Line-aligning celery harvester and use method thereof

A harvester and celery technology, which is applied in the field of agricultural machinery, can solve the problems of celery surface tissue damage, inability to arrange neatly automatically, unfavorable packaging and transportation, etc., and achieve the effect of light weight, constant transmission ratio, and low center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

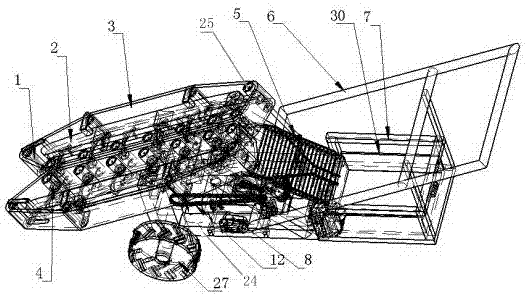

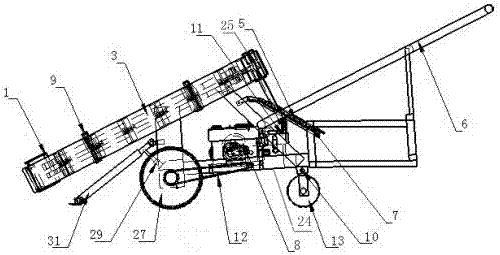

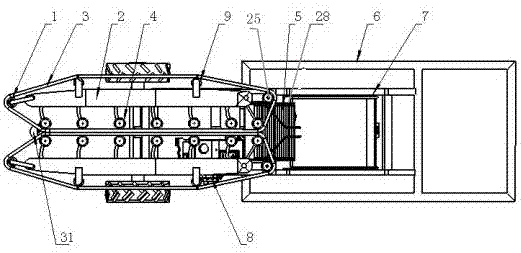

[0047] Such as figure 1 , 2 , Shown in 3, the present invention comprises frame 24, power unit 8, transmission device, driving device, root cutting device 31, clamping conveying device, collecting device and handrail 6.

[0048] The power unit 8 is connected with the transmission device and installed on the frame 24; the driving device is installed below the frame 24; the clamping and conveying device is installed in front of the frame 24, and the collecting device is installed behind the clamping and conveying device on the frame 24; the power unit 8 is connected with the traveling device and the clamping conveying device through a transmission device and provides power; the root cutting device 31 is fixed on the frame 24 between the traveling device and the clamping conveying device superior.

[0049] The clamping conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com