Patents

Literature

35results about How to "Increase frictional damping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

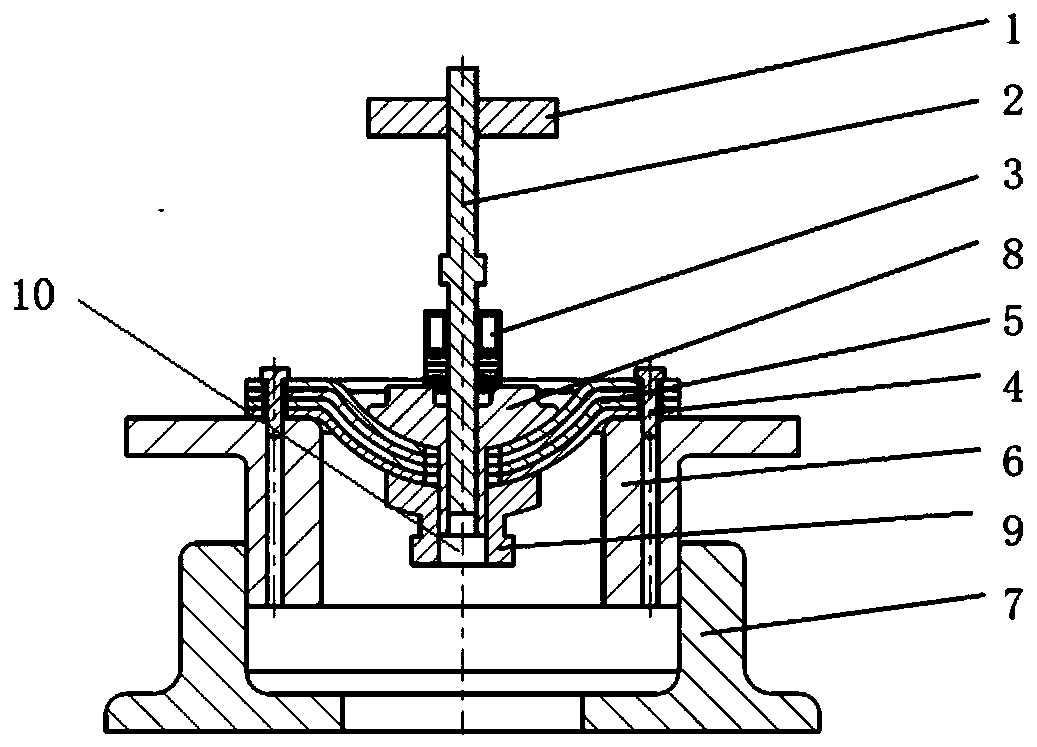

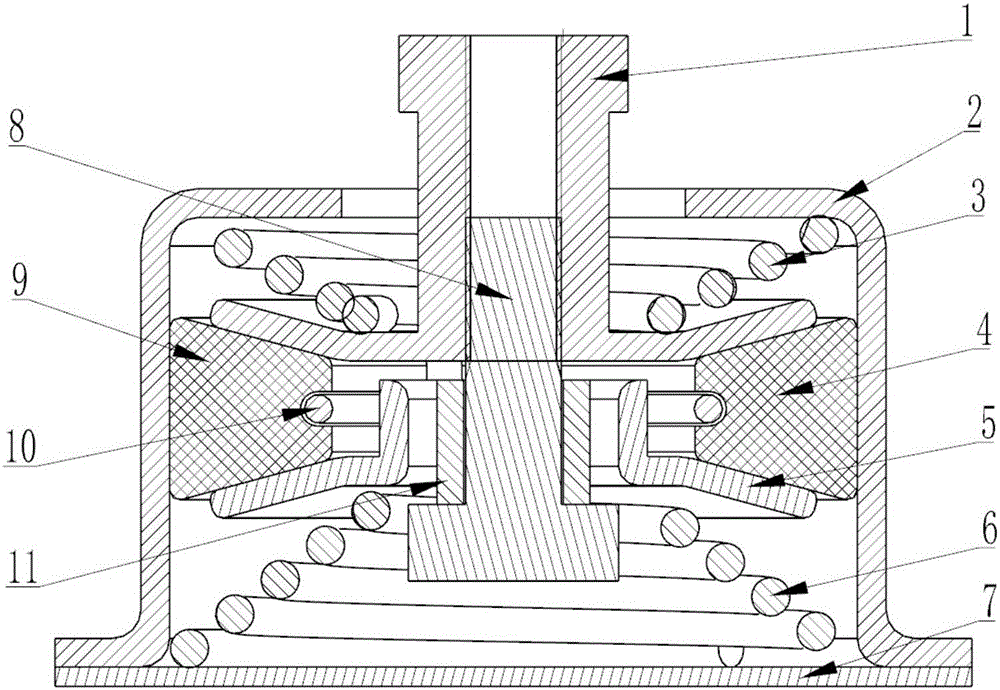

High-effect dry friction damping spring vibration isolator

ActiveCN104930100ACompact structureHeavy loadShock absorbersFriction dampersReciprocating motionMechanical energy

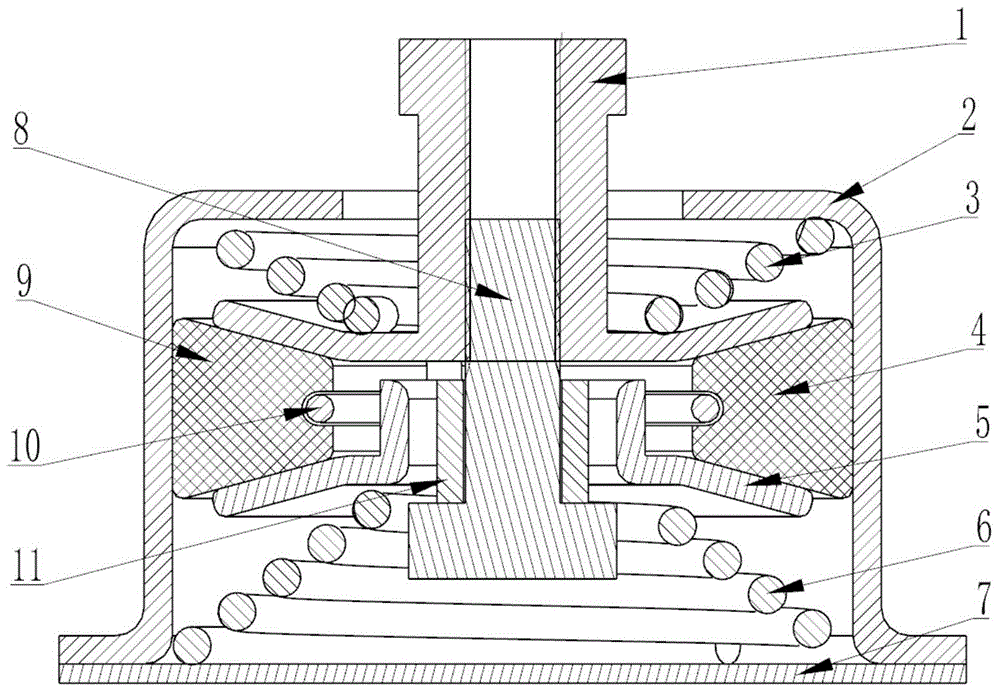

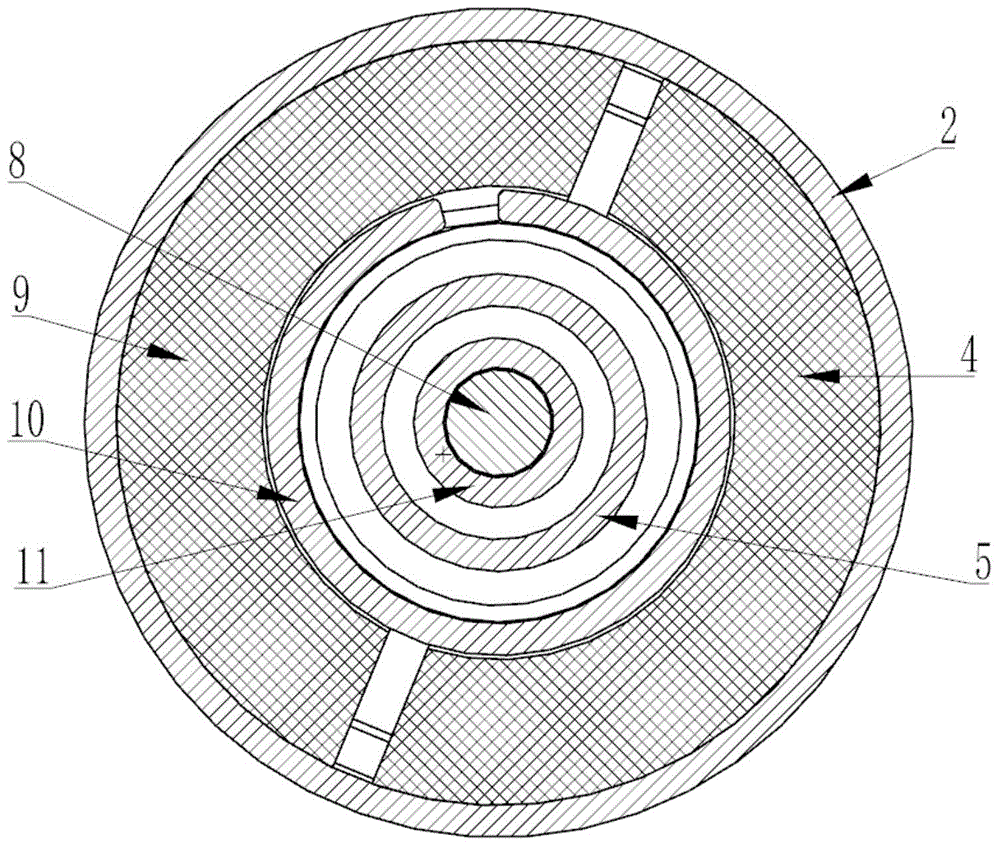

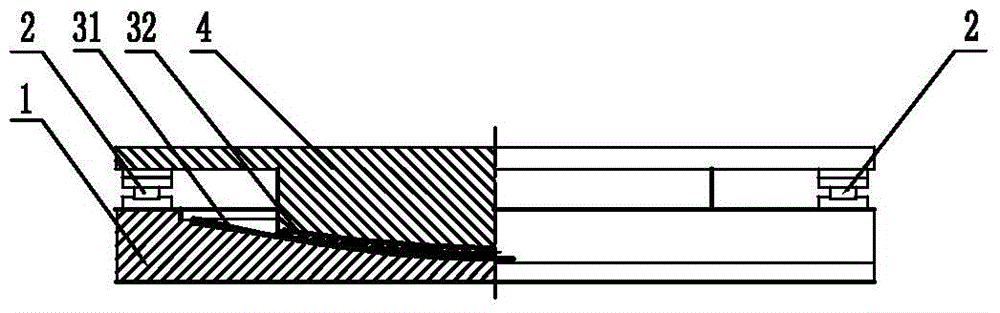

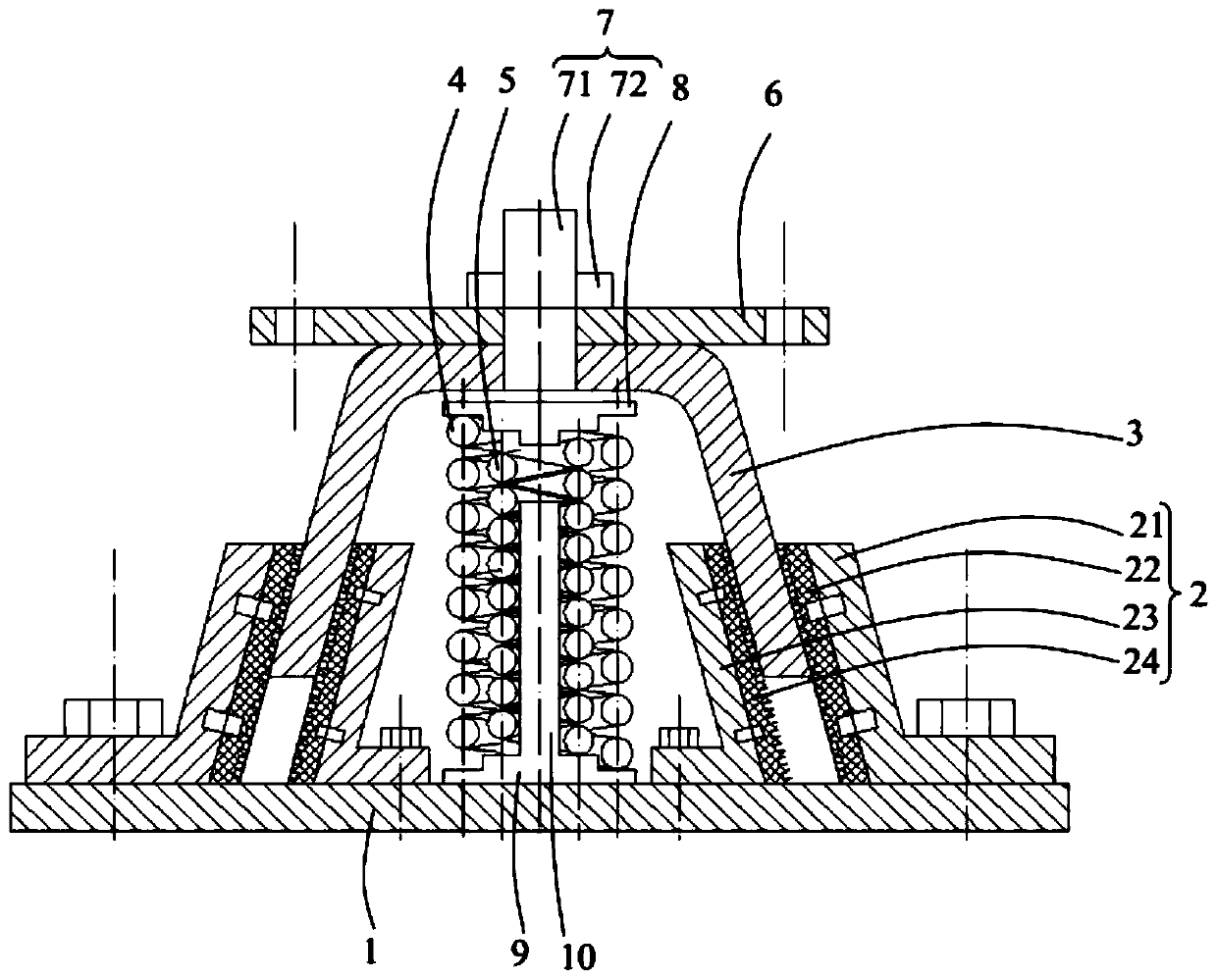

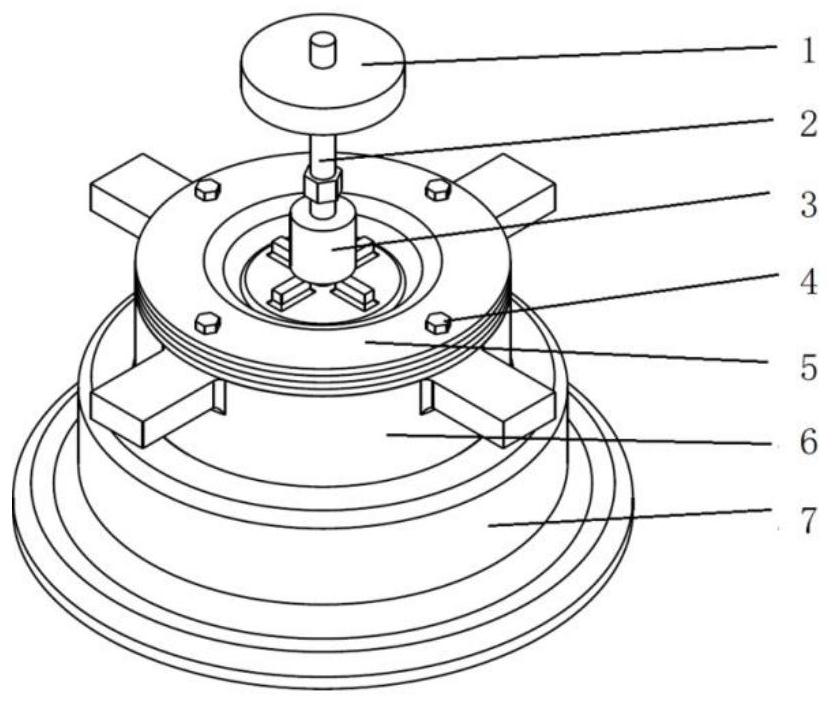

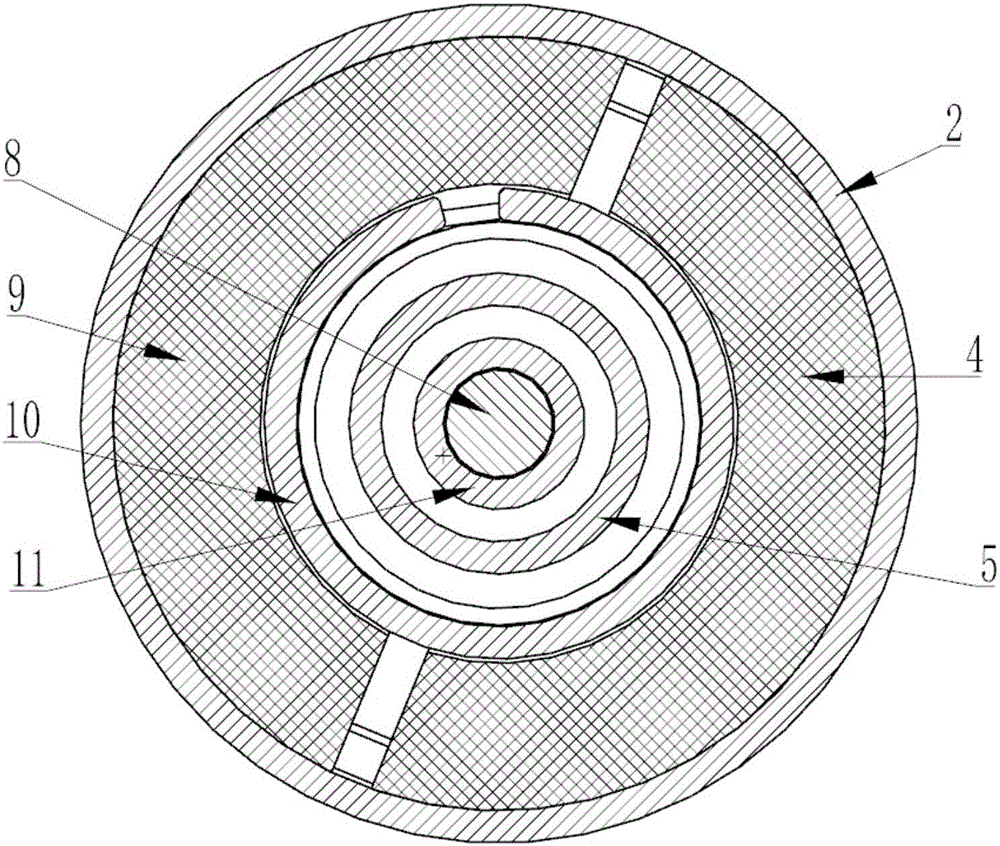

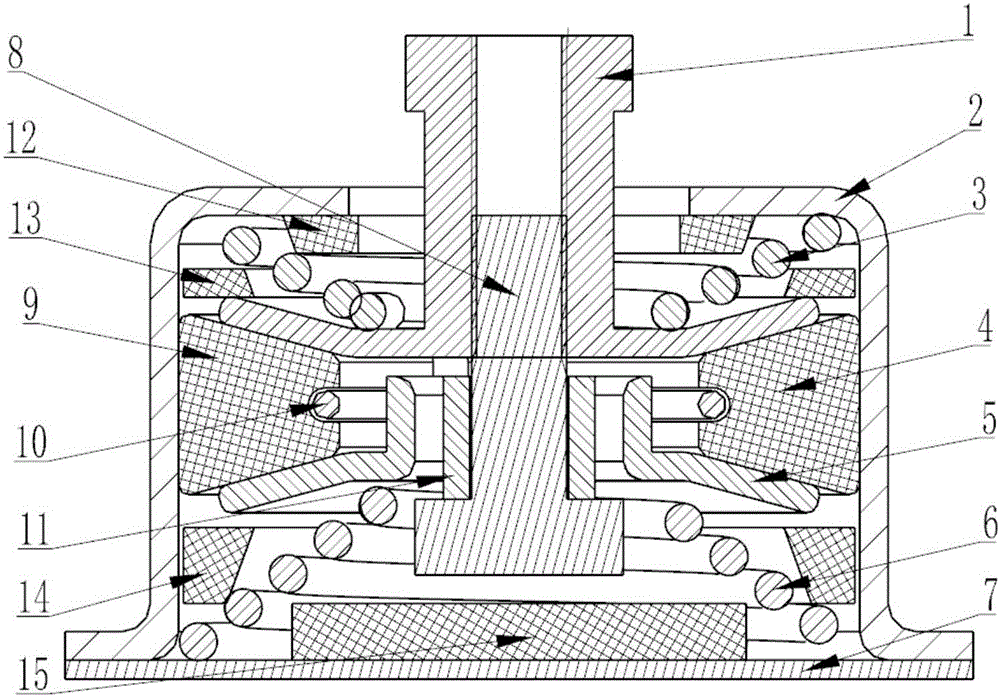

The invention discloses a high-effect dry friction damping spring vibration isolator and aims at providing a friction damping vibration isolator which is compact in structure, large in friction damp, high in load and good in environmental adaptation. According to the technical scheme, in a vibration environment, left friction pieces and right friction pieces of a disc-pressing upper cone spring (3) and a disc-pressing lower cone spring (6) perform reciprocating motion to axially extrude a right friction ring piece (4) and a left friction ring piece (9) on two sides, the left friction ring piece, the right friction ring piece, an upper guide umbrella disc (1) and a lower guide umbrella disc (5) are driven to perform constant friction motion on the inner wall of a housing (2), vibration mechanical energy is converted into heat energy so as to achieve vibration energy consumption and reduction. The high-effect dry friction damping spring vibration isolator utilizes low frequency of a conical spring and a damping characteristic of a symmetric semi-ring damping pad, can effectively inhibit spring fluctuation during high-frequency impact, also has composite multiple vibration isolation effect and has large damp under the low-frequency condition compared with a traditional rubber vibration isolator.

Owner:10TH RES INST OF CETC

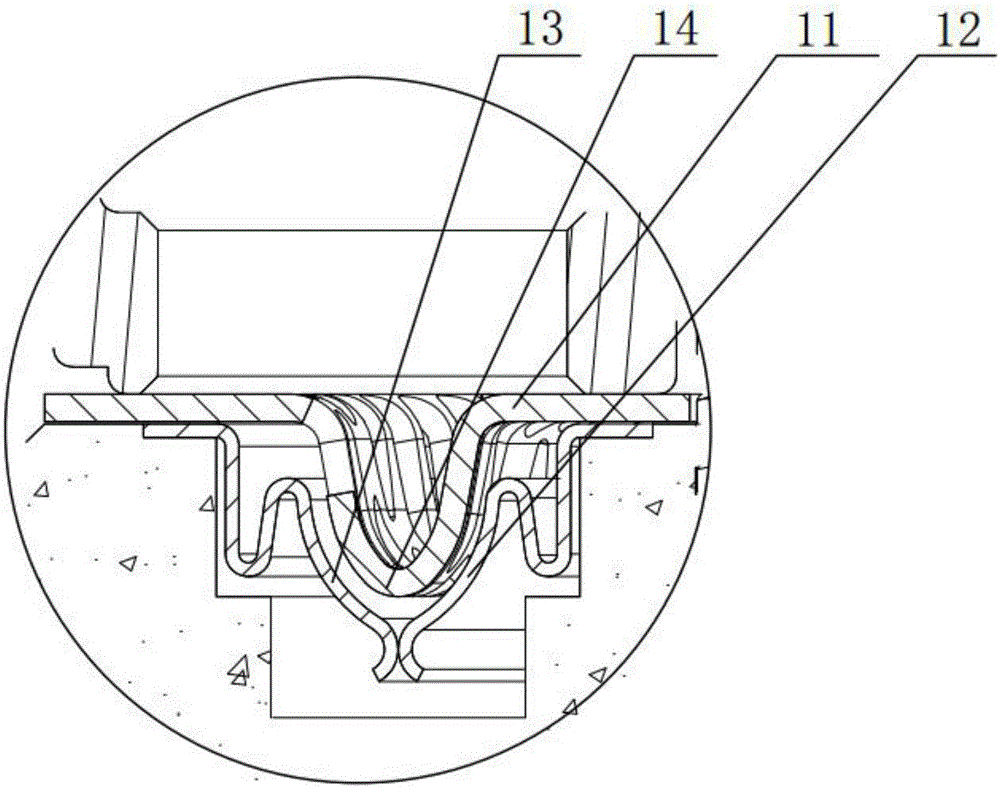

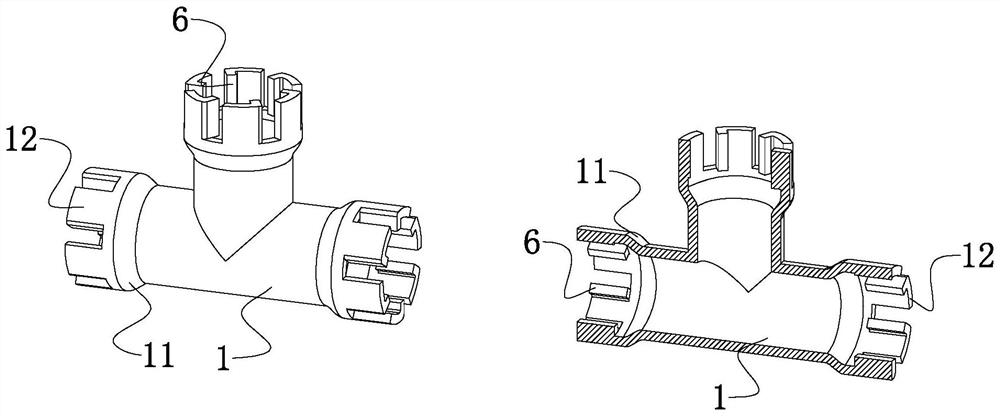

Variable friction damping vibration isolator with adjustable central position

ActiveCN111649087AImprove wear resistanceIncrease frictional dampingSpringsShock absorbersIsolatorClassical mechanics

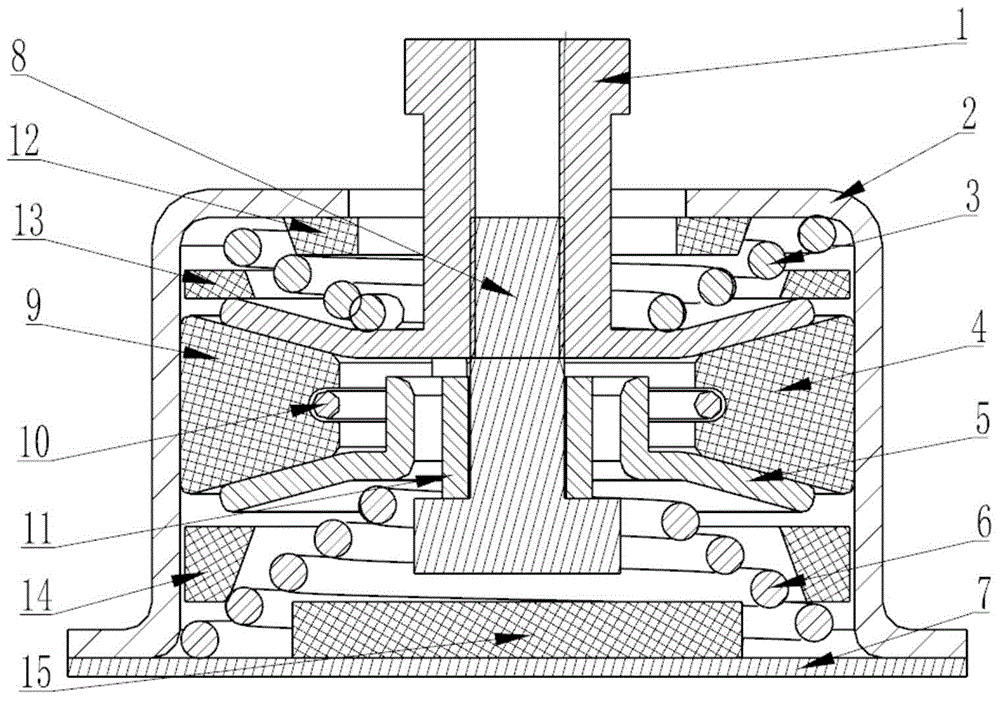

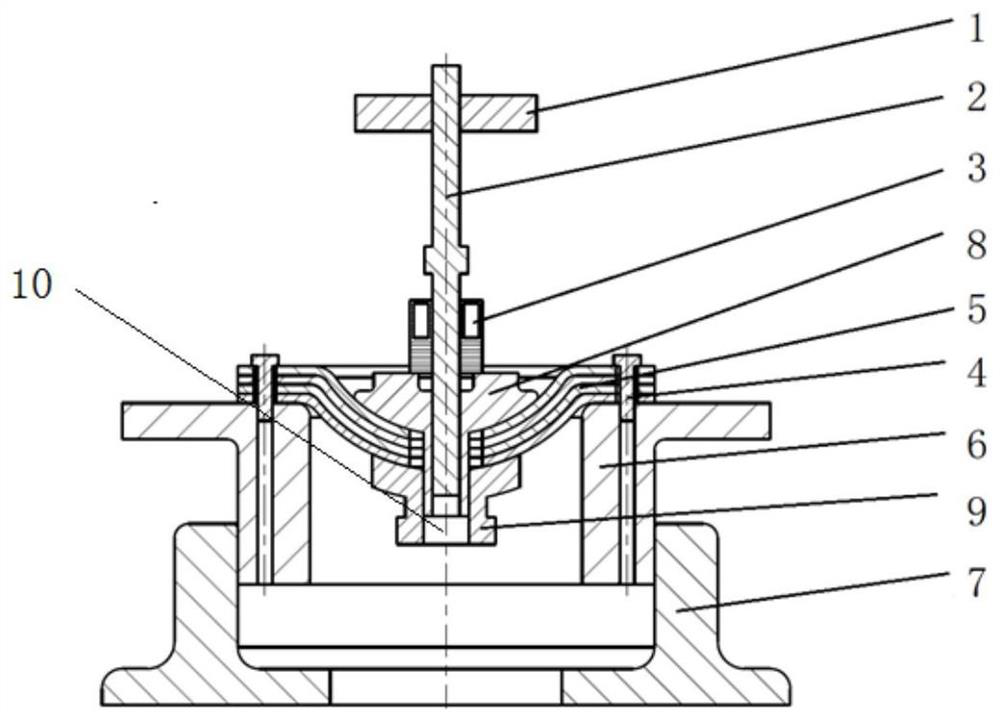

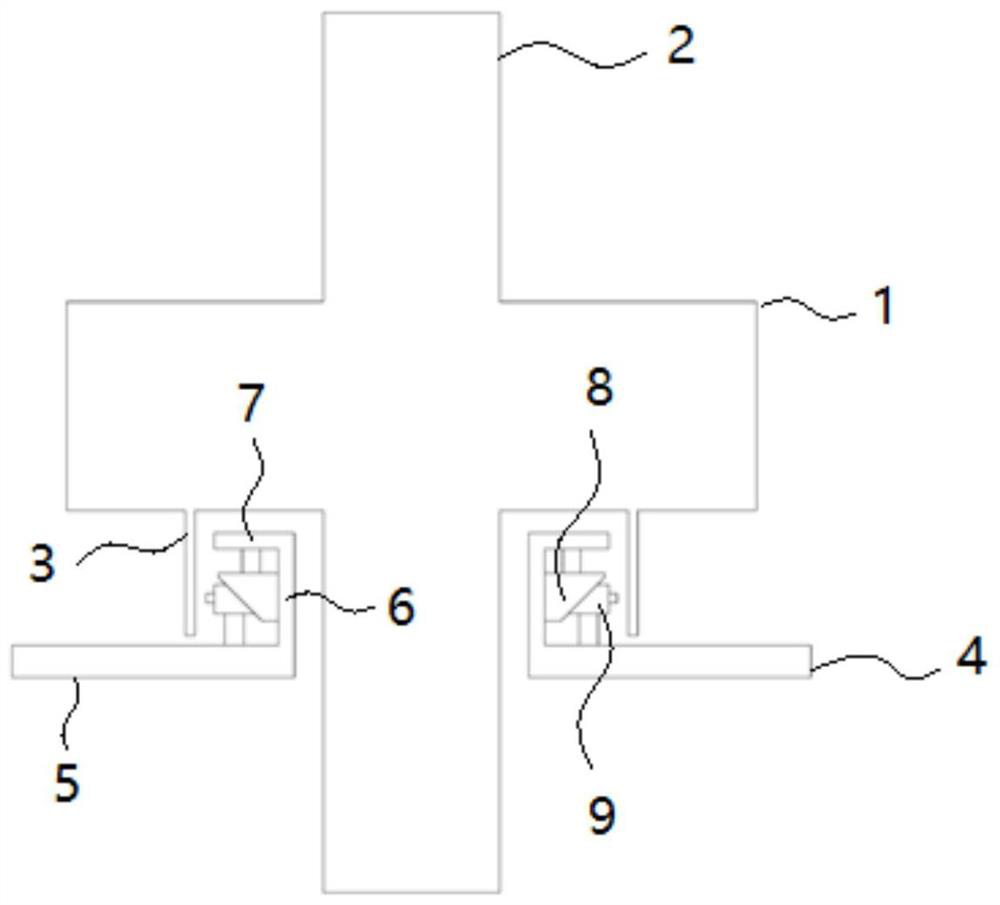

The invention relates to a variable friction damping vibration isolator with an adjustable central position, and belongs to the field of vibration isolators of electronic equipment. The problem that the vibration isolation capacity of the vibration isolator on a high-frequency vibrating load is weakened due to the fact that an existing vibration isolator cannot adjust the central position of variable friction damping, and when loaded actual weight is different from rated bearing capacity of the vibration isolator, the vibration center of the vibration isolator is deviated from the central position of low-friction damping force of a damping spring piece is solved. The variable friction damping vibration isolator comprises a base, a clamping spring, friction guide rails, an upper cover, a loading installation seat, friction pressure springs, friction heads and a main isolation spring; and the friction guide rails are matched with the clamping spring through a friction guide rail height adjustment conical surface, and the upper cover covers the friction guide rails. According to the variable friction damping vibration isolator with the adjustable central position, by adjusting pretightening force of the upper cover, the central positions of the friction guide rails can move up and down, and the central position of the variable friction damping vibration isolator is adjusted.

