Patents

Literature

73results about How to "Guaranteed maintenance efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

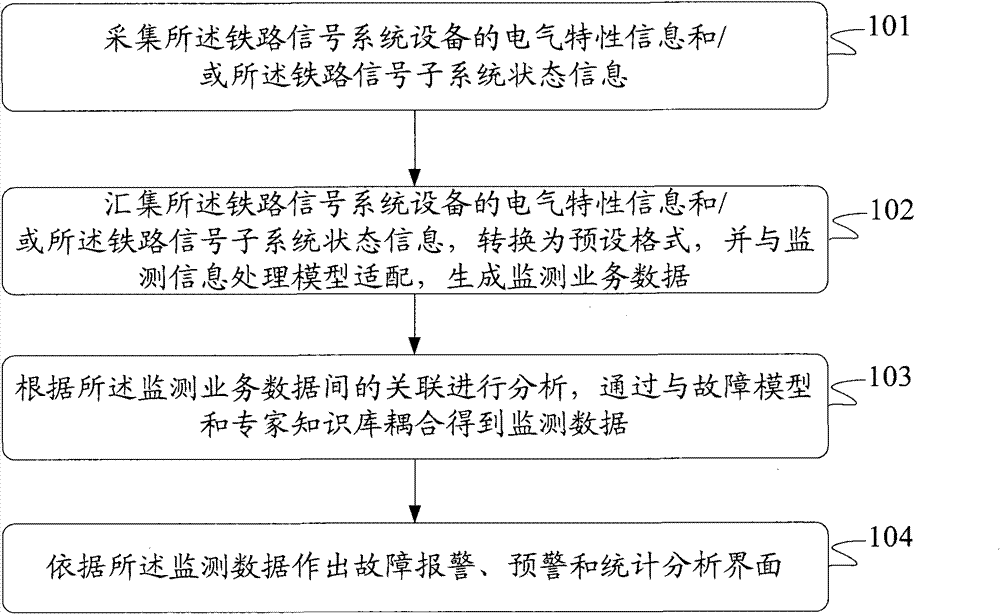

Railway signal monitoring method and system

ActiveCN101917237AOptimize resource allocationHigh degree of centralizationTransmitters monitoringData switching networksInformation processingStatistical analysis

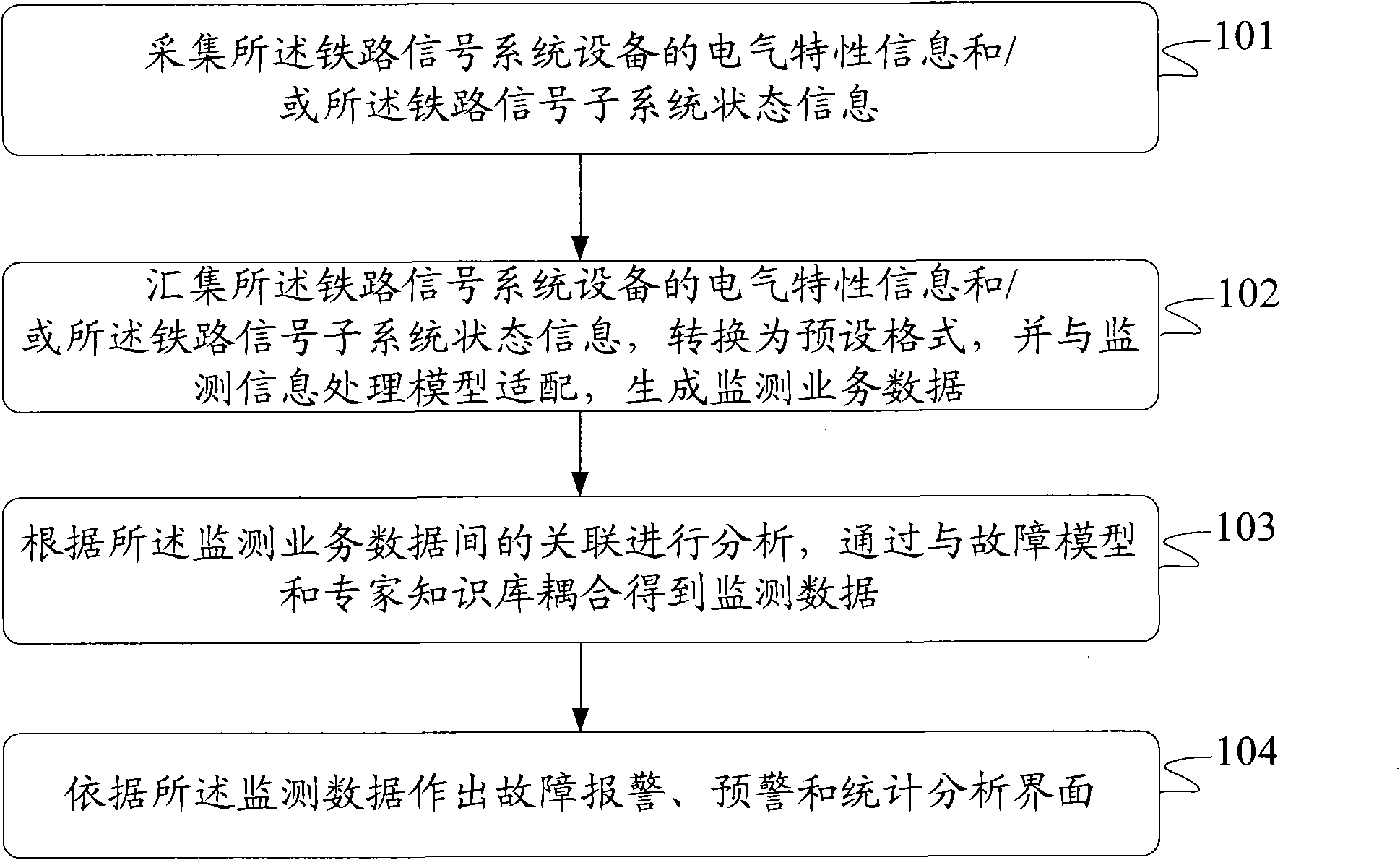

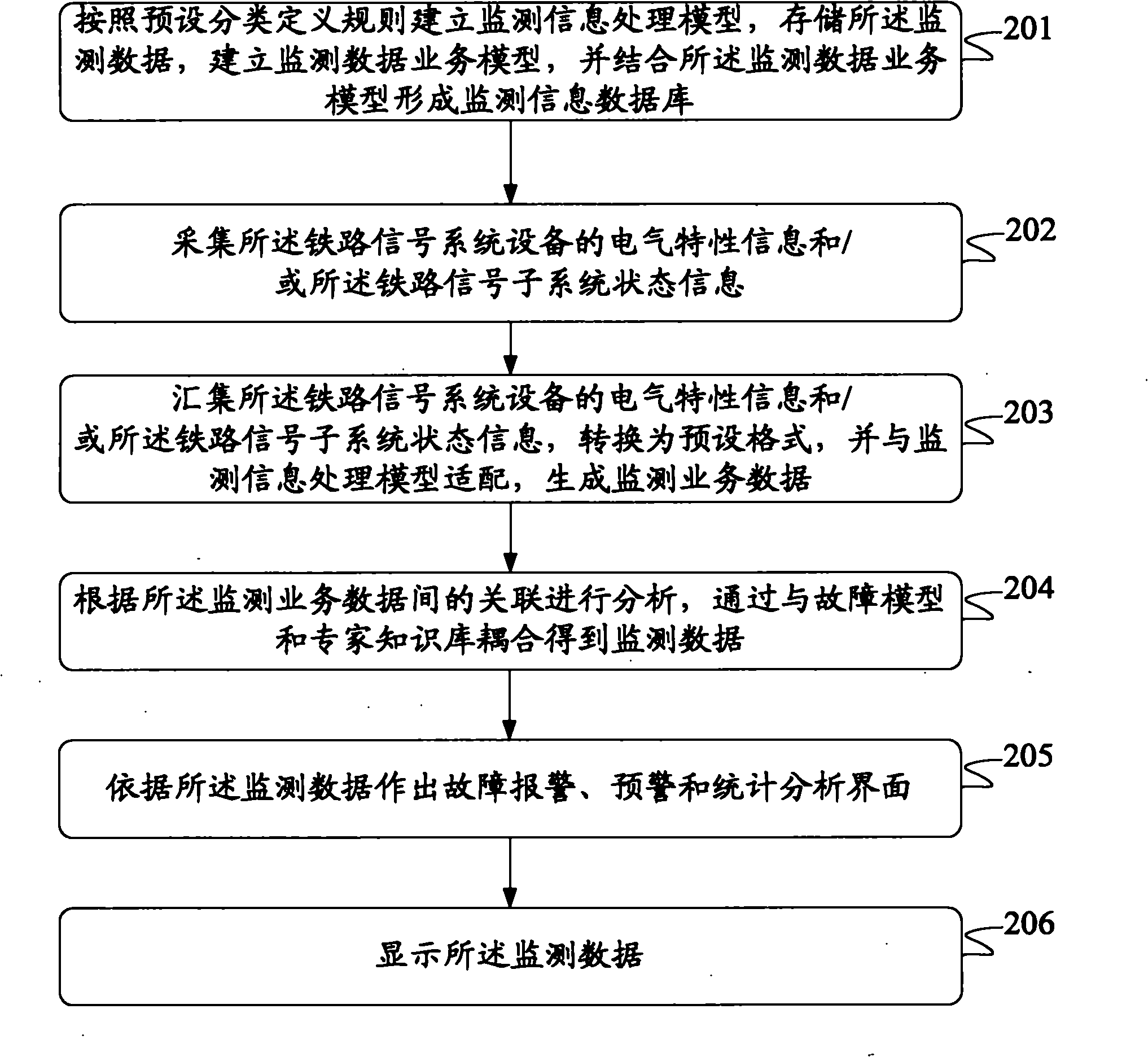

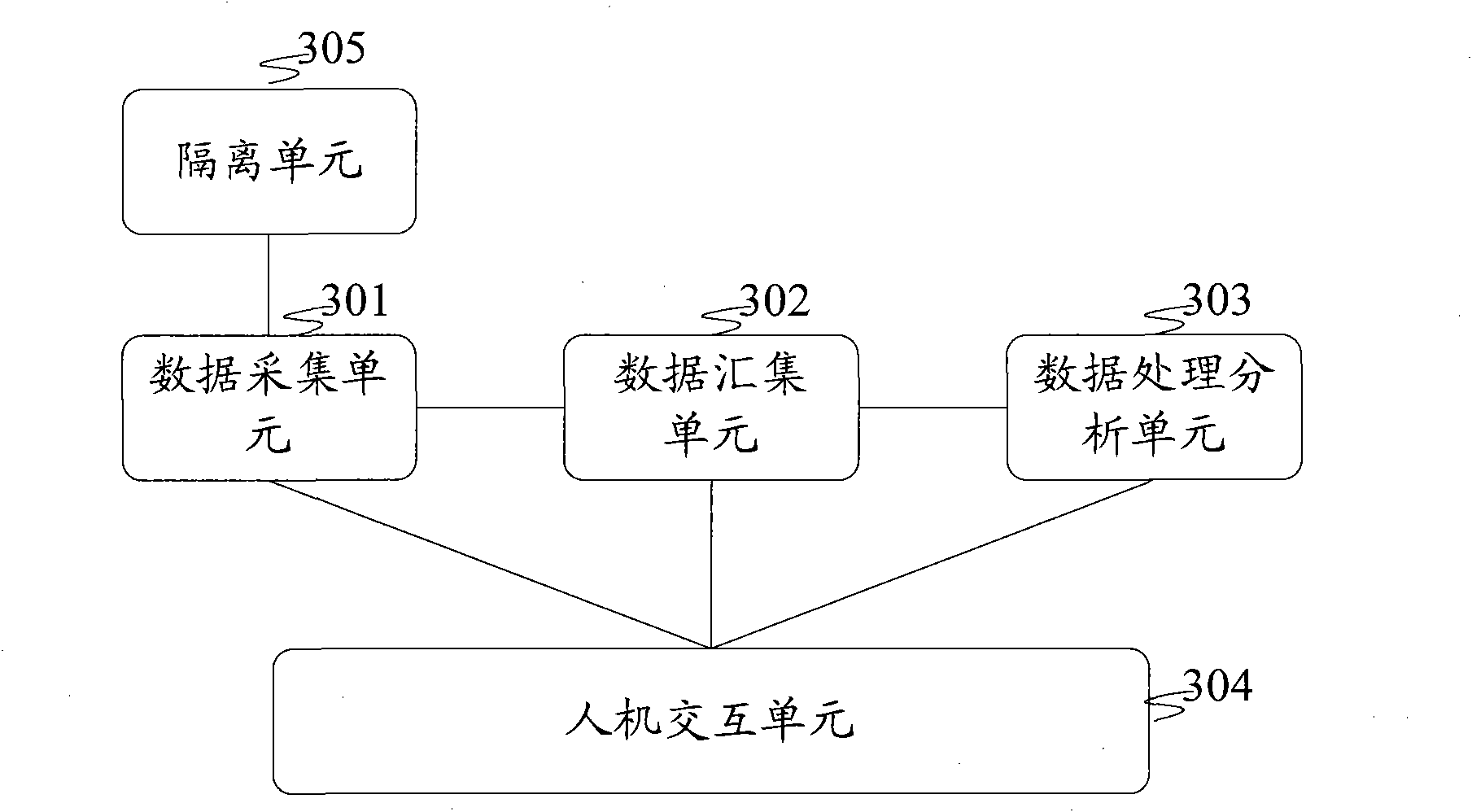

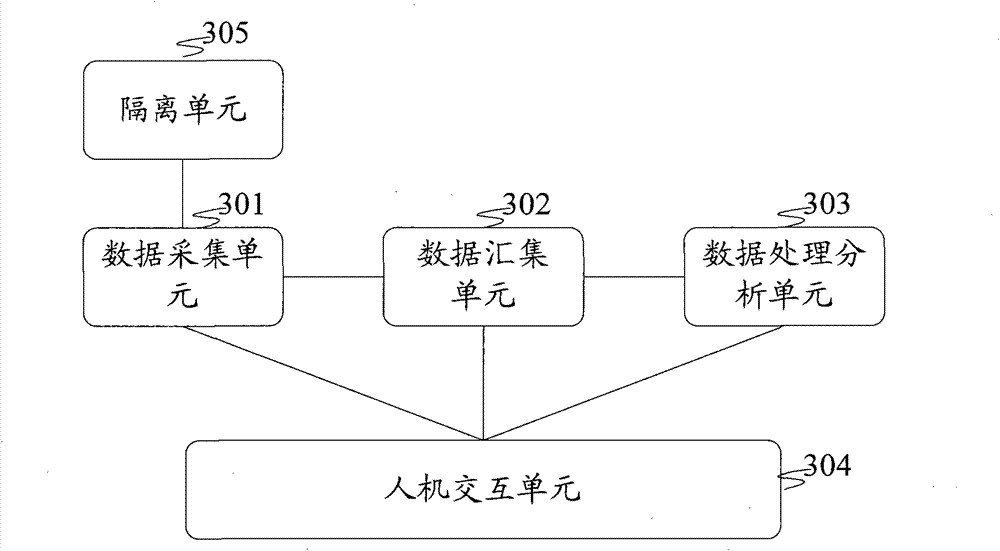

The embodiment of the invention discloses a railway signal monitoring method and a railway signal monitoring system. The method comprises the following steps of: performing acquisition, convergence and format conversion on electrical characteristic information of equipment of the railway signal system and / or railway signal subsystem state information, adapting the information after the format conversion and a monitoring information processing module to form monitoring service data, and making a fault warning, early warning and statistical analysis interface according to the monitoring data after analysis and associated coupling. Because the embodiment adopts a uniform conversion format and is adapted to the information processing module of a fixed form, centralized monitoring of the equipment of the railway signal system is realized, the defects of decentralized management and decentralized maintenance of the railway signal system in the prior art are overcome, and a brand-new early warning mechanism and an intelligent expert diagnosis technique are provided. Because of high centralized degree, the embodiment optimizes the resource allocation of the railway signal monitoring system, and ensures corresponding maintenance efficiency at the same time of reducing the false alarm and missing alarm rate.

Owner:CRSC RESEARCH & DESIGN INSTITUTE GROUP CO LTD

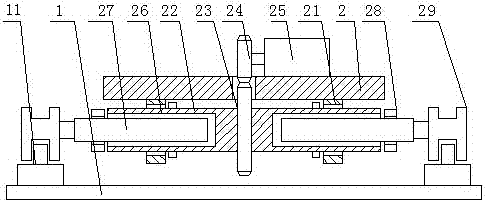

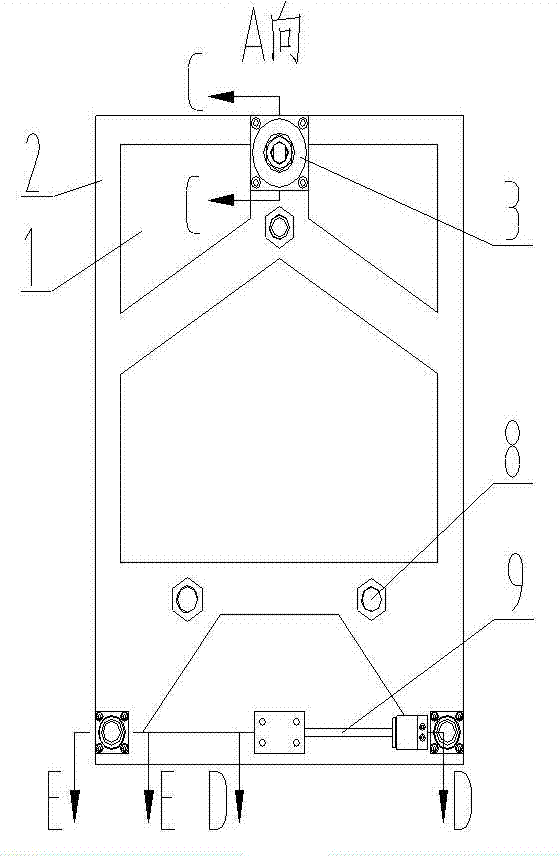

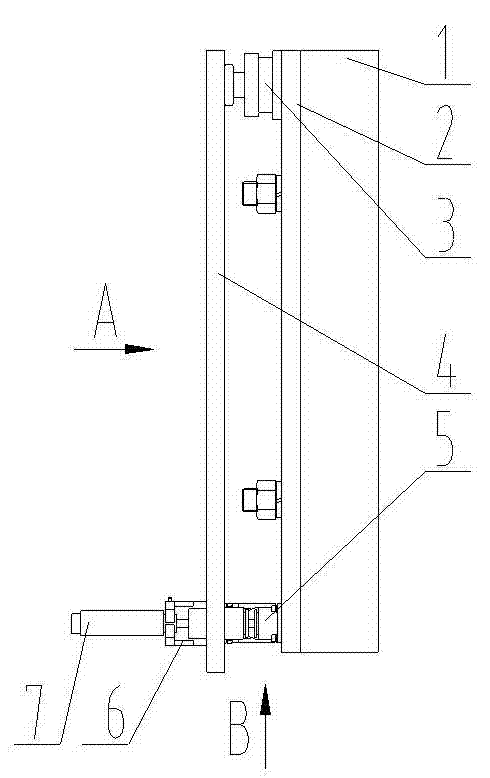

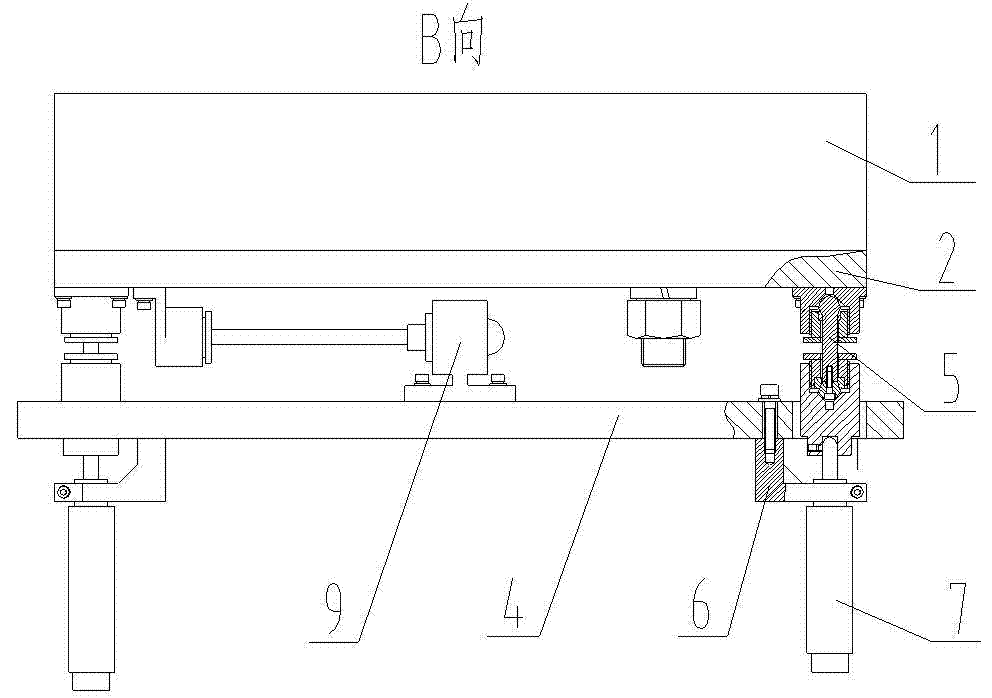

Flexible back supporting device for large-caliber reflector

InactiveCN104280858AGuaranteed cleanlinessGuaranteed stabilityMountingsEngineeringRotational degrees of freedom

