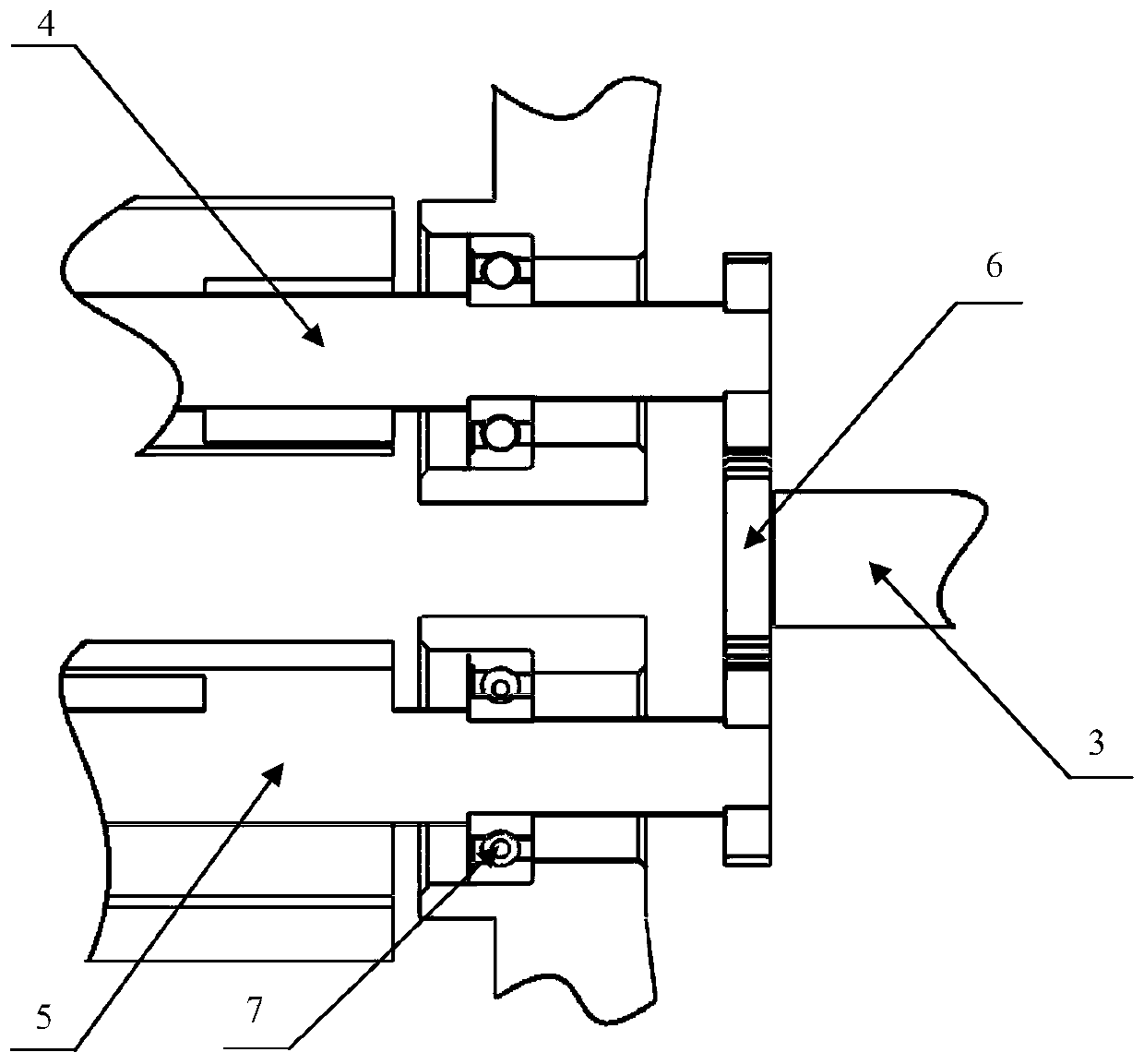

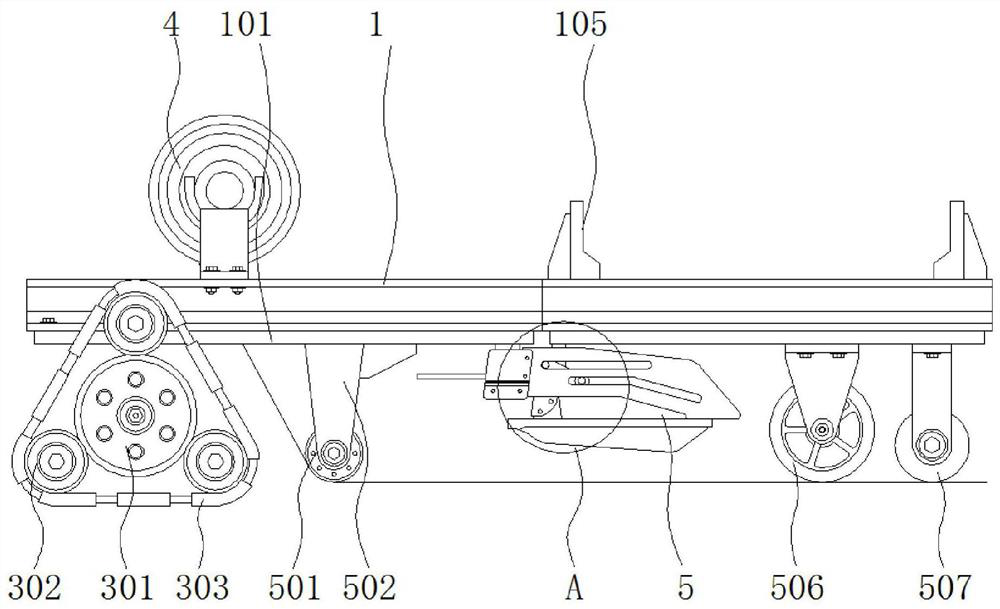

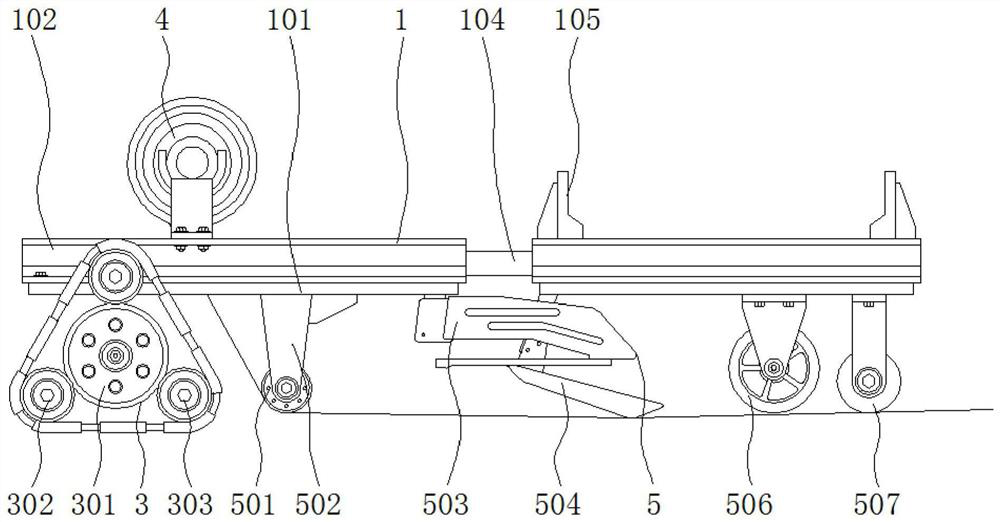