Owner:36TH RES INST OF CETC

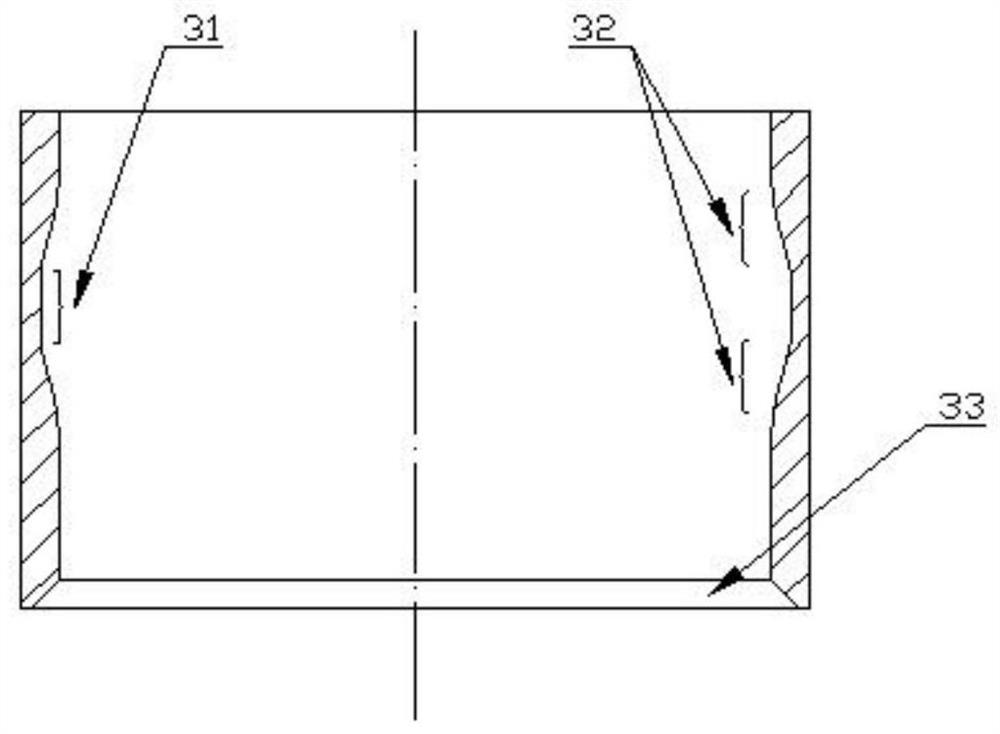

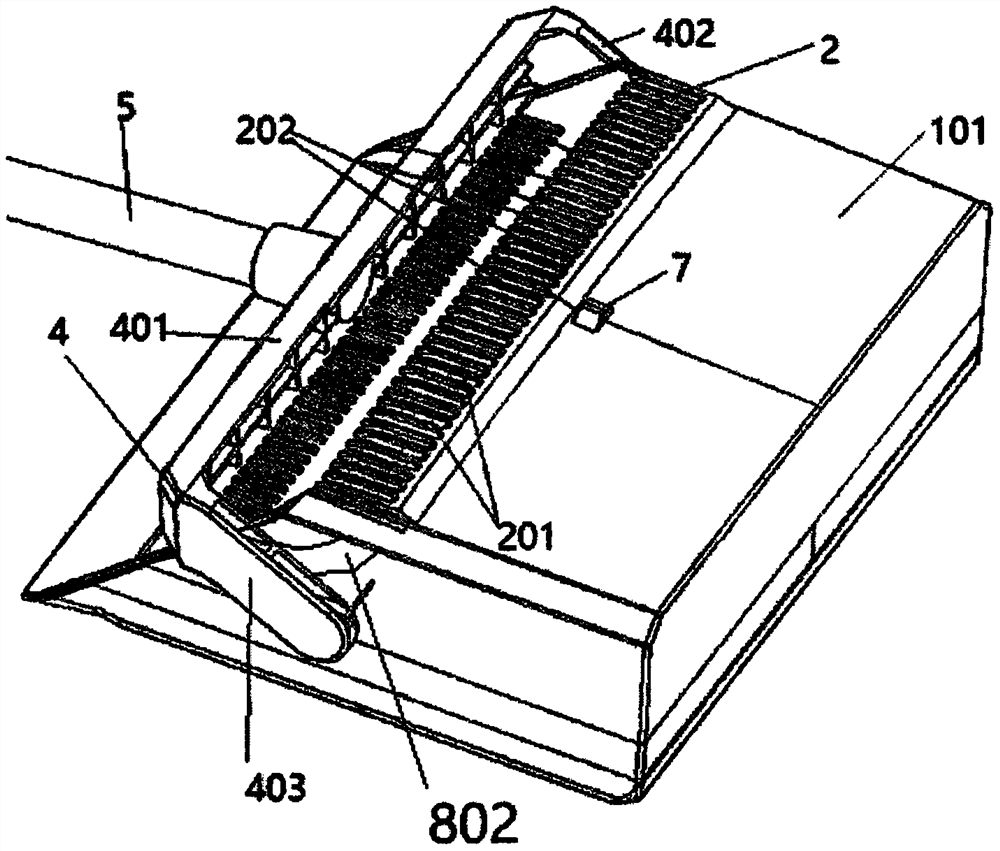

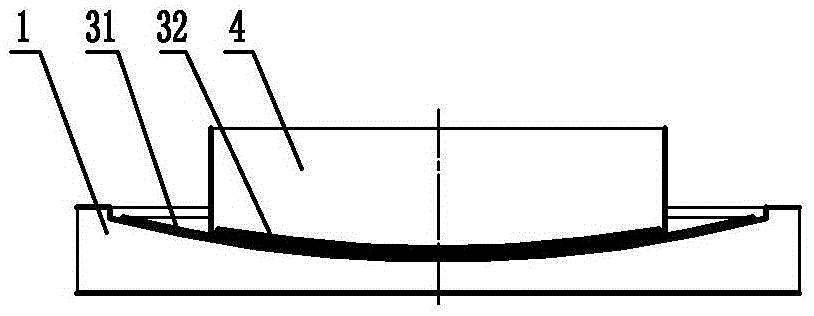

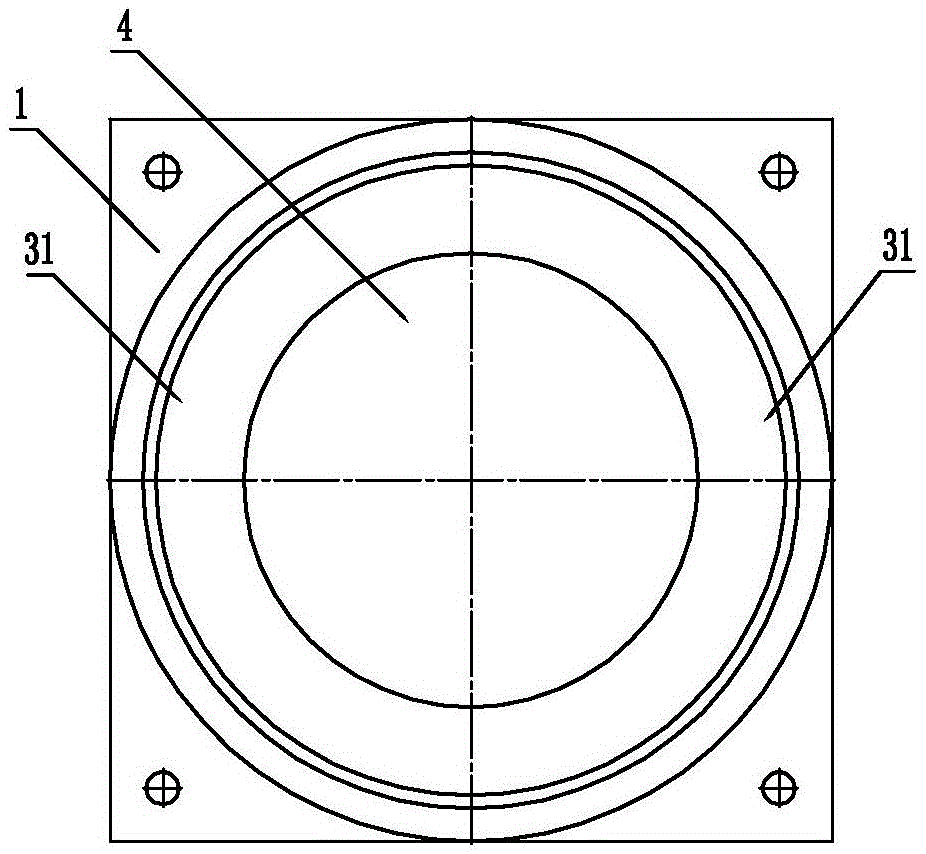

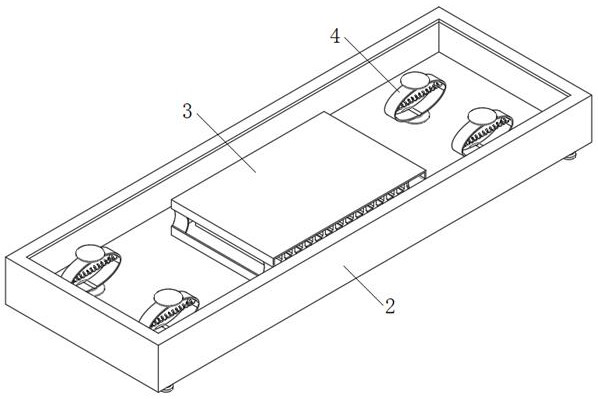

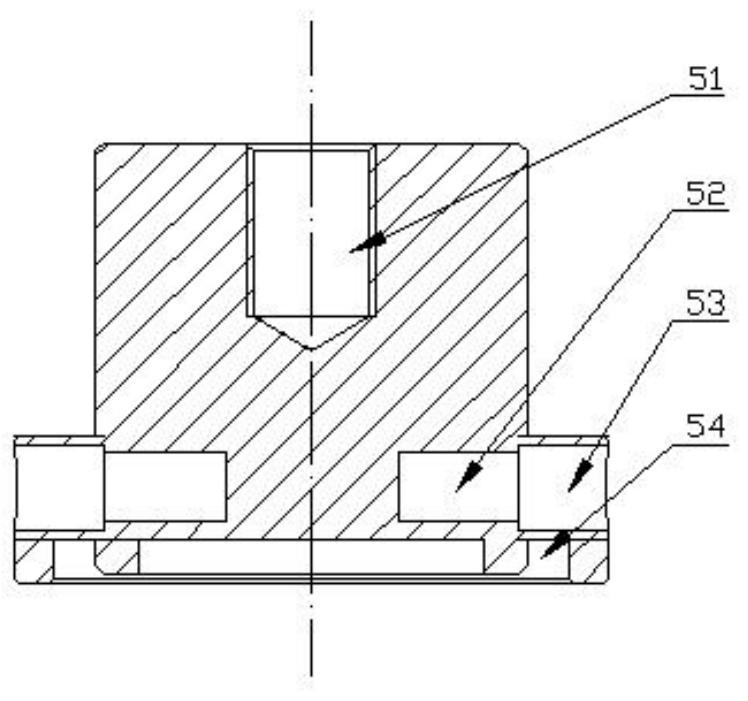

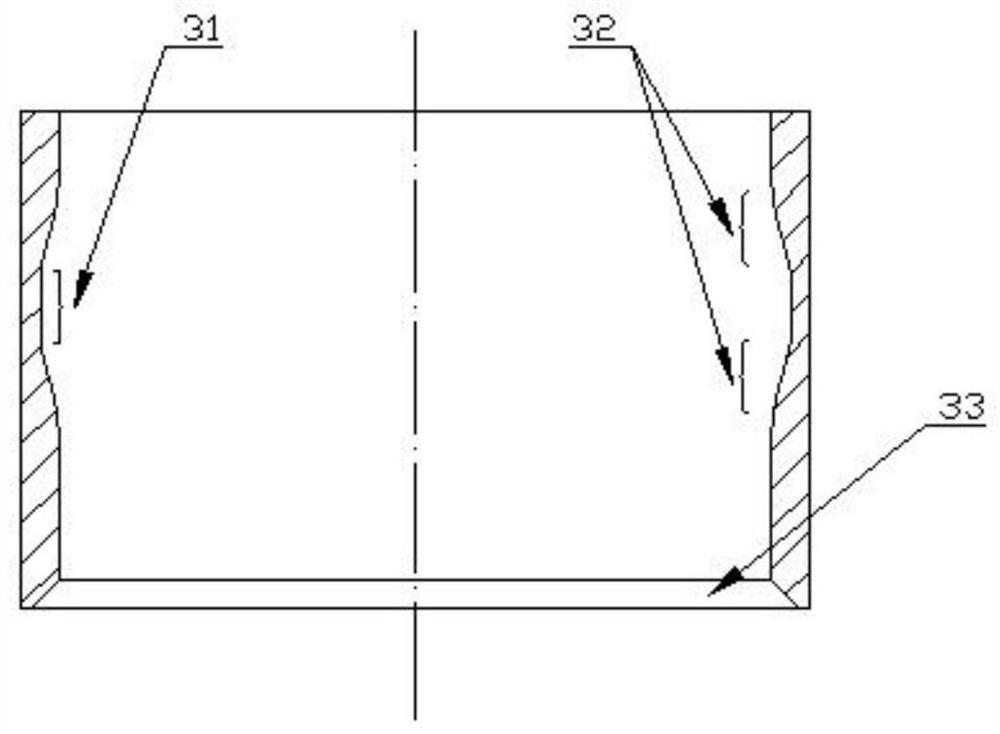

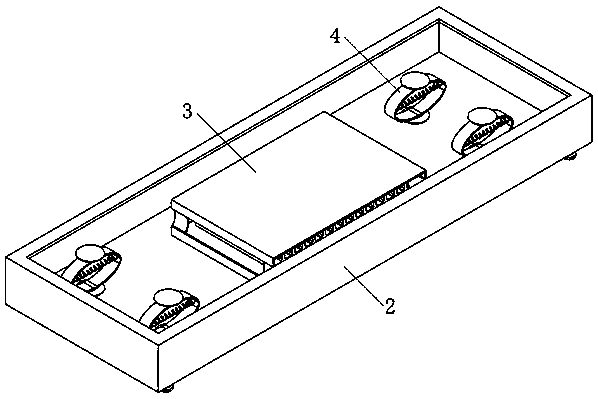

Spherical surface TMD shock absorption control device

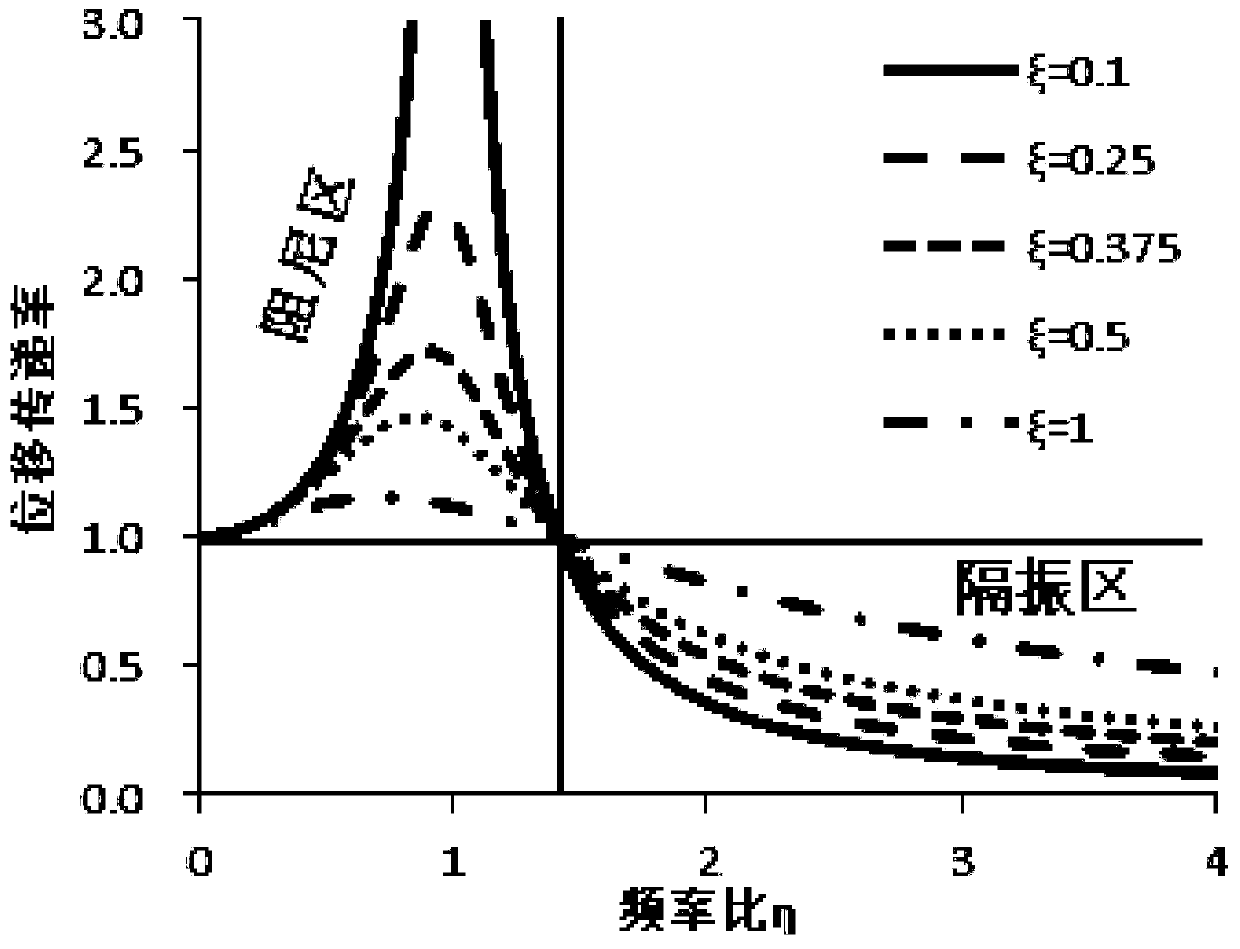

ActiveCN104018594APlay the role of tuning frequencyDesign scienceBridge structural detailsShock proofingEngineeringLow frequency vibration

The invention provides a spherical surface TMD (Turning Mass Damper) shock absorption control device, which comprises a bottom plate component and a mass block component glidingly matched with the bottom plate component, wherein the weight of the mass block component is m; the top of the bottom plate component is provided with N concave spherical surfaces; the bottom of the mass block component is provided with N convex spherical surfaces glidingly matched with the concave spherical surfaces; the concave spherical surfaces and the convex spherical surfaces have the identical spherical surface radius R; a sliding friction pair is arranged between the convex spherical surfaces and the concave spherical surfaces; and a damping device is arranged between the mass block component and the bottom plate component. The spherical surface TMD shock absorption control device has the advantages that the additional damping can be increased through setting different friction factors; meanwhile, through a single pendulum simple harmonic moving principle, an elastic element of a traditional TMD is replaced; the design is scientific; the structure is compact; the operation and the use are convenient; the problems that for the existing TMD technology, the manufacturing cost is high, a greater installation space is needed, a structural element can be easily damaged, and the like can be solved; and the spherical surface TMD shock absorption control device is particularly applicable to the control of low-frequency vibration of a structure.

Owner:柳州东方工程橡胶制品有限公司

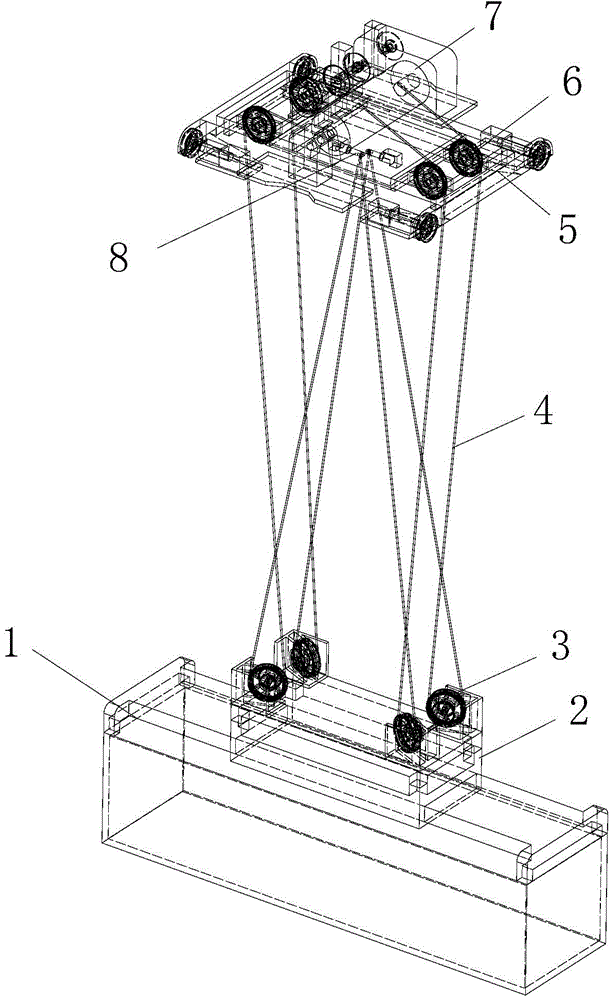

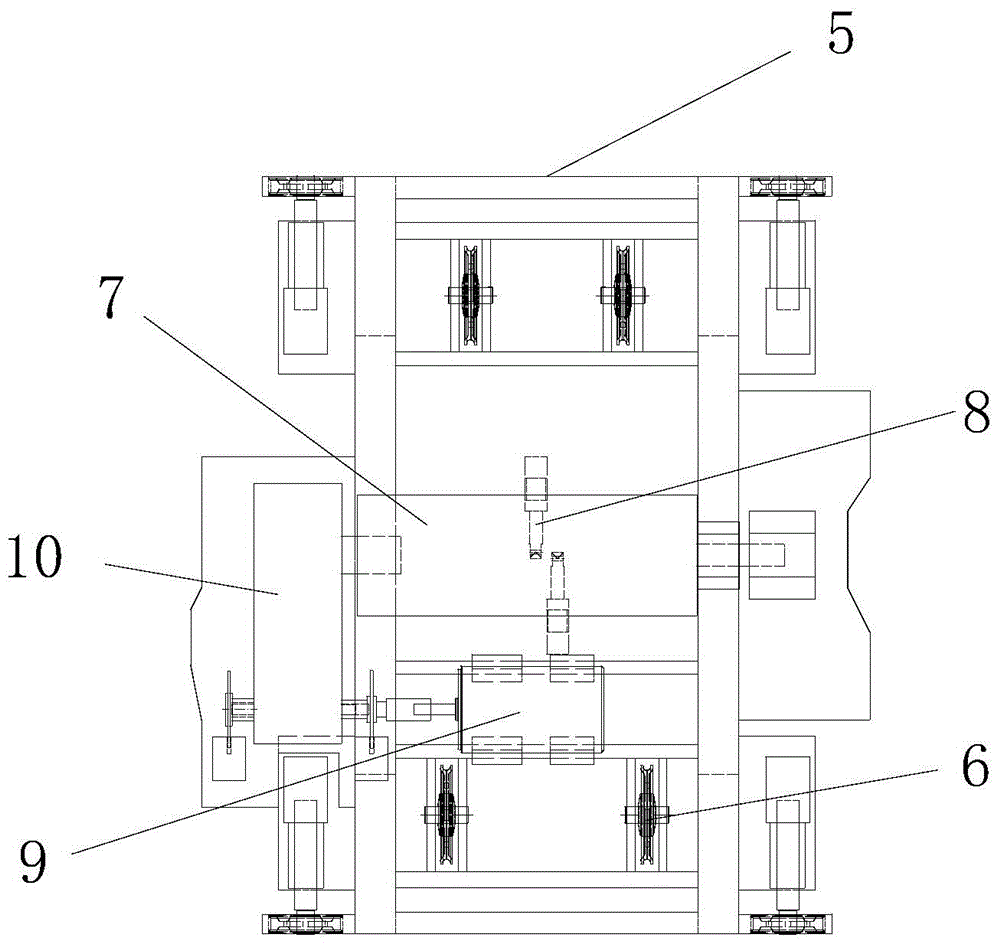

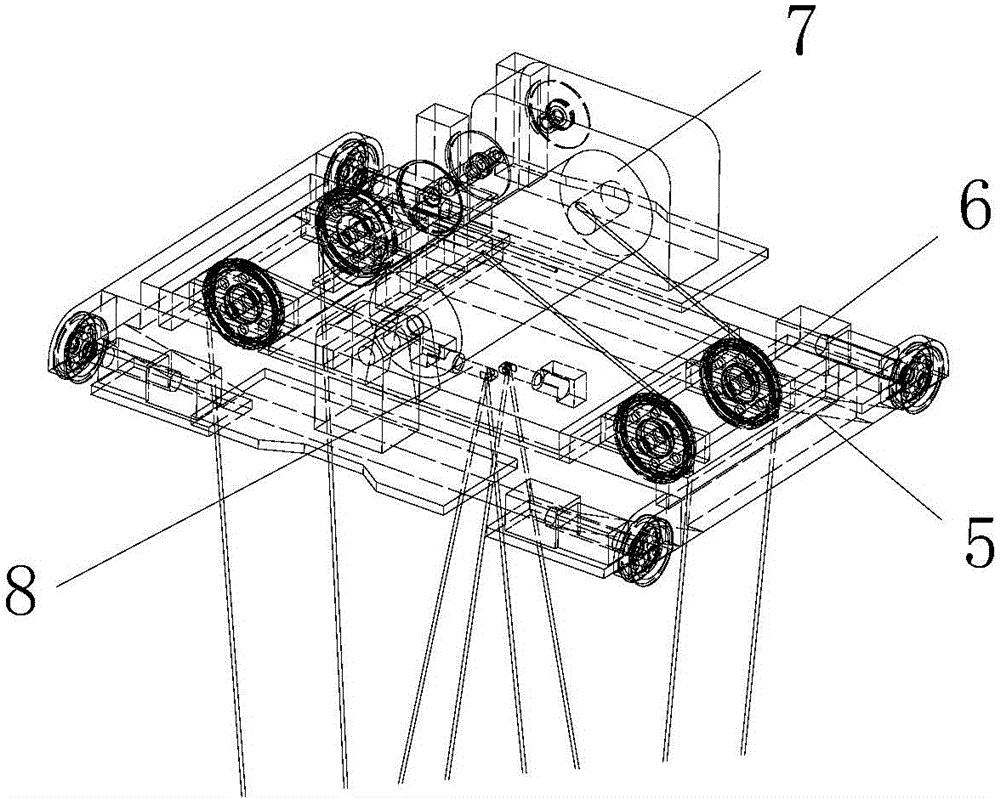

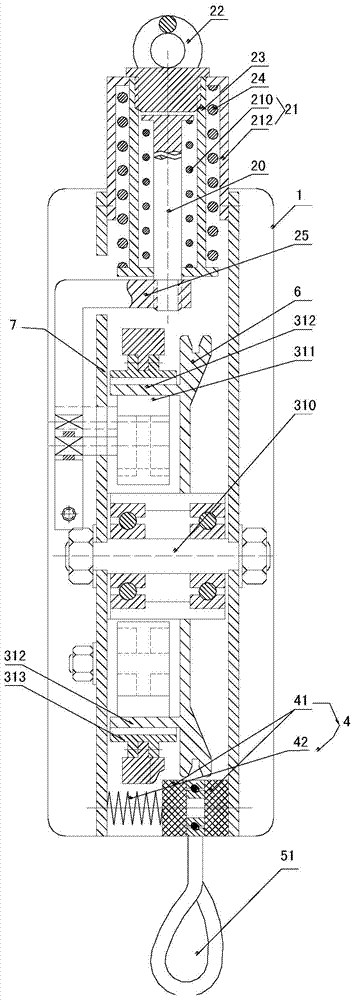

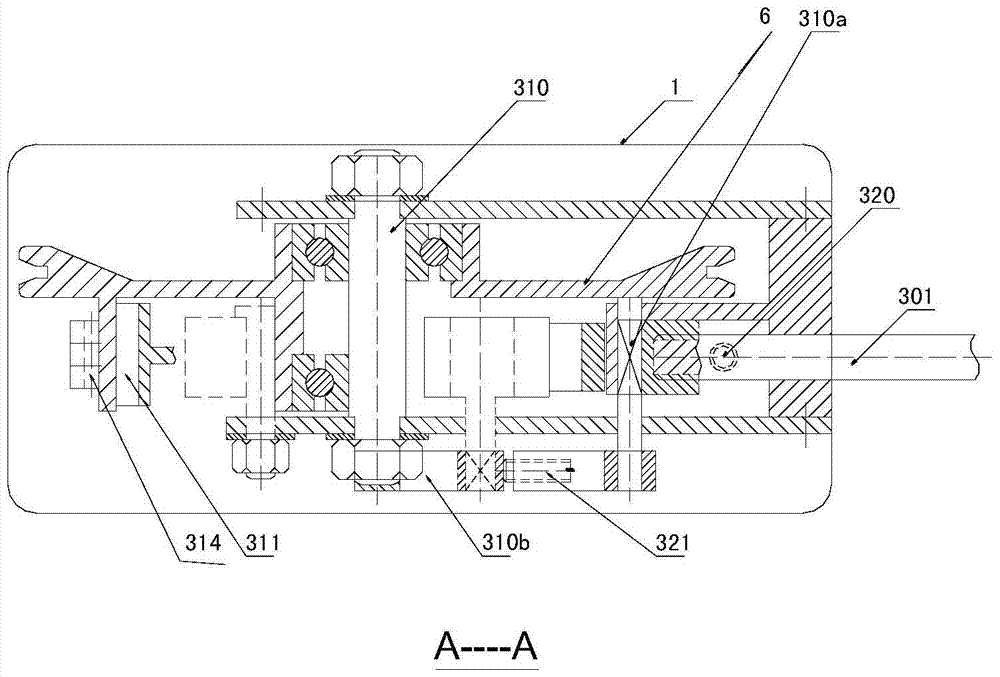

Lifting anti-rolling device for container gantry crane

The invention discloses a lifting anti-rolling device for a container gantry crane. The lifting anti-rolling device comprises a hanger, a hanger upper frame arranged on the top end surface of the hanger and a crane arranged above the hanger upper frame, wherein a winding drum is arranged on the center of the top end of the crane; four steel wire ropes are wound on the winding drum; two first slide wheels are arranged at each of the two sides of the top end of the crane; two electric push rods are arranged at the bottom end of the crane; the two electric push rods are oppositely arranged; a steel wire rope fixing part is arranged on each electric push rod; second slide wheels are arranged on four top corners at the top end of the hanger upper frame; each second slide wheel is arranged in an inclined mode; the four second slide wheels are in one-to-one correspondence with four first slide wheels; and the trend of each steel wire rope is along the winding drum, the first slide wheels, the second slide wheels opposite to the first slide wheels, and the steel wire rope fixing parts of the electric push rods. According to the lifting anti-rolling device, needs on output torque of a speed reducer are reduced, rigid impact on a crane steel frame is reduced, and the service life of the crane is prolonged.

