Tilting pad bearing capable of actively controlling oil film gap

A technology of oil film clearance and active control, applied in rotating bearings, sliding contact bearings, bearings, etc., can solve problems such as the inability to ensure the best working state of tilting pad bearings, and achieve the purpose of suppressing journal vibration, improving sensitivity, and improving Effect of Rotation Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further elaborate the technical means and effects that the present invention adopts for reaching the intended invention purpose, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the present invention are described in detail as follows:

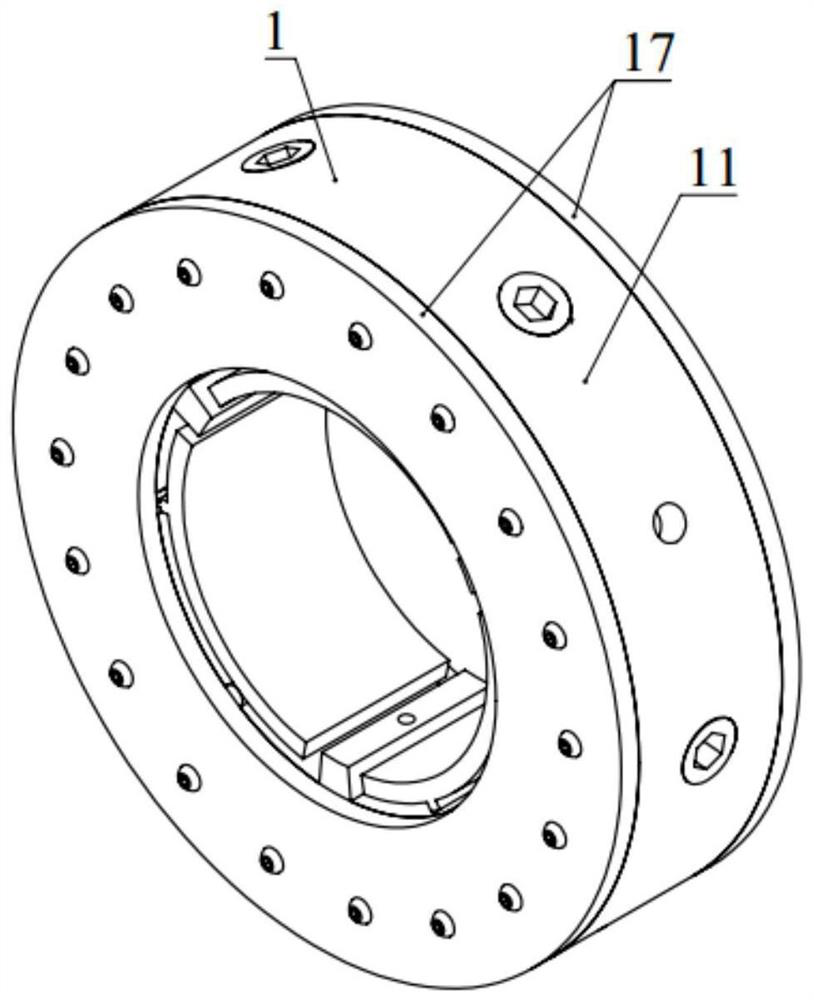