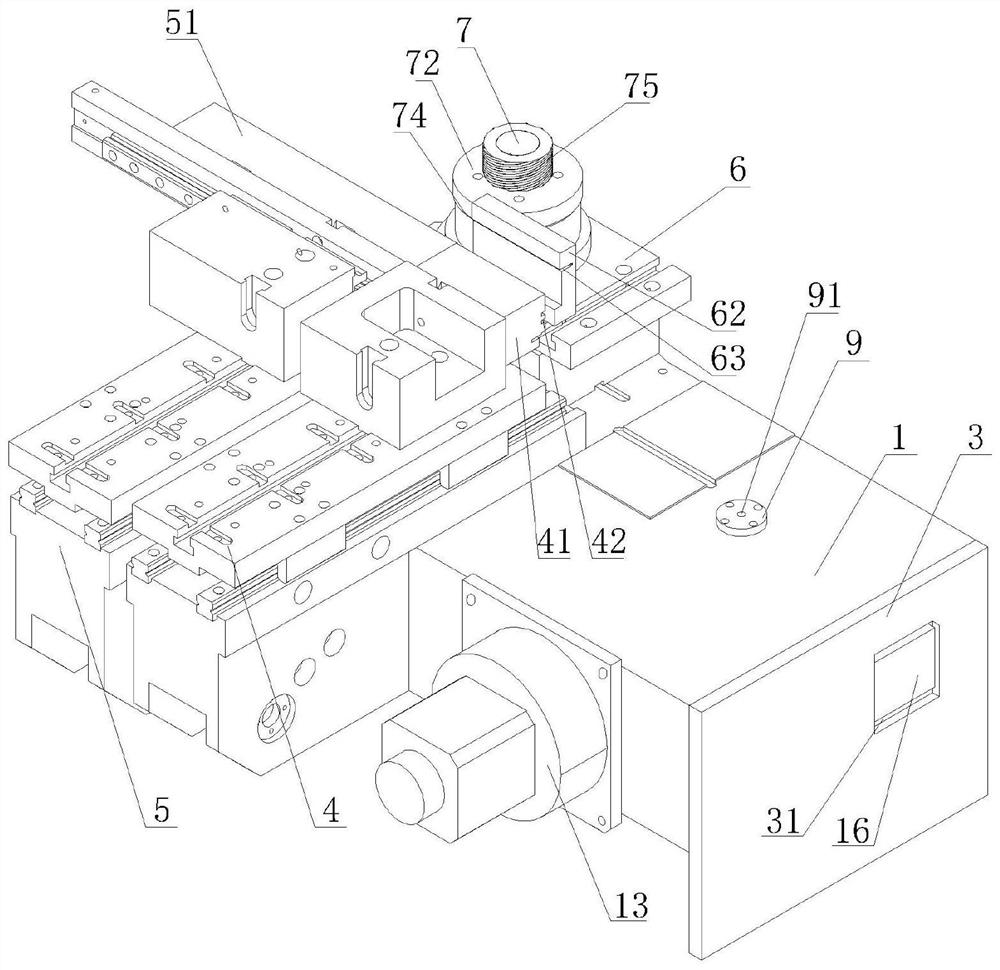

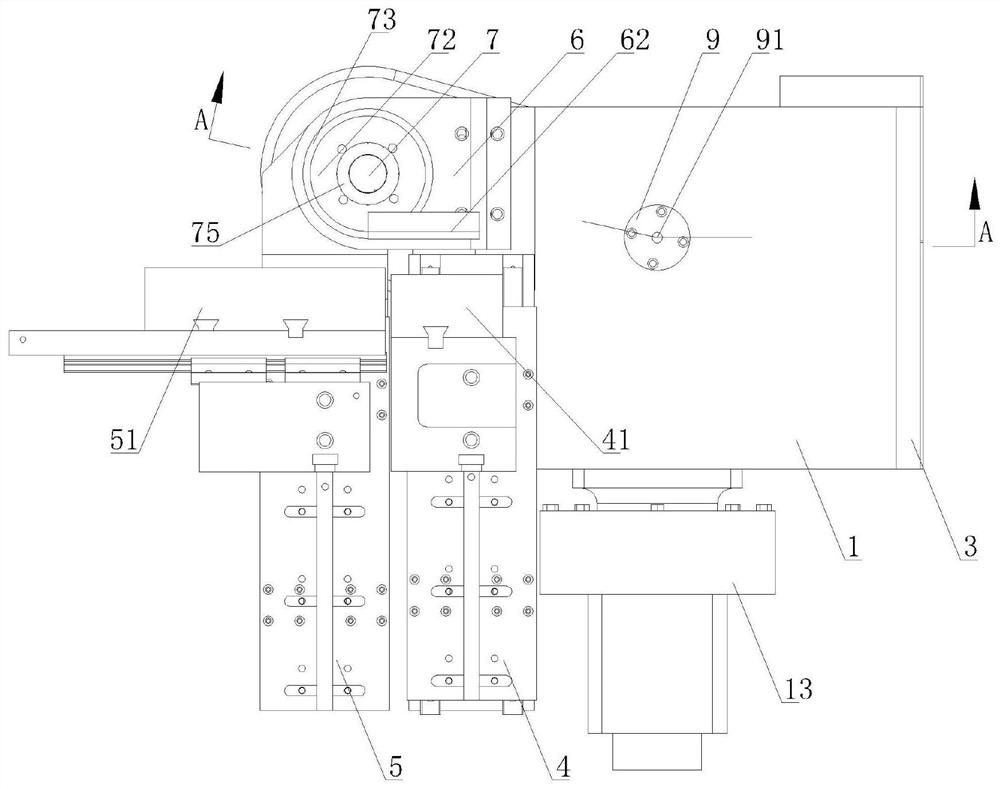

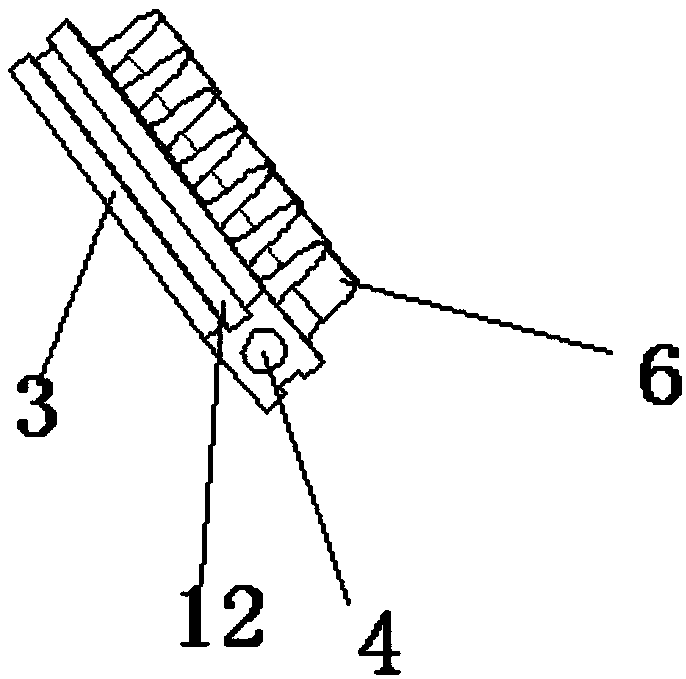

Vehicle-mounted pavement crack detection system inspection device based on gear transmission