Owner:QINGDAO HAIXI HEAVY DUTY MASCH CO LTD

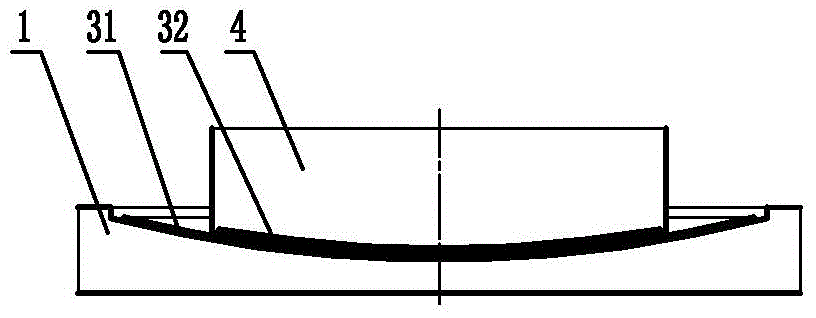

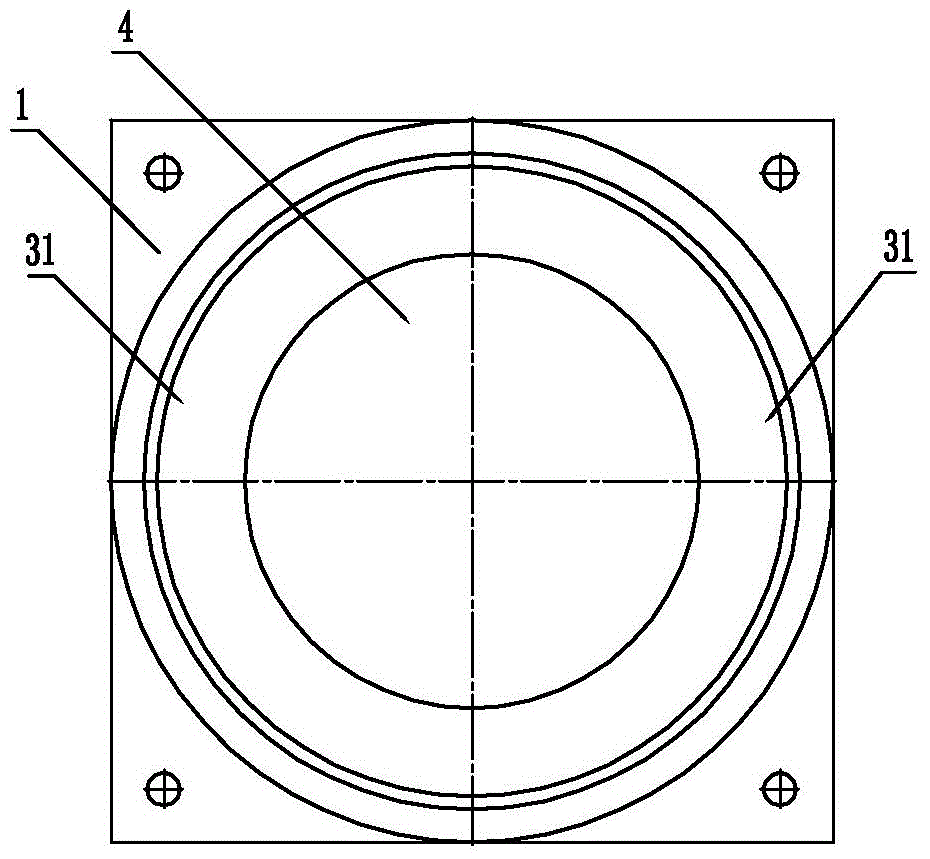

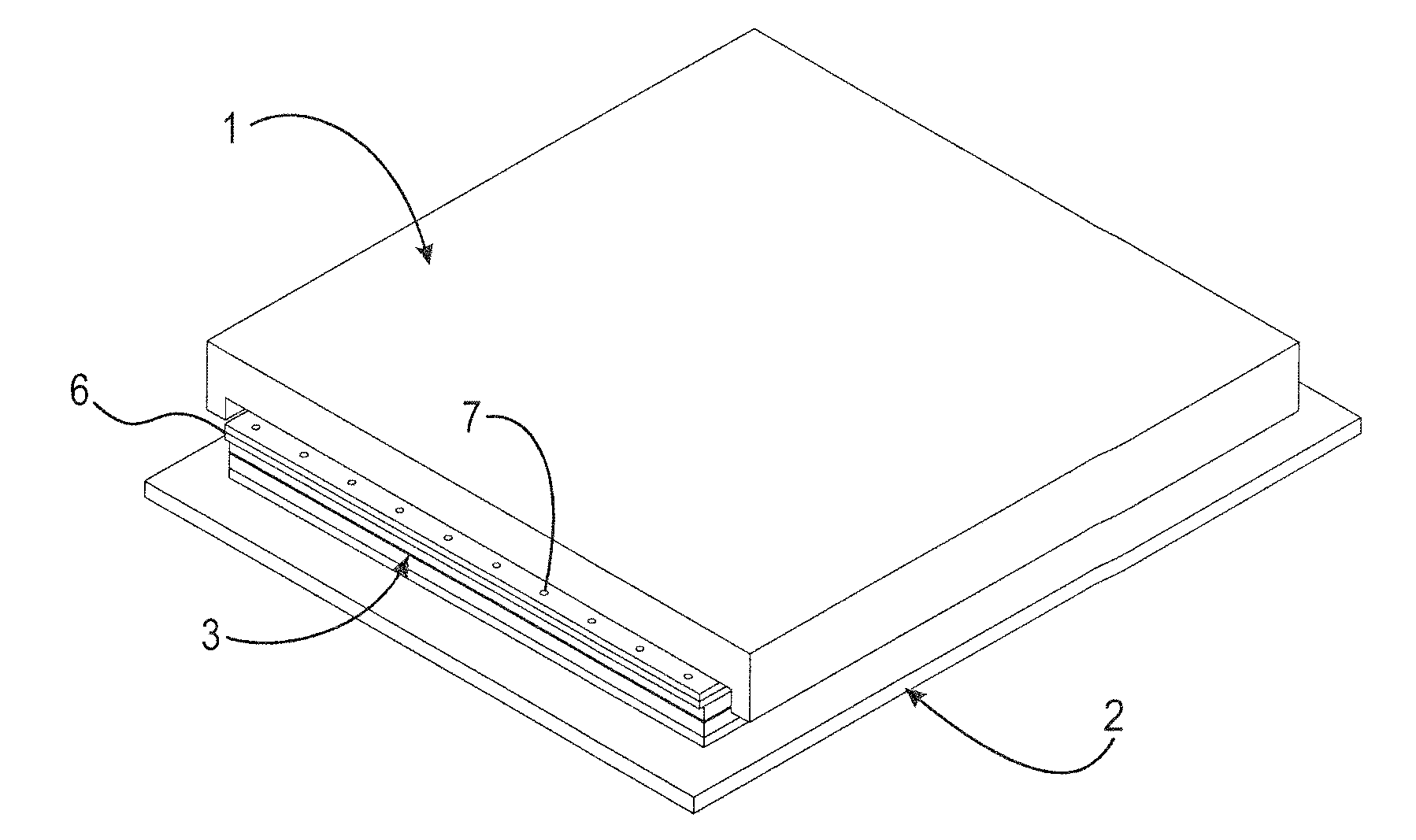

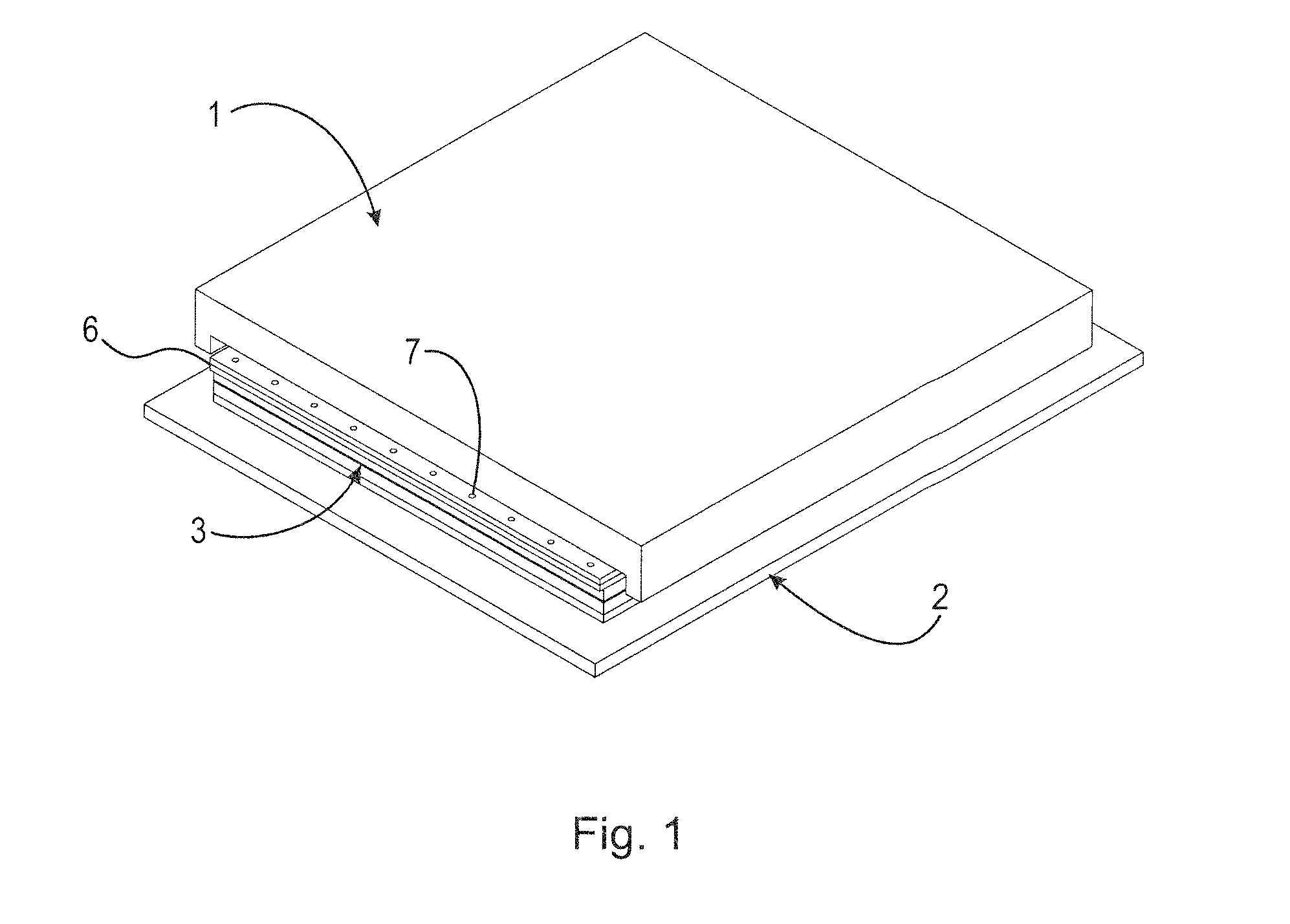

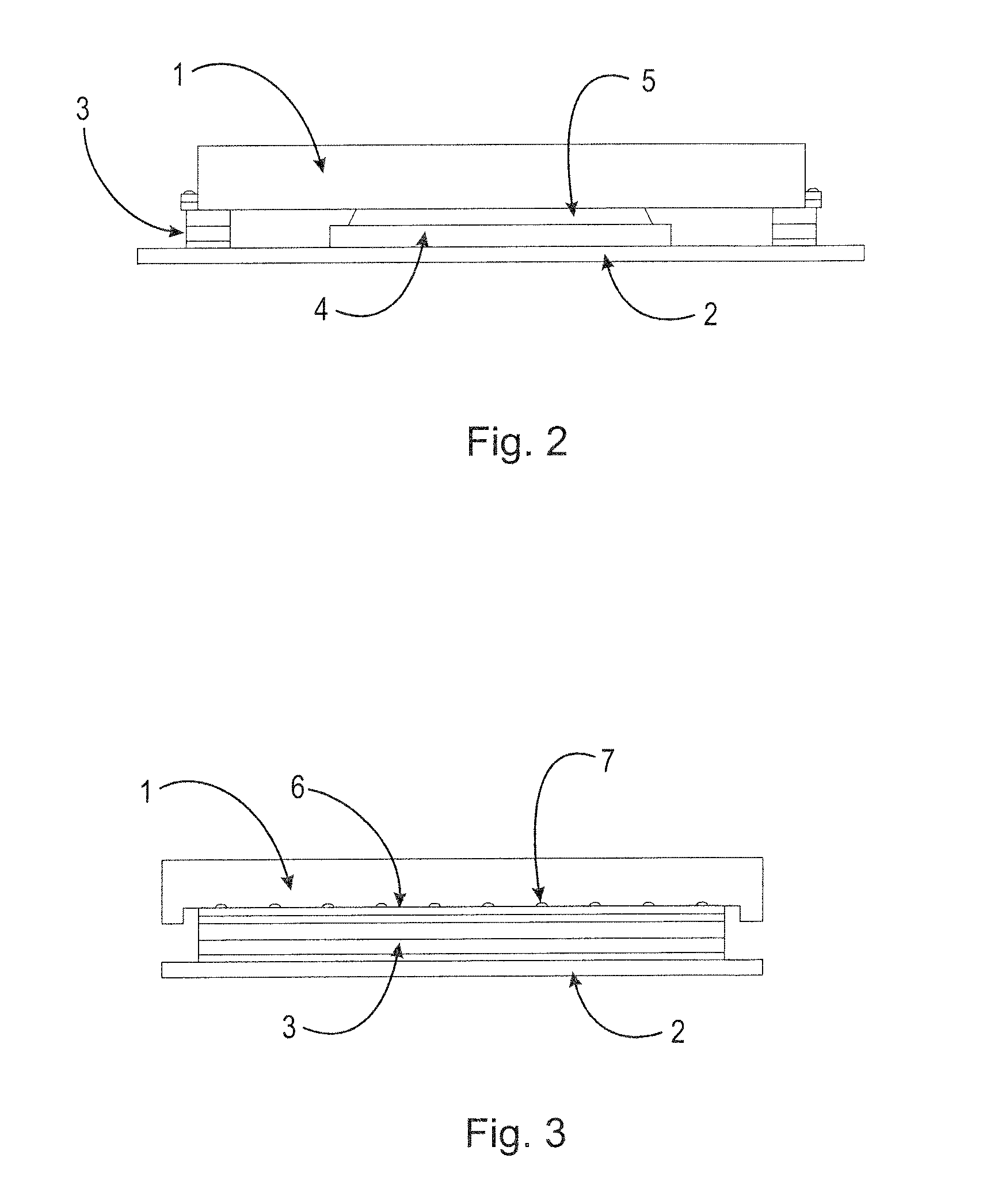

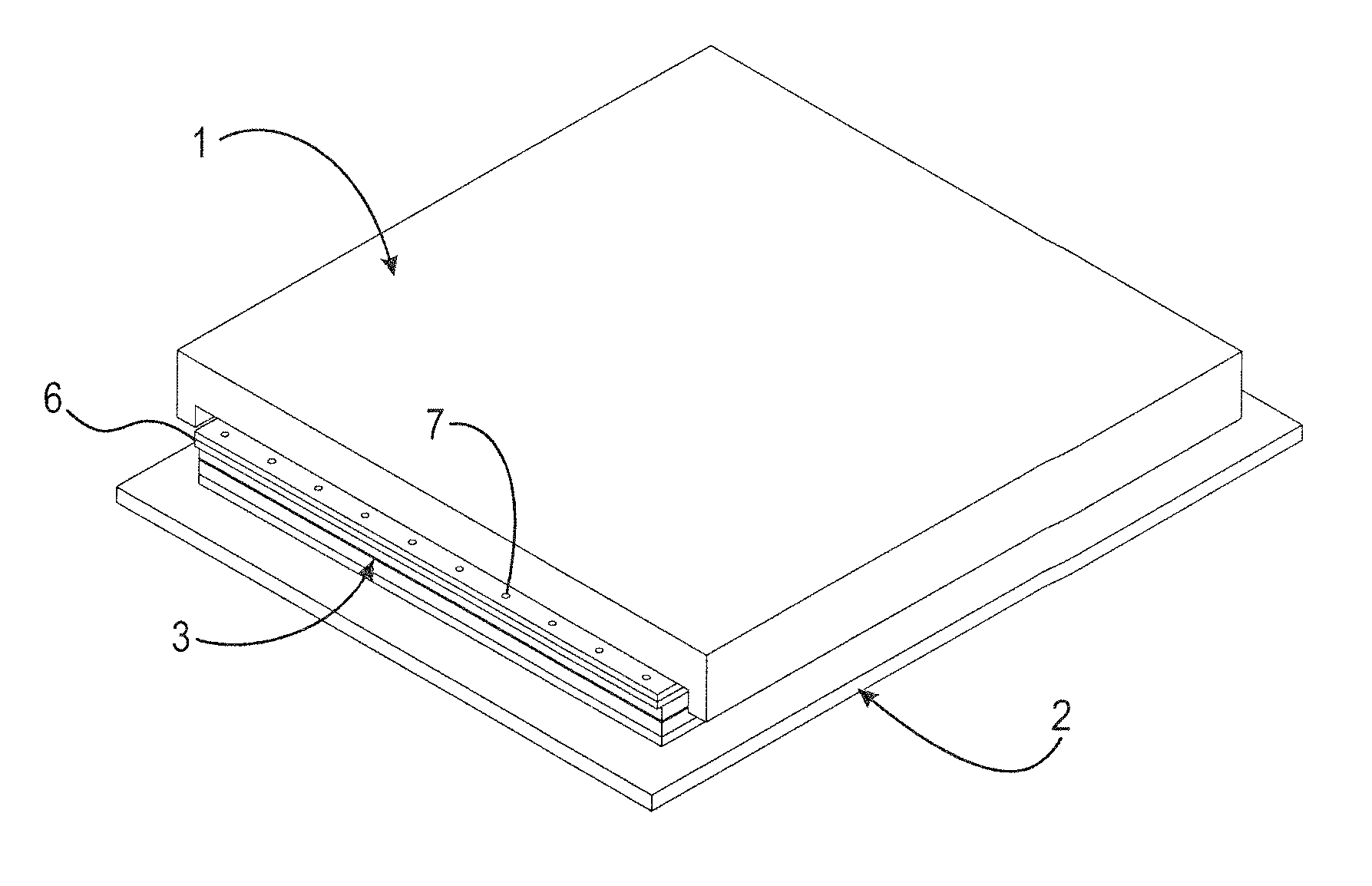

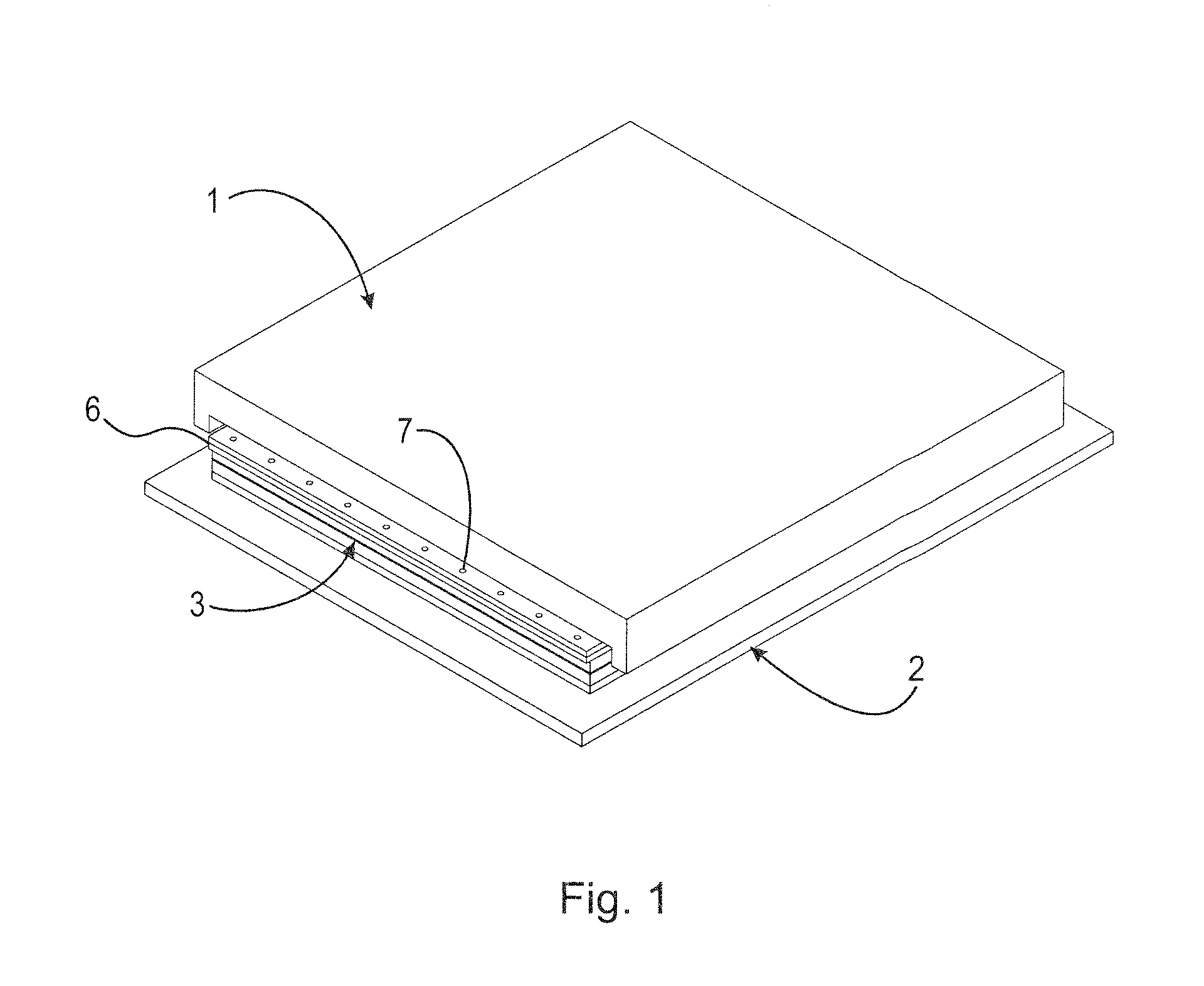

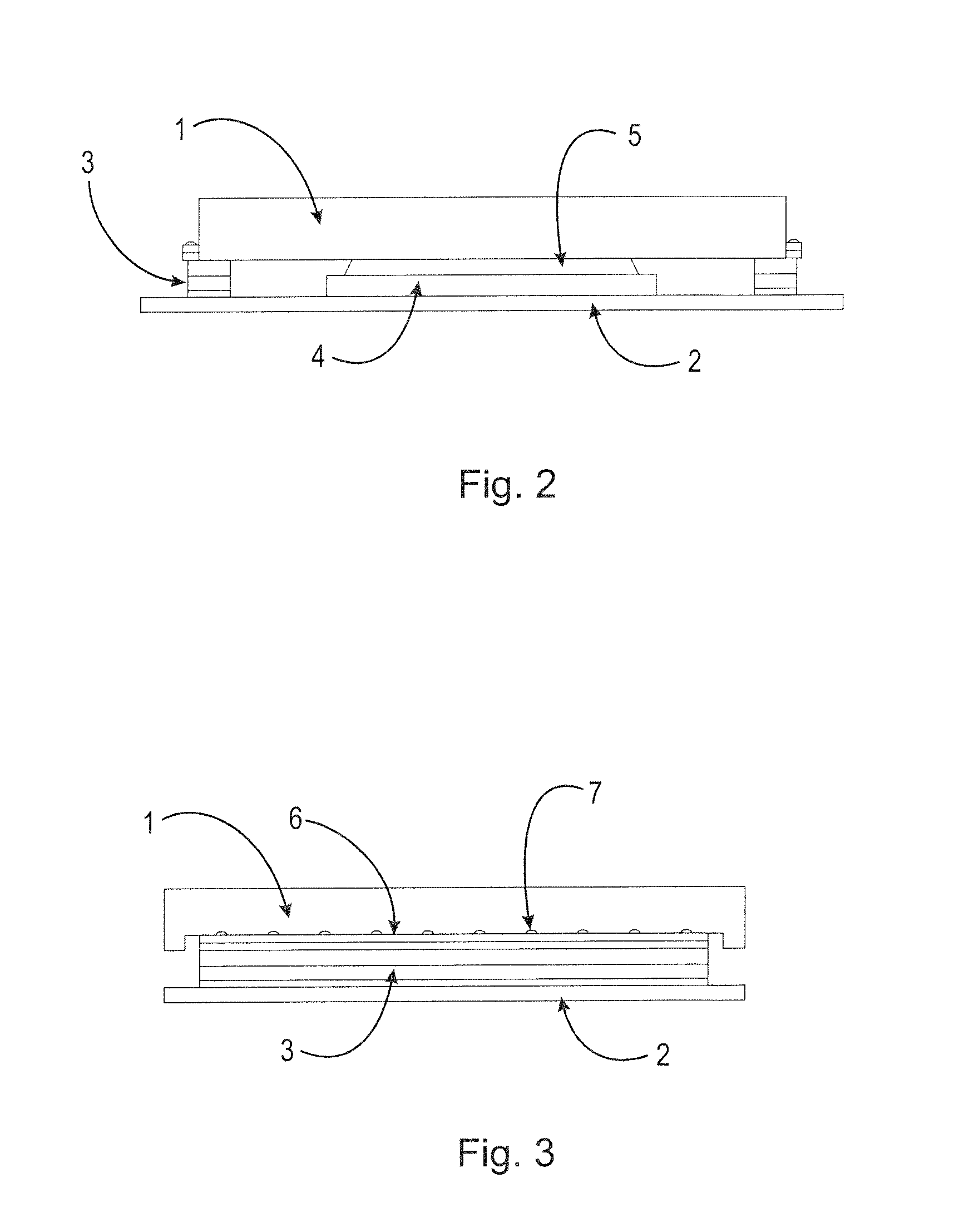

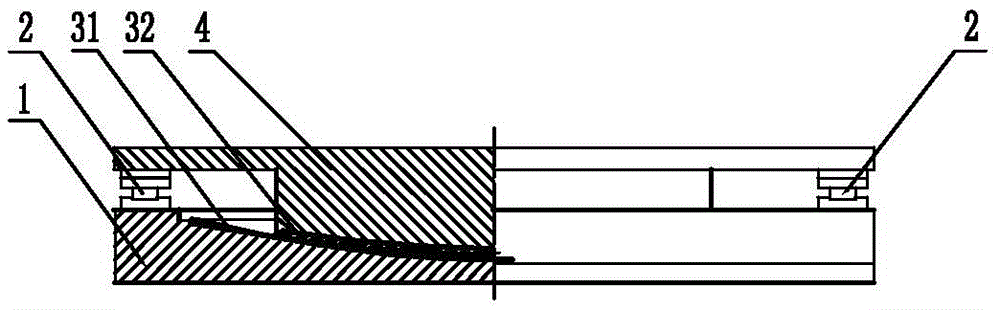

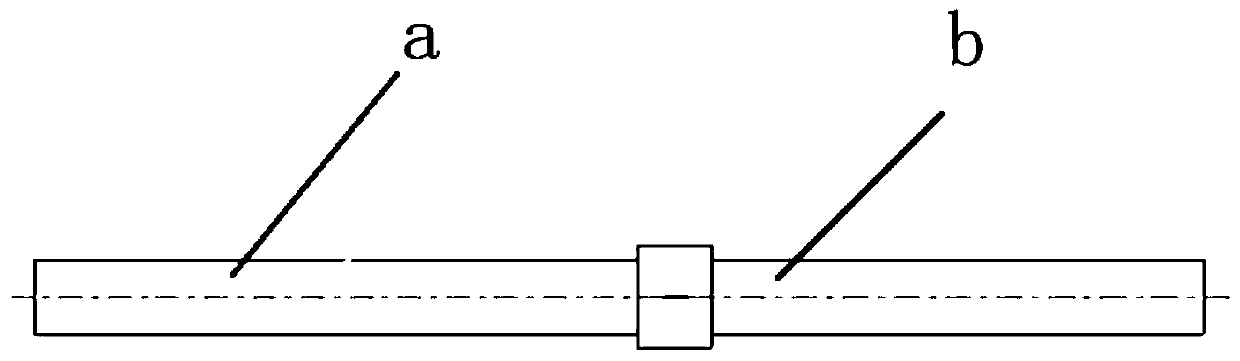

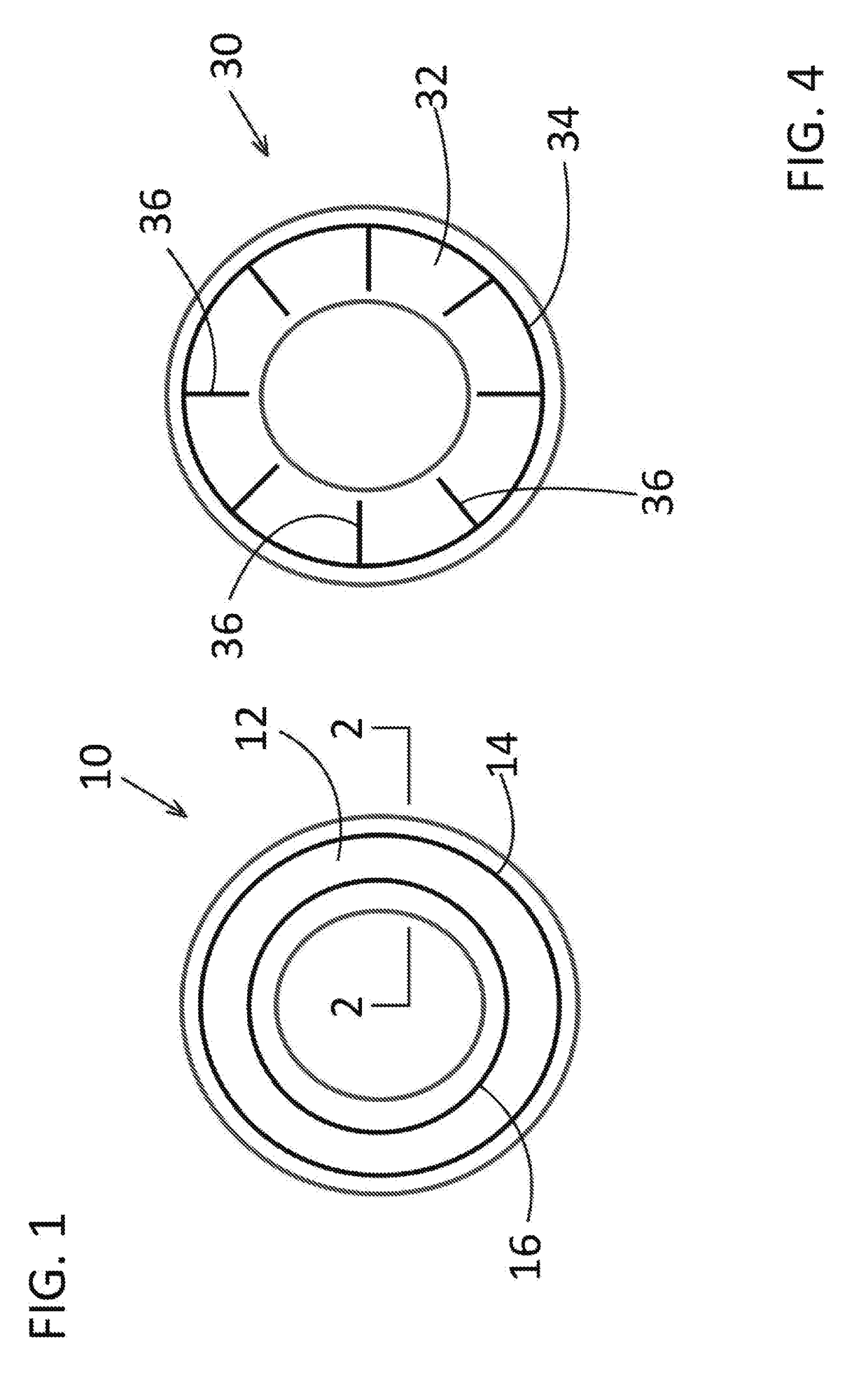

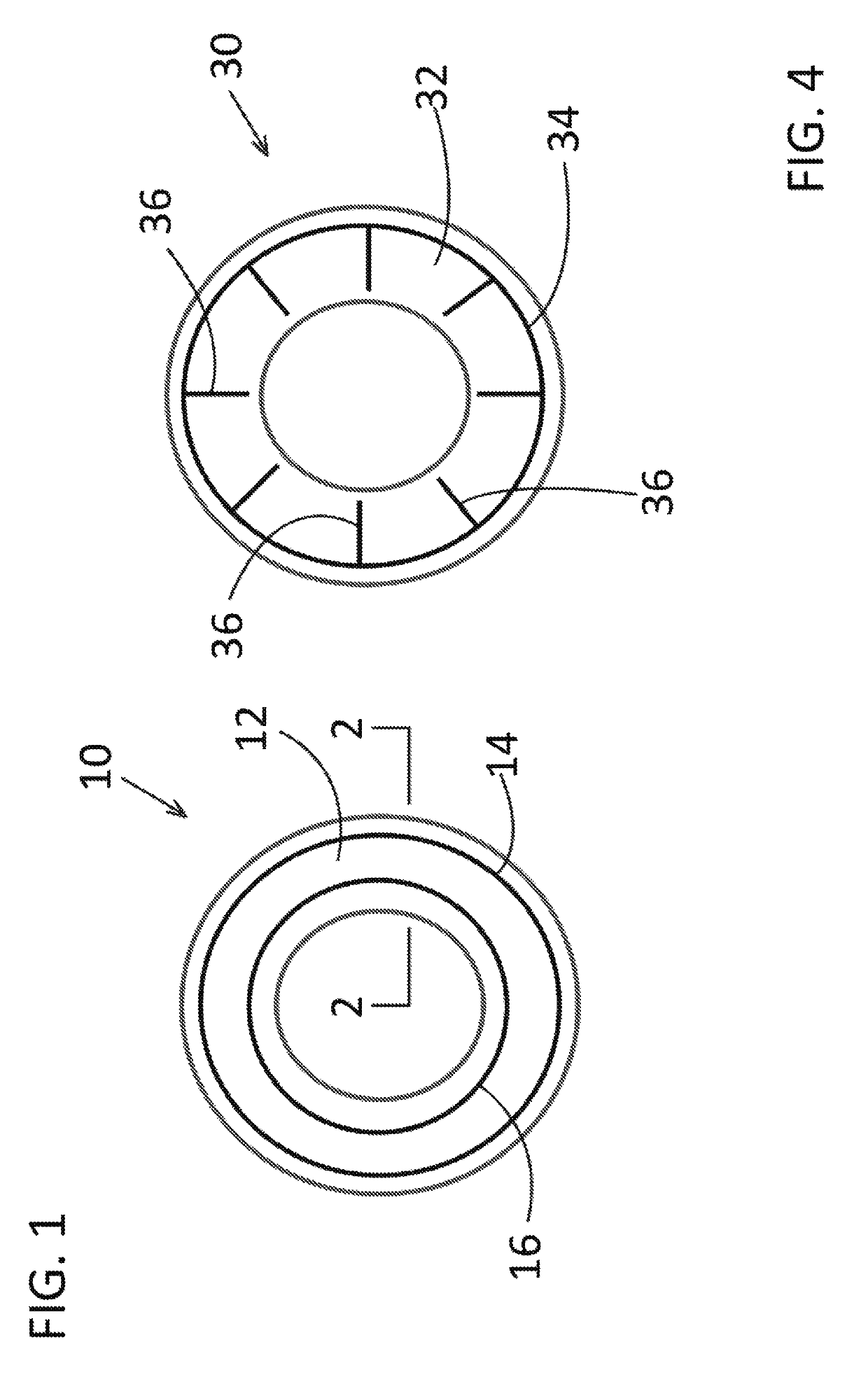

Disc and Spring Isolation Bearing

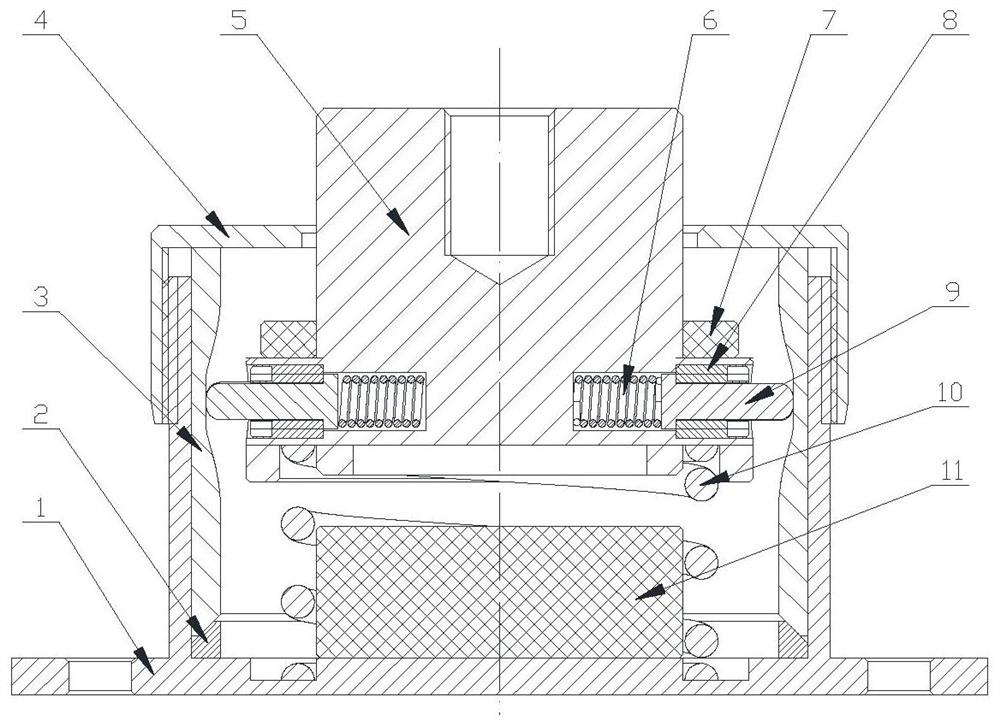

ActiveUS20140270602A1Reduced footprintIncrease frictional dampingLinear bearingsBearing assemblyMechanical engineeringSeismic isolation

The disclosed seismic isolation bearing includes an upper base plate, a lower base plate, a disc bearing core, and at least one shear spring. The upper and lower base plates each have an upper surface and a lower surface. The disc bearing core is centrally positioned with respect to the planes of the upper and lower base plates and is in contact with the lower surface of the upper base plate and the upper surface of the lower base plate, where the disc bearing core allows the lower surface of the upper base plate to slide along the disc bearing core. The shear spring is coupled to the lower surface of the upper base plate and the upper surface of the lower base plate, deforms in shear upon lateral movement of the upper base plate relative to the lower base plate, and exerts a lateral return force on the upper base plate when laterally displaced.

Owner:R J WATSON

Vibration isolator

ActiveCN110925345ASmall dampingIncrease stiffnessHigh internal friction springsFriction dampersVibration attenuationFriction force

The invention belongs to the technical field of an automobile and discloses a vibration isolator. The vibration isolator comprises a bottom plate, a friction assembly arranged on the bottom plate, a shell, a first reset piece and a second reset piece, wherein the bottom of the shell is arranged in the friction assembly in a sliding mode and can abut against the friction assembly, the first reset piece is arranged in the shell, two ends of the first reset piece abut against an inner wall of the shell and the bottom plate respectively, the second reset piece is arranged in the first reset pieceand connected with the first reset piece in parallel, and two ends of the second reset piece selectively abut against an inner wall of the shell and the bottom plate respectively. The vibration isolator is advantaged in that when high frequency and small load exist, the first reset piece provides rigidity needed by vibration attenuation, the small friction force between the friction assembly and the shell provides damping, rigidity and damping at the moment are small, and high-frequency vibration attenuation is facilitated; when an impact or large-load working condition is met, the two stagesof reset pieces act at the same time, rigidity of the system is improved, the shell can abut against the friction assembly, friction damping is increased, and the requirement for large-rigidity and large-damping isolation impact at low frequency is met.

Owner:WEICHAI POWER CO LTD

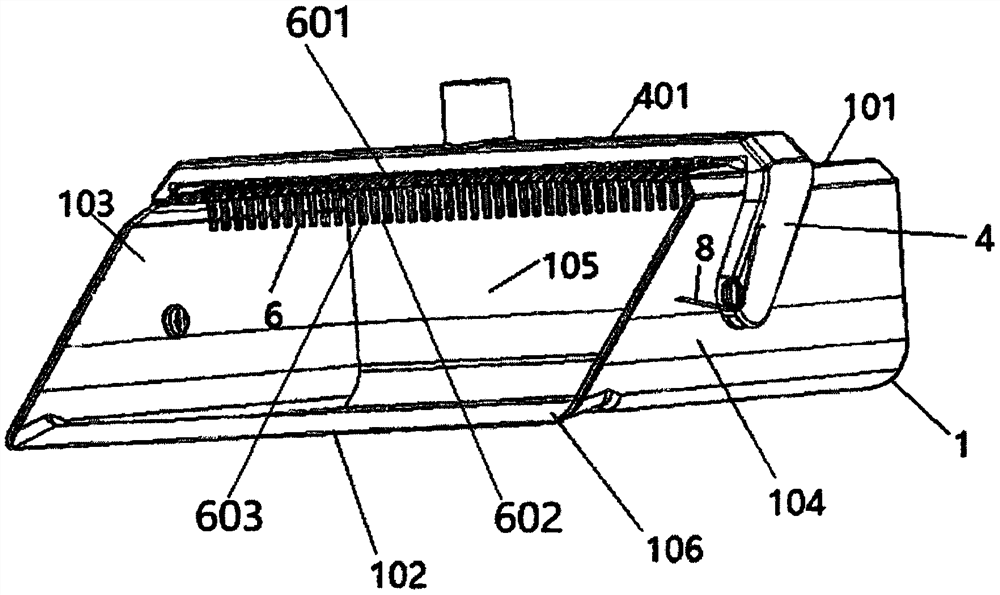

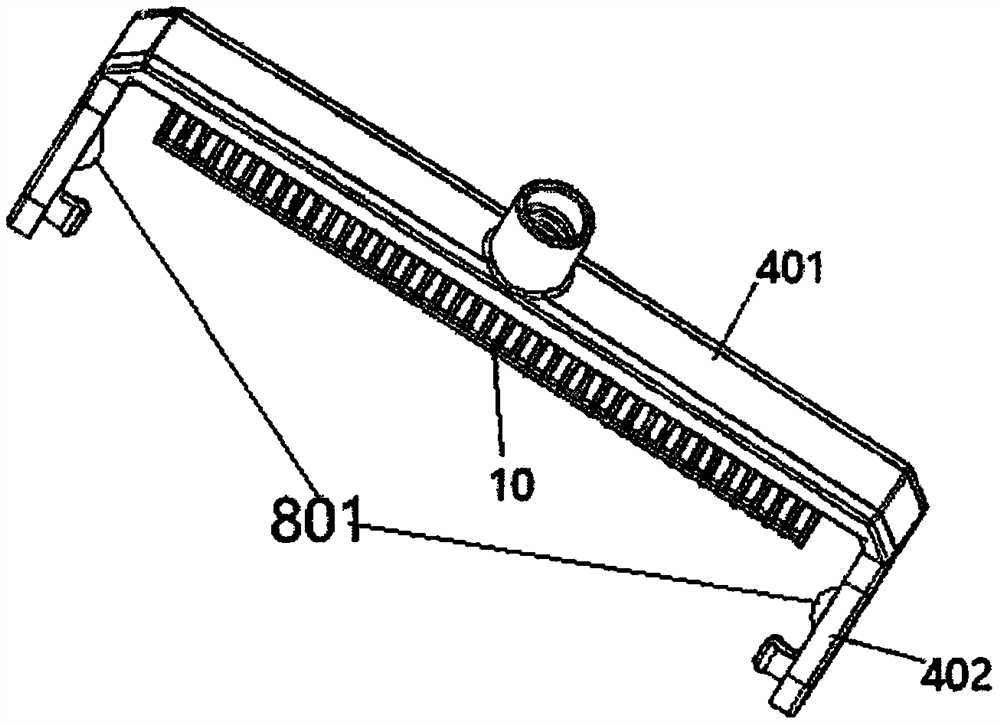

Rotary supporting frame for displayer

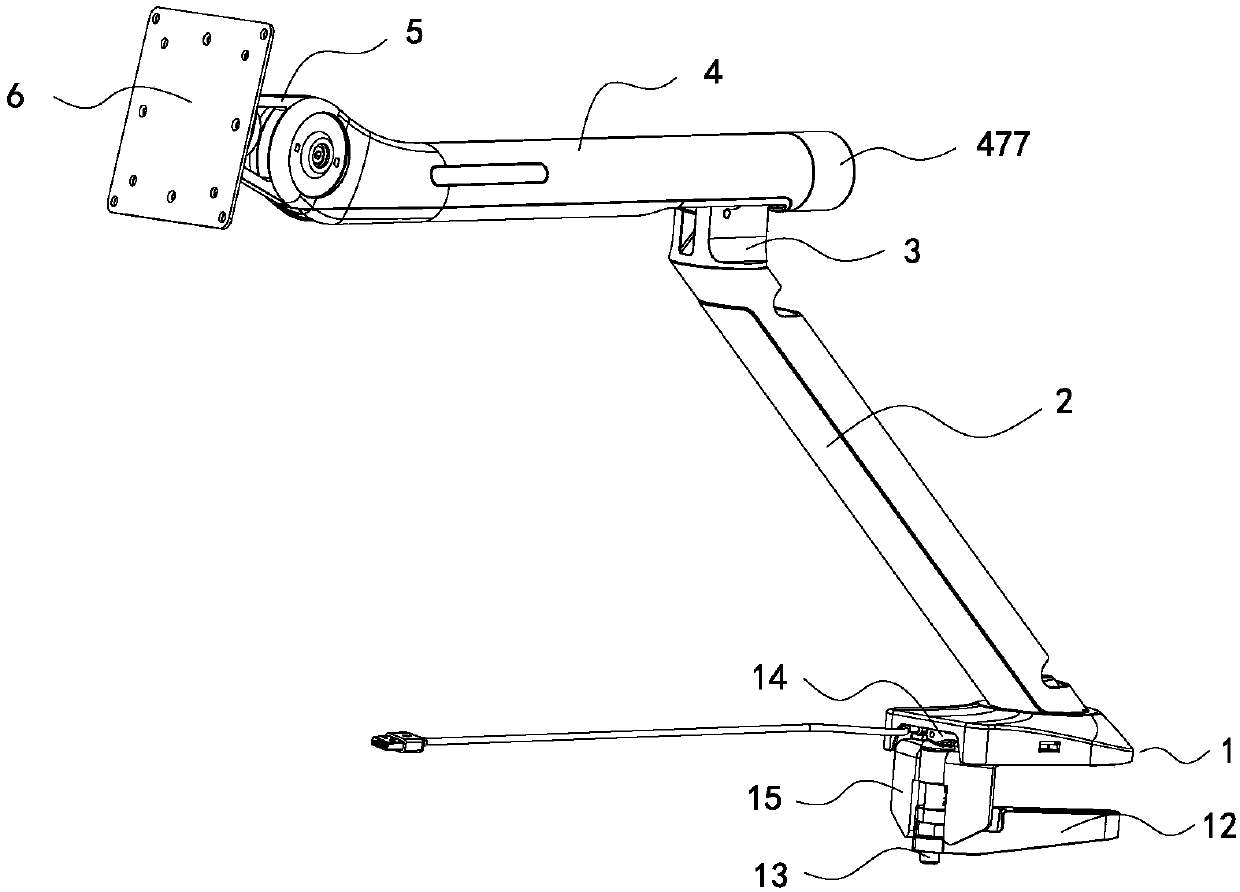

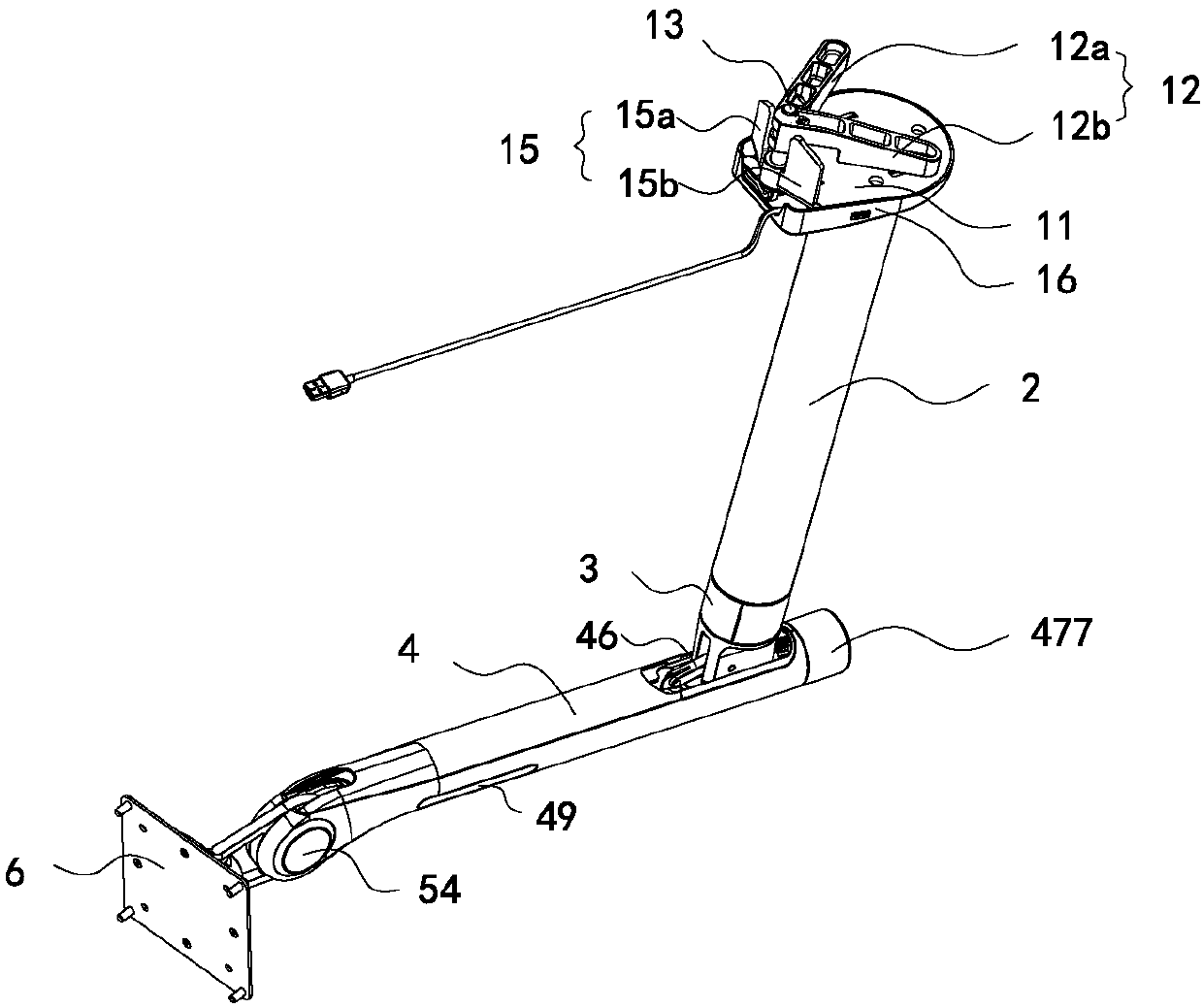

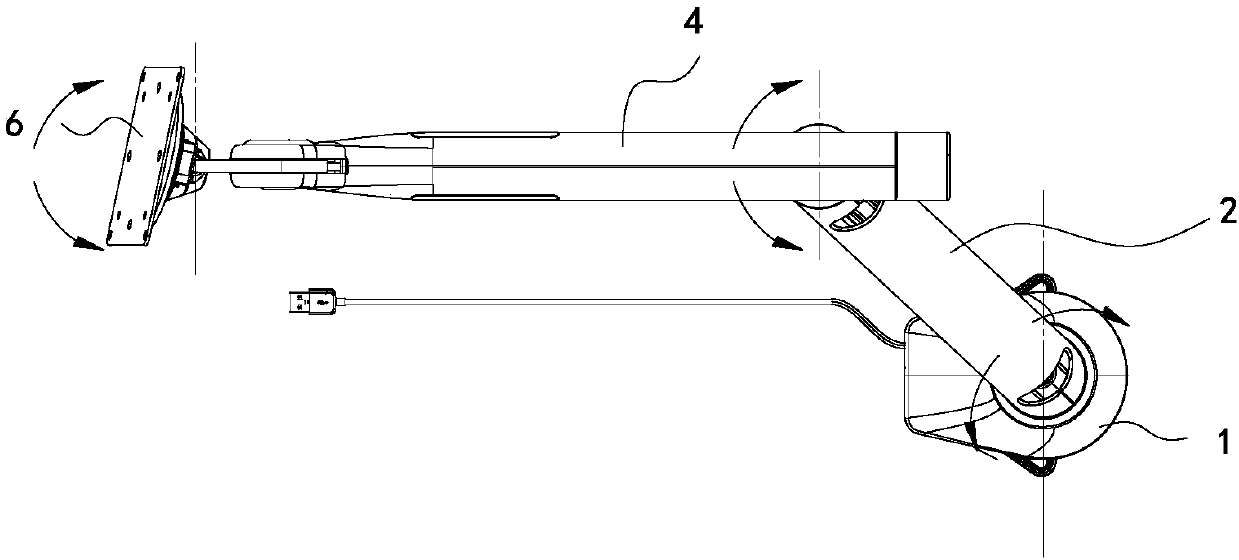

PendingCN107631142AAppropriate viewing angleHem avoidStands/trestlesPivotal connectionsDisplay deviceEngineering

The invention discloses a rotary supporting frame for a displayer and belongs to the field of displayer auxiliary connection fittings. The rotary supporting frame comprises a clamping seat for being fixed to a target object, and supporting arms are rotationally connected to the clamping seat; a hanger for installing the displayer is connected to the upper supporting arm; a rocker arm disc frame isconnected between the upper supporting arm and the hanger and rotationally installed on the upper supporting arm; and a friction plate is further arranged inside the upper supporting arm and keeps making contact with the surface of the rocker arm disc frame. The rotary supporting frame has the advantage that the load bearing capacity of the hanger can be improved.

Owner:ZHEJIANG JUYOU INTELLIGENT TECH CO LTD

Disc and spring isolation bearing

ActiveUS8926180B2Reduce earthquake forceLarge displacementLinear bearingsBearing assemblyEngineeringLateral displacement

The disclosed seismic isolation bearing includes an upper base plate, a lower base plate, a disc bearing core, and at least one shear spring. The upper and lower base plates each have an upper surface and a lower surface. The disc bearing core is centrally positioned with respect to the planes of the upper and lower base plates and is in contact with the lower surface of the upper base plate and the upper surface of the lower base plate, where the disc bearing core allows the lower surface of the upper base plate to slide along the disc bearing core. The shear spring is coupled to the lower surface of the upper base plate and the upper surface of the lower base plate, deforms in shear upon lateral movement of the upper base plate relative to the lower base plate, and exerts a lateral return force on the upper base plate when laterally displaced.

