Fixer andits scanning electronic microscope for testing sample

A technology for electron microscopes and fixtures, which is applied in microscopes, semiconductor/solid-state device testing/measurement, circuits, etc. It can solve problems such as low test efficiency, sample drop, and image blurring, so as to improve sample manufacturing efficiency and speed. The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

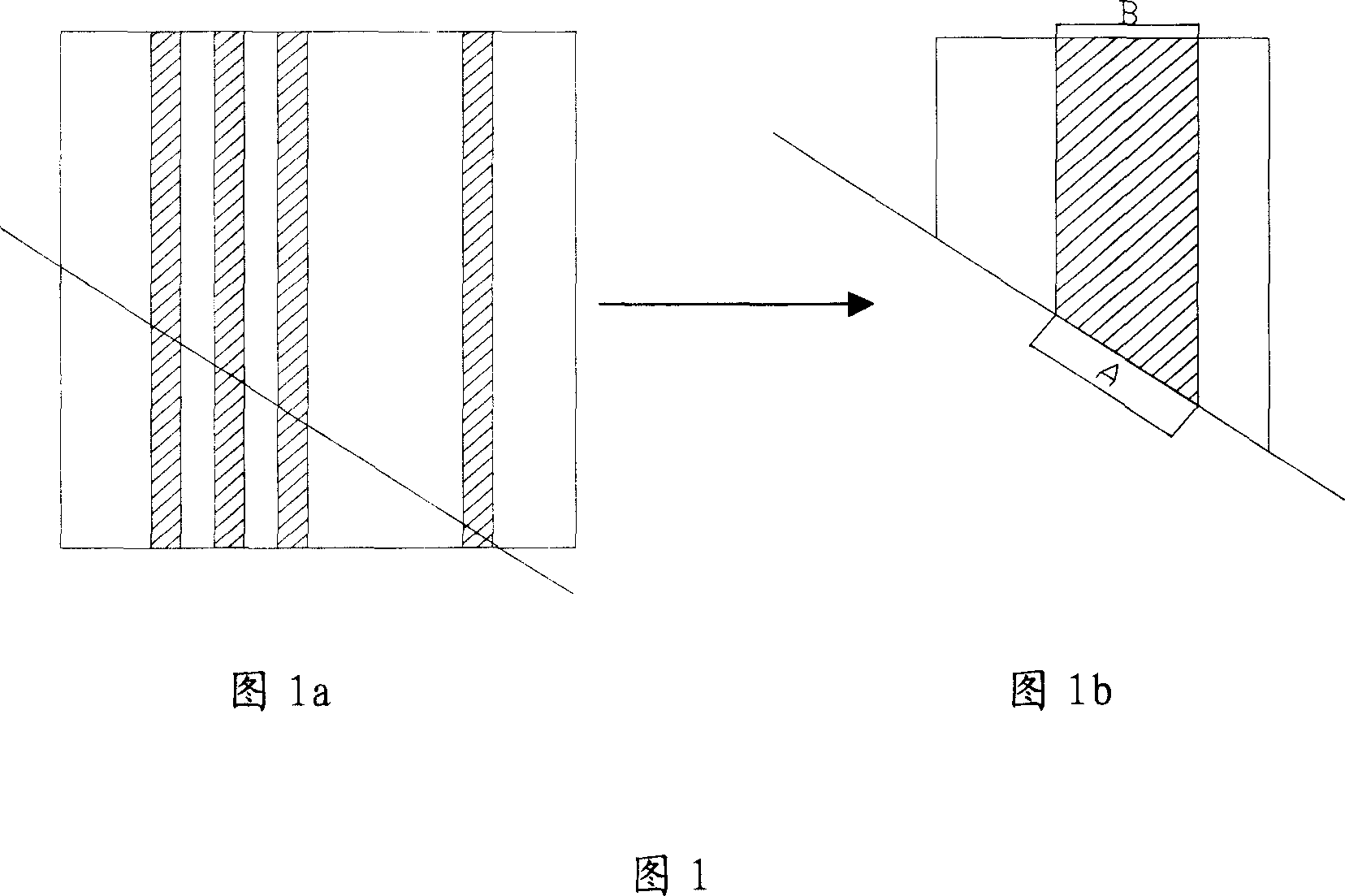

[0032] The core idea of the present invention is to change the situation in the prior art that the test sample is adhered to the fixing device by using hot melt to achieve fixation, and to realize the fixation by mechanically pressing the fixed wall and the movable wall, so that the test sample can be avoided. Vibration during electron beam scanning improves the quality of SEM scanning images; and because the distance between the fixed wall and the movable wall is adjustable, multiple test samples can be fixed at the same time to improve test efficiency.

