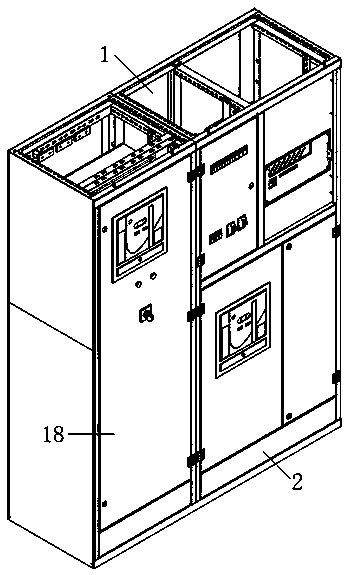

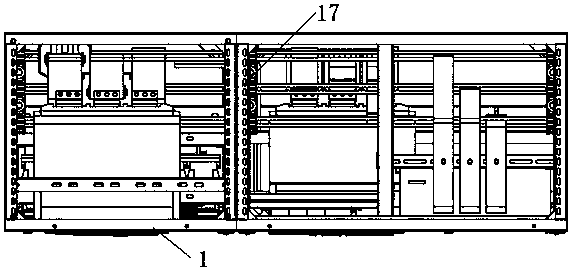

Power cabinet with nonlinear damping platform

A kind of power cabinet, non-linear technology, applied in the direction of seismic equipment, electrical components, substation/distribution device casing, etc., can solve the problem of the spring structure is not very ideal, less consideration of energy dissipation, vibration energy dissipation and other problems, to achieve space Small size, good bearing capacity and stability, stable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

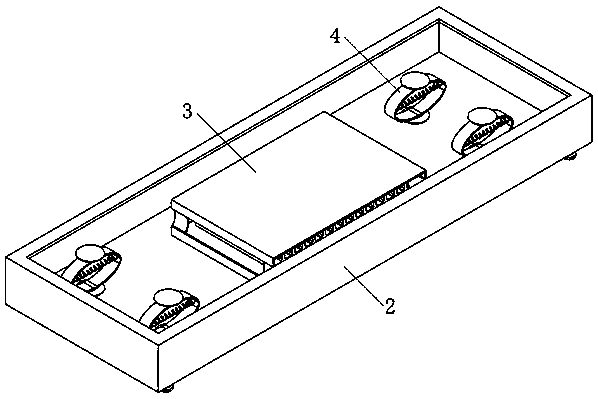

[0041] The ratio of the width and thickness of the shock absorbing ring 11 is between 0.5-2 and the thickness of the shock absorbing ring 11 is greater than 5 millimeters. At this time, the rigidity of the shock absorbing ring 11 is relatively large, and the longitudinal flexible hinge 15 and the horizontal hinge on the shock absorbing ring 11 The flexible hinge 16 plays a role of rotation, and the four parts connected by the vertical flexible hinge 15 and the horizontal flexible hinge 16 of the shock absorbing ring 11 play the role of a rigid link frame. Enhance the stability of the overall structure.

Embodiment 2

[0043] The ratio of the width and thickness of the shock absorbing ring 11 is between 0.5-2 and the thickness of the shock absorbing ring 11 is at 3-5 millimeters. At this moment, the rigidity of the shock absorbing ring 11 is less, and the longitudinal flexible hinge 15 on the shock absorbing ring 11 And the horizontal flexible hinge 16 plays a role of rotation, the main body of the shock absorbing ring 11 plays a part of the elastic effect, and the four parts connected by the vertical flexible hinge 15 and the horizontal flexible hinge 16 of the shock absorbing ring 11 play the role of an elastic link frame, reducing The installation quantity of shock ring 11 is not less than 4, to enhance the stability of the overall structure.

Embodiment 3

[0045] The ratio of the width to the thickness of the shock absorbing ring 11 is greater than 3. At this time, the stiffness of the shock absorbing ring 11 is small, and the vertical flexible hinge 15 and the horizontal flexible hinge 16 on the shock absorbing ring 11 play a role of rotation, and the main body of the shock absorbing ring 11 plays a role of rotation. To achieve a part of the elastic effect, the four parts connected by the vertical flexible hinge 15 and the horizontal flexible hinge 16 of the shock absorbing ring 11 play the role of an elastic link frame and have an orientation function. The number of shock absorbing rings 11 installed is not less than 2, To enhance the stability of the overall structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com