InactiveCN108414733BInstantaneous gear ratio constantImprove transmission stabilityMaterial testing goodsGear driveIn vehicle

The invention discloses a vehicle-mounted pavement crack detection system verifying device based on gear driving and aims at solving the verifying problem of a width variation crack detection result of a vehicle-mounted pavement crack detection system. The vehicle-mounted pavement crack detection system verifying device based on gear driving is mainly composed of a base (1), a bearing seat (2), amotor (3), a clockwise triangular prism rotary shaft (4), a counter clockwise triangular prism rotary shaft (5), a straight gear (6) and a bearing (7). The system provides a vehicle-mounted pavement crack detection system verifying device based on gear driving which is small in space occupation, simple in structure, high in verifying precision, easy and convenient to operate, easy to mount, low incost and reliable in property.

Owner:JILIN UNIV

Chemical mechanical device with rotational speed fuzzy control and dust prevention

InactiveCN109092491ARealize automatic inflowEasy to operateGrain treatmentsFuzzy control systemEngineering

The invention discloses a chemical mechanical device with rotational speed fuzzy control and dust prevention. The chemical mechanical device with the rotational speed fuzzy control and the dust prevention comprises a base, a bearing spring and an outer surrounding. A material collecting bin is arranged below the base, a filtering device is connected to the right side of a liquid storage box, a fixing block is arranged at the left end above the base, a fixing nut is arranged on the right side of an adjusting rod, a locking nut is arranged in a supporting base, and adjusting nuts are separatelyarranged at the front end and the rear end of a bearing plate. Compared with an existing common chemical machinery device, the chemical mechanical device with the rotational speed fuzzy control and the dust prevention greatly improves the use performance of the device while increasing structures, the device with good performance has sufficient stability in the use process, can carry out comprehensive crushing operation on chemical materials, can also carry out solid-liquid separation operation during discharging, can limit a diffusion range of dust during crushing at the same time, and effectively meets the use requirements of people.

Owner:李诗颖

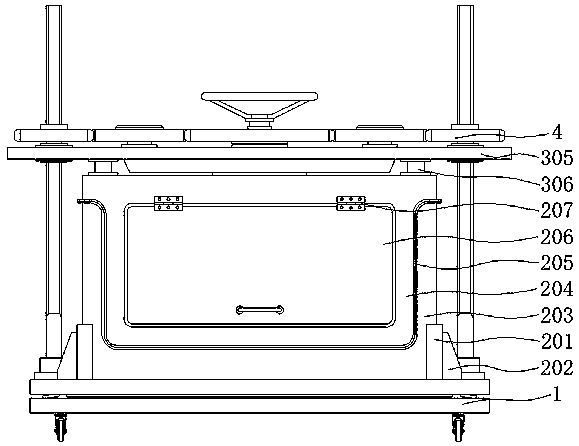

Gantry rolling concrete film coating equipment

ActiveCN110593589AGuaranteed continuityImprove ground adhesionBuilding material handlingLeveling mechanismAgricultural engineering

The invention discloses gantry rolling concrete film coating equipment, and relates to the technical field of concrete film coating equipment, in particular to gantry rolling concrete film coating equipment. The gantry rolling concrete film coating equipment comprises a support stretching mechanism and a leveling mechanism; a suspension mechanism is arranged under the front end of the support stretching mechanism; a material shaft mechanism is arranged above the support stretching mechanism; the leveling mechanism comprises a guide shaft, joint bases, a guide plate, a leveling block, a joint shaft, a support wheel and a flat pressing shaft; the joint bases are arranged at the left and right ends of the guide shaft; the joint shaft is arranged in the upper end of the leveling block; and thesupport wheel is arranged behind the leveling block. The gantry rolling concrete film coating equipment greatly improves overall usability when structures are added; and the improved equipment not only can realize autonomous power control, but also can perform the leveling operation after film coating to maintain the upper surface levelness of concrete so as to effectively meet people use demands.

