Bearing ring blank carrying manipulator

A technology of bearing rings and manipulators, applied in the field of manipulators, can solve the problems of low product precision, low processing efficiency, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

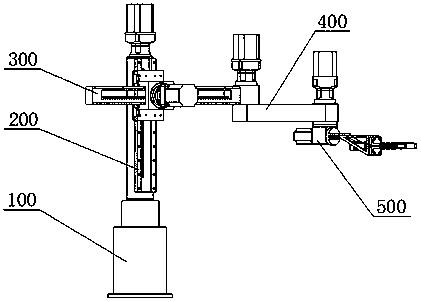

[0027] Such as figure 1 As shown, the bearing ring blank handling manipulator includes a spindle rotation module 100 , a longitudinal movement module 200 , a transverse movement module 300 , a swing module 400 , and a gripper module 500 .

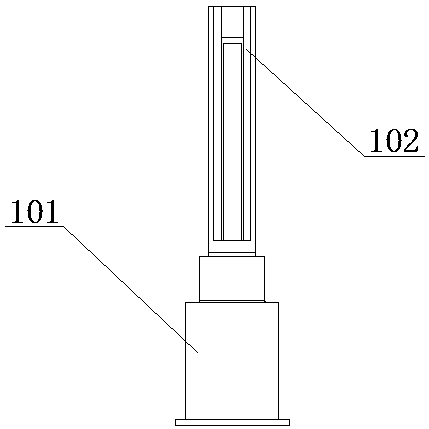

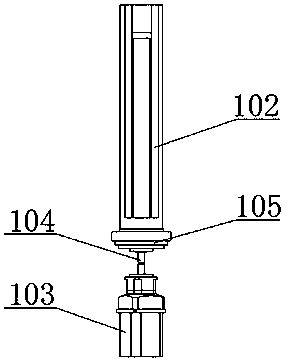

[0028] Such as figure 2 , image 3 The main shaft rotation module 100 shown is characterized in that: the upper end of the base 101 and the lower end of the column 102 are designed with threaded holes, the base 101 and the column 102 are connected by screws, the bearing 105 is set in the circular hole at the bottom of the column 102, and the column drives the shaft 104 is set in the hole of the bearing 105, and the first motor 103 is placed in the cavity of the base 101.

[0029] Such as Figure 4 , Figure 5 The longitudinal movement module 200 shown is characterized in that: the first slider 202 and the second slider 204 are respectively set on the first guide rail 201, the third slider 208 and the fourth slider 210 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com