The invention provides a flexible back supporting device for a large-caliber reflector. The supporting device comprises the large-caliber reflector, a lens back plate, a supporting plate, a joint plate, a screw, flexible branch hinges, sliding flexible hinge supports, a flexible hinge connecting rod and a driving system. The three flexible branch hinges and the joint plate together form a combined hinge to constrain three degrees of horizontal moving freedom of the large-caliber reflector, the pitching and deflecting movements of the large-caliber reflector are achieved through flexible hinge blocks of the sliding flexible hinge supports and the driving system, when the driving system is tightly locked, the two degrees of rotating freedom of the large-caliber reflector are constrained, and the degree of the plane inner rotating freedom of the large-caliber reflector is constrained through the flexible hinge connecting rod. The flexible hinge structure is adopted as the supporting and positioning mechanism of the large-caliber reflector, nanoscale positioning precision is achieved, and the structural stability and the precision stability are ensured through matched design of the flexibility and the moving precision of the large-caliber reflector. The flexible back supporting device has the advantages of being simple in structure, stable in movement, free of friction or gaps, needless for lubrication and high in moving sensitivity.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

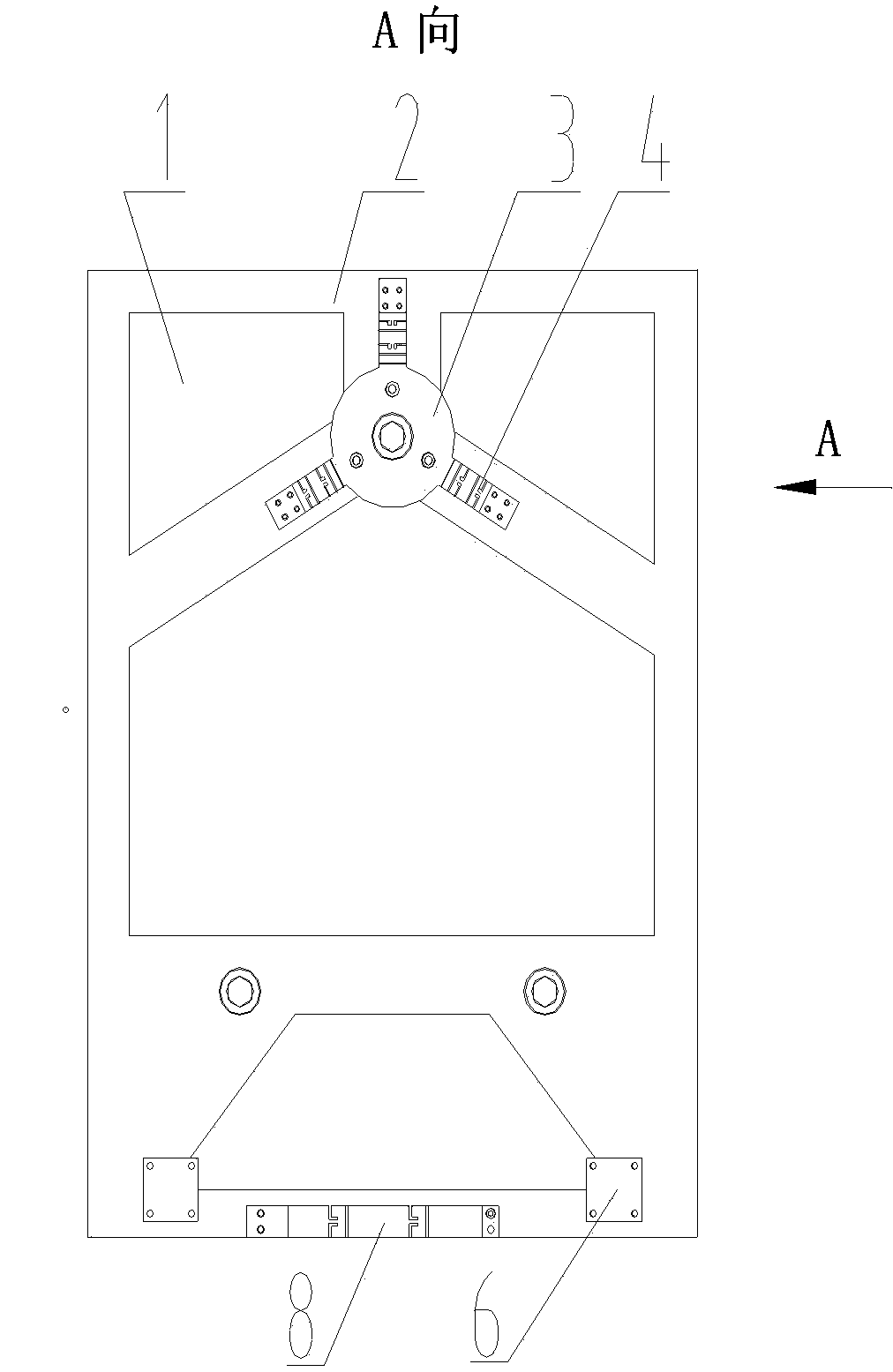

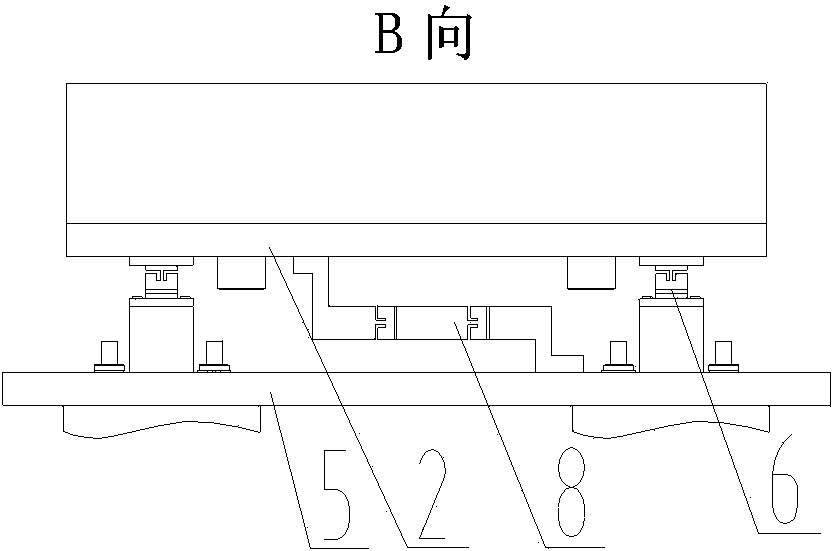

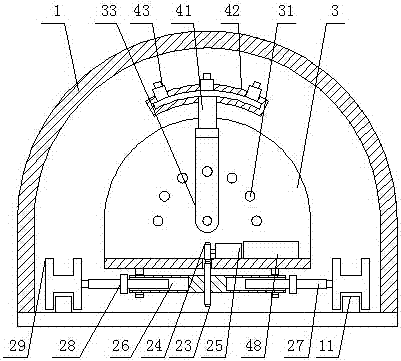

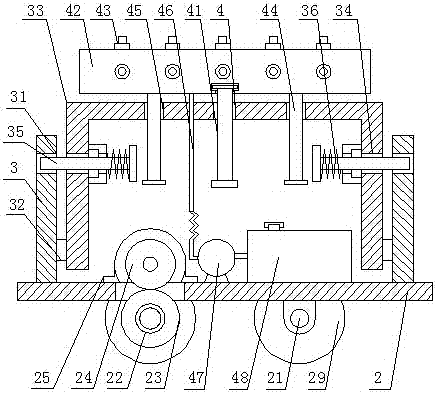

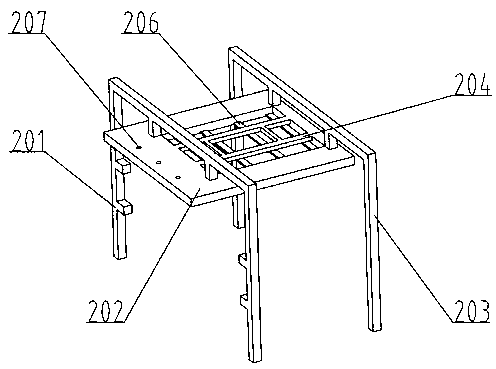

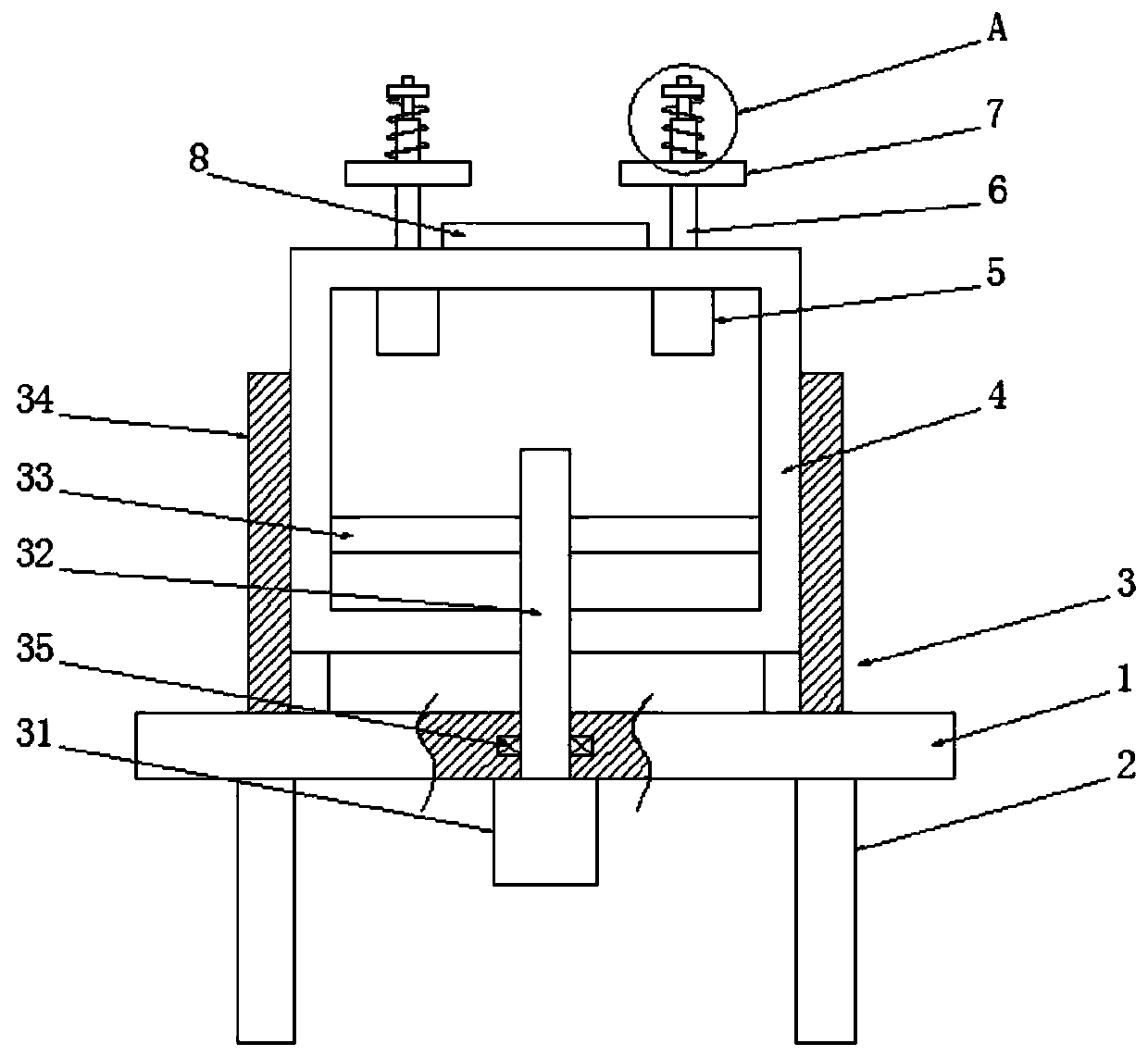

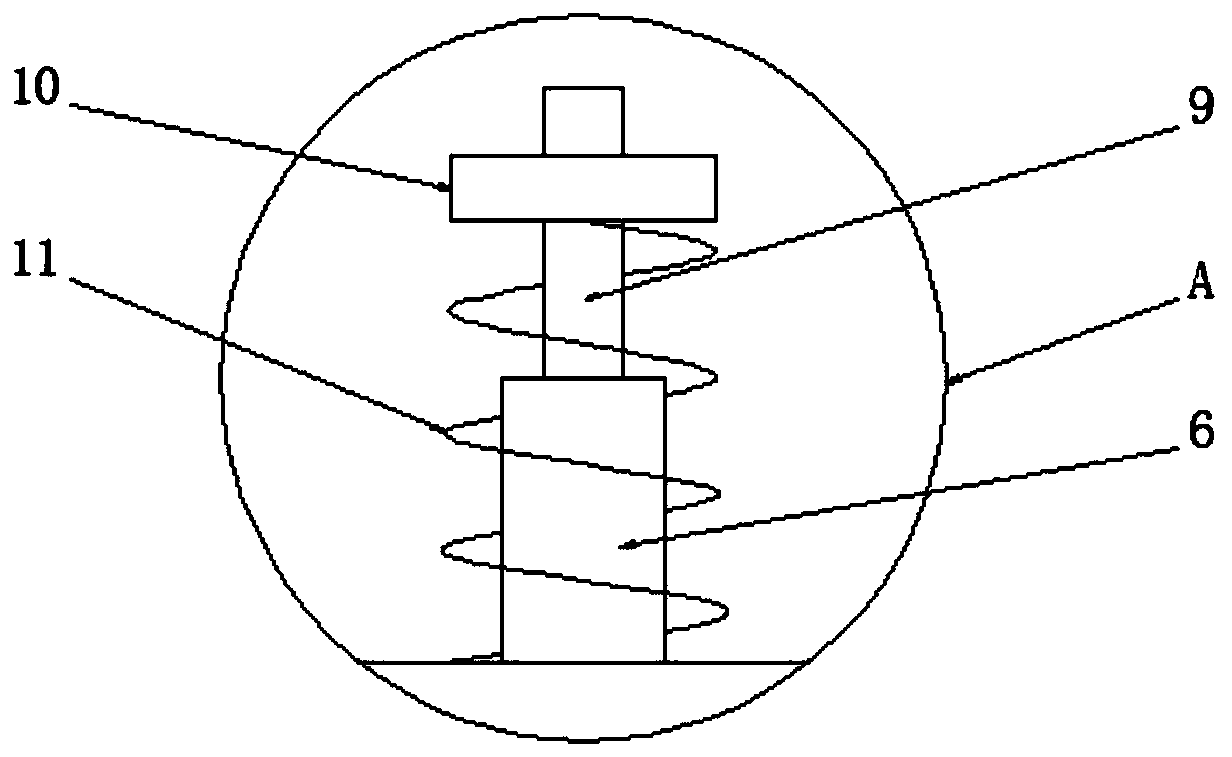

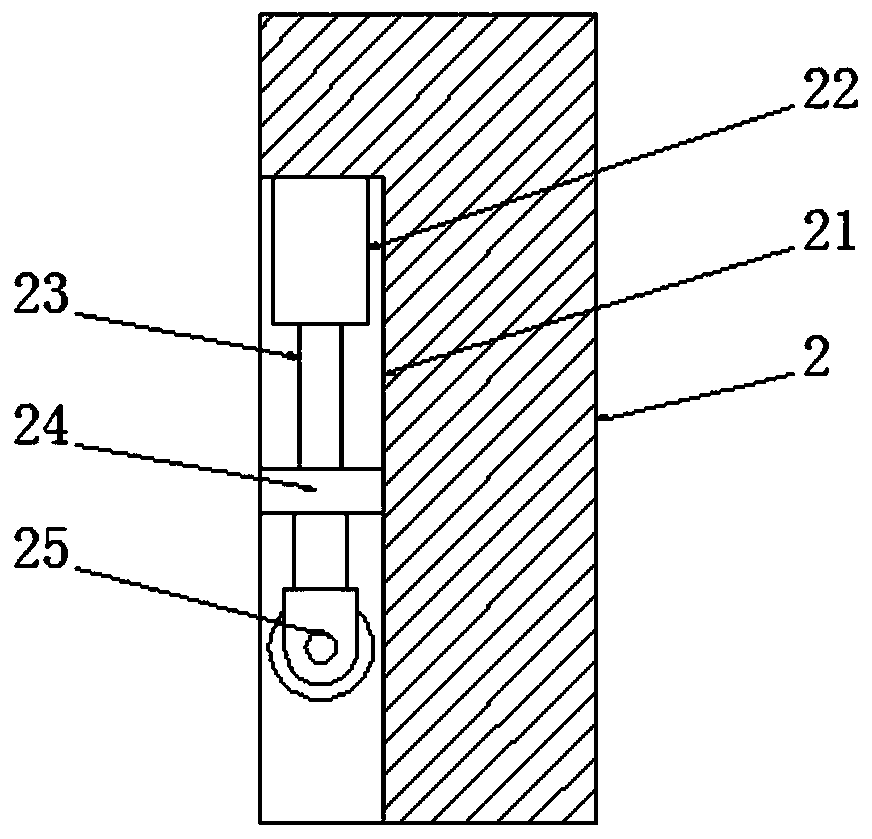

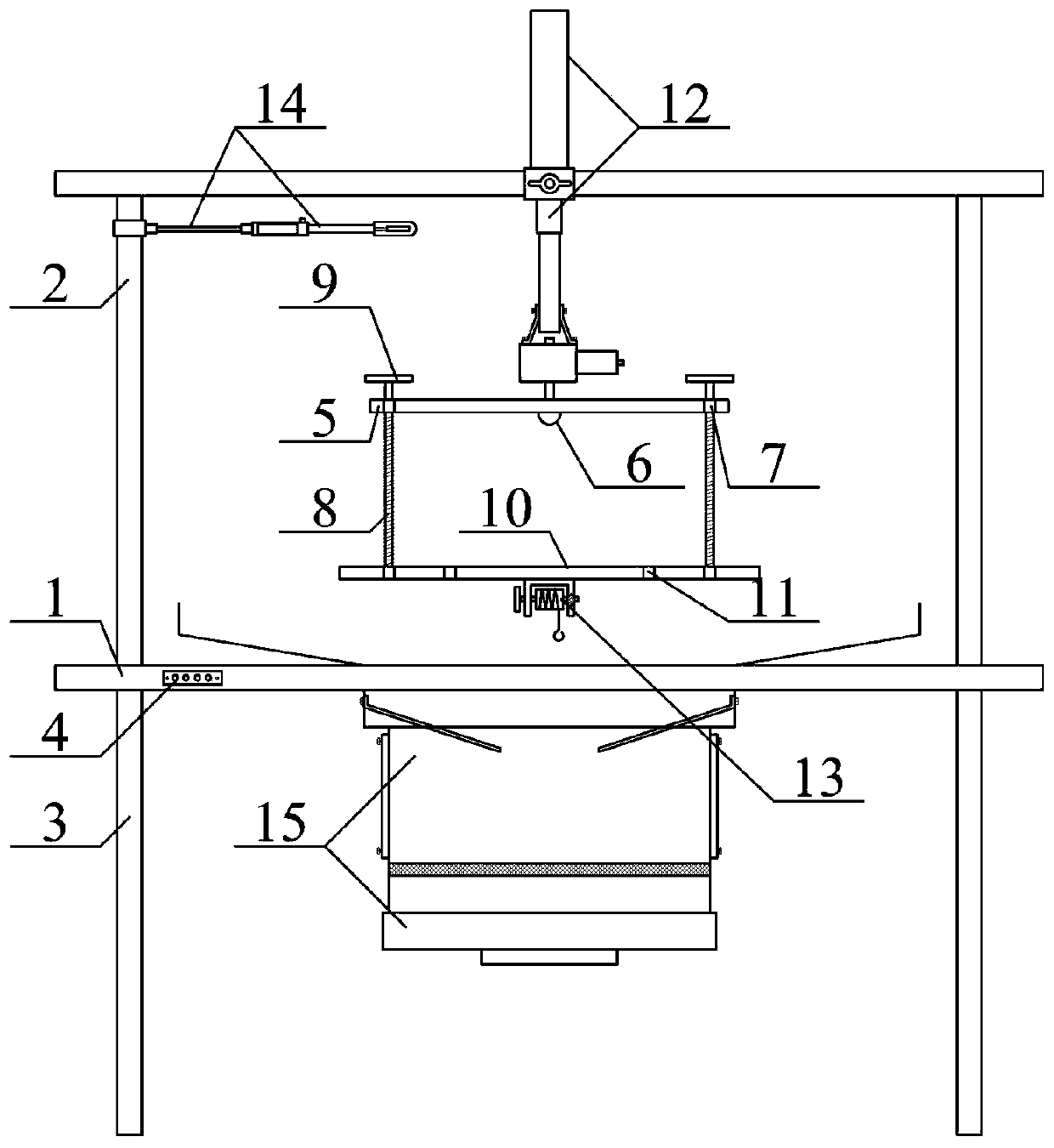

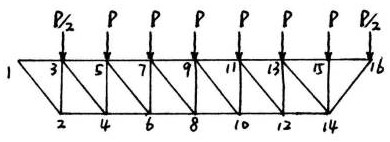

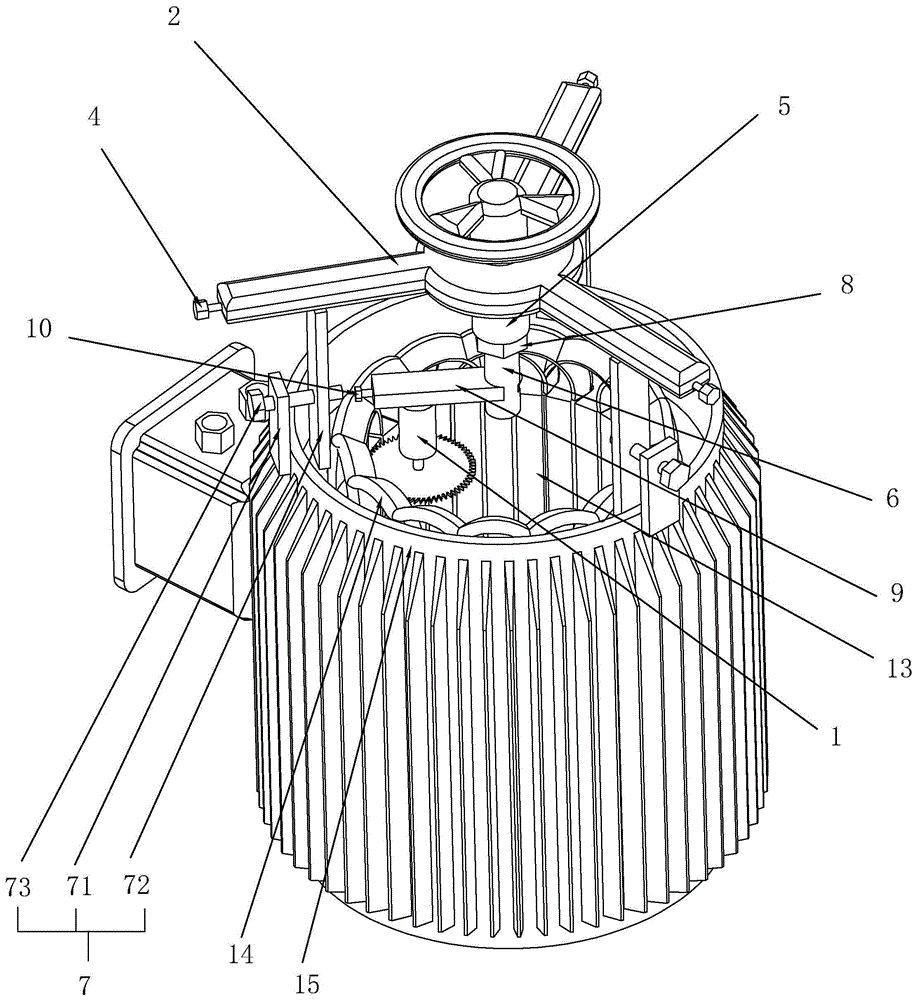

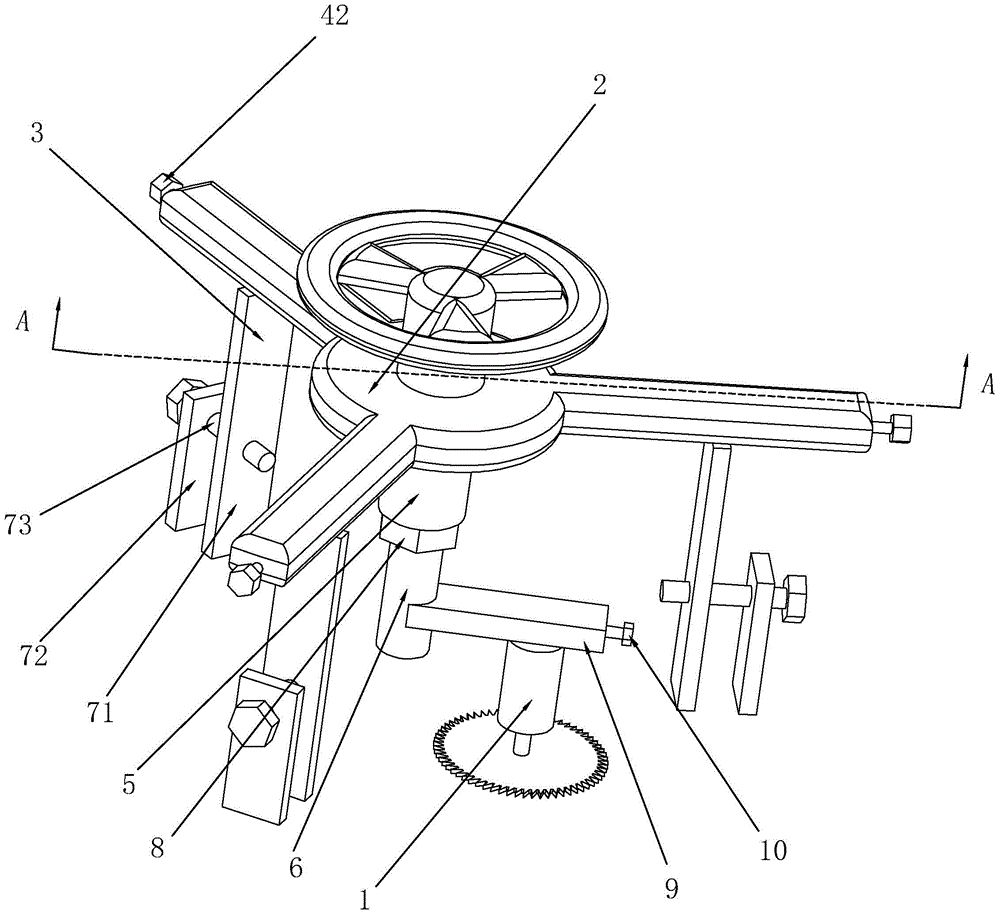

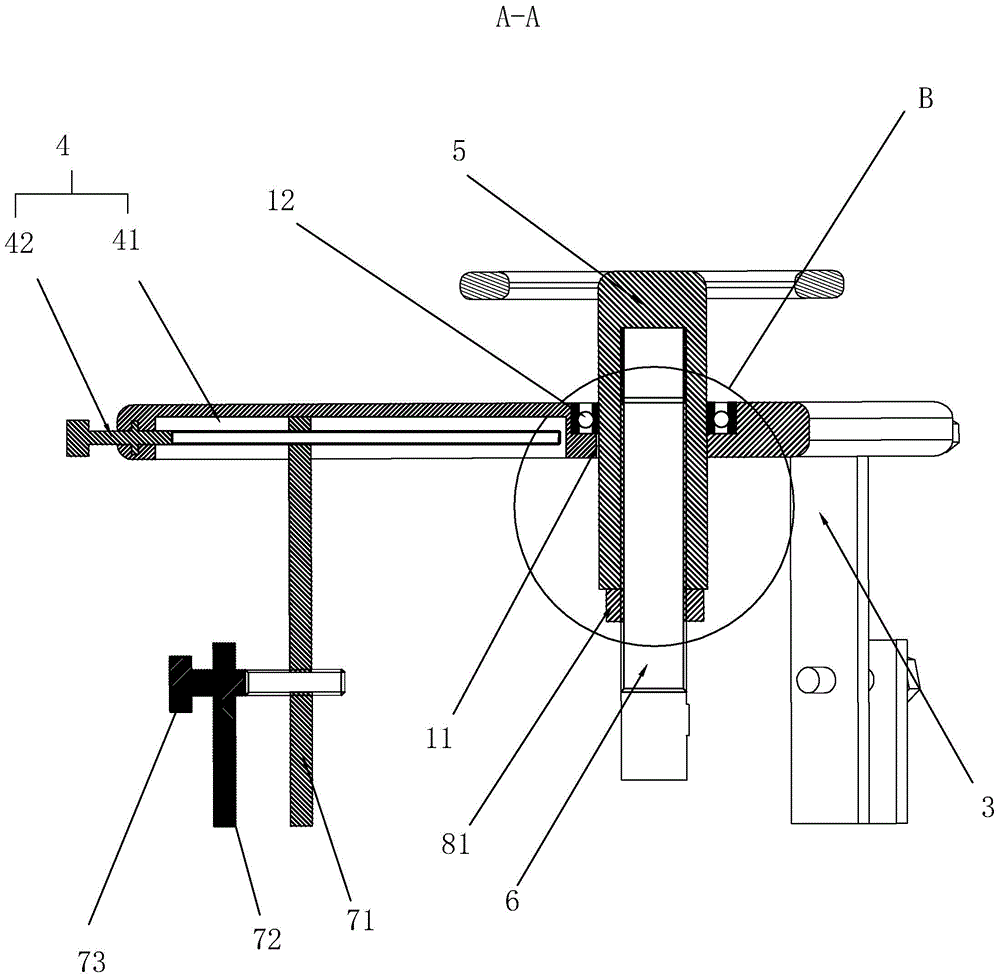

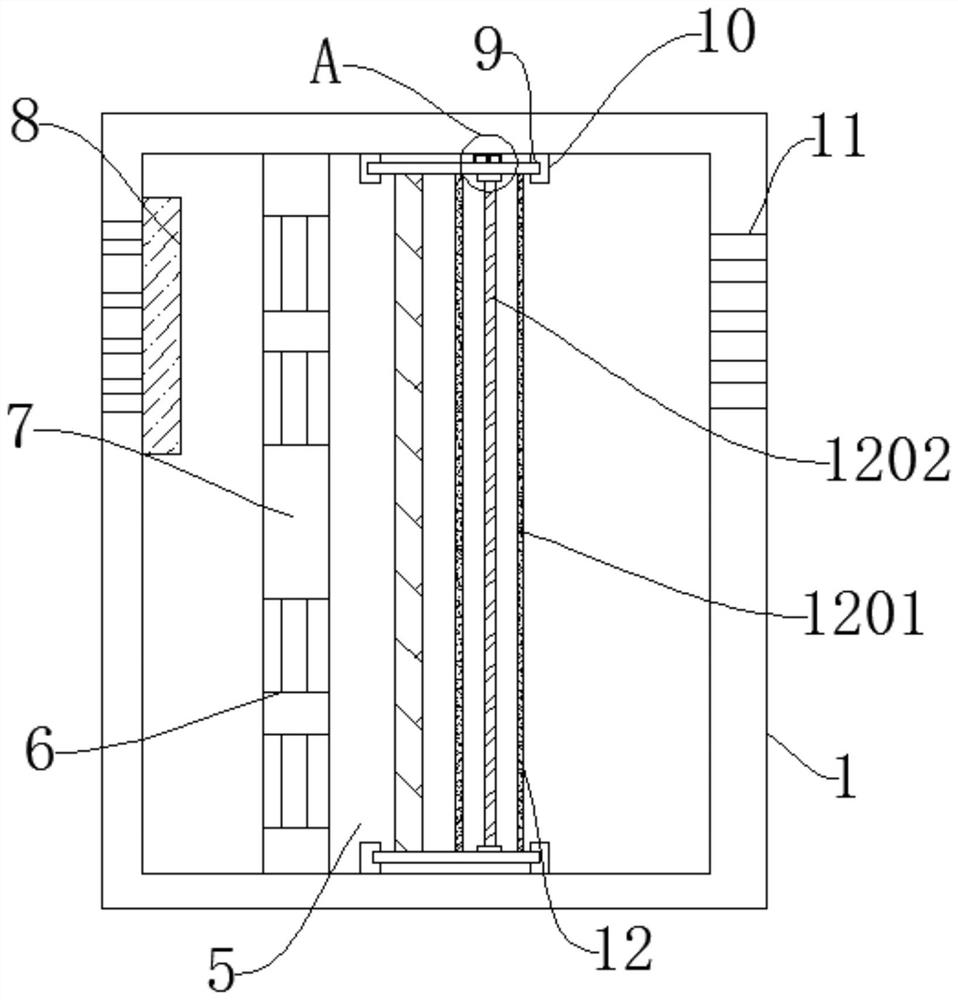

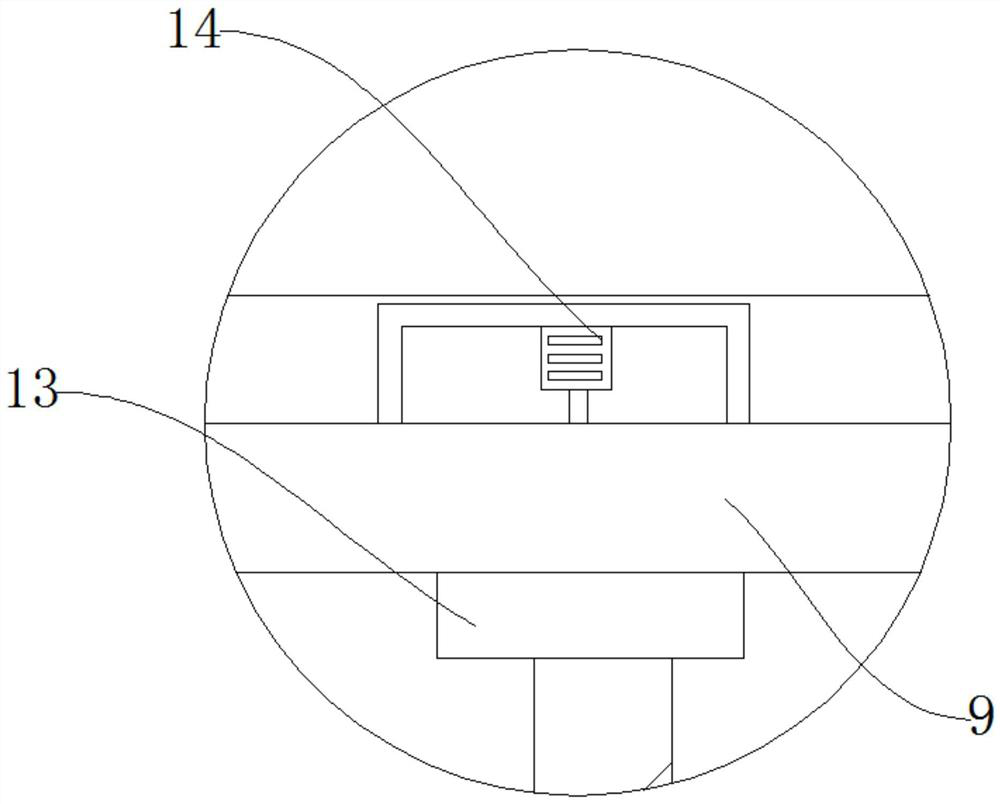

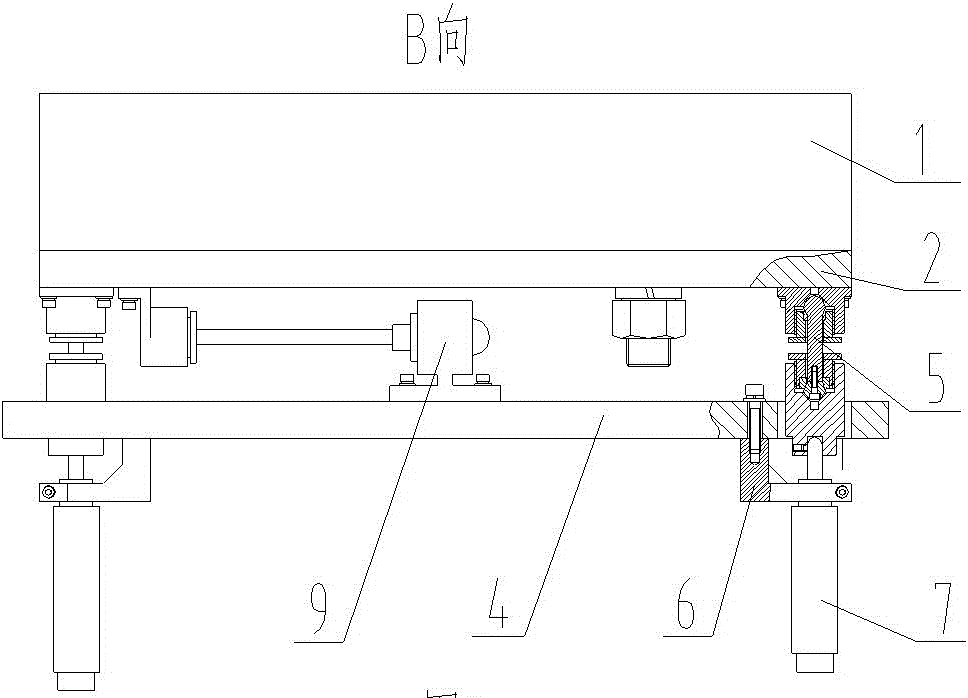

Self-propelled tunnel lining concrete curing stand

ActiveCN107143356AImprove convenienceGuaranteed maintenance efficiencyUnderground chambersTunnel liningGear wheelArchitectural engineering

Owner:江苏钦宇建设工程有限公司

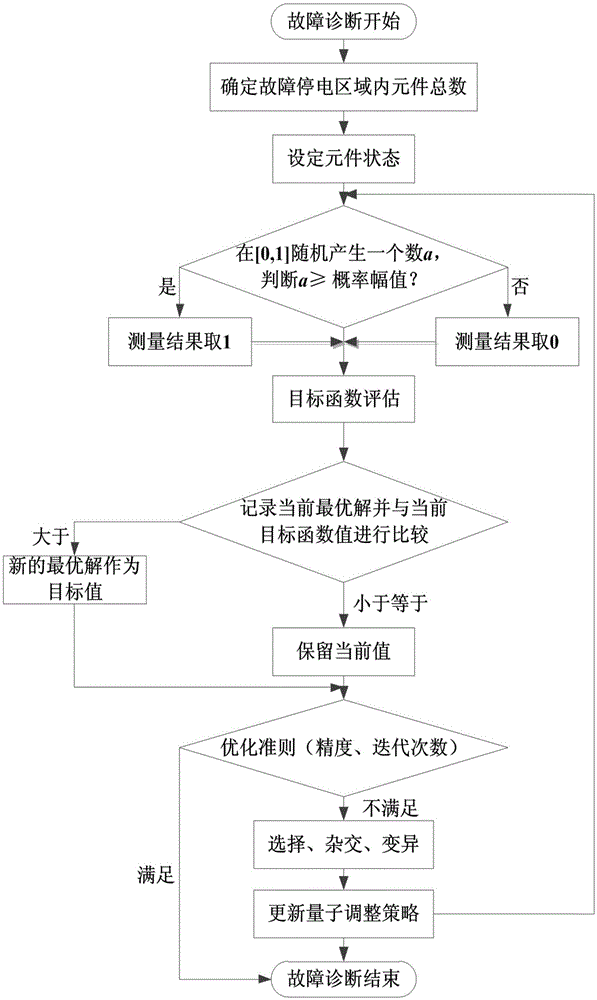

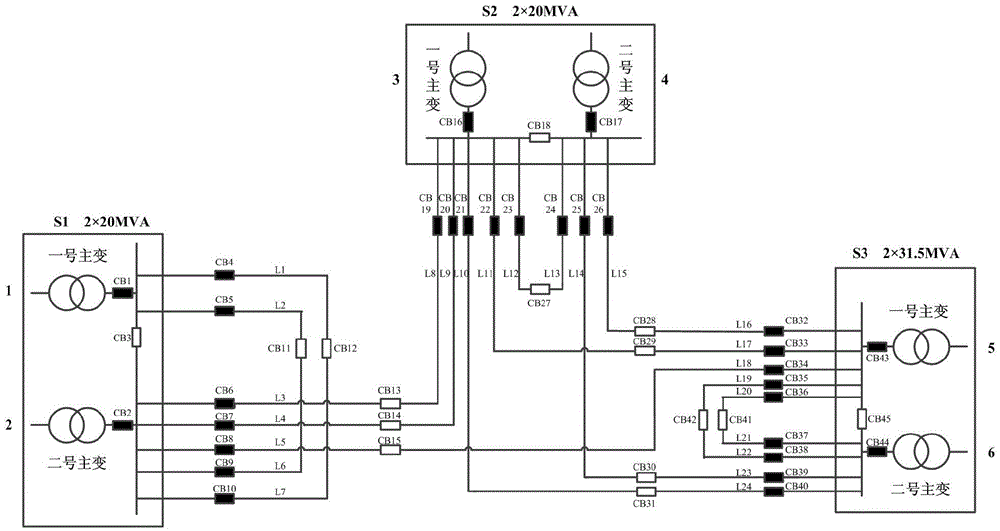

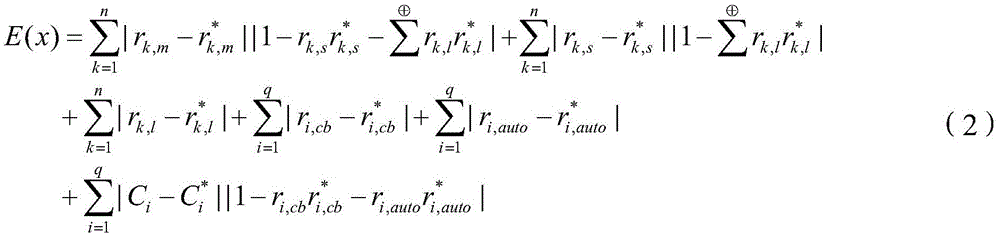

Quantum-genetic-algorithm-based fault diagnosis method for medium-voltage distribution network

