Manual gear type column switch hoisting device and application thereof

A lifting device and pole-mounted switch technology, which is applied in the direction of switchgear, hoisting device, electrical components, etc., can solve the problems that the lifting vehicle cannot be on call, the workplace occupies a large area, and the lifting vehicle cannot enter, etc. , to achieve long service life, reduce operating personnel, good economic benefits and market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

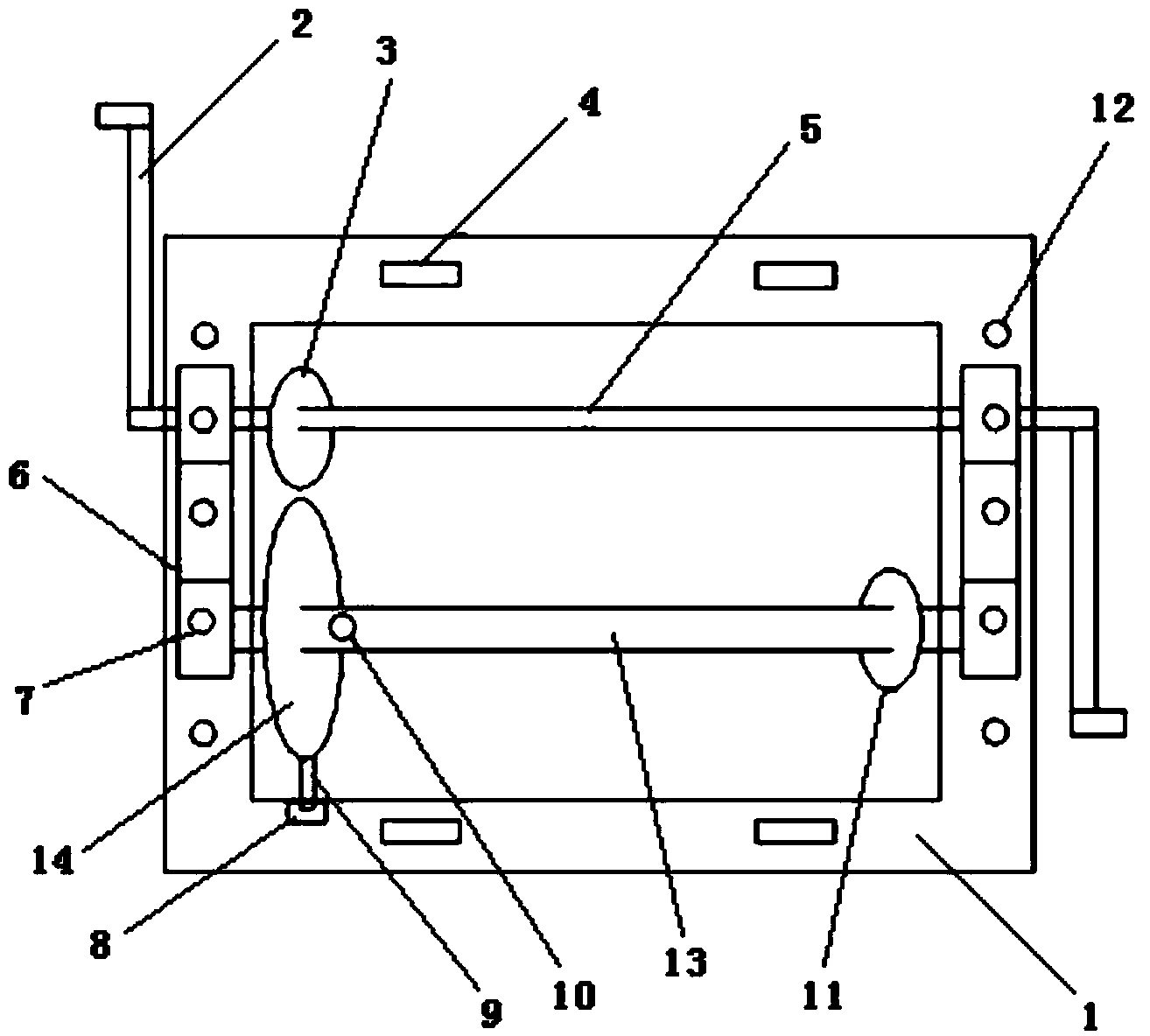

[0042] A lifting device for a switch on a manual gear type column, the lifting device includes a main body, a transmission device and a fixing device,

[0043] Wherein, the main body includes a three-dimensional frame 1 which is welded vertically by four angle steels, and the angle steel sizes used are ∠80×8, 54 cm and ∠80×8, 32 cm; fixed supports 6 are symmetrically arranged on the angle steels on both sides of the three-dimensional frame 1, The fixed bracket 6 is installed on the angle steel on both sides through the fixed bracket mounting holes 12 at the upper and lower ends;

