Automobile part maintenance pressing and fixing device and pressing method thereof

A fixing device and pressing technology, applied in the field of auto parts maintenance, can solve the problems of lack of fine-tuning function, convenient application and operation process, etc., and achieve the effect of ensuring maintenance efficiency, convenient height adjustment, and easy handling and transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

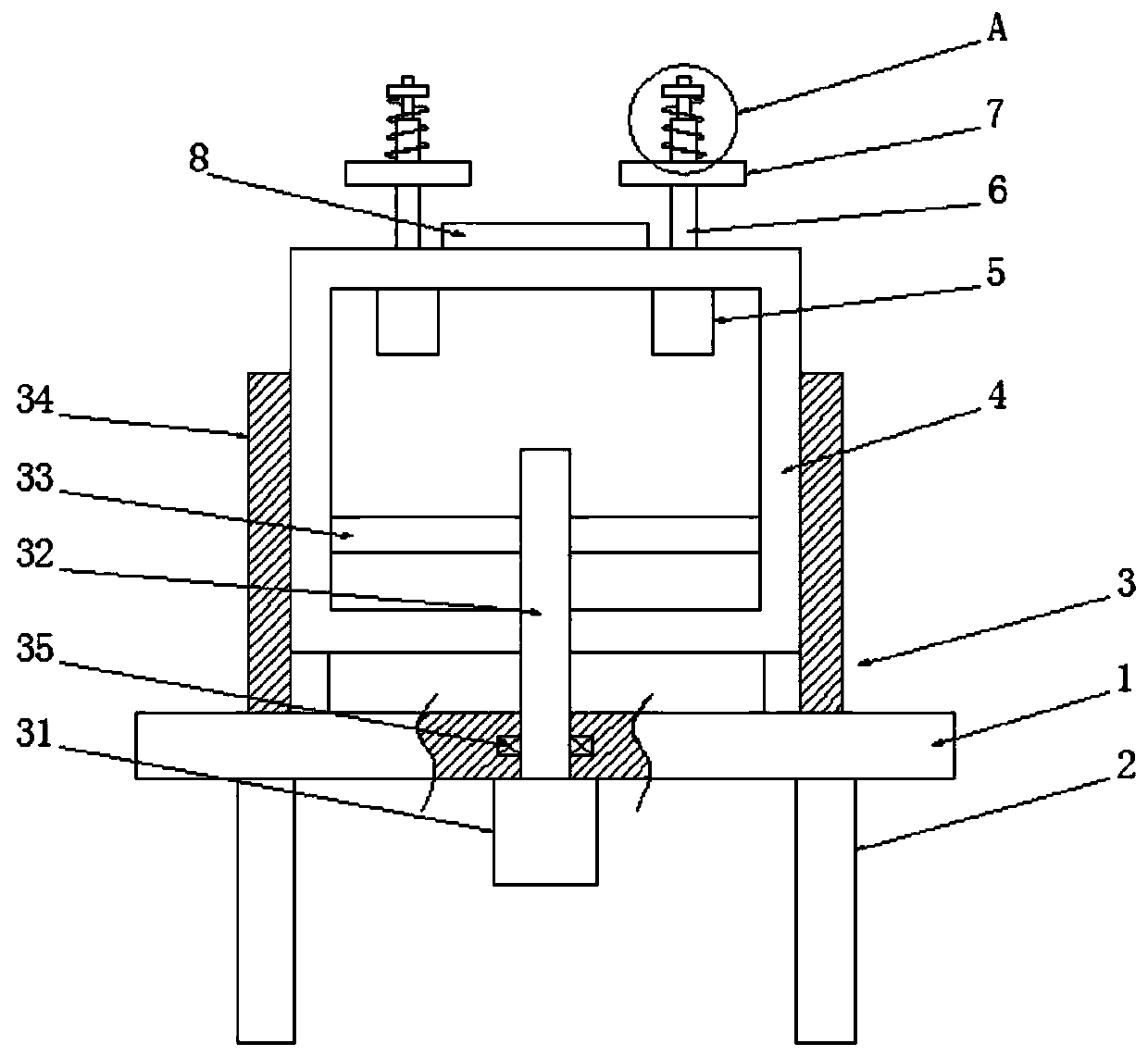

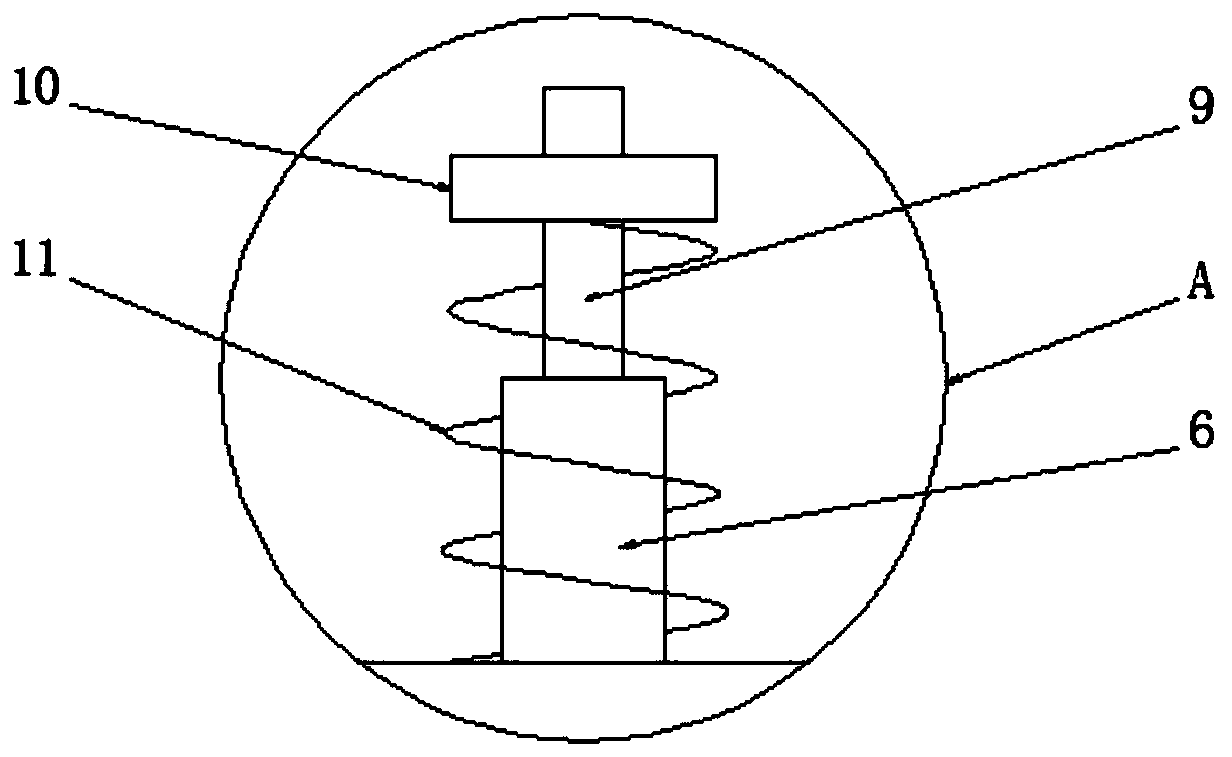

[0032] See Figure 1-2, a pressing and fixing device for repairing auto parts, comprising a bottom plate 1, a plurality of legs 2 are uniformly arranged on the bottom end of the bottom plate 1, and a lifting mechanism 3 is arranged on the top end of the bottom plate 1, and a lifting mechanism 3 is installed on the lifting mechanism 3. Lifting frame 4, described lifting frame 4 is a rectangular frame structure, workbench 8 is fixedly installed in the top middle part of lifting frame 4, and electric telescopic device 5 is installed symmetrically on the inner cavity top wall of lifting frame 4, and described electric telescopic device 5 The top of the telescopic rod 6 on the top runs through the top wall of the lifting frame 4 and is fixedly connected with a fine-tuning screw 9. The outer side of the telescopic rod 6 is provided with a pressing plate 7 matched with the workbench 8. Between the telescopic rod 6 and the pressing plate 7 It is a sliding connection, the fine-tuning s...