InactiveCN105606931APrecise positioningQuick TroubleshootingFault location by conductor typesInformation technology support systemQuantum genetic algorithmDiagnosis methods

The invention relates to a quantum-genetic-algorithm-based fault diagnosis method for a medium-voltage distribution network. The method is characterized in that the method comprises the following steps that: step one, an improved medium-voltage distribution network fault diagnosis model is established by employing actual and expected values of element movement and combining the circuit breaker failure protection and the protection state of automatic opening and closing of the circuit breaker; and step two, a quantum-genetic-algorithm-based improved medium-voltage distribution network fault diagnosis model is solved to carryout fault diagnosis on the medium-voltage distribution network. According to the invention, the distribution network fault diagnosis model is established by analyzing the element type and the protection configuration situation of the distribution system; protection and the movement situation of and circuit breaker after a fault scene are simulated; and then the fault model is solved by using the quantum genetic algorithm. Therefore, functions that a fault element can be localized accurately after fault occurrence at a distribution network and the fault of the distribution network can be diagnosed rapidly and comprehensively can be realized.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

Back supporting device for large-caliber reflector

InactiveCN104267481AAchieve angle adjustmentEasy to disassembleMountingsAngular degreesRotational degrees of freedom

The invention provides a back supporting device for a large-caliber reflector. The supporting device comprises the large-caliber reflector, a lens back plate, a rotating shaft assembly, an adjusting connecting assembly, an adjusting rod assembly, a clamping block, a supporting plate and bolts. The rotating shaft assembly serves as a rotating shaft fulcrum of the large-caliber reflector, a spherical surface knuckle bearing of a standard component is adopted as a rotation main structure, the function of the spherical surface knuckle bearing and the function of a spherical hinge are the same, and the three translational motion freedom degrees of the reflector are restrained. A spiral driver is manually rotated to drive the adjusting connecting assembly to push the large-caliber reflector to do pitching and deflecting movement. After adjusting is finished, an adjusting nut is locked to limit the two rotating freedom degrees of the reflector. The face internal rotation freedom degree of the large-caliber reflector is restrained through the adjusting rod assembly. The back supporting device has the submicron-level positioning precision, can meet the requirements for various using angles and is simple in structure and accurate in positioning, pitching and deflecting two-dimensional precise adjustment of the online state and the offline state is achieved, and the designing cost and the manufacturing cost are reduced.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

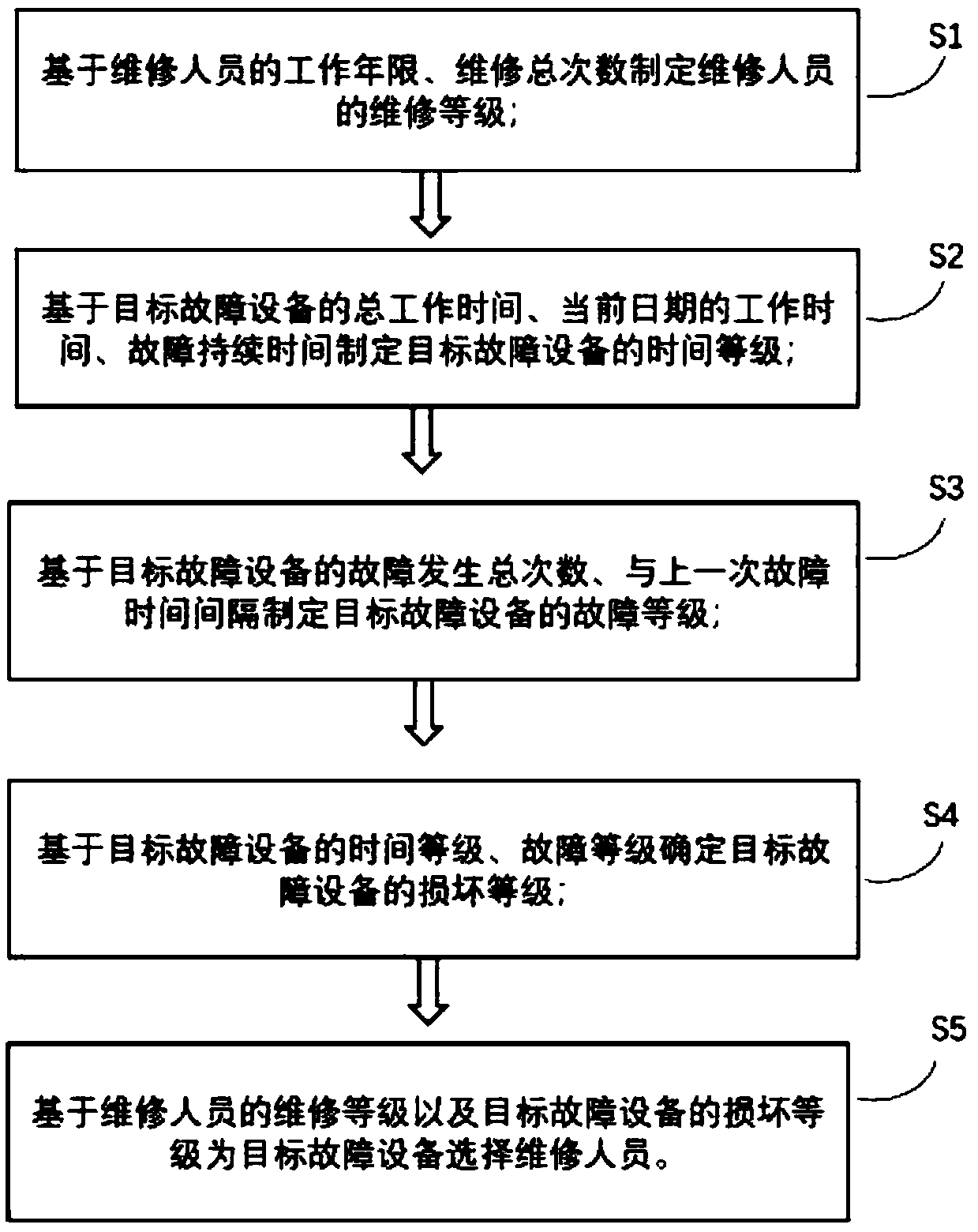

An intelligent control method of maintenance work order management

InactiveCN109272200AImprove maintainabilityImprove work efficiencyOffice automationResourcesFault occurrenceDevice failure

The invention discloses an intelligent control method for maintenance work order management. The method includes: S1, determining the maintenance level of the maintenance personnel based on the service life and the total maintenance times; 2, based on the total working time, the work time of the current date and the failure duration time, determining the time grade of the target failure equipment;3, based on the total number of fault occurrence and the time interval between the last fault and the target fault equipment, determining the fault level of the target fault equipment; S4, determining the damage level of the target faulty equipment based on the time level and the fault level; S5, selecting a serviceman for the target faulty equipment based on the maintenance level of the serviceman and the damage level of the target faulty equipment. The invention combines the damage grade of the faulty equipment and the maintenance grade of the maintenance personnel to select the maintenancepersonnel, which is conducive to improving the matching degree between the maintenance personnel and the equipment faults, improving the maintenance effect of the faulty equipment, enabling the maintenance personnel to carry out effective maintenance on the faulty equipment quickly and accurately, and improving the work efficiency of the maintenance personnel.

Owner:HEFEI HDB INFORMATION TECH CO LTD

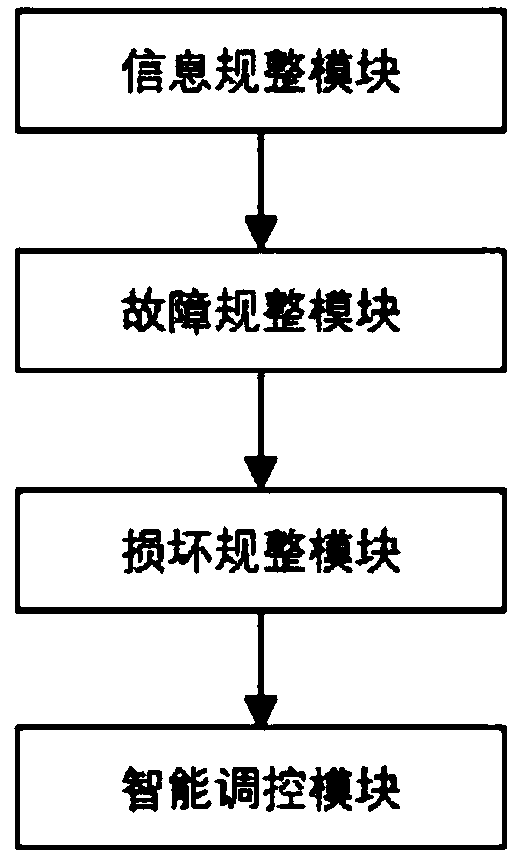

Intelligent fault reporting and repairing control system

InactiveCN109190958AImprove monitoringImprove repair effectTesting/monitoring control systemsStructural/machines measurementWork periodControl system

The invention discloses an intelligent fault reporting and repairing control system. An information regulating module is used for establishing the time grade of the target fault equipment based on thetotal working time, the working time of the current date and the fault duration. A fault regulating module is used for determining the fault level of the target fault equipment based on the fault type. The damage regularization module is used for determining the damage level of the target fault equipment based on the total number of times of fault occurrence and the time interval between the lastfault and the fault. An intelligent control module is used to make fault reporting strategy for the target fault equipment. The invention collects the actual parameter information such as number of fault times, the fault time and the fault type of the fault equipment in real time to analyze and classify the fault of the equipment; according to the analysis results, different repair methods are selected to improve the overall and effective monitoring of the fault situation of the fault equipment in the working process, and the repair effect of the fault equipment, which is conducive to ensurethe maintenance efficiency of the fault equipment.

Owner:HEFEI HDB INFORMATION TECH CO LTD

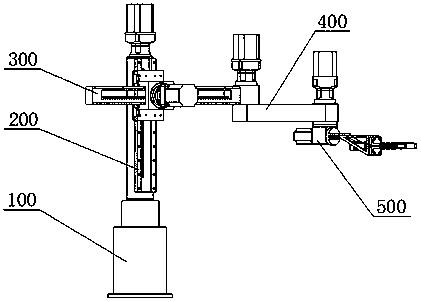

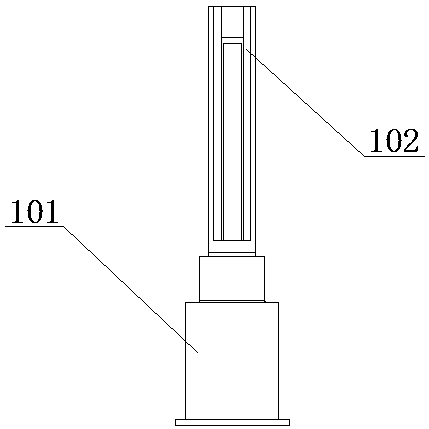

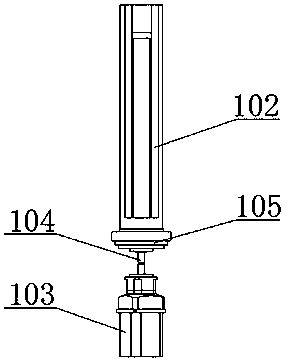

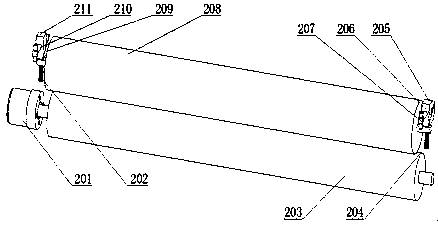

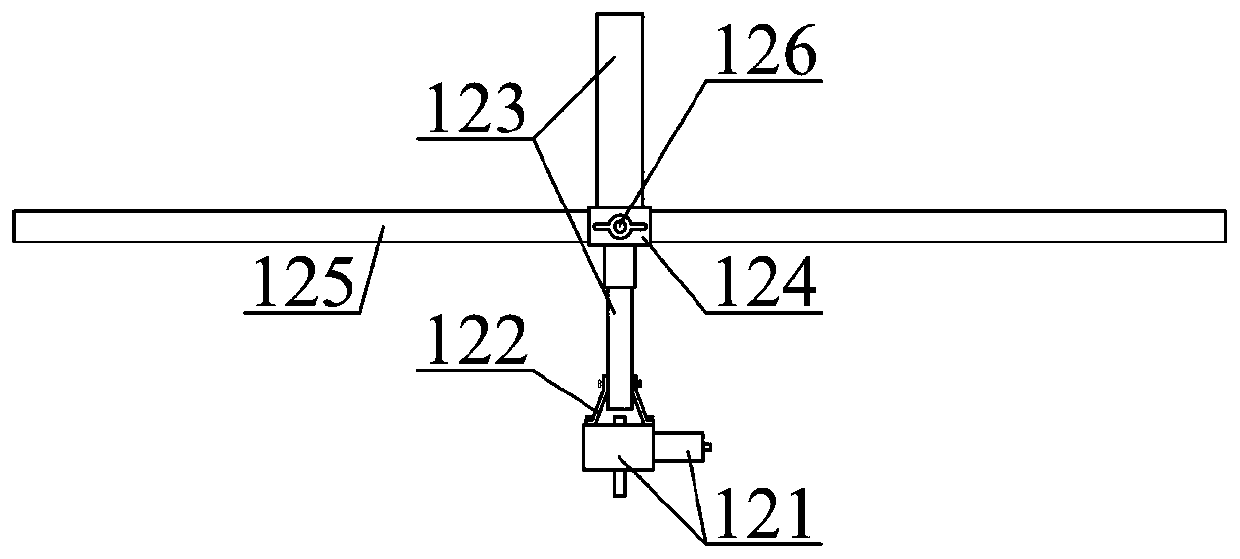

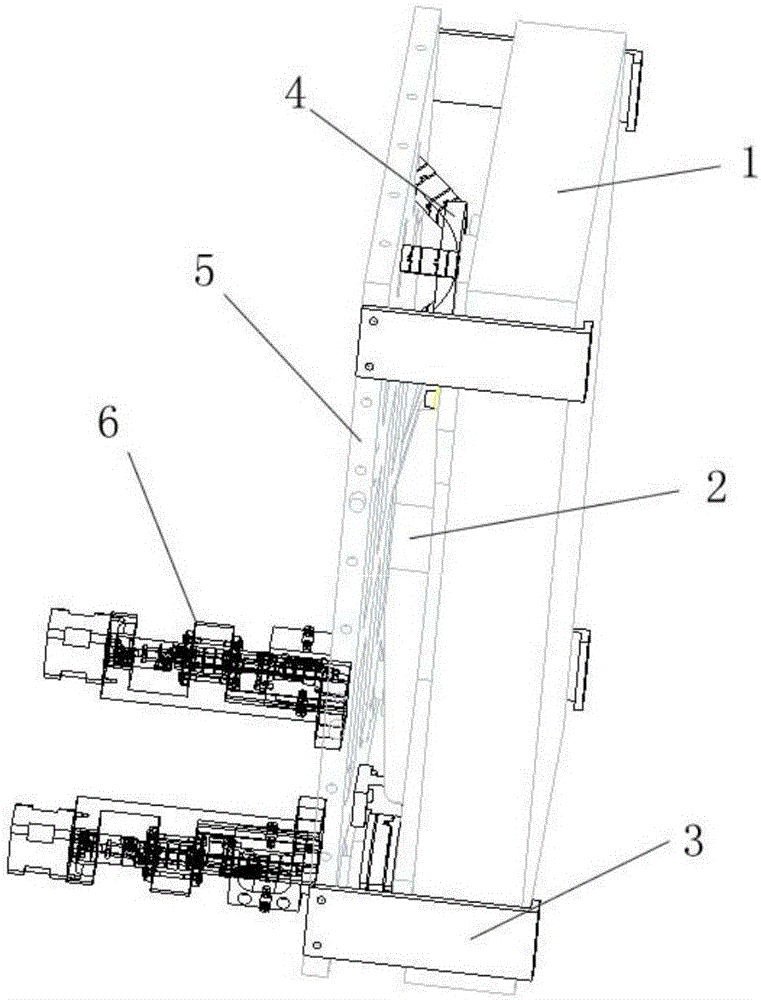

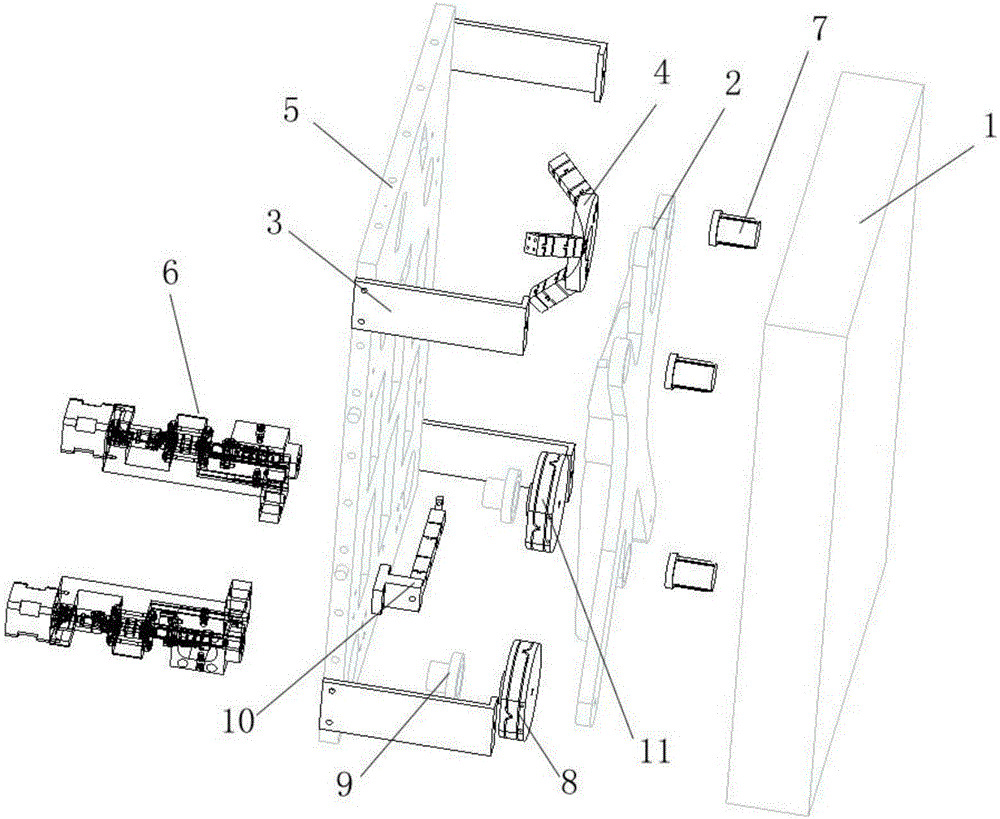

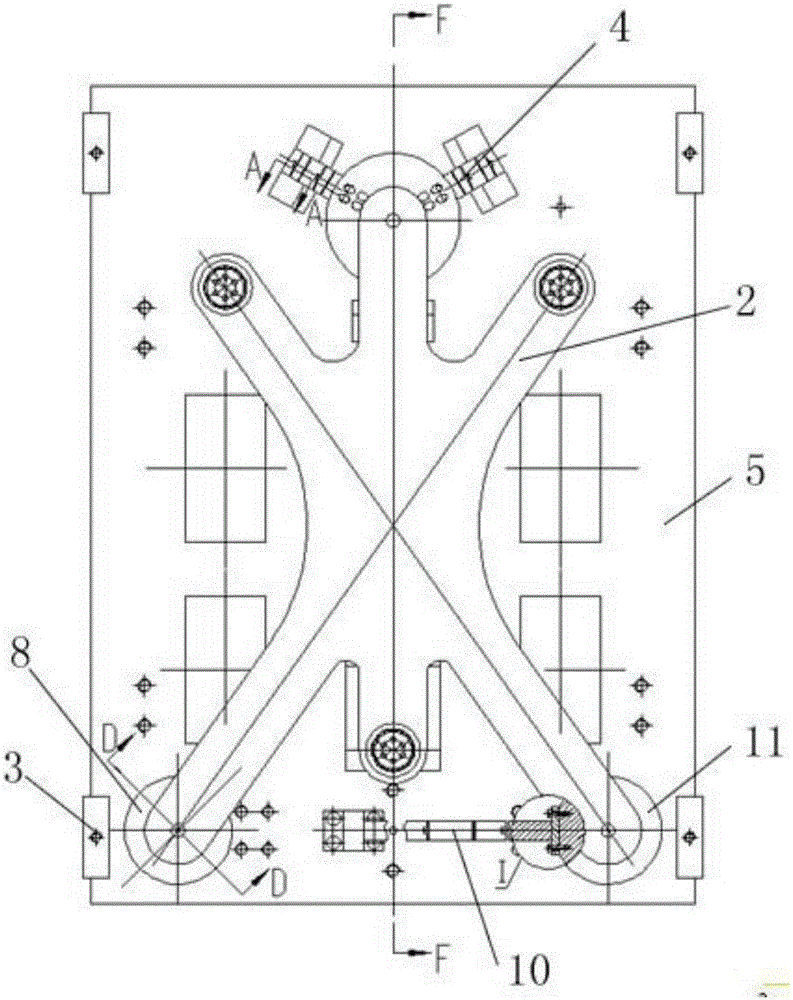

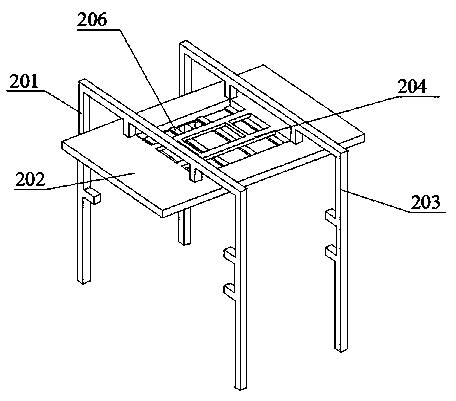

Bearing ring blank carrying manipulator

InactiveCN110394787AGuaranteed maintenance efficiencyGuaranteed replacement efficiencyProgramme-controlled manipulatorArmsWhole bodyEngineering