Owner:广西北海大都混凝土有限公司

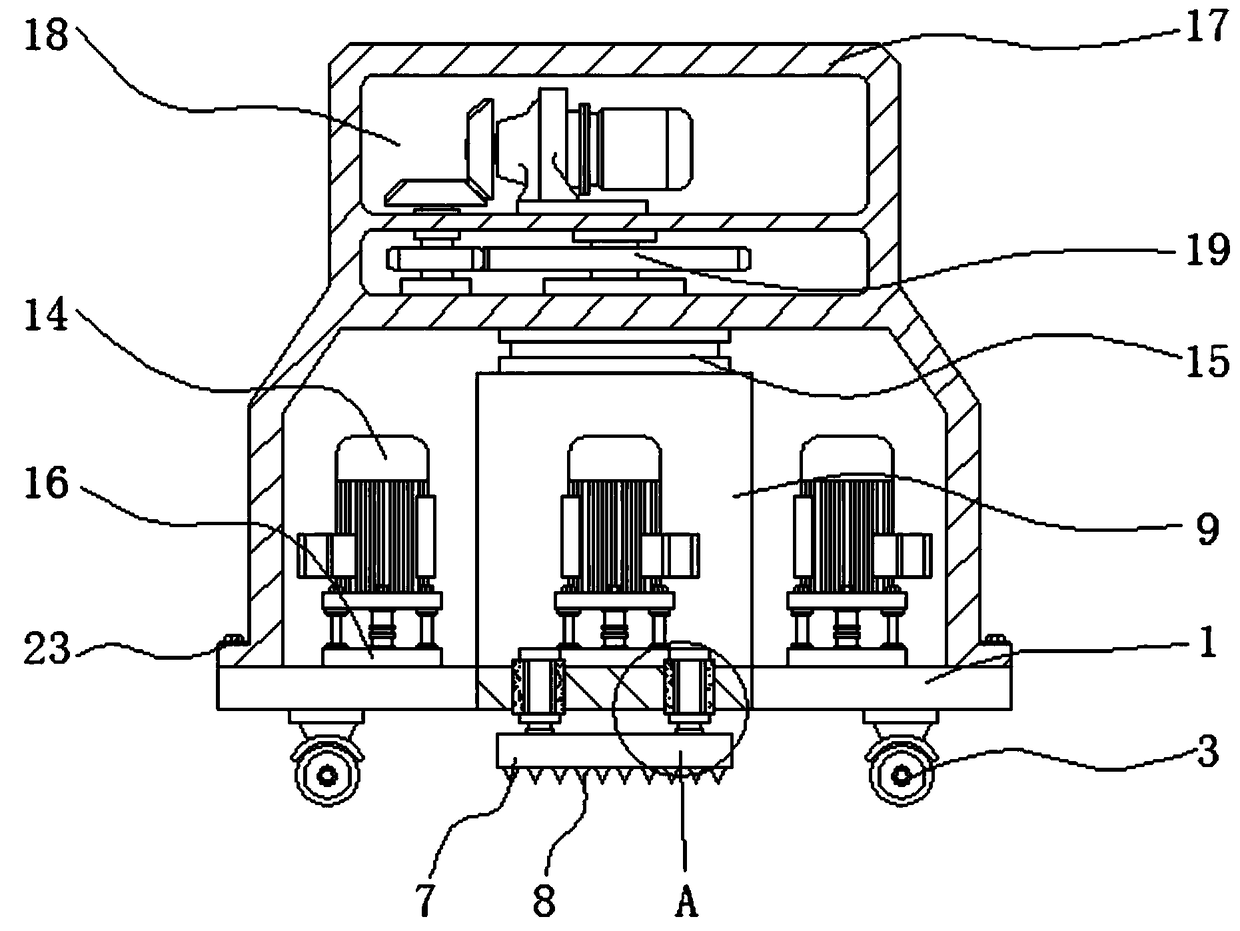

Drilling machine for multi-directional support for petroleum drill and exploitation

InactiveCN109209225AImprove gripReduce security risksConstructionsDerricks/mastsFixed bearingShear stress

The present invention discloses a drilling machine for multi-directional support for petroleum drill and exploitation. The drilling machine comprises a fixed pedestal and a sleeve, one side, far awayfrom a central line, of the fixed pedestal is provided with lateral ears, the lower portions of the lateral ears are provided with universal wheels, the fixed pedestal is internally provided with a fixed sleeve, the fixed sleeve is internally provided with a hydraulic pressure rod, the lower portion of the hydraulic pressure rod is provided with a connection base, the lower portion of the supportplate is provided with a claw nail, the upper portion of the internal portion of the sleeve is provided with a fixed bearing, an installation rack is fixed at the lower portion of the fixed bearing, and the middle portion of a tip cone is provided with a spacing ring. The drilling machine for multi-directional support for petroleum drill and exploitation greatly improves the practical performancesof the device while increasing the structure compared to a current drilling machine, employs a multi-directional support fixed structure to allow the whole device to be more stable in the usage process so as to reduce the shear stress of the internal drilling structure and effectively meet the people's usage demands.

