Patents

Literature

50results about How to "High movement sensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Handheld robot for orthopedic surgery and control method thereof

ActiveUS9561082B2High precisionError minimizationProgramme-controlled manipulatorJointsEngineeringPlastic surgery

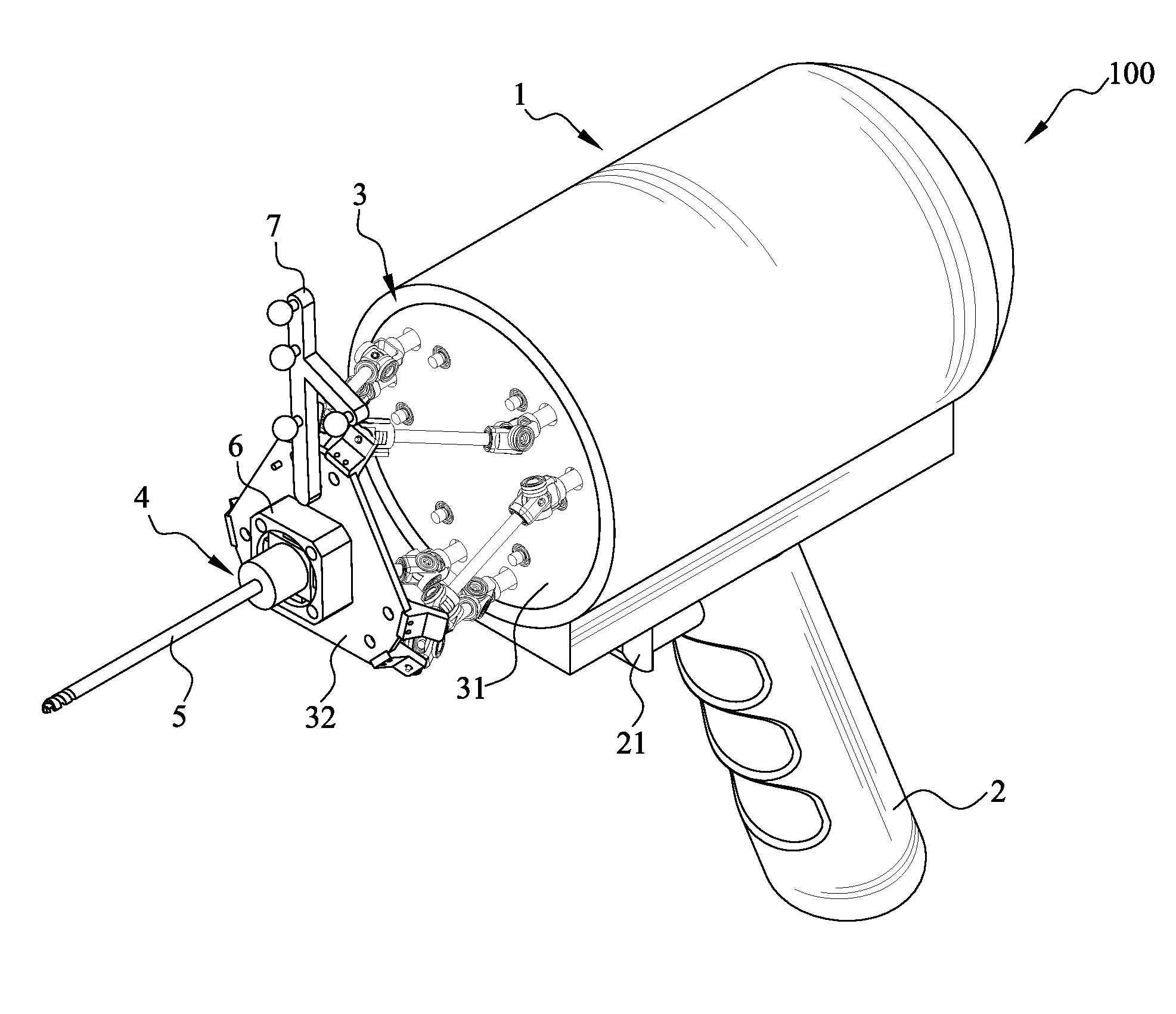

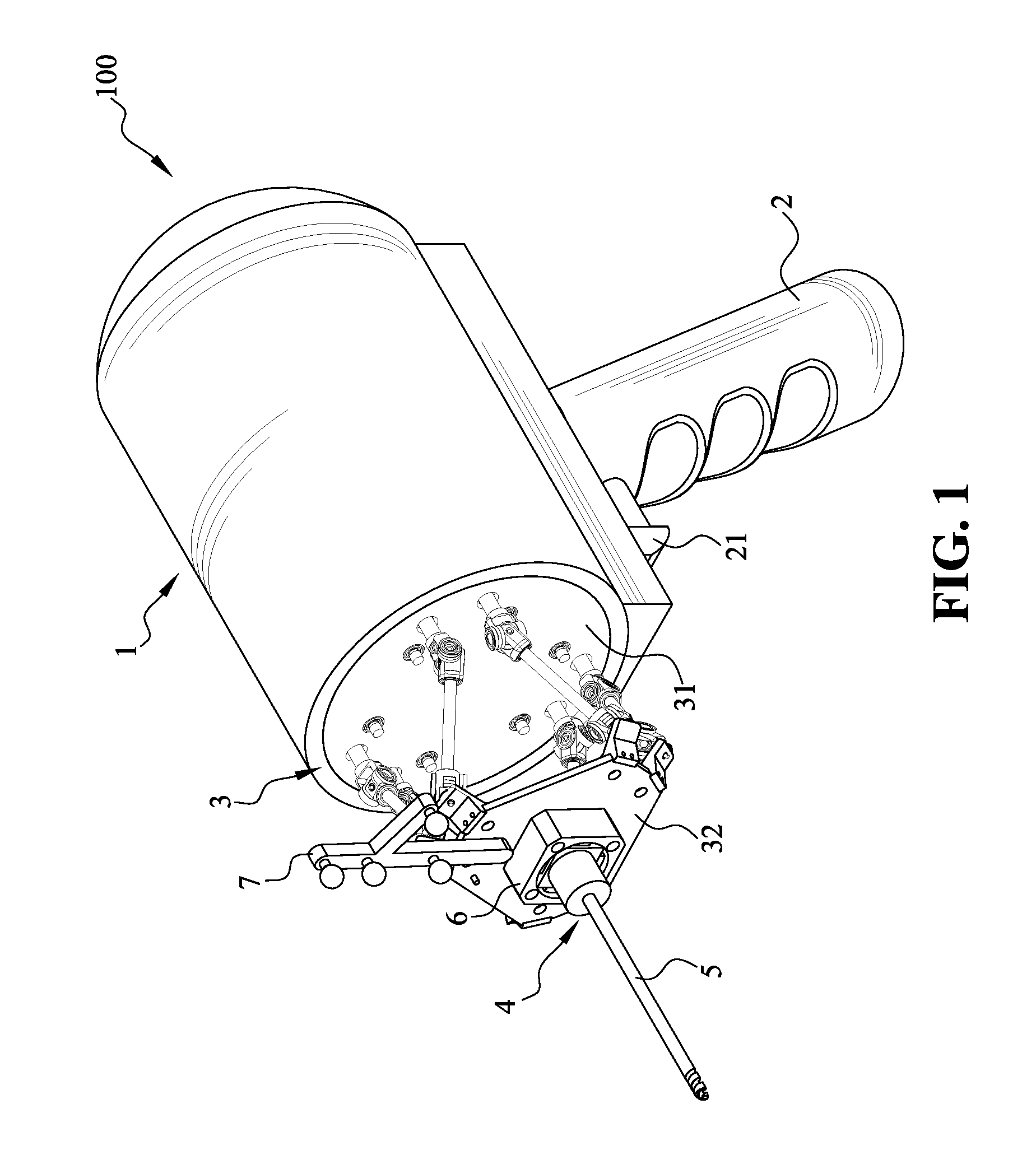

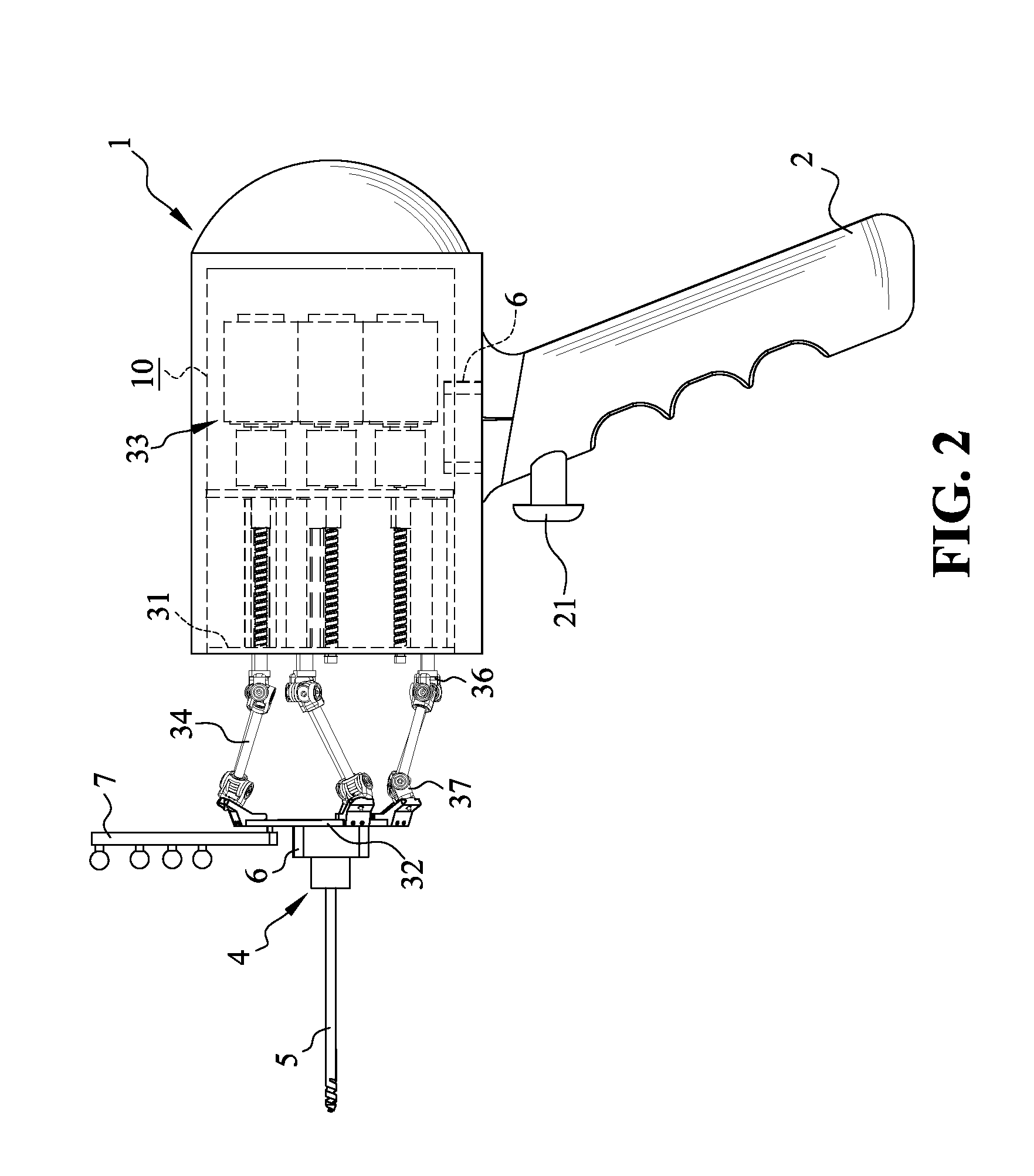

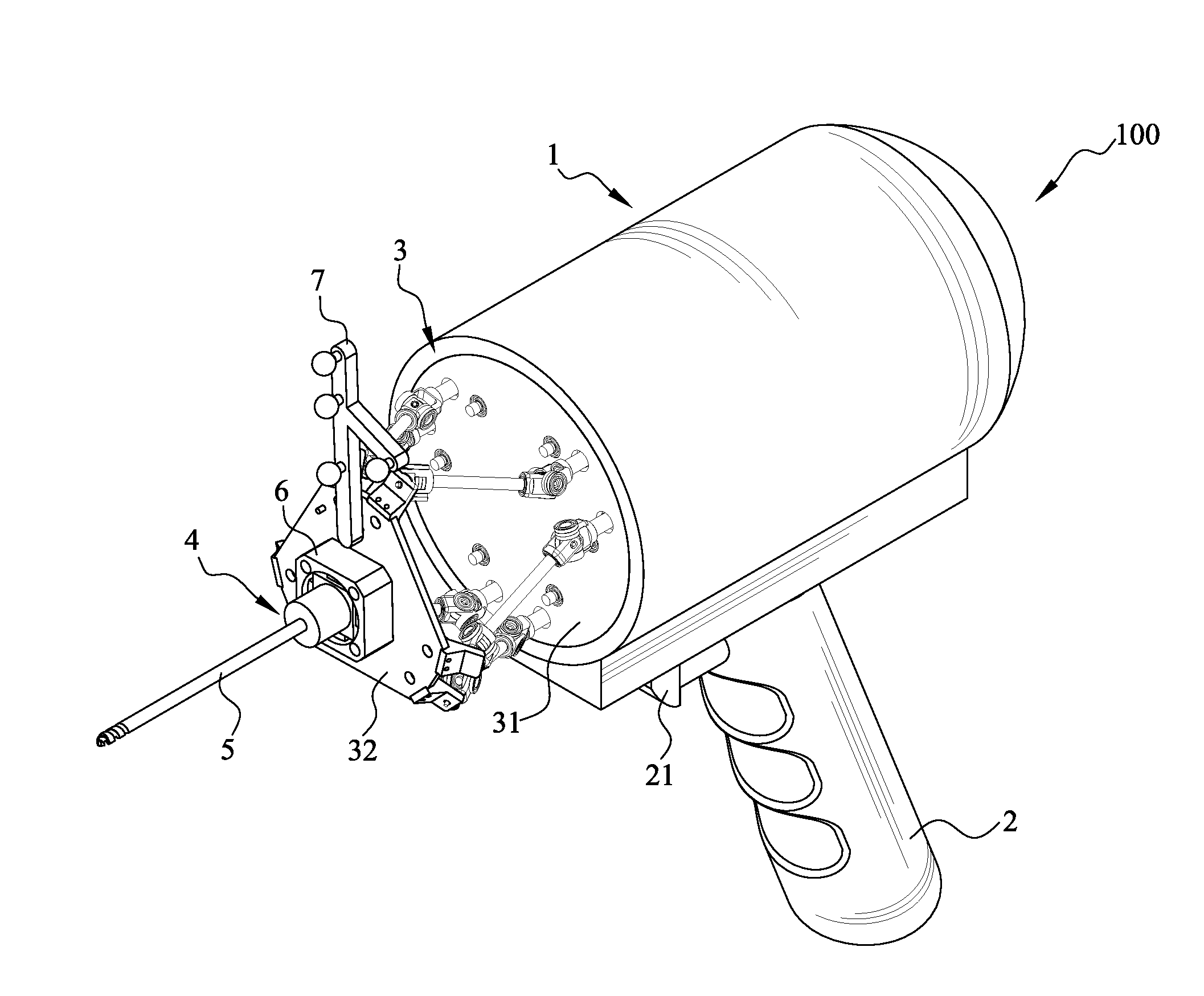

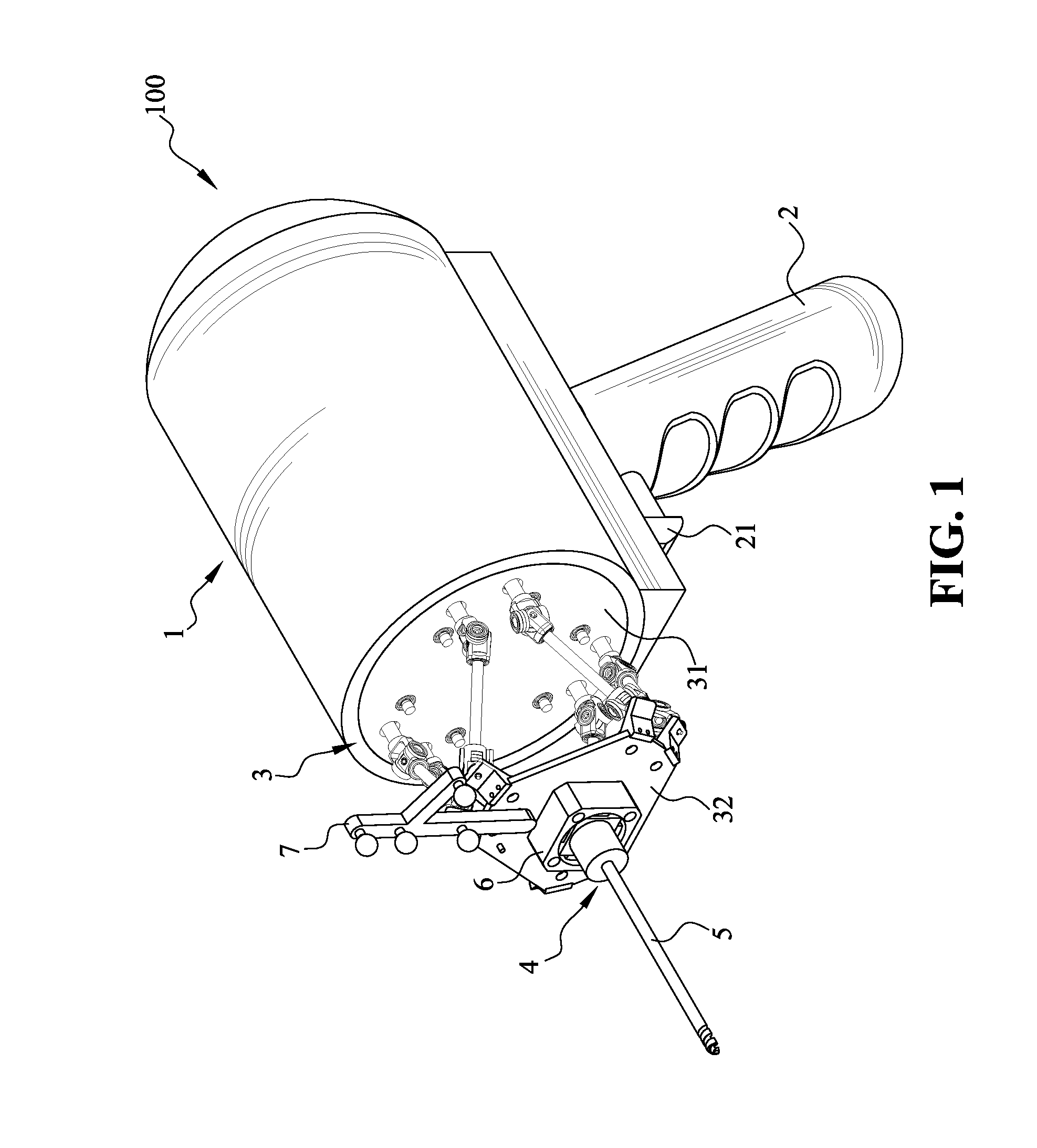

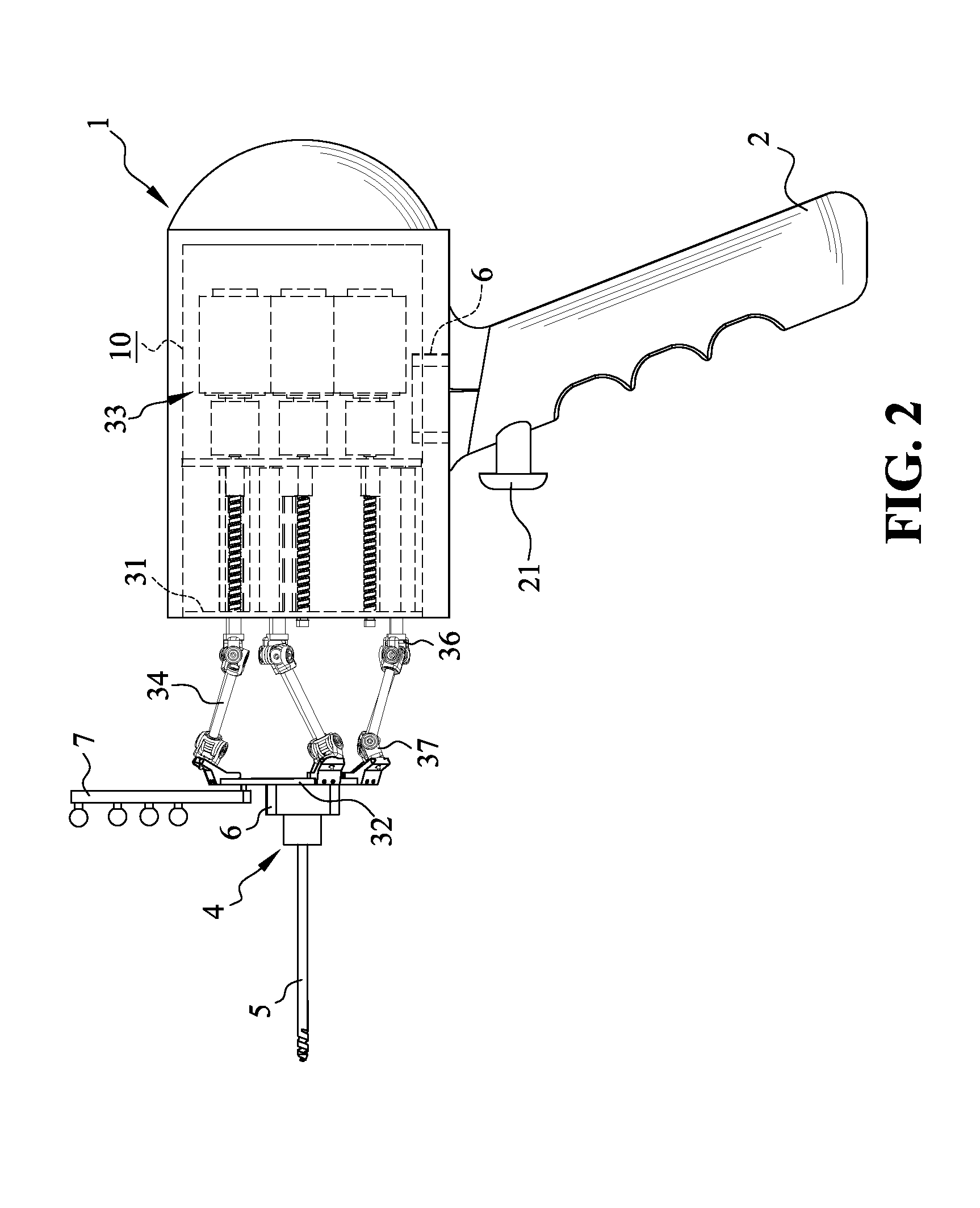

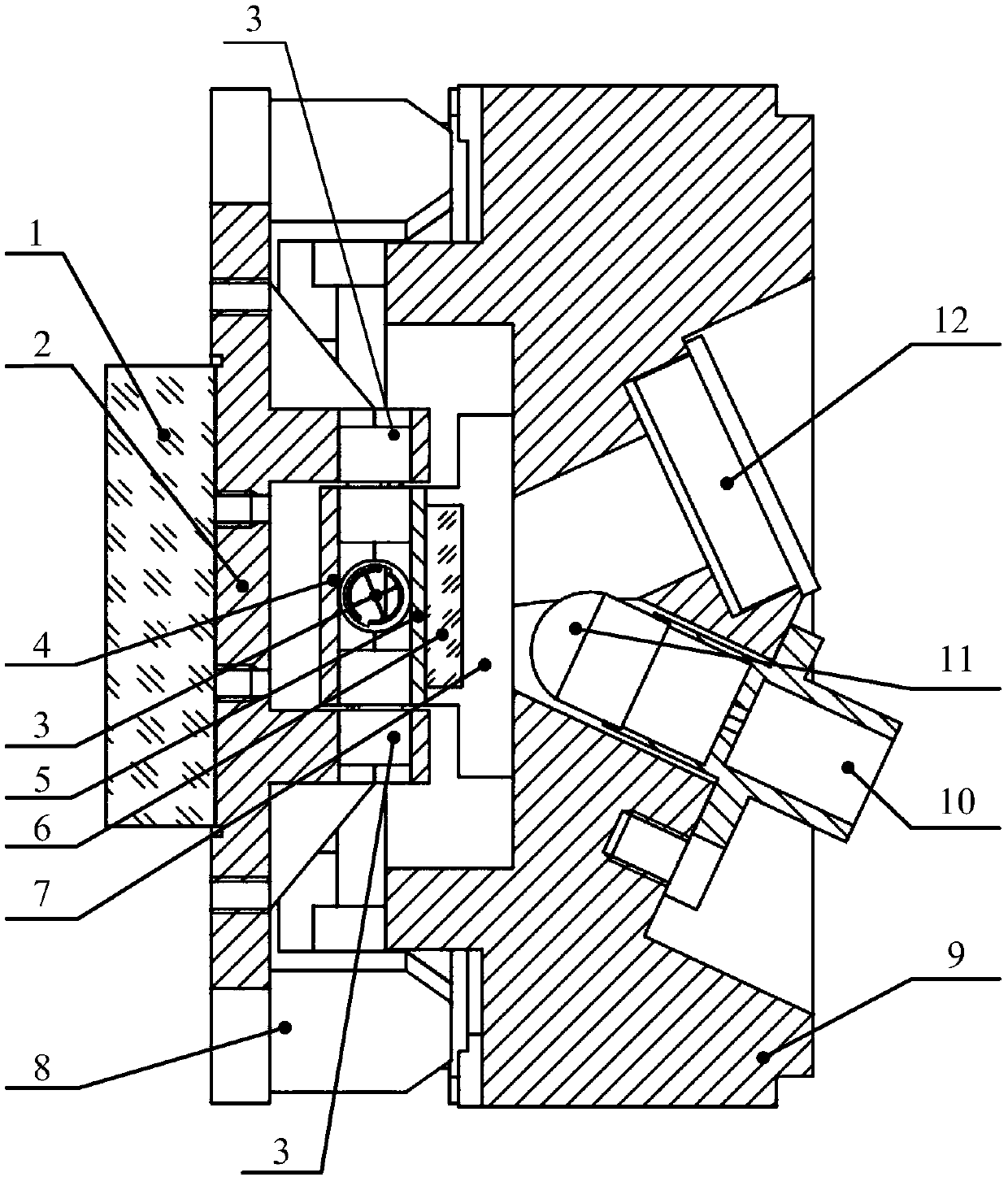

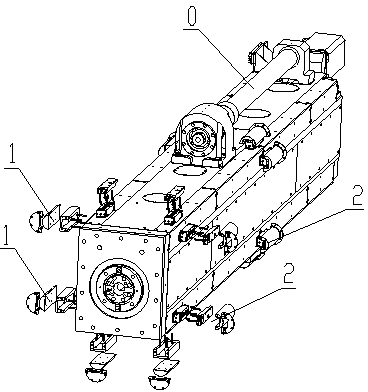

The present invention provides a handheld robot for orthopedic surgery and a control method thereof. The handheld robot of the present invention includes a main body, a grip, a kinematic mechanism, a tool connector, a tool, a force sensor and a positioning unit. The handheld robot of the present invention combines the position / orientation information of the tool acquired by the positioning unit with the force / torque information acquired by the force sensor, and utilizes the combined information to adjust the position of the tool so as to keep the tool within the range / path of a predetermined operation plan. In this way, the precision of the orthopedic surgery can be enhanced, and the error occurred during the surgery can be minimized.

Owner:NAT TAIWAN UNIV +1

Handheld robot for orthopedic surgery and control method thereof

ActiveUS20150182285A1High precisionError minimizationProgramme-controlled manipulatorJointsEngineeringPlastic surgery

The present invention provides a handheld robot for orthopedic surgery and a control method thereof. The handheld robot of the present invention includes a main body, a grip, a kinematic mechanism, a tool connector, a tool, a force sensor and a positioning unit. The handheld robot of the present invention combines the position / orientation information of the tool acquired by the positioning unit with the force / torque information acquired by the force sensor, and utilizes the combined information to adjust the position of the tool so as to keep the tool within the range / path of a predetermined operation plan. In this way, the precision of the orthopedic surgery can be enhanced, and the error occurred during the surgery can be minimized.

