Novel linear rolling and sliding composite guide rail pair

A guide rail pair and straight line technology, applied in the field of guide rail pairs, can solve problems such as difficulty in meeting performance indicators and precision requirements of heavy-duty machine tools, large contact area of sliding guide rails, poor vibration resistance, poor rigidity, etc., and achieve excellent manufacturing process and good motion performance , the effect of large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

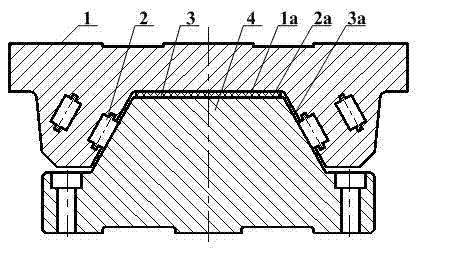

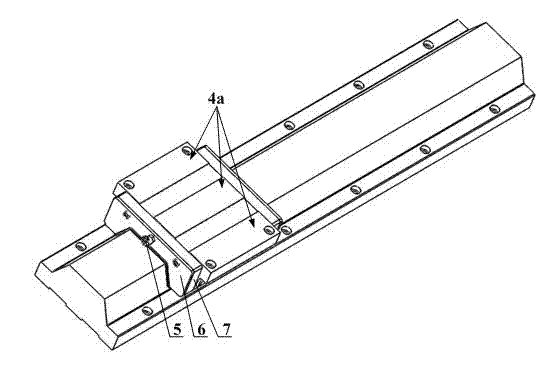

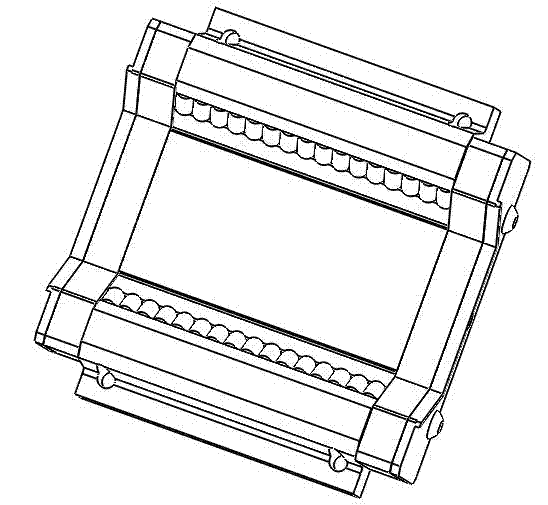

[0028] A new type of linear rolling-sliding composite guide rail pair of the present invention comprises a guide rail 4 and a slider 1 that cooperate with each other, the guide rail 4 is a trapezoidal guide rail, the two sides of the trapezoidal guide rail are guide surfaces 3a, and the upper surface of the trapezoidal guide rail is bearing surface 2a,

[0029] A trapezoidal groove matching the trapezoidal guide rail is provided at the bottom of the slider 4, and a row of cylindrical roller rows 2 are respectively arranged on the two sides of the trapezoidal groove along the length direction, and the upper surface 1a of the trapezoidal groove of the slider 4 and the load bearing The flexible belt 3 of the guide rail is arranged along the length direction of the guide rail 4 between the surfaces 2a.

[0030] The material of the guide rail 4, the cylindrical roller and the slide block 1 is steel. Both the guide surface 3a and the bearing surface 2a of the guide rail are quenche...

Embodiment 2

[0033] A new type of linear rolling-sliding composite guide rail pair of the present invention comprises a guide rail 4 and a slider 1 that cooperate with each other, the guide rail 4 is a trapezoidal guide rail, the two sides of the trapezoidal guide rail are guide surfaces 3a, and the upper surface of the trapezoidal guide rail is Bearing surface 2a.

[0034] The bottom of the slider 4 is provided with a trapezoidal groove matching the trapezoidal guide rail. Two rows of cylindrical roller columns 2 are respectively arranged on the two sides of the trapezoidal groove along the length direction. The upper surface 1a of the trapezoidal groove of the slider 4 and the load bearing The flexible belt 3 of the guide rail is arranged along the length direction of the guide rail 4 between the surfaces 2a.

[0035] The material of the guide rail 4, the cylindrical roller and the slide block 1 is steel. Both the guide surface 3a and the bearing surface 2a of the guide rail are quenche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com