The invention belongs to the field of mechanical arms, and relates to a metal blank carrying manipulator, in particular to a bearing ring carrying manipulator capable of automatically clamping, overturning as well as protecting and holding. The mechanical arm comprises a main shaft rotating module, a longitudinal movement module, a transverse movement module, a swinging module and a paw module, and is characterized in that the main shaft rotating module is mainly used for supporting a whole system, and realizing the rotating movement of a whole body around a stand column driving shaft, whereinthe whole body is composed of the longitudinal movement module, the swinging module, the swing module and the paw module the longitudinal movement module around a stand column driving shaft, the longitudinal movement module is used for realizing the movement of a whole body in the vertical direction, wherein the whole body is composed of the transverse movement module, the swinging module and thepaw module, and the longitudinal movement module is used for realizing the movement of the whole body in the vertical direction, wherein the whole body is composed of the transverse movement module,the swinging module and the paw module; and the swinging module and the paw module are used for realizing swinging and rotating functions of the paw. According to the bearing ring blank carrying manipulator, the defects of the bearing ring blank clamping, overturning and shifting procedures in the bearing ring forging process are overcome, the product precision, the production efficiency and the automation level are improved, and the cost is reduced for enterprises as well.

Owner:SHENYANG POLYTECHNIC UNIV

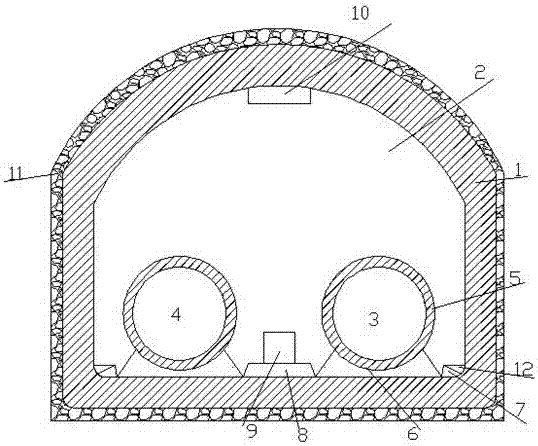

Shock-proof damping type confluence regulation and storage type deep layer tunnel

The invention provides a shock-proof damping type confluence regulation and storage type deep layer tunnel. The outermost layer of the deep layer tunnel between a lining and a surrounding rock medium is a pressure-injection damping layer, a bulkhead of the deep layer tunnel is a door-opening-shaped cross section, and the left side and the right side of the bulkhead are provided with a rainwater compartment and a waste water compartment correspondingly; the cross sections of the rainwater compartment and the waste water compartment are each in a circular or square-like shape, and the circular shape is selected in preference; and water compartment abutments are installed on the lower portions of the rainwater compartment and the waste water compartment, a car driving inspection gallery is formed between the rainwater compartment and the waste water compartment, and the two sides of the car driving inspection gallery are separately a people walking inspection gallery and an escape gallery. The shock-proof damping type confluence regulation and storage type deep layer tunnel has the beneficial effects that rainwater is effectively separated from waste water, and thus water pollution is prevented to the greatest extent; and efficient, reliable and safe maintaining system and space are ensured, the space using rate is increased, and the earthquake disaster is effectively resisted.

Owner:广州深卓信息科技有限公司

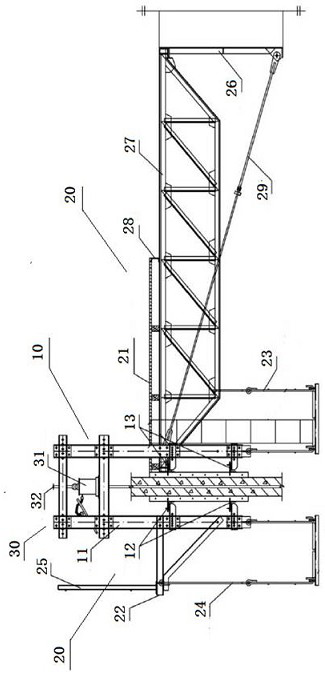

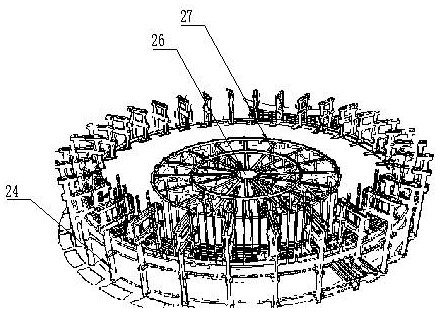

Profile combination frame for silo and method for manufacturing silo of vertical shaft structure using same

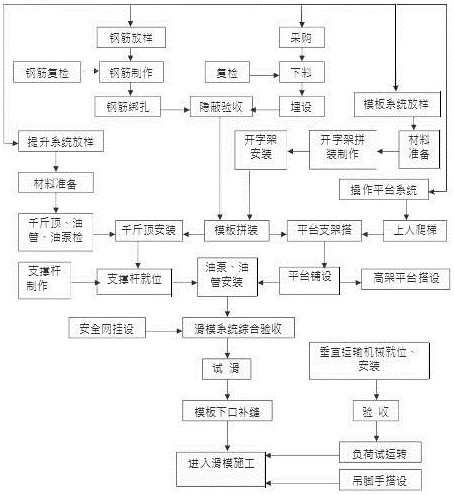

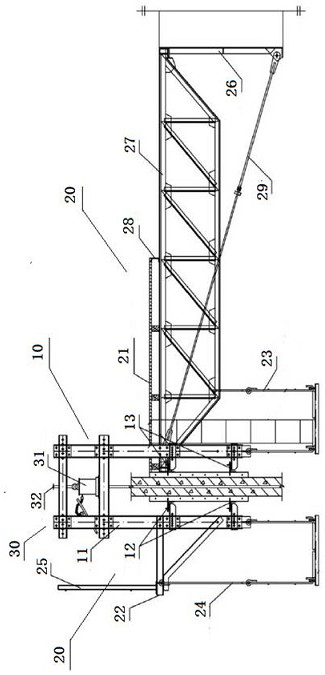

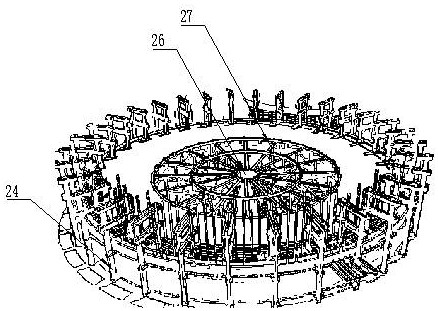

ActiveCN111946124AImprove work efficiencyReduce riskBuilding material handlingBulk storage containerRebarReinforced concrete

The invention provides a profile combination frame for a silo and a method for manufacturing the silo of a vertical shaft structure using the same, and belongs to the field of storage equipment. The profile combination frame comprises a formwork assembly, an operation platform assembly, a hydraulic lifting assembly and a maintenance assembly. The formwork assembly is used for lifting of the formwork assembly. The operation platform assembly comprises an inner platform and an outer platform, and is used for operators or equipment to bind reinforcing steel bars, pour concrete or place control equipment; the inner platform is arranged on the inner ring of the formwork assembly; and the outer platform is arranged on the outer ring of the formwork assembly. The maintenance assembly is arrangedat the lower end of the outer platform and sprays water outwards to maintain concrete. According to the combination frame and the method, the working efficiency is improved, the construction risk is reduced, thin iron plates are welded into an inverted cone for overall construction, the safety of overall bearing and supporting of conical hopper construction is guaranteed, and a fair-faced concreteeffect is achieved on the appearance of a conical hopper.

Owner:POWERCHINA MUNICIPAL CONSTR GRP CO LTD

Photoelectric sensor packaging structure

InactiveCN112531032AGuaranteed tightnessFor quick maintenanceSemiconductor devicesEngineeringMechanical engineering

The invention relates to the technical field of sensor packaging, and discloses a photoelectric sensor packaging structure. The structure comprises a substrate and a packaging plate, the upper surfaceof the substrate is attached to the lower surface of the packaging plate, a frame body is fixedly connected to the upper surface of the substrate, a groove corresponding to the frame body is formed in the lower surface of the packaging plate, the frame body and the groove are arranged in a clamped mode, ,a matched sealing strip is installed at the joint of the frame body and the groove, a matchedcontrol processing chip is arranged in the frame body and electrically connected with the substrate, a matched photoelectric sensor chip is arranged at the groove bottom of the groove, the lower surface of the photoelectric sensor chip is attached to the top of the frame body, an opening is formed in the groove bottom of the groove and matched glass is fixedly mounted in the opening. According tothe invention, the packaging effect of the photoelectric sensor can be effectively ensured, the packaged photoelectric sensor can be conveniently maintained as required, and the maintenance efficiency is effectively ensured.

Owner:西安远讯光电科技有限公司

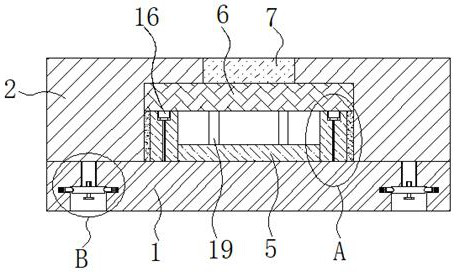

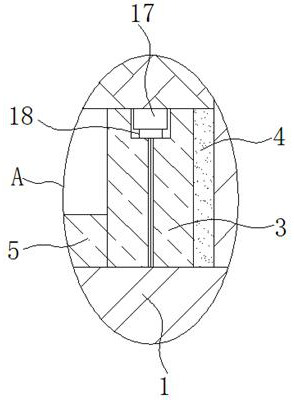

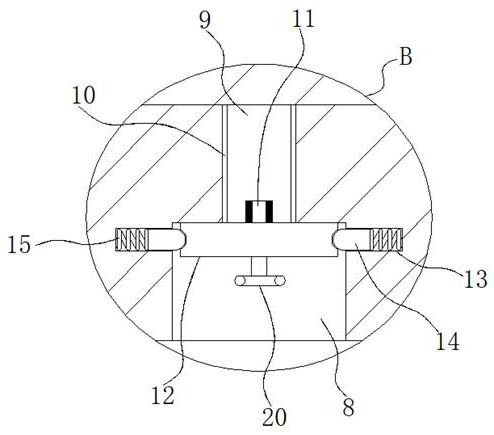

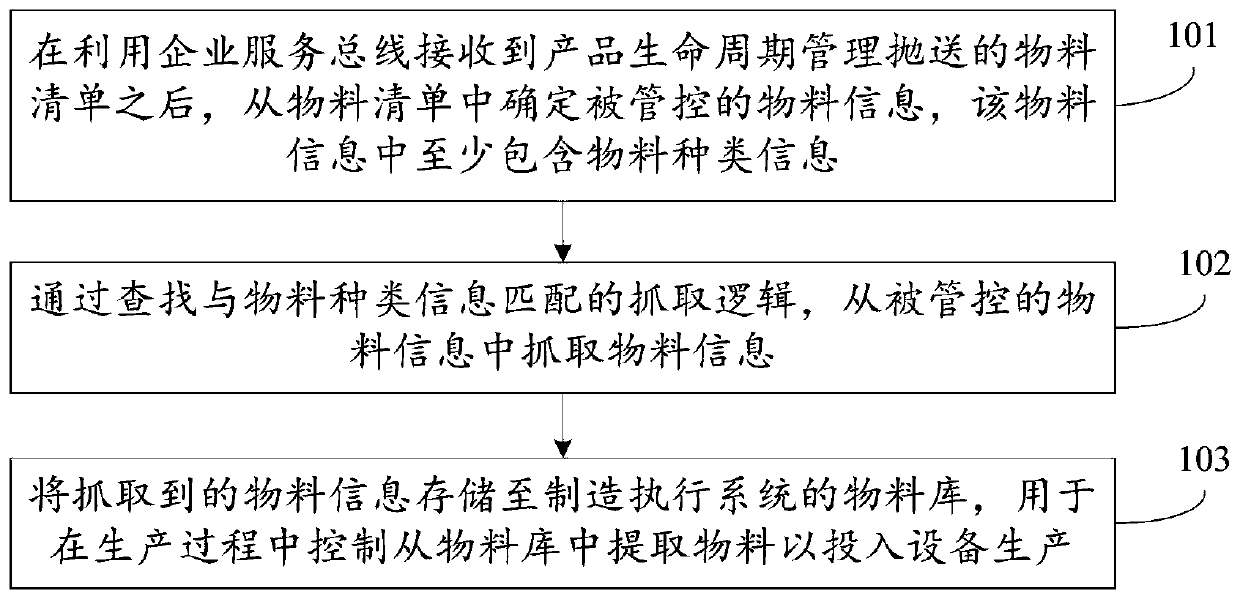

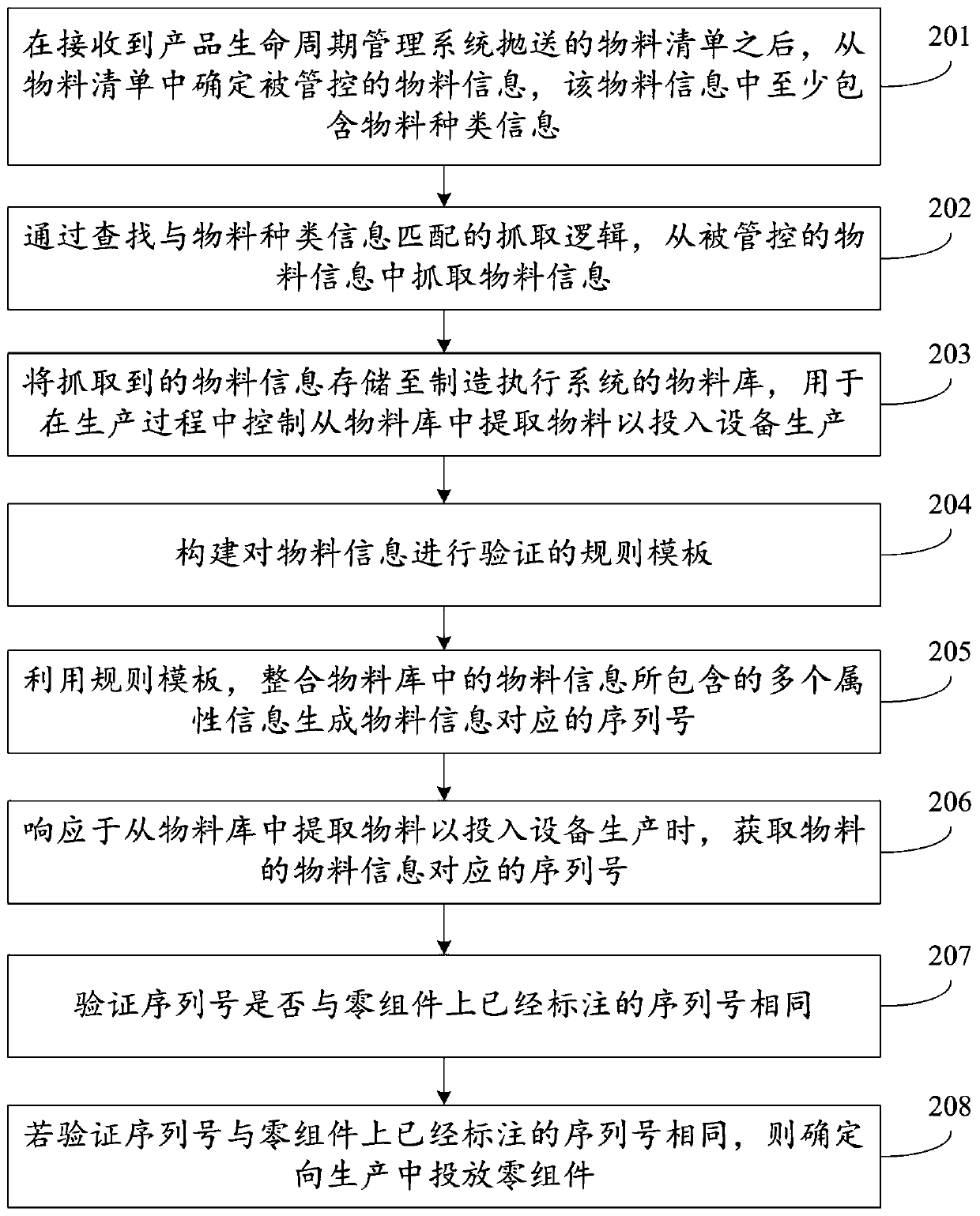

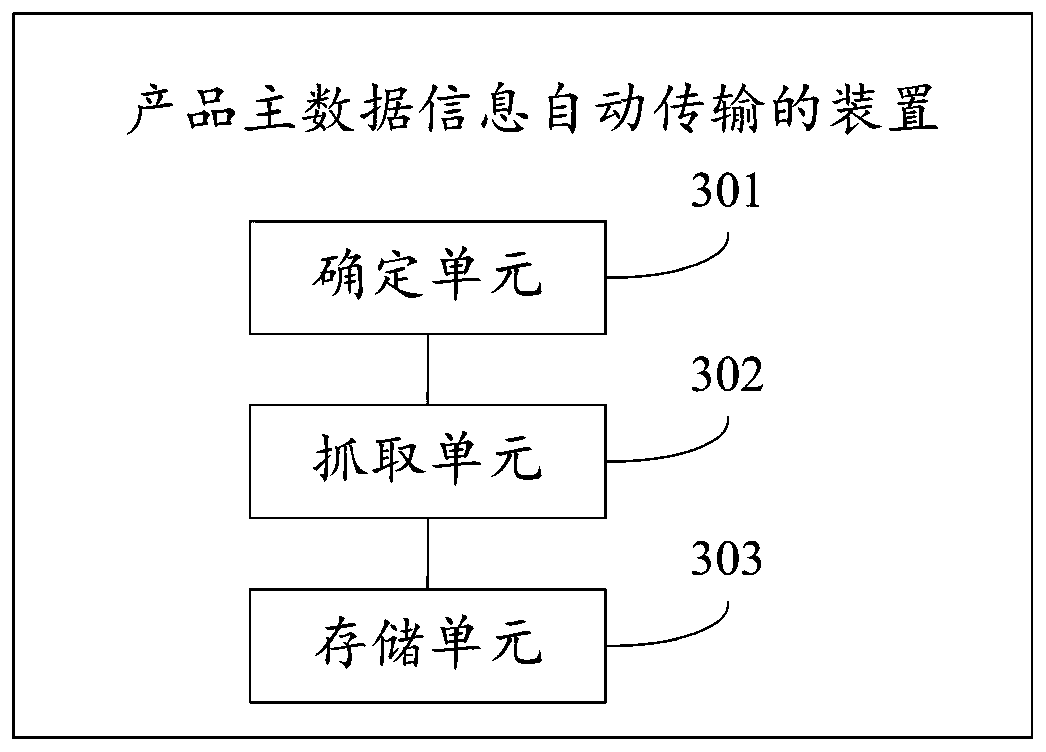

Method and device for automatically transmitting product main data information

ActiveCN110443552ASolve efficiency problemsSolve insufficient maintenanceRelational databasesOffice automationManufacture execution systemAutomatic transmission

The invention discloses a method and a device for automatically transmitting product main data information, and relates to the technical field of manufacturing execution systems. The automatic transmission of the product main data information between the PLM and the MES is realized. The maintenance efficiency, timeliness and accuracy of the MES on the main data information of the product are ensured. According to the main technical scheme, the method comprises: after an enterprise service bus is used for receiving a bill of materials thrown by product life cycle management, determining controlled material information from the bill of materials, and the material information at least comprising material type information; capturing material information from the managed and controlled materialinformation by searching a capturing logic matched with the material type information; and storing the grabbed material information into a material library of a manufacturing execution system, and controlling to extract materials from the material library in the production process so as to put the materials into equipment for production. The method and the device are applied to automatically capturing the main data information of the product to be maintained by using the MES.