Owner:NAT TAIWAN UNIV +1

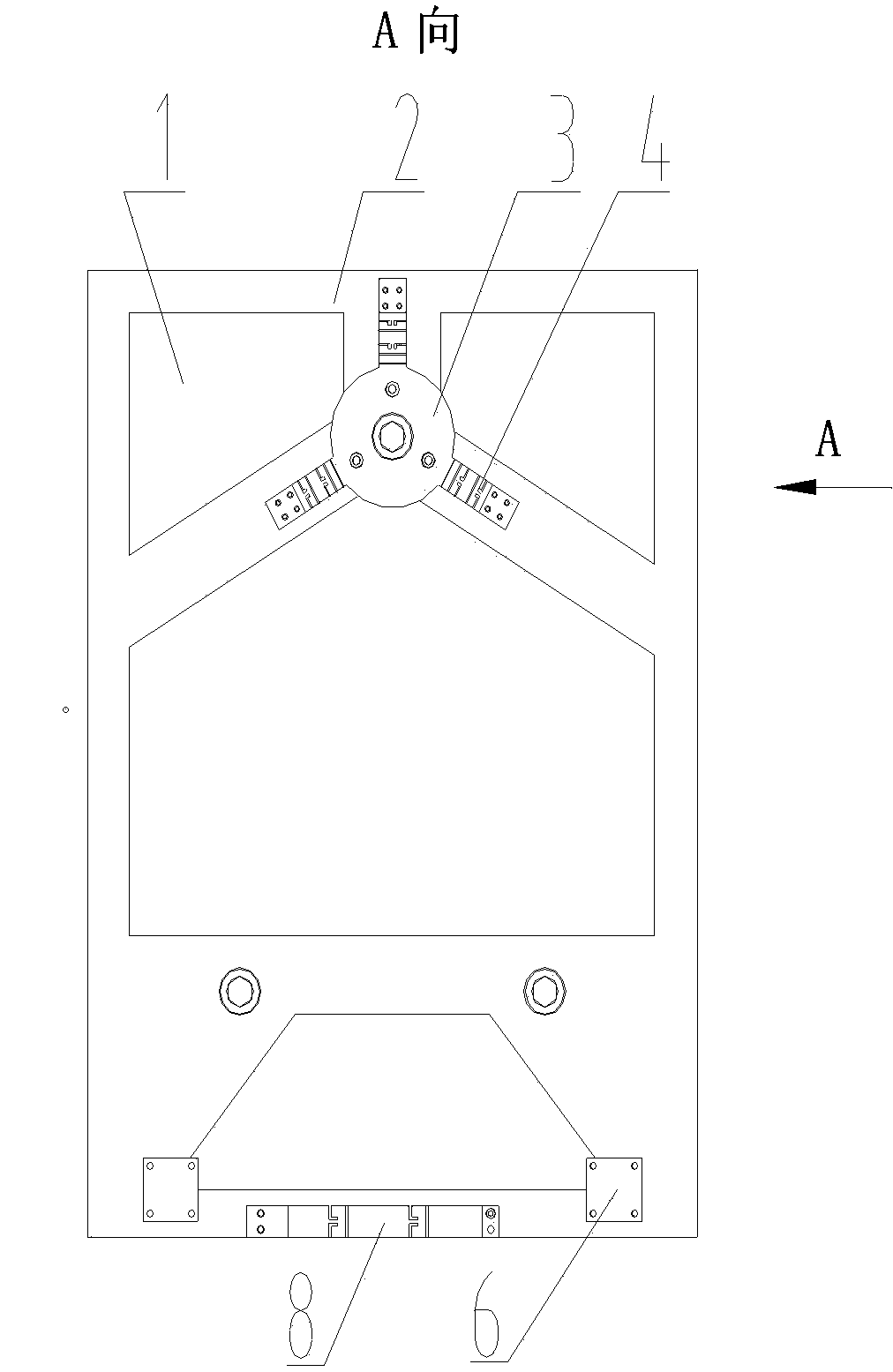

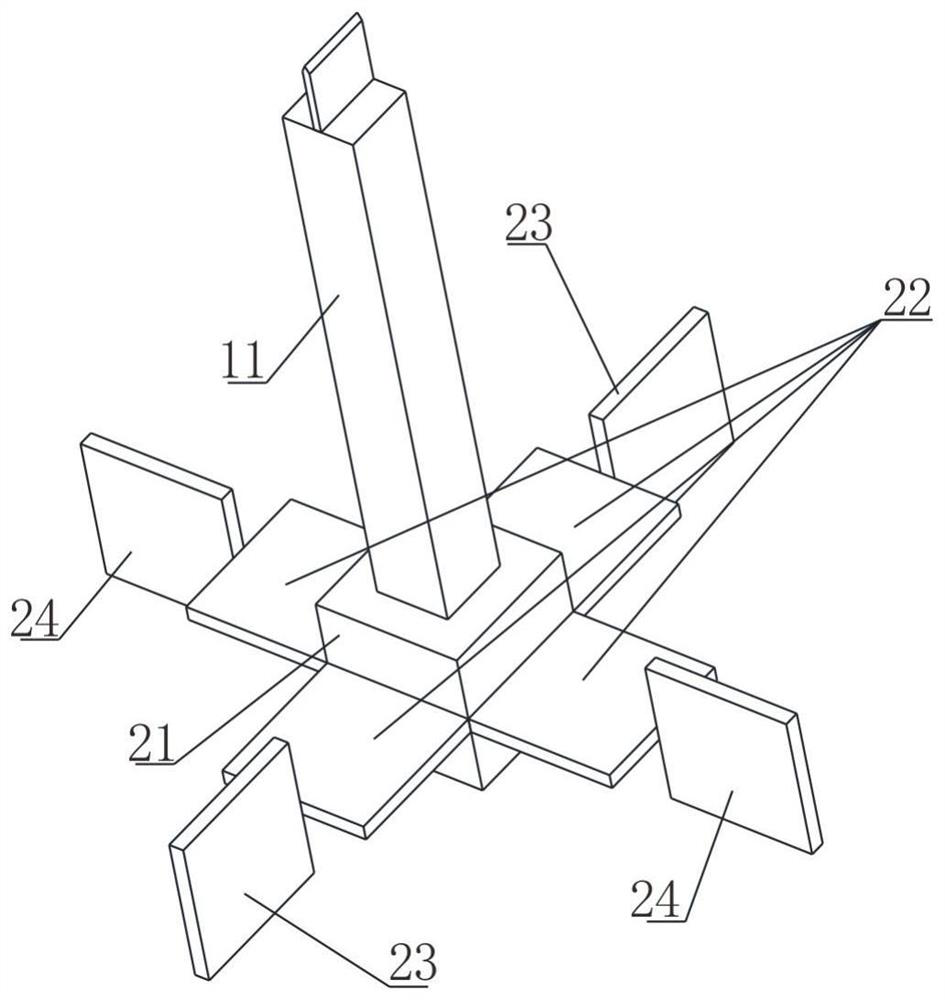

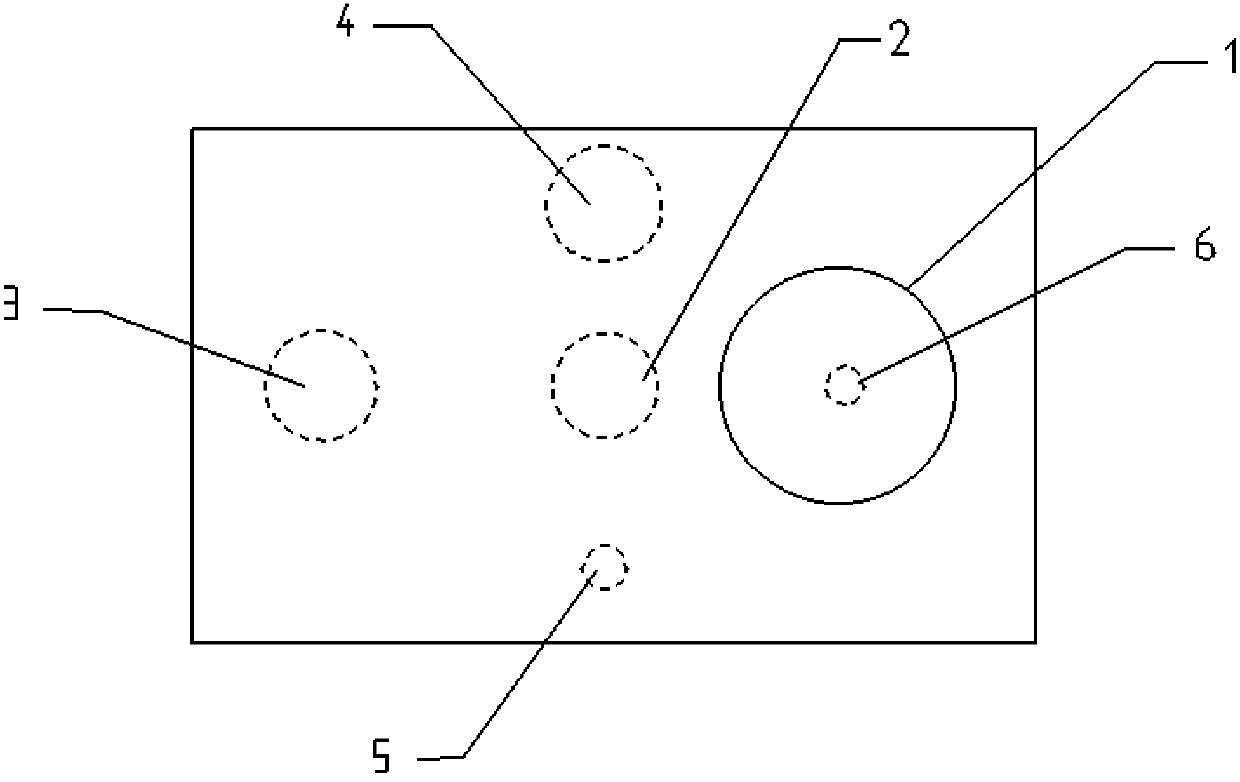

Large-caliber optical reflector with back flexible supporting structure

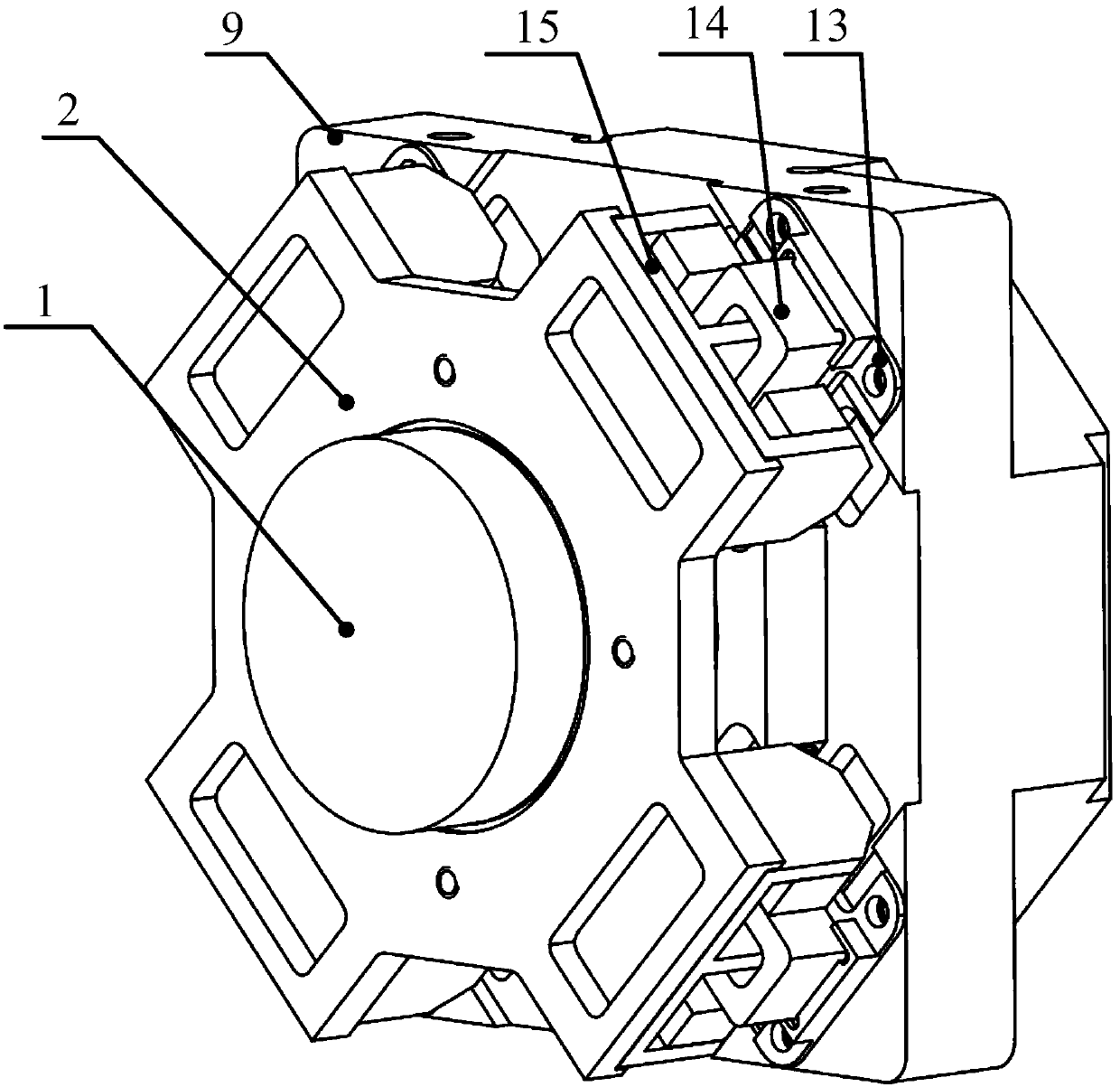

PendingCN109633859AImproved Gravity DeformationImplementation constraintsMountingsOptical reflectionEngineering

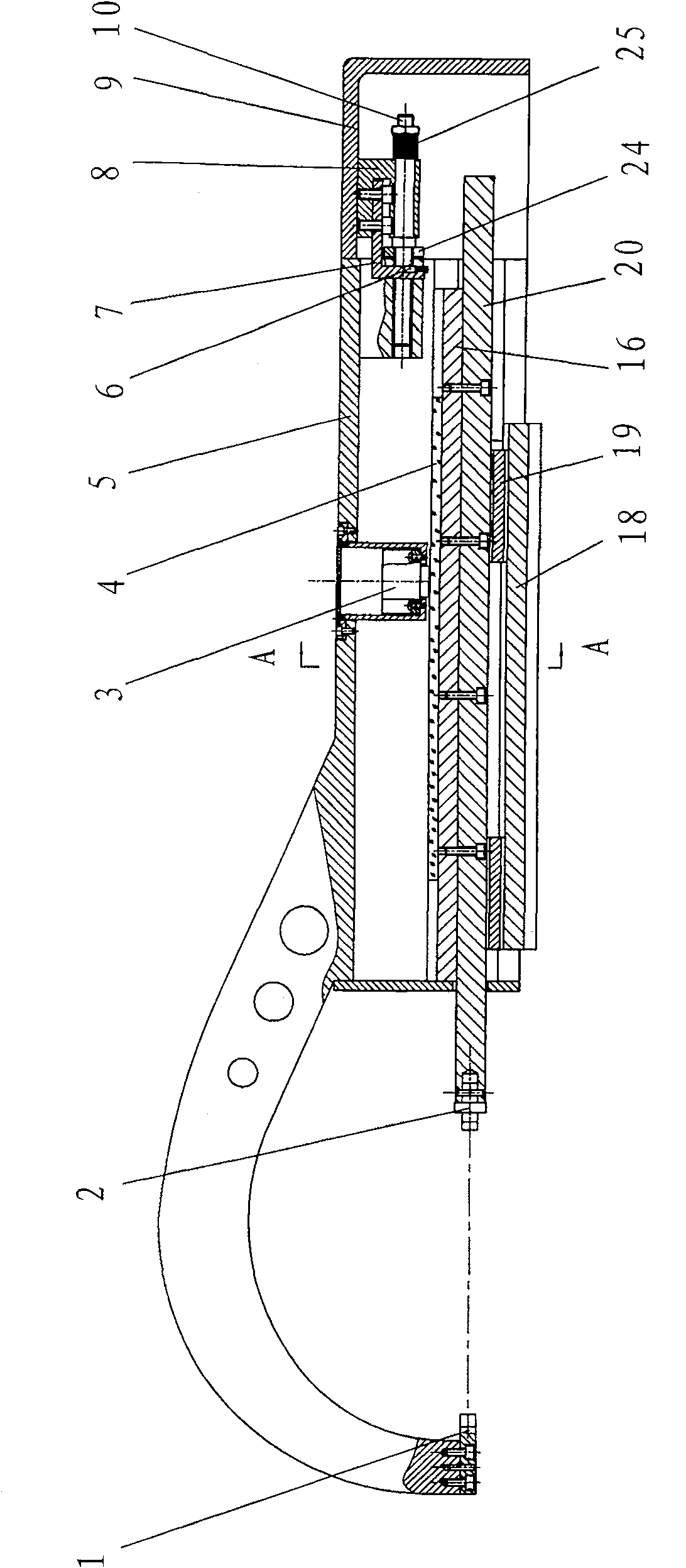

The invention relates to a large-caliber optical reflector with a back flexible supporting structure. The problems that too much supporting links exist, the assembling process is complex, the size andthe quality of the supporting back plate are too large in the existing large-caliber reflector back multi-point supporting technology, and the requirement for surface type precision is high under theworking conditions of gravity release and environment temperature change is difficult to be ensured at the same time are effectively solved. The reflector comprises a reflector mirror body, flexiblesupports and a supporting back plate, the number of the flexible supports is three, and the flexible supports are uniformly distributed between the reflector mirror body and the supporting back platein the circumferential direction; each flexible support comprises an isosceles triangular bottom frame and a trapezoid vertical frame which are perpendicular to each other; the three vertexes of the isosceles triangular bottom frame are connected with the back of the reflector mirror body; the top edge of the trapezoid vertical frame is connected with the isosceles triangle bottom frame, the bottom edge of the trapezoid vertical frame is connected with the side surface of the supporting back plate; and the bottom edge of the trapezoid vertical frame adopts a flexible hinge structure, and the two waist parts of the trapezoid vertical frame are correspondingly of a flexible reed structure.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI +1

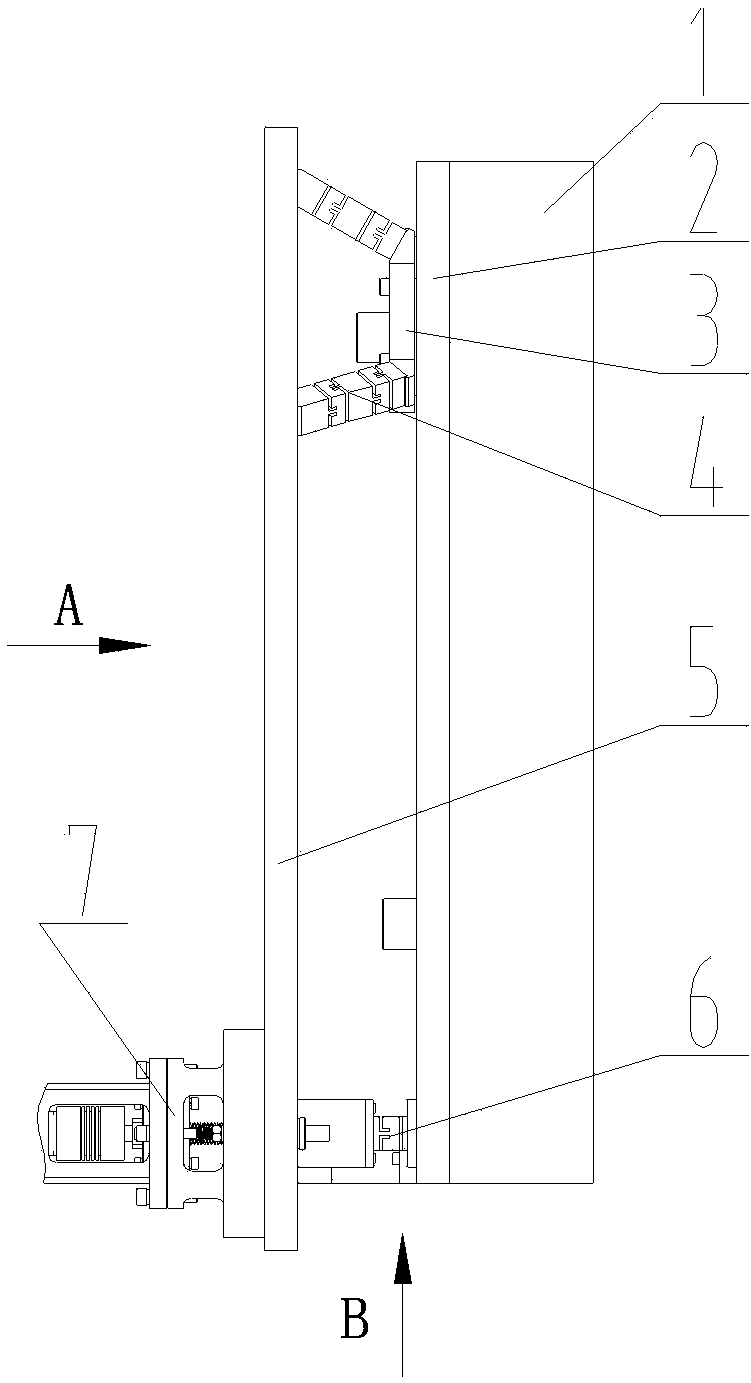

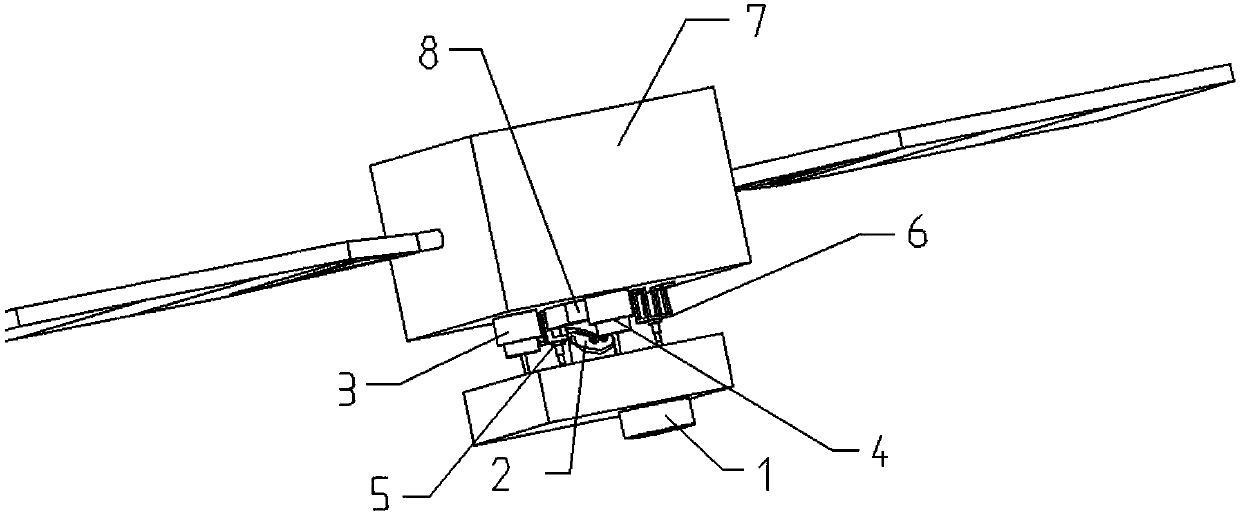

Flexible back supporting device for large-caliber reflector

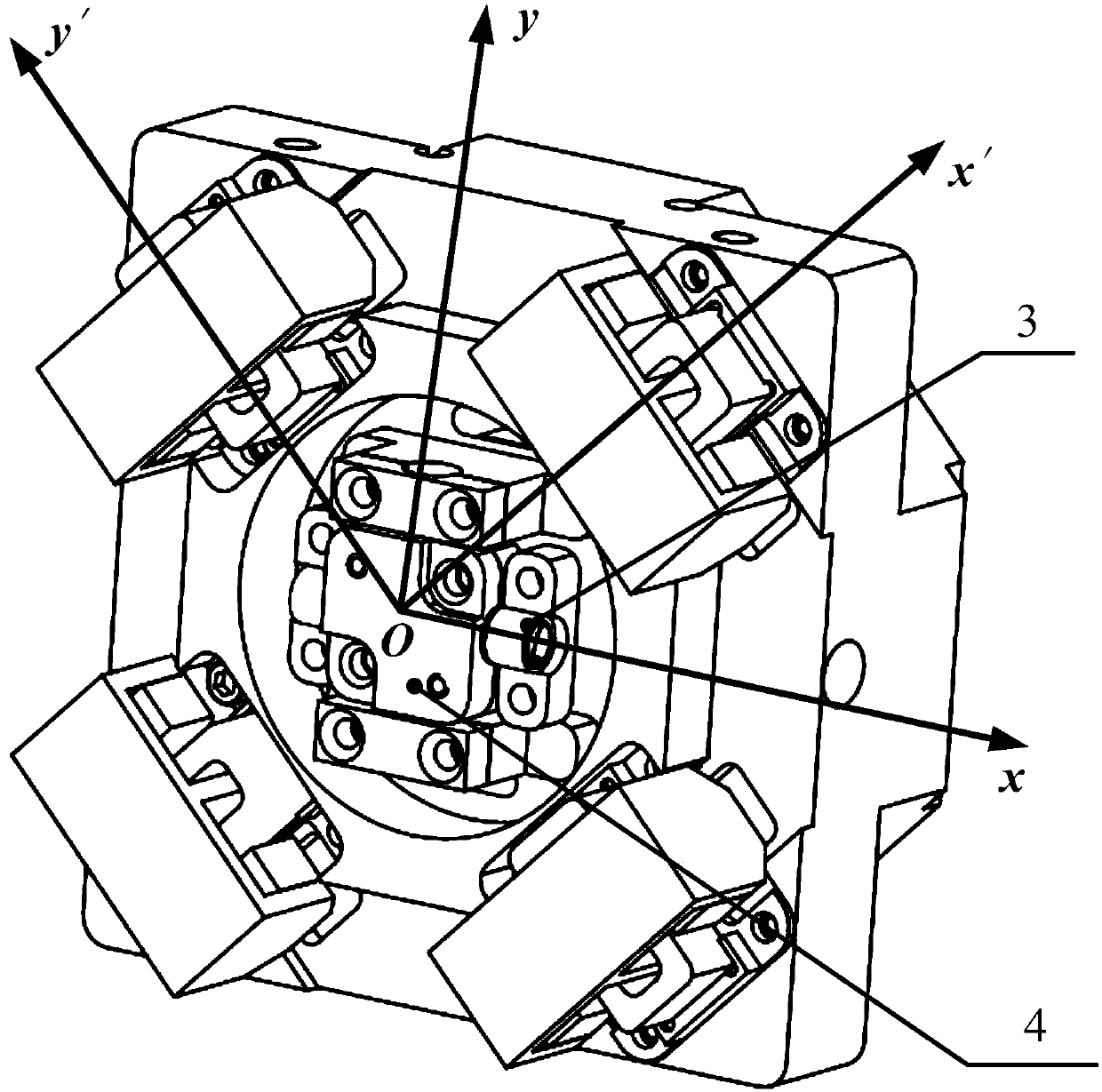

InactiveCN104280858AGuaranteed cleanlinessGuaranteed stabilityMountingsEngineeringRotational degrees of freedom

The invention provides a flexible back supporting device for a large-caliber reflector. The supporting device comprises the large-caliber reflector, a lens back plate, a supporting plate, a joint plate, a screw, flexible branch hinges, sliding flexible hinge supports, a flexible hinge connecting rod and a driving system. The three flexible branch hinges and the joint plate together form a combined hinge to constrain three degrees of horizontal moving freedom of the large-caliber reflector, the pitching and deflecting movements of the large-caliber reflector are achieved through flexible hinge blocks of the sliding flexible hinge supports and the driving system, when the driving system is tightly locked, the two degrees of rotating freedom of the large-caliber reflector are constrained, and the degree of the plane inner rotating freedom of the large-caliber reflector is constrained through the flexible hinge connecting rod. The flexible hinge structure is adopted as the supporting and positioning mechanism of the large-caliber reflector, nanoscale positioning precision is achieved, and the structural stability and the precision stability are ensured through matched design of the flexibility and the moving precision of the large-caliber reflector. The flexible back supporting device has the advantages of being simple in structure, stable in movement, free of friction or gaps, needless for lubrication and high in moving sensitivity.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

Fast reflection mirror

InactiveCN107942473ALarge deflection rangeHigh rotation accuracyMountingsMedical equipmentMeasuring instrument

The invention discloses a fast reflection mirror, comprising a base, a working mirror body, cross spring bearings and a driver; the working mirror body is assembled on a reflection mirror seat; two cross spring bearings constitute one group, there are totally two groups, wherein the axes of the two cross spring bearings in the first group of cross spring bearings coincide with a first straight line, and the axes of the two cross spring bearings in the second group of cross spring bearings coincide with a second straight line; the first straight line and the second straight line are perpendicular to each other and intersected at an origin; each cross spring bearing is connected to the reflection mirror seat and the base respectively; and the driver is used for driving the reflection mirrorseat to rotate within a preset angle range around the first straight line and / or the second straight line. According to the fast reflection mirror, the cross spring bearings support the reflection mirror seat, the cross spring bearings have the advantages of large deflection range and high rotating precision, and when the cross spring bearings are used with the driver, the deflection angle and therotating precision of the working mirror body can be improved, so that the fast reflection mirror is applicable in the fields of precision machinery, precision measuring instruments, medical equipment and the like.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