Owner:广州榕创新能源科技有限公司

Sludge recovery equipment based on water treatment

PendingCN113698061AGuaranteed stabilityEasy to operateSludge treatmentMeasurement devicesFixed bearingSludge

The invention discloses sludge recovery equipment based on water treatment, which comprises a support frame and a mounting panel, a pressure reduction seat is fixedly connected above the support frame, a pressure bearing plate is arranged above the pressure reduction seat in parallel, the left side of the mounting panel is fixedly connected with a power motor, and the mounting panel is located at the left end of the support frame; a driving gear is fixedly connected to the upper end of the power motor, a transmission gear is connected to the upper portion of the right end of the driving gear in a meshed mode, a feeding shaft is arranged above the bearing plate, and a fixed bearing is embedded in the left end of the feeding shaft. According to the sludge recovery equipment based on water treatment, the structure is increased, and meanwhile, the use performance of the whole equipment is greatly improved. The improved equipment is of a spliced structure, automatic operation of sludge recovery can be achieved, and the use requirements of people are effectively met.

Owner:袁保娣

A gantry rolling concrete coating equipment

ActiveCN110593589BGuaranteed continuityImprove ground adhesionBuilding material handlingClassical mechanicsStructural engineering

The invention discloses a gantry rolling type concrete coating equipment, relates to the technical field of concrete coating equipment, in particular to a gantry rolling type concrete coating equipment, comprising a supporting stretching mechanism and a smoothing mechanism, the supporting pulling A suspension mechanism is arranged under the front end of the stretching mechanism, and a material shaft mechanism is arranged above the supporting and stretching mechanism. The left and right ends of the guide shaft are provided with connecting seats, the upper end of the smoothing block is provided with a connecting shaft, and the rear of the smoothing block is provided with supporting wheels. The gantry rolling concrete film coating equipment greatly improves the performance of the whole device while increasing the structure. The improved equipment can not only realize independent power control, but also perform smoothing operations after film coating to maintain the upper surface of the concrete. The flatness effectively meets people's needs.

Owner:广西北海大都混凝土有限公司

An obstacle-free carbon-free car that walks in the shape of "∽"

ActiveCN104998419BReduce weightAccurately Control Range of MotionToy gearsToy vehiclesDrive wheelBobbin

The present invention relates to an obstacle-free carbon-free trolley with a "∽" shape walking. The potential energy bracket 4 is installed with a wire wheel bracket 3 and a secondary fixed pulley 1 through a wire wheel shaft 14. The front wheel bracket 6 is installed with a front wheel 7 through a front wheel steering shaft. Drive wheel 20 and driven wheel 11 are installed on the drive shaft 16, pinion 12 is installed on the drive shaft 16, bull gear 13 and small pulley 17 are installed on the bobbin shaft 14, and large pulley 18 is installed on the axle that is connected with crank connecting rod 9. The small gear 12 meshes with the large gear 13, the small pulley 17 is connected to the large pulley 18 through the belt 19, one end of the wire rope 22 is connected to the potential energy block 2, the wire rope 22 is wound around the secondary fixed pulley 1 and wound in the winding groove 15, and the wire rope 22 The other end of the pin is positioned through the wire hole on the secondary fixed pulley 1. The invention utilizes the falling potential energy of the potential energy block to convert into the kinetic energy of the trolley, and through gear meshing and belt transmission, the trolley avoids obstacles periodically and remotely according to a predetermined track, and the structure is simple and convenient.

Owner:CHANGZHOU UNIV

High-precision aluminum profile bending mechanism

PendingCN112742920AExtended service lifeImprove wear resistanceMetal-working feeding devicesPositioning devicesGear wheelSlide plate

The invention discloses a high-precision aluminum profile bending mechanism which comprises a rack, a main shaft tube arranged on the rack, a first gear arranged on the main shaft tube, a servo motor arranged on the rack, a second gear connected to the servo motor and a rack plate slidably arranged in the rack, wherein a first rack meshed with the second gear is arranged at the bottom of the rack plate, and a second rack meshed with the first gear is arranged at the left end of the rack plate; a sliding plate die is arranged on the outer side of the rack; and a mounting seat is arranged on the rack, a bearing is arranged in the mounting seat, the main shaft tube is in close fit to the bearing, a rotating shaft is arranged in the main shaft tube in a penetrating manner, the lower end of the rotating shaft is connected to a lifting mechanism, a wheel die group consisting of a plurality of mutually independent wheel dies is sleeved at the upper end of the rotating shaft, and a pressing and blocking mechanism is arranged at the top of the rotating shaft. The high-precision aluminum profile bending mechanism has the advantages that the service life is prolonged, aluminum profile demolding is facilitated, and the bending precision and the bending quality of the aluminum profile are greatly improved.