Owner:BOE TECH GRP CO LTD +1

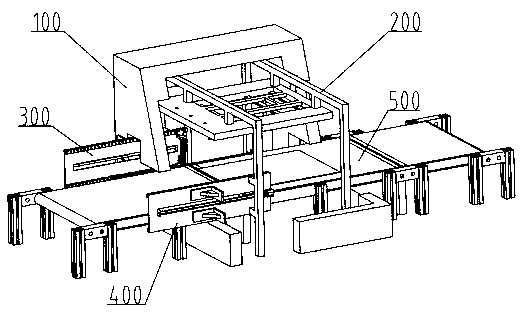

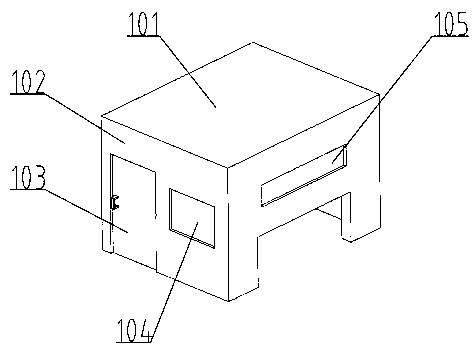

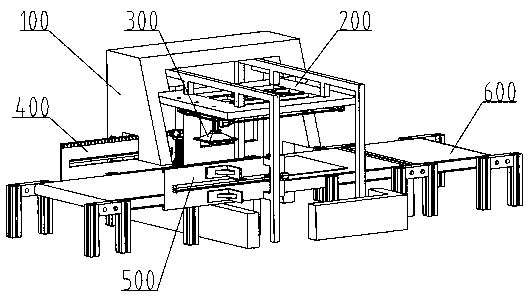

Automatic turnover overall vision detection device for end part of scarf

InactiveCN109884084AReduce in quantityOvercome labor intensiveMaterial analysis by optical meansUsing optical meansVision inspectionEngineering

The invention belongs to the field of textile machinery and equipment, relates to a plane and three-dimensional defect detection device of upper and lower surfaces of a scarf, and specifically relatesto a device capable of performing a turnover operation on the end part of the scarf and detecting plane and three-dimensional defects of the upper and lower surfaces of the scarf by means of machinevision. The device comprises a darkroom module, a vision inspection module, a bottom turnover shaft module, a top turnover shaft module and a conveying module, wherein a darkroom protection module provides a closed darkroom environment and supports a turnover mechanism; and the vision detection module mainly realizes the detection of the plane information of the upper and lower surfaces of the scarf. The bottom turnover shaft module and the top turnover shaft module realize the turnover of the scarf. The main function of the conveying module is to realize the transmission of the scarf. The device overcomes the defects that the manual detection of the upper and lower surfaces of an existing scarf occupies a lot of labor forces, the detection efficiency is low and detection deviation exists,and improves the quality detection efficiency and accuracy of the upper and lower surfaces of the scarf.

Owner:SHENYANG POLYTECHNIC UNIV

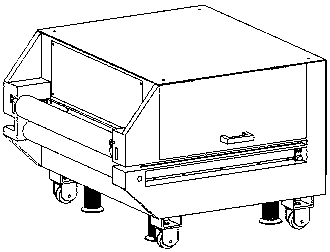

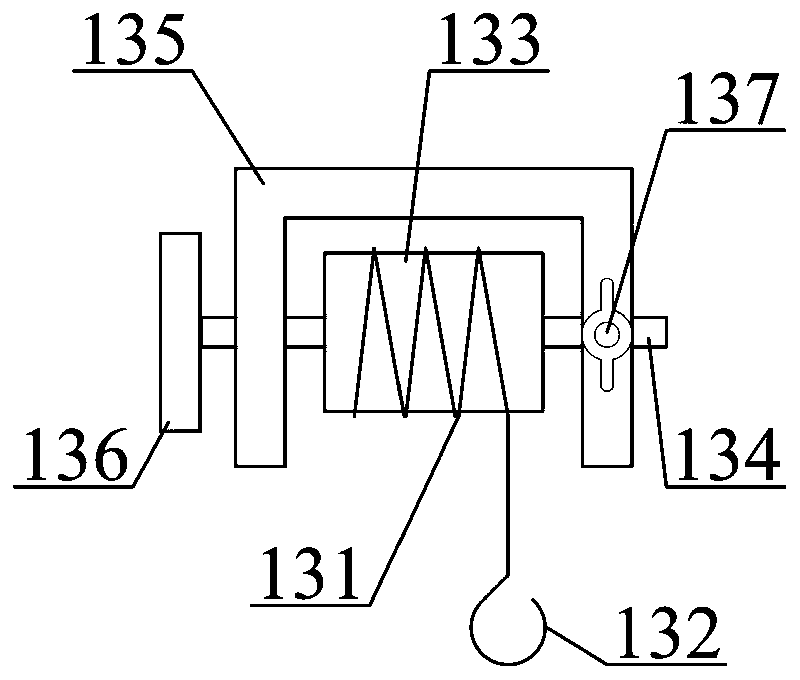

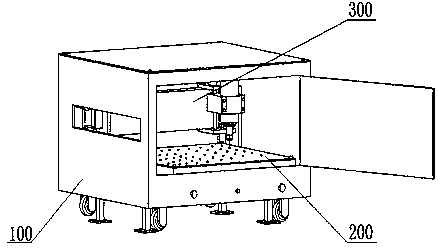

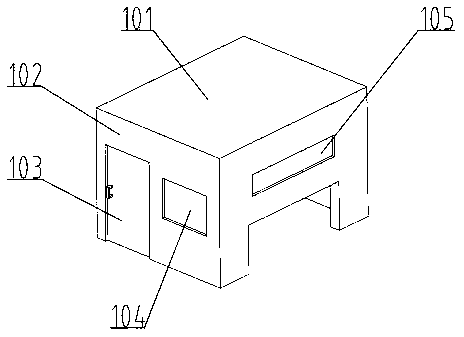

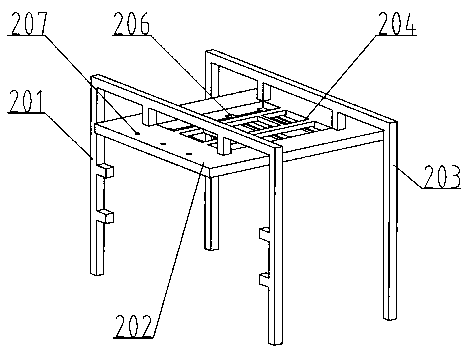

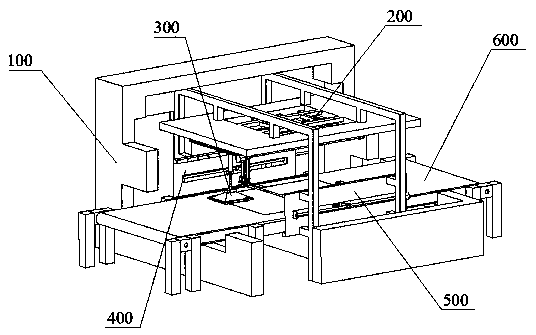

Small-size opening conveying type gasket numerical control cutting machine

InactiveCN110295256ASolve efficiency problemsSolve the accuracy problemLeather clicking/perforating/clickingMetal working apparatusEngineeringWaste material

The invention belongs to the field of numerical control cutting machines, and particularly relates to a numerical control cutting device for clamping, conveying, tensioning, cutting and forming soft materials such as leather and removing waste materials. The device mainly solves the problems that the precision of a soft material gasket such as leather is not guaranteed in manual cutting and traditional numerical control cutting machine cutting, and the traditional numerical control cutting equipment is large in size. The device comprises a box body module, a conveying and clamping module, a tensioning module, a cutting movement module and a waste material cutting module, the box body module is mainly used for supporting the device main body and the other modules are contained, so that themobility of the device is increased; the clamping and conveying of the raw materials are realized by the conveying and clamping module; the tensioning module is used for tensioning the raw materials;the cutting movement module is used for controlling the numerical control system to control the cutter to move; the waste material cutting module is used for removing the waste materials after the cutting of the raw materials is finished. According to the cutting machine, the precision and the efficiency are improved by adopting numerical control cutting, the cutting machine is small in size and high in mobility.

Owner:SHENYANG POLYTECHNIC UNIV

Automobile part maintenance pressing and fixing device and pressing method thereof

ActiveCN110539259AAchieve local recompressionAchieve partial relaxationWork holdersWork benchesScrew threadEngineering

Owner:湖南容光汽车部件有限公司

Convenient-to-install device for overhauling and protecting electrical automation device

InactiveCN111376218AQuick installationChange spacingLighting elementsWork benchesDevice formControl switch

The invention provides a convenient-to-install device for overhauling and protecting an electrical automation device. The convenient-to-install device comprises a rack, supporting rods, supporting legs, a control switch, a supporting frame, a hanging ring, fixing nuts, adjusting screw rods, an adjusting handle, an installing frame, installing holes, a movable rotating adjusting overhauling rod structure, a protecting rope structure preventing the device form falling during overhauling and a bendable moving adjusting overhauling illuminating lamp structure. According to the convenient-to-install device, by arranging the supporting frame, the fixing nuts, the adjusting screw rods, the adjusting handle, the installing frame and the installing holes, the electrical automation device can be rapidly installed and fixed, and the overhauling operation can be conveniently carried out; according to the size or model of the electrical automation device, the adjusting handle is rotated, and the adjusting screw rods are adjusted to act in the fixing nuts, so that the adjusting screw rods drive the installing frame to move through bearings, and the distance between the supporting frame and the installing frame can be changed; and through the installing holes, the electrical automation device can be fixed and installed thorough bolts so that overhauling can be conveniently carried out, and the operation is convenient.

Owner:魏中云

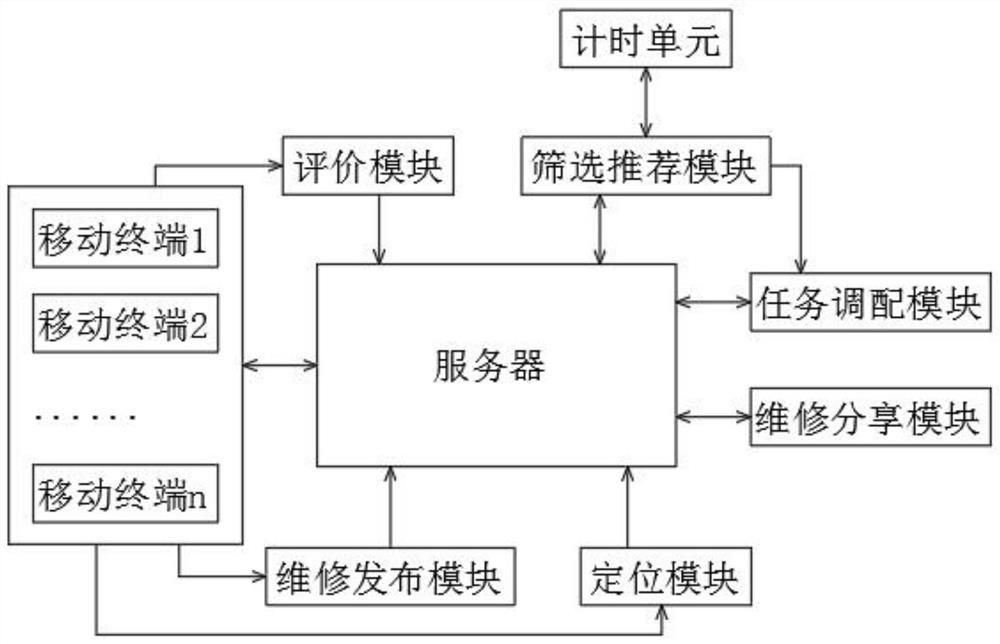

Solar photovoltaic intelligent maintenance management system

InactiveCN112257881AMaintenance Efficiency GuaranteeReasonable distributionResourcesInformation technology support systemMaintenance managementComputer science

A solar photovoltaic intelligent maintenance management system disclosed by the present invention comprises a maintenance sharing module, a task allocation module and a screening recommendation module, the maintenance sharing module is used for the maintenance personnel to share the maintenance experience, and the maintenance experience is published and shared in the form of the manuscript or thevoice. Maintenance experience is published and shared through the maintenance sharing module, and mutual learning and advantage and defect summarization of maintenance personnel are facilitated; the screening recommendation module is used for intelligently screening and recommending maintenance personnel of solar photovoltaic equipment fault maintenance tasks, the maintenance personnel are screened out according to the maintenance value and the recommendation value obtained through calculation, maintenance resources are effectively and reasonably distributed, and the maintenance efficiency ofthe solar photovoltaic equipment is guaranteed. The task allocation module is used for allocating maintenance tasks. According to the invention, maintenance personnel do not accept the maintenance task within the effective time, and the maintenance tasks are allocated through the task allocation module, so that the maintenance efficiency and progress of the solar photovoltaic equipment are ensured.

Owner:刘朝永

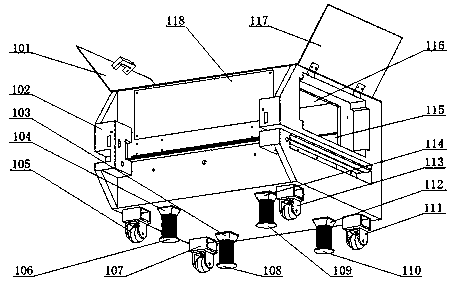

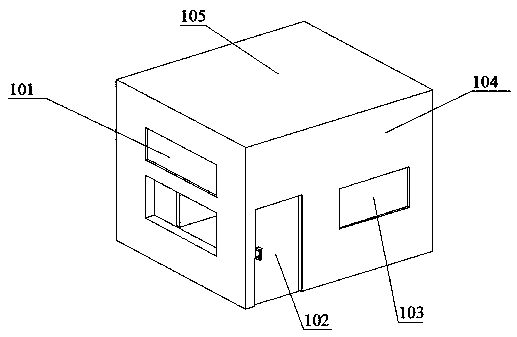

Small and portable sealed sucking-type numerical control cutting machine for gaskets

InactiveCN110281287AGuaranteed cutting accuracyIncrease productivityMetal working apparatusNumerical control systemEngineering

The invention belongs to the field of numerical control cutting machines and particularly relates to numerical control cutting equipment used for clamping soft materials such as leather and cutting the materials into a certain shape. With the adoption of the numerical control cutting machine, the problems of high labor cost, large device size, poor overall mobility and the like in manual cutting of gaskets made of leather or other soft materials and cutting of the gaskets by traditional numerical control cutting machines are mainly solved. The equipment mainly comprises a box module, a material sucking and fixing module and a cutting motion module, wherein the box module is mainly used for supporting an equipment main body, accommodating the material sucking and fixing module and the cutting motion module and improving the mobility of the equipment; the material sucking and fixing module is used for determining the position of a processed leather-type soft material; the cutting motion module is used for moving a cutter along X, Y and Z coordinate axes under control of a numerical control system to complete the cutting motion. The numerical control cutting equipment has the beneficial effects that the equipment can complete high-precision cutting of gaskets in specified specifications, has the advantages of small size, portability and the like and is low in cost and suitable for medium and small enterprises.