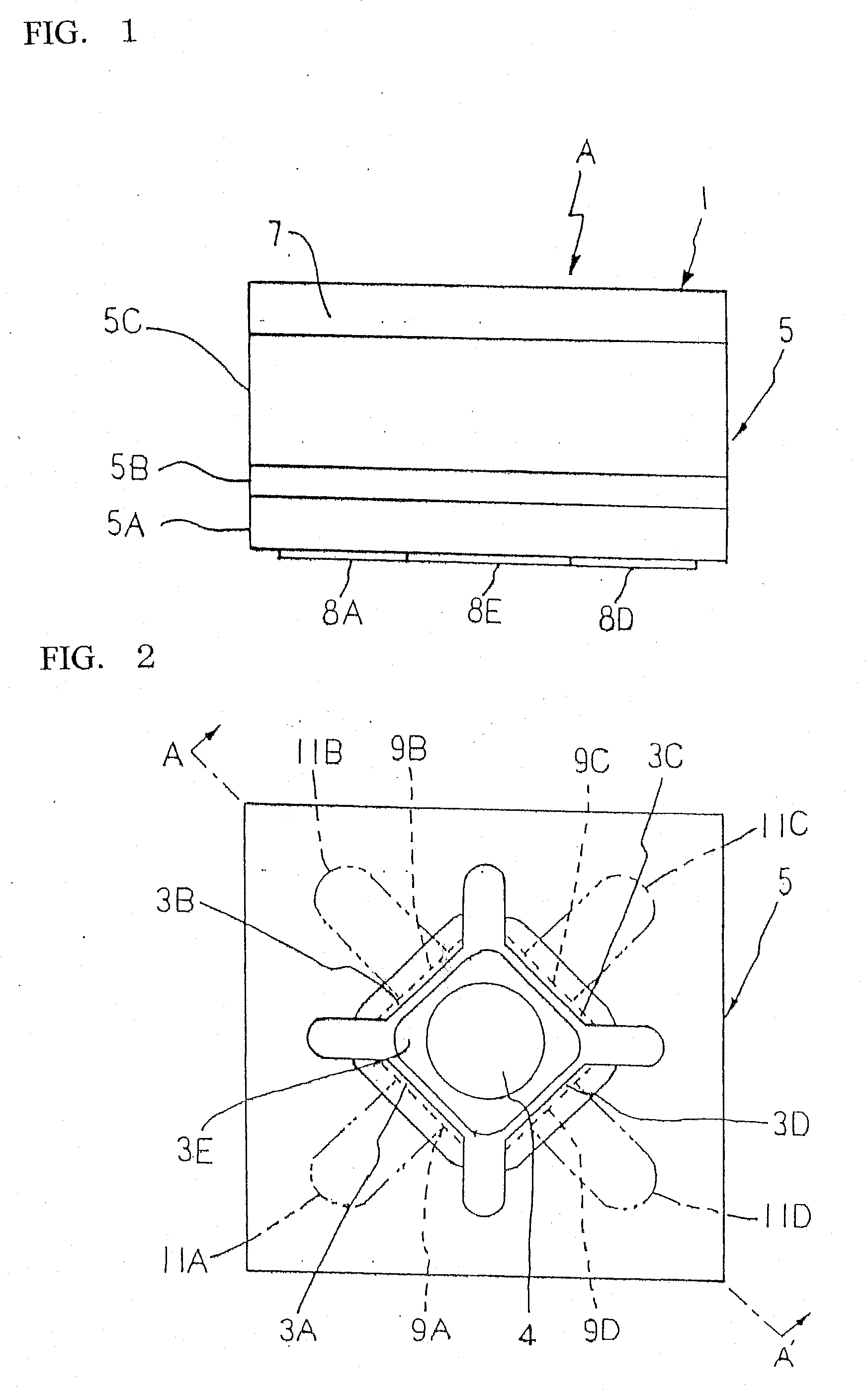

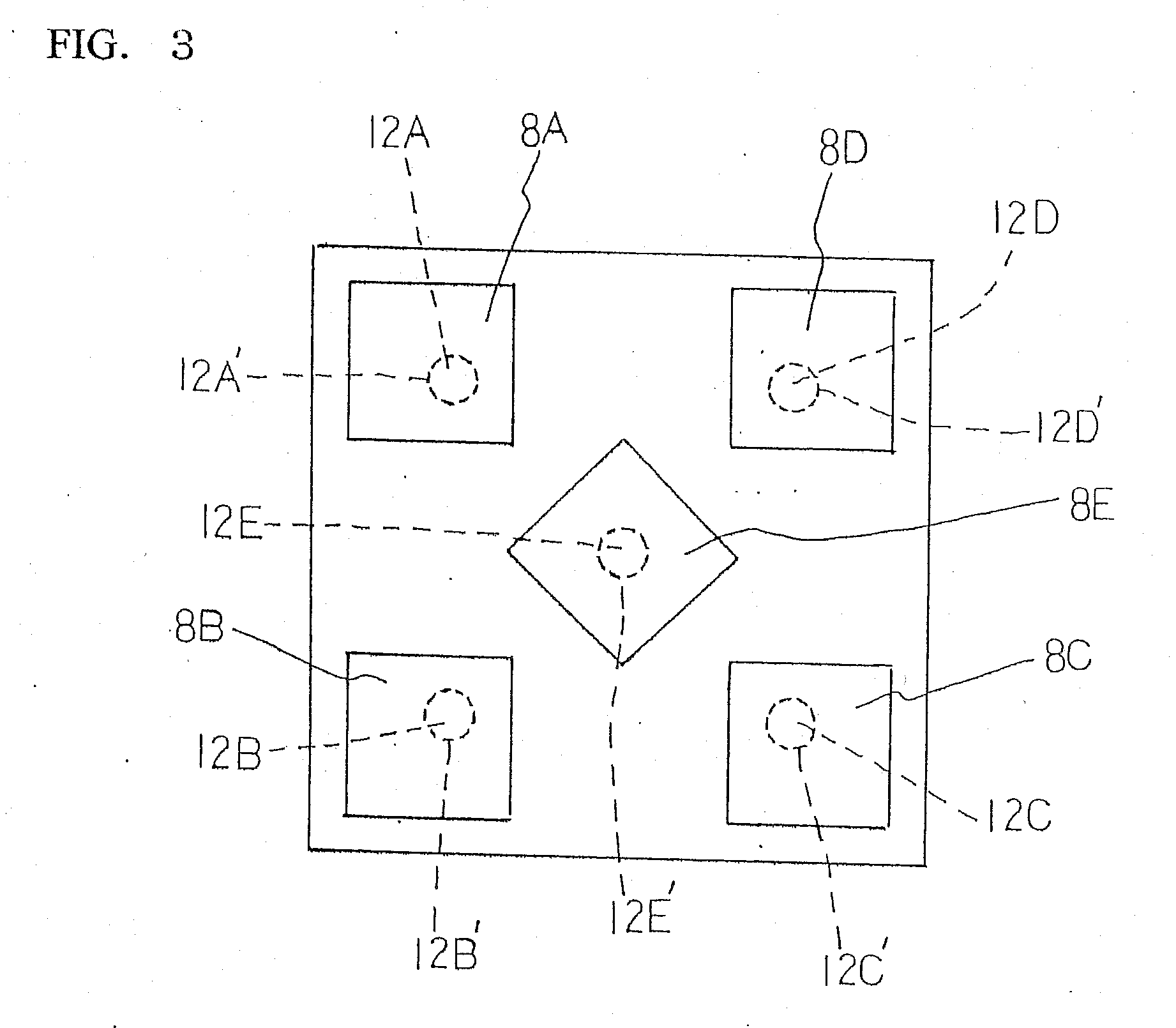

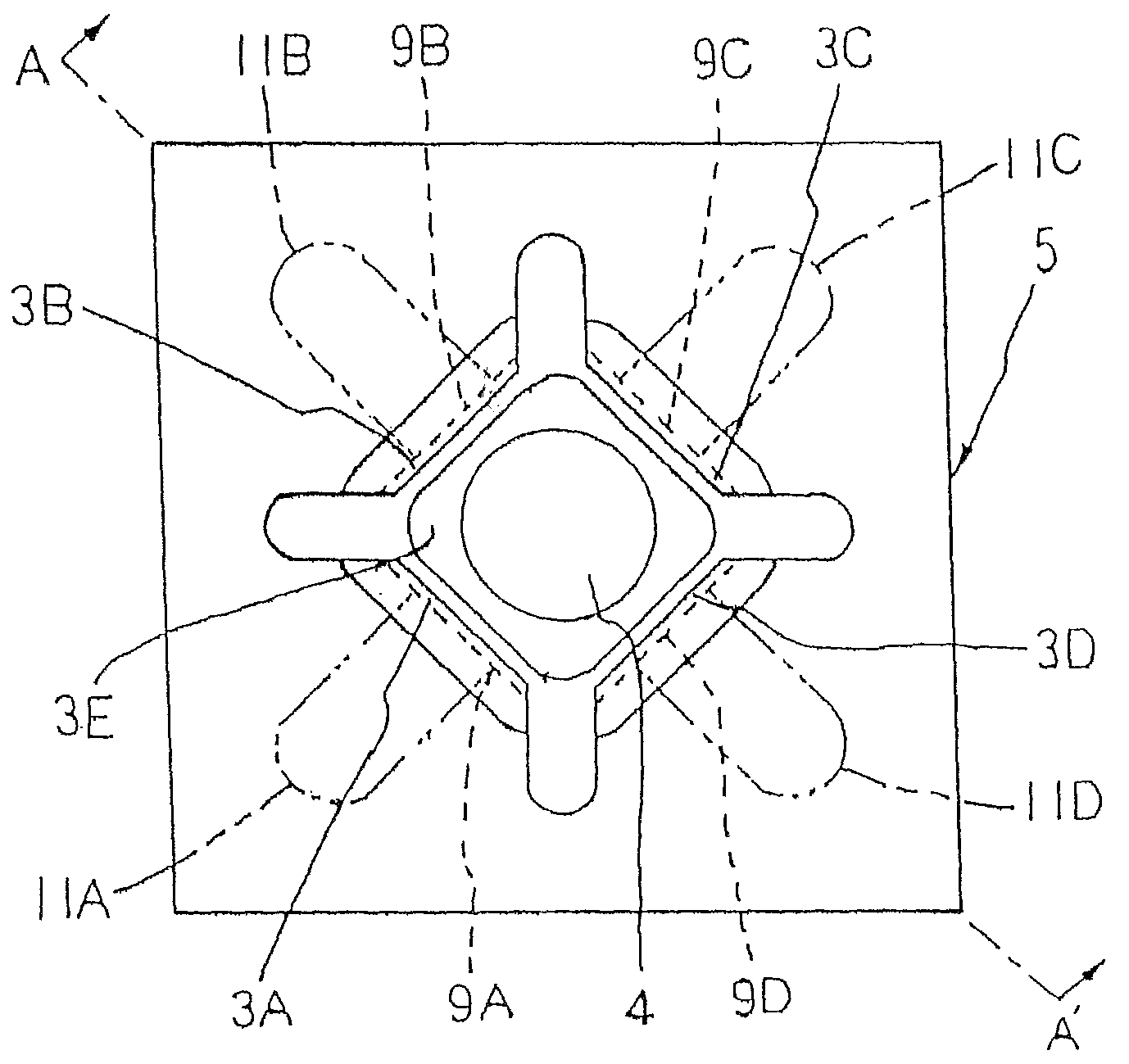

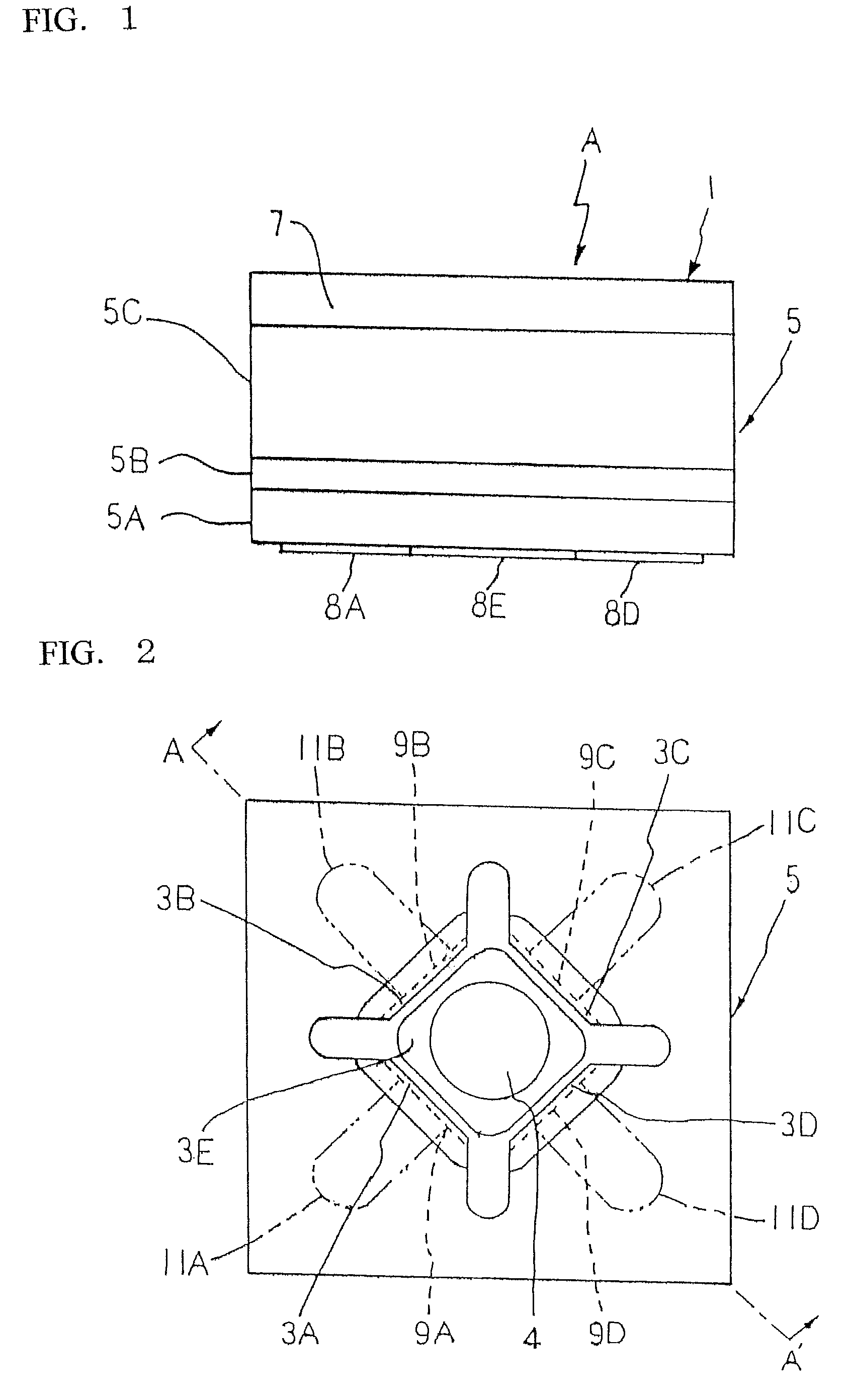

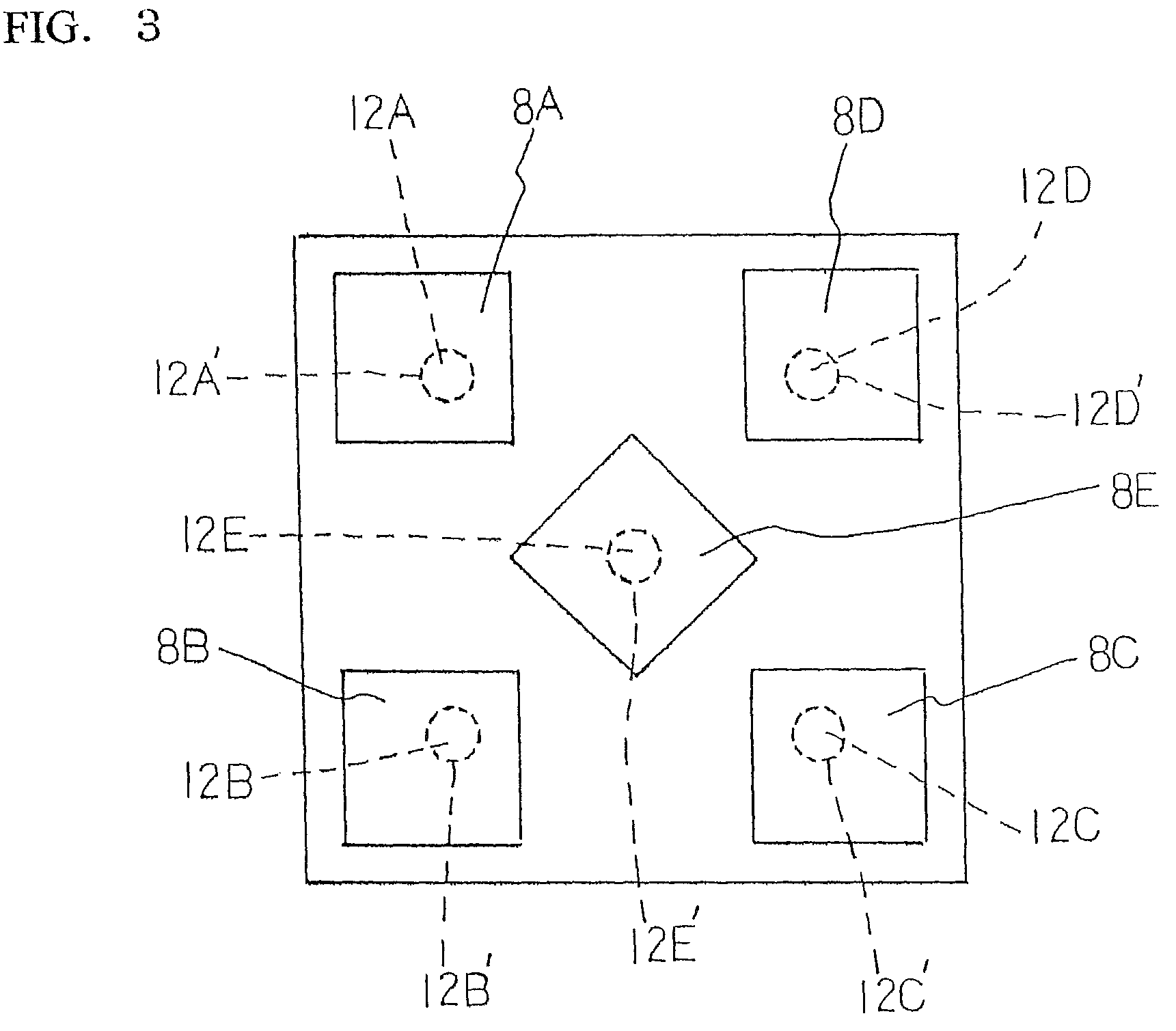

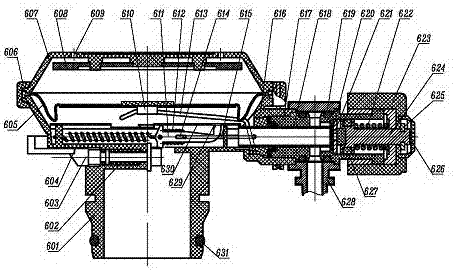

Compact tilt and vibration sensor and method for manufacturing the same

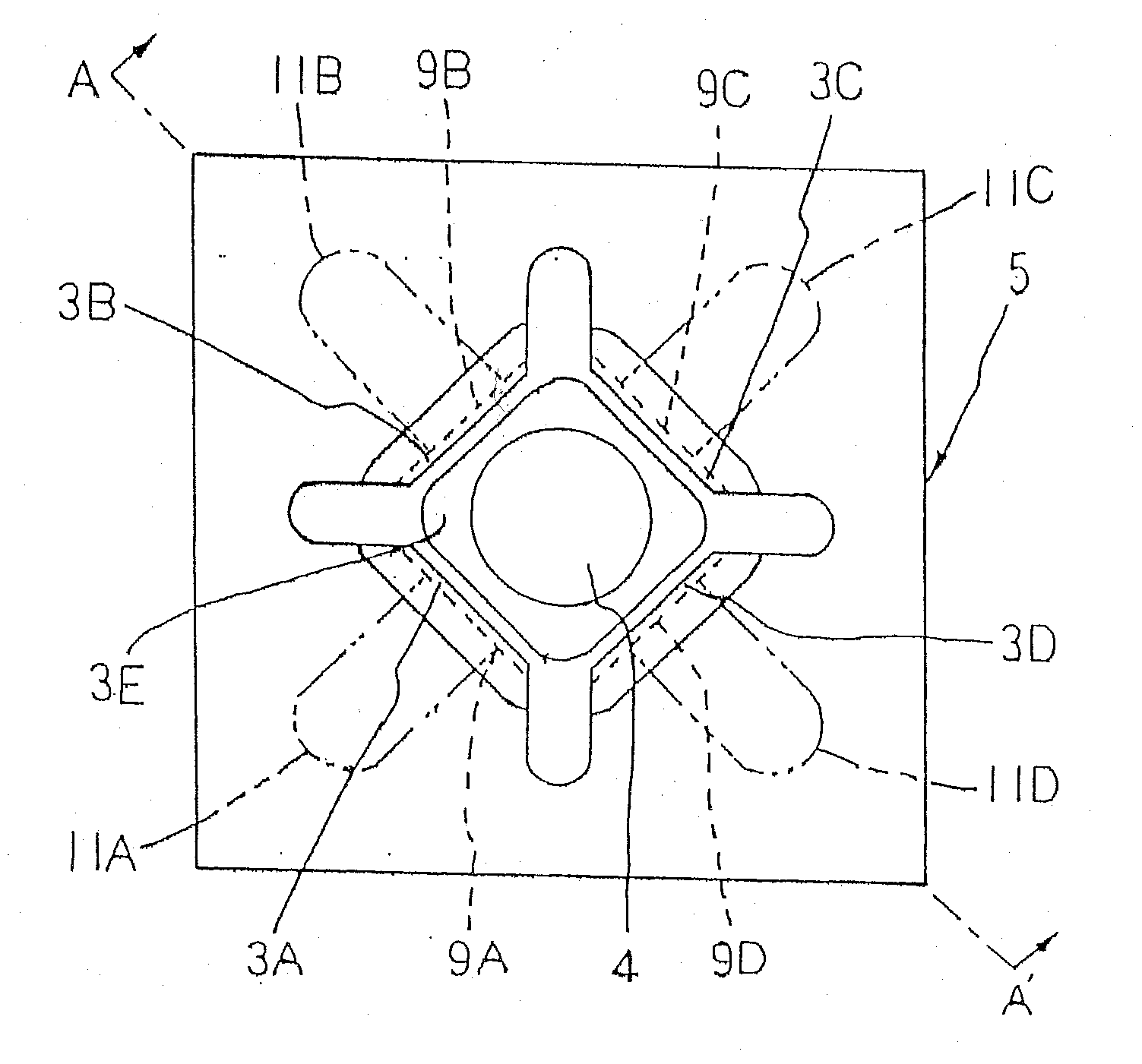

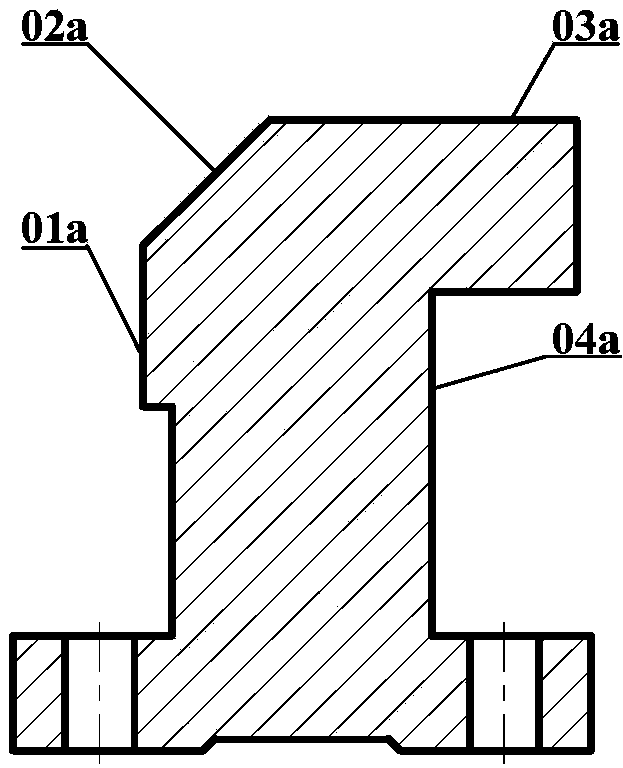

InactiveUS20090266168A1Improve performanceHigh movement sensitivityLine/current collector detailsAcceleration measurement using interia forcesParticulatesEngineering

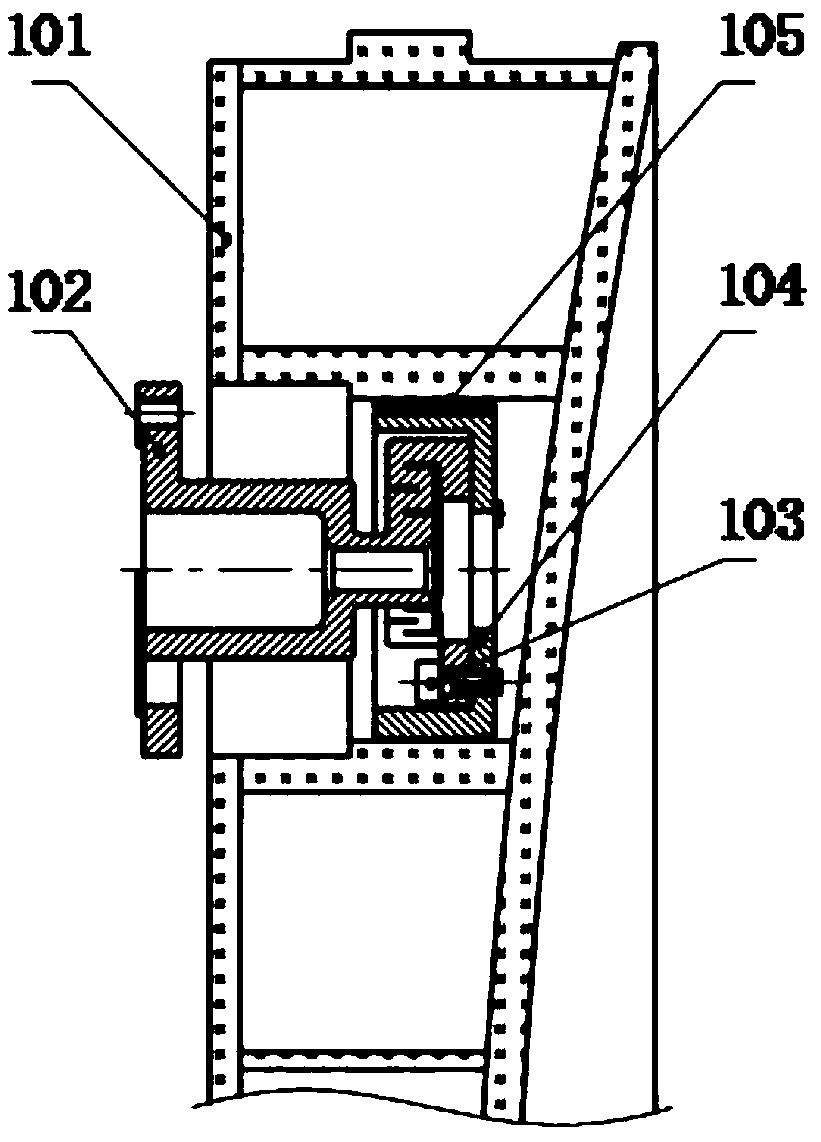

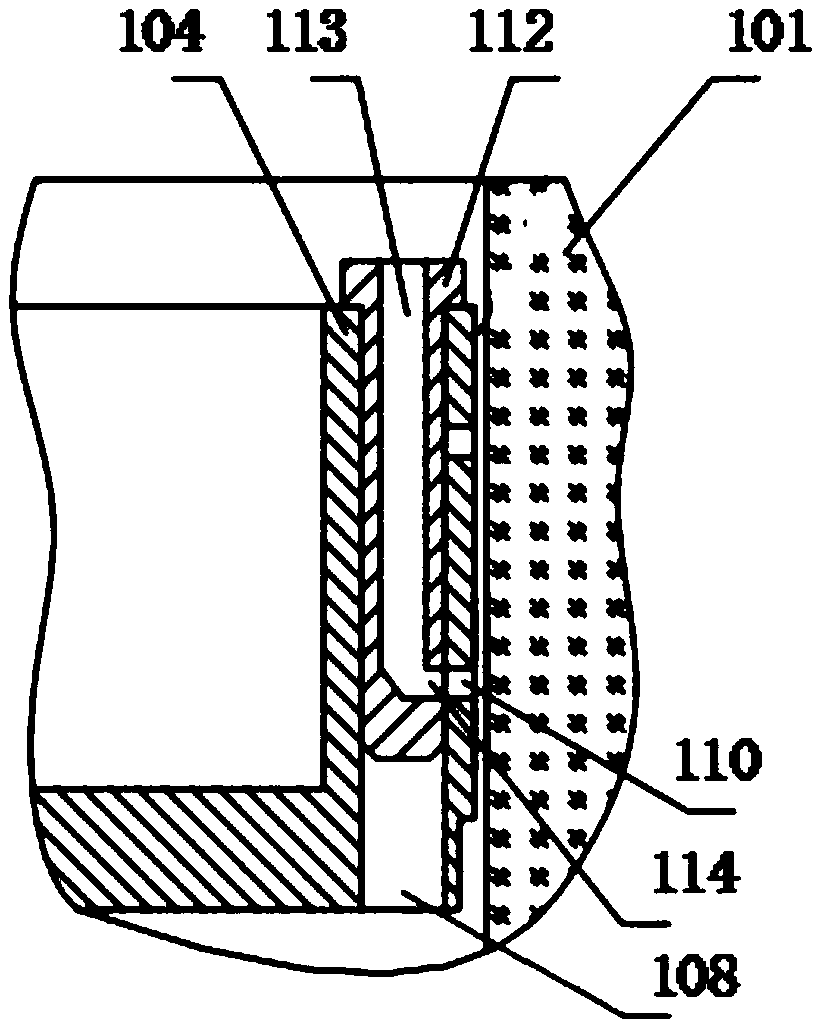

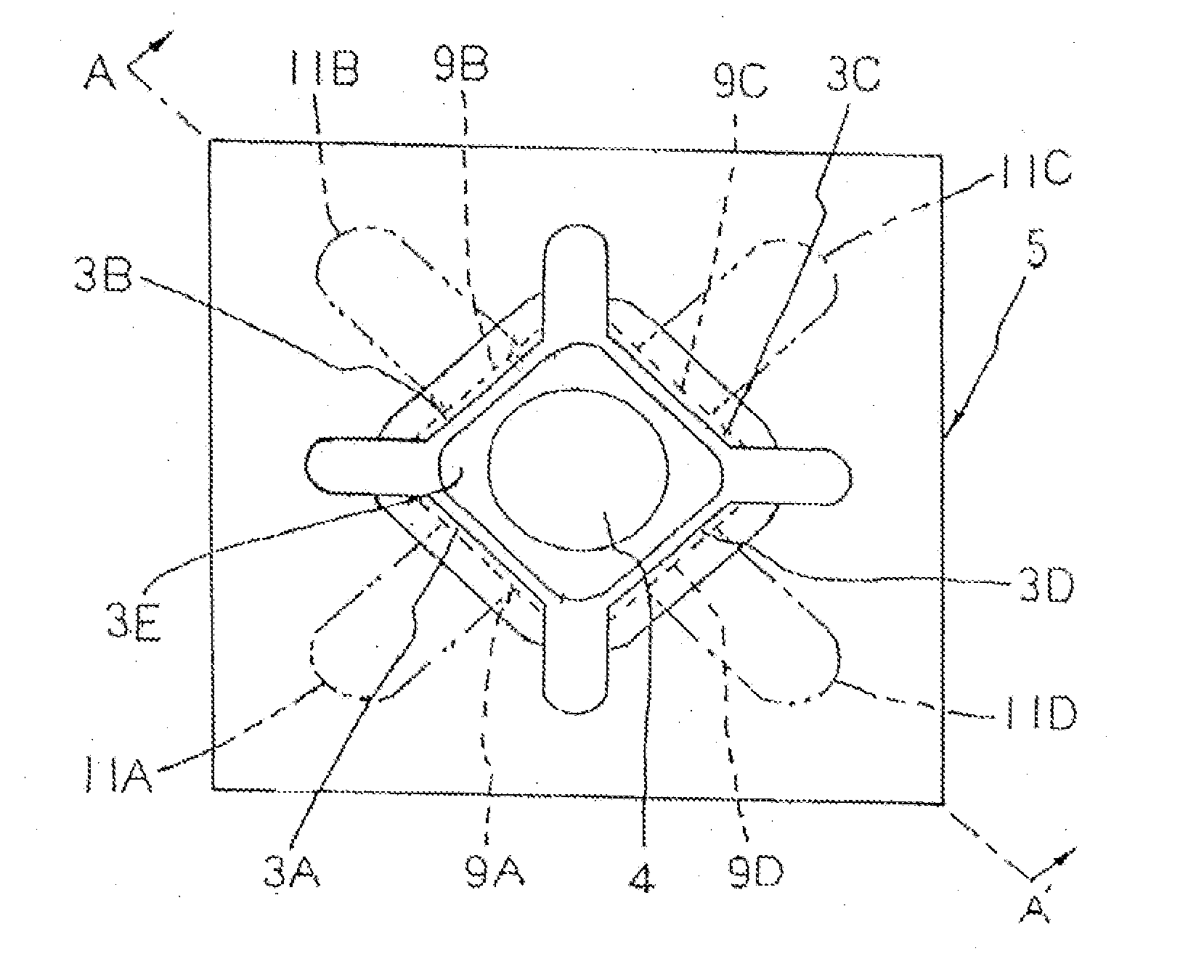

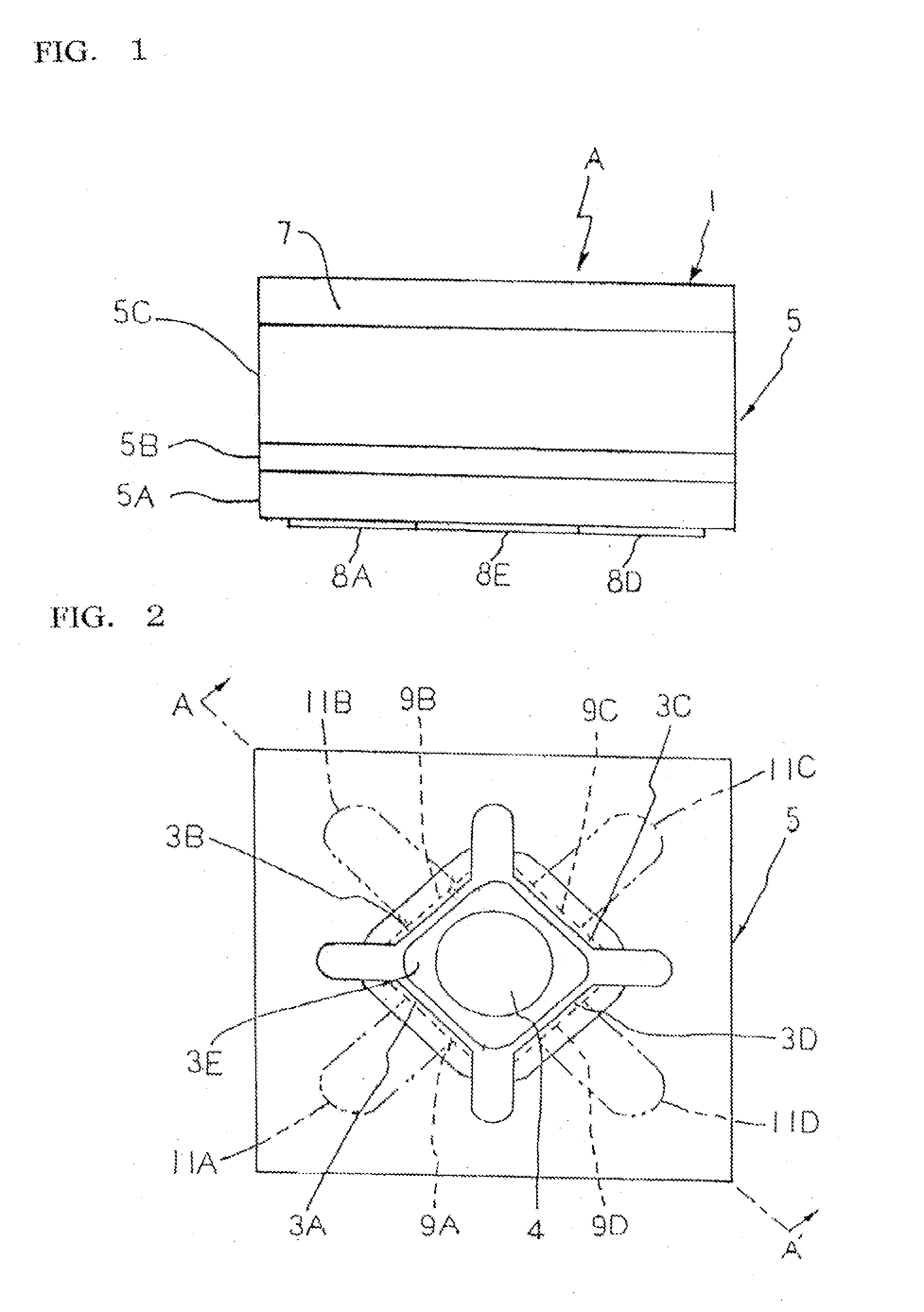

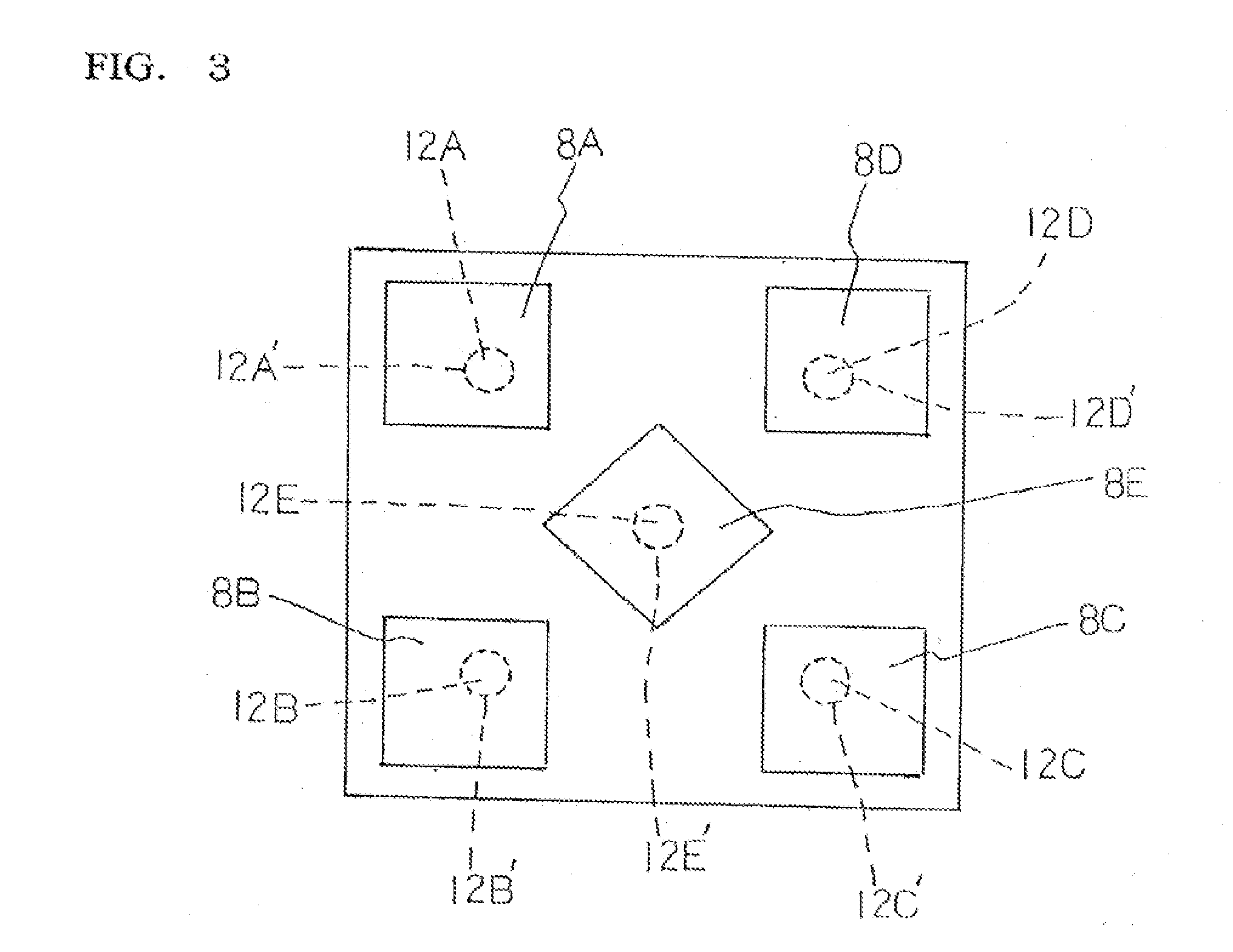

Provided are a tilted vibration sensor incorporating a plurality of electrodes and a conductive spherical body which is turned on and off by the moving displacement of the spherical body, and which may be remarkably reduced in size and may have high performance and high operating sensitivity, high durability, and high reliability; and a method of manufacturing the sensor. The case (1) of the sensor comprises a case body (5) formed of a non-conductive material having such excellent gas-barrier property and heat resistance that can stop the transmission of gases which affects on the on / off operation of the sensor due to the moving displacement of the conductive spherical body (4) and a cover body (7) sealing airtight the opening part (6) of the case body. In the method of manufacturing the vibration sensor, moisture and particulate impurities affecting the on / off operation are removed from the hollow part (2) of the case (1), and the hollow part is evacuated.