Owner:R J WATSON

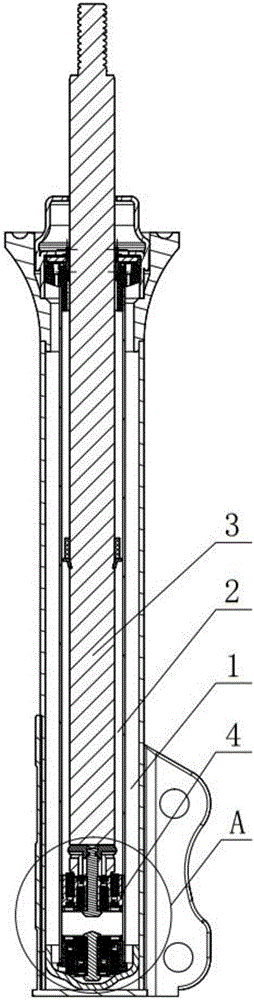

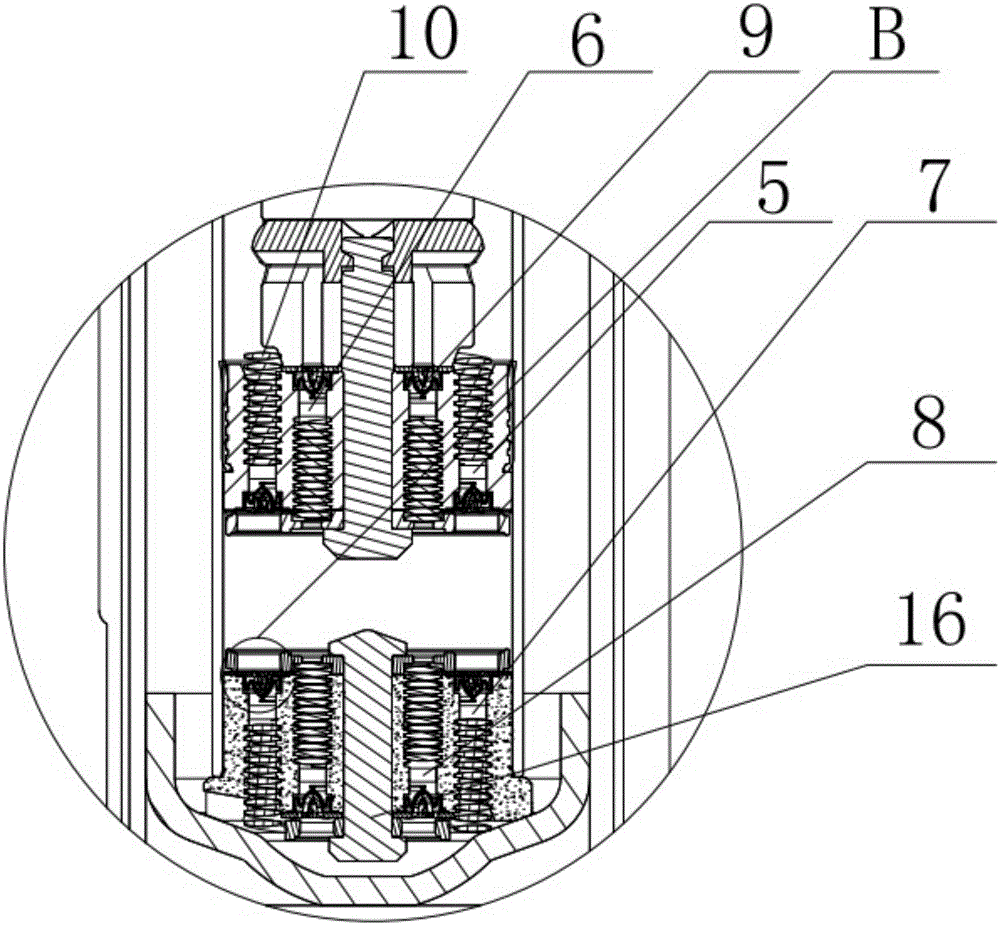

Low-bubble spiral flow channel damping suspension shock absorber

The invention relates to the technical field of vehicle shock absorbers, in particular to a low-bubble spiral flow channel damping suspension shock absorber. A piston (3) is provided with two annular through holes, namely a first outer annular through hole (5) and a first inner annular through hole (6). A base (16) is provided with two annular through holes, namely a second outer annular through hole (7) and a second inner annular through hole (8). Spiral channels (15) are arranged in the first outer annular through hole (5), the first inner annular through hole (6), the second outer annular through hole (7) and the second inner annular through hole (8) respectively. The lower end of the first outer annular through hole (5) and the lower end of the second inner annular through hole (8) are provided with one-way valves (9) for preventing damping fluid from flowing downwards, and the upper end of the first inner annular through hole (6) and the upper end of the second outer annular through hole (7) are provided with one-way valves (9) for preventing the damping fluid from flowing upwards. The suspension shock absorber can be adapted to different loads and road conditions and is not prone to generating air bubbles.

Owner:汉驭(杭州)科技发展有限公司

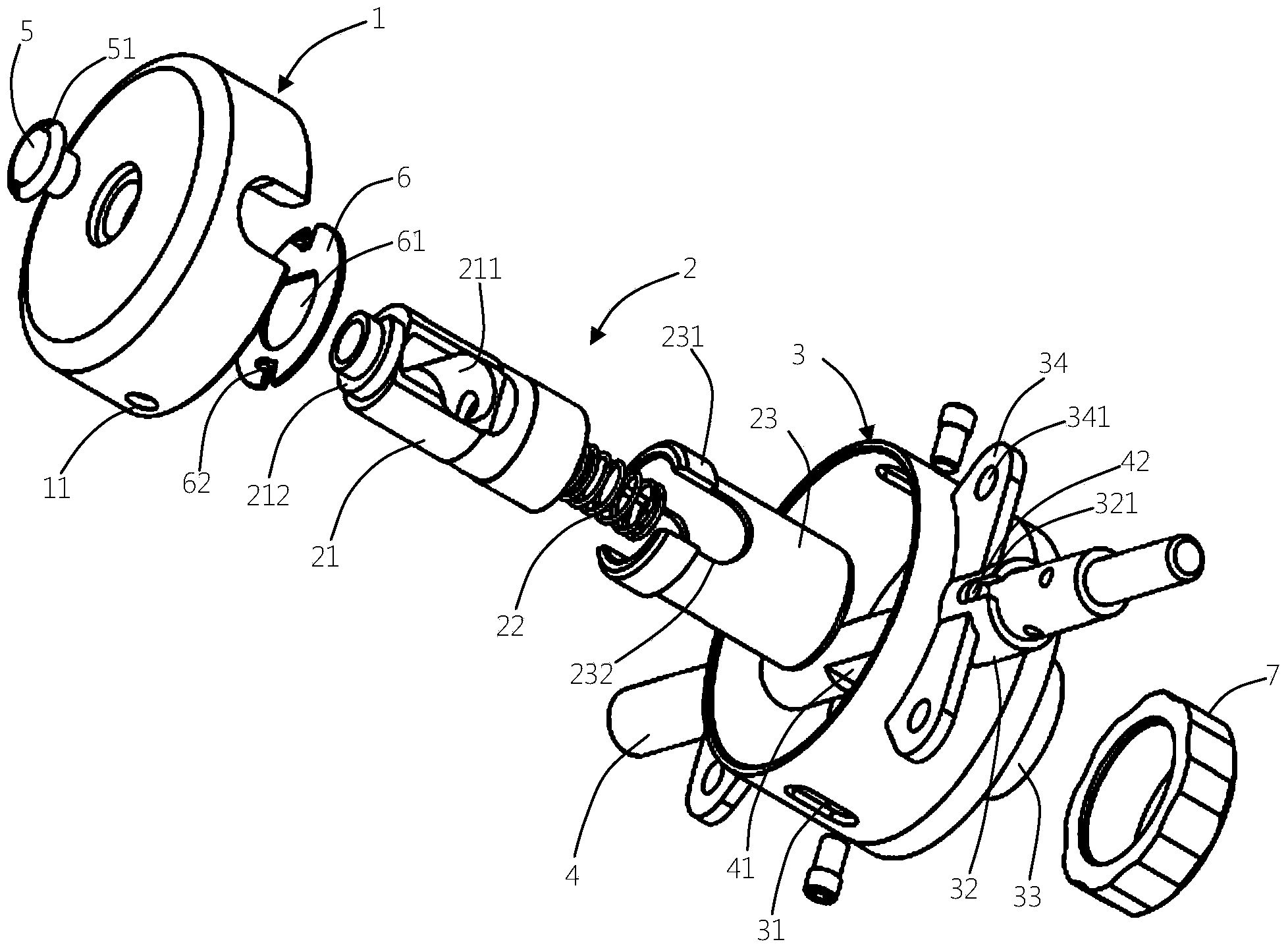

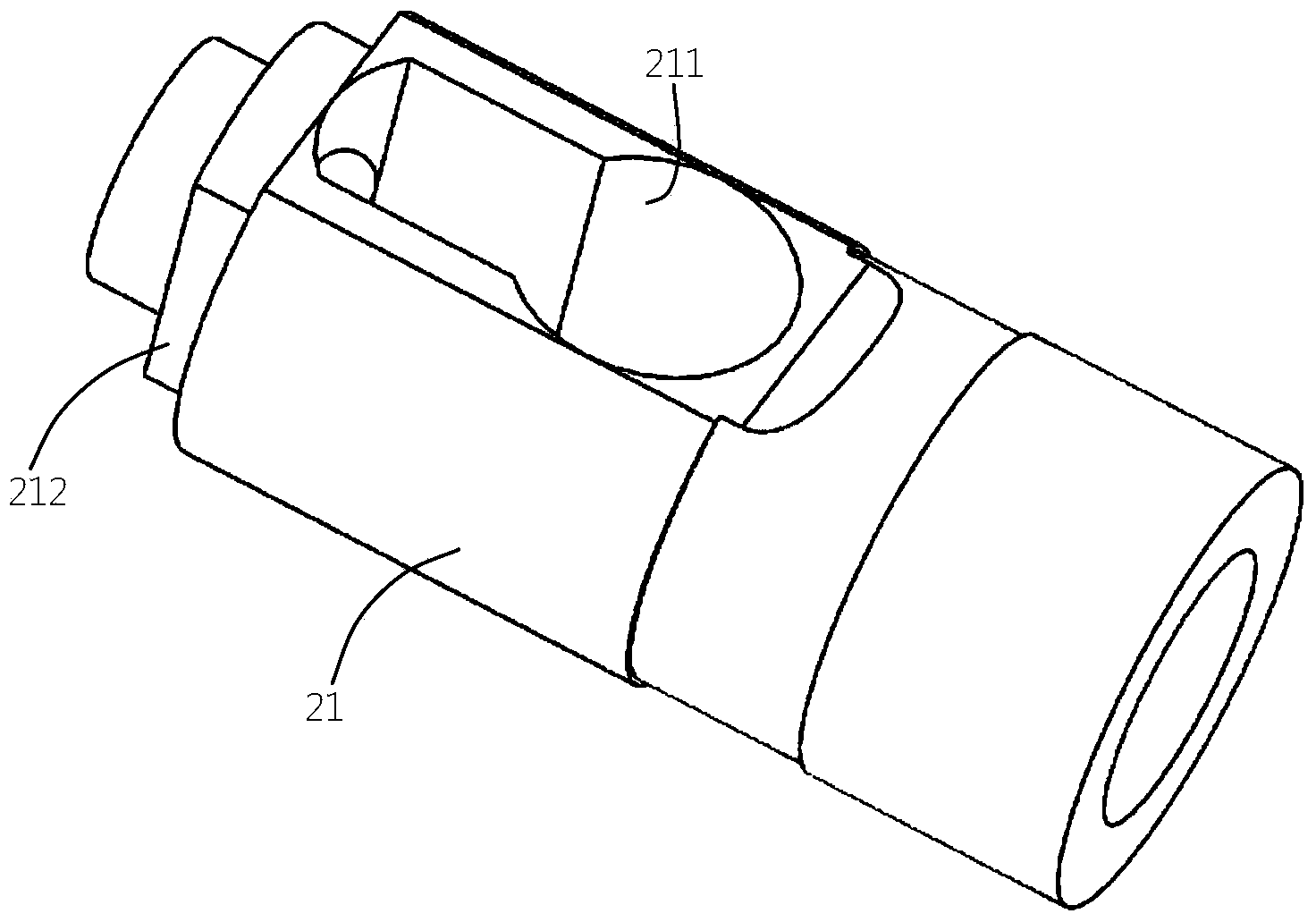

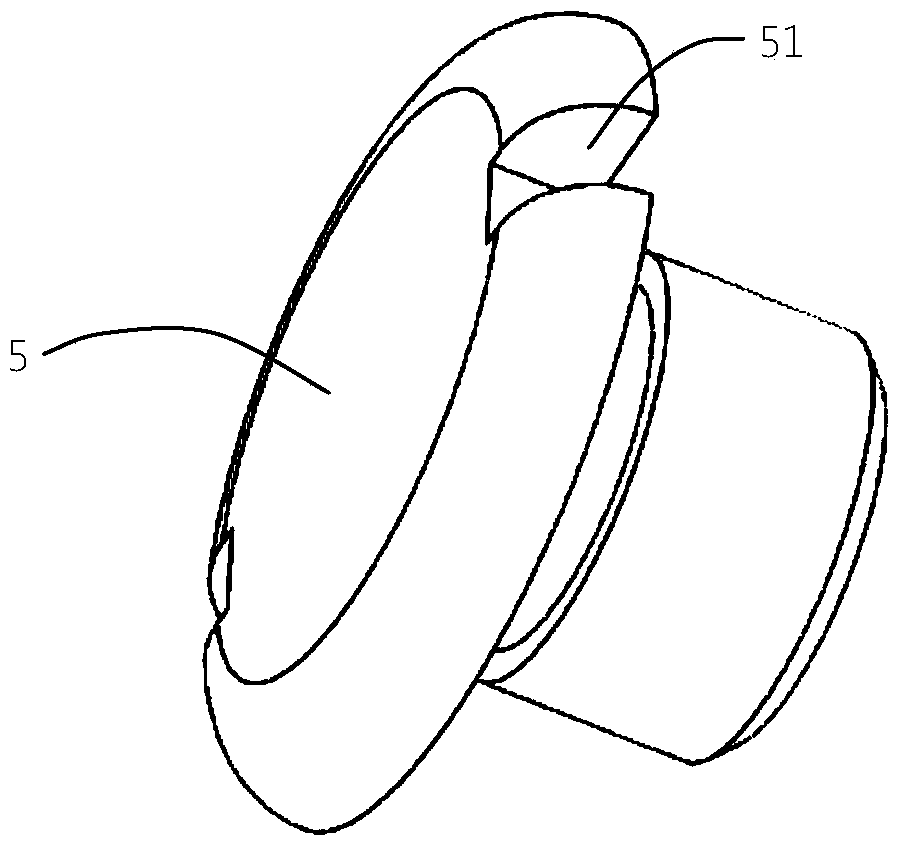

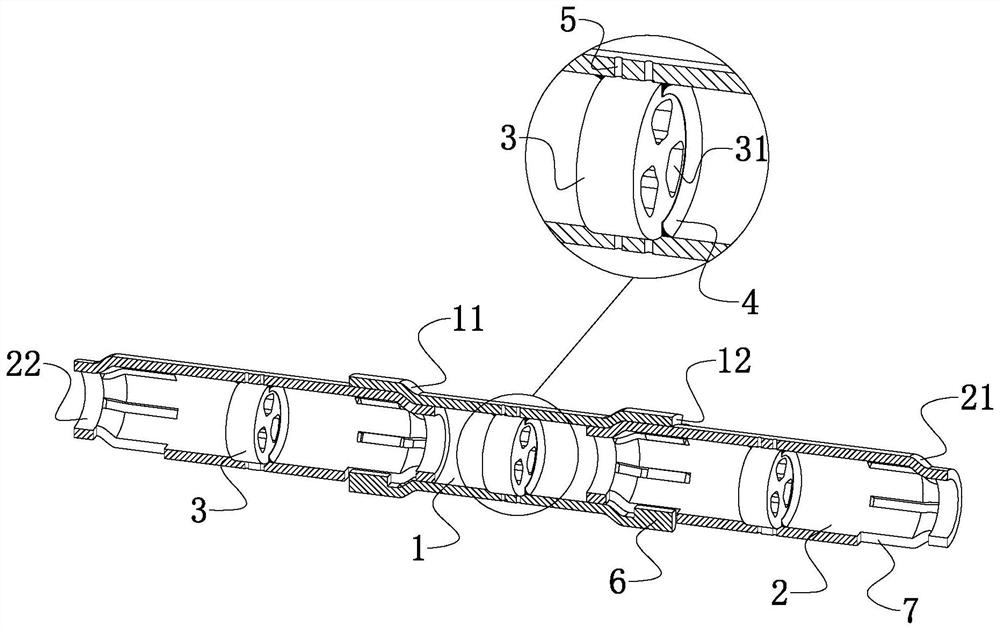

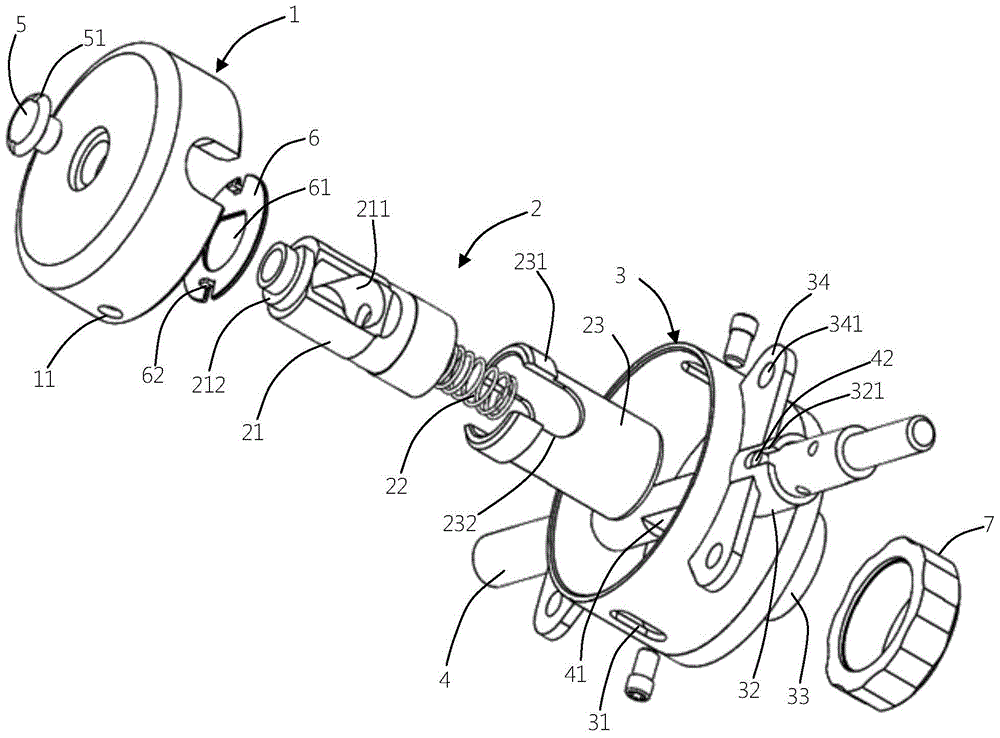

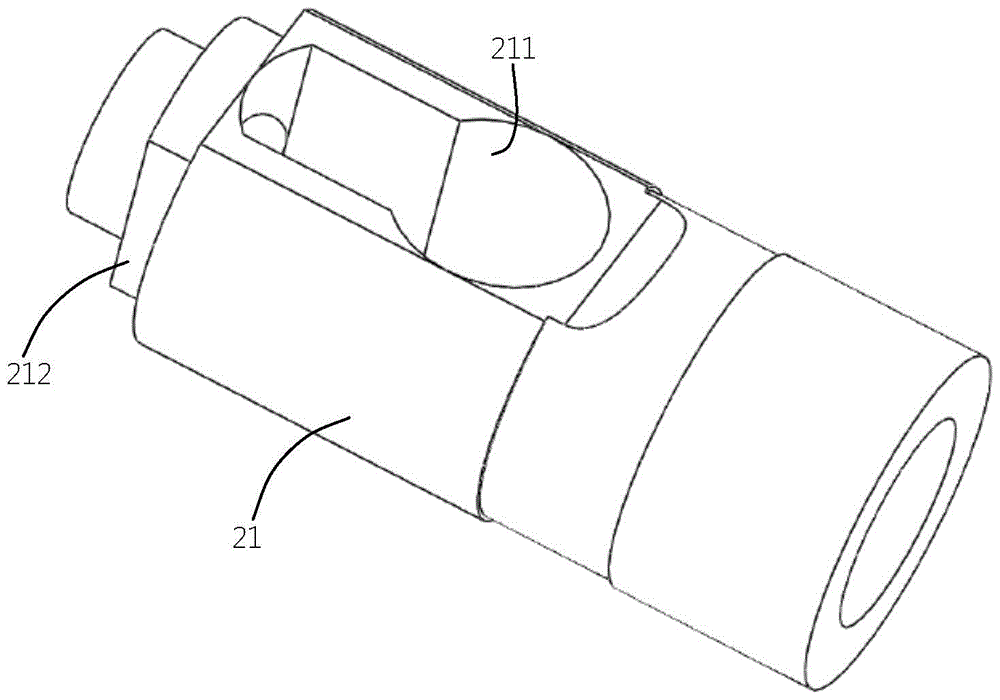

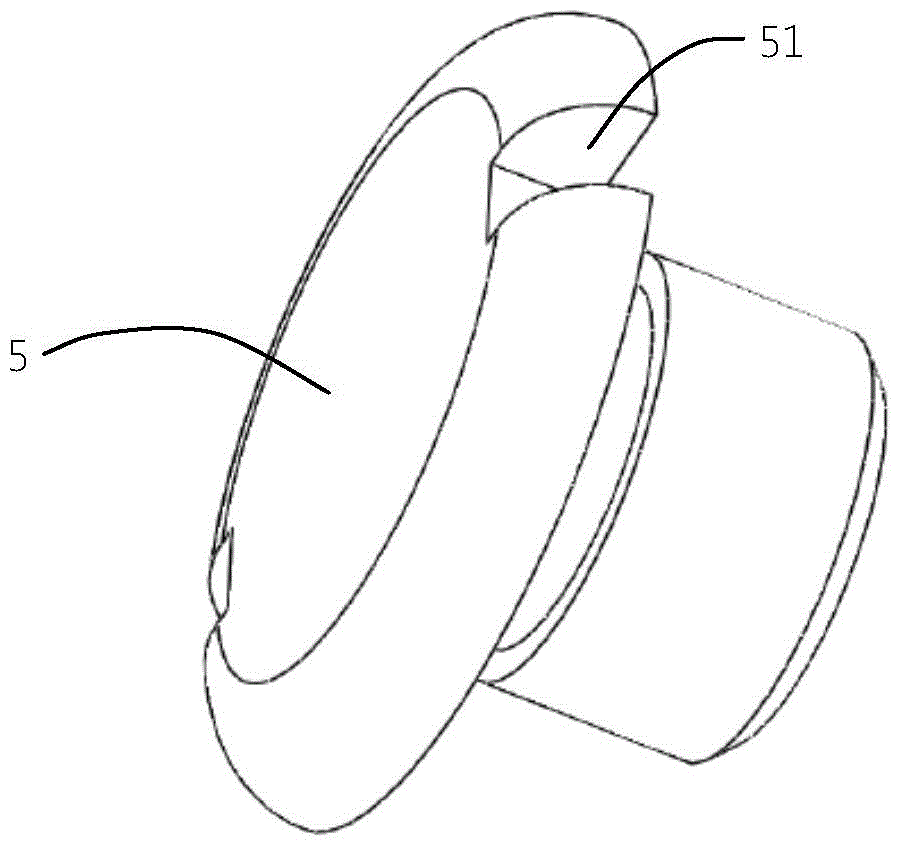

Mechanical pressure sensing and locking safety device

The invention discloses a mechanical pressure sensing and locking safety device which comprises an inductive head, a locking mechanism and a guide sleeve. Two ends of the guide sleeve are respectively provided with a guide hole, a latch rod is inserted into the guide sleeve through the guide holes, the inductive head is connected to the guide sleeve and matched with the guide sleeve to form a mounting space, the locking mechanism is arranged in the mounting space and connected with the inductive head and the latch rod, and the inductive head and the locking mechanism control axial locking and unlocking of the latch rod in a matched manner. The mechanical pressure sensing and locking safety device has the advantages that the device is compact in structure, reliable in action execution, convenient to mount, applicable to occasions with sanitary and anti-explosion requirements and passive sites, high in safety and sensitive in response, and can be automatically locked and unlocked.

Owner:SHANGHAI MORIMATSU PHARMA EQUIP ENG

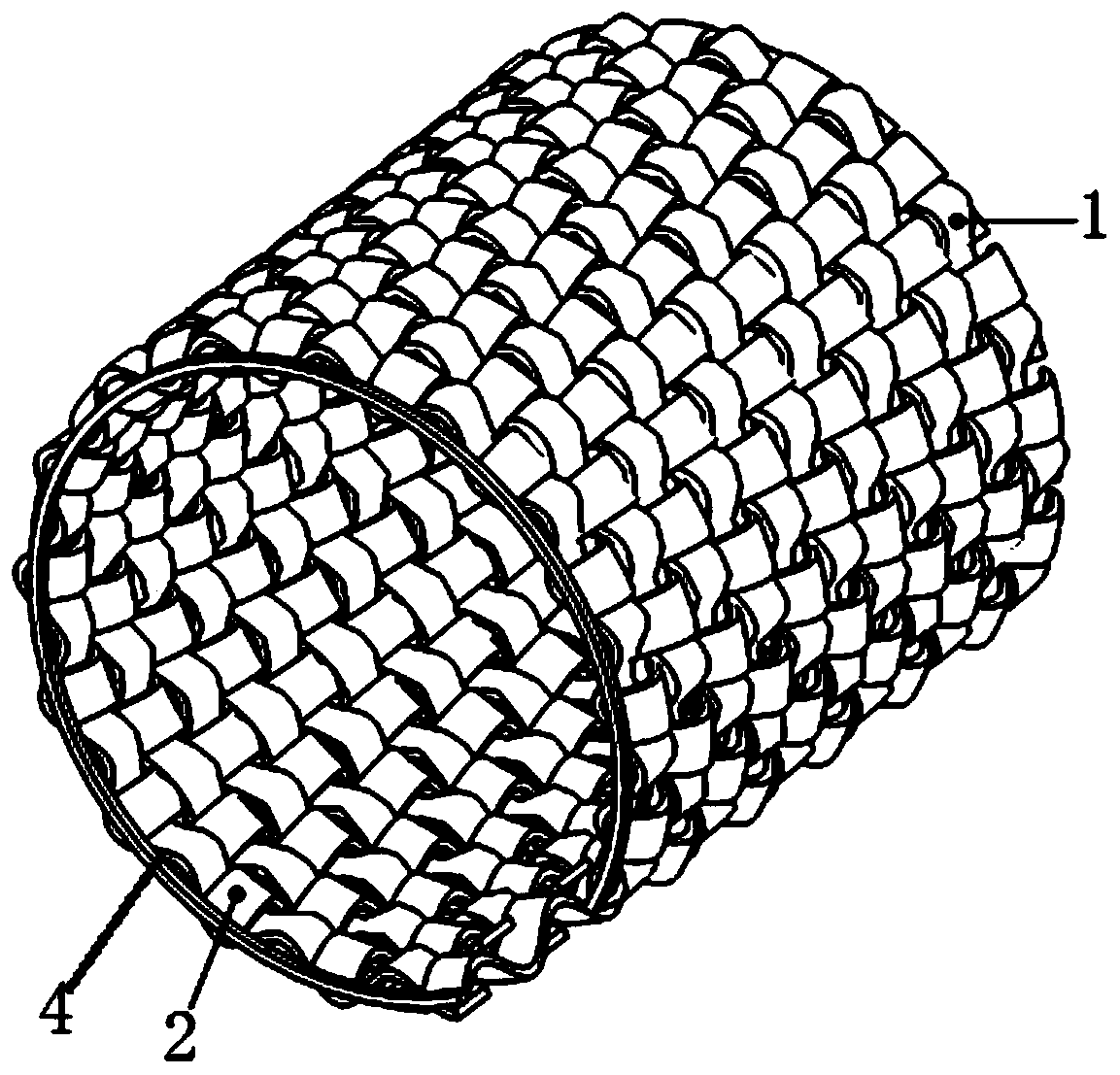

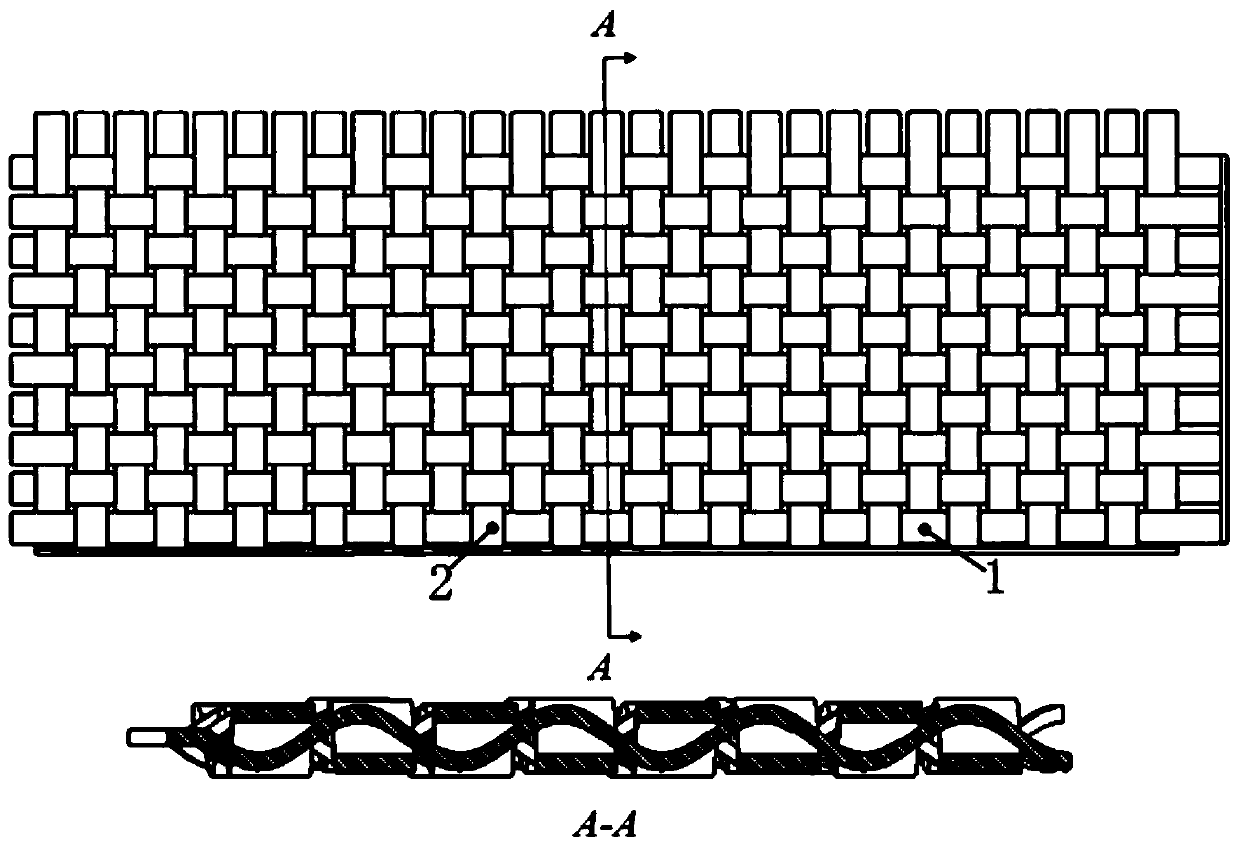

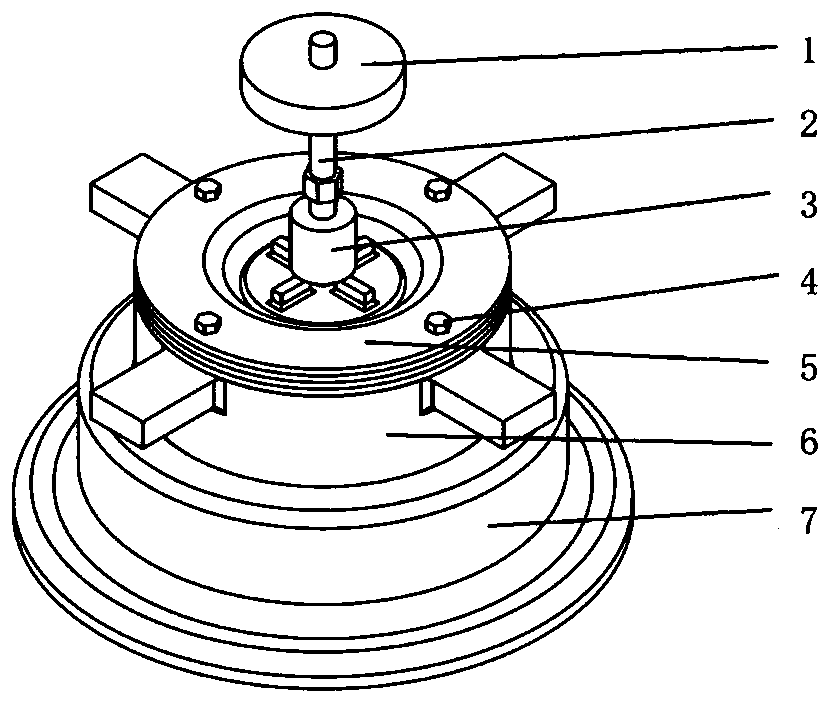

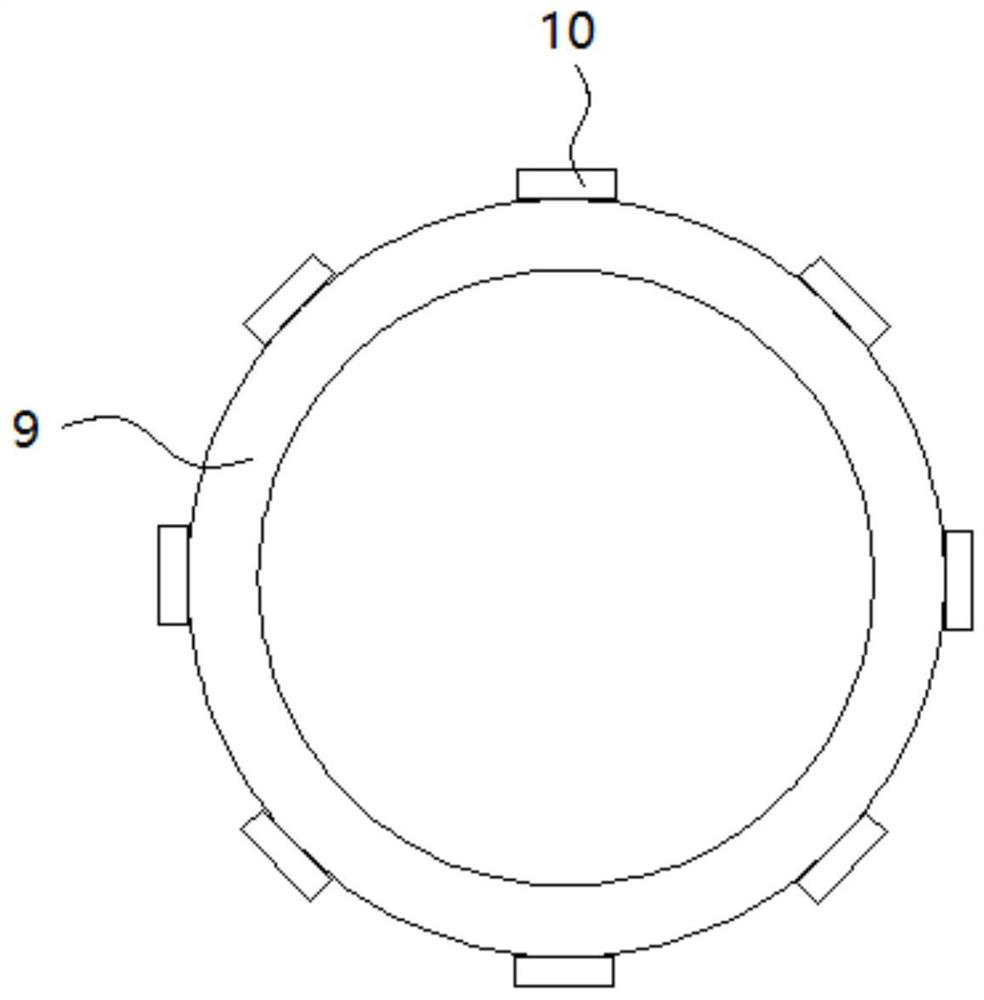

Flexible assembly and dynamic pressure radial gas bearing

InactiveCN109780051AIncrease structural dampingIncrease frictional dampingSliding contact bearingsBearing unit rigid supportProduct gasEngineering

