Double-color plastic part injection molding device and injection molding technology

A two-color plastic and plastic technology, applied in signal transmission systems, instruments, non-electrical signal transmission systems, etc., can solve the problems of high product rejection rate, increased drive device displacement, and products cannot be dropped in time for recycling, and achieves safety. High performance, ensure overall plasticity, and accelerate the effect of cooling and demoulding work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

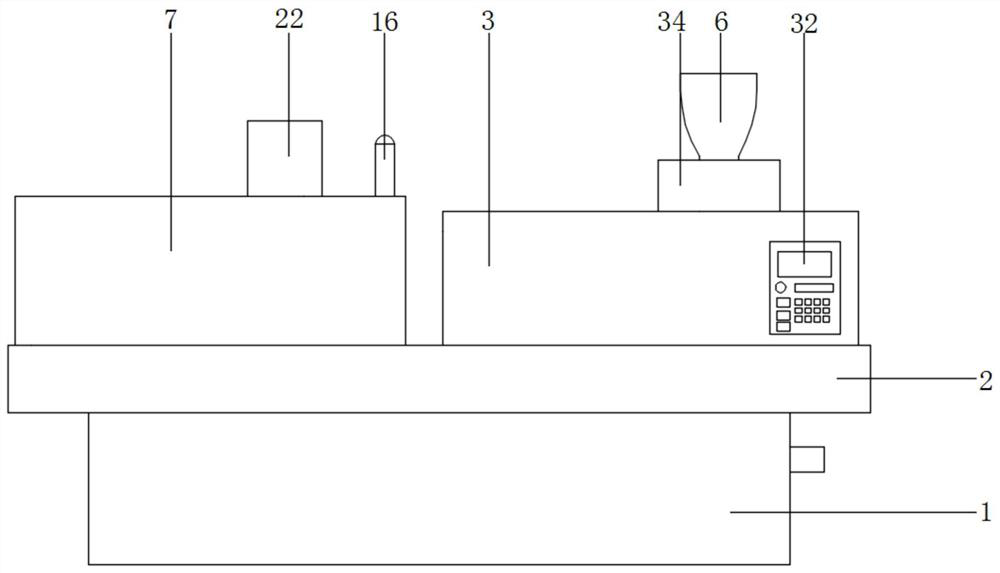

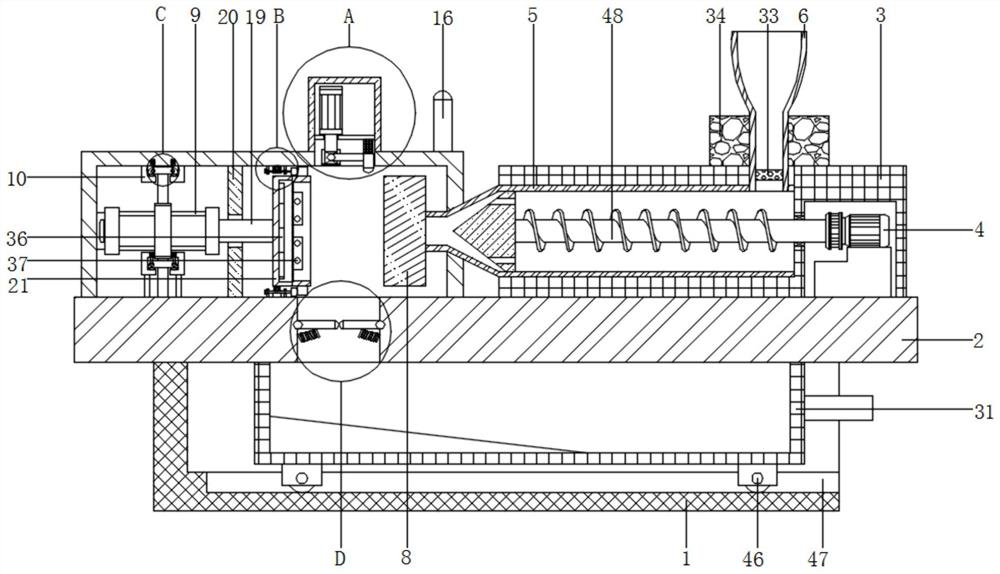

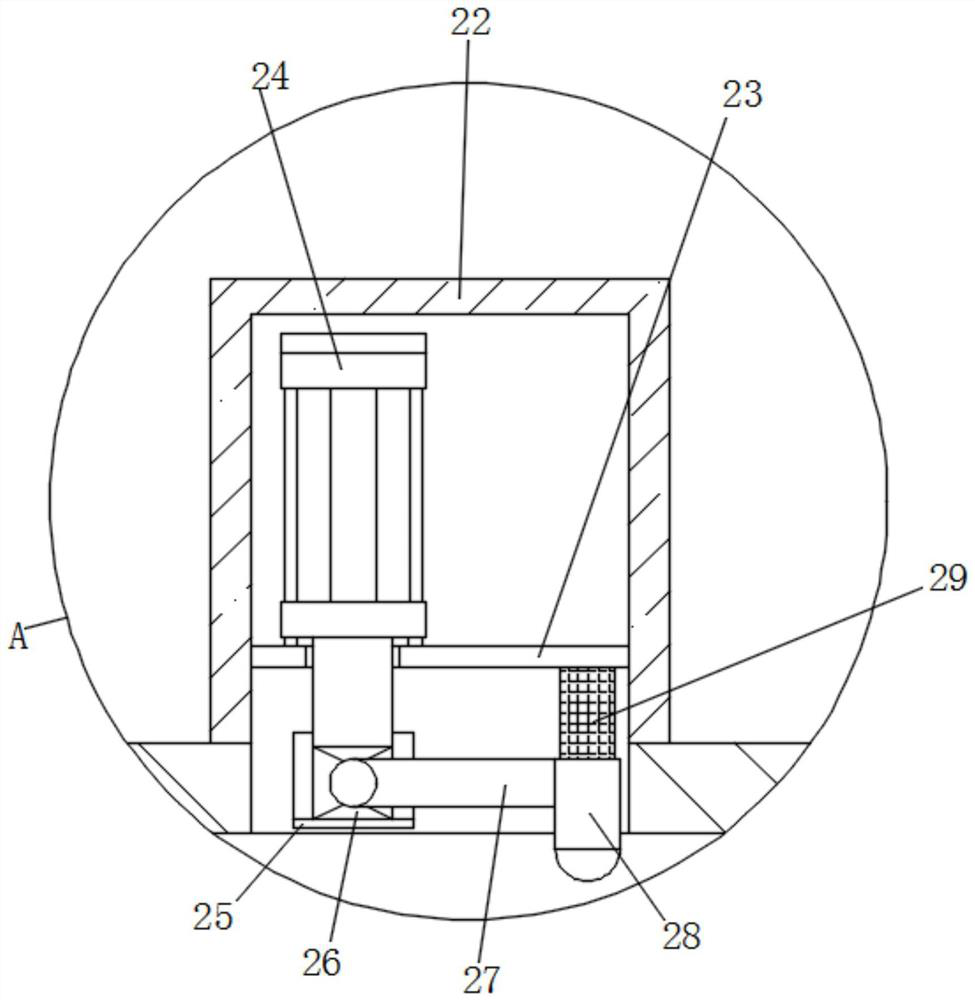

[0042] Embodiment 1: A kind of two-color plastic parts injection molding device, such as figure 2 As shown, including the bottom platform 1, the upper surface of the bottom platform 1 is fixedly connected with the injection molding workbench 2, the top of the injection molding workbench 2 close to its right side is fixedly connected with the stirring platform 3, and the bottom of the stirring platform 3 close to its right side There is a notch, and the bottom of the inner wall of the notch is fixedly installed with a driver 4 through a bracket, the output end of the driver 4 is fixedly connected with a guide rod 48, and the inside of the mixing table 3 is fixedly connected with a transport pipe 5, and the guide rod 48 is away from One end of the driving machine 4 penetrates into the inside of the transport pipe 5, and the top of the mixing table 3 near its right side is fixedly connected with the feeding pipe 6, which ensures the stable guiding transportation of the round mate...

Embodiment 2

[0057] Embodiment 2: An injection molding process for an instrument housing, the specific steps are as follows:

[0058] 1. Fill the raw materials into the inside of the mixing table 3 through the feeding pipe 6, and start the hydraulic cylinder 9 through the control controller 32;

[0059] 2. The start of the hydraulic cylinder 9 can drive the round rod 19 to move, and the movement of the round rod 19 can drive the left plastic plate 21 to move until the left plastic plate 21 and the right plastic plate 8 are completely attached;

[0060] 3. The driving machine 4 operates under the control of the controller 32, and the driving machine 4 drives the guide rod 48 to rotate to transport the dissolved raw materials into the inside of the right plastic plate 8;

[0061] 4. After the plasticity of the molds inside the left plastic plate 21 and the right plastic plate 8 is completed, the controllable cold plate 36 can operate for cooling, and the cold air circulation groove 37 can tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com