Owner:G DEVICE CORP

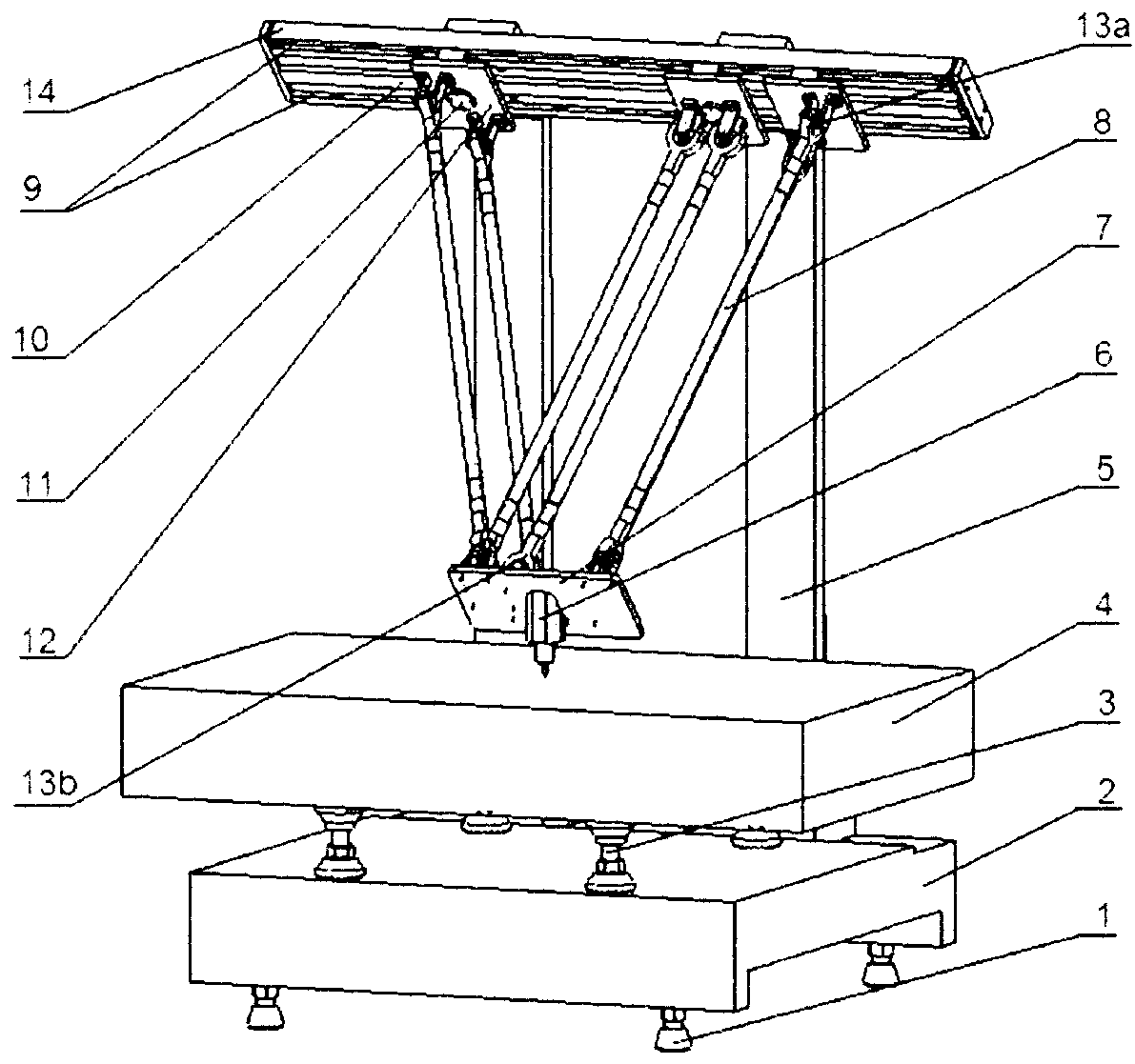

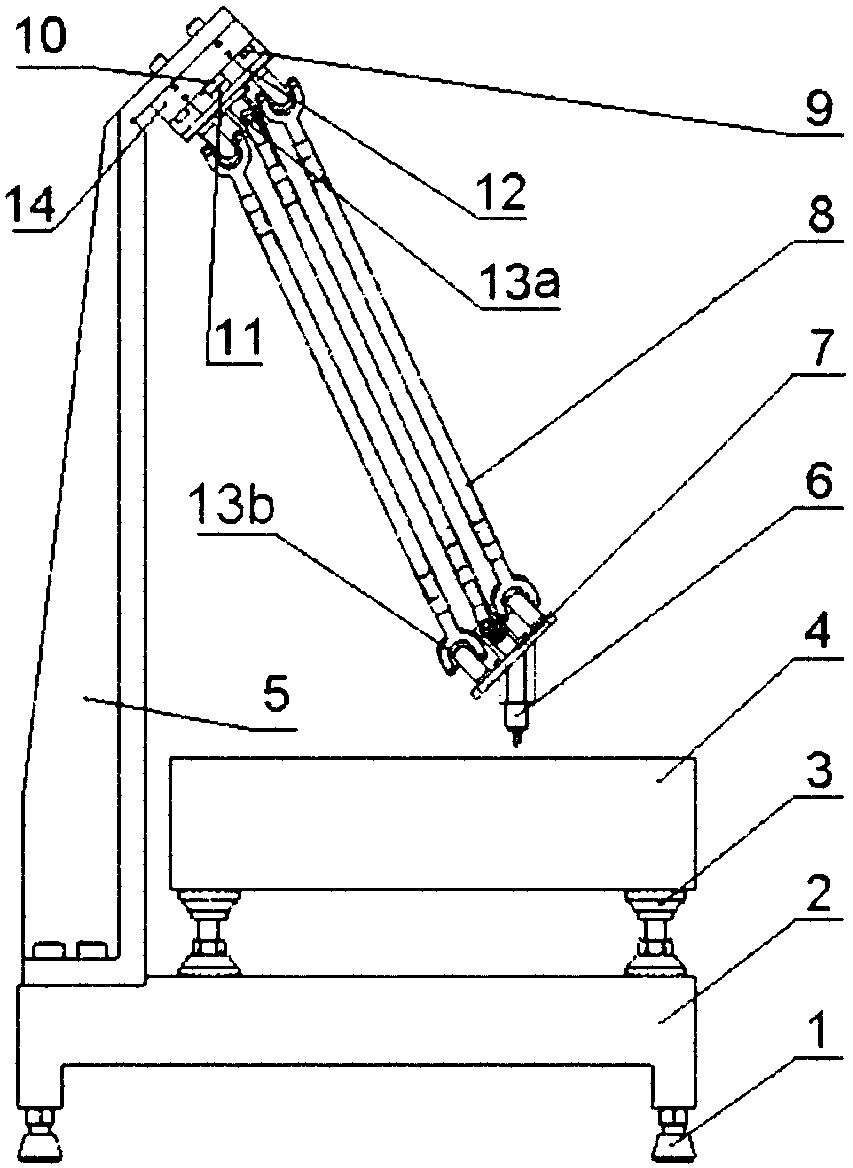

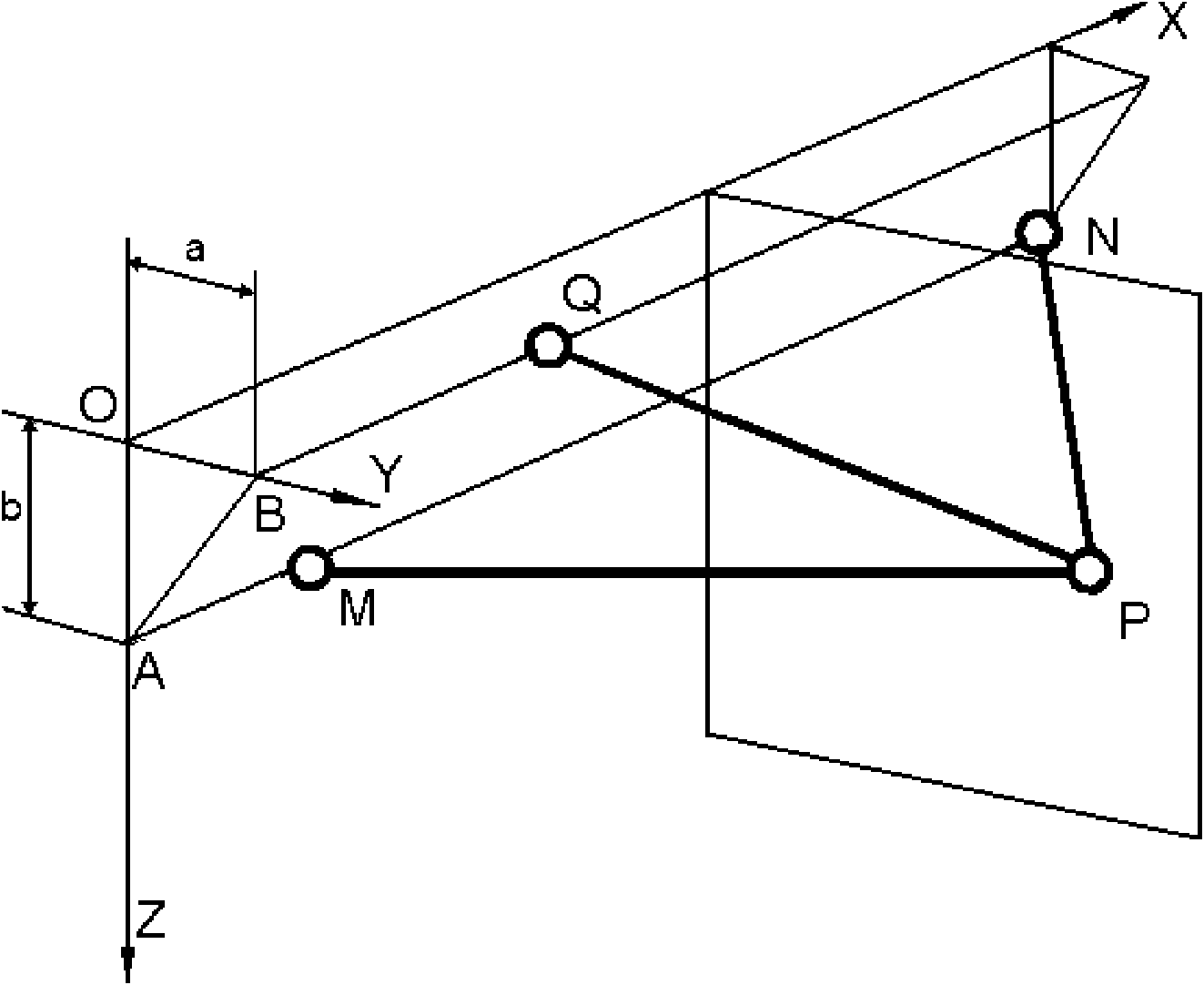

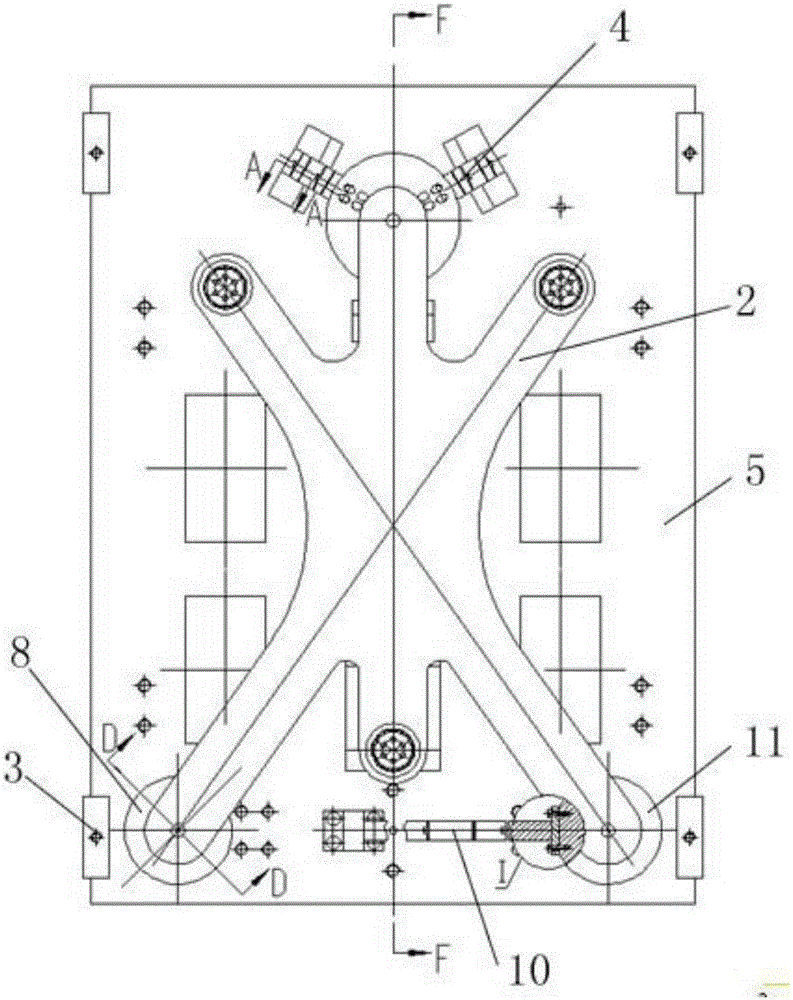

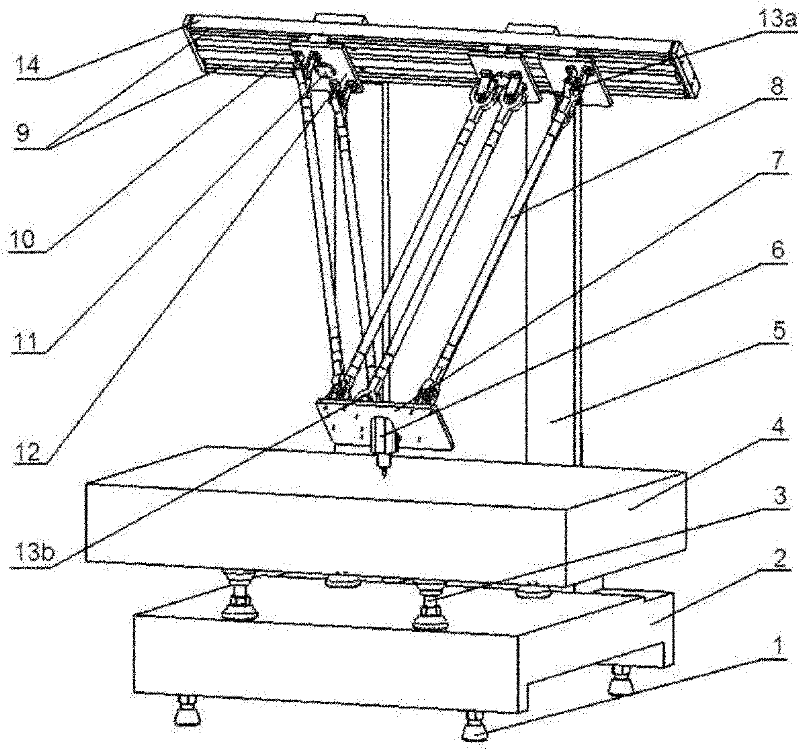

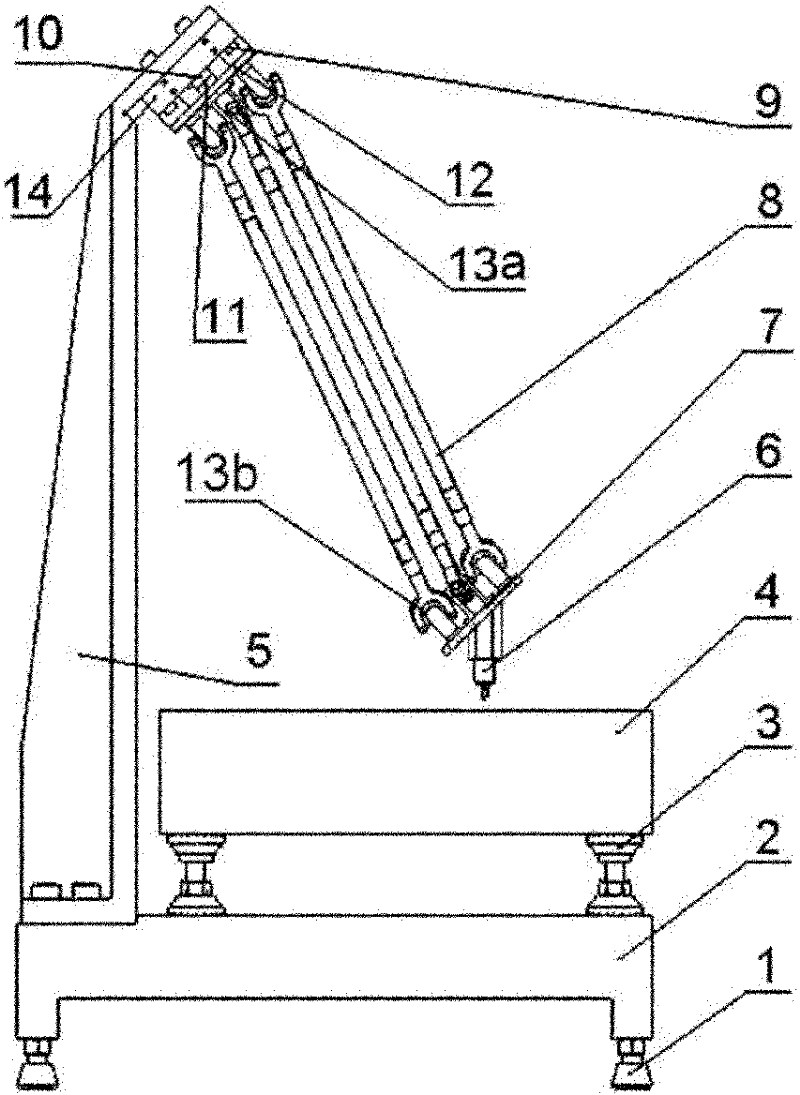

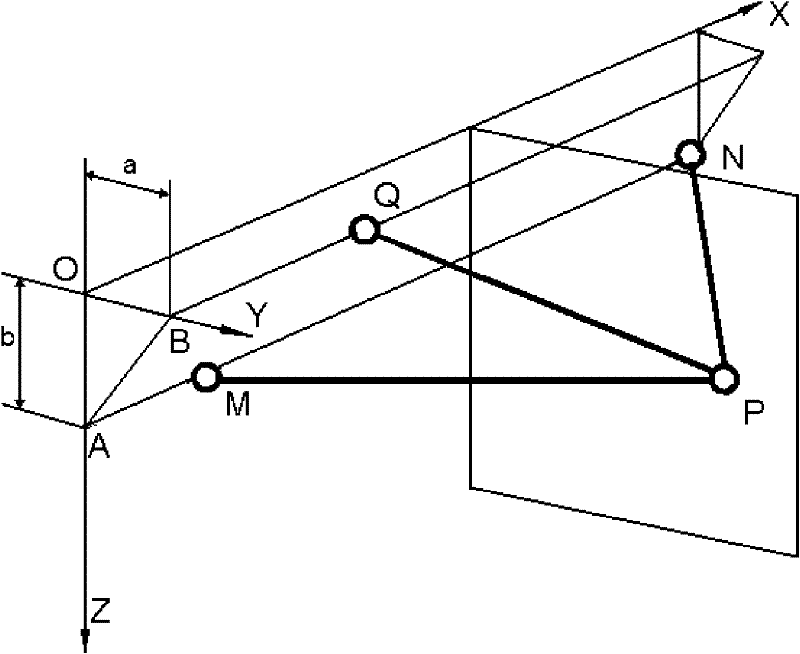

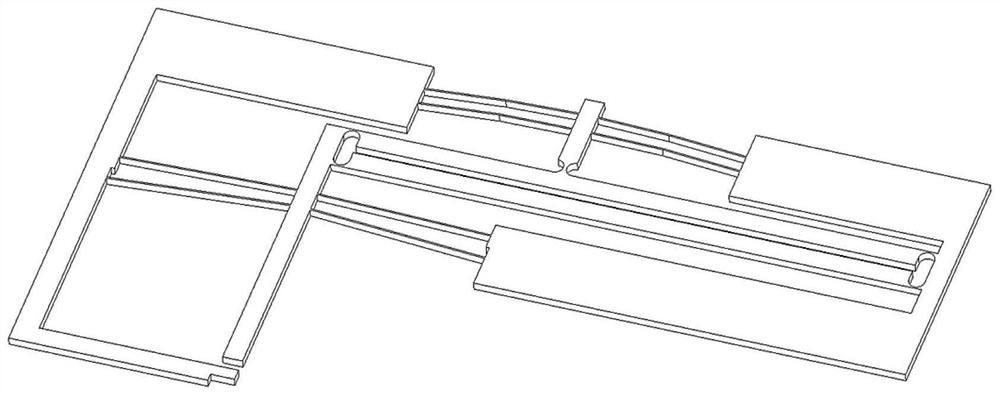

Three pairs of sliding pair-spherical hinge-spherical hinge (3-PSS) mechanism-based coordinate measuring machine

InactiveCN102012211AReduce the error factorHigh measurement accuracyUsing optical meansGratingSpherical bearing

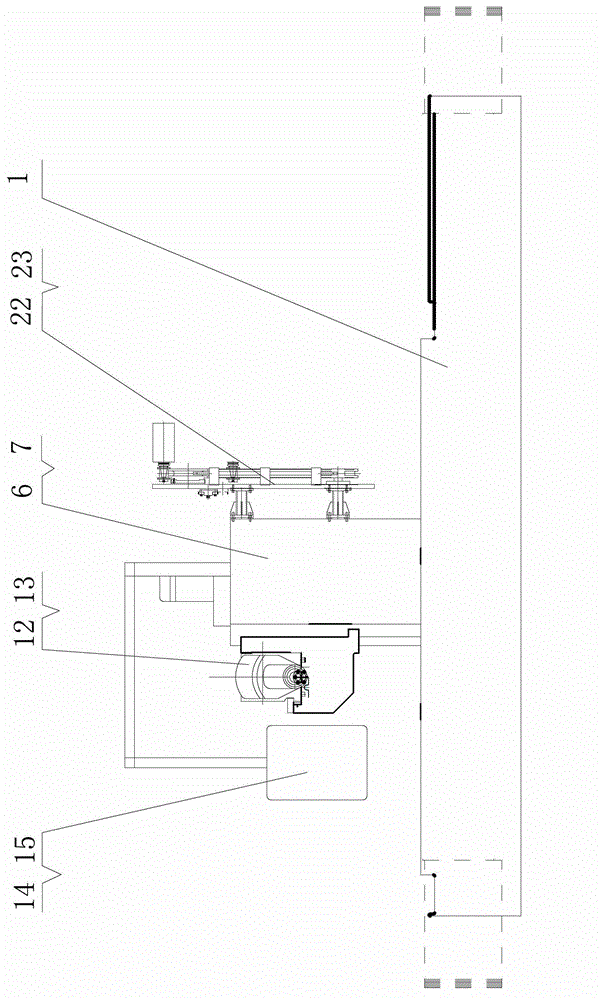

The invention discloses a three pairs of sliding pair-spherical hinge-spherical hinge (3-PSS) mechanism-based coordinate measuring machine. The 3-PSS mechanism-based coordinate measuring machine is characterized in that: a three pairs of sliding pair-spherical hinge-spherical hinge parallel mechanism is provided; three motion sliding blocks are independently arranged on a pair of ball guide rails which are arranged in parallel and can slide freely along the ball guide rails respectively; the three motion sliding blocks are connected with one end of each of three pairs of link rods through one end of a universal joint respectively; the other end of each of three pairs of link rods are connected with a measuring moveable platform through the other end of the universal joint respectively; a measuring head is arranged on the lower plane of the measuring moveable platform; three indication gratings are fixedly connected to the three motion sliding blocks respectively; a scale grating and the pair of ball guide rails are arranged in parallel and are arranged on the guide rail mounting surfaces of guide rail cross beams; and the guide rail cross beams are suspended and fixedly connected to a pair of brackets. The 3-PSS mechanism-based coordinate measuring machine has high rigidity, a simple structure, high processing assembly property and low cost and can measure the three-dimensional space sizes, the shapes and the mutual positions of parts quickly and precisely.

