A grid hollow brick filling frame fitted with centripetal compaction

A hollow brick and compaction technology, applied in the field of brick manufacturing, can solve the problems of difficult demoulding of hollow bricks and inconvenient compaction of hollow bricks, and achieve the effect of easy demoulding work and convenient and quick operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

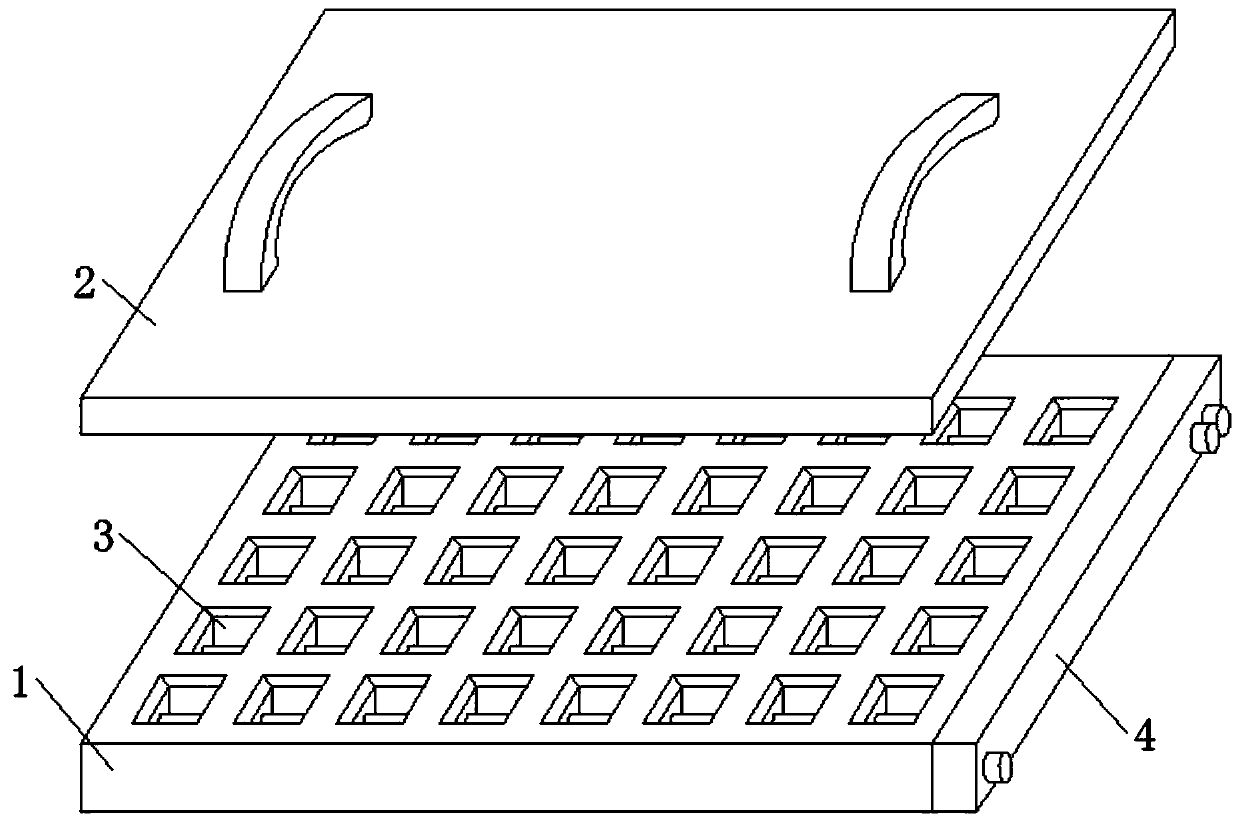

