Multi-mass-sheet two-side clamping device for rail vibration reduction

A clamping device and multi-mass technology, which can be used in tracks, roads, buildings, etc., can solve problems such as noise pollution, poor vibration and noise reduction effects, and short life of rubber pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

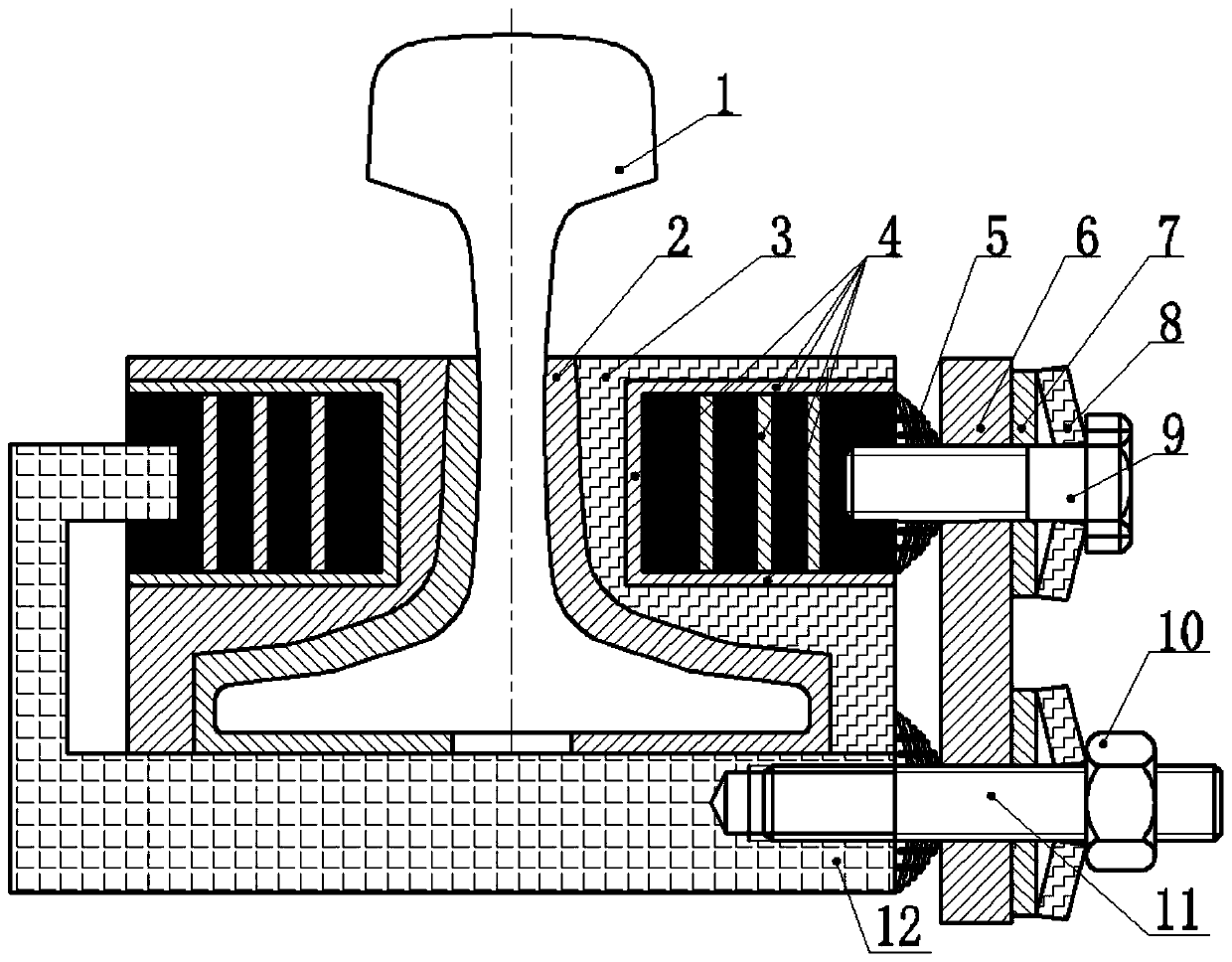

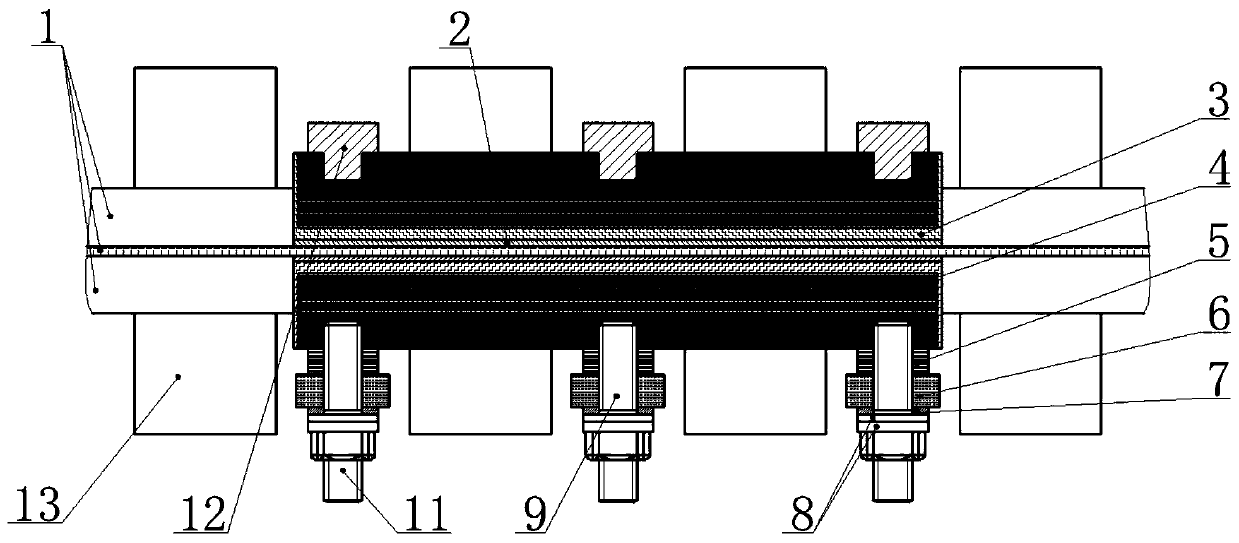

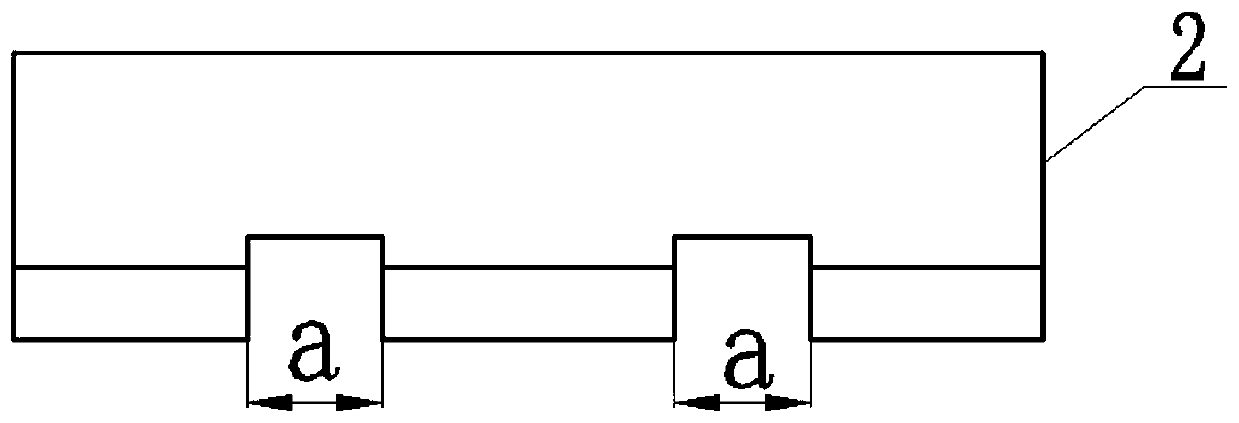

[0035] Please refer to figure 1 with figure 2 This embodiment provides a multi-mass sheet clamping device for vibration damping on both sides of a track, which includes an elastic body 2, a bracket 3, an elastic body-steel member combination arranged on the first side and the second side of the track 1. Body 4, compression plate 6, first locking member, second locking member, compression bar 12 with a compression end, leaf spring 5 between the compression plate 6 and the elastomer-steel component assembly 4, Rail washer 7 and spring washer 8, of which rail 1, rail washer 7 and spring washer 8 are common structures in railways, elastomer 2 is closely attached to the middle and lower part of rail 1, and bracket 3 wraps elastomer 2 Inside and forming a whole structure, the whole structure spans two sleepers 13, the whole structure has a section of elastic body-steel component assembly 4 on both sides of the track 1, and the bottom of the whole structure is provided with three comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com