Owner:合肥工大科教开发部

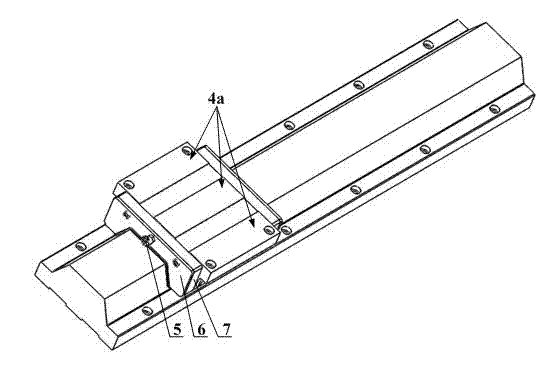

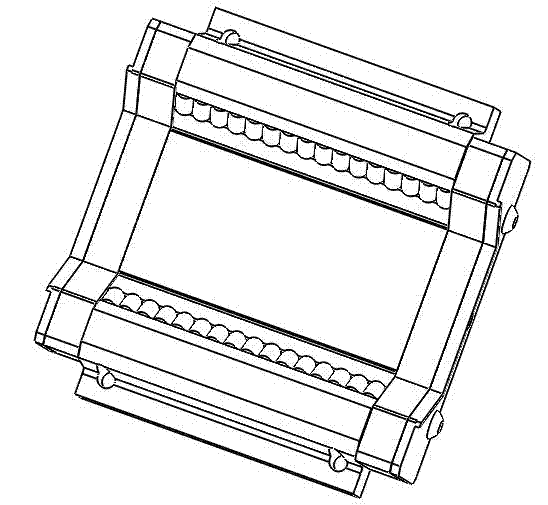

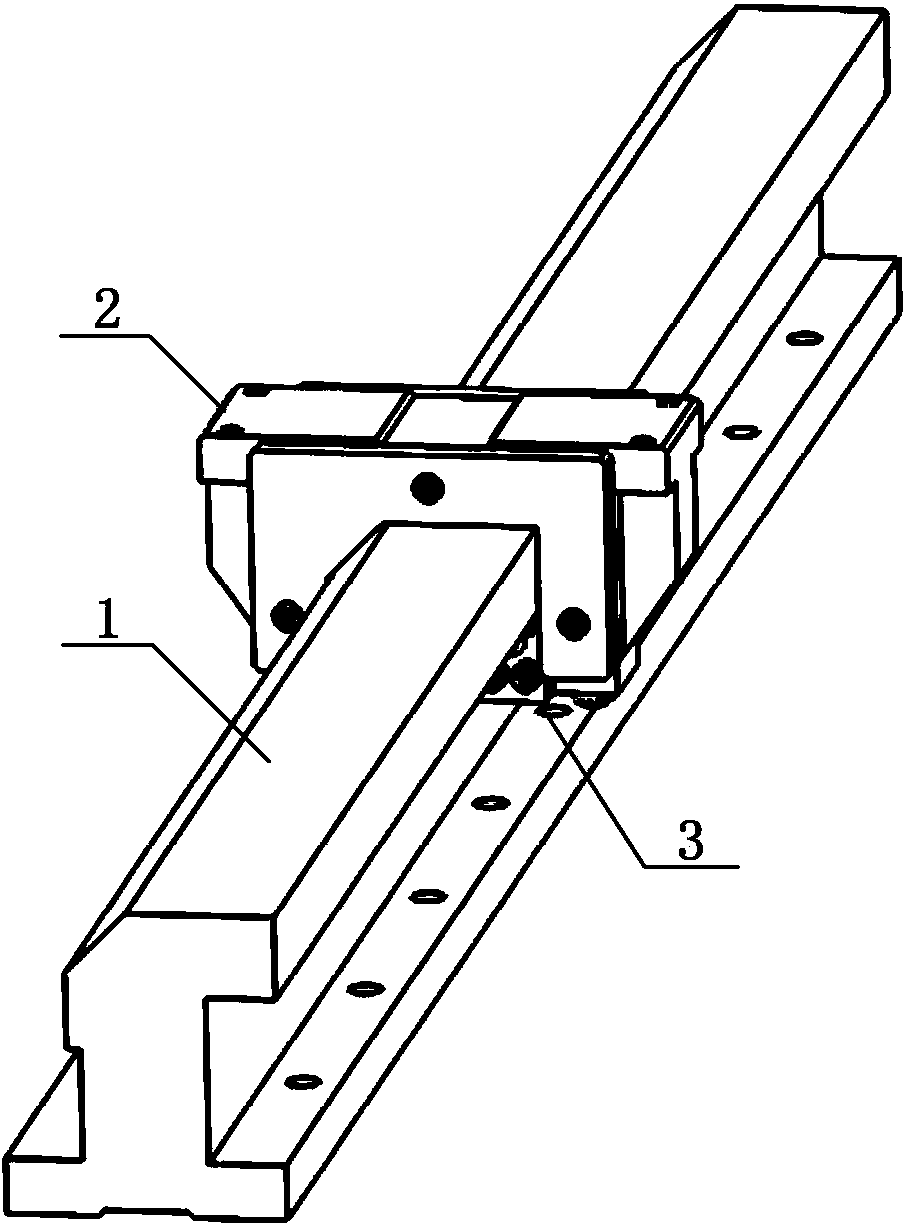

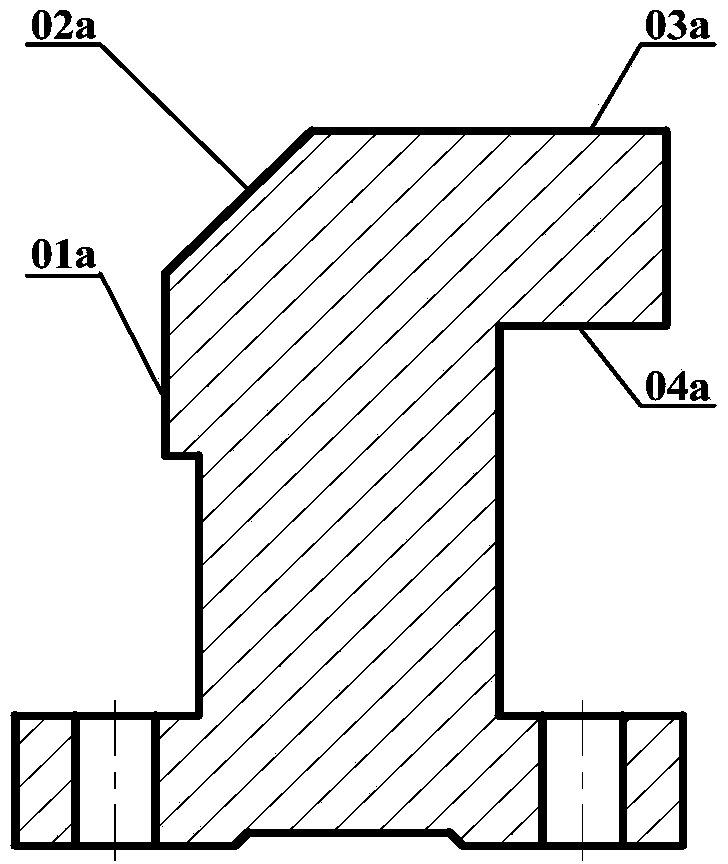

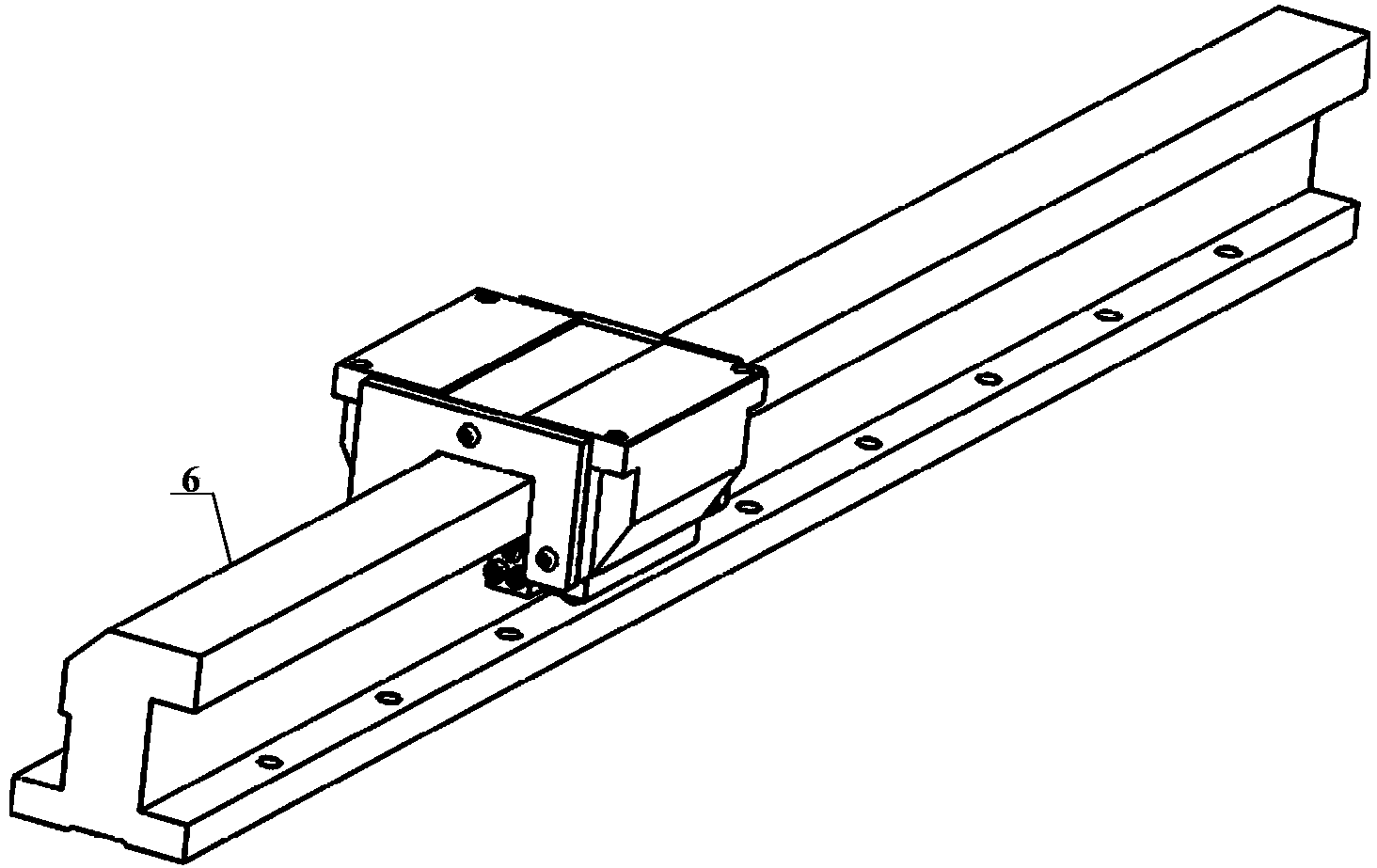

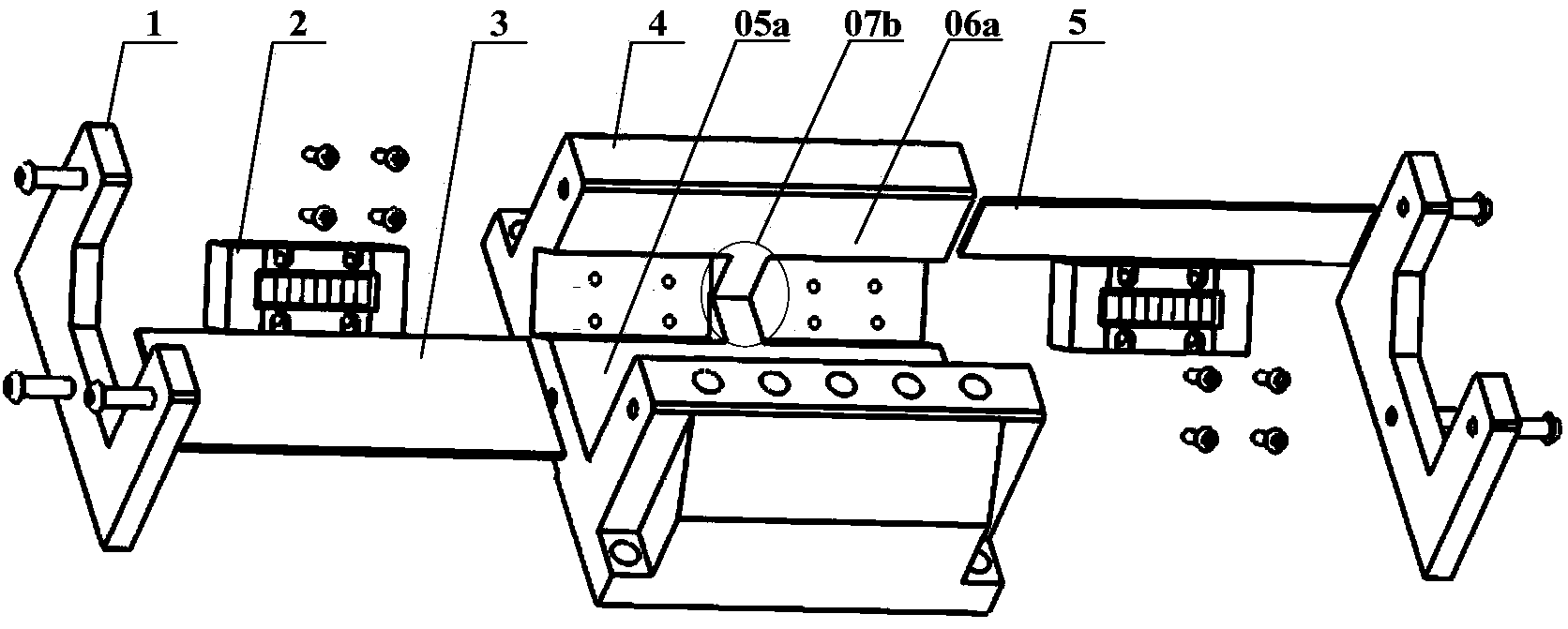

Novel linear rolling and sliding composite guide rail pair

InactiveCN103921133AHigh sensitivityShort response timeLarge fixed membersBearing surfaceMotion resistance

The invention discloses a novel linear rolling and sliding composite guide rail pair, comprising a guide rail and a sliding block fit with each other, wherein the guide rail is trapeziform, two side faces of the trapeziform guide rail are guiding faces, the upper surface of the trapeziform guide rail is a bearing surface, the bottom of the sliding block is provided with a trapeziform groove fit with the trapeziform guide rail, the two side faces of the trapeziform groove are respectively provided with at least one row of cylindrical rollers along the length direction, a guide rail soft strip is arranged between the upper surface of the trapeziform groove of the sliding block and the bearing surface of the trapeziform guide rail along the length direction of the guide rail. The novel linear rolling and sliding composite guide rail pair integrates the advantages of a rolling guide rail and a sliding guide rail, ensures the guiding and positioning accuracies of the motion guide rail and the bearing capacity of the guide rail and simultaneously reduces motion resistance reasonably in the case of loading heavily and cutting heavily, promotes sensitivity, rigidity and vibration resistance of the motion guide rail, improves machining efficiency and prolongs the service life of the guide rail.

Owner:NANJING UNIV OF SCI & TECH

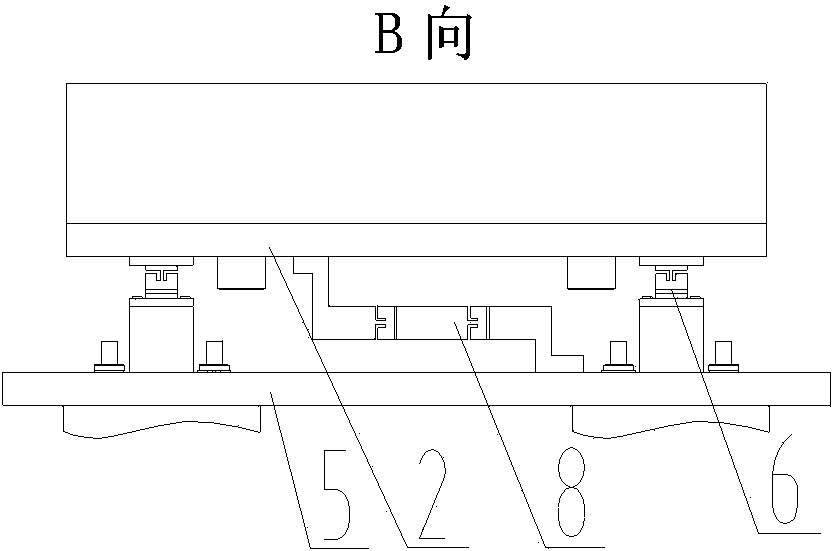

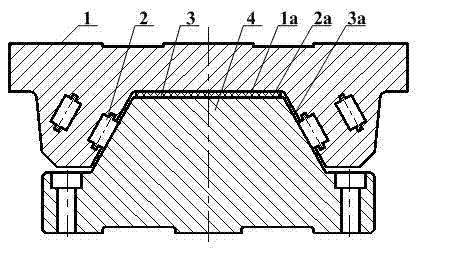

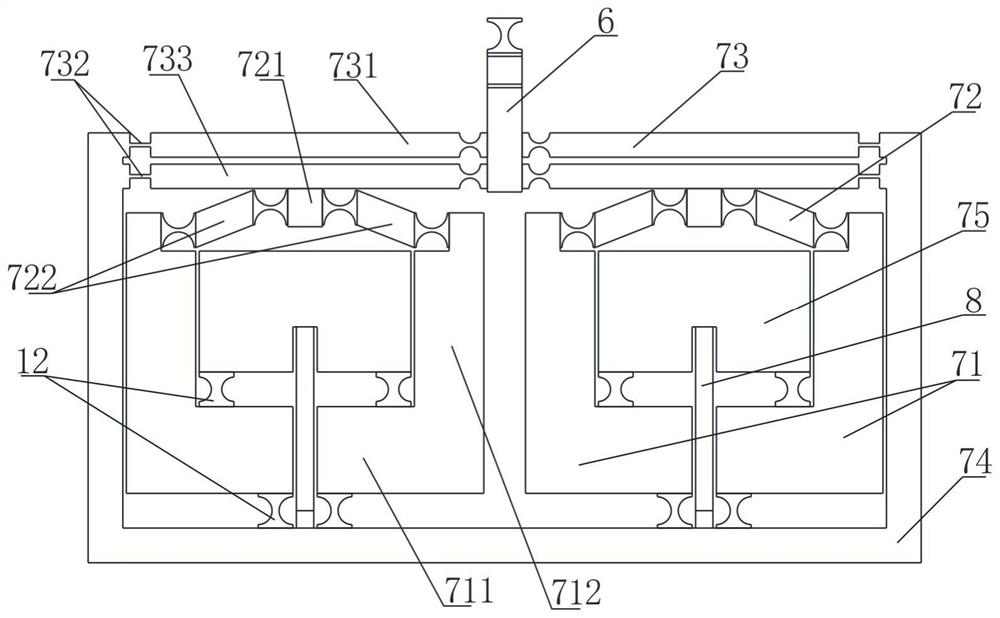

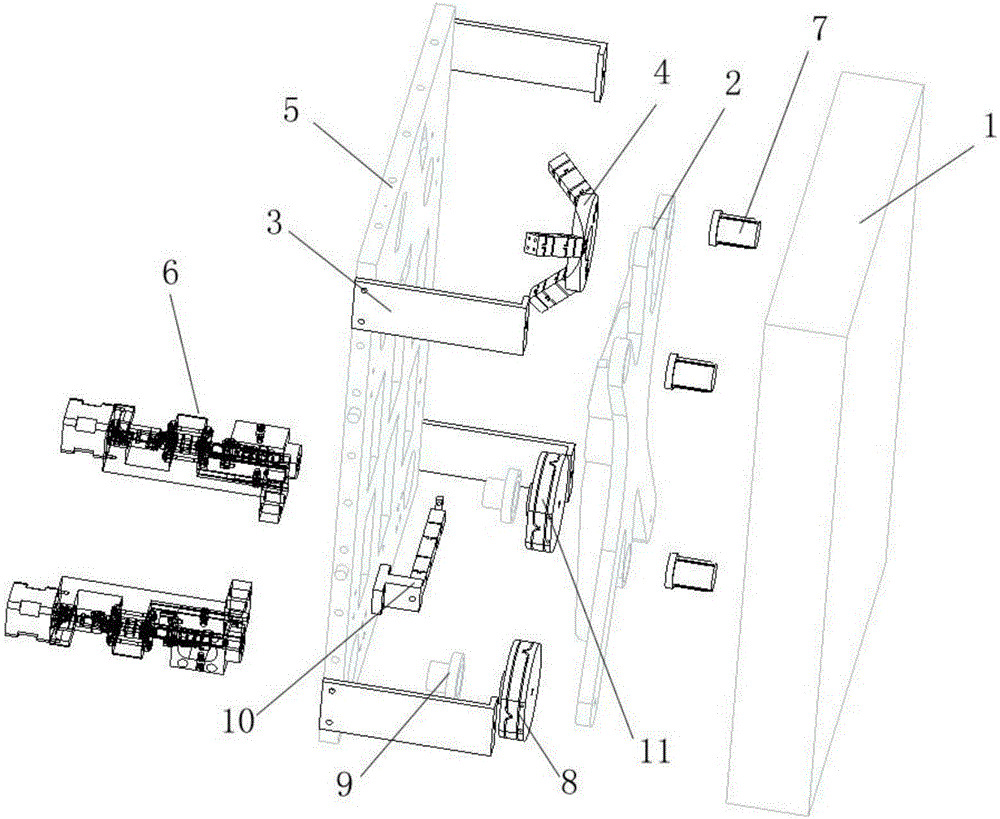

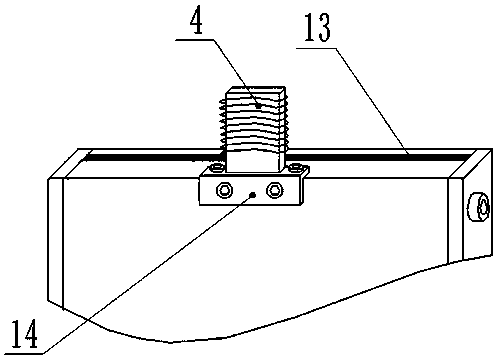

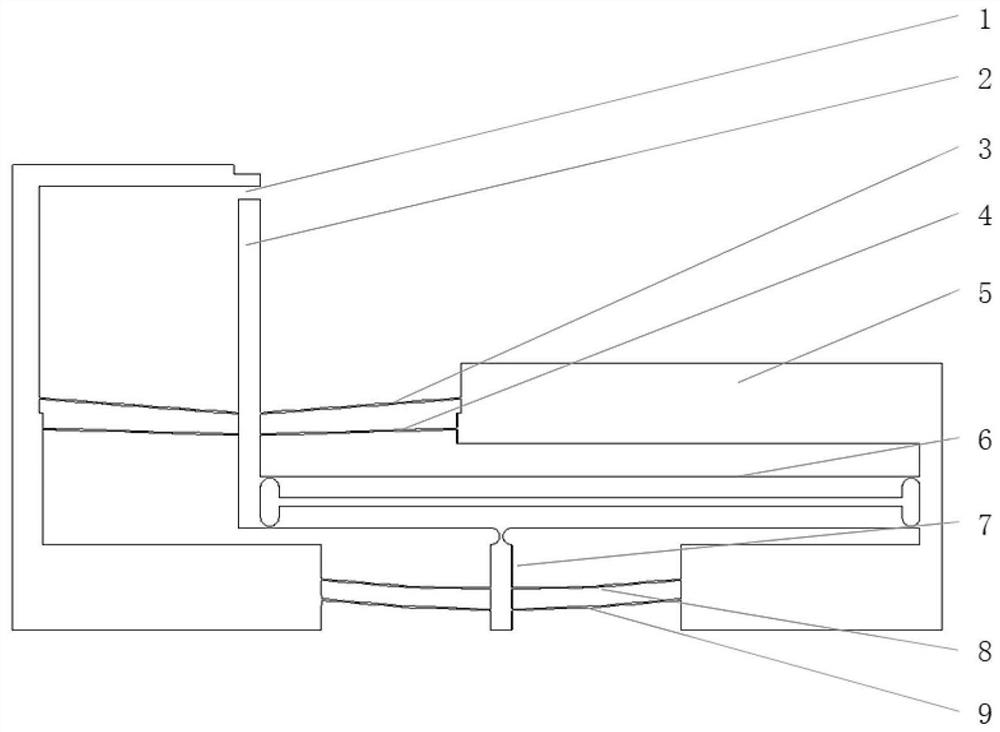

Gap-adjustable rolling slide composite guide rail pair

ActiveCN103769868AHigh movement sensitivityHigh sensitivityLarge fixed membersCarrying capacityEngineering

The invention discloses a gap-adjustable rolling slide composite guide rail pair. The gap-adjustable rolling slide composite guide rail pair comprises a guide rail, a slider and a gas adjusting mechanism which are in mutual match; the slider comprises two end surface baffles and a slider body; a groove matched with the guide rail is arranged at the bottom of the slider; a guide rail soft belt is arranged between the left side surface of the groove and the lateral carrying surface of the guide rail along the length direction of the guide rail; a guide rail soft belt is arranged between the upper surface of the groove and the normal carrying surface of the guide rail along the length direction of the guide rail; a U-shaped slot is arranged at the left lower corner of the groove; a rolling block matched with the guide surface of the guide rail is arranged in the U-shaped slot along the length direction of the guide rail. The gap-adjustable rolling slide composite guide rail pair integrates the advantages of a rolling guide rail and a slide rail, the guide and positioning precision and the carrying capacity of the guide rail are ensured under the heavy load and heavy cutting conditions, the motion resistance is reasonably effectively reduced, the sensitivity, rigidity and vibration resistance of the motion guide rail are improved, the machining efficiency is improved, and the service life of the guide rail is prolonged.

Owner:NANJING UNIV OF SCI & TECH

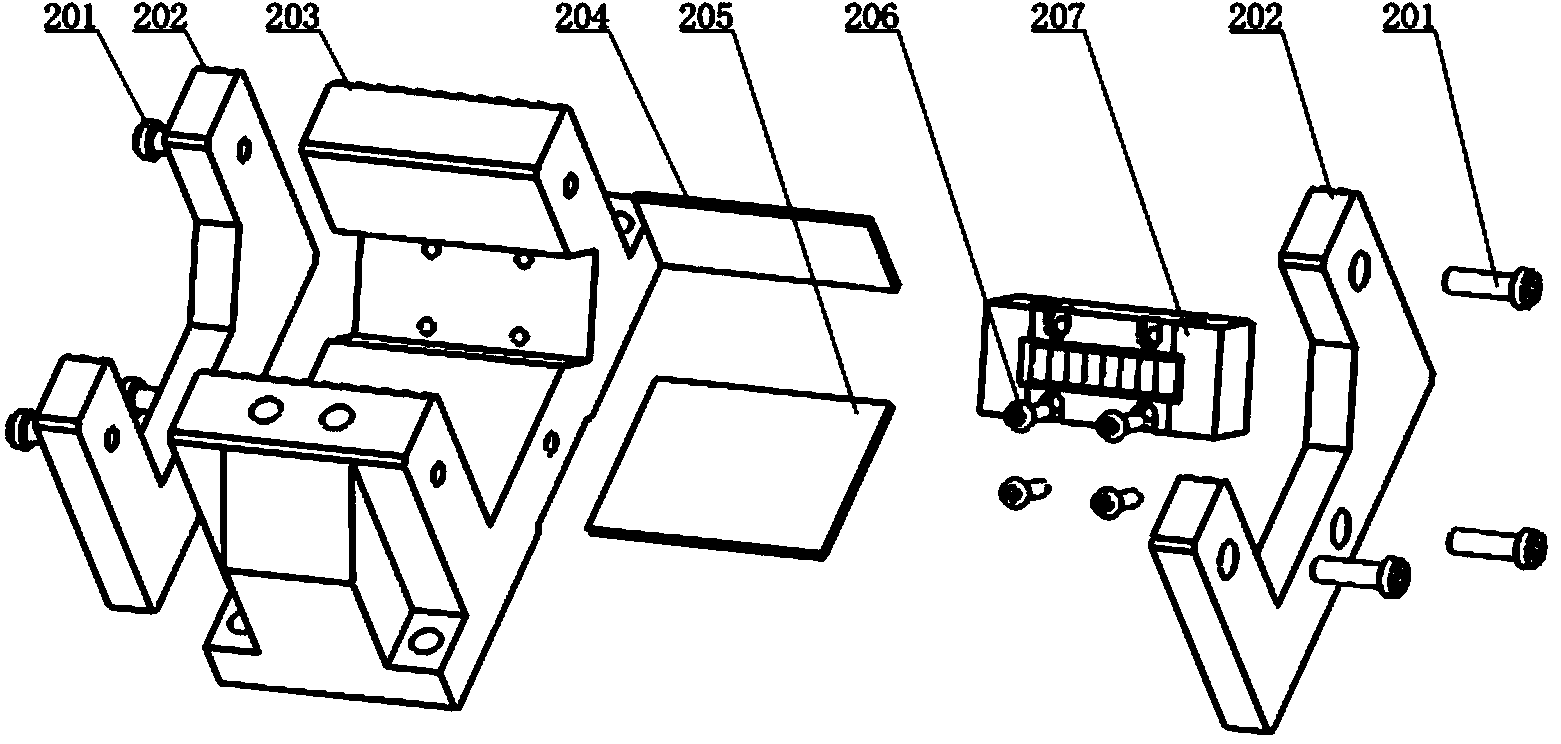

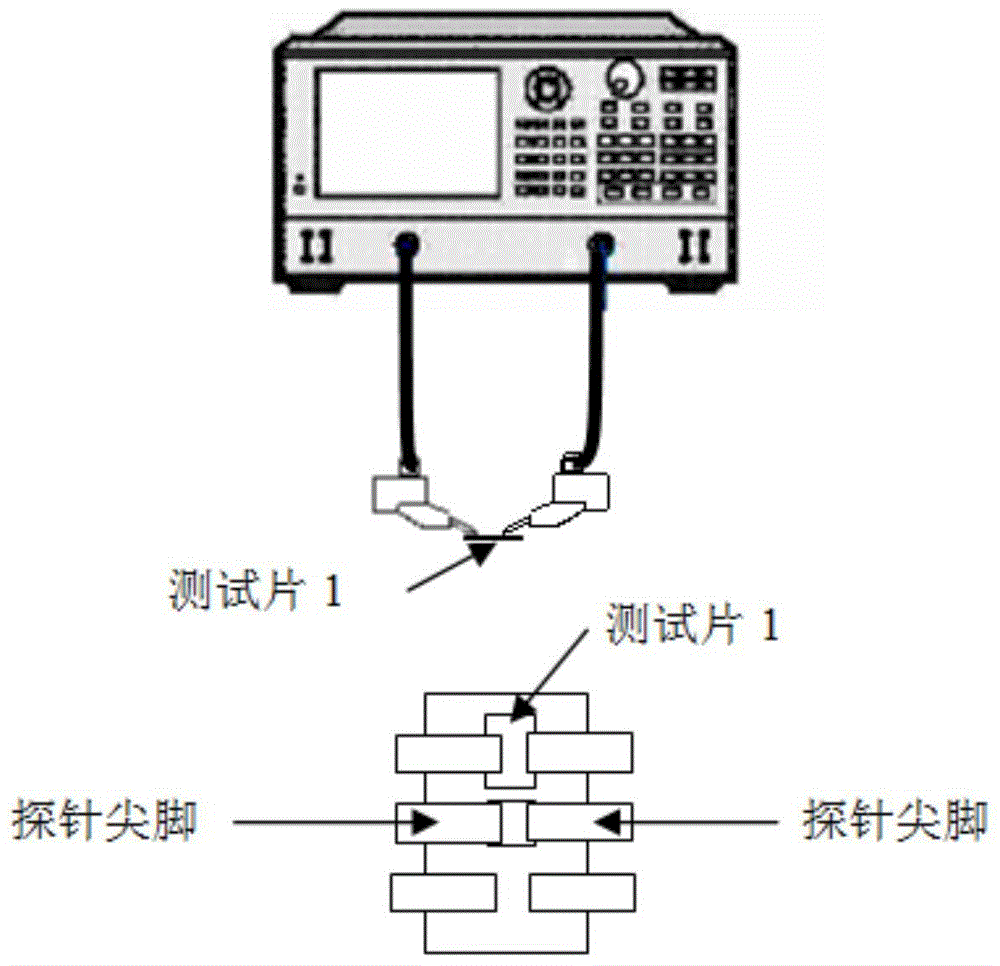

Controllable high-frequency-response probe test moving device for microwave and millimeter wave chips

ActiveCN104793121AFast testShorten the test cycleIndividual semiconductor device testingGratingEngineering

