Moving post double-side ram lathe body milling machine

A ram and double-sided technology, which is applied in the field of moving column double-sided ram bed milling machines, can solve the problems of difficult installation and debugging, large machine tool footprint, and large changes, and achieve superior performance of CNC servo drive and easy installation Easy debugging and small friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

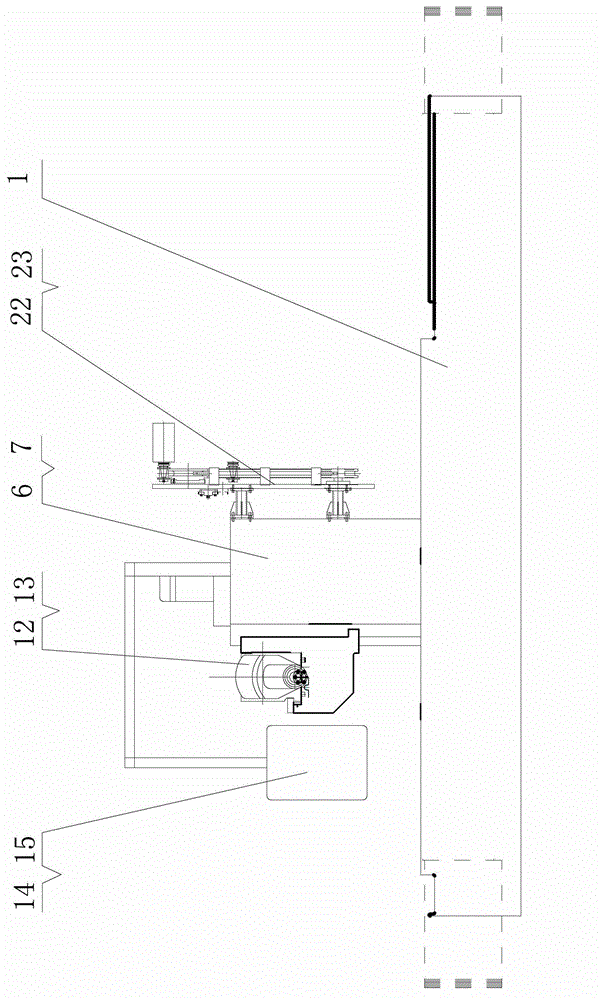

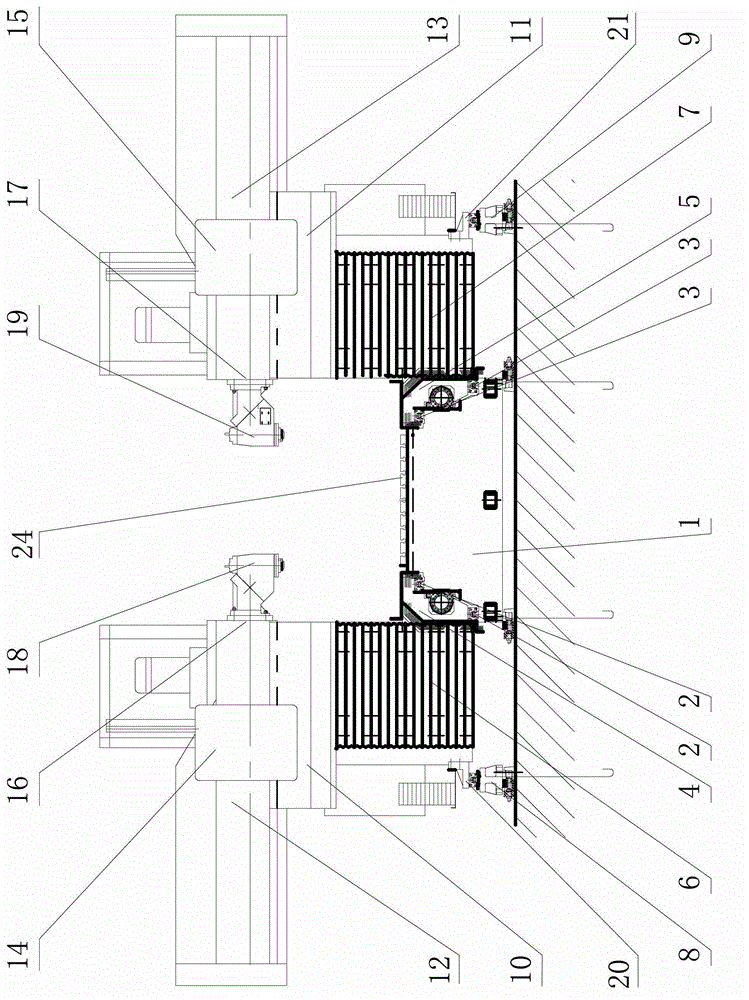

[0021] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

[0022] The milling machine with moving column double-sided ram bed of the present invention is mainly composed of the following parts: workbench base 1, workbench 24, left longitudinal guide rail 2, right longitudinal guide rail 3, left longitudinal guide slide seat 4, right longitudinal guide slide seat 5. Left column 6, right column 7, left longitudinal auxiliary guide rail 8, right longitudinal auxiliary guide rail 9, left longitudinal auxiliary slide seat 20, right longitudinal auxiliary slide seat 21, left lift slide seat 10, right lift slide seat 11, left slide Pillow 12, right ram 13, left spindle 16, right spindle 17, left milling head 18, right milling head 19, left tool magazine and tool automatic exchange device 22, right tool magazine and tool automatic exchange device 23, left electrical operation station 14 and right electric appliance ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com