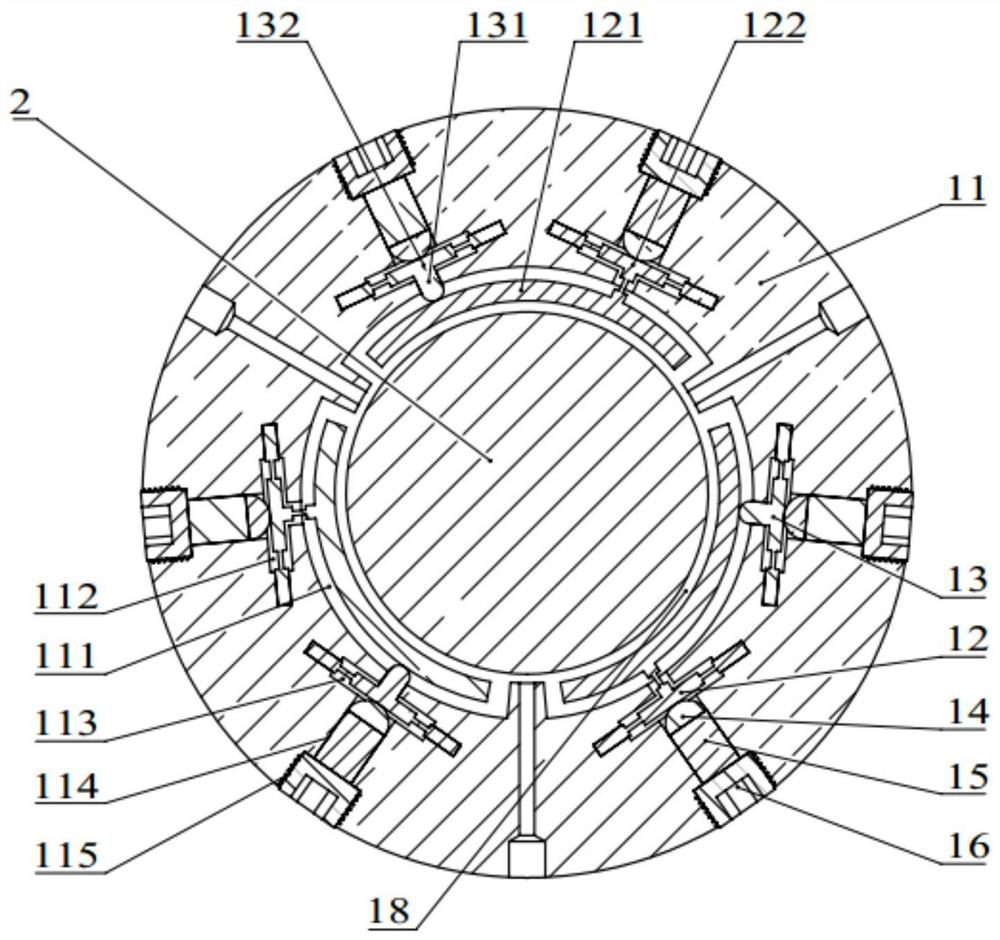

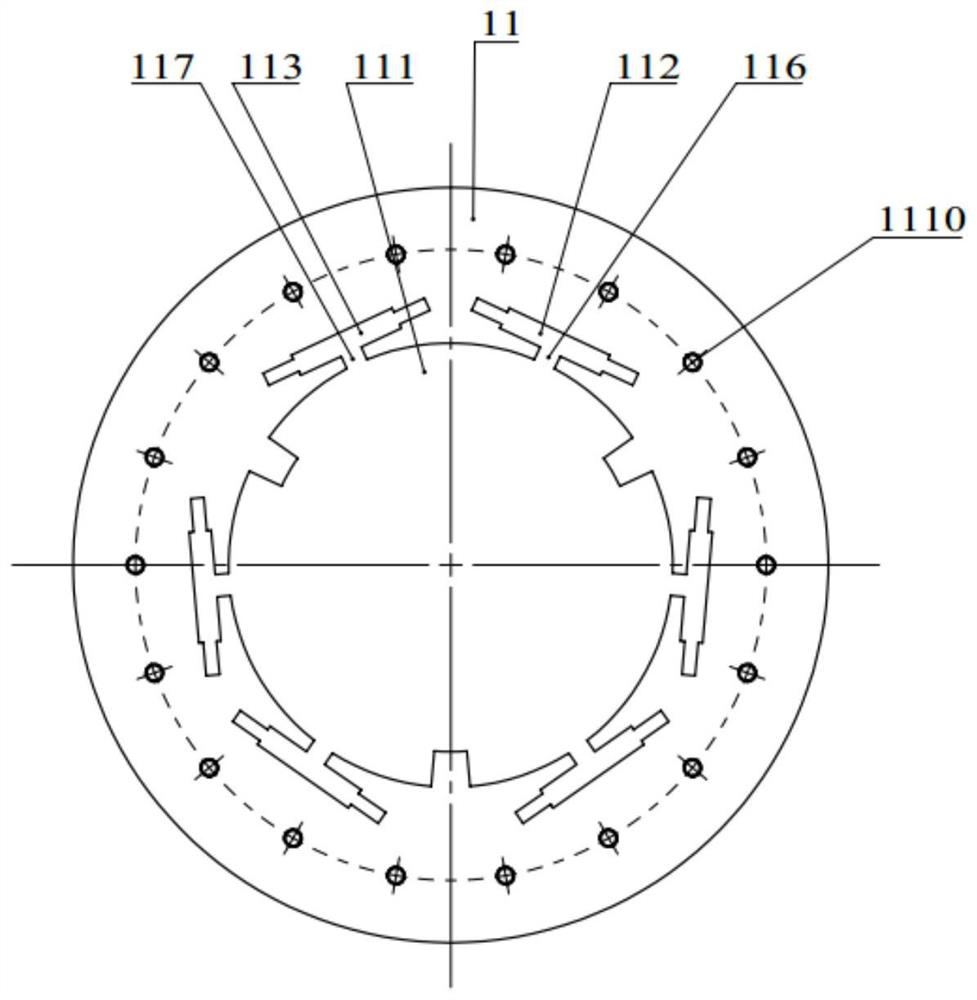

[0029] A tilting pad bearing with actively controlled oil film clearance, such as Figure 1 to Figure 7 As shown, it includes a bearing 1, and also includes a journal 2 matched with the bearing 1. The bearing 1 includes a body 11, a flexible hinge bearing bush 12, a flexible hinge push rod 13, a thrust hemisphere 14, a piezoelectric ceramic driver 15, bolts 16 and a cover plate 17. Among them, the flexible hinge bearing bush 12 includes a bearing bush 121 and a flexible hinge mechanism A122; the flexible hinge push rod 13 includes a push rod mechanism 131 and a flexible hinge mechanism B132; Cavities 111, each bearing cavity 111 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com