The invention belongs to the technical field of mechanical equipment, and in particular relates to a flexible assembly and a dynamic pressure radial gas bearing. The variable range of stiffness is limited due to the fact that in a traditional foil bearing structure, the wave foil arch bottom only contacts with the upper surface of a bearing seat in one direction; and at the same time, the effect of friction damping on energy dissipation is poor due to the fact that the space of a wave foil bearing structure is not fully utilized. The flexible assembly comprises a first foil group and a secondfoil group, the first foil group intersects with the second foil group, and the space phase of the first foil group is opposite to the space phase of the second foil group; and the flexible assembly is provided higher structural damping. According to the dynamic pressure radial gas bearing, by adopting the flexible assembly, the limited working space of the foil bearing is fully utilized, the contact area among the flexible assembly and the flat foil surface and the bearing seat surface is increased, bearing friction damping is improved, thus energy dissipation in the bearing is enhanced, andthe stability of a rotor-bearing system is effectively maintained.

Owner:XI AN JIAOTONG UNIV

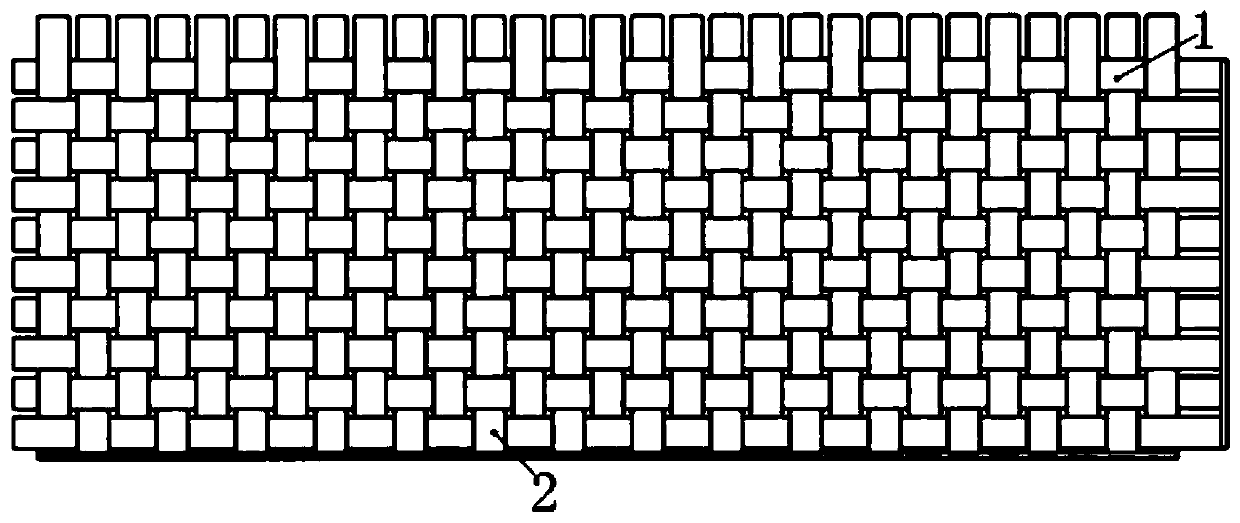

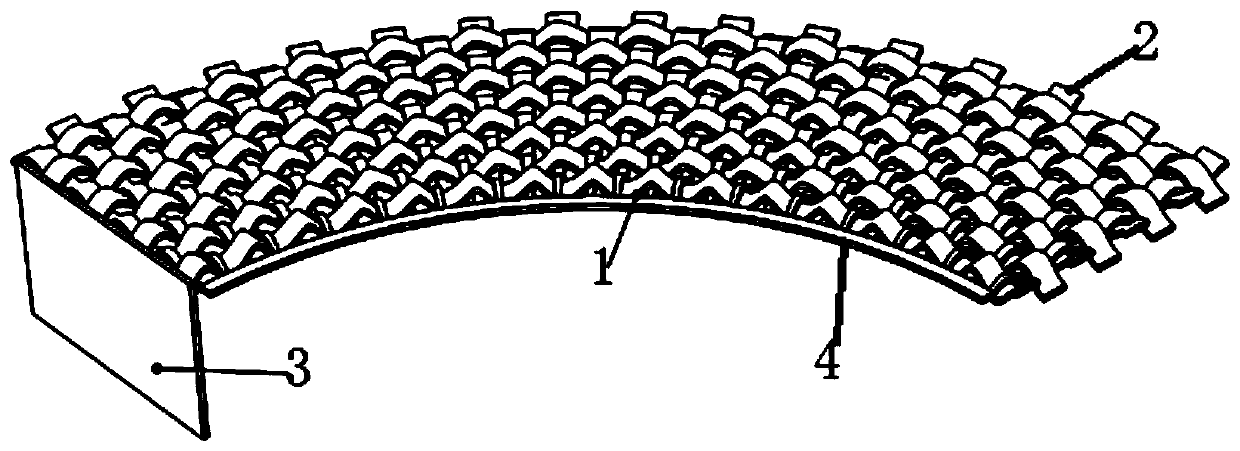

Flexible assembly and dynamic-pressure thrust gas bearing

InactiveCN109737140AIncrease structural dampingIncrease frictional dampingBearingsMechanical equipmentEngineering

The invention belongs to the technical field of mechanical equipment, and particularly relates to a flexible assembly and a dynamic-pressure thrust gas bearing. In a conventional foil sheet bearing structure, a wave foil arch base is only in single-direction linear contact with the upper surface of a bearing base, so that the variable range of rigidity is limited; and the space of a wave foil bearing structure is not sufficiently utilized, so that friction damping is relatively poor in energy dissipation effect. The invention provides a flexible assembly which comprises a foil sheet group anda second foil sheet group, wherein the first foil sheet group is mutually crossed with the second foil sheet group; and the space phase of the first foil sheet group is reverse to that of the second foil sheet group. The flexible assembly has higher structure damping. According to the dynamic-pressure thrust gas bearing disclosed by the invention, the flexible assembly is adopted, and limited working space of the foil sheet bearing is sufficiently utilized, so that the contact area among the flexible assembly, a top-layer flat foil and a bearing base surface is increased, and bearing frictiondamping is improved, and therefore, energy dissipation in the bearing is strengthened, and stability of a rotor-bearing system is effectively kept.

Owner:XI AN JIAOTONG UNIV

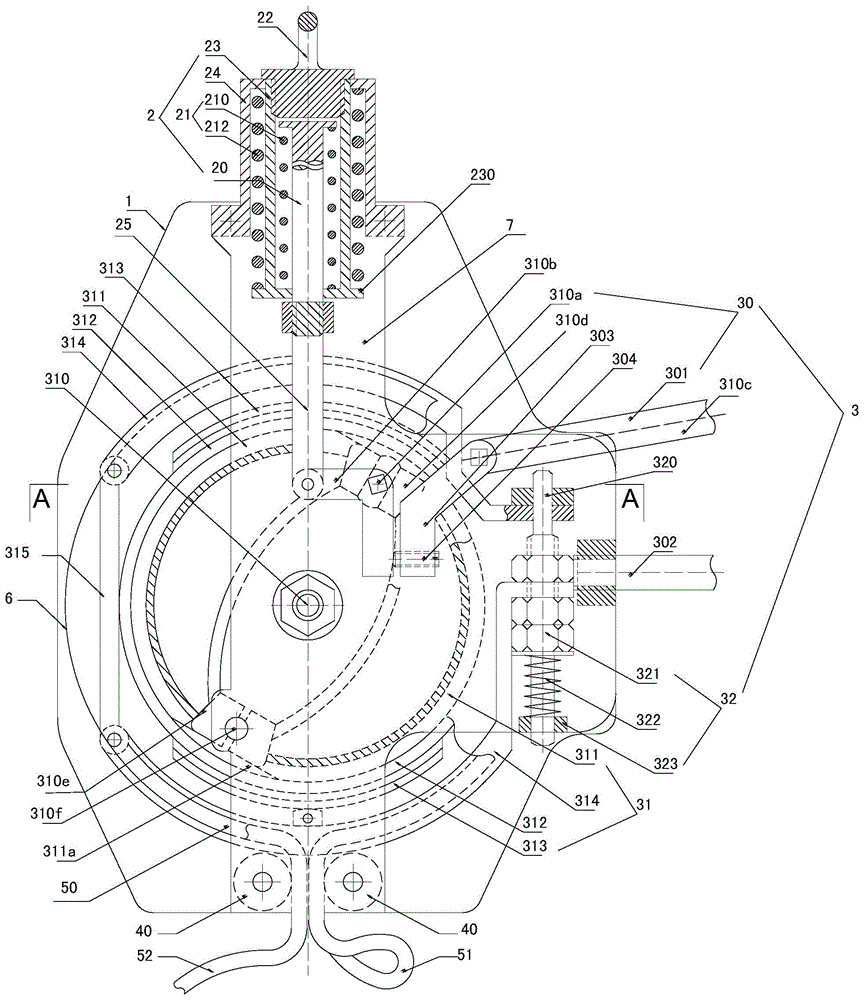

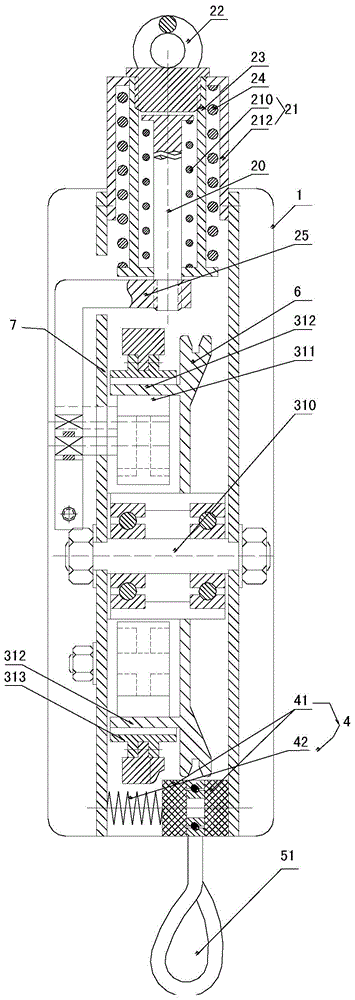

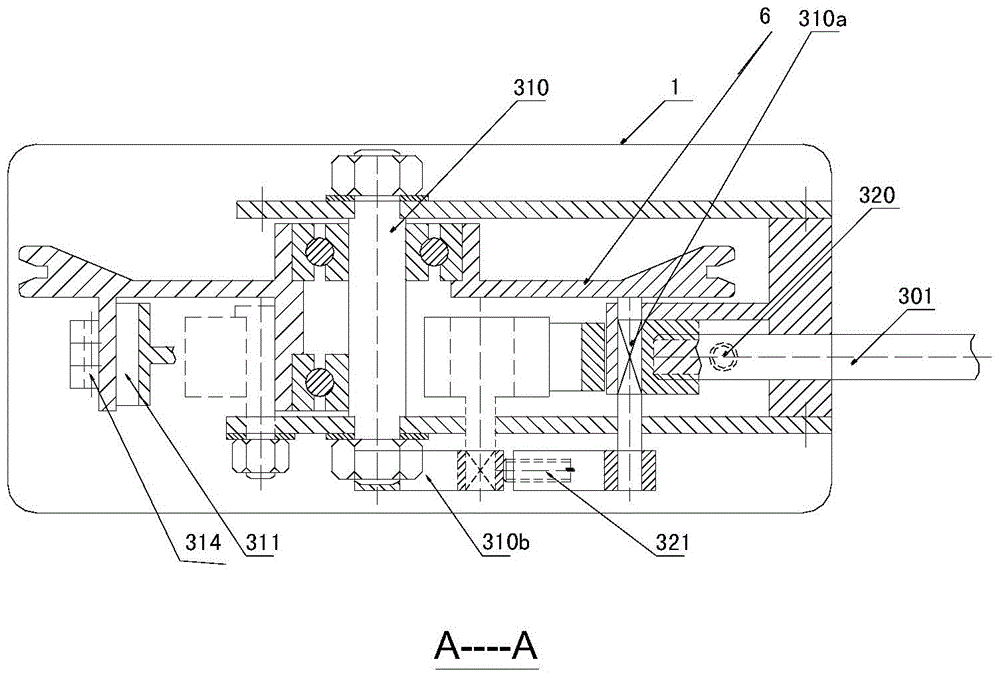

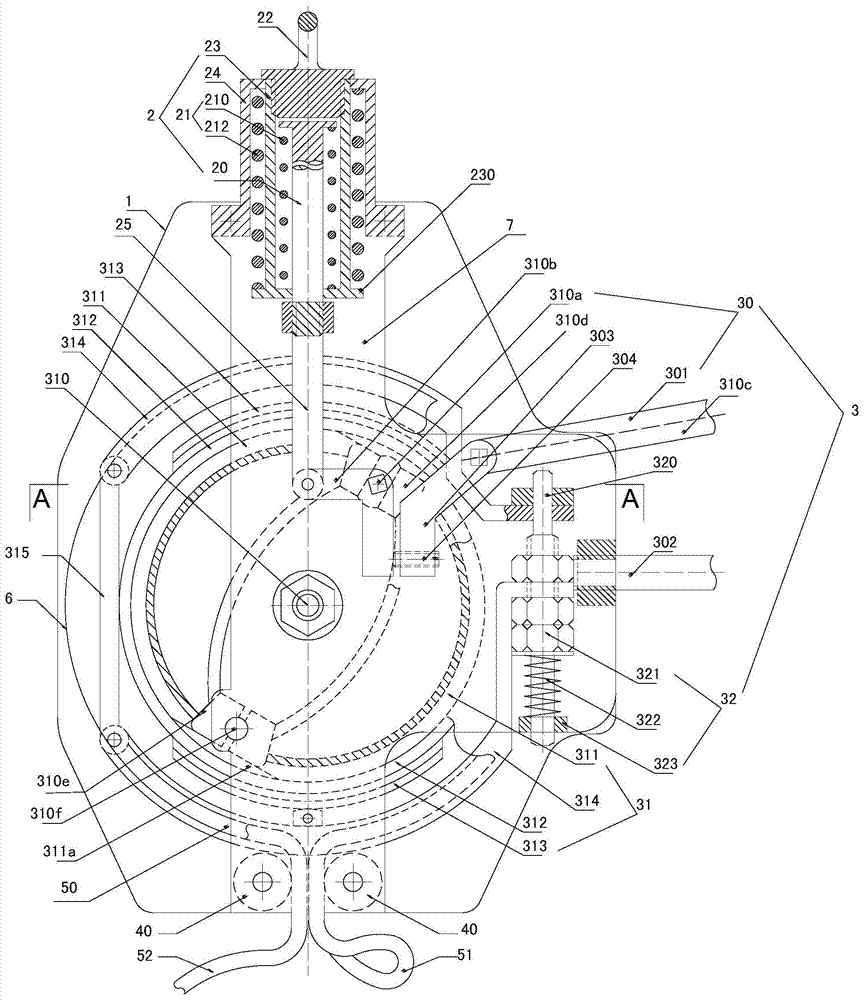

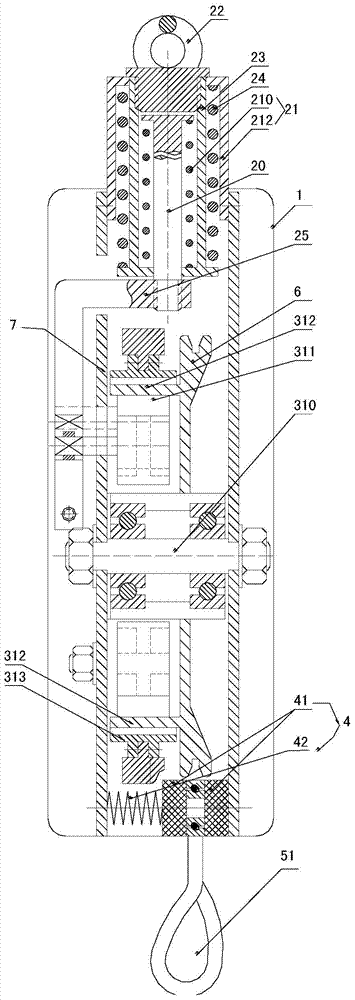

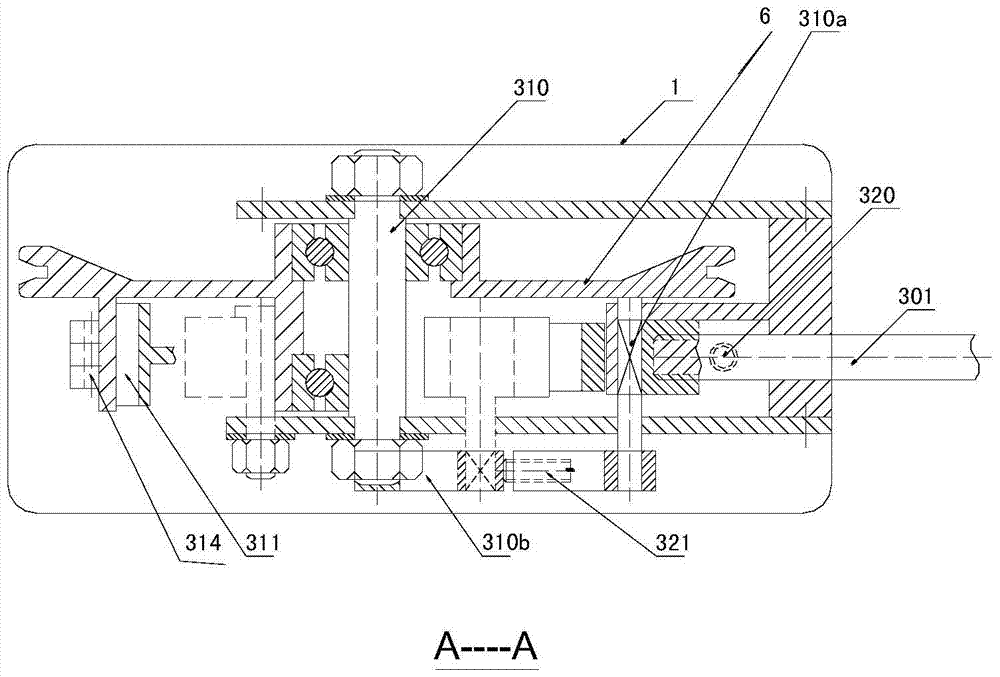

Double-brake back-and-forth controllable descent control device

The invention discloses a double-brake back-and-forth controllable descent control device. The double-brake back-and-forth controllable descent control device comprises an outer shell, a pulling mechanism, a double-brake mechanism and a rope guiding mechanism, wherein the pulling mechanism, the double-brake mechanism and the rope guiding mechanism are arranged in the outer shell; the pulling mechanism is mutually linked with the double-brake mechanism and comprises an energy conversion regulating screw rod and a buffer piece which is arranged at the periphery of the pulling mechanism; the double-brake mechanism comprises an outer brake assembly, an inner brake assembly and a self locking mechanism, the inner brake assembly is mutually linked with the energy conversion regulating screw rod of the pulling mechanism, a wedge wheel is arranged at the periphery of the inner brake assembly, a steel wire rope is wound on the wedge wheel and is in rolling friction, and the self locking mechanism is movably arranged between the outer brake assembly and the outer shell in a leaning way; when the outer brake assembly is in an unstressed state or a maximum stress state, the inner brake assembly is in a semi-brake state to generate friction damping, and the steel wire rope wound on the peripheral wedge wheel can be tensioned and locked; when the outer brake assembly is in a semi-clutch state, the inner brake assembly and a brake hub are in a friction state by the locking of the inner brake assembly on the steel wire rope, the steel wire rope is enabled to be guided out along the rope guiding mechanism by friction force difference, and slow and uniform-speed descending can be realized.

Owner:广东专哲电子科技有限公司

A double-brake back-and-forth controllable descending device

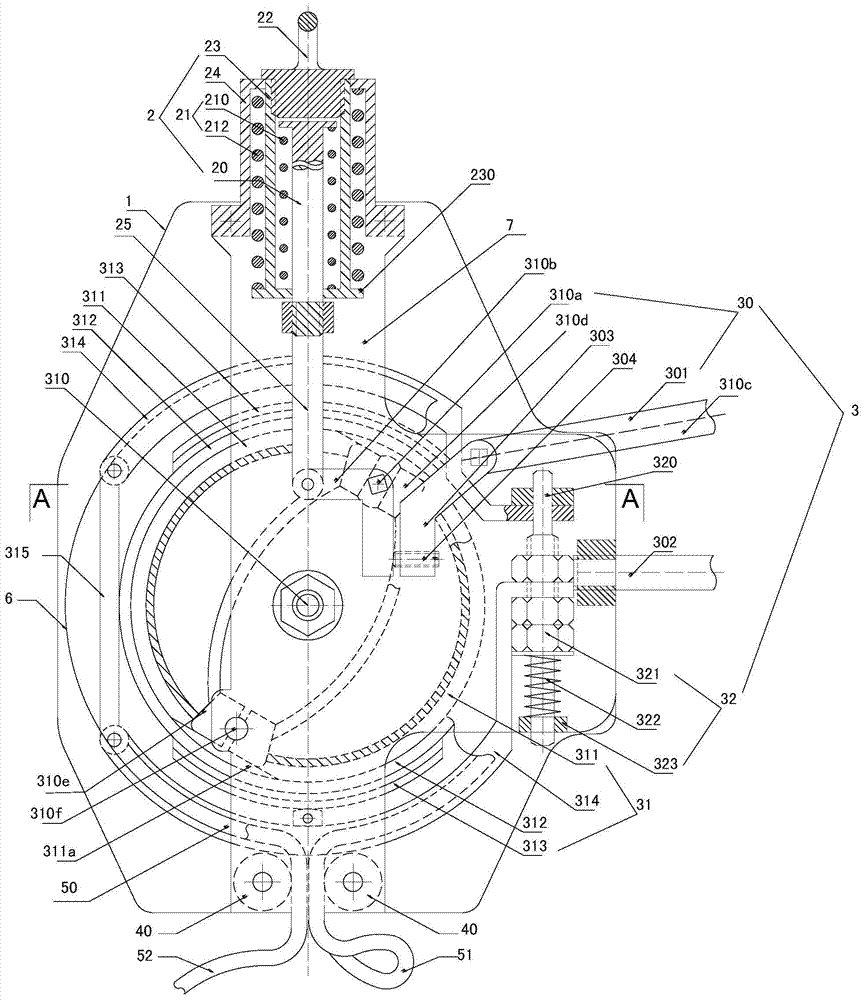

ActiveCN104667445BImprove controllabilityIncrease frictional dampingBuilding rescueRolling resistanceLocking mechanism

The invention discloses a double-brake back-and-forth controllable descent control device. The double-brake back-and-forth controllable descent control device comprises an outer shell, a pulling mechanism, a double-brake mechanism and a rope guiding mechanism, wherein the pulling mechanism, the double-brake mechanism and the rope guiding mechanism are arranged in the outer shell; the pulling mechanism is mutually linked with the double-brake mechanism and comprises an energy conversion regulating screw rod and a buffer piece which is arranged at the periphery of the pulling mechanism; the double-brake mechanism comprises an outer brake assembly, an inner brake assembly and a self locking mechanism, the inner brake assembly is mutually linked with the energy conversion regulating screw rod of the pulling mechanism, a wedge wheel is arranged at the periphery of the inner brake assembly, a steel wire rope is wound on the wedge wheel and is in rolling friction, and the self locking mechanism is movably arranged between the outer brake assembly and the outer shell in a leaning way; when the outer brake assembly is in an unstressed state or a maximum stress state, the inner brake assembly is in a semi-brake state to generate friction damping, and the steel wire rope wound on the peripheral wedge wheel can be tensioned and locked; when the outer brake assembly is in a semi-clutch state, the inner brake assembly and a brake hub are in a friction state by the locking of the inner brake assembly on the steel wire rope, the steel wire rope is enabled to be guided out along the rope guiding mechanism by friction force difference, and slow and uniform-speed descending can be realized.

Owner:嘉善罗星创业投资有限公司

A spherical tuned mass damper vibration reduction control device

ActiveCN104018594BPlay the role of tuning frequencyDesign scienceBridge structural detailsShock proofingEngineeringTuned mass damper

The invention provides a spherical surface TMD (Turning Mass Damper) shock absorption control device, which comprises a bottom plate component and a mass block component glidingly matched with the bottom plate component, wherein the weight of the mass block component is m; the top of the bottom plate component is provided with N concave spherical surfaces; the bottom of the mass block component is provided with N convex spherical surfaces glidingly matched with the concave spherical surfaces; the concave spherical surfaces and the convex spherical surfaces have the identical spherical surface radius R; a sliding friction pair is arranged between the convex spherical surfaces and the concave spherical surfaces; and a damping device is arranged between the mass block component and the bottom plate component. The spherical surface TMD shock absorption control device has the advantages that the additional damping can be increased through setting different friction factors; meanwhile, through a single pendulum simple harmonic moving principle, an elastic element of a traditional TMD is replaced; the design is scientific; the structure is compact; the operation and the use are convenient; the problems that for the existing TMD technology, the manufacturing cost is high, a greater installation space is needed, a structural element can be easily damaged, and the like can be solved; and the spherical surface TMD shock absorption control device is particularly applicable to the control of low-frequency vibration of a structure.