Embodiment 2

[0034] See figure 1 The difference from Embodiment 1 is that the lifting mechanism 3 includes a lifting motor 31 and two guide grooves 34 that match the lifting frame 4, the guide grooves 34 are U-shaped structures, and the two guide grooves 34 are slidably connected On the left and right sides of the lifting frame 4, the guide groove 34 is fixedly mounted on the base plate 1, and the lifting motor 31 is fixedly mounted on the bottom end of the base plate 1, and the lifting motor 31 is rotatably connected with a lifting screw rod 32, and the lifting screw rod 32 The top end passes through the bottom plate 1 and is screwed on the lifting frame 4. By rotating the lifting motor 31 in the forward direction, the lifting screw 32 is driven to rotate forward, and the lifting screw 32 is used to push the lifting frame 4 up along the guide groove 34, thereby adjusting the workbench upwards. At the same time, reversely rotate the lifting motor 31, thereby driving the lifting screw 32 to...

Embodiment 3

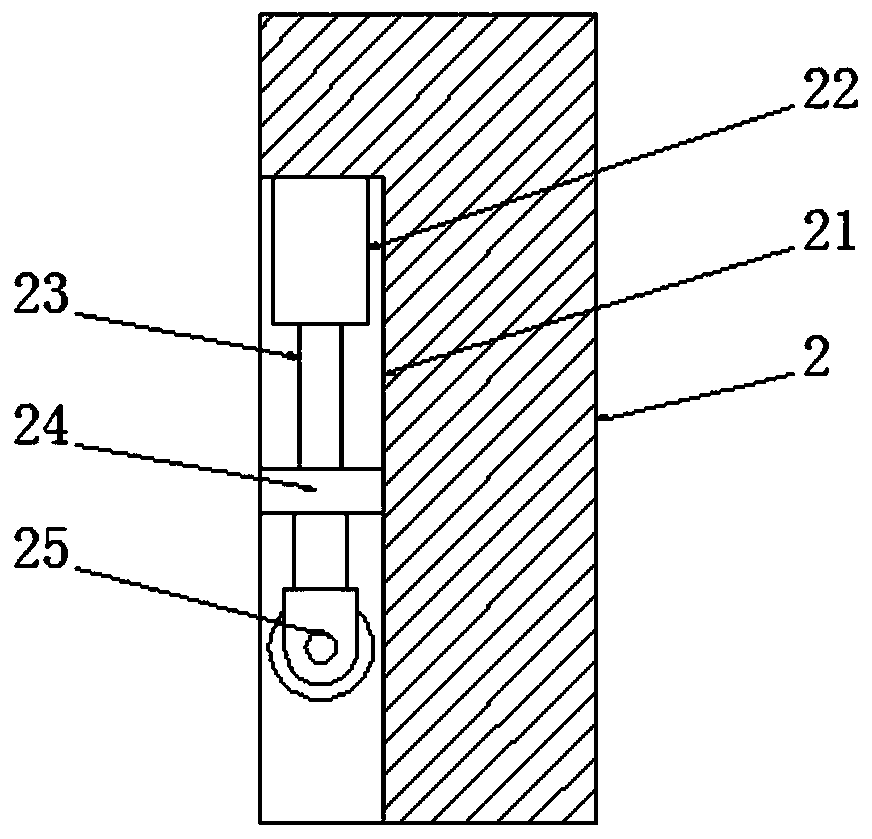

[0037] See image 3 , the difference from Embodiment 1 is that: one end of the leg 2 is provided with a storage chamber 21, and a hydraulic cylinder 22 is fixedly installed on the inner cavity top wall of the storage chamber 21, and the hydraulic rod 23 on the hydraulic cylinder 22 The bottom end of the bottom of the stable plate 24 is fixedly connected with the stable plate 24 matched with the storage chamber 21, and the stable plate 24 is slidingly connected with the storage cavity 21, and the bottom end of the stable plate 24 is fixedly equipped with a universal wheel 25. The universal wheel 25 is a universal self-locking wheel. When the whole device needs to be transferred, the hydraulic rod 23 is extended through the hydraulic cylinder 22, and the hydraulic rod 23 pushes the stabilizing plate 24 to slide down along the storage cavity 21, thereby lowering the universal wheel. 25. Utilize universal wheels 25 to support the entire device, so that the mobility of the entire d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com