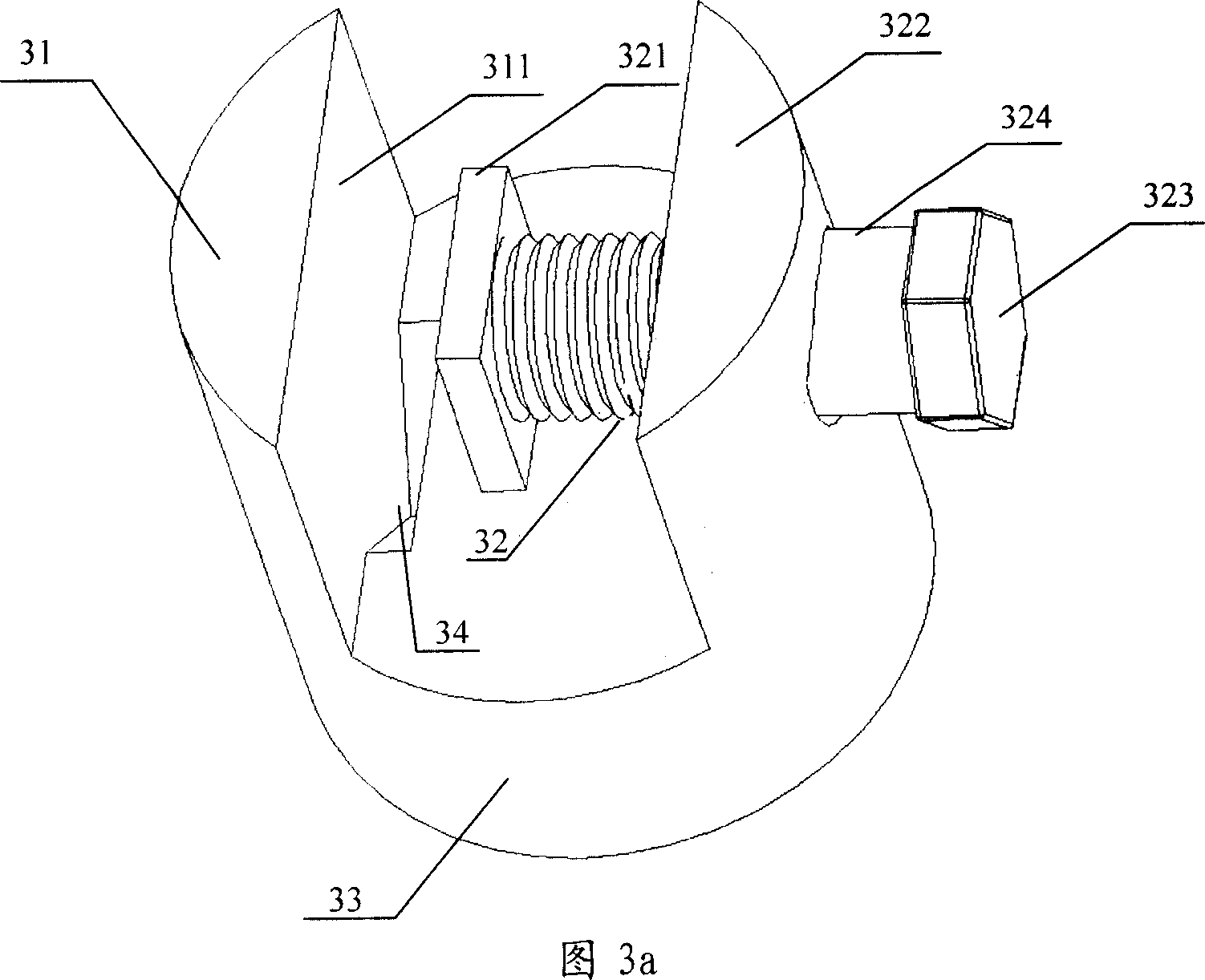

[0033] Referring to FIG. 3 , it is the first embodiment of the test sample fixing device of the present invention. Fig. 3a is a three-dimensional structure diagram of the first embodiment. Fig. 3b is a perspective view of the structure of the first embodiment, showing the internal and bottom structures invisible from the front with light-colored lines.

[0034]The test sample fixing device of the present invention is main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com