Gas purifying chamber for coal mine electrical equipment

A technology for electrical equipment and clean rooms, applied to chemical instruments and methods, separation of dispersed particles, combined devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

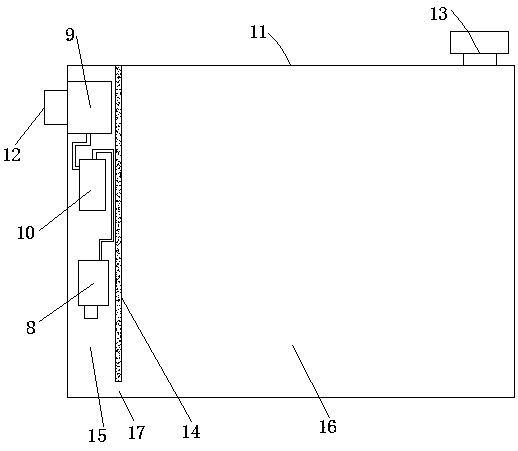

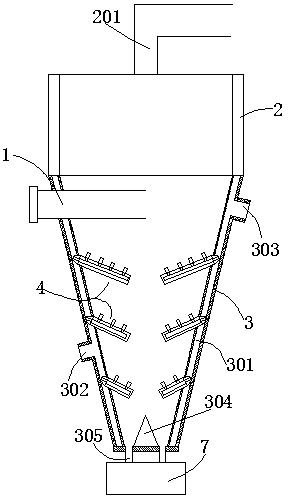

[0042] In this embodiment, the gas purification room for coal mine electrical equipment includes a sealed cavity structure with an internal space formed by a plurality of wall panels 11 butted against each other. The sealed cavity is provided with an air inlet 12 and an exhaust port. A fan 13 is provided at the mouth, and a sound insulation board 14 is arranged in the sealed cavity. The lower end surface of the sound insulation board 14 and the bottom wallboard of the sealed cavity have a certain ventilation gap 15, and the remaining end surfaces of the sound insulation board 14 are sealed with the inner wall of the sealed cavity. The sound insulation board 14 divides the space of the sealed cavity into a ventilation cavity 15 and a clean cavity 16. Coal mine electrical equipment is mainly installed in the clean cavity 16, and the ventilation cavity 15 communicates with the air inlet 12. In the ventilation cavity 15 The inner air inlet 12 is sequentially connected to the coarse...

Embodiment 2

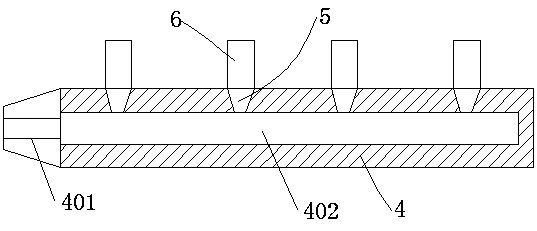

[0045] In this embodiment, except that the structure of the gas nozzle is different from that in Embodiment 1, the rest of the structures are completely the same, so only the structure of the gas nozzle is described here, such as Figure 5 As shown, the gas nozzle structure includes a screw joint 5 and a pipe body 6 connected to the screw joint. The air uniform plate 604, the buffer chamber 605, the dispersion plate 606 and the exhaust port 607, the air flow channel II501 in the screw joint and the air inlet chamber 601 realize the sealing connection, and the air uniform plate 604 is evenly equipped with several cone-shaped The vent hole 6041, the larger end of the vent hole 6041 faces the air storage chamber 603, a cotton layer is arranged in the buffer chamber 605, and a plurality of through holes are arranged on the dispersion plate 606, and the through holes are located in the dispersion It is composed of a central hole in the middle of the plate and a plurality of incline...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com