Owner:SHENYANG POLYTECHNIC UNIV

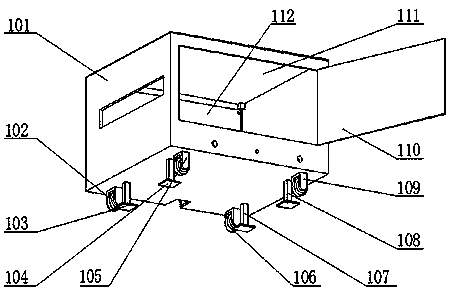

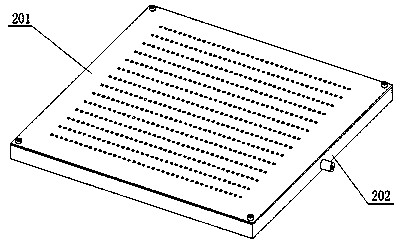

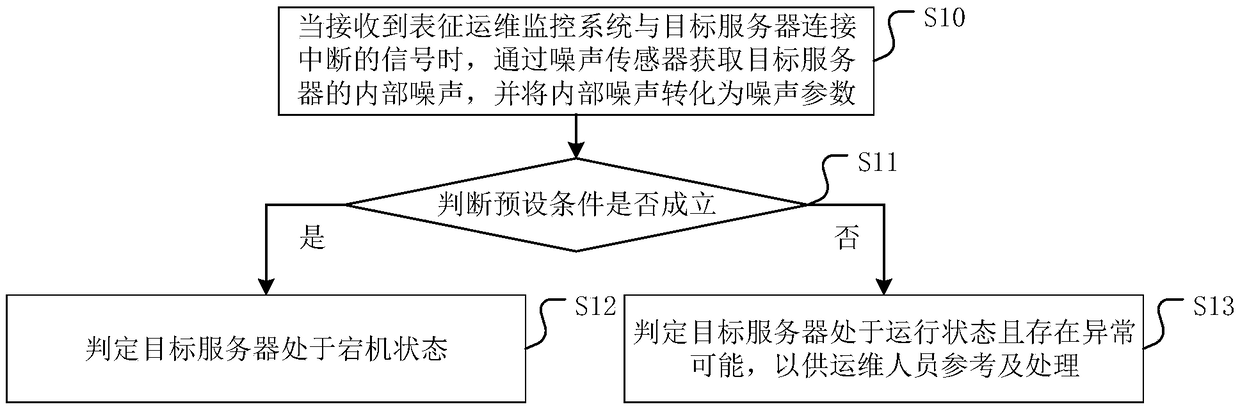

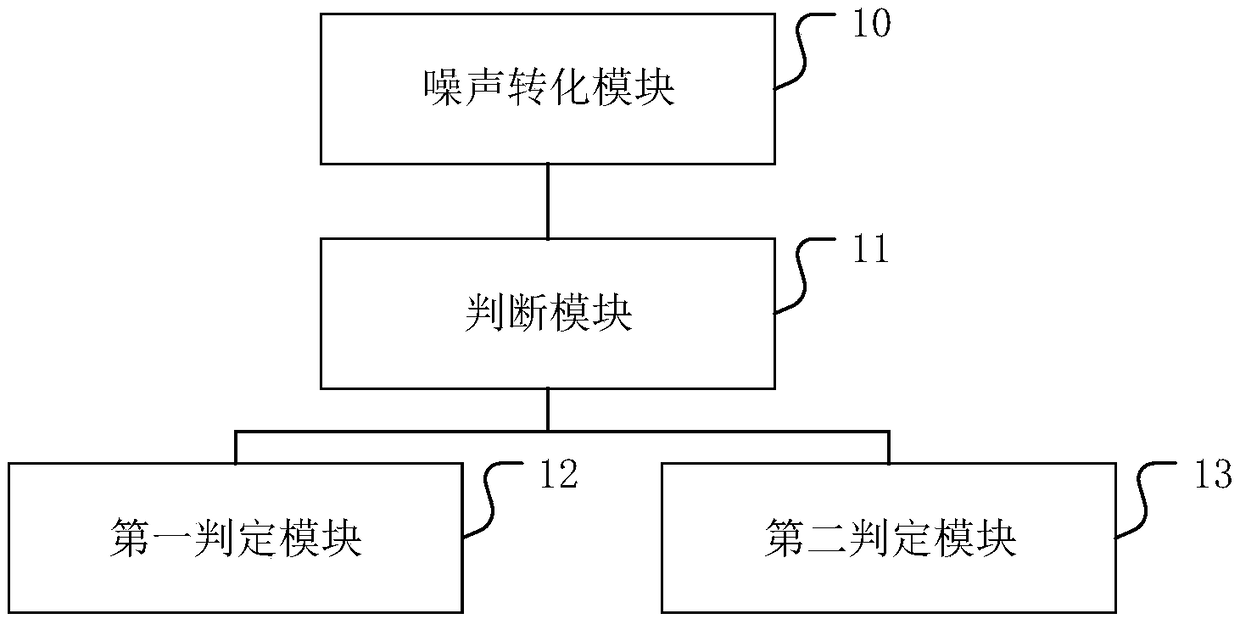

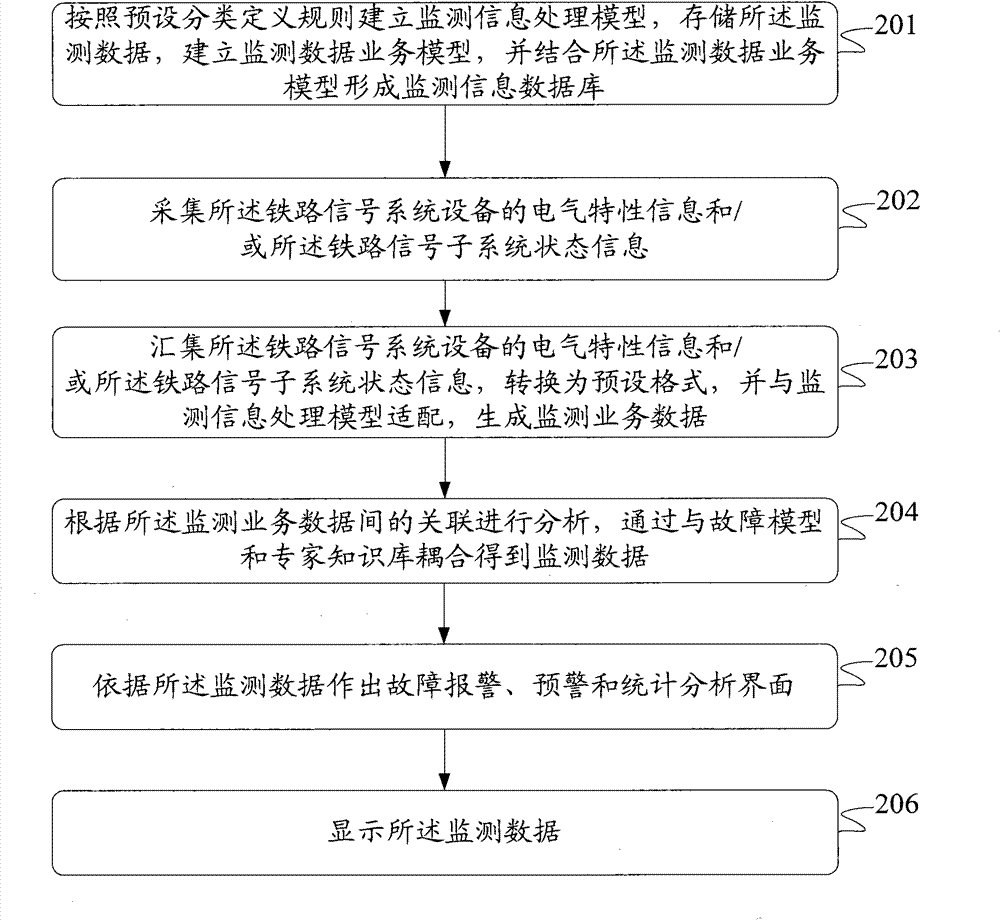

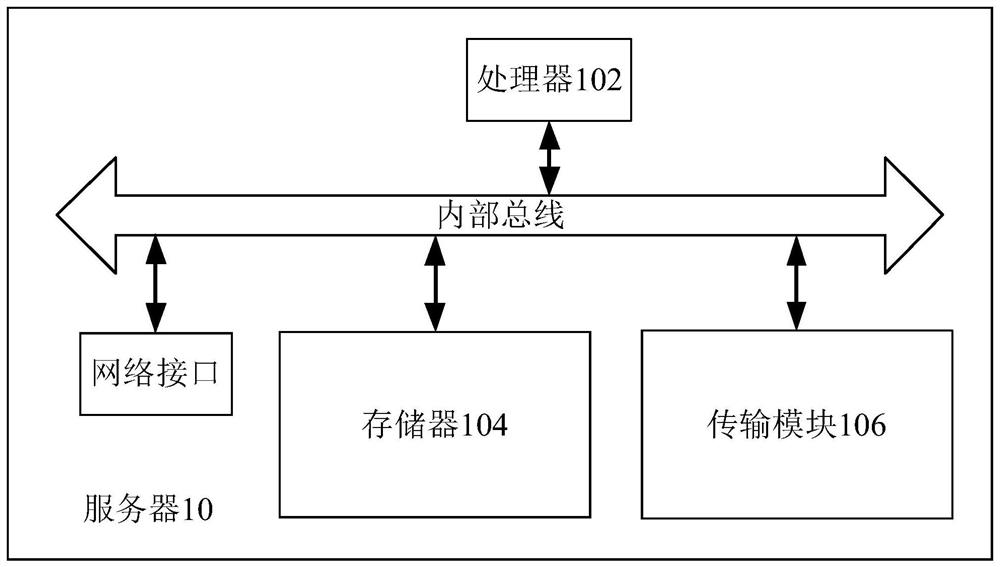

Server monitoring method, device and equipment, and medium

InactiveCN108647129AGuaranteed maintenance efficiencyEnsure safetyHardware monitoringInternal noiseReal-time computing

The invention discloses a server monitoring method, a server monitoring device, server monitoring equipment and a medium. The method comprises the steps of when a signal for representing connection interruption between an operation and maintenance monitoring system and a target server is received, acquiring internal noise of the target server through a noise sensor, and transforming the internal noise into a noise parameter; judging whether a preset condition is correct, wherein the preset condition at least includes that the noise parameter is within a preset first parameter range; if so, determining that the target server is in a downtime state; and if not, determining that the target server is in a running state and has an abnormality possibility so as to be referred and processed by operation and maintenance staff. Through the method, a current state of the server can be known in the first time when the server and the operation and maintenance monitoring system are switched off, thereby guaranteeing the maintenance efficiency for the server and the safety of the whole server. In addition, the invention further provides the server monitoring device, the server monitoring equipment and the medium. The beneficial effects are described as above.

Owner:山东中创软件商用中间件股份有限公司

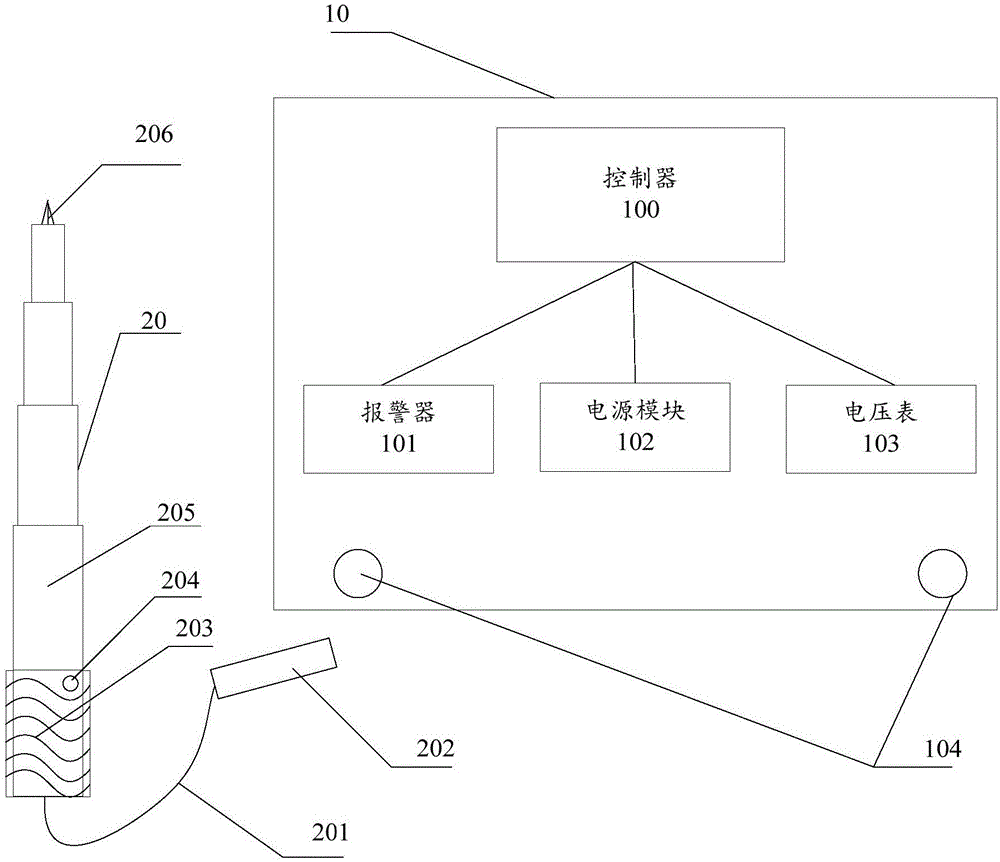

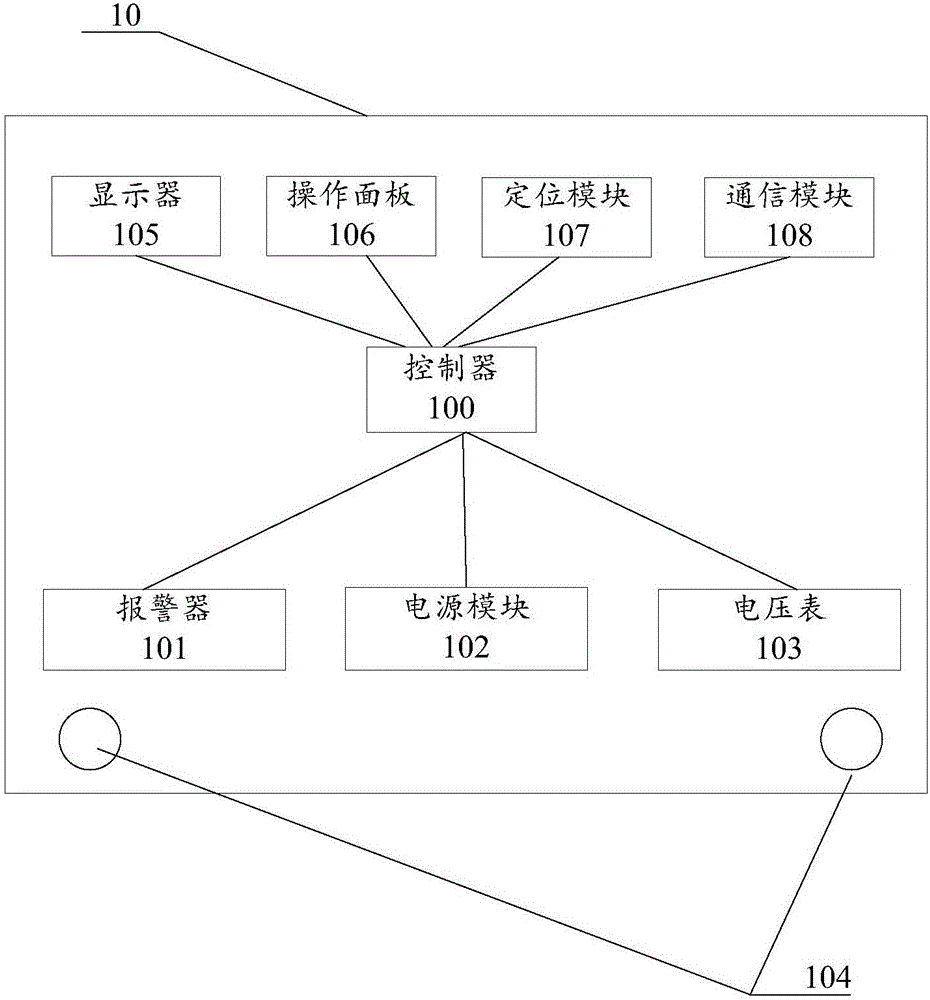

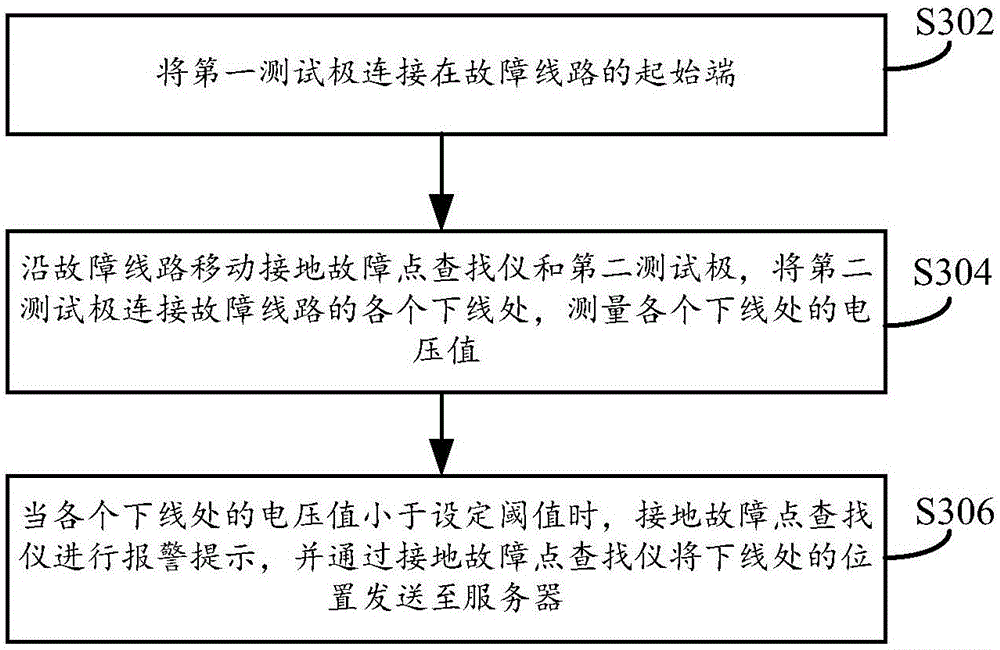

Ground fault search instrument, and ground fault point search method and system

ActiveCN106646119AEasy to operateImprove work efficiencyElectrical measurement instrument detailsFault location by conductor typesElectricityVoltmeter

The present invention relates to a ground fault search instrument, and a ground fault point search method and system, and relates to the electrical instrument technology field. The ground fault search instrument comprises a ground fault search instrument body and a ground test pole consisting of a first test pole, a second pole and a switch key, the first test pole is configured to connect the starting end of a fault line, the second test pole is configured to connect each inserting coil position connected with the fault line, and the ground fault point search instrument body comprises a controller, a power module, a voltmeter and an alarm which are arranged in the housing. The ground fault search instrument provided by the invention is configured to connect the first test pole and the second test pole with the starting end and the inserting coil position of the fault line to gradually reduce the range of the area where the fault points are located through the test of the changing of the fault line voltage value, shorten the fault search time, improve the maintainers' work efficiency and reduce the electricity users' financial loss caused by long-time power failure.

Owner:CHENGWU POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO LTD +1

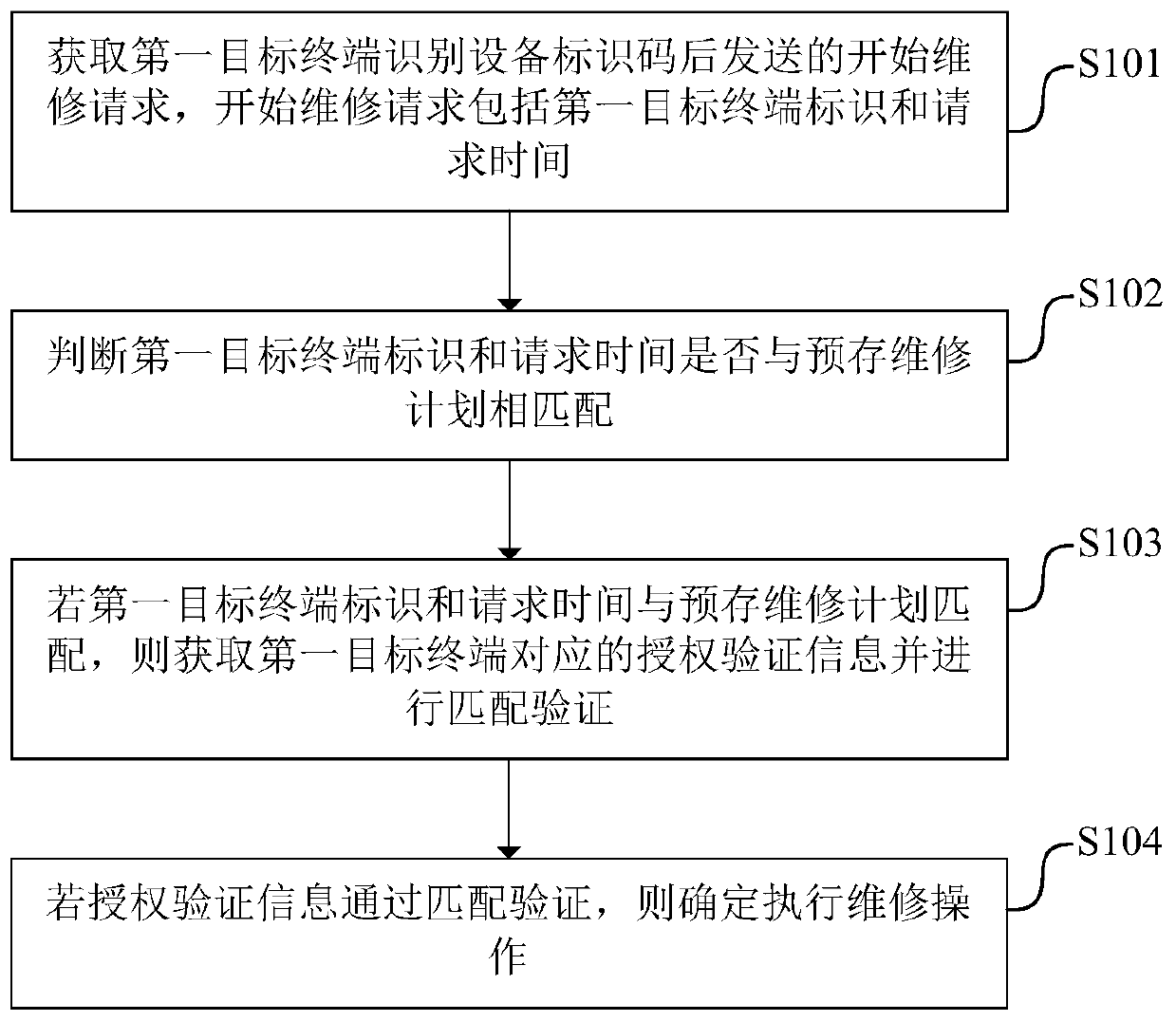

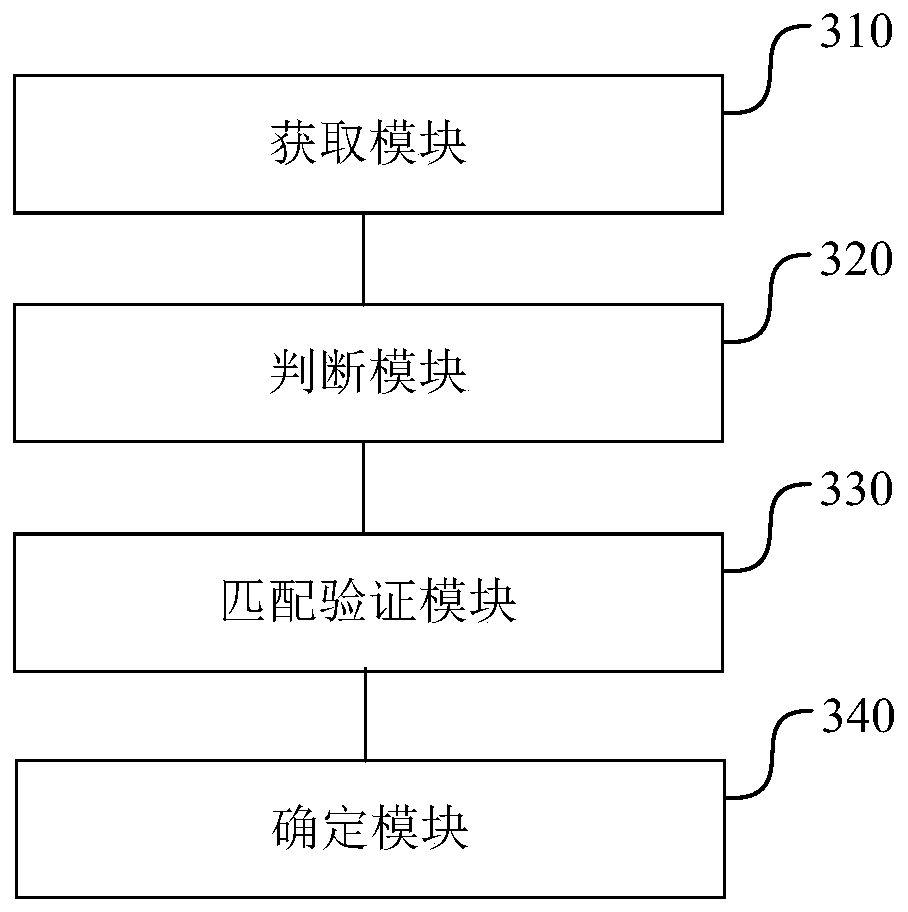

Maintenance request processing method and device and electronic equipment

PendingCN111242327ASolve the problem of experienceGuaranteed maintenance efficiencyOffice automationCommerceMaintenance planningAuthorization

The invention discloses a maintenance request processing method. The method comprises the steps: obtaining a maintenance starting request sent after a first target terminal identifies a device identification code, wherein the maintenance starting request comprises a first target terminal identifier and a request time; judging whether the first target terminal identifier and the request time are matched with a pre-stored maintenance plan or not; if the first target terminal identifier and the request time are matched with the pre-stored maintenance plan, obtaining authorization verification information corresponding to the first target terminal and performing matching verification; and if the authorization verification information passes the matching verification, determining to execute themaintenance operation. According to the method, after the maintenance starting request is obtained, verification matching processing is conducted on the maintenance starting request twice, if matching verification is passed, it is indicated that maintenance personnel prepares to conduct maintenance according to the pre-stored maintenance plan, and therefore, it is determined that maintenance operation is executed, and maintenance efficiency is guaranteed; in addition, the invention further provides a maintenance request processing device, electronic equipment and a computer-readable storage medium with the above advantages.

