Profile combination frame for silo and method for manufacturing silo of vertical shaft structure using same

A combination frame and silo technology, applied in the direction of building type, building structure, and building material processing, can solve problems such as hidden dangers in engineering quality, small structural size, cracks, etc., and achieve the effect of reducing danger and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

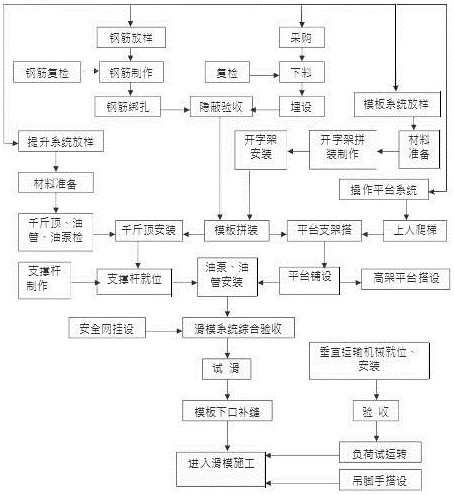

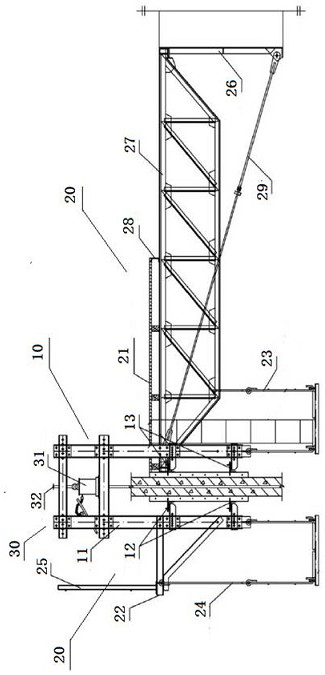

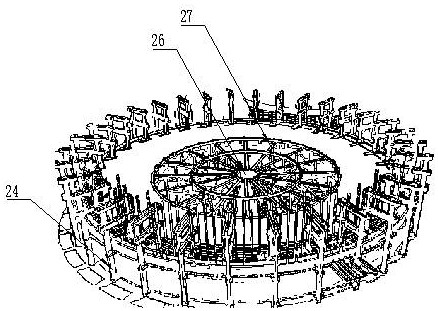

[0088] Example: The diameter of the silo is 11m, and it is an overseas project. Considering that all construction equipment is imported from China by sea, the design of the formwork system is slightly different from that in China, and it is required to facilitate modular packaging and transportation. The template for the sliding form adopts a 5mm thick combined special steel template, the height of the template is 1200mm, the size is 200×1200mm, 300×1200㎜, and 100×1200mm is used for making up the difference; In strips, the length is 6m; the lifting frame adopts the open type frame, and the single frame is composed of two 2.39m columns and four beams, which are transported to the site in bulk and then assembled and formed. In order to adapt to different silo diameters, the columns and beams are designed and formed according to the generality, which can be used for the sliding form of silos with a diameter of 10m~60m and the construction of chimneys, square silos, and water tower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com