Flexible assembly and dynamic pressure radial gas bearing

A technology of flexible components and gas bearings, applied in sliding contact bearings, rotating bearings, bearings, etc., can solve the problem that the structural space of wave foil bearings is not fully utilized, the variable range of rigidity is limited, and the frictional damping energy dissipation effect is poor to achieve the effects of maintaining stability, enhancing energy dissipation, and high structural damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

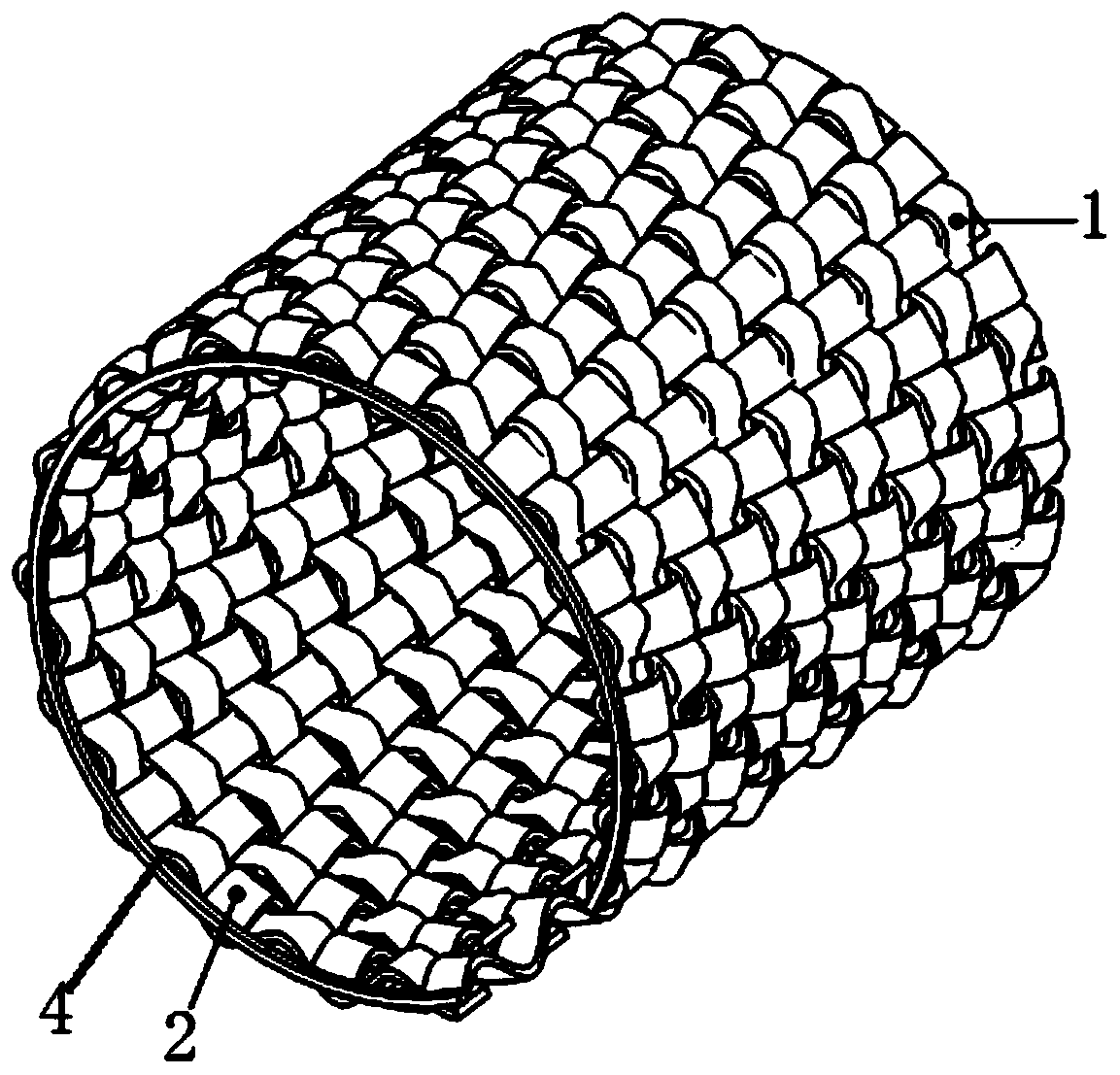

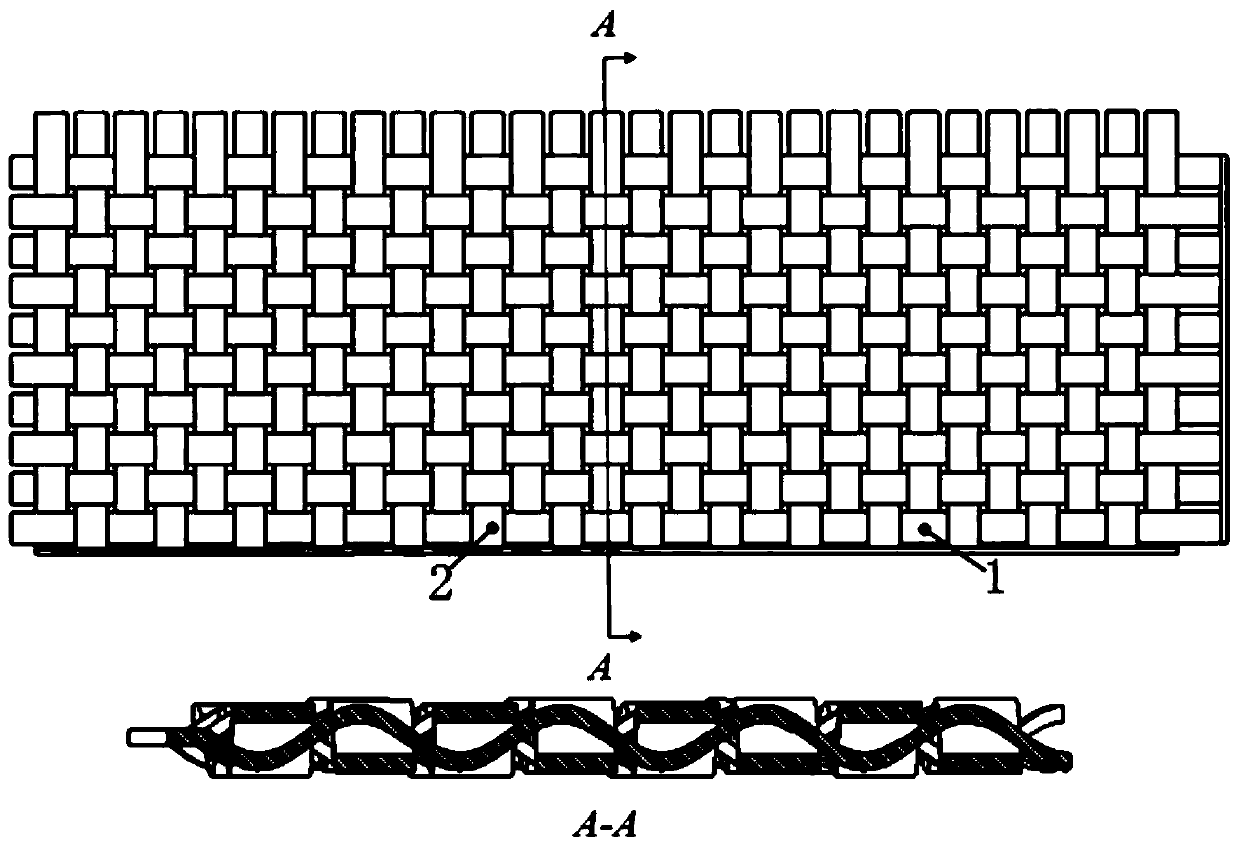

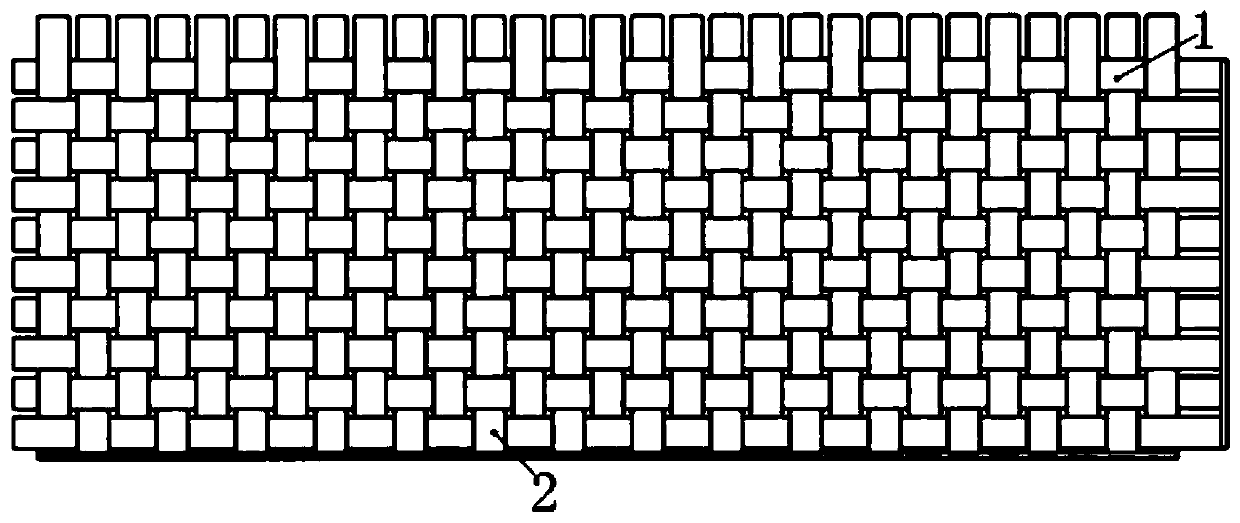

[0029] Hereinafter, specific embodiments of the present application will be described in detail with reference to the accompanying drawings. According to these detailed descriptions, those skilled in the art can clearly understand the present application and can implement the present application. Without departing from the principle of the present application, the features in different embodiments can be combined to obtain new implementations, or some features in certain embodiments can be replaced to obtain other preferred implementations.

[0030] With the development of technologies in the fields of aerospace, energy and power, in order to maintain the cleanliness, stability and reliability of high-speed machinery, higher and higher requirements are placed on lubrication technology. When turbomachinery works at extreme temperatures, such as low-temperature helium liquefaction devices, ultra-high temperature turbojet systems, etc., and the oil medium can no longer achieve lub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com