Owner:张家港市和力机械制造有限公司

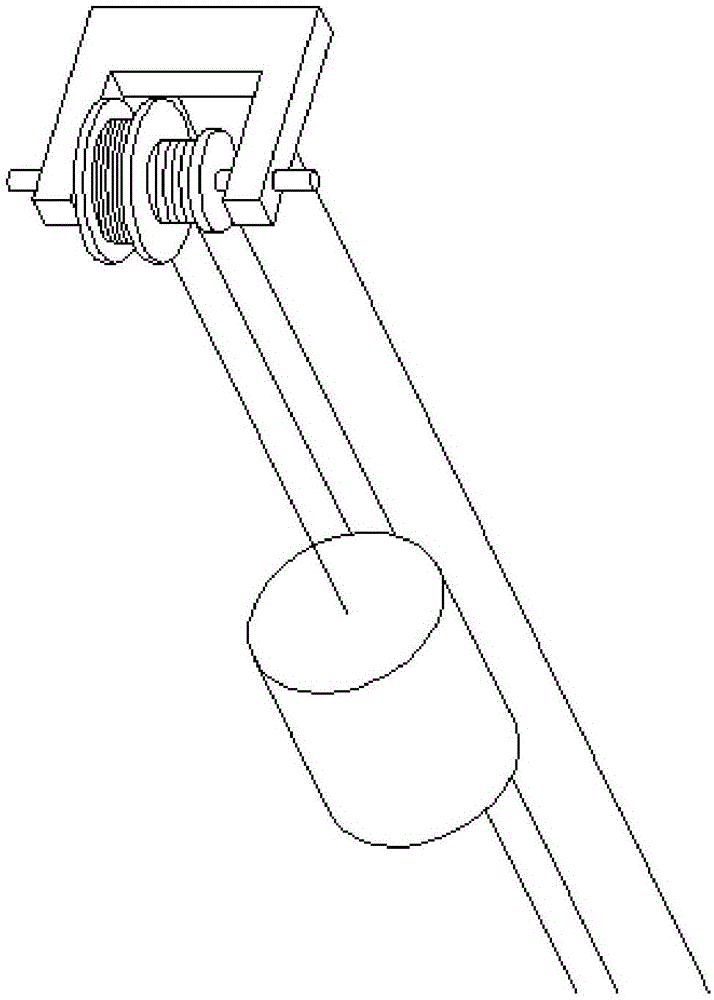

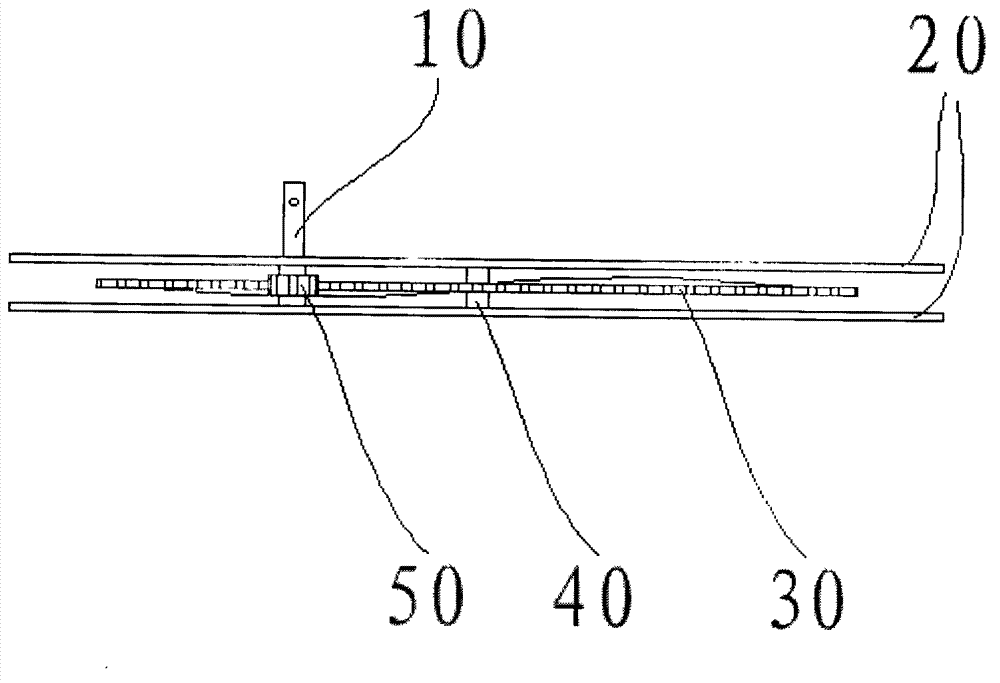

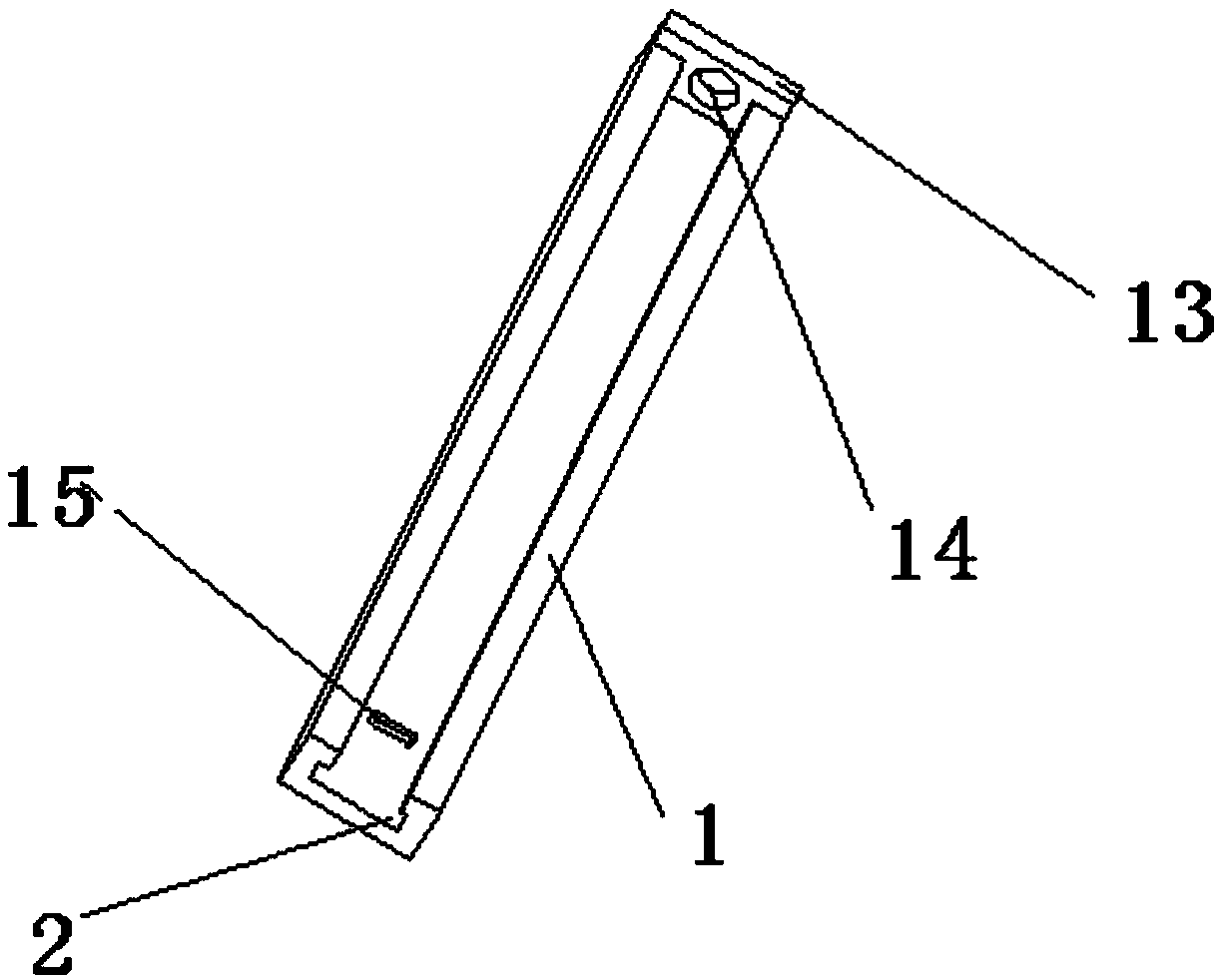

A device for attitude control of missiles

InactiveCN107525441BSimple structureCompact structureSelf-propelled projectilesAttitude controlScrew thread

The invention discloses a device for controlling the posture of a projectile. The device for controlling the posture of the projectile comprises a guide rail; a groove is formed in the guide rail; a sliding strip is embedded in the groove; a thread channel is formed in the length direction of the sliding strip; the sliding strip is connected with a lead screw through the thread channel; a plurality of sawteeth are arranged sequentially on the upper surface of the sliding strip; the sliding strip is engaged with an incomplete gear through the sawteeth; the incomplete gear is connected to a fixing ring through two connecting rods; a rudder shaft is sleeved with the fixing ring; and rudder pieces are connected to the two ends of the rudder shaft correspondingly. Pneumatic control force is generated by changing the deflection angles of the rudder pieces, and the purpose of controlling the posture of the projectile is achieved, and the rudder pieces are simple in structure, convenient to mount and low in cost; and screw transmission and incomplete gear transmission are adopted, the structure is compact, response is rapid, transmission is efficient and accurate, and the constant instantaneous transmission ratio is achieved.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com