Spherical surface TMD shock absorption control device

A technology for tuning mass damping and control devices, applied in bridge parts, building components, bridges, etc., to achieve the effects of convenient operation and use, compact structure, and overcoming high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

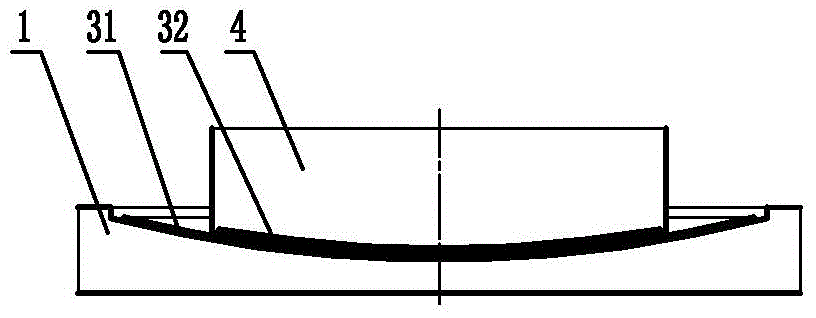

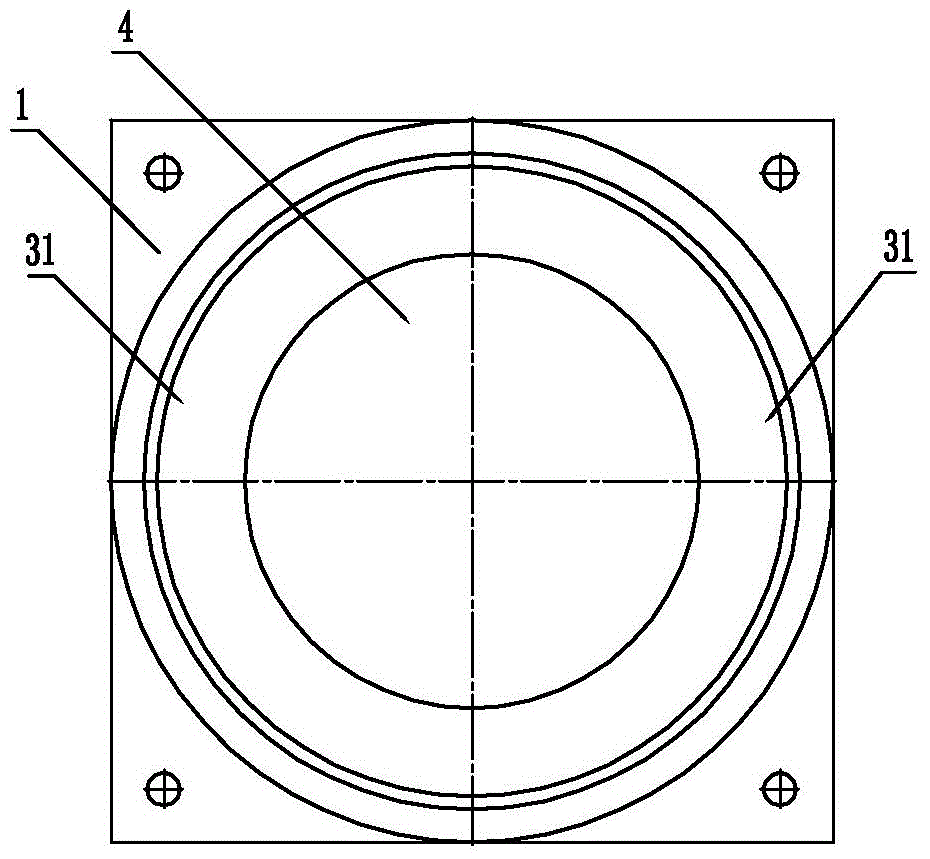

[0037] Embodiment one ,Such as Figure 1 ~ Figure 2 , a spherical tuned mass damper vibration control device, comprising a bottom plate part and a mass block part slidingly fitted therewith, the weight of the mass block part is m, the top of the bottom plate part has a concave spherical surface, the The bottom of the mass block part has a convex spherical surface that slides with the concave spherical surface of the bottom plate. The radius R of the convex spherical surface is the same as that of the concave spherical surface. A sliding friction pair is arranged between the convex spherical surface and the concave spherical surface. The friction pair is composed of a stainless steel plate and a polytetrafluoroethylene plate, the stainless steel plate and the concave spherical surface of the bottom plate are compacted and welded, and the polytetrafluoroethylene plate and the convex spherical surface of the mass block are compacted and connected by bolts or rivets.

[0038] In ...

Embodiment 2

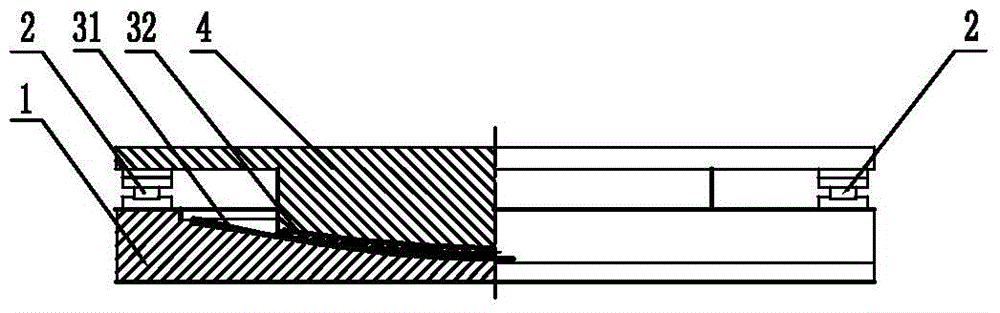

[0044] Such as Figure 3 ~ Figure 4 , a spherical tuned mass damper vibration control device, comprising a bottom plate part and a mass block part slidingly fitted therewith, the weight of the mass block part is m, the top of the bottom plate part has a concave spherical surface, the The bottom of the mass block part has a convex spherical surface that slides with the concave spherical surface of the bottom plate. The radius R of the convex spherical surface is the same as that of the concave spherical surface. A sliding friction pair is arranged between the convex spherical surface and the concave spherical surface. The sliding friction The pair is composed of a stainless steel plate and a ball bearing, the stainless steel plate and the concave spherical surface of the bottom plate part are connected by welding, and the ball bearing is connected to the convex spherical surface of the mass block part through bolts or inlaid grooves.

[0045] Four damping devices 2 are arranged...

Embodiment 3

[0047] Such as Figure 5 ~ Figure 6 , a spherical tuned mass damper vibration control device, comprising a bottom plate part and a mass block part slidingly fitted therewith, the weight of the mass block part is m, the top of the bottom plate part has two concave spherical surfaces, the The bottom of the mass block part has two convex spherical surfaces slidingly matched with the concave spherical surface of the bottom plate. The radius R of the convex spherical surface and the concave spherical surface is the same, and a sliding friction pair is arranged between the convex spherical surface and the concave spherical surface. The pair is composed of a stainless steel plate and a ball bearing, the stainless steel plate and the concave spherical surface of the bottom plate part are connected by welding, and the ball bearing is connected to the convex spherical surface of the mass block part through bolts or inlaid grooves.

[0048] Two damping devices are arranged between the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com