Owner:柳州东方工程橡胶制品有限公司

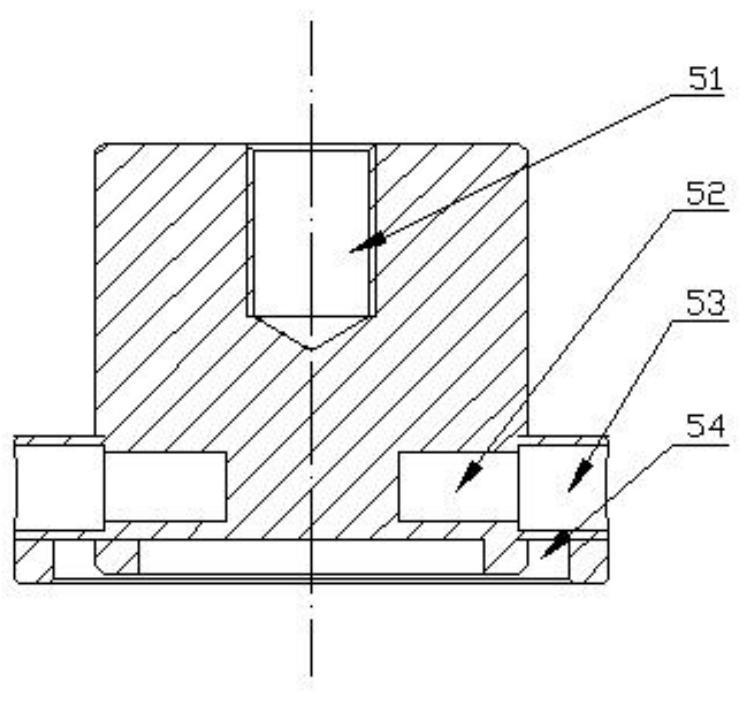

Damping type precise machine tool adjusting pad iron

ActiveCN111590338AAvoid the Consequences of VibrationIncrease frictional dampingMachine framesNon-rotating vibration suppressionMachine toolPhysics

The invention provides a damping type precise machine tool adjusting pad iron. The damping type precise machine tool adjusting pad iron comprises a barrel-shaped rapid adjusting sleeve arranged in a base in a sleeved mode; the rapid adjusting sleeve is fixed on the base; an elastic gasket is fixed at the position of the top opening of the rapid adjusting sleeve; a spherical surface supporting seatis arranged above the elastic gasket; the bottom end of an adjusting bolt penetrates through the centers of the spherical surface supporting seat and the elastic gasket in sequence, and is fixed by acambered surface fixing sleeve; the middle part of the elastic gasket is squeezed by the spherical surface supporting seat and is concaved into an arc shape; the edges of the elastic gasket extend tothe edges of the top opening of the rapid adjusting sleeve and are fixed; the adjusting bolt is connected with the spherical surface supporting seat in a threaded mode; the diameter of a through holein the elastic gasket penetrated by the adjusting bolt is larger than the diameter of the adjusting bolt; and a supporting plate is vertically connected with the adjusting bolt. The damping type precise machine tool adjusting pad iron solves the defect that, when the levelness of the ground is poor, a machine tool pad iron may cause a machine tool to generate extra stress, and the position of themachine tool is changed after use for a long time.