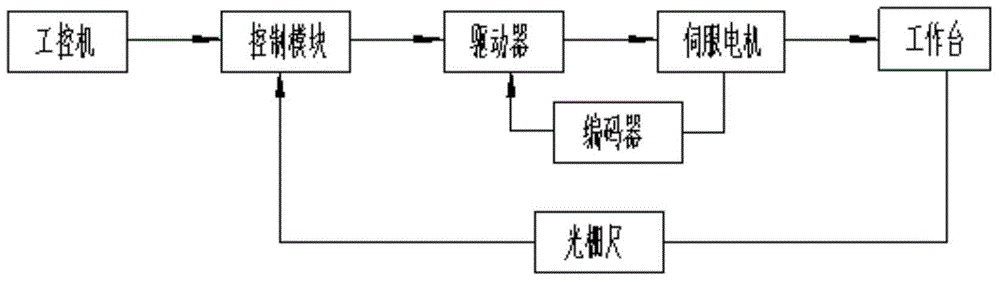

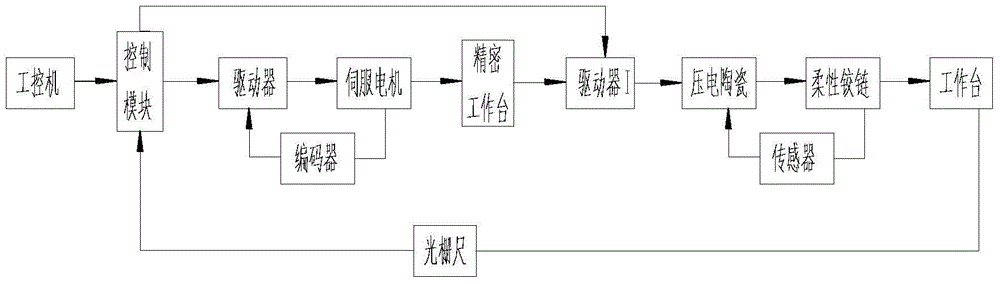

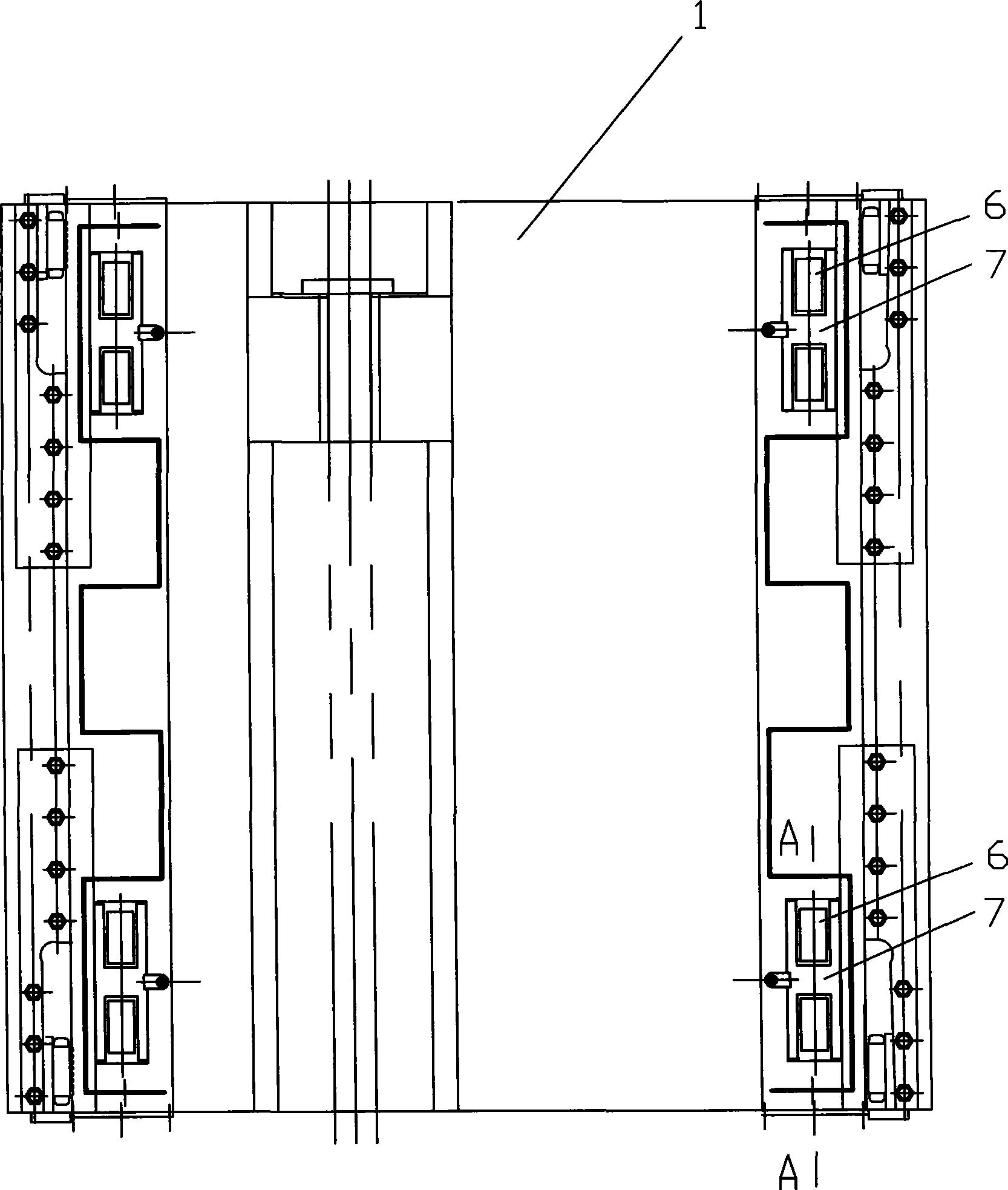

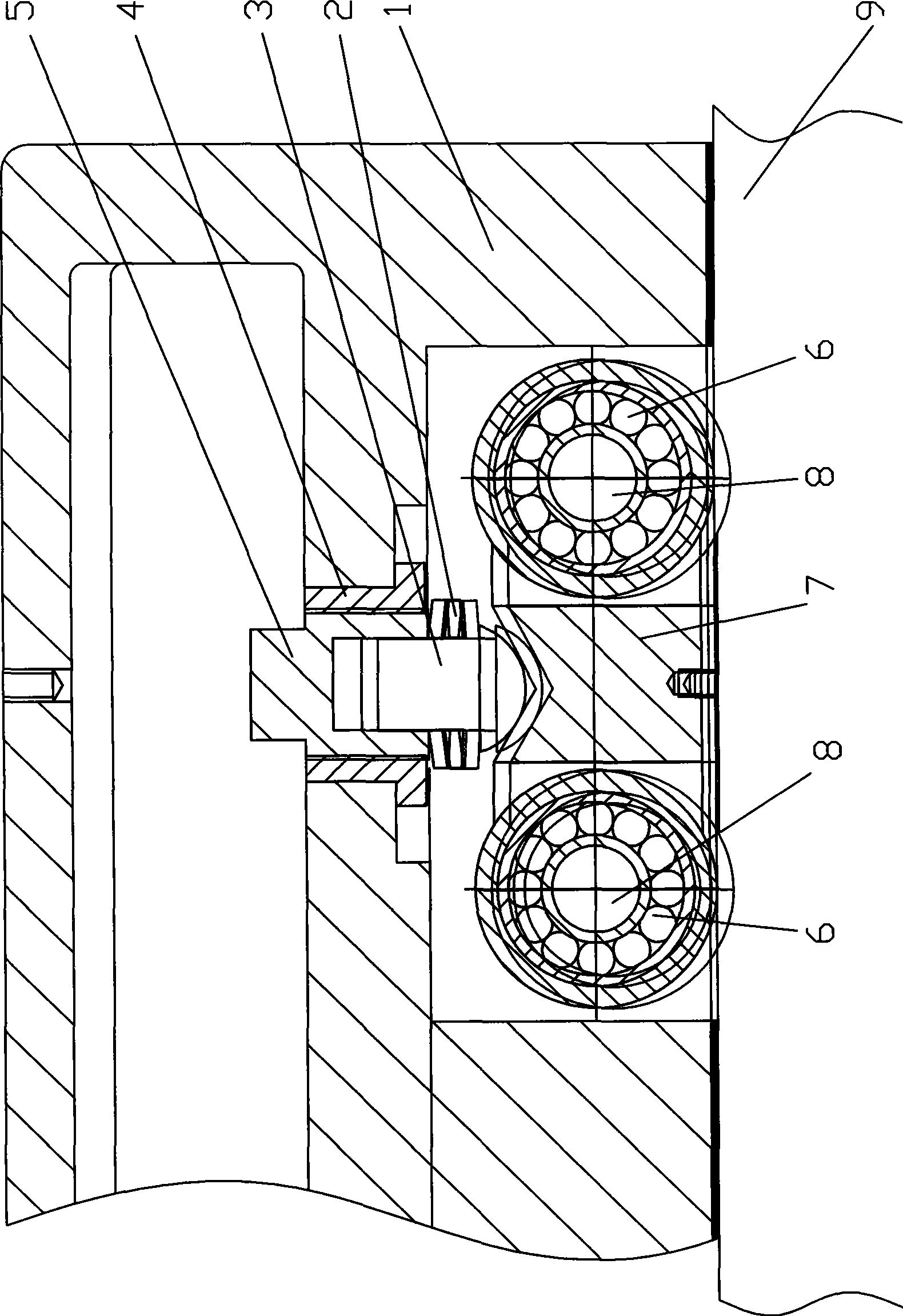

The invention discloses a controllable high-frequency-response probe test moving device for microwave and millimeter wave chips. The controllable high-frequency-response probe test moving device comprises an industrial personal computer, a control module, a driver, a servo motor, a precision displacement device and a grating ruler. The precision displacement device comprises a precision workbench, a driver I, piezoelectric ceramics and a flexible hinge. The industrial personal computer is connected with the control module, the control module is connected with the driver, the driver is connected with the servo motor, the servo motor is connected with the driver through an encoder, the servo motor is connected with the precision workbench, the precision workbench is connected with the driver I, the driver I is connected with the piezoelectric ceramics, the piezoelectric ceramics is connected with the flexible hinge, the flexible hinge is connected with the workbench, the workbench is connected with the control module through the grating ruler, the driver I is connected with the control module, prior one-time positioning is changed into coarse positioning in which the motor drives a lead screw, and the precision displacement device belongs to secondary positioning of fine positioning. A fine positioning system is high in test speed, and on the premise of not affecting test acceptability, test cycle is shortened greatly, efficiency and productivity are improved, and test cost is reduced.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

Sliding guide rolling unloading device

InactiveCN101508076AImprove contact stiffnessReduce friction areaLarge fixed membersEngineeringLubrication

The invention discloses a sliding device, in particular a slide guide rail rolling and unloading device for machine tool equipment. The device comprises a guide rail and a slide seat (1) which is positioned on the guide rail and can slide relative to the guide rail, and is characterized in that: at least three positions matched with the guide rail on the bottom surface of the slide seat (1) are provided with roller wheels (6), and the circumferential lateral surfaces of the roller wheels (6) are contacted with the upper surface of the guide rail positioned under the slide seat (1). In the device, as the slide seat and the guide rail do not directly contact, are supported by the roller wheel, and slide, the device realizes line contact of the roller wheel and the guide rail, greatly reduces the mutual friction area, reduces moving resistance, saves energy and lowers the requirement on lubrication compared with a sliding mode of surface contact.

Owner:DALIAN MACHINE TOOL GROUP CO LTD

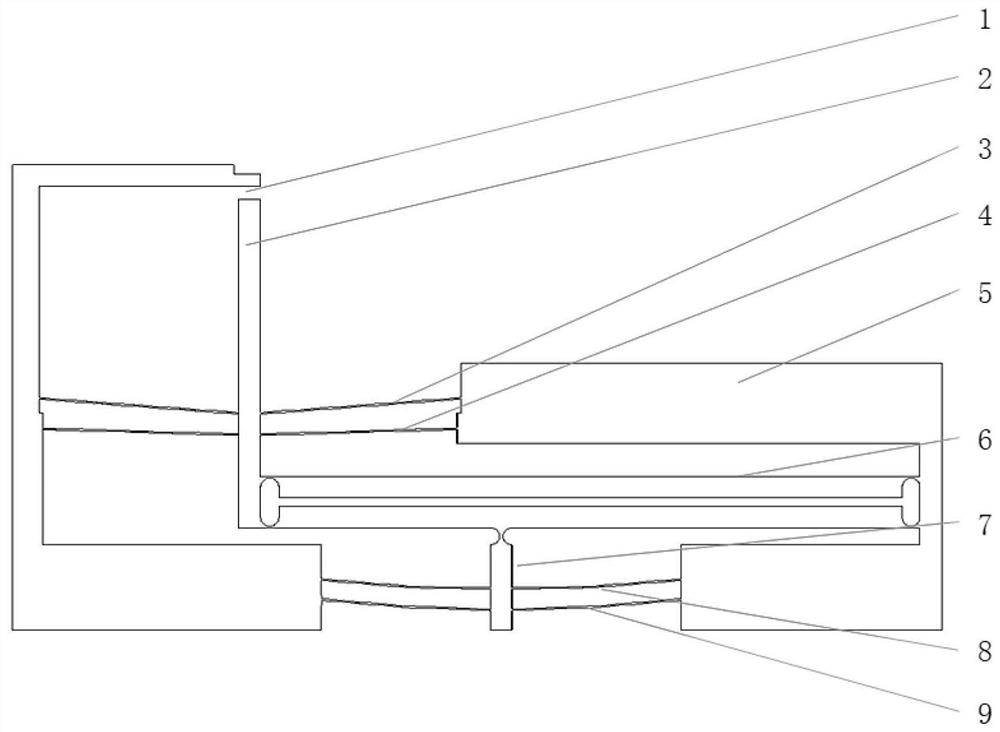

Compact tilt and vibration sensor and method for manufacturing same

InactiveUS20110088478A1Improve performanceHigh movement sensitivityLine/current collector detailsMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringConductive materials

A tilt and vibration sensor incorporating a plurality of electrodes and a conductive spherical. body which is turned on and off by the moving displacement of the spherical body, and which may be remarkably reduced in size and may have high performance and high operating sensitivity, high durability, and high reliability; and a method of manufacturing the sensor. The case (1) of the sensor comprises a case body (5) formed of a non-conductive material having such excellent gas-barrier property and heat resistance that can stop the transmission of gases which affects the on / off operation of the sensor due to the moving displacement of the conductive spherical body (4) and a cover body (7) sealing airtight the opening part (6) of the case body.

Owner:G DEVICE CORP

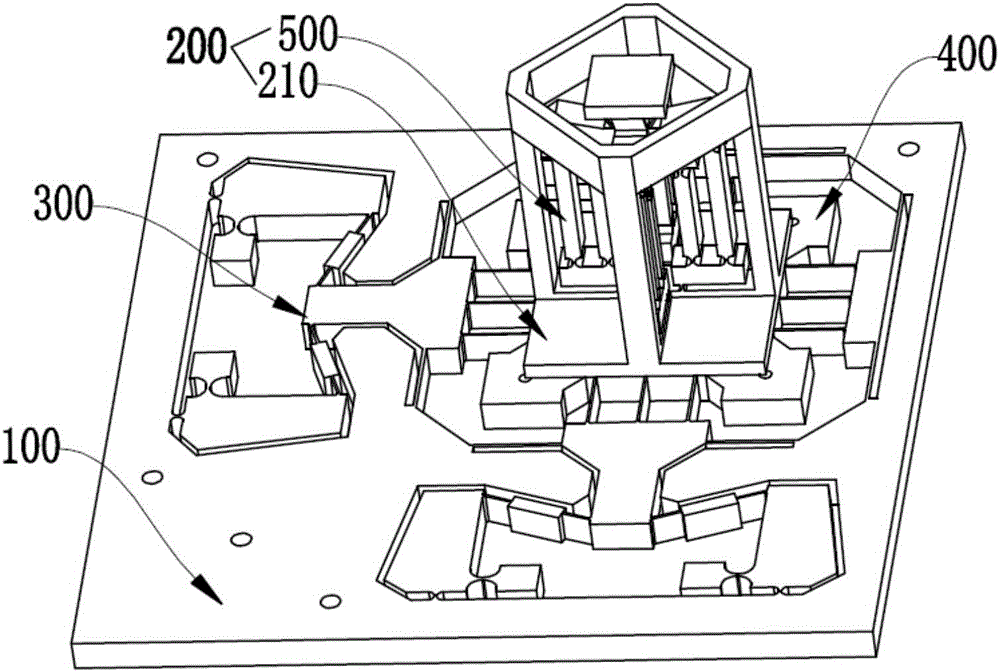

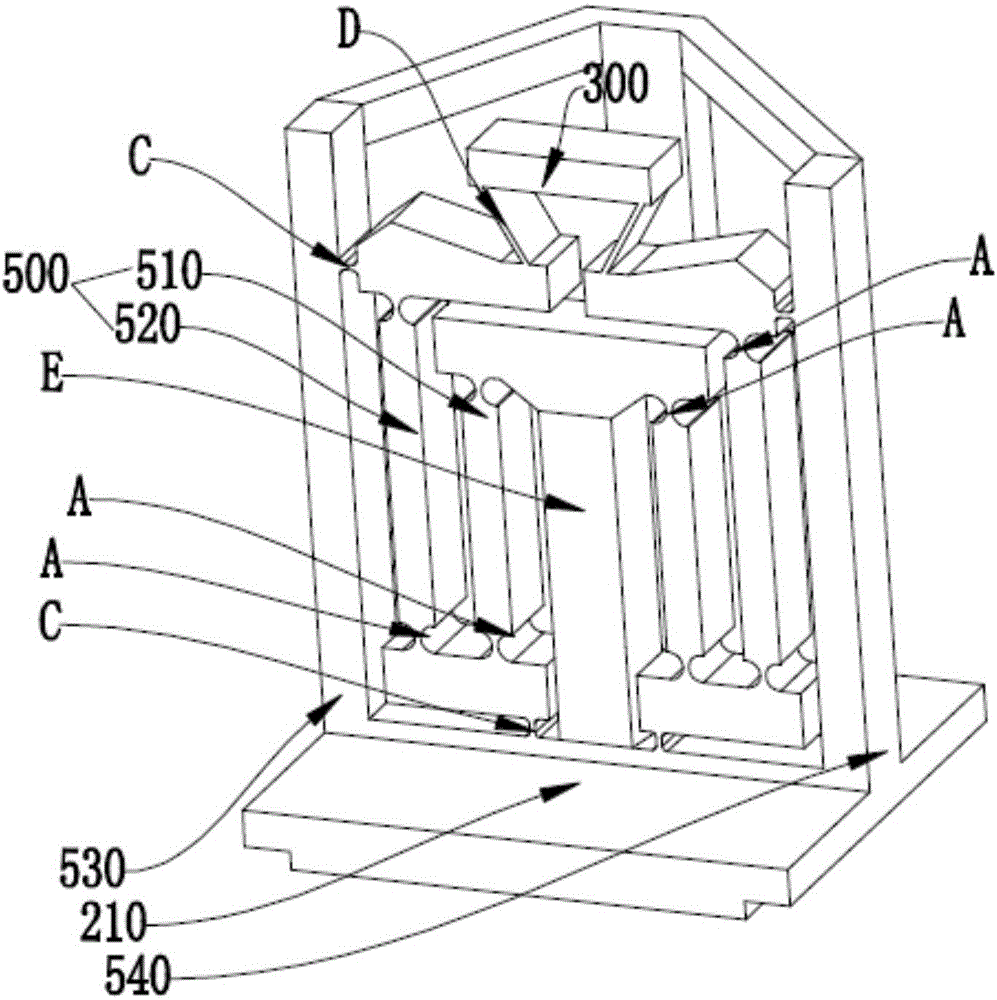

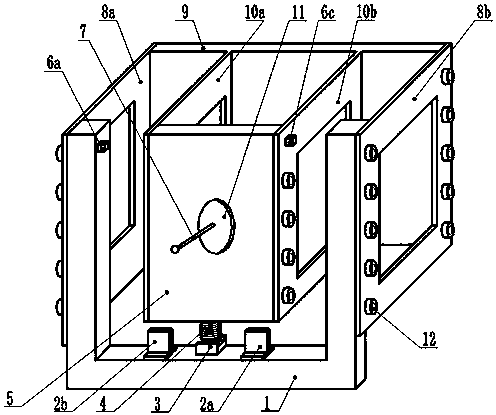

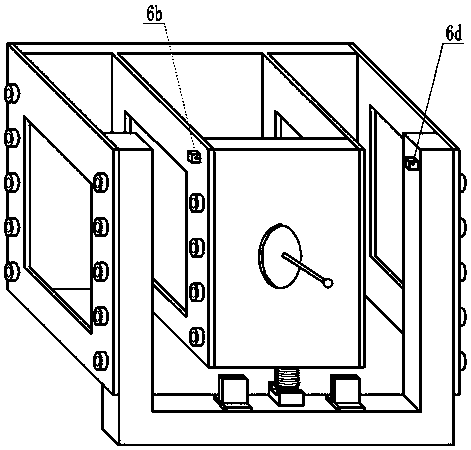

Three-way decoupled force measurement type piezoelectric fast tool servo device

PendingCN111890128AEnables decoupled measurementsHigh force measurement accuracyMeasurement/indication equipmentsApparatus for force/torque/work measurementReciprocating motionEngineering

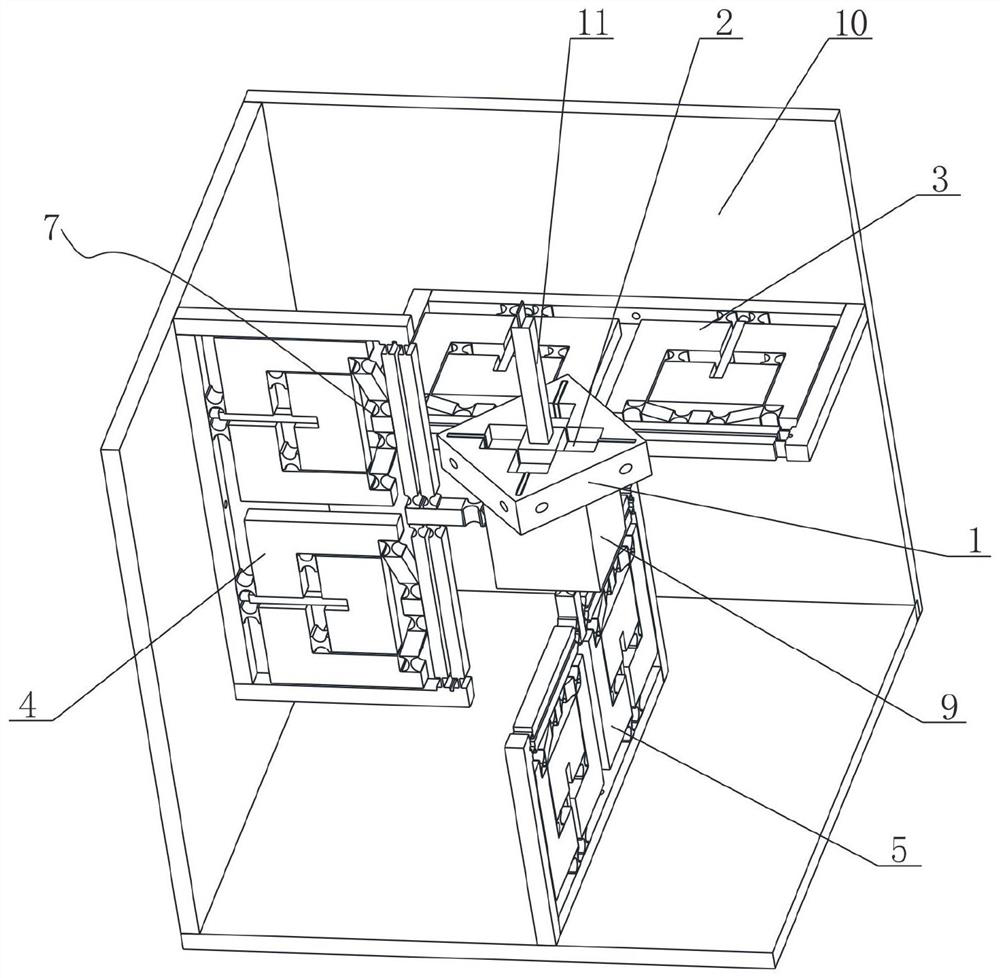

The invention provides a three-way decoupled force measurement type piezoelectric fast tool servo device, and relates to the technical field of ultra-precision machining. The device comprises a tool holder seat, an X-direction drive platform, a Y-direction drive platform and a Z-direction drive platform, wherein a three-way force measuring device for measuring the turning force of a tool in a decoupling mode is arranged in the tool holder seat, the X-direction drive platform, the Y-direction drive platform and the Z-direction drive platform are of same structures and all comprise flexible connectors connected with the tool holder seat, both sides of the flexible connectors are symmetrically connected with displacement amplifying mechanisms through flexible hinges, the displacement amplifying mechanisms are connected with piezoelectric drivers, the displacement amplifying mechanisms comprise multi-stage amplifying mechanisms connected through flexible hinges, and displacement detectingmechanisms are arranged on the flexible connectors. The device solves the problems that a fast tool servo device in the prior art is difficult to simultaneously achieve the large-stroke synchronous reciprocating movement in the X-direction, the Y-direction and the Z-direction, and the cutting force and the movement position in the machining process cannot be simultaneously detected, resulting in low machining quality.

Owner:HENAN POLYTECHNIC UNIV

XYZ three-freedom-degree precise positioning device

ActiveCN106737597ALarge rotation rangeSatisfies the input coupling phenomenonProgramme-controlled manipulatorFlexible MechanismsEngineering

An XYZ three-freedom-degree precise positioning device comprises an XY motion base and a Z axis motion module; the Z axis motion module is mounted on the XY motion base, and the XY motion base comprises a base plate; displacement devices and a motion platform are arranged on the base plate, two displacement devices are located on the X axis and the Y axis correspondingly, and are flexible mechanisms with piezoelectric ceramics, and each displacement device comprises a left lever, a right lever, an input end mounting block and an output end mounting block, first containing grooves are formed in the base plate, the displacement devices are mounted in the first containing grooves, the lower ends of the left levers and the lower ends of the right levers are hinged to the lower groove walls of the first containing grooves through hinges, the input end mounting blocks are hinged to the lower portions of the right sides of the left levers and the lower portions of the left sides of the right levers through hinges, the output end mounting blocks are hinged to the upper portions of the right sides of the left levers and the upper portions of the left sides of the right levers through straight beam type flexible hinges, and the output end mounting blocks are mounted on the motion platform through the straight beam type flexible hinges.

Owner:GUANGDONG UNIV OF TECH

Compact tilt and vibration sensor and method for manufacturing the same

InactiveUS7845234B2Improve performanceHigh movement sensitivityLine/current collector detailsMaterial analysis using sonic/ultrasonic/infrasonic wavesParticulatesEngineering

Provided are a tilted vibration sensor incorporating a plurality of electrodes and a conductive spherical body which is turned on and off by the moving displacement of the spherical body, and which may be remarkably reduced in size and may have high performance and high operating sensitivity, high durability, and high reliability; and a method of manufacturing the sensor. The case (1) of the sensor comprises a case body (5) formed of a non-conductive material having such excellent gas-barrier property and heat resistance that can stop the transmission of gases which affects on the on / off operation of the sensor due to the moving displacement of the conductive spherical body (4) and a cover body (7) sealing airtight the opening part (6) of the case body. In the method of manufacturing the vibration sensor, moisture and particulate impurities affecting the on / off operation are removed from the hollow part (2) of the case (1), and the hollow part is evacuated.

Owner:G DEVICE CORP

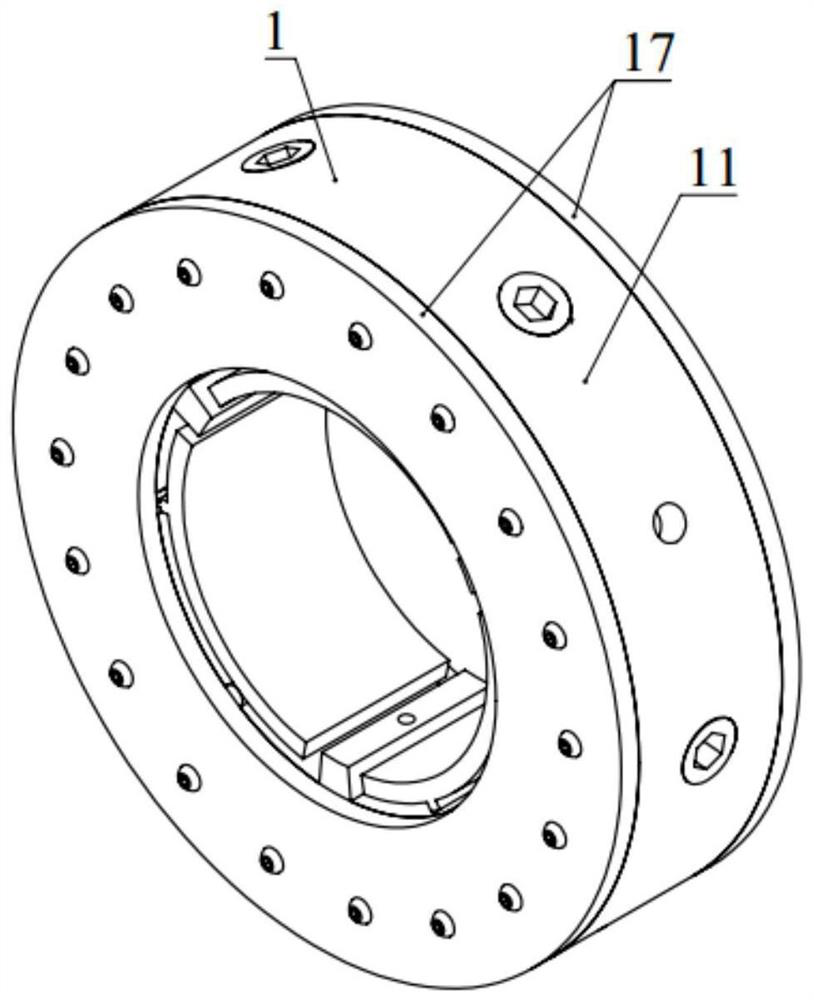

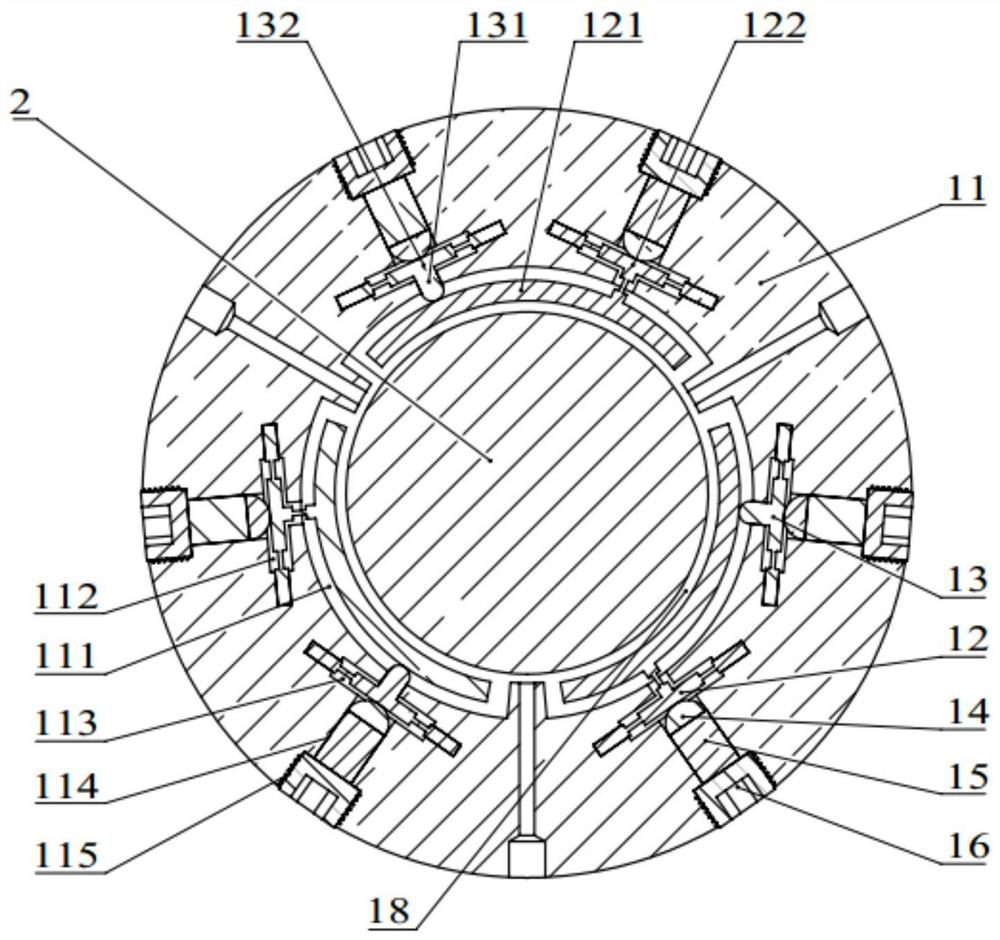

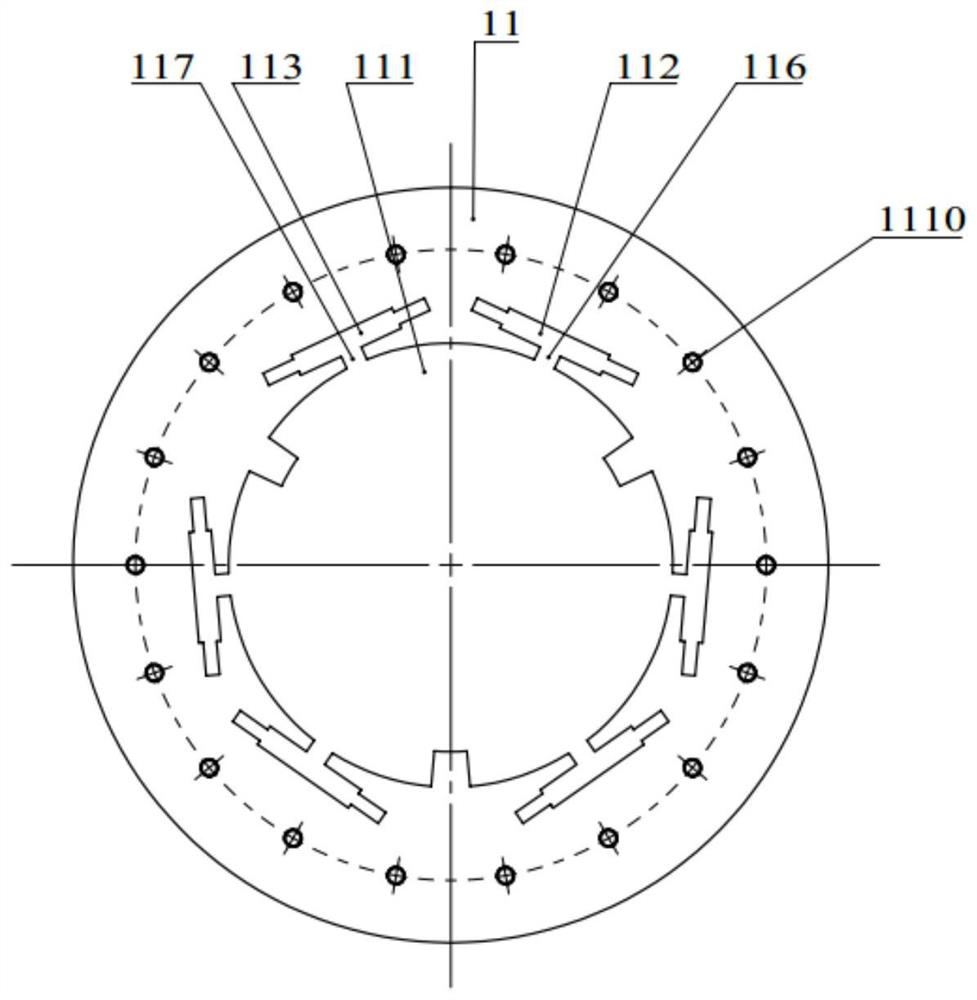

Tilting pad bearing capable of actively controlling oil film gap

ActiveCN113669362AImprove working conditionReduce local supportHydro energy generationSliding contact bearingsRadial motionEngineering

The invention discloses a tilting pad bearing capable of actively controlling an oil film gap. The bearing comprises a body, a flexible hinge bearing bush, a flexible hinge push rod, a thrust hemisphere, a piezoelectric ceramic driver, a bolt and a cover plate, the flexible hinge bearing bush comprises a bearing bush and a flexible hinge mechanism A; the flexible hinge push rod comprises a push rod mechanism and a flexible hinge mechanism B; at least three bearing bush cavities are formed in the circumferential direction of the inner cylindrical surface of the body, and a hinge cavity A and a hinge cavity B are further formed in each bearing bush cavity; the bearing bush is placed in the bearing bush cavity, the flexible hinge mechanism A is placed in the hinge cavity A, and the flexible hinge mechanism B is placed in the hinge cavity B; cylindrical cavities communicated with the hinge cavities A and the hinge cavities B are further formed in the body, and piezoelectric ceramic drivers are placed in the cylindrical cavities; the piezoelectric ceramic driver is controlled to drive the flexible hinge mechanism A and the flexible hinge mechanism B to move in the radial direction, so that the radial displacement and the swing angle of the bearing bush are controlled, and active control over the oil film gap can be achieved.