Owner:LAUNCH TECH CO LTD

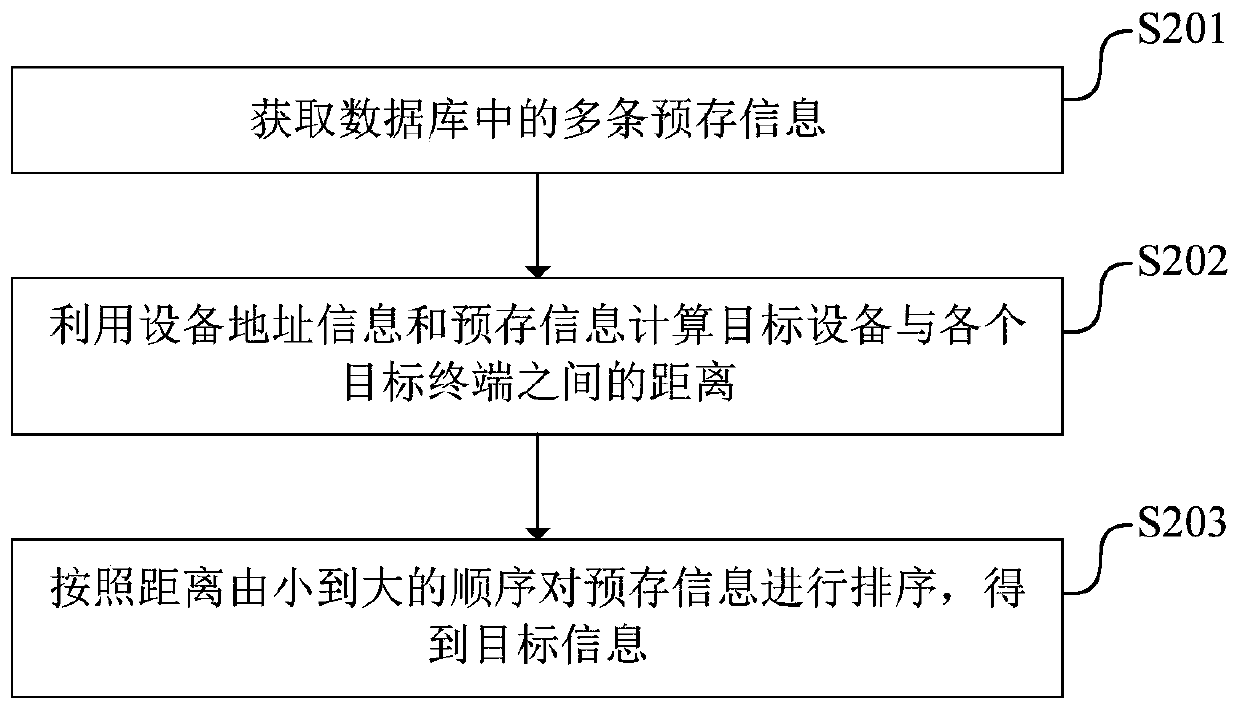

Railway signal monitoring method and system

ActiveCN101917237BOptimize resource allocationHigh degree of centralizationTransmitters monitoringData switching networksInformation processingStatistical analysis

The embodiment of the invention discloses a railway signal monitoring method and a railway signal monitoring system. The method comprises the following steps of: performing acquisition, convergence and format conversion on electrical characteristic information of equipment of the railway signal system and / or railway signal subsystem state information, adapting the information after the format conversion and a monitoring information processing module to form monitoring service data, and making a fault warning, early warning and statistical analysis interface according to the monitoring data after analysis and associated coupling. Because the embodiment adopts a uniform conversion format and is adapted to the information processing module of a fixed form, centralized monitoring of the equipment of the railway signal system is realized, the defects of decentralized management and decentralized maintenance of the railway signal system in the prior art are overcome, and a brand-new early warning mechanism and an intelligent expert diagnosis technique are provided. Because of high centralized degree, the embodiment optimizes the resource allocation of the railway signal monitoring system, and ensures corresponding maintenance efficiency at the same time of reducing the false alarm and missing alarm rate.

Owner:CRSC RESEARCH & DESIGN INSTITUTE GROUP CO LTD

Graphical database establishing method and device and readable storage medium

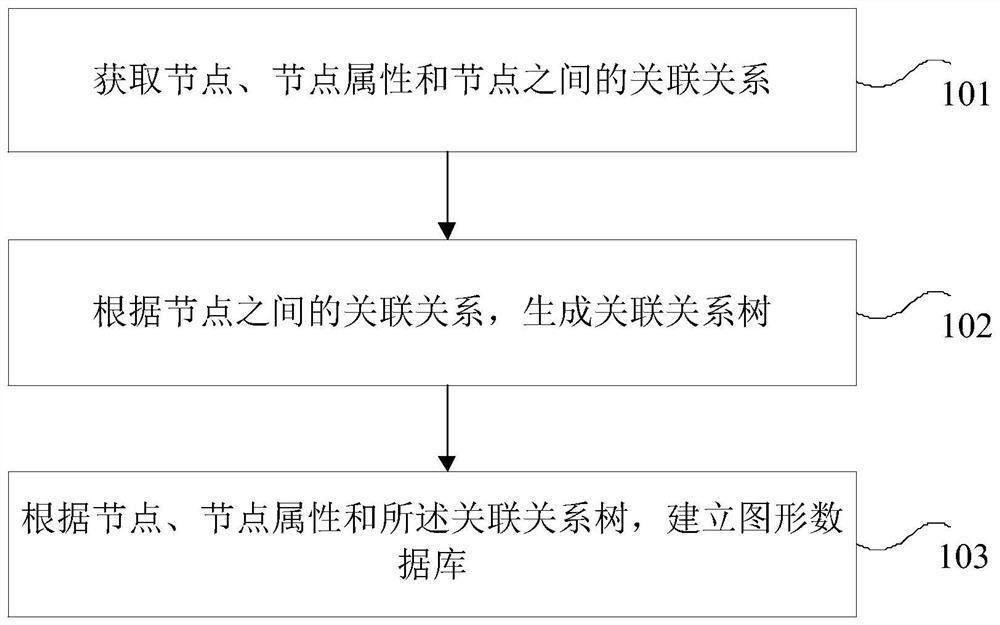

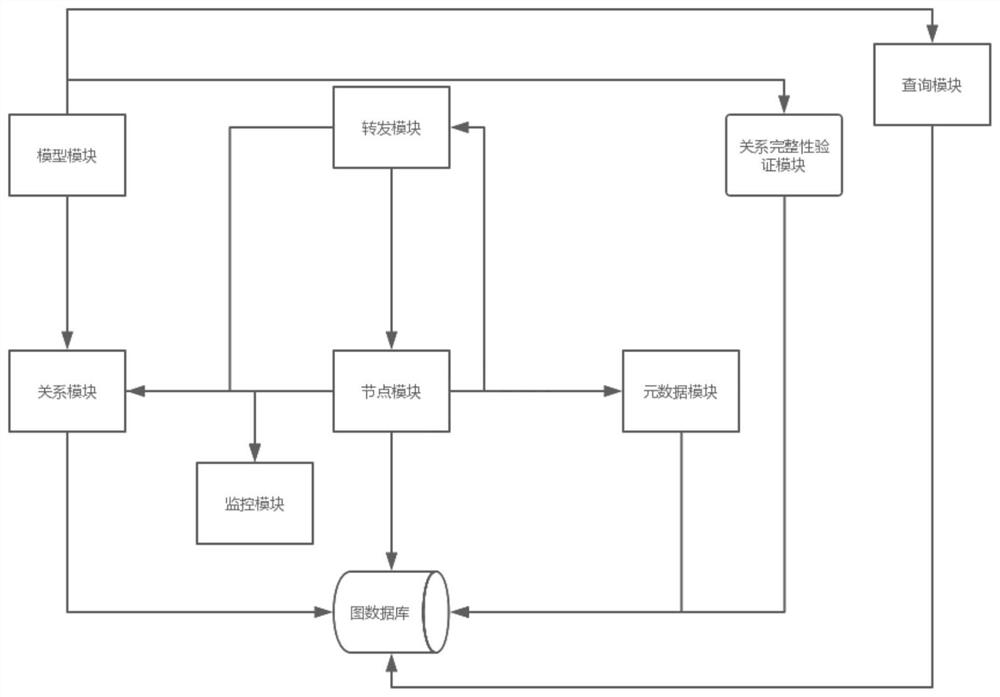

ActiveCN111949831AGuaranteed maintenance efficiencyEnsure safetyOther databases indexingEnergy efficient computingGraphicsTheoretical computer science

The invention provides a graphic database establishing method and device and a readable storage medium, and the method comprises the steps: obtaining nodes, node attributes and the incidence relationship between the nodes; generating an association relationship tree according to the association relationship between the nodes; and establishing a graphic database according to the nodes, the node attributes and the association relationship tree. By utilizing the technical scheme provided by the embodiment of the invention, under the condition that the architecture is changed, the database does not need to be redesigned, so that the database maintenance efficiency and the data security and accuracy are ensured.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA +1

Back support form support structure for large-aperture reflector

PendingCN106680965AGuaranteed Surface AccuracyGuaranteed flexibilityMountingsCircular discEngineering

The invention discloses a back support form support structure for a large-aperture reflector. The back support form support structure comprises an optical lens, a rib plate and a back plate, wherein the rib plate is parallel with the back plate, a three-claw flexible hinge, a disc flexible hinge I and a disc flexible hinge II are arranged between the rib plate and the back plate, and the back plate is provided with an anti-rotation flexible hinge, four protecting pieces and two drive components; three blind holes with precise expansion bushings are formed in the back of the optical lens, and the three precise expansion bushings are fixedly connected with the rib plate; the front portion of the three-claw flexible hinge is connected with the rib plate, and the rear portion of the three-claw flexible hinge is connected with the back plate; one ends of disc flexible hinge I and the disc flexible hinge II are in one-to-one correspondence to the two drive components and are connected through a connector, the other end of the disc flexible hinge I and the other end of the disc flexible hinge II are connected with the rib plate, and the anti-rotation flexible hinge is connected to the lateral side of the disc flexible hinge II; the four protecting pieces are connected to the back plate through lifting bolts, and the optical lens is located among the four protecting pieces. The back support form support structure is simple, stable in motion, free of friction, free of gaps, high in motion sensitivity and high in reliability and does not need lubrication.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

Integral visual detection and floating hair adsorption device with scarf end automatic turning function

InactiveCN110130086ASolve the disadvantages caused by manual inspectionGuaranteed maintenance efficiencyMechanical cleaningPressure cleaningYarnMachine vision

The invention belongs to the field of textile machinery, and relates to a device for detecting quality of upper and lower surfaces of a scarf and the overall appearance structure and removing impurities on the surface of the scarf, in particular to an integral visual detection device which has a scarf end automatic turning function and can automatically detect planar quality information such as holes in the upper and lower surfaces of the scarf and three-dimensional quality information such as surface yarn knots by means of machine vision and remove impurities such as floating hair on the surface of the scarf. The device comprises a darkroom module, a visual detection module, a floating hair adsorption module, a bottom turnover shaft module, a top turnover shaft module and a conveying module. The defects of high requirement for worker detection experience, large labor number, low detection efficiency and detection deviation in existing manual detection of the upper and lower surfaces of the scarf are overcome, the number of workers is greatly reduced, the production cost is reduced, automation is realized in the whole turnover, detection and floating hair adsorption process, and efficiency and accuracy of quality detection of the upper and lower surfaces of the scarf and cleaning of the floating hair on the surface are improved.

Owner:SHENYANG POLYTECHNIC UNIV

Automatic scarf middle portion overturning surface detecting and floating fluff adsorbing device

InactiveCN110125016AReduce in quantityOvercoming detectionOverturning articlesInspecting textilesMachine visionEngineering

The invention belongs to the field of spinning mechanical equipment, and relates to a device capable of conducting scarf upper and lower surface quality detection and adsorbing attached thread residues on the surface of a scarf, in particular to an automatic scarf middle portion overturning surface detecting and floating fluff adsorbing device capable of conducting automatic scarf upper and lowersurface quality detection through machine vision and removing scarf surface floating fluff and other impurities through a floating fluff adsorption device. The device comprises a darkroom module, a vision detection module, a floating fluff adsorption module, a bottom overturning shaft module, a top overturning shaft module and a conveying module. The device overcomes the defects that during existing scarf upper surface and lower surface manual detection, the worker detection experience requirement is high, the occupied labor is large, the detection efficiency is low, and the detection deviation exists; and the number of workers is greatly reduced, the production cost is reduced, the whole face overturning, detecting and floating fluff adsorbing process is automatic, and the scarf upper andlower surface quality detection and surface floating fluff cleaning efficiency and accuracy rate are improved.

Owner:SHENYANG POLYTECHNIC UNIV

Method for making a shaft structure silo by using the profile combination frame for silo

ActiveCN111946124BTechnological innovationImprove work efficiencyBuilding material handlingBulk storage containerReinforced concreteRebar

The invention provides a profile combination frame for a silo and a method for making a vertical shaft structure silo, belonging to the field of storage equipment, including a template assembly, an operation platform assembly, a hydraulic lifting assembly and a maintenance assembly. The hydraulic lifting assembly is used for For the lifting of the formwork assembly, the operation platform assembly includes an inner platform and an outer platform, which are used for operators or equipment to bind steel bars, pour concrete or place control equipment. The inner platform is arranged on the inner circle of the template assembly, and the outer platform On the outer ring of the formwork assembly, the curing assembly is arranged at the lower end of the outer platform, and water is sprayed outward to maintain the concrete. The invention improves work efficiency and reduces construction risk, adopts thin iron plates welded into inverted cones for overall construction, ensures the safety of the overall load-bearing support of the cone bucket construction, and makes the cone bucket appearance achieve the effect of fair-faced concrete.

Owner:POWERCHINA MUNICIPAL CONSTR GRP CO LTD

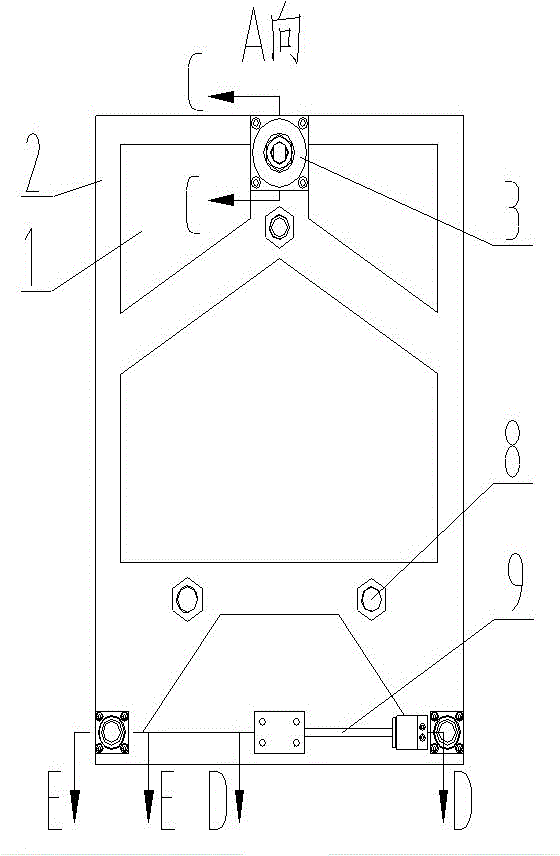

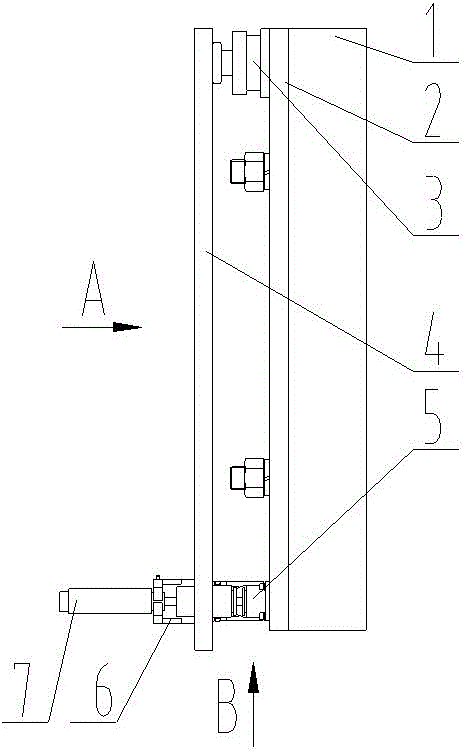

A portable motor coil cutter

InactiveCN104682636BReduce volumeReduce weightManufacturing dynamo-electric machinesRotational axisElectric machinery

The invention discloses a motor coil cutter and aims at providing a portable motor coil cutter. Key points of the technical solution are that the portable motor coil cutter comprises a cutting motor and further comprises a main support arm, wherein at least two auxiliary support arms onnected with the main support arm in a sliding manner, a first limiting part for locating the auxiliary support arms at specified positions, a rotation shaft rotationally connected with the main support arm and a placement shaft isolated from the rotation shaft are arranged on the main support arm; a clamping part for clamping a motor base is arranged on the auxiliary support arms; a lifting part for controlling the lifting of the placement shaft is arranged between the placement shaft and the rotation shaft; a placing part for placing a cutting motor is arranged on the side wall of the placement shaft; the cutting motor is connected with the placing part in a sliding manner and slides horizontally; a second limiting part for locating the cutting motor at the specified position is arranged on the placing part.

Owner:STATE GRID CORP OF CHINA +1

Energy-saving and efficient hydroxyl radical air purifier

PendingCN113757879AGuaranteed quantityThe irradiated area is limited to avoidMechanical apparatusLighting and heating apparatusMotor driveHydroxyl radical

The invention discloses an energy-saving and efficient hydroxyl radical air purifier which comprises a machine body, an operation panel, an air inlet grille and a filter screen, the operation panel is installed at the upper end of the machine body, the air inlet grille is installed on one side wall of the machine body, the filter screen is arranged on one side of the air inlet grille, a partition plate is installed on one side of the filter screen, and an exhaust fan is fixed on the partition plate. The energy-saving and efficient hydroxyl radical air purifier has the beneficial effects that a rotating seat and a motor are arranged, in the purification process, the motor drives a lamp bar to rotate at a constant speed through the rotating seat, and then the TiO2 photocatalyst reaction filter screen is integrally irradiated, so that the situation that the irradiated area of the TiO2 photocatalyst reaction filter screen is limited due to a certain illumination angle is avoided, the number of generated hydroxyl radicals is guaranteed, purification time is shortened, energy consumption of the device is reduced, high purification efficiency of the device is guaranteed, and practicability of the device is reduced.

Owner:江苏米嘉乐智能科技有限公司

A back support device for a large-aperture mirror

InactiveCN104267481BAchieve angle adjustmentEasy to disassembleMountingsRotational degrees of freedomEngineering

The invention provides a back supporting device for a large-caliber reflector. The supporting device comprises the large-caliber reflector, a lens back plate, a rotating shaft assembly, an adjusting connecting assembly, an adjusting rod assembly, a clamping block, a supporting plate and bolts. The rotating shaft assembly serves as a rotating shaft fulcrum of the large-caliber reflector, a spherical surface knuckle bearing of a standard component is adopted as a rotation main structure, the function of the spherical surface knuckle bearing and the function of a spherical hinge are the same, and the three translational motion freedom degrees of the reflector are restrained. A spiral driver is manually rotated to drive the adjusting connecting assembly to push the large-caliber reflector to do pitching and deflecting movement. After adjusting is finished, an adjusting nut is locked to limit the two rotating freedom degrees of the reflector. The face internal rotation freedom degree of the large-caliber reflector is restrained through the adjusting rod assembly. The back supporting device has the submicron-level positioning precision, can meet the requirements for various using angles and is simple in structure and accurate in positioning, pitching and deflecting two-dimensional precise adjustment of the online state and the offline state is achieved, and the designing cost and the manufacturing cost are reduced.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com