Owner:SHANDONG JIAOTONG UNIV

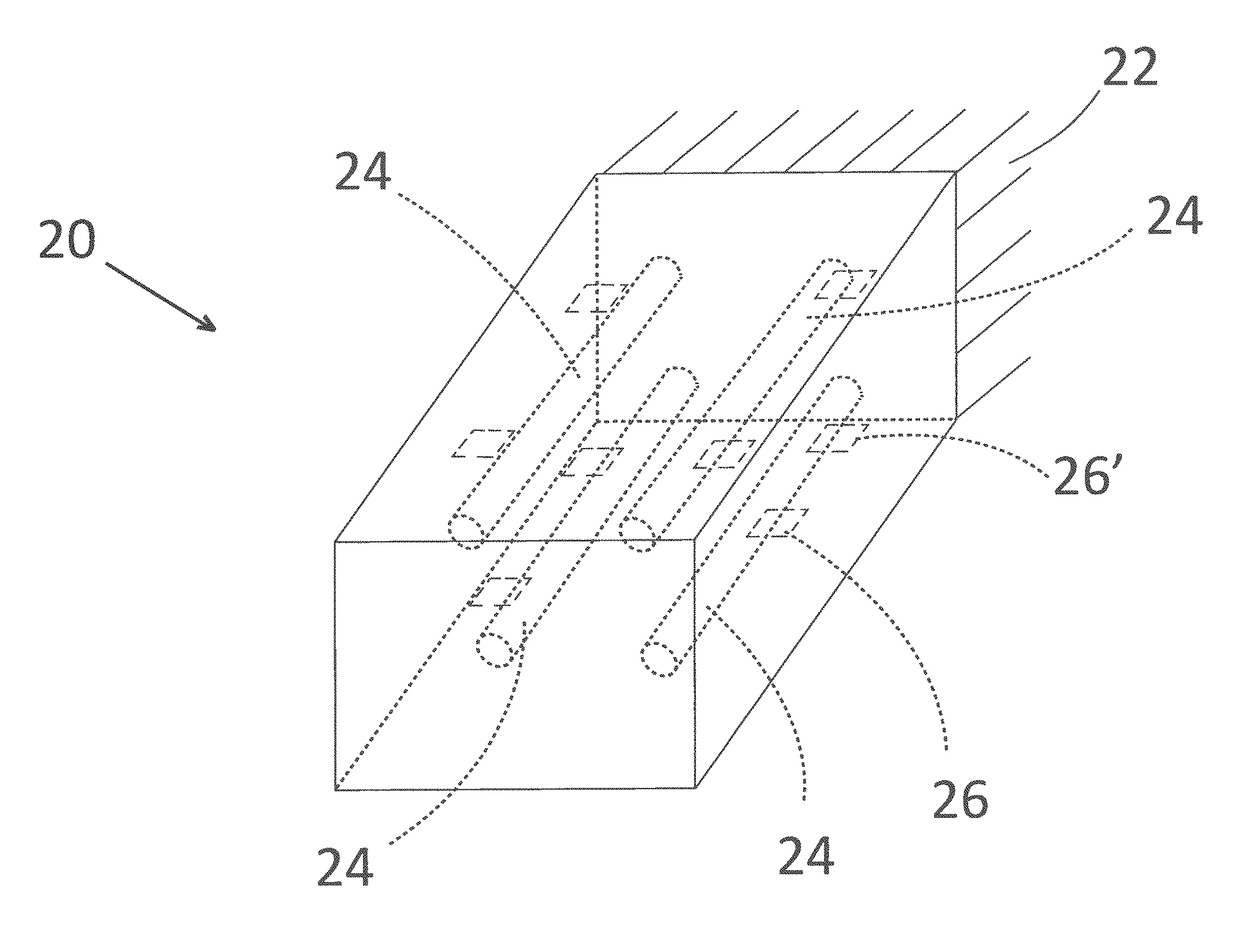

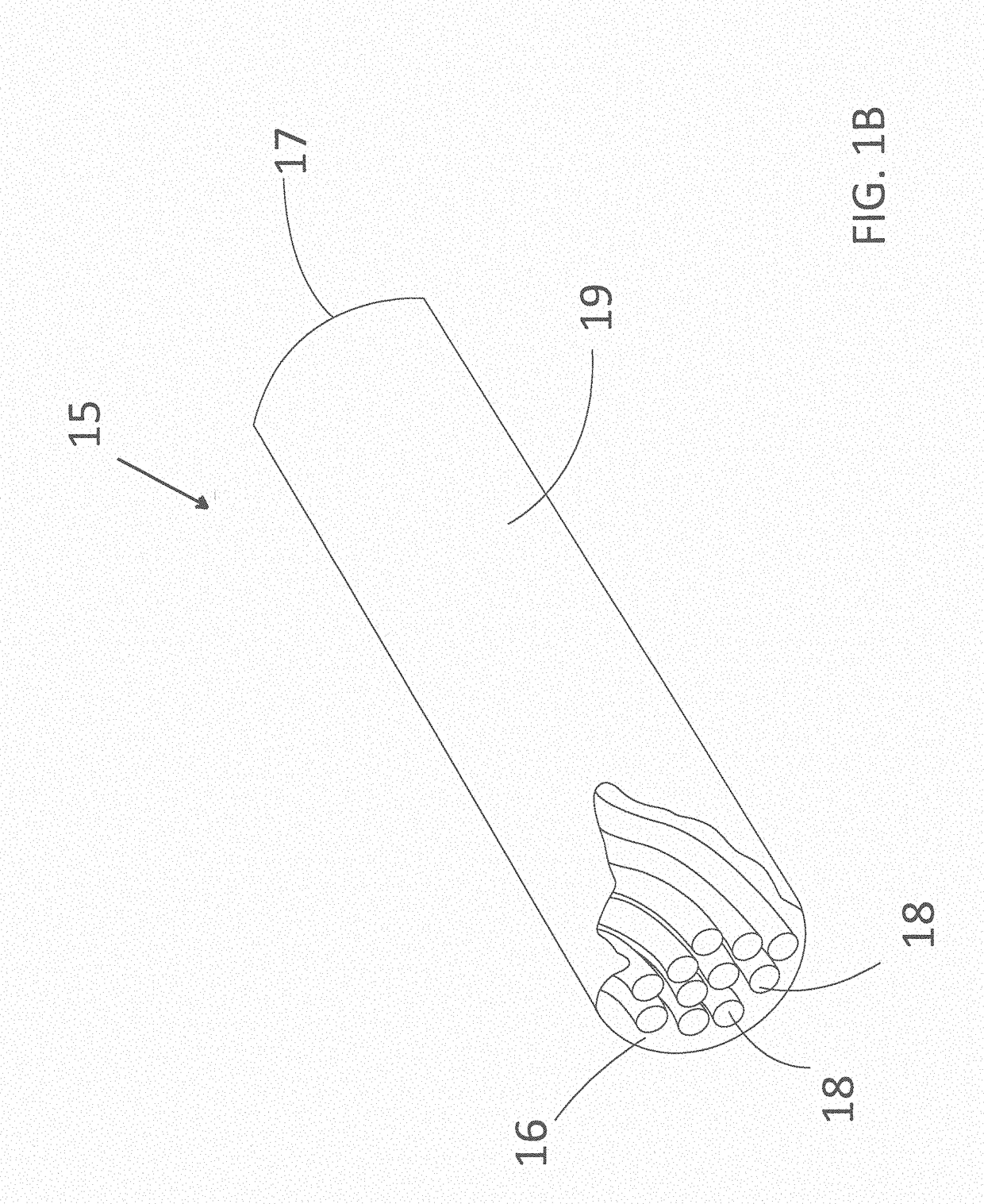

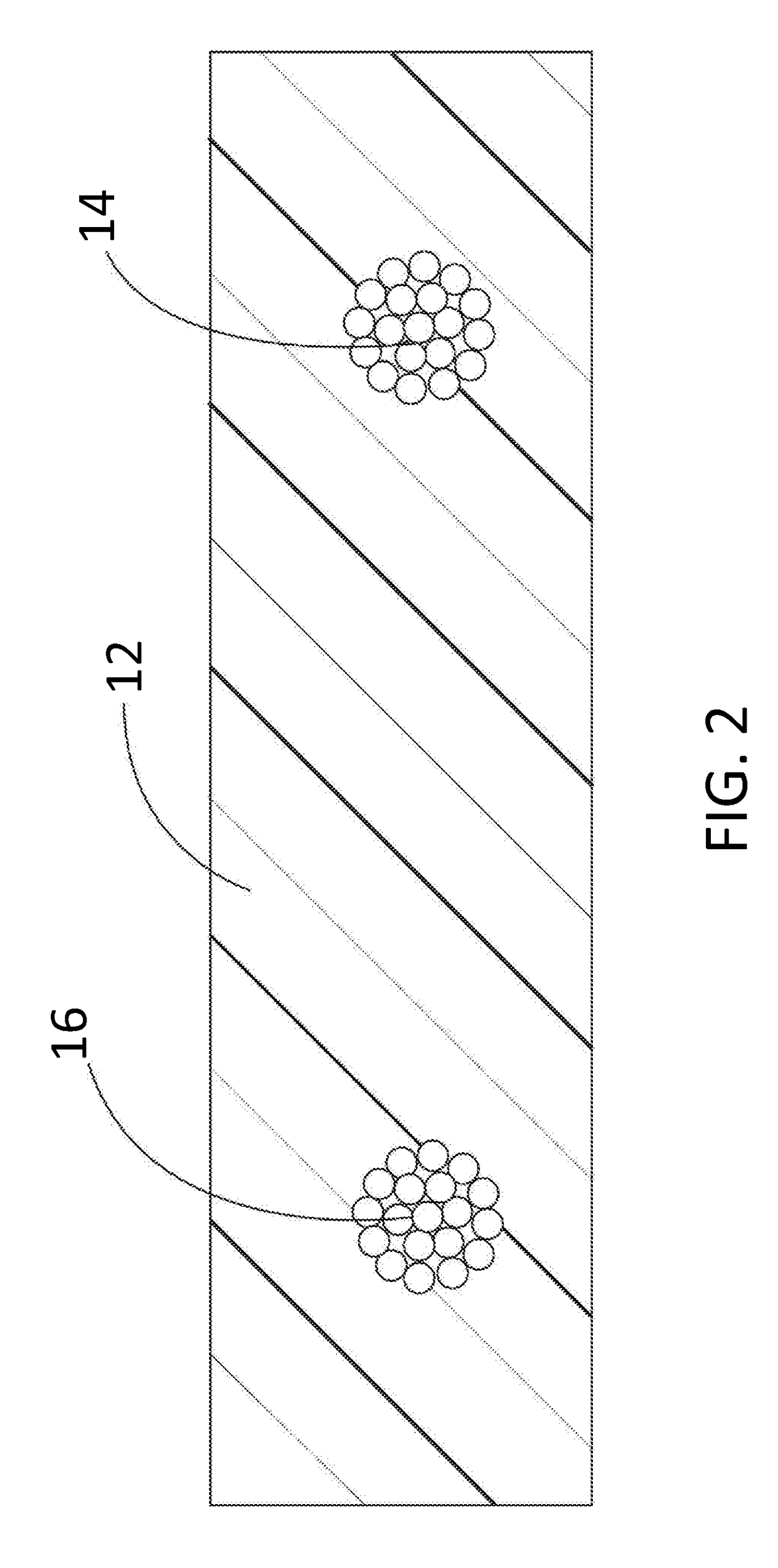

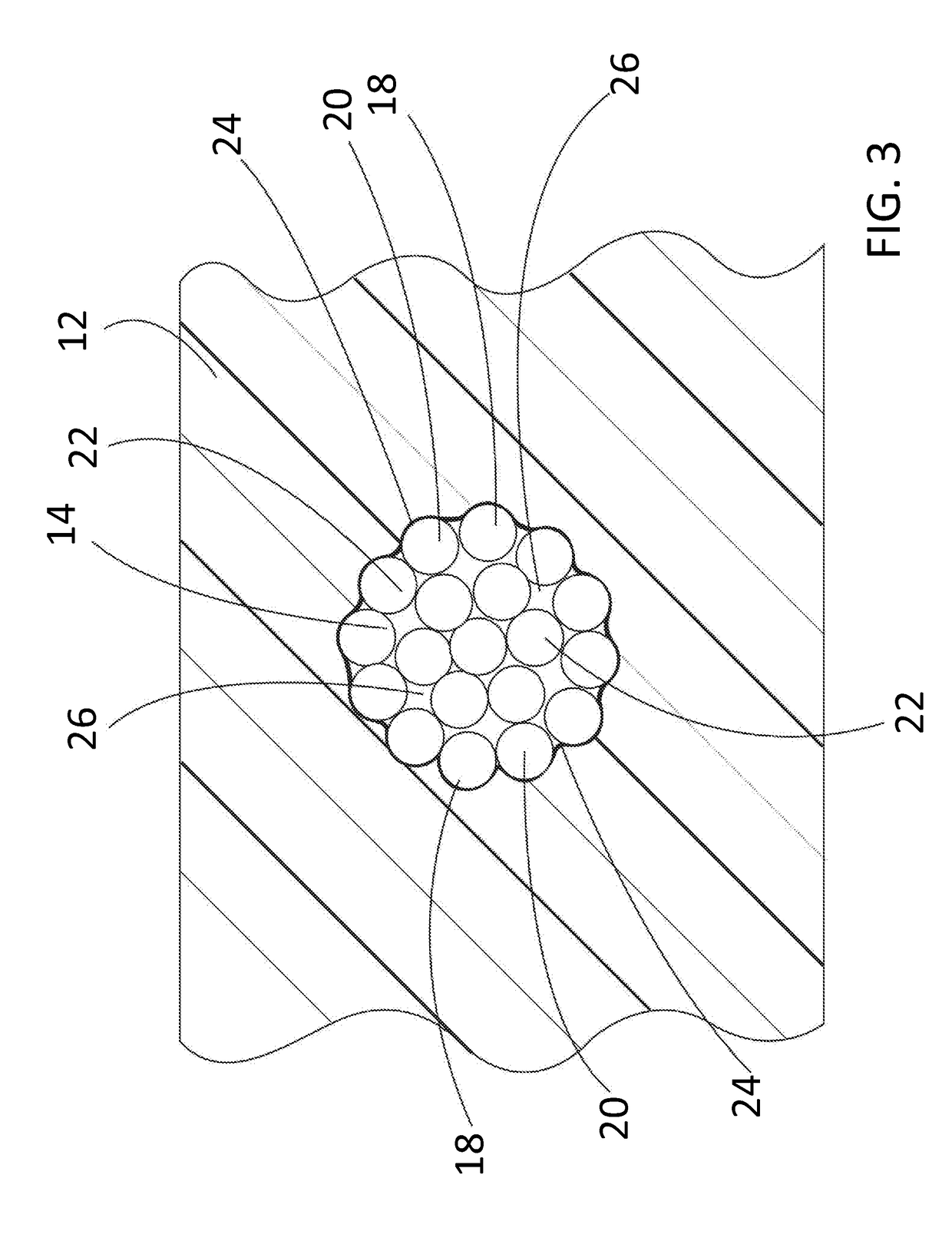

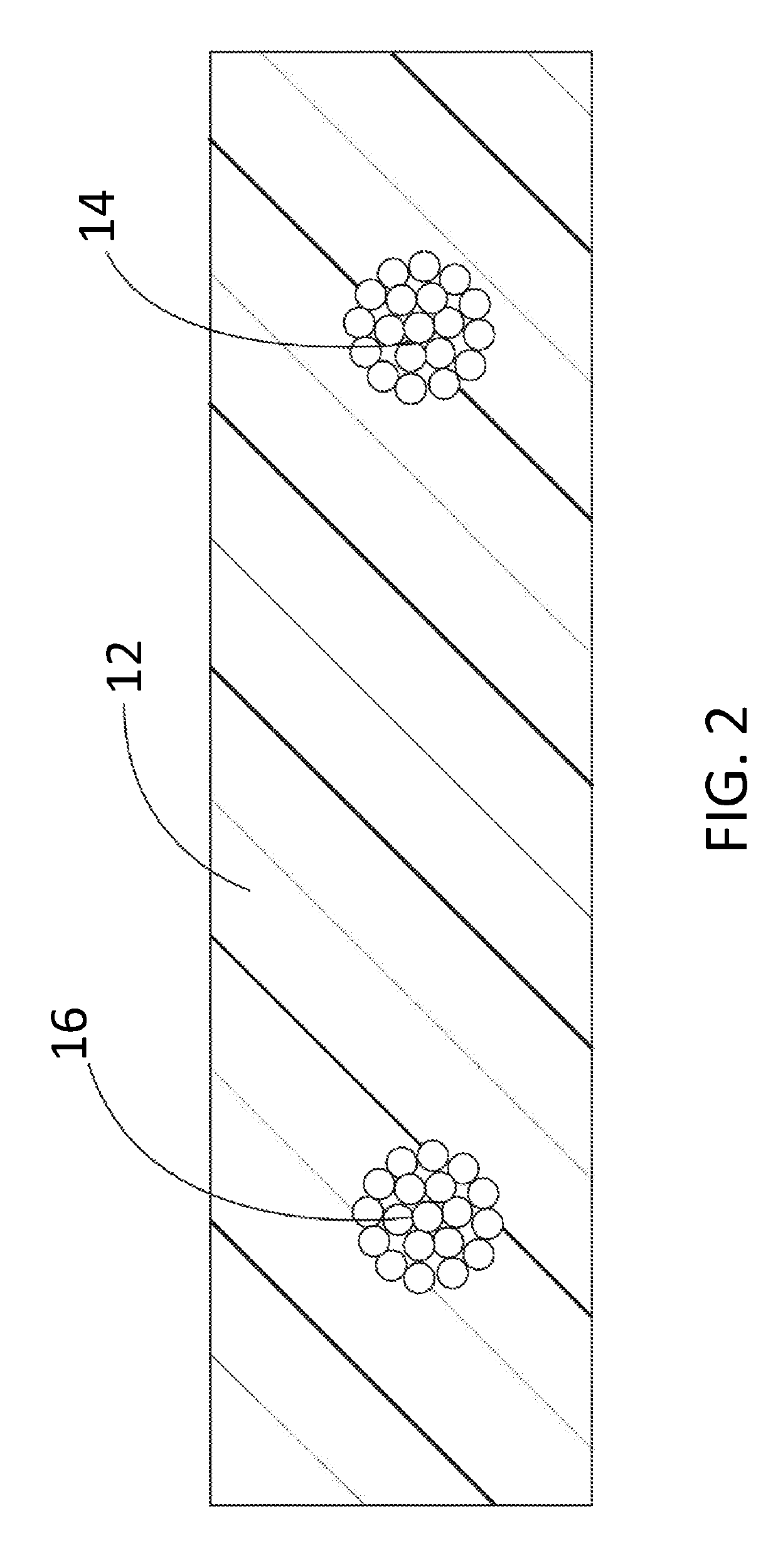

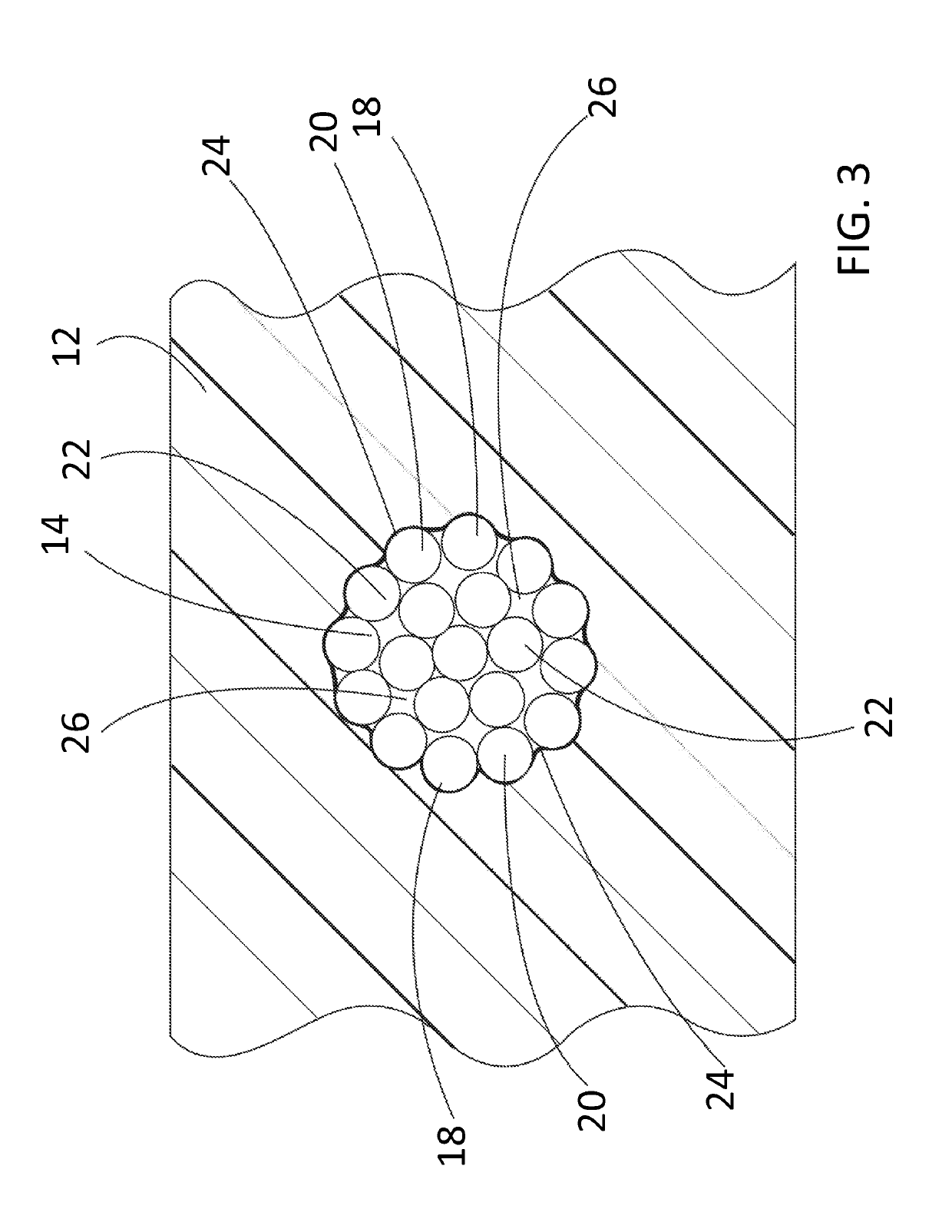

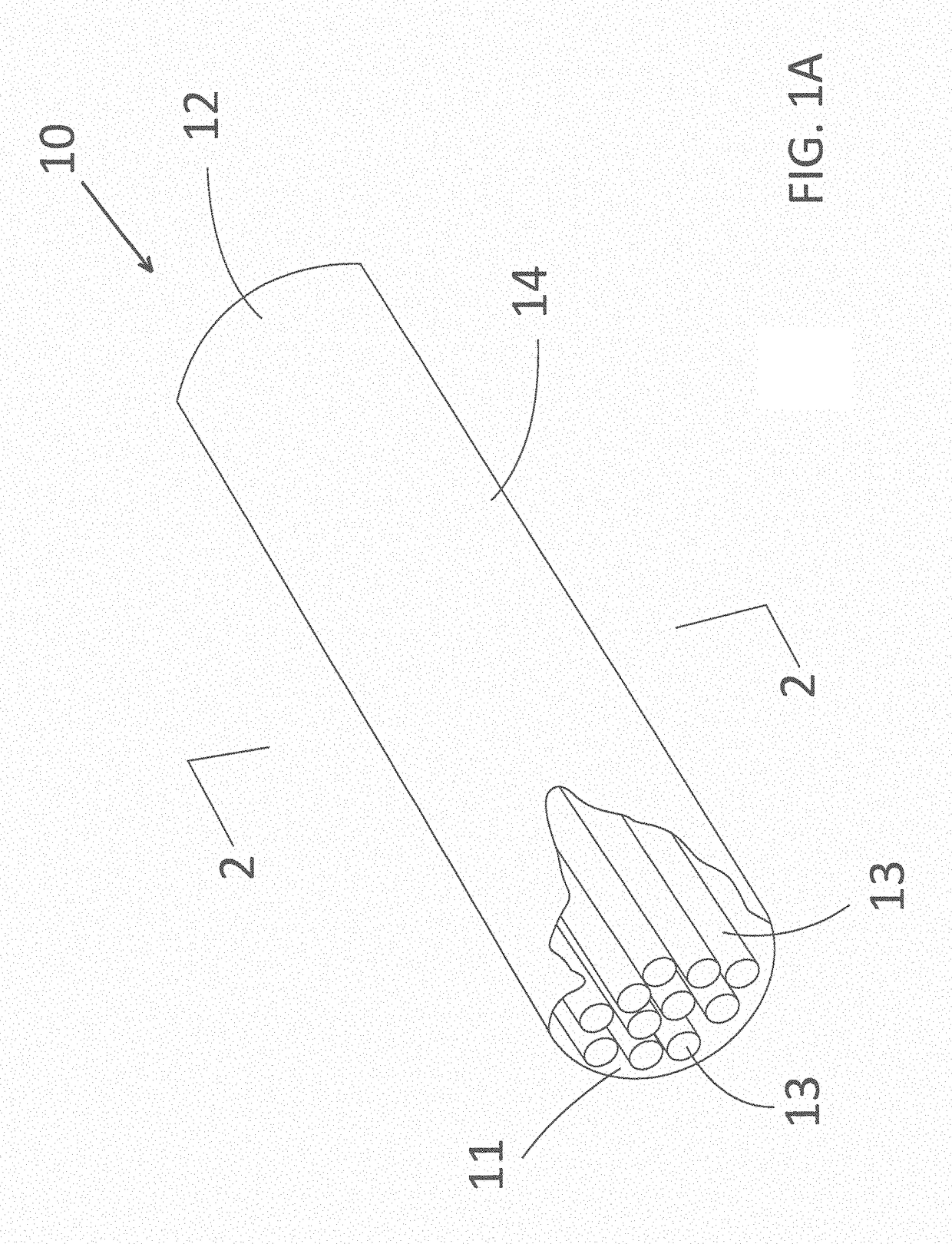

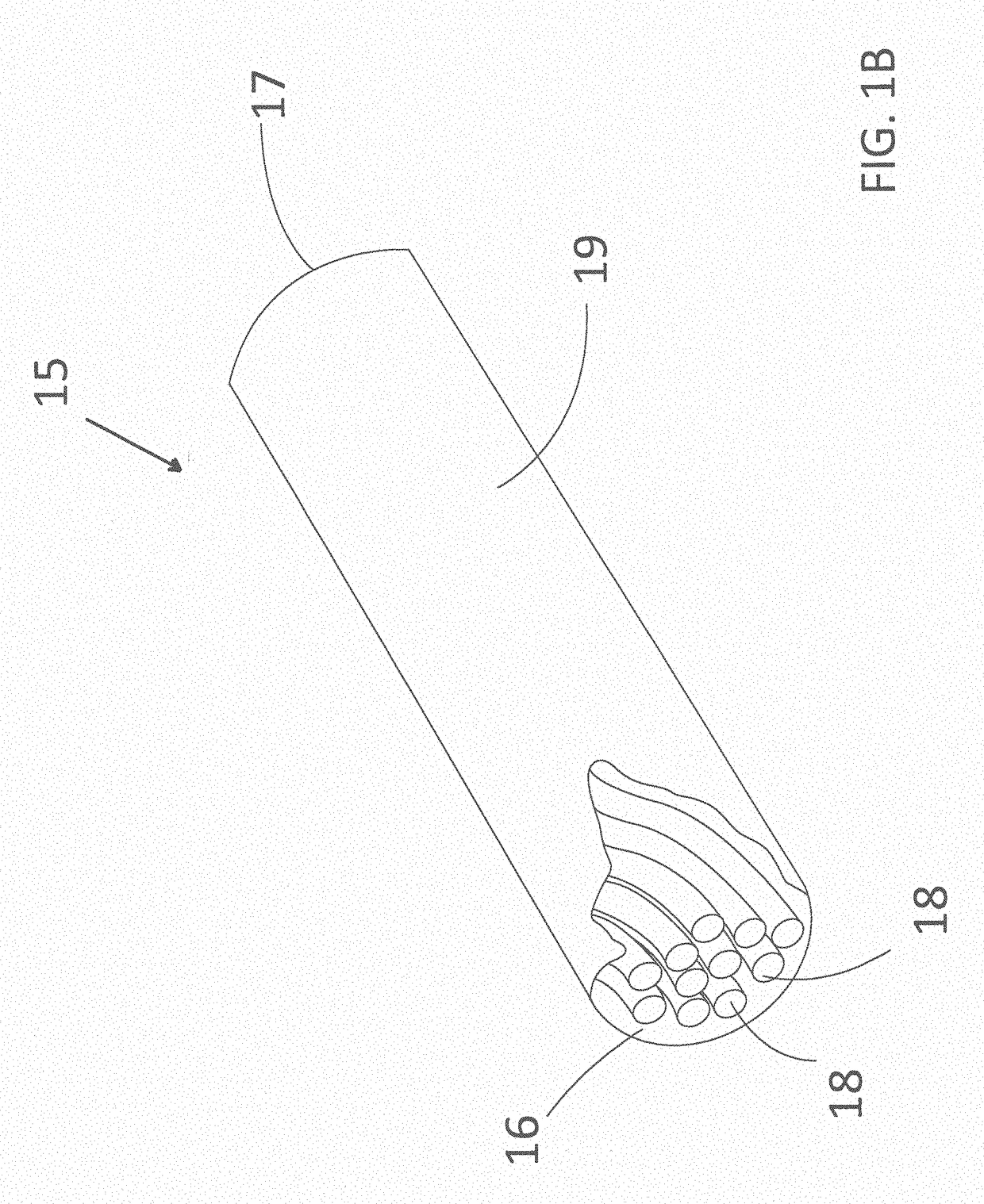

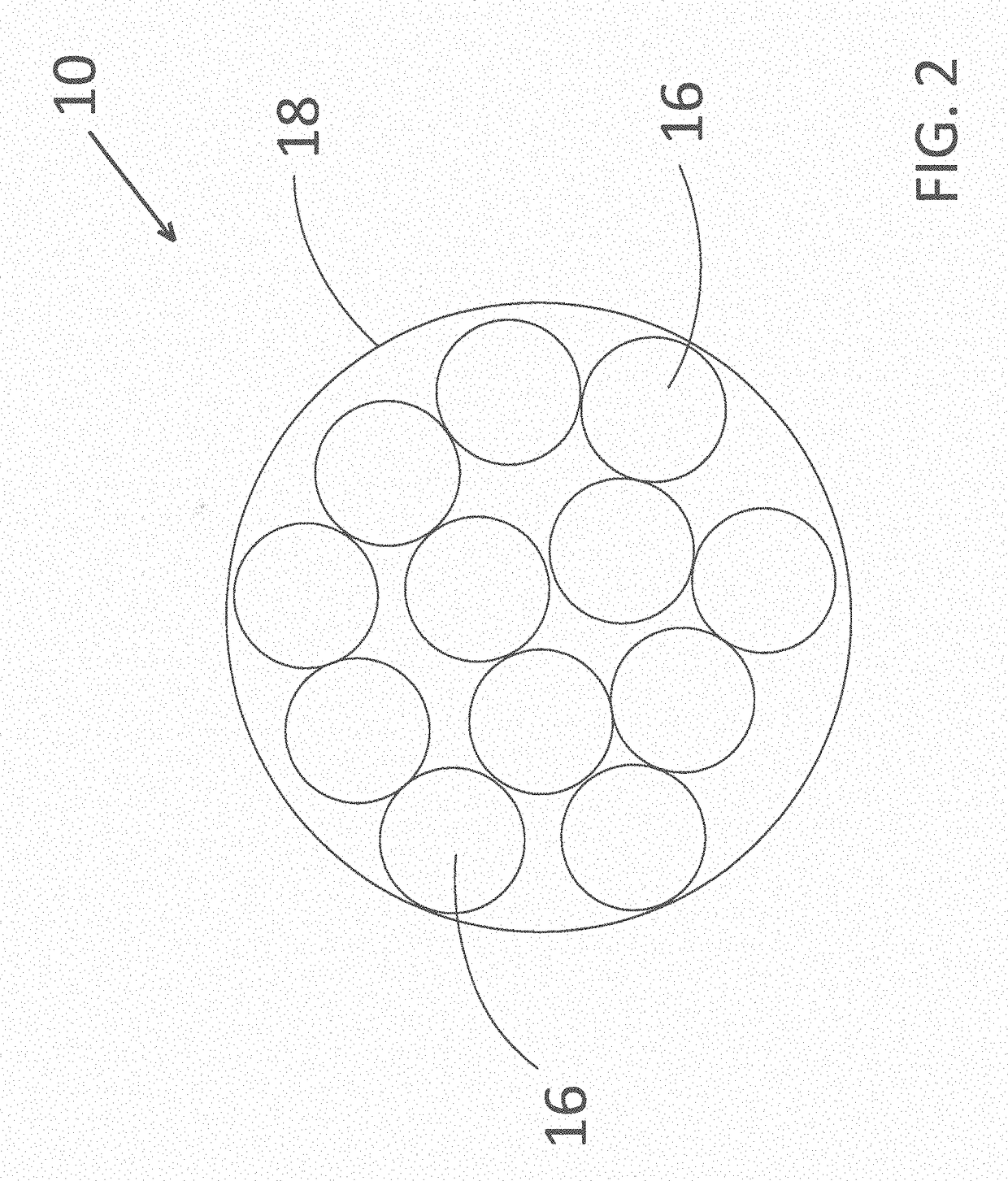

Dry friction damped mechanical and structural metal components and methods of manufacturing the same

ActiveUS20180073588A1Minimize impactStable damp propertySpringsSprings/dampers manufactureThin layerAssignment methods

A method and system for increasing damping capacity in cast metal parts by utilizing dry friction between individual wires of a sheathed rope is disclosed. The rope is embedded into the part during casting. Sheathing the ropes in a thin layer of the same metal as the casting prevents molten metal from infiltrating individual wires during casting, thus allowing inter-wire friction during the part vibration. There are two ways to distribute the ropes within a part during casting. The first way is to distribute the ropes uniformly across an entire part whereby damping capacity of the metal part increases uniformly as well. The second way of distributing the ropes is to spatially distribute them according to a pattern to increase the damping capacity only in the part regions that have the highest vibration amplitudes or stress during system vibration. Both methods of distribution may be combined in a single part.

Owner:FORD GLOBAL TECH LLC

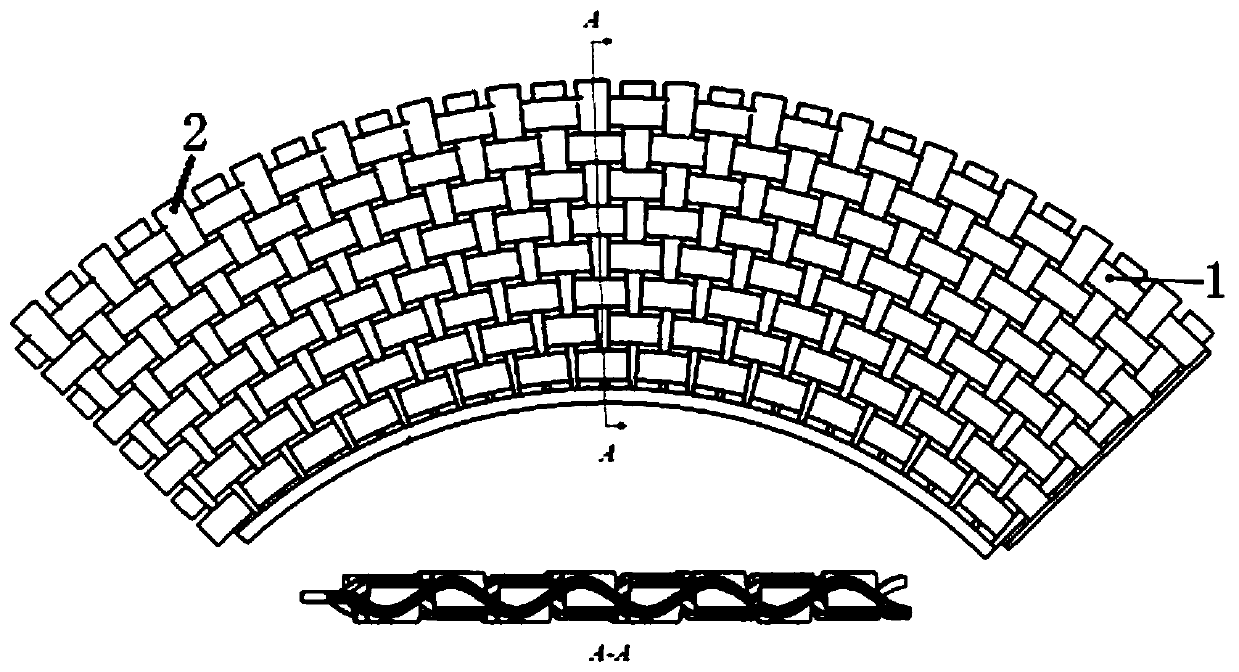

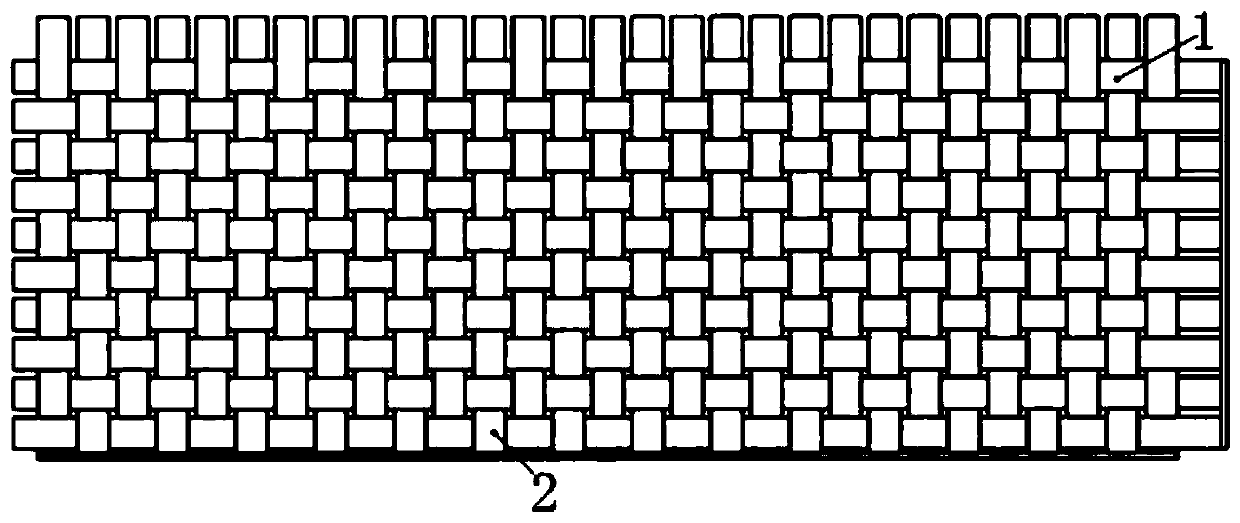

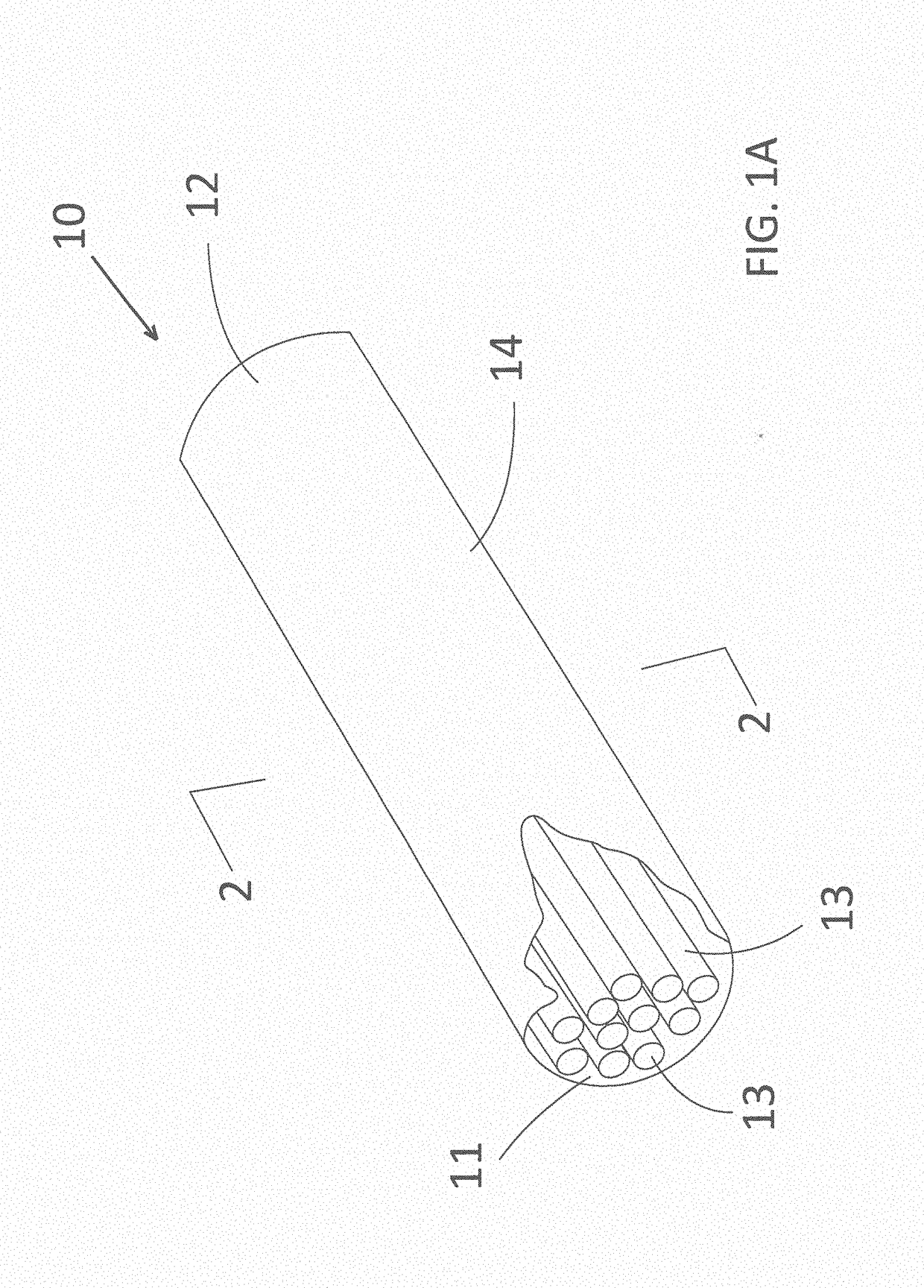

Composite materials having embedded metal ropes for increased damping capacity and methods of manufacturing same

ActiveUS20190048958A1Improve damping performanceIncrease frictional dampingSpringsNon-rotating vibration suppressionPolymerMetal

A method and system for increasing damping capacity utilizing dry friction between individual wires of a rope embedded in a component formed from a composite is illustrated. The individual wires allow inter-wire friction to occur during part vibration. The component includes a body that is a molded matrix formed form a composite material. The body may be of any material selected from the group consisting of a polymer, a metal or a ceramic material. One or more vibration-damping ropes are embedded in the body. The vibration-damping ropes may be elongated segments or may be a rope having connected ends that form one or more rings. Each vibration-damping rope includes an outer layer of wires that surrounds a plurality of inner wires. Inflowing composite material is prevented from passing by the outer layer of wires and into the inner wires during the manufacturing process, thereby forming voids between the inner wires.

Owner:FORD GLOBAL TECH LLC

A damping type precision machine tool adjustment shim iron

ActiveCN111590338BAvoid the Consequences of VibrationIncrease frictional dampingMachine framesNon-rotating vibration suppressionStructural engineeringMachine

The invention provides a damping type precision machine tool adjustment pad iron, comprising: the barreled quick adjustment sleeve is sleeved in the base, the quick adjustment sleeve is fixed on the base; the quick adjustment sleeve is fixed at the top opening There is an elastic gasket, and a spherical support seat is arranged above the elastic gasket; after the bottom end of the adjustment bolt passes through the center of the spherical support seat and the elastic gasket in turn, it is fixed by an arc fixed sleeve; The middle part of the elastic washer is pressed and depressed into an arc shape by the spherical support seat, and the edge of the elastic washer extends to the edge extension of the top opening of the quick adjustment sleeve and is then fixed; the adjusting bolt is threadedly connected with the spherical support seat; The diameter of the through hole through which the elastic gasket is passed by the adjusting bolt is larger than the diameter of the adjusting bolt; the support plate is vertically threaded with the adjusting bolt. The invention overcomes the defects that when the level of the ground is poor, the backing iron of the machine tool may cause additional force on the machine tool, and the position of the machine tool may change due to long-term use.

Owner:SHANDONG JIAOTONG UNIV

A double-brake back-and-forth controllable descending device

ActiveCN104667446BImprove controllabilityIncrease frictional dampingBuilding rescueBrakeClassical mechanics

Owner:嘉善罗星创业投资有限公司

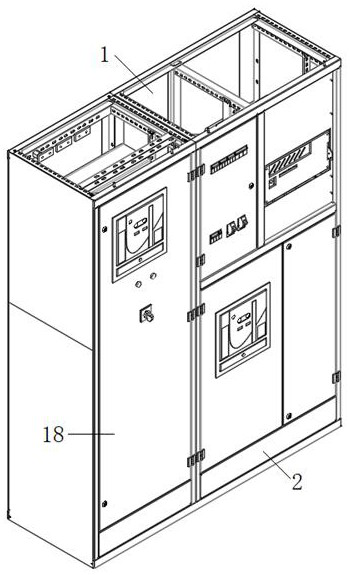

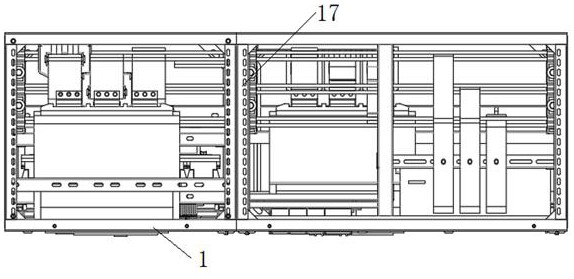

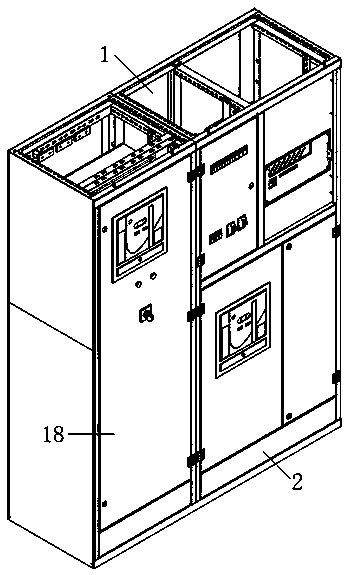

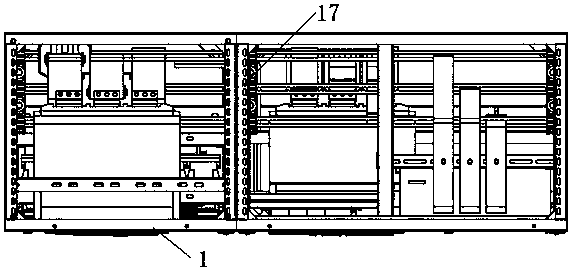

A kind of power cabinet with nonlinear damping platform

ActiveCN110676704BViscoelasticIncrease frictional dampingSubstation/switching arrangement casingsAnti-seismic devicesEngineeringVibration isolation

Owner:山东博安泰电气有限公司

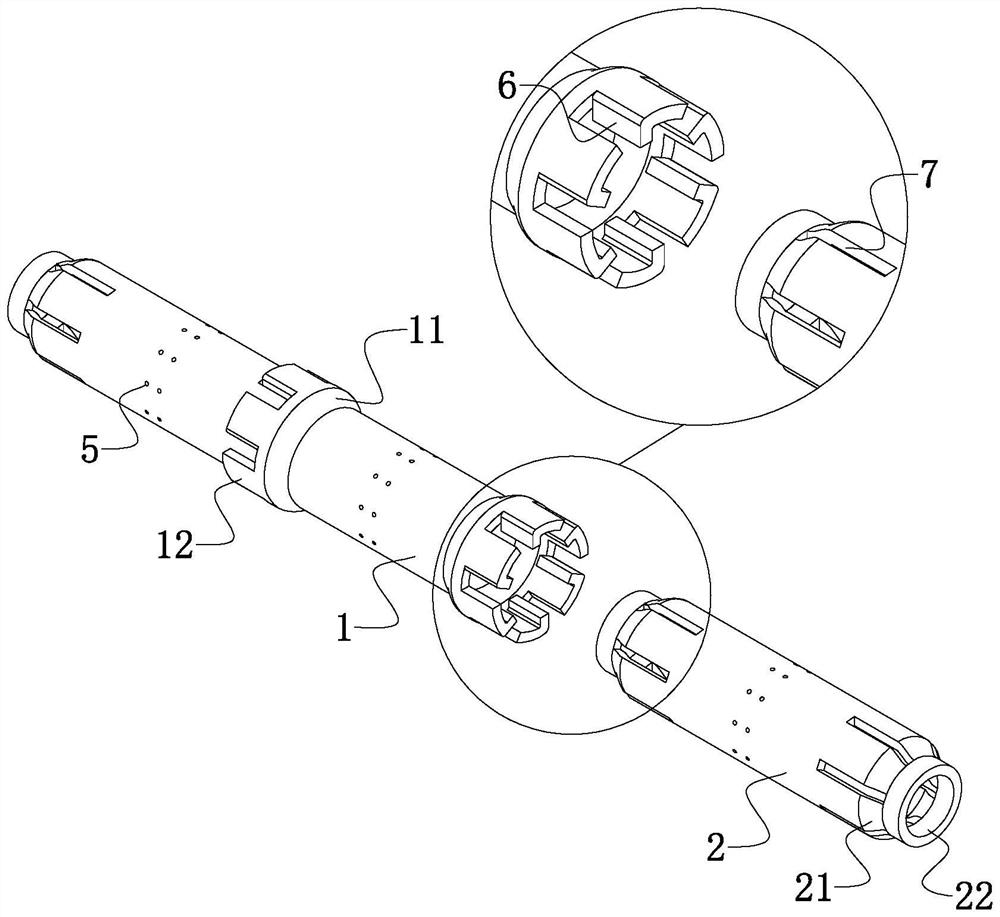

Light metal high-strength pure electric bus composite structure and connecting process

ActiveCN114802486AMeet cross-connect requirementsSimple structureSuperstructure connectionsNon-electric welding apparatusLanternHollow core

The light metal high-strength pure electric bus composite structure comprises an active connecting section and a passive connecting section, the active connecting section and the passive connecting section are each of a hollow pipe structure, sandwich cores are arranged in the active connecting section and the passive connecting section, the end of the active connecting section is provided with an outward expansion section expanding outwards, and the end of the passive connecting section is provided with a hollow pipe. An outer lantern ring with the inner diameter equal to the outer diameter of the passive connecting section is arranged at the free end of the outer expansion section, an inner shrinkage section which shrinks inwards and is matched with the outer expansion section is arranged at the end of the passive connecting section, an inner lantern ring with the outer diameter equal to the inner diameter of the active connecting section is arranged at the free end of the inner shrinkage section, and the side wall of the outer lantern ring is cut and folded inwards to form a plurality of clamping strips. Clamping grooves in one-to-one correspondence with the clamping strips are inwards formed in the two ends of the passive connecting section and the inward shrinkage sections at the two ends. The active connection section and the passive connection section are connected through magnetic pulses. The simple cavity is adopted as the framework, and the advantages of being simple in structure, low in cost, high in design efficiency, good in lightweight effect and the like are achieved.

Owner:HUNAN UNIV

Mechanical pressure sensing locking safety device

The invention discloses a mechanical pressure sensing locking safety device, which comprises an induction head, a locking mechanism and a guide sleeve; two ends of the guide sleeve respectively form a corresponding guide hole, and a latch rod passes through the guide hole inserted into the guide sleeve; the induction head is connected to the guide sleeve and cooperates with the guide sleeve to form an installation space, and the locking mechanism is arranged in the installation space and connects the induction head and the The latch rod, the induction head and the locking mechanism cooperate to control the axial locking and unlocking of the latch rod. Due to the use of a mechanical pressure sensing locking safety device of the present invention, it has compact structure, reliable execution, convenient installation, and is suitable for occasions with sanitary requirements, passive sites and explosion-proof requirements. High security, responsive, automatic locking and unlocking features.

Owner:SHANGHAI MORIMATSU PHARMA EQUIP ENG

High-efficiency dry friction damping spring vibration isolator

ActiveCN104930100BCompact structureHeavy loadShock absorbersFriction dampersReciprocating motionMechanical energy

