A double-brake back-and-forth controllable descending device

A technology of double brakes and slow descenders, which is used in building rescue and life-saving equipment, etc., can solve the problems of inability to use elevators, inconvenience to carry, and few descenders, and achieves strong controllability, high precision and high precision. Avoid loss or offset effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

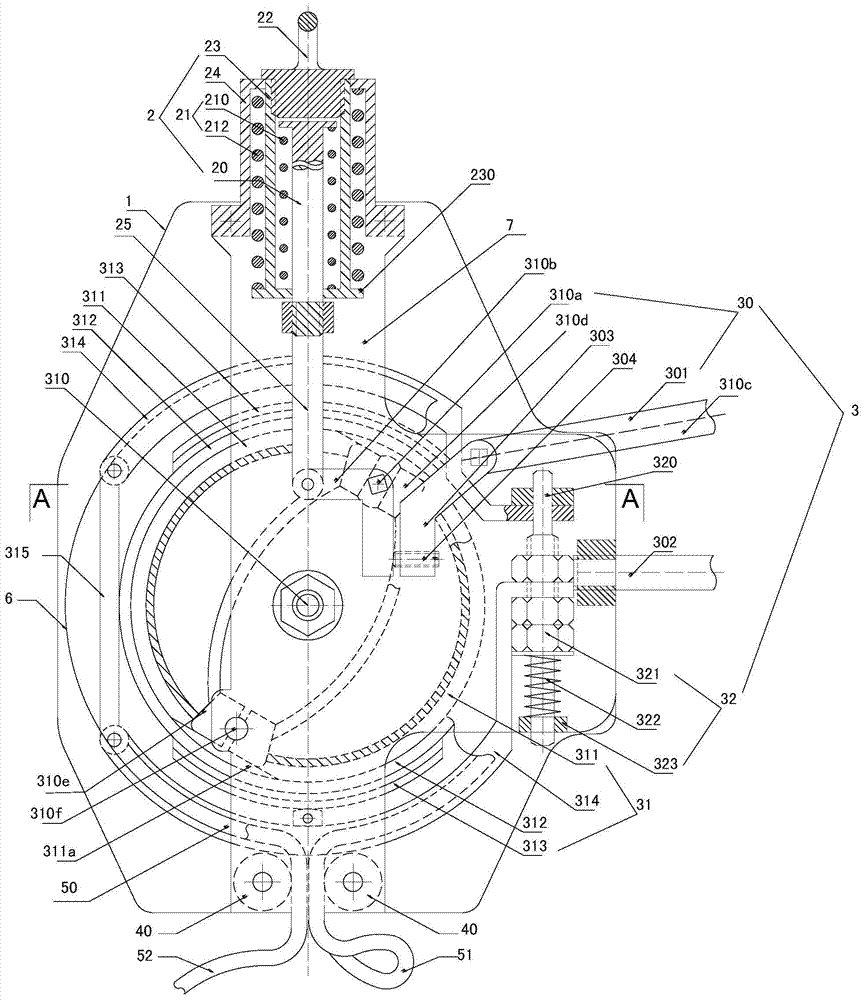

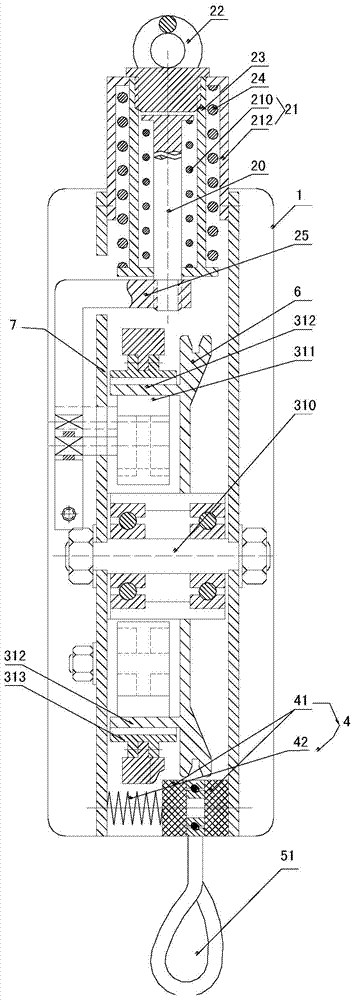

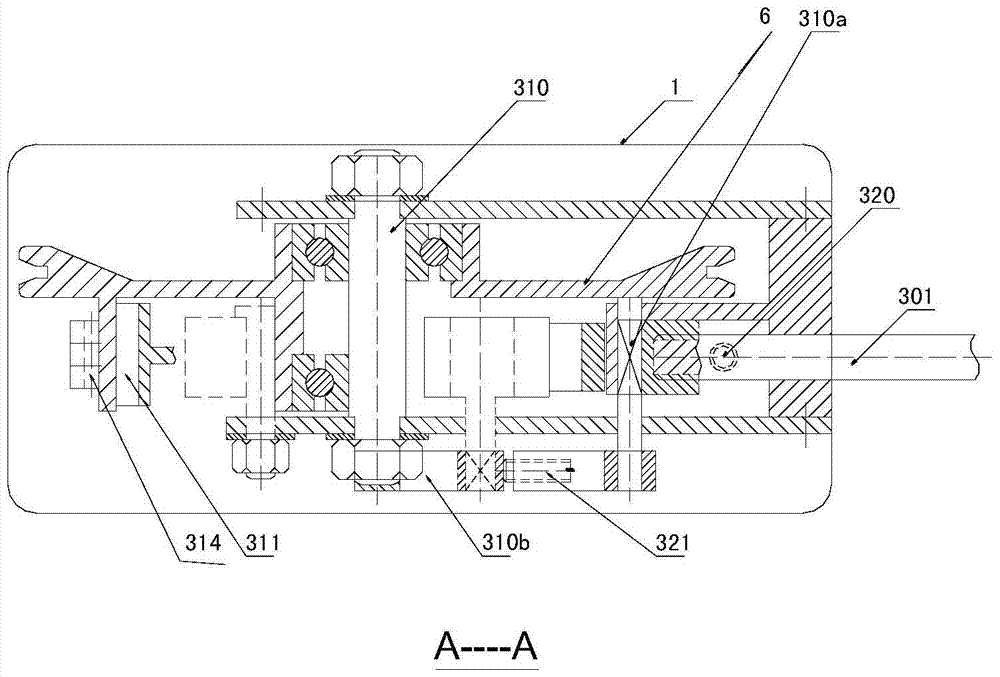

[0041] refer to Figure 1 to Figure 3 As shown, the present invention provides a dual-brake back-and-forth controllable descent device 100, which includes an outer shell 1 and a lifting mechanism 2 built in it, a double-braking mechanism 3, a rope guide mechanism 4 and a wedge wheel 6 , the pulling mechanism 2 is linked with the double brake mechanism 3, the pulling mechanism 2 includes an energy conversion adjustment screw 20 and a buffer member 21 arranged on its outer periphery, and the double brake mechanism 3 includes an outer brake assembly 30. An inner brake assembly 31 and a self-locking mechanism 32. The inner brake assembly 31 is linked with the energy conversion adjustment screw 20 of the lifting mechanism 2. The outer circumference of the inner brake assembly 31 is provided with a wedge wheel 6. A wire rope 50 is wound on the wedge wheel 6, and the self-locking mechanism 32 can be movably resisted between the outer brake assembly 30 and the outer casing 1. In this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com