Axis part diameter high precision rapid measuring device

A technology for measuring devices and shaft parts, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inability to realize online measurement, size limitation of the measured part, and drift of measurement results, so as to achieve light and flexible movement and avoid The effect of backlash error and high motion sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

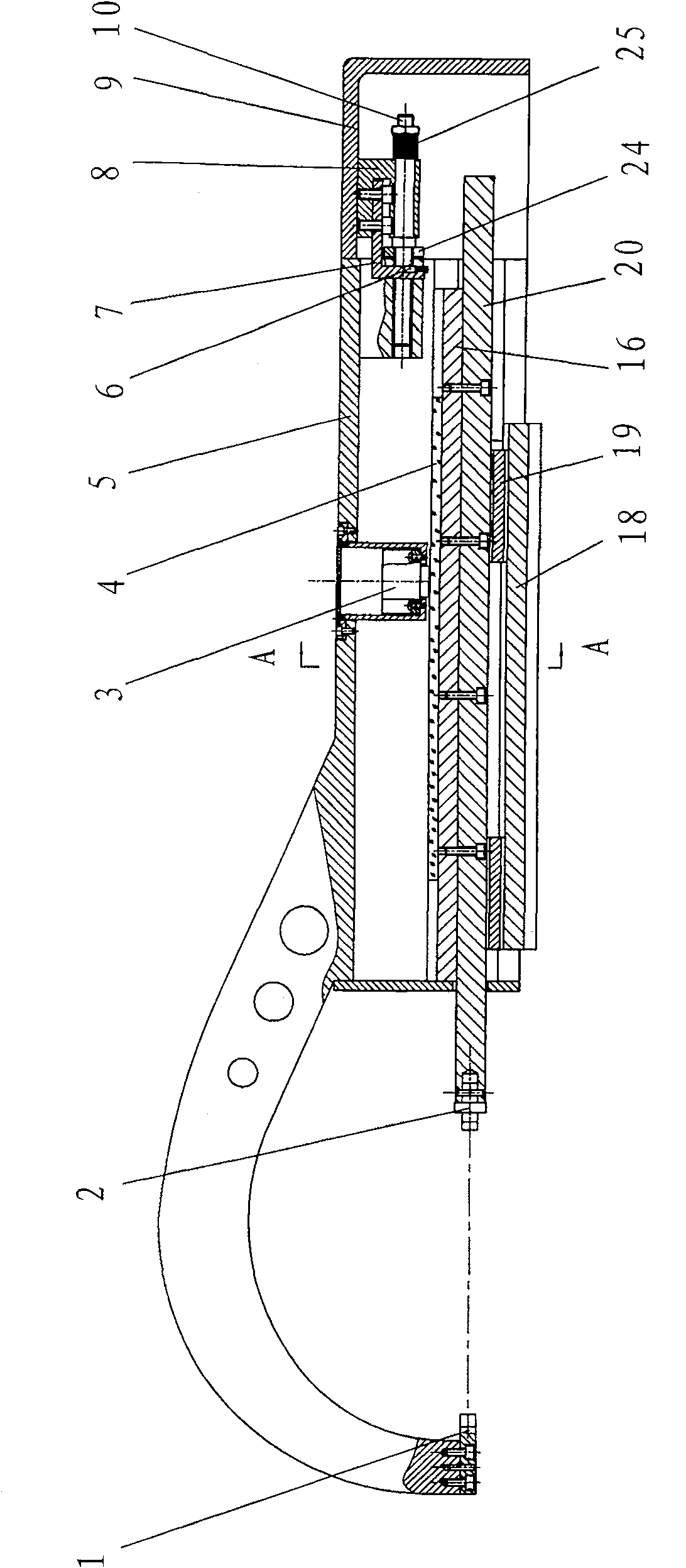

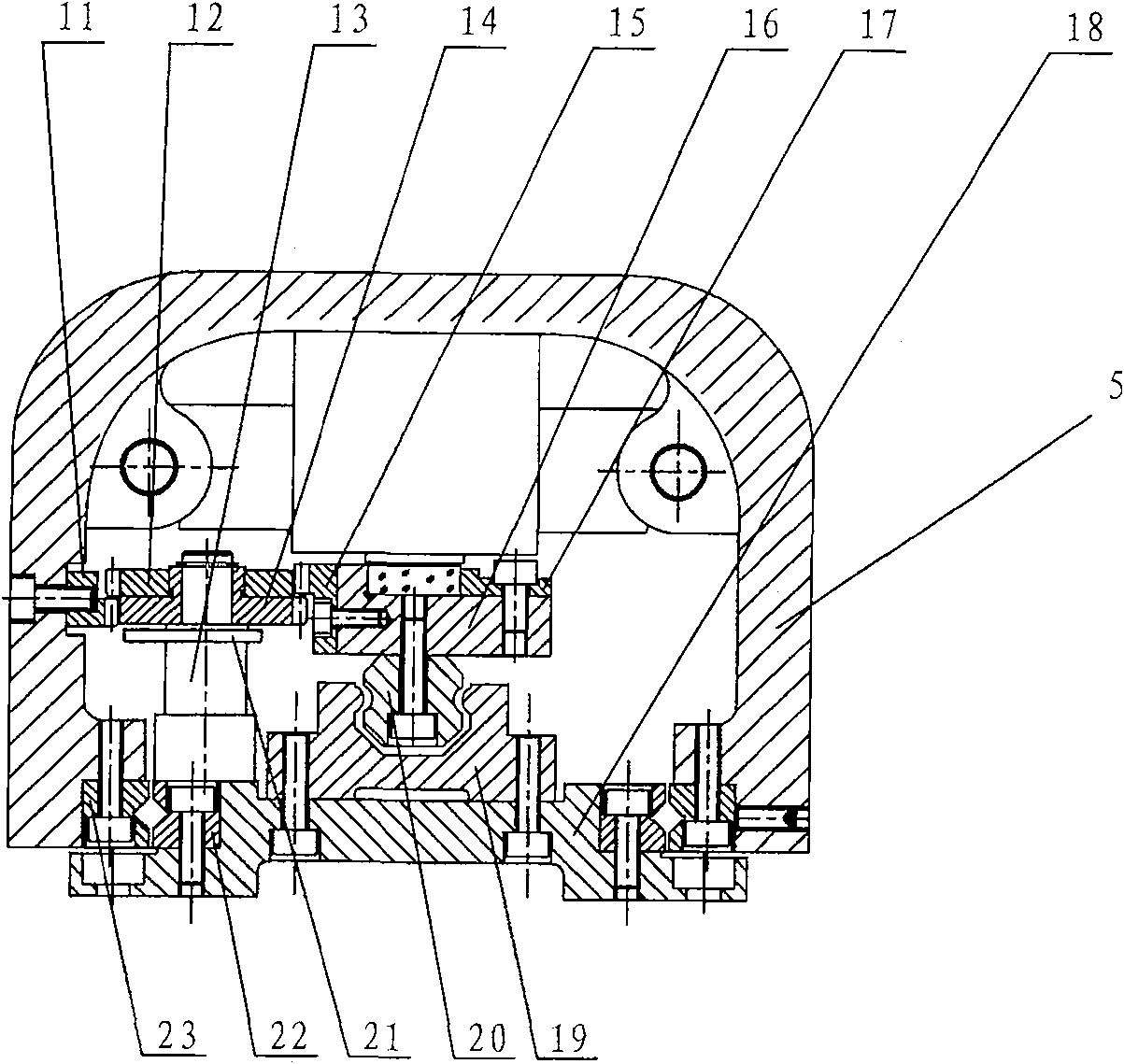

[0023] see figure 1 , a pair of left-end movable bayonet 1 and right-end movable bayonet 2 that can slide toward each other along the diameter direction of the measured shaft constitute a bayonet-type probe, and the left-end movable bayonet 1 and right-end movable bayonet 2 that can slide in Between them, a grating measuring device for measuring the relative sliding distance between the left-end movable bayonet 1 and the right-end movable bayonet 2 is provided. The sliding direction of the grating head 3 is fixedly connected with the right end movable bayonet 2, and the opposite grating head 3 is fixedly connected with the left end movable bayonet 1.

[0024] figure 1 As shown, in the specific implementation:

[0025] The movable bayonet 1 at the left end is fixedly connected with the slidable casing 5 through the bow arm, and the grating head 3 is fixedly arranged on the slidable casing 5; At the end of the rail 20, the grating ruler 4 is fixed on the grating base 16 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com