The invention discloses a high-effect dry friction damping spring vibration isolator and aims at providing a friction damping vibration isolator which is compact in structure, large in friction damp, high in load and good in environmental adaptation. According to the technical scheme, in a vibration environment, left friction pieces and right friction pieces of a disc-pressing upper cone spring (3) and a disc-pressing lower cone spring (6) perform reciprocating motion to axially extrude a right friction ring piece (4) and a left friction ring piece (9) on two sides, the left friction ring piece, the right friction ring piece, an upper guide umbrella disc (1) and a lower guide umbrella disc (5) are driven to perform constant friction motion on the inner wall of a housing (2), vibration mechanical energy is converted into heat energy so as to achieve vibration energy consumption and reduction. The high-effect dry friction damping spring vibration isolator utilizes low frequency of a conical spring and a damping characteristic of a symmetric semi-ring damping pad, can effectively inhibit spring fluctuation during high-frequency impact, also has composite multiple vibration isolation effect and has large damp under the low-frequency condition compared with a traditional rubber vibration isolator.

Owner:10TH RES INST OF CETC

A flywheel protection structure and energy storage system

ActiveCN113241893BAvoid instabilityAvoid damageMechanical energy handlingSupports/enclosures/casingsFlywheel energy storageClassical mechanics

The invention relates to the technical field of flywheel energy storage, and provides a flywheel protection structure and an energy storage system. The flywheel protection structure includes a shaft assembly, including a flywheel arranged in a housing and a rotating shaft fixedly connected to the flywheel. The rotating shaft and the flywheel Coaxial arrangement; the end surface of the flywheel is connected with a limit protection end arranged around the rotation shaft, and there is an accommodation space between the limit protection end and the rotation shaft; the fixed seat is arranged around the rotation axis, including a space extending into the accommodation space The support end; the elastic protection structure is located between the support end and the limit protection end, one end is connected to the support end, and the other end rubs against the side of the limit protection end facing the rotating shaft. The flywheel protection structure provided by the present invention, when the unbalance of the flywheel increases suddenly or the operating conditions change greatly, so that the vibration amplitude of the flywheel increases, the limit protection end and the elastic protection structure have flexible collision friction, which avoids the flywheel and the elastic protection structure. The direct friction of the shell will cause the flywheel to be unstable and damaged.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Composite materials having embedded metal ropes for increased damping capacity and methods of manufacturing same

ActiveUS10495175B2Improve damping performanceIncrease frictional dampingSpringsNon-rotating vibration suppressionPolymerMetal

A method and system for increasing damping capacity utilizing dry friction between individual wires of a rope embedded in a component formed from a composite is illustrated. The individual wires allow inter-wire friction to occur during part vibration. The component includes a body that is a molded matrix formed form a composite material. The body may be of any material selected from the group consisting of a polymer, a metal or a ceramic material. One or more vibration-damping ropes are embedded in the body. The vibration-damping ropes may be elongated segments or may be a rope having connected ends that form one or more rings. Each vibration-damping rope includes an outer layer of wires that surrounds a plurality of inner wires. Inflowing composite material is prevented from passing by the outer layer of wires and into the inner wires during the manufacturing process, thereby forming voids between the inner wires.

Owner:FORD GLOBAL TECH LLC

Dry friction damped mechanical and structural metal components and methods of manufacturing the same

ActiveUS10060495B2Improve damping performanceIncrease frictional dampingSpringsBraking elementsVibration amplitudeThin layer

A method and system for increasing damping capacity in cast metal parts by utilizing dry friction between individual wires of a sheathed rope is disclosed. The rope is embedded into the part during casting. Sheathing the ropes in a thin layer of the same metal as the casting prevents molten metal from infiltrating individual wires during casting, thus allowing inter-wire friction during the part vibration. There are two ways to distribute the ropes within a part during casting. The first way is to distribute the ropes uniformly across an entire part whereby damping capacity of the metal part increases uniformly as well. The second way of distributing the ropes is to spatially distribute them according to a pattern to increase the damping capacity only in the part regions that have the highest vibration amplitudes or stress during system vibration. Both methods of distribution may be combined in a single part.

Owner:FORD GLOBAL TECH LLC

A Variable Friction Damping Vibration Isolator with Adjustable Center Position

ActiveCN111649087BImprove wear resistanceIncrease frictional dampingSpringsShock absorbersIsolatorClassical mechanics

The invention relates to a variable friction damping vibration isolator with adjustable center position, which belongs to the field of vibration isolators for electronic equipment, and solves the problem that the existing vibration isolator cannot adjust the center position of variable friction damping when the actual weight of the load is different from the vibration isolation When the rated load capacity of the vibration isolator is different, the vibration center of the vibration isolator deviates from the center position of the low friction damping force of the damping spring sheet, thereby weakening the vibration isolation ability of the vibration isolator to the high frequency vibration load. The variable friction damping vibration isolator of the present invention comprises: a base, a circlip, a friction guide rail, an upper cover, a load mounting seat, a friction pressure spring, a friction head and a main vibration isolation spring; the friction guide rail and the circlip pass through the friction guide rail height adjustment cone The upper cover is pressed on the friction guide rail. The present invention adjusts the pre-tightening force of the upper cover so that the center position of the friction guide rail can move up and down, thereby realizing the adjustment of the center position of the vibration isolator.

Owner:36TH RES INST OF CETC

Power cabinet with nonlinear damping platform

ActiveCN110676704AViscoelasticIncrease frictional dampingSubstation/switching arrangement casingsAnti-seismic devicesEngineeringVibration isolation

The invention discloses a power cabinet with a nonlinear damping platform. The power cabinet comprises a power cabinet body composed of hot galvanizing lace angle iron and a sheet metal skin. A powercabinet base body with an upper opening cavity structure is embedded in a bottom of the power cabinet body. An organ-shaped damping shock absorption unit is arranged in a center of the bottom of the power cabinet base body. The damping shock absorption unit can efficiently consume shock energy of components in multiple directions. A periphery of the bottom of the power cabinet base body is provided with a plurality of nonlinear damping units. Sensitivity and stability of the non-linear damping unit are improved by applying a flexible hinge. A damping ring in the non-linear damping unit plays arole of a connecting rod frame through four parts connected via a longitudinal flexible hinge and a transverse flexible hinge. A non-linear rigidity vibration isolation effect is generated between folding and contraction of the connecting rod frame structure and an elastic element, the power cabinet base body, the damping shock absorption unit and the multiple non-linear damping units are combined into a non-linear damping platform, and the non-linear damping platform is designed through a non-linear structure and has a good bearing capacity and stability.

Owner:山东博安泰电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com