Light metal high-strength pure electric bus composite structure and connecting process

A pure electric passenger car and composite structure technology is applied in the field of lightweight metal high-strength pure electric passenger car composite structure and connection technology, which can solve the problems of high manufacturing cost, hindering excellent application prospects, and limited improvement of lightweight effect, and improving the connection quality. , The effect of improving NVH performance and reducing trial and error costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below with reference to the accompanying drawings.

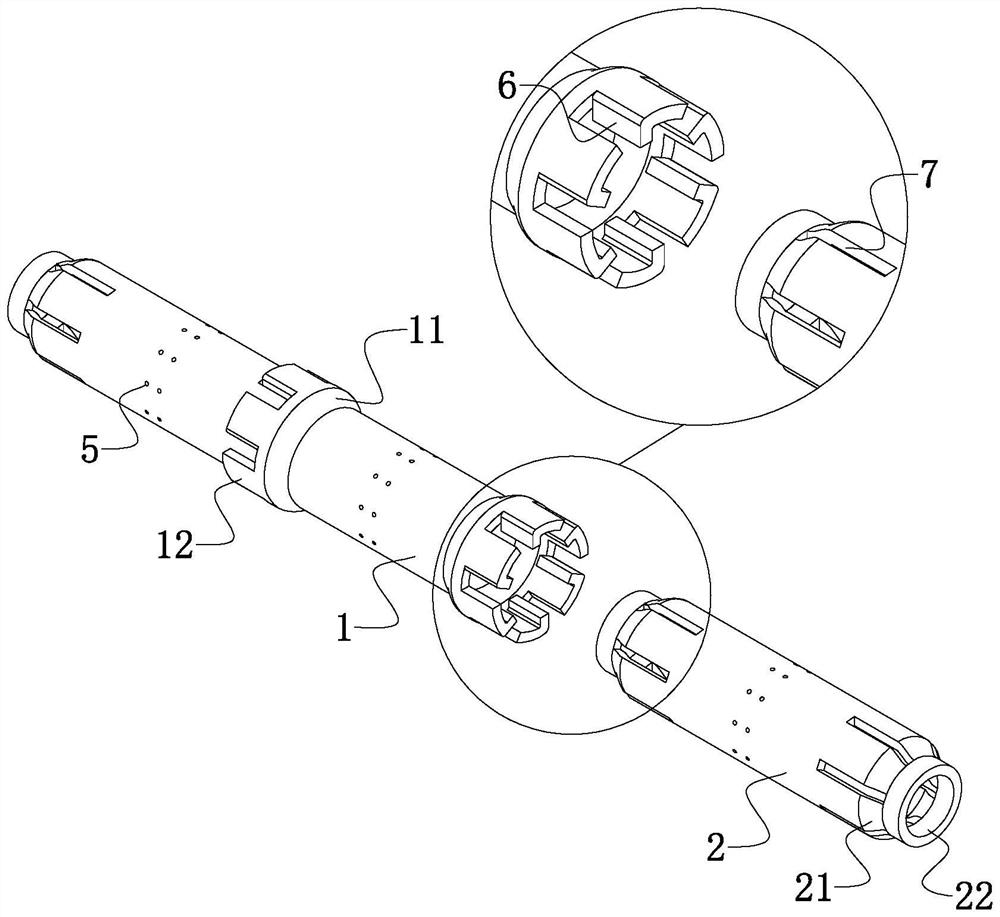

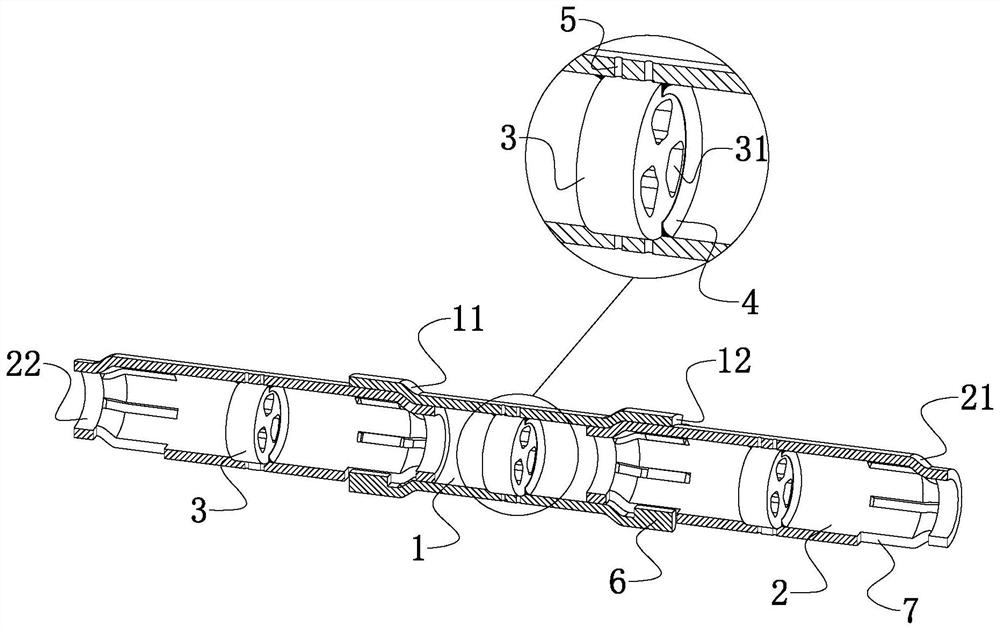

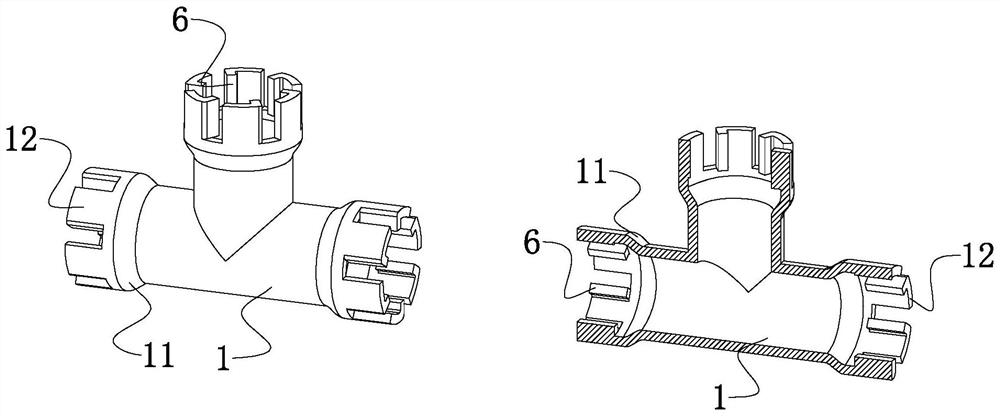

[0035] example, see Figure 1-4 , a lightweight metal high-strength pure electric passenger car composite structure, including an active connecting section 1 and a passive connecting section 2, the active connecting section 1 and the passive connecting section 2 are both hollow tube structures, and the active connecting section 1 can be a bidirectional active connecting section 1 , the three-way active connection section 1 or the four-way active connection section 1, the two-way active connection section 1 is used in this embodiment, the active connection section 1 and the passive connection section 2 are circular or rectangular, and this embodiment uses a circular Cross-sectional structure, both the active connection section 1 and the passive connection section 2 are provided with a number of ≥ 0 sandwich cores 3 that match their inner diameters, and the three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com