Owner:QINGDAO UNIV OF SCI & TECH

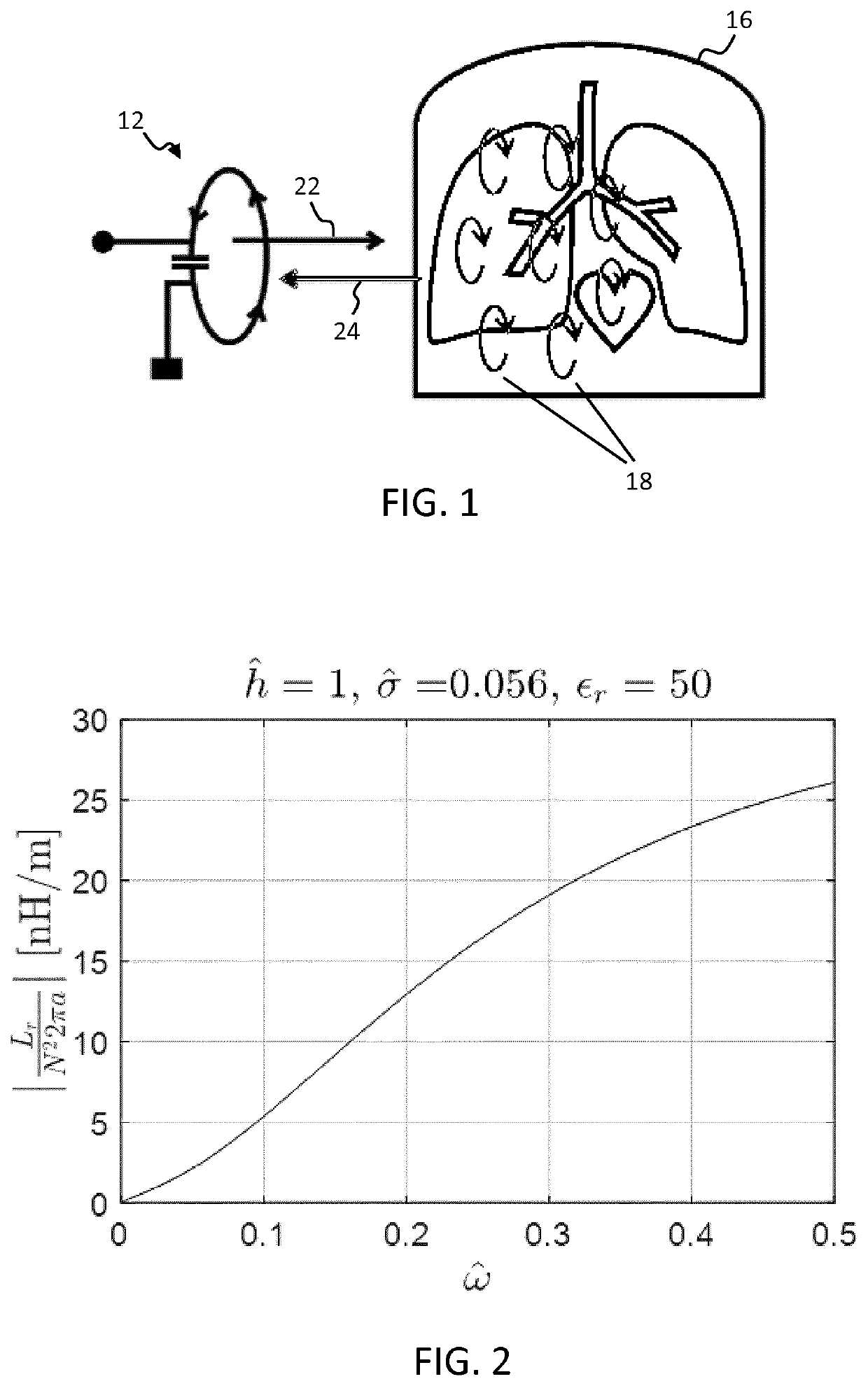

Inductive sensing system for sensing electromagnetic signals from a body

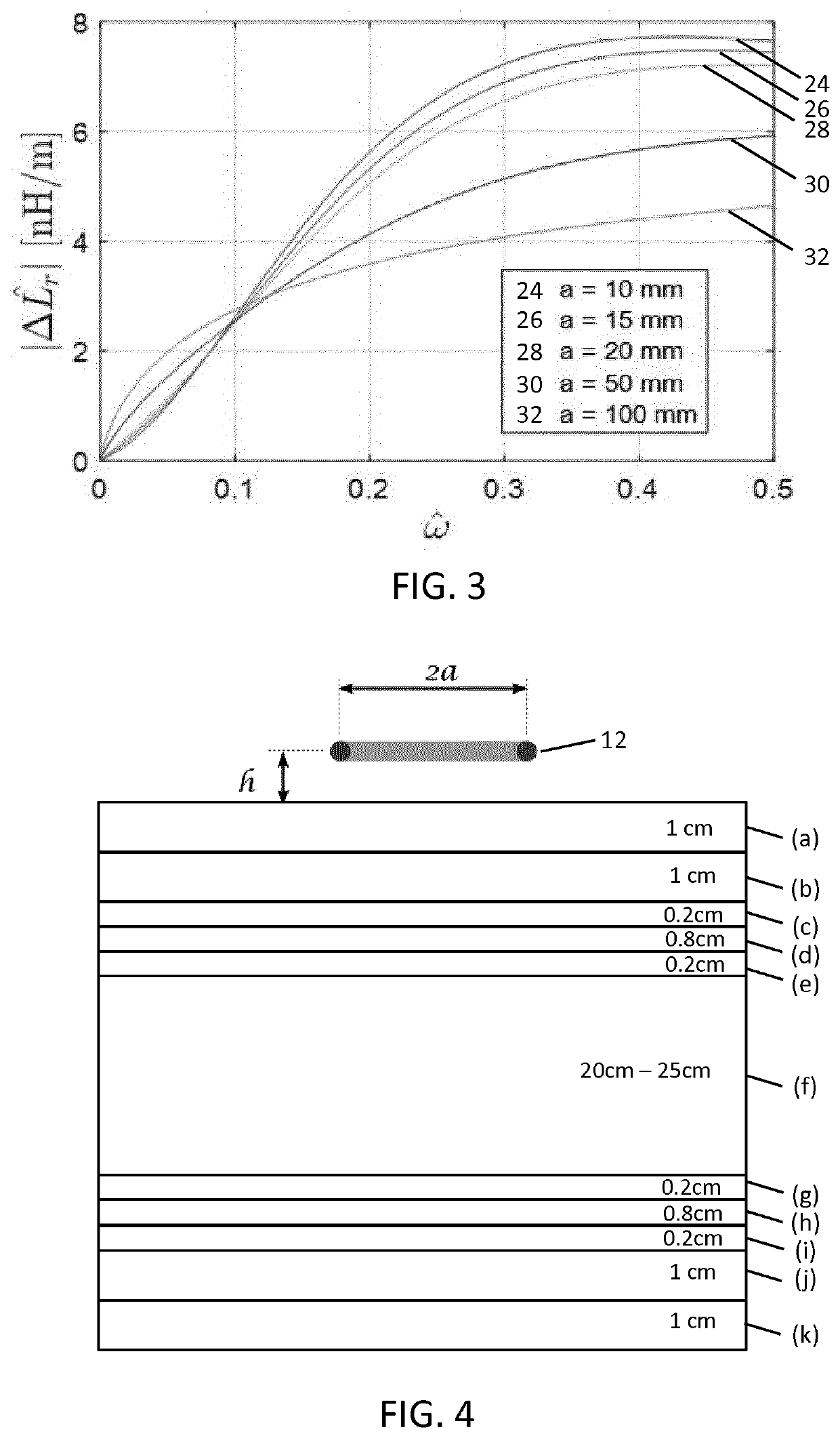

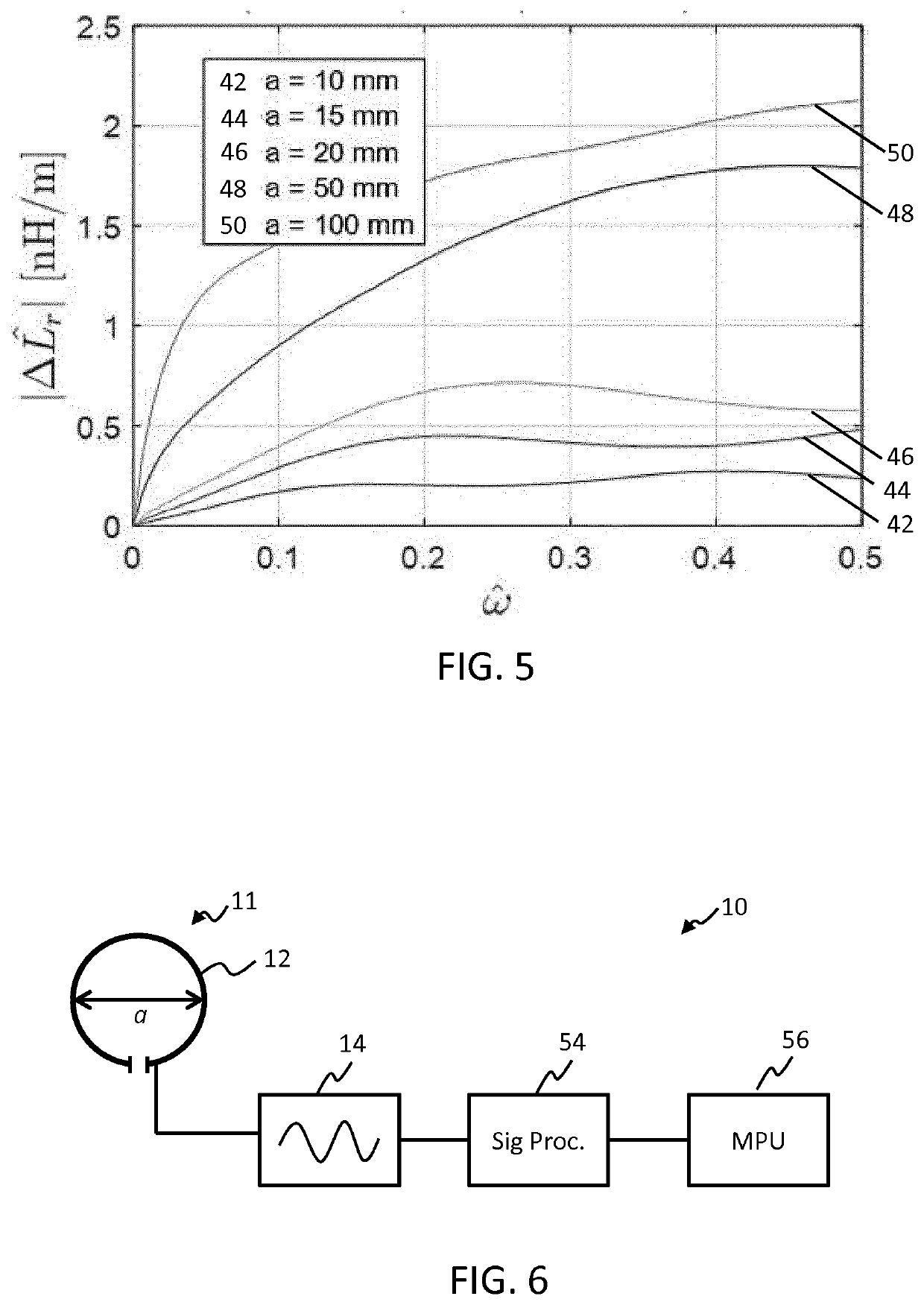

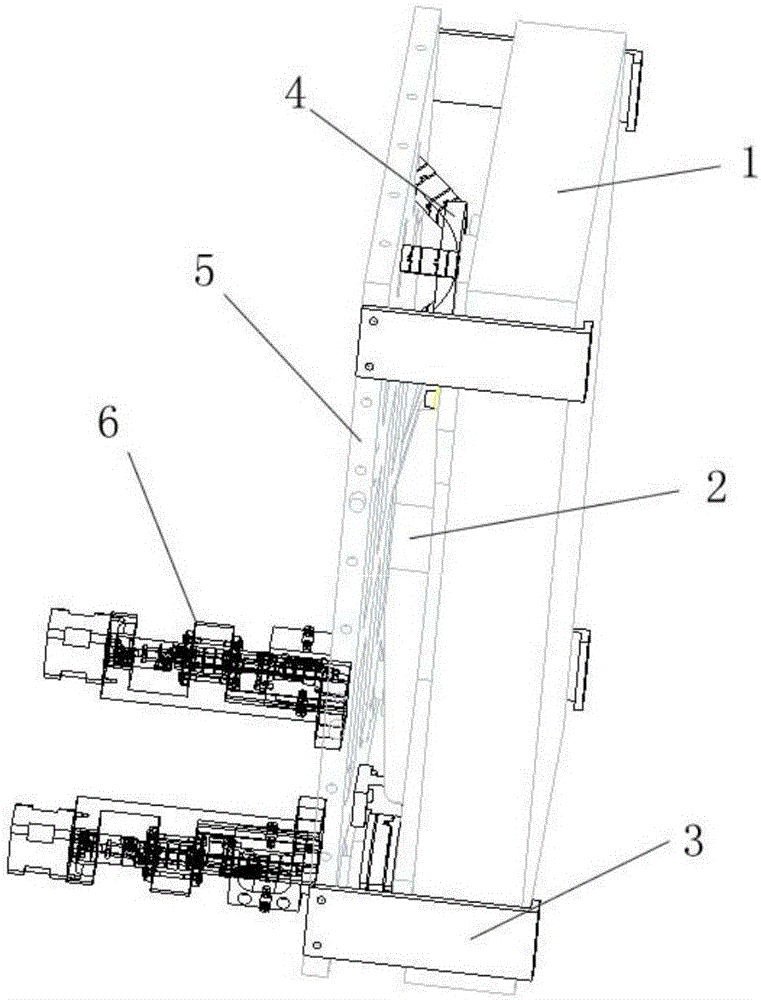

ActiveUS20190336014A1Reduce energy consumptionReduce required computing powerAuscultation instrumentsDiagnostic recording/measuringElectromagnetic shieldingLength wave

The invention provides a magnetic inductive sensing system for sensing electromagnetic signals emitted from a body in response to electromagnetic excitation signals applied to the body. The electromagnetic signals are generated and sensed by the same loop resonator which comprises a single-turn loop antenna and a tuning capacitor. The loop antenna of the resonator and a signal generation means for exciting the resonator to generate excitation signals are together configured so as to optimize the value of a ratio between the radial frequency of the generated electromagnetic excitation signals and a reference frequency of the antenna, where the reference frequency is the frequency for which one wavelength of the generated excitation signals (waves) matches the circumferential length of the antenna. This ratio, which corresponds to a normalized radial frequency of the generated excitation signals, is maintained between a value of 0.025 and 0.50.

Owner:KONINKLJIJKE PHILIPS NV

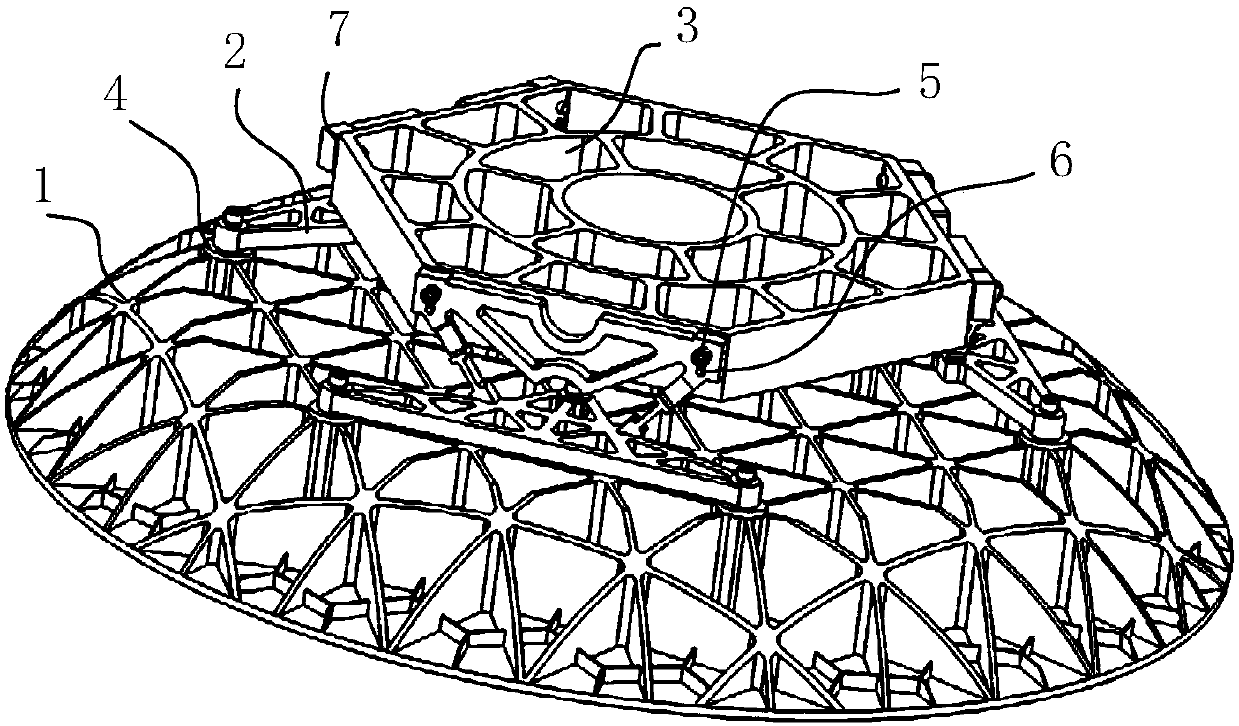

Back support form support structure for large-aperture reflector

PendingCN106680965AGuaranteed Surface AccuracyGuaranteed flexibilityMountingsCircular discEngineering

The invention discloses a back support form support structure for a large-aperture reflector. The back support form support structure comprises an optical lens, a rib plate and a back plate, wherein the rib plate is parallel with the back plate, a three-claw flexible hinge, a disc flexible hinge I and a disc flexible hinge II are arranged between the rib plate and the back plate, and the back plate is provided with an anti-rotation flexible hinge, four protecting pieces and two drive components; three blind holes with precise expansion bushings are formed in the back of the optical lens, and the three precise expansion bushings are fixedly connected with the rib plate; the front portion of the three-claw flexible hinge is connected with the rib plate, and the rear portion of the three-claw flexible hinge is connected with the back plate; one ends of disc flexible hinge I and the disc flexible hinge II are in one-to-one correspondence to the two drive components and are connected through a connector, the other end of the disc flexible hinge I and the other end of the disc flexible hinge II are connected with the rib plate, and the anti-rotation flexible hinge is connected to the lateral side of the disc flexible hinge II; the four protecting pieces are connected to the back plate through lifting bolts, and the optical lens is located among the four protecting pieces. The back support form support structure is simple, stable in motion, free of friction, free of gaps, high in motion sensitivity and high in reliability and does not need lubrication.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

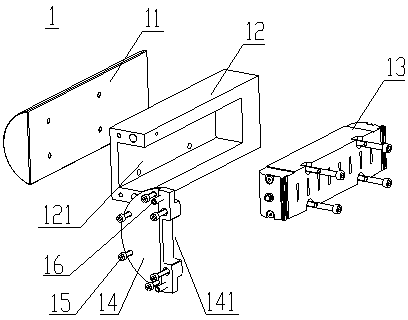

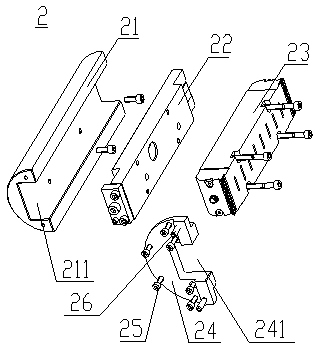

Light-small type space laser communication terminal rough tracking device

ActiveCN108039913AReduce volumeReduce weightCosmonautic vehicle trackingSatellite communication transmissionEngineeringOptical communication

For solving the technical problem that the existing rough tracking device is unsuitable for a small-satellite optical communication terminal due to large volume, large weight and low precision, the invention provides a light-small type space laser communication terminal rough tracking device. An optical transmitter and receiver is connected with a base through a flexible hinge, a two-point drivingadjusting way is performed on the optical transmitter and receiver by using a linear actuator, so that the problems of large volume and large weight caused by using pitching azimuth frame are avoided; since the linear actuator is large in thrust, small in volume, light in weight, and high in displacement precision, the weight can be controlled within 1kg, and the weight of the flexible hinge is within 0.5Kg, and the total weight of the rough tracking device can be controlled at 2-3Kg by adding the necessary connection joints.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

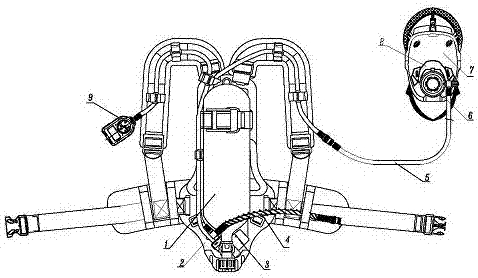

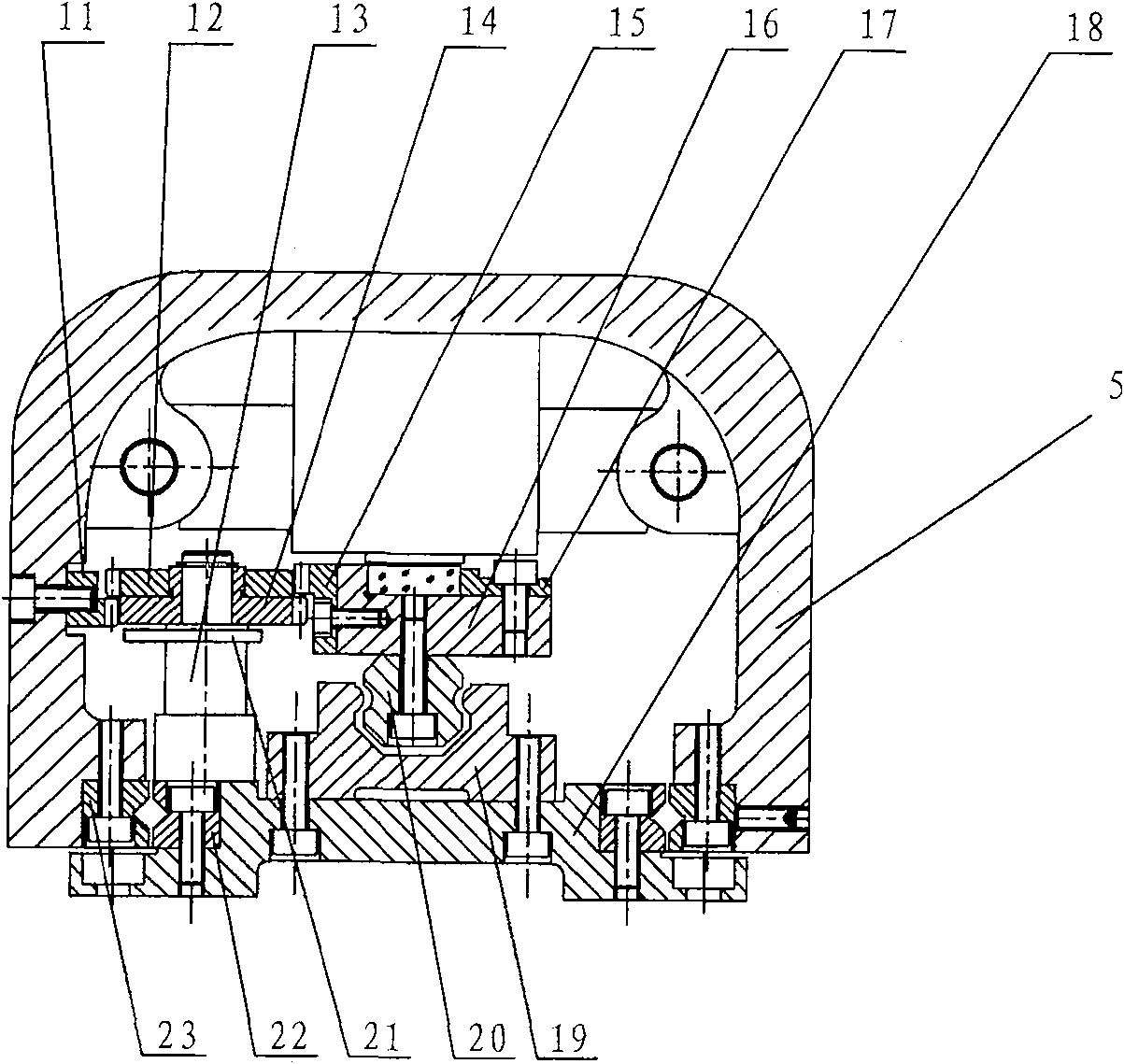

Positive pressure type air respirator

InactiveCN107096142AClose reliableClose smoothlyBreathing masksFire rescuePositive pressureEngineering

The invention discloses a positive pressure type air respirator. The positive pressure type air respirator comprises a backboard assembly and an air bottle assembly fixed on the backboard assembly. The air bottle assembly is leaded to a respirator air supply valve through a pressure reducing valve and a face mask air supply hose. An air-guide pipe sliding seat is fixedly installed on the respirator air supply valve. An air-guide pipe is slidably installed on the air-guide pipe sliding seat. The inner end of the air-guide pipe is connected with the outer end of an air supply pull rod. The inner end of the air supply pull rod is movably connected on a locking hook. An air supply pullback spring is installed between the locking hook and an air supply valve body. A locking board is fixedly installed on the air supply valve body. A locking hole is arranged on the locking board. The hook part of the locking hook corresponds to the position of the locking hole. The air supply valve body is hinged to an air supply lever. The other end of the air supply lever opposite to the hinged end is connected on a membrane. The air supply lever contacts with and is connected with the outer end of the air supply pull rod. The positive pressure type air respirator is sensitive in movement, low in respiratory resistance, and good in sealing property, and is suitable for all kinds of positive pressure type air respirator.

Owner:DONGTAI CITY JIANGHAI LIFESAVING & FIREFIGHTING EQUIP

Lateral pre-tightening type rolling and sliding composite guide rail structure

ActiveCN103846682AHigh sensitivityGuaranteed carrying capacityLarge fixed membersEngineeringBearing surface

The invention discloses a lateral pre-tightening type rolling and sliding composite guide rail structure. The lateral pre-tightening type rolling and sliding composite guide rail structure comprises guide rails, a sliding block and a lateral pre-tightening mechanism, wherein the guide rails are mutually matched, the sliding block comprises two end-surface baffle plates and a sliding block body, the bottom part of the sliding block is provided with a groove which is matched with the guide rails, a first guide rail soft belt is arranged between the upper surface of the groove and normal-direction bearing surfaces of the guide rails along the length direction of the guide rails, a second guide rail soft belt is arranged between the bottom surface of the groove and lateral bearing surfaces of the guide rails along the length direction of the guide rails, the upper left corner of the groove is symmetrically provided with two U-shaped grooves along the length direction of the sliding block, a positioning convex shoulder is arranged between the two U-shaped grooves, and the two U-shaped grooves are respectively and internally provided with rolling blocks which are matched with the guiding surfaces of the guide rails. The lateral pre-tightening type rolling and sliding composite guide rail structure disclosed by the invention integrates the advantages of rolling guide rails and sliding guide rails, the moving resistance can be reasonably and effectively reduced while the guiding and positioning accuracy of moving guide rails and the bearing capacity of the moving guide rails are ensured under the situation of heavy load cutting, and the sensitivity, the rigidity and the vibration resistance of the moving guide rails are increased.

Owner:NANJING UNIV OF SCI & TECH

Rolling and sliding compound guide track and manufacturing method thereof

InactiveCN102528467BGuaranteed guide accuracyHigh movement sensitivityLarge fixed membersProcess efficiencyEngineering

The invention discloses a rolling and sliding compound guide track and a manufacturing method thereof. The rolling and sliding compound guide track comprises a rolling and sliding positioning compound guide track and a rolling guide track, wherein the rolling and sliding positioning compound guide track comprises a first positioning block, a second positioning block, a first rolling body and a first positioning baffle plate, the first rolling body is sequentially fixedly connected with the second positioning block and the first positioning block, and the outward surface of the first positioning block is of a circular arc surface; and the rolling guide track comprises a third positioning block, an adjusting wedge block, a second rolling body and a second positioning baffle plate, wherein the second rolling body is sequentially fixedly connected with the adjusting wedge block and the third positioning block, and the outward surface of the third positioning block is of the circular arc surface. The rolling and sliding compound guide track provided by the invention can ensure the guide precision of motion of a ram and the bearing capacity of the guide track, simultaneously reduce the friction force between the ram and a transmission mechanism, and upgrade the sensitivity, the rigidity and the vibration resistance of the motion of the ram by combining the advantages of a rolling guide track and a sliding guide track; and furthermore, not only geometric tolerance requirement of a guide track mounting groove is ensured, but also processing efficiency can be greatly improved.

