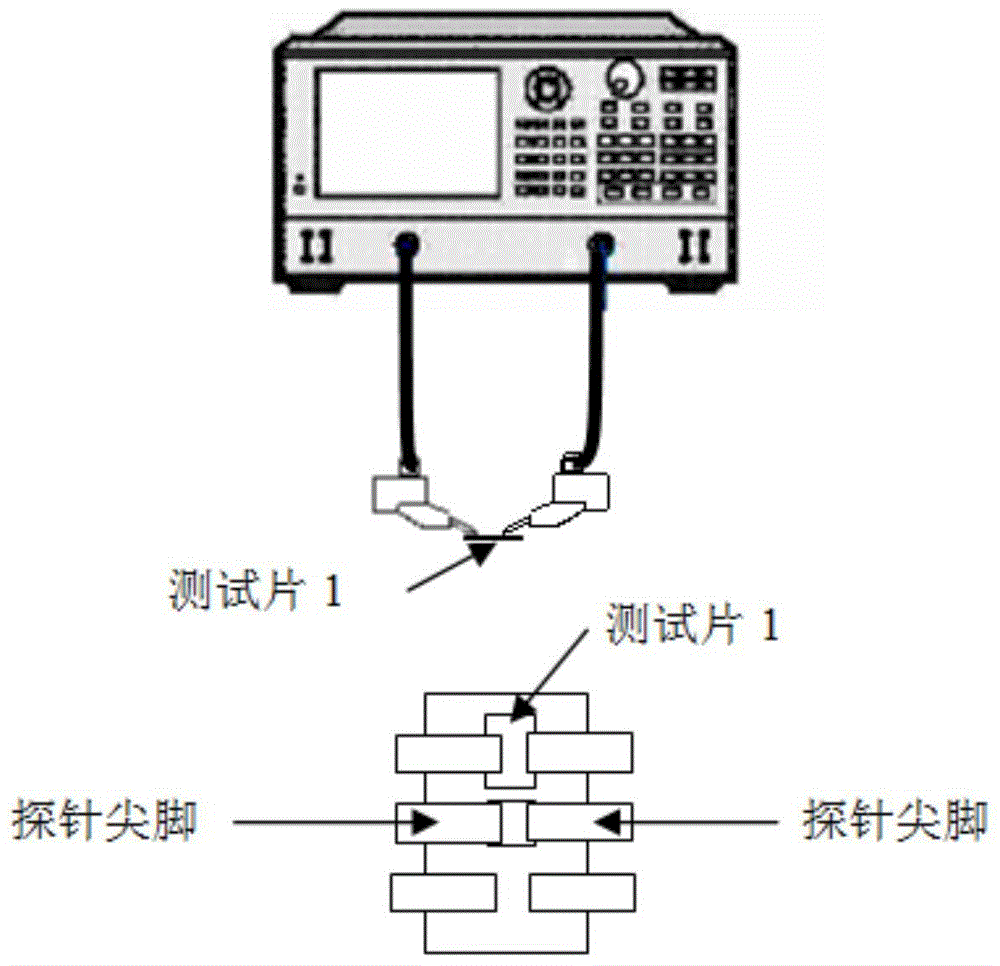

Controllable high-frequency-response probe test moving device for microwave and millimeter wave chips

A motion device and millimeter-wave technology, which is applied in the field of high-frequency response probe test motion devices, can solve the problems of uncontrollable contact stress between probes and chips, high test difficulty, and low test accuracy, so as to shorten the test period and reduce the test time. Cost, the effect of improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

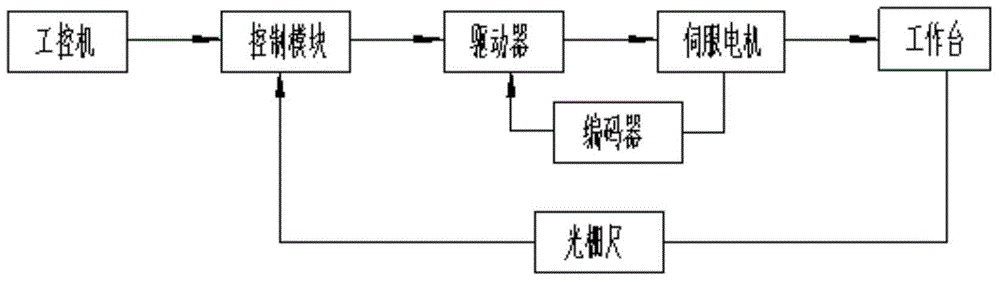

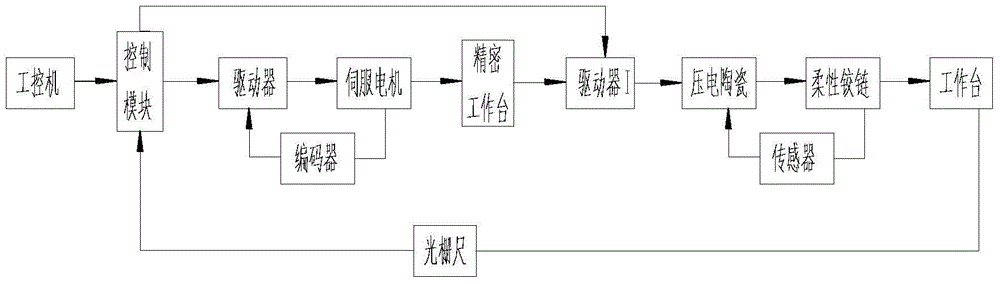

[0052] The invention adds a set of precision displacement device on the basis of the existing device. The existing one-time positioning is changed to a secondary positioning in which the motor drives the screw for rough positioning and the precision displacement device is for fine positioning. image 3 Its control schematic diagram, the precision positioning device is driven by piezoelectric ceramics, and the flexible hinge is used as the transmission mechanism.

[0053] As a power device, piezoelectric ceramics use the inverse piezoelectric effect of piezoelectric ceramics to achieve small displacements. When the voltage of piezoelectric ceramics is changed, the length of piezoelectric ceramics changes accordingly, and the elongation is proportional to the voltage within a certain range. Can provide high-frequency, high-precision reciprocating motion,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com