Back support form support structure for large-aperture reflector

A large-diameter reflector and support structure technology, which is applied in the direction of instruments, installation, optics, etc., can solve problems such as the inability to realize lens array installation, affect the quality and energy of the transmitted beam, and the thick structure of large-diameter reflectors, etc., to achieve a simple structure , high reliability and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

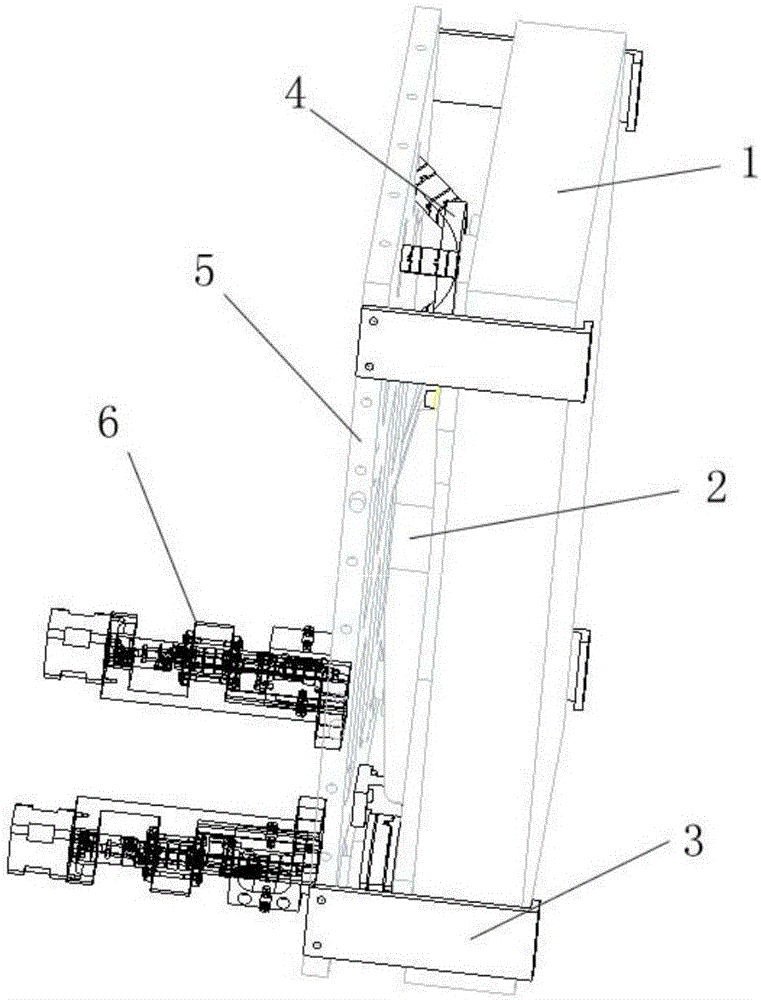

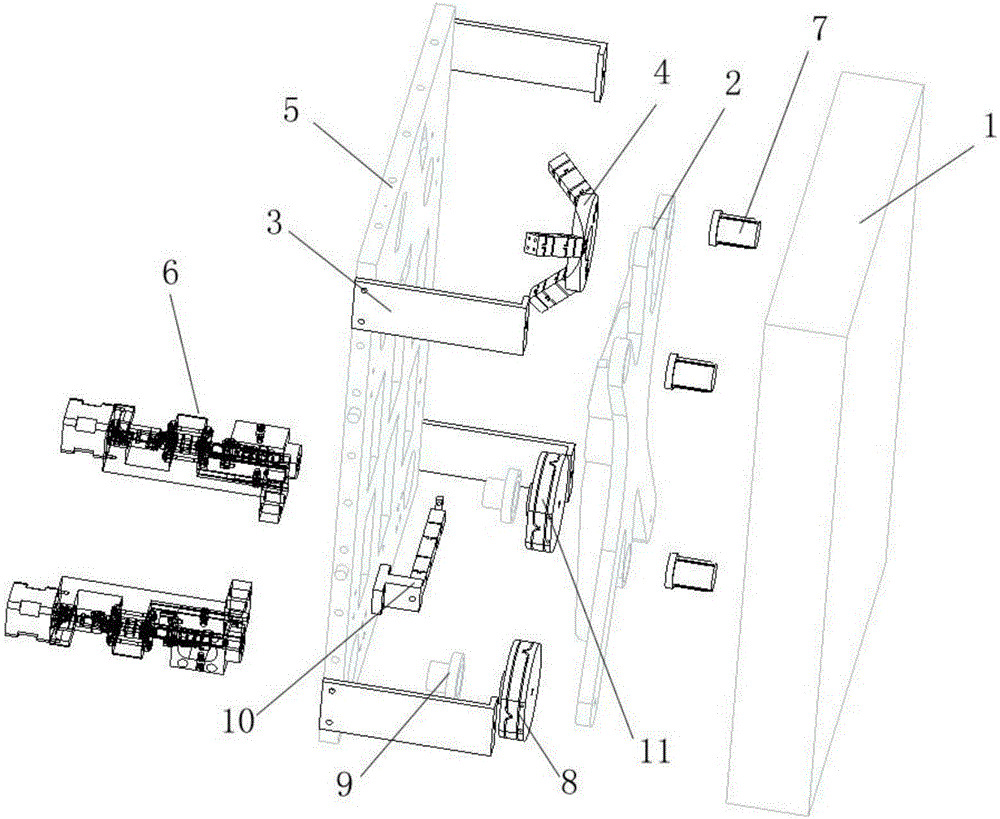

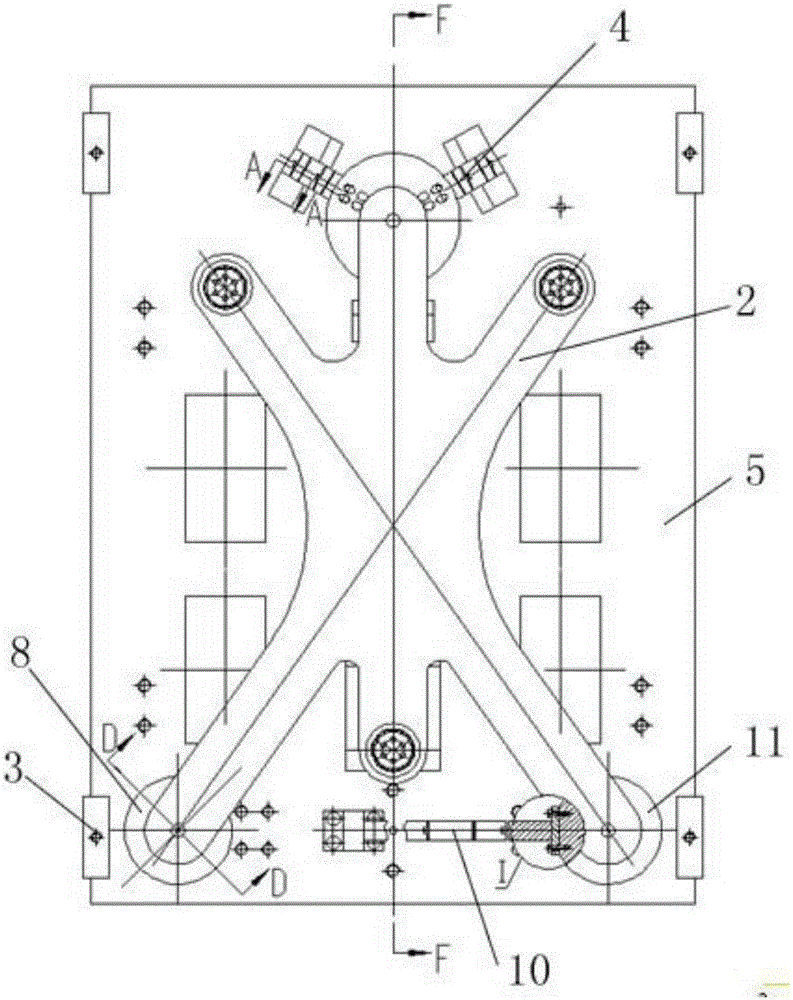

[0032] The present invention will be further described below in conjunction with accompanying drawing:

[0033] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, the present invention includes an optical lens 1, ribs 2 and a back plate 5 parallel to each other, a three-claw flexible hinge 4, a disc flexible hinge I8 and a disc flexible hinge II11 are arranged between the ribs 2 and the back plate 5, and the rear The plate 5 is equipped with an anti-rotation flexible hinge 10, four protective sheets 3 and two driving components 6, and the optical lens 1 can be placed at any angle with the ground.

[0034] There are three blind holes on the back of the optical lens 1, and the positions of the blind holes are calculated by mechanics. A precision expansion sleeve 7 is respectively installed in the three blind holes, and the three precision expansion sleeves 7 are fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com