Owner:SANY GRP

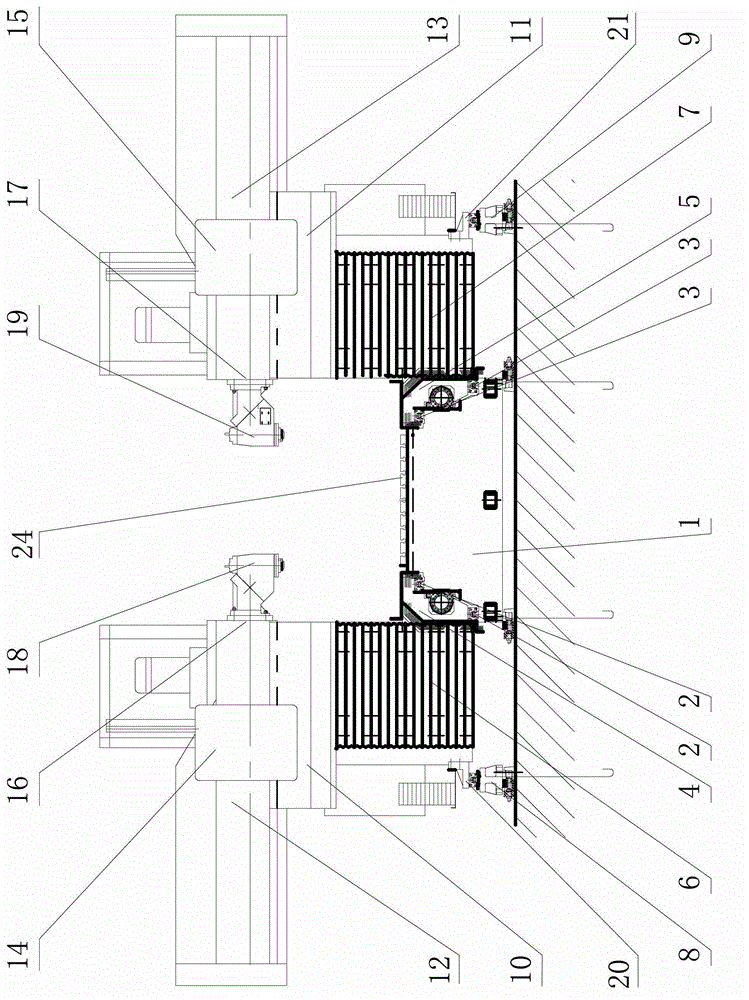

Moving post double-side ram lathe body milling machine

InactiveCN102873382AImprove rigidityGuaranteed Longitudinal AccuracyAutomatic control devicesMilling machinesGravity centerEngineering

The invention discloses a moving post double-side ram lathe body milling machine, which comprises a work bench base mounted to a ground foundation, left and right upright posts arranged at the left and right sides of the work bench base, left and right lifting slide seats arranged on the left and right upright posts, left and right rams arranged on the left and right lifting slide seats, left and right main shafts mounted to front ends of the left and right rams, and left and right mill heads mounted to the left and right main shafts, wherein the left and right upright posts are respectively mounted in position through left and right longitudinal orientation guide rails and left and right longitudinal auxiliary guide rails; the left and right longitudinal orientation guide rails are arranged on two steps inwardly formed on the left and right side faces of the work bench base in a manner of being higher in the front position and lower in the back position; and the left and right longitudinal auxiliary guide rails are mounted on the ground foundation and do not need limiting in the horizontal direction. By adopting the moving post double-side ram lathe body milling machine provided by the invention, the support span of the double upright posts can be increased to obtain higher support stability and effectively prevent disturbing moment produced by forward tilting of the gravity center of the upright posts due to forward movement of the rams.

Owner:GUILIN MACHINE TOOL

Axis part diameter high precision rapid measuring device

InactiveCN100562706CRealize measurementMovement is light and flexibleUsing optical meansGratingMeasurement device

The high-precision and fast measuring device for the diameter of shaft parts is characterized by a pair of left-end movable bayonet and right-end movable bayonet that can slide toward each other along the diameter direction of the measured shaft to form a bayonet-type probe. Between the moving bayonets, a grating measuring device for measuring the relative sliding distance between the left end moving bayonet and the right end moving bayonet is installed. The grating measuring device is composed of a grating ruler and a grating head. The moving direction is set in parallel and is fixedly connected with the right-end movable bayonet, and the grating head arranged opposite is fixedly connected with the left-end movable bayonet. The invention can realize fast and accurate measurement of the diameter of shaft parts, and can directly display the measurement results on the computer screen to realize the functions of data storage and transmission; it can also calculate the shaft parts by processing and analyzing the measurement data Data information such as cylindricity and conicity.

Owner:HEFEI UNIV OF TECH

Three pairs of sliding pair-spherical hinge-spherical hinge (3-PSS) mechanism-based coordinate measuring machine

InactiveCN102012211BReduce the error factorHigh measurement accuracyUsing optical meansGratingUniversal joint

The invention discloses a three pairs of sliding pair-spherical hinge-spherical hinge (3-PSS) mechanism-based coordinate measuring machine. The 3-PSS mechanism-based coordinate measuring machine is characterized in that: a three pairs of sliding pair-spherical hinge-spherical hinge parallel mechanism is provided; three motion sliding blocks are independently arranged on a pair of ball guide railswhich are arranged in parallel and can slide freely along the ball guide rails respectively; the three motion sliding blocks are connected with one end of each of three pairs of link rods through oneend of a universal joint respectively; the other end of each of three pairs of link rods are connected with a measuring moveable platform through the other end of the universal joint respectively; a measuring head is arranged on the lower plane of the measuring moveable platform; three indication gratings are fixedly connected to the three motion sliding blocks respectively; a scale grating and the pair of ball guide rails are arranged in parallel and are arranged on the guide rail mounting surfaces of guide rail cross beams; and the guide rail cross beams are suspended and fixedly connected to a pair of brackets. The 3-PSS mechanism-based coordinate measuring machine has high rigidity, a simple structure, high processing assembly property and low cost and can measure the three-dimensional space sizes, the shapes and the mutual positions of parts quickly and precisely.

Owner:合肥工大科教开发部

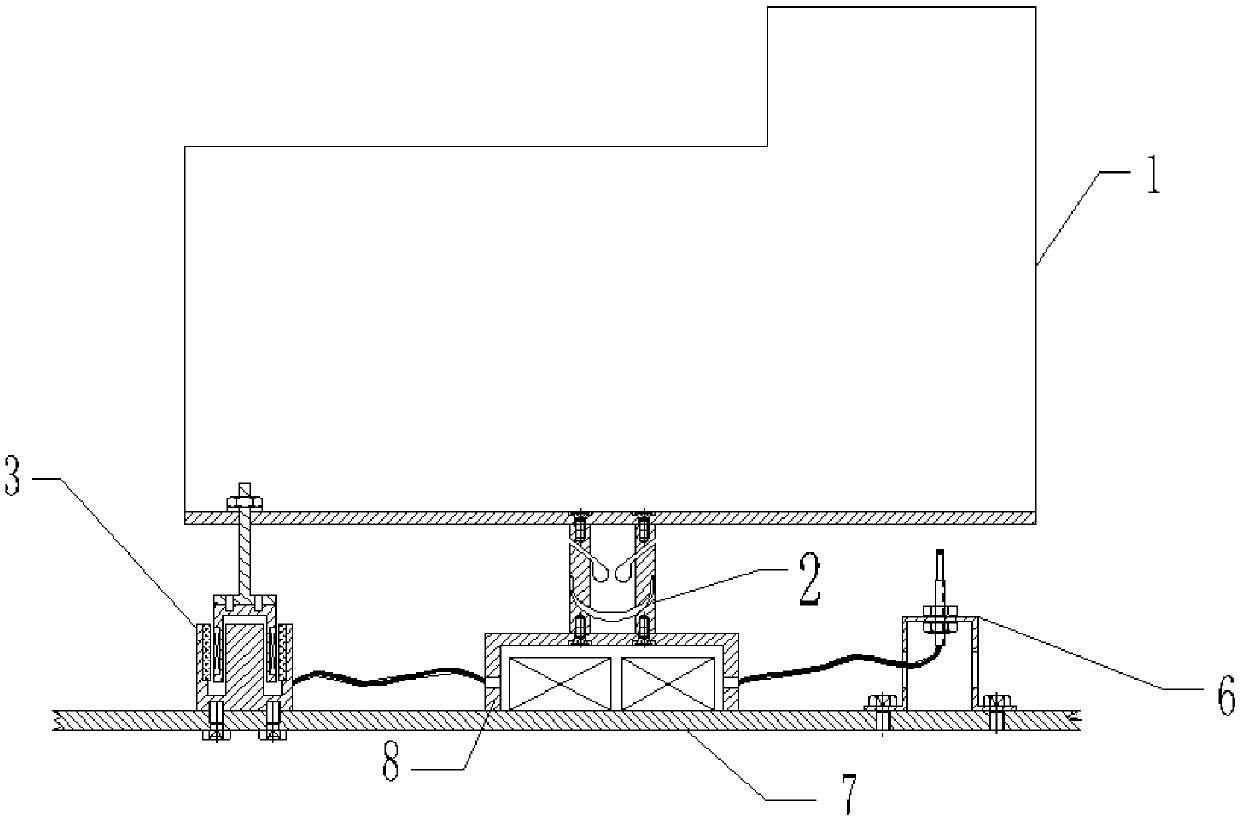

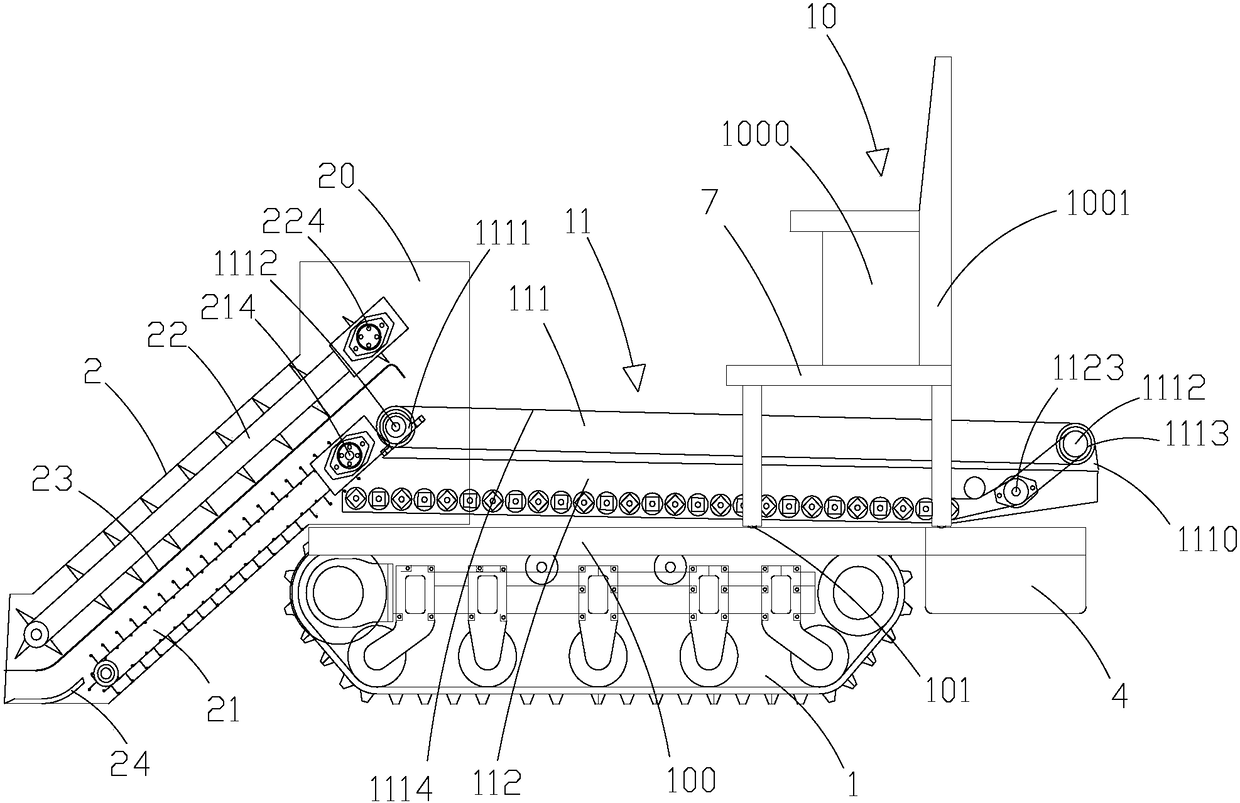

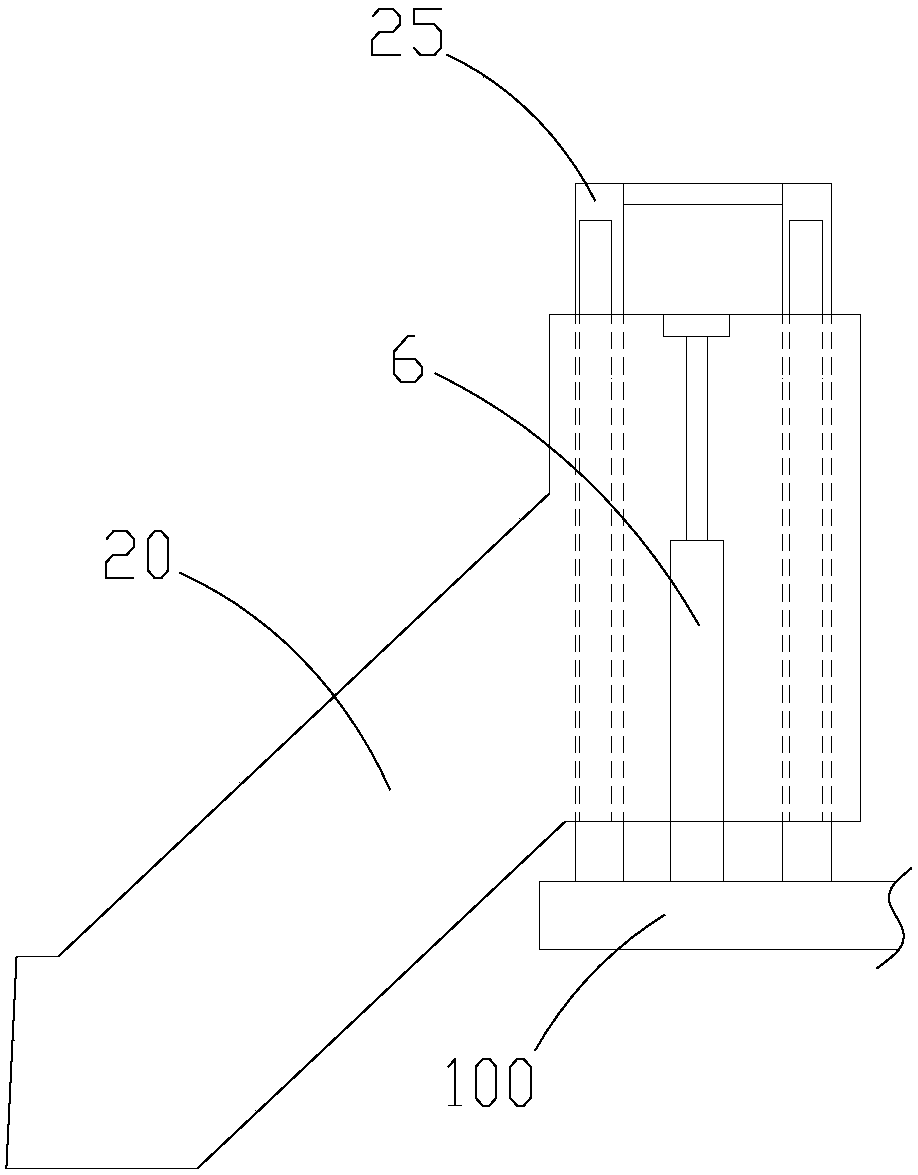

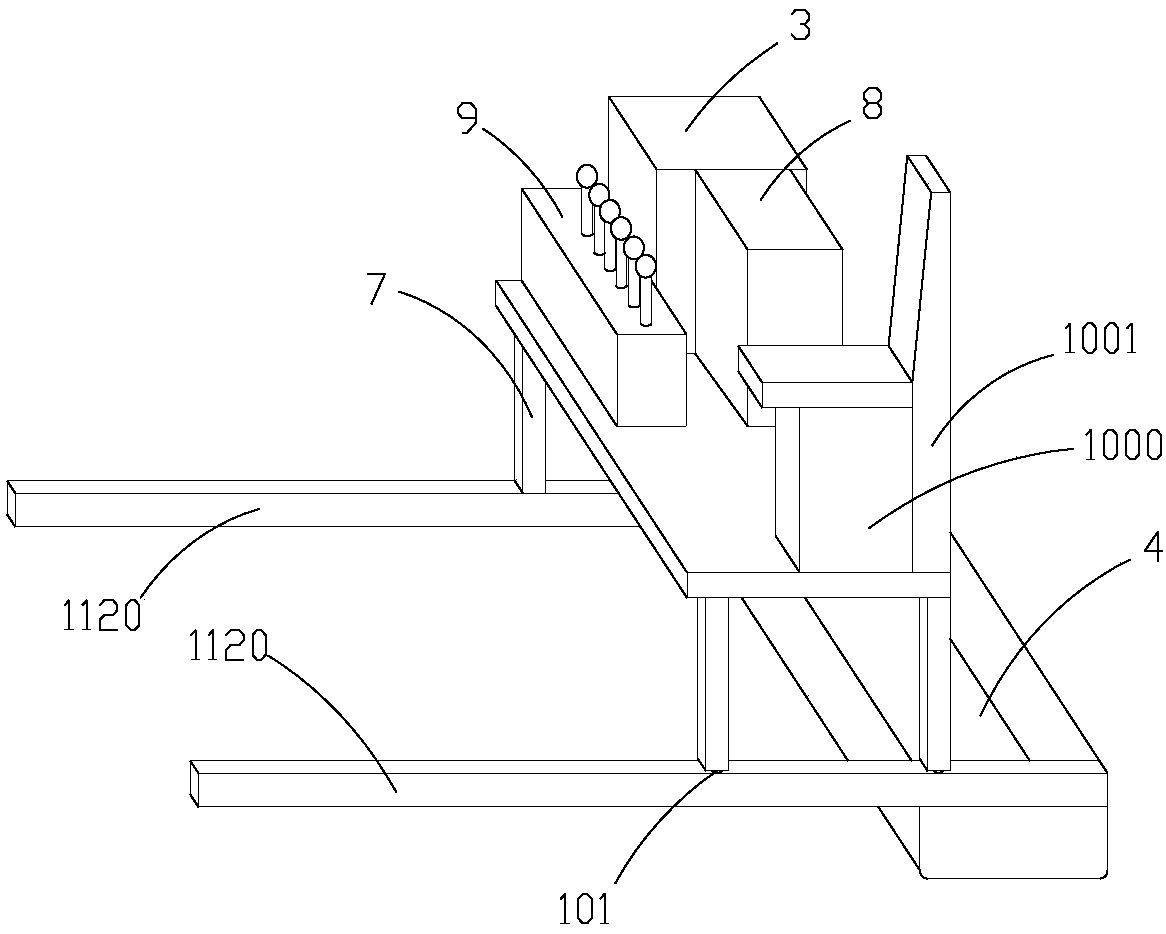

A layered water chestnut excavator

The invention discloses a layered water chestnut excavator, which comprises a traveling mechanism, an excavating device and a driving mechanism. Fixed frames are respectively arranged on both sides of the traveling mechanism, and a control frame is also provided on the fixed frame. , the control frame is provided with a driving mechanism, a hydraulic station, a hydraulic control valve and a driving position; the present invention also includes a transport mechanism, which is installed on a fixed frame and located above the traveling mechanism. The excavator can excavate the water chestnut fruit and the soil in layers, can improve the separation effect of the water chestnut and the soil, and is simple and reliable in operation.

Owner:安徽铸星机械制造有限公司

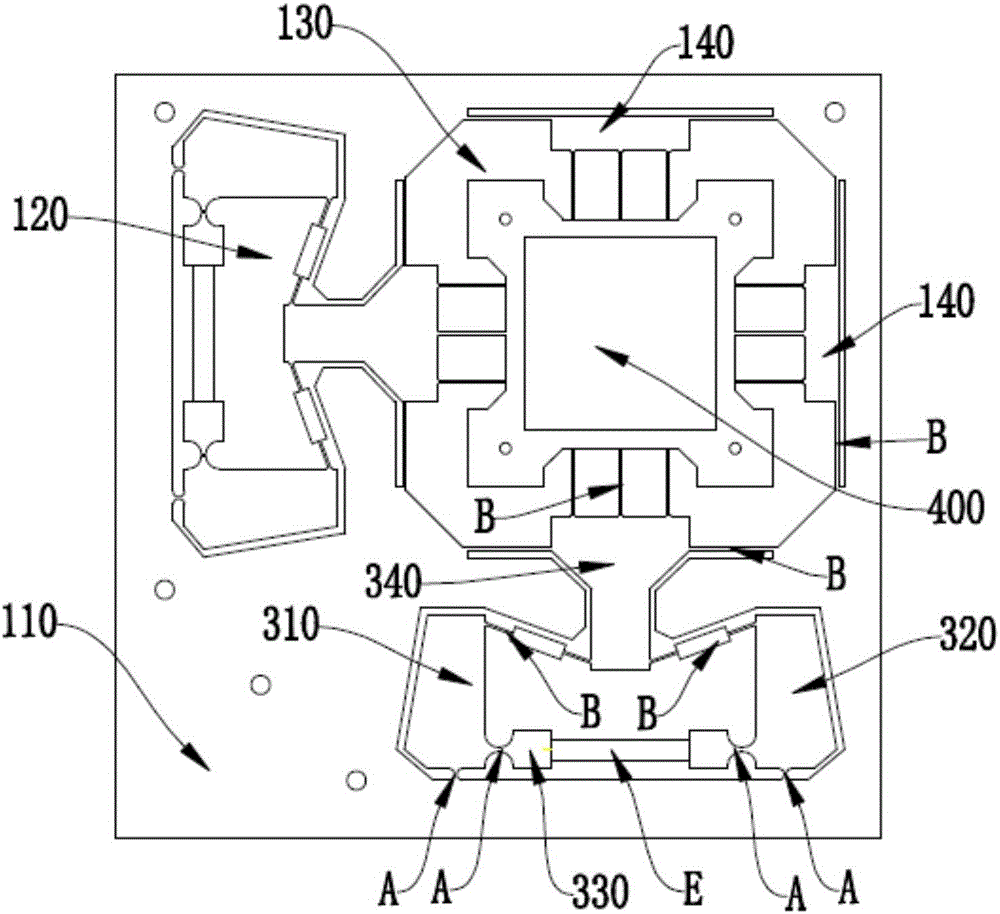

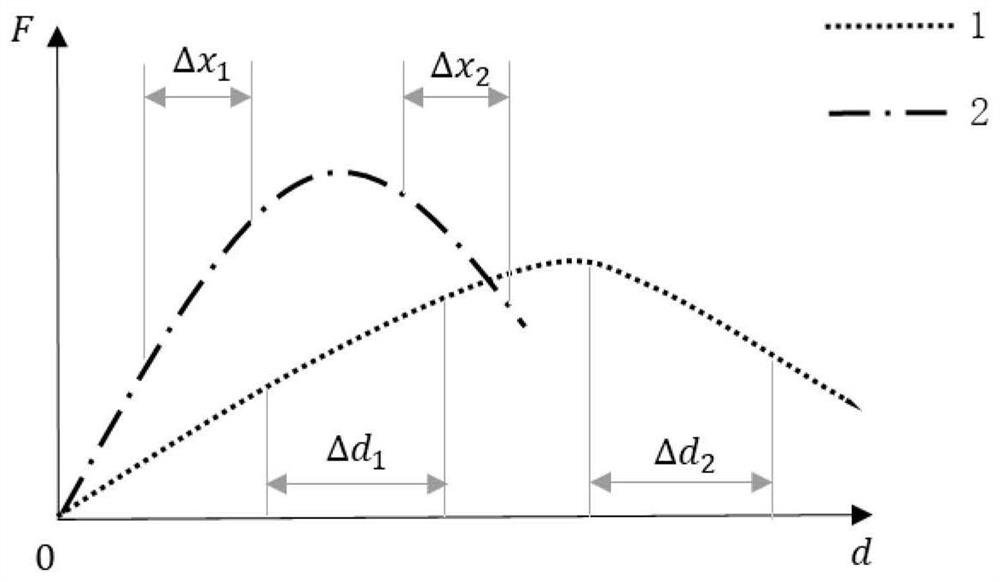

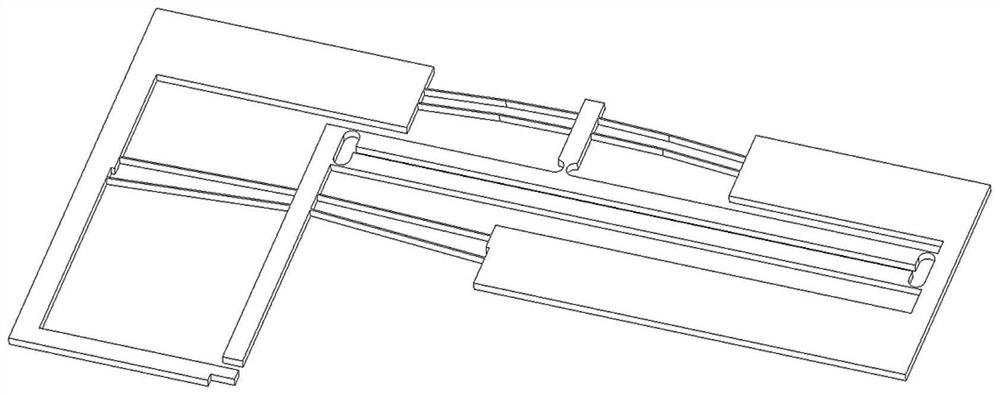

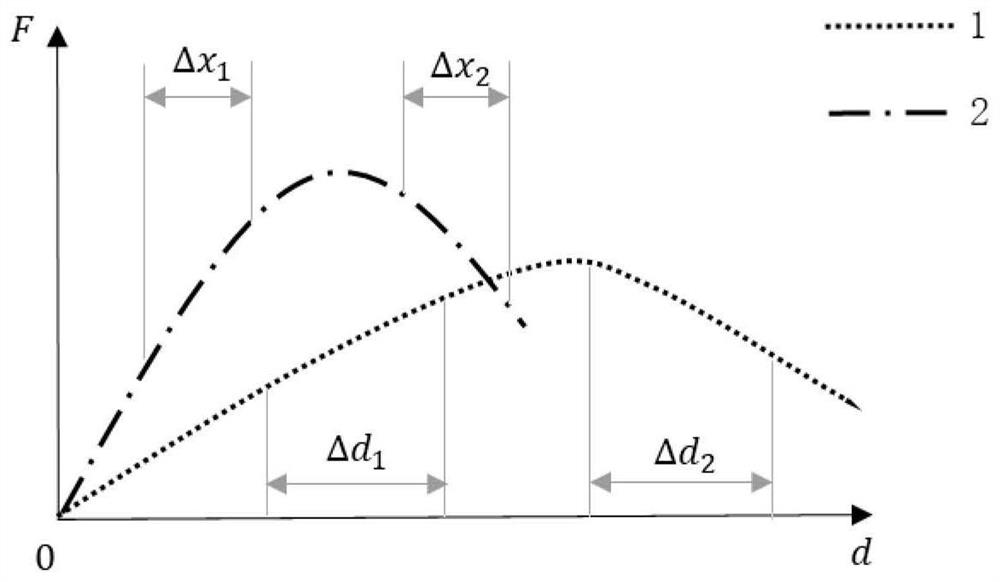

A continuous two-stroke two-stage constant force output micro gripper and its control method

ActiveCN111843980BAdaptable to multiple sizesReduce volumeProgramme-controlled manipulatorMicromanipulatorEngineeringNegative stiffness

The invention provides a continuous two-stroke two-stage constant force output micro-clamp and a control method, the clamp belongs to a flexible integrated mechanism. Among them, the constant force mechanism is composed of four sets of bistable negative stiffness beams and lever parts. The principle of the two-stage constant force mechanism is to obtain two-stage negative stiffness curves through the parameter design of four sets of bistable negative-stiffness beams, and then connect the lever part in parallel to realize positive stiffness compensation, thereby obtaining continuous two-stage zero-stiffness curves. The micro gripper can output two stages of constant clamping force in two stages of effective travel respectively. The invention has the advantages of multi-size adaptability, small volume, no friction, no assembly, high motion sensitivity and the like.

Owner:WUHAN UNIV

One-dimensional precision translational mechanism

PendingCN107740812AAchieve precision transmissionZero Abbe errorLinear bearingsShaftsLubricationPotential energy

The invention discloses a one-dimensional precision translational mechanism which can achieve the functions of precision transmission and precise measurement. The one-dimensional precision translational mechanism conducts transmission through two parallel reed mechanisms. The two parallel reed mechanisms are arranged in a sleeved mode. The one-dimensional precision translational mechanism has constant potential energy and continuous motion balance within the travel range. On one hand, the motion track of a translational plate and a displacement detection device are located on the same straightline to accord with the Abbe principle, so that the Abbe error of mechanism transmission is zero. Accordingly, precision transmission of the translational plate relative to a fixed plate is realized;on the other hand, the translational mechanism can guarantee that the accumulated motion error is zero in the axial direction of coordinates orthogonal to the motion direction of the translational mechanism. Thus, the one-dimensional precision translational mechanism has the advantages of being high in motion precision, good in motion sensitivity, free of mechanical friction, gaps and lubricationin the motion process and the like. The one-dimensional precision translational mechanism can be widely applied to the technical fields such as precision measurement, precision manufacturing and precision transmission.

Owner:XIAN TECHNOLOGICAL UNIV

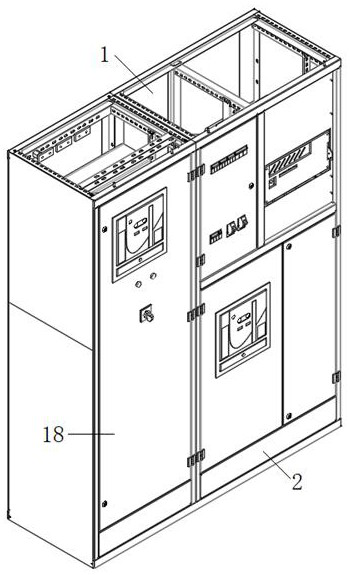

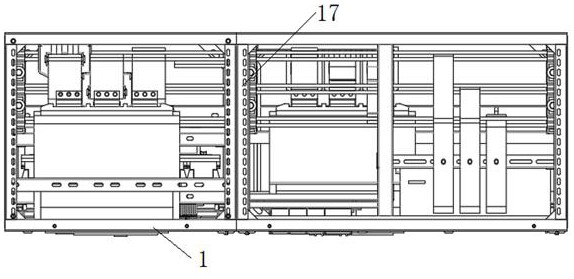

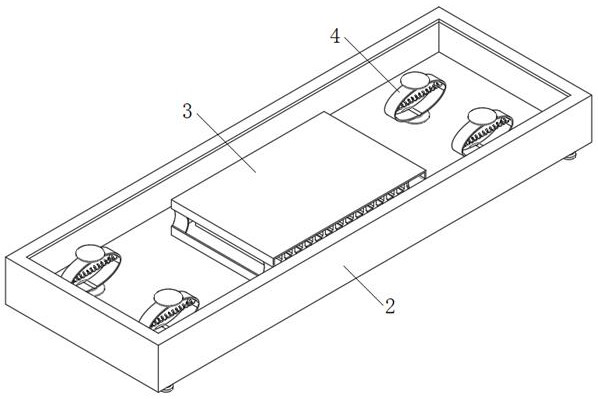

A kind of power cabinet with nonlinear damping platform

ActiveCN110676704BViscoelasticIncrease frictional dampingSubstation/switching arrangement casingsAnti-seismic devicesEngineeringVibration isolation

Owner:山东博安泰电气有限公司

Microgripper with two-stage constant force output in continuous two strokes and control method

ActiveCN111843980AAdaptable to multiple sizesReduce volumeProgramme-controlled manipulatorMicromanipulatorConstant forceNegative stiffness

The invention provides a microgripper with two-stage constant force output in continuous two strokes and a control method. The microgripper is of a flexible integrated structure, wherein a constant force mechanism is composed of four groups of bistable negative stiffness beams and a lever part. The principle of a two-stage constant force mechanism is that a two-stage negative stiffness curve is obtained through the parameter design of the four groups of bistable negative stiffness beams, then the lever part is connected in parallel to achieve positive stiffness compensation, and thus a continuous two-stage zero stiffness curve is obtained. The microgripper can output two stages of constant clamping force in two effective strokes. The microgripper has the advantages that multi-size adaptability is achieved, the volume is small, no friction is achieved, no assembly is achieved, and the motion sensitivity is high.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com