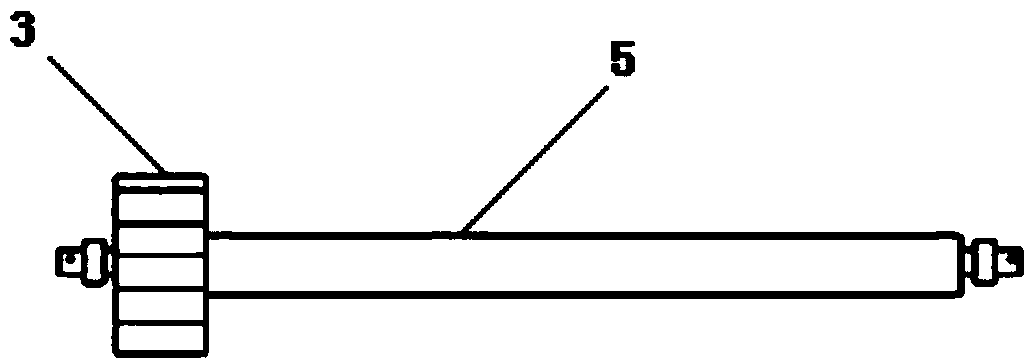

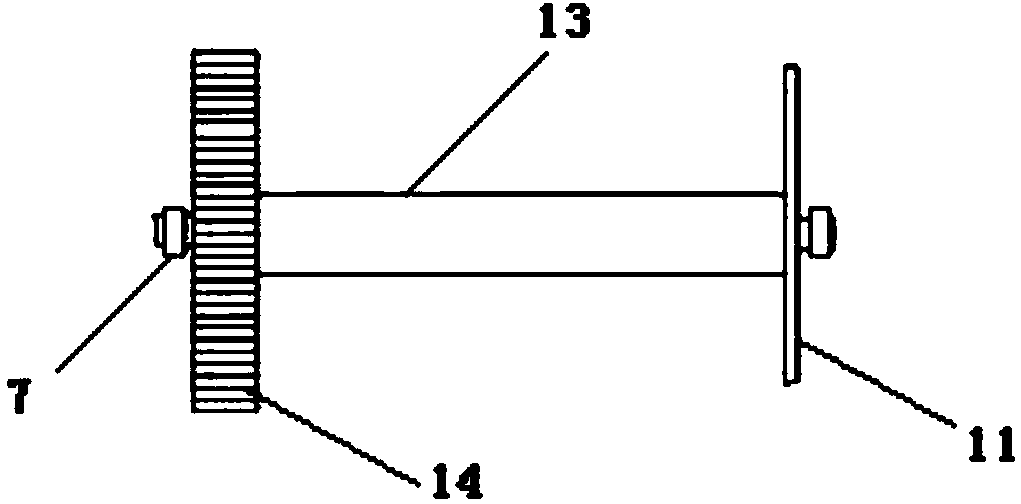

[0044]The transmission device includes a first transmission shaft 5 and a second transmission shaft 13, the first transmission shaft 5 is also called a moving shaft, the second transmission shaft 13 is also called a winch shaft, the first transmission shaft 5 and the second transmission shaft 13 The gears are respectively welded on the top, wherein the gear on the first transmission shaft 5 is the dr...

Embodiment 2

[0049] A lifting device for a switch on a manual gear type column, the structure is as described in Embodiment 1, the only difference is that the lifting device also includes an automatic pawl mechanism, the automatic pawl mechanism includes a fixed piece 8 and a brake piece 9, the fixed The sheet 8 is arranged on the three-dimensional frame and is located below the driven wheel, the brake sheet 9 is connected to the fixed sheet 8 in rotation, and the end of the brake sheet 9 is set on the driven wheel 14 . During the lifting operation, it is sometimes necessary to suspend the operation during the lifting process, and the automatic pawl mechanism can function as a pause switch to prevent the gear from reversing. At the same time, due to the heavy weight of the switch, in order to avoid the accidental fall of the switch, the automatic pawl mechanism can effectively block the reverse rotation of the gear and prevent accidents.

Embodiment 3

[0051] The method for using the manual gear type lifting device to lift the switch on the column includes the following steps,

[0052] (1) According to the diameter of the pole of the distribution line at the place where the switch is installed, select a suitable U-shaped hoop, pass the two ends of the U-shaped hoop through the guide rail slide groove 4 on the three-dimensional frame 1, and then tighten the lifting device to fix it on the on the pole;

[0053] (2) Put the two rocking handles 2 into the two ends of the first transmission shaft 5 respectively, so that the screw holes on the rocking handle 2 correspond to the screw holes on the first transmission shaft 5, and insert bolt pins into the screw holes , and tighten the bolt pin to fix the rocking handle 2 and the first drive shaft 5 together;

[0054] (3) One end of the wire rope is fixed in the rope hole 10 on the second transmission shaft 13 with bayonet pins, and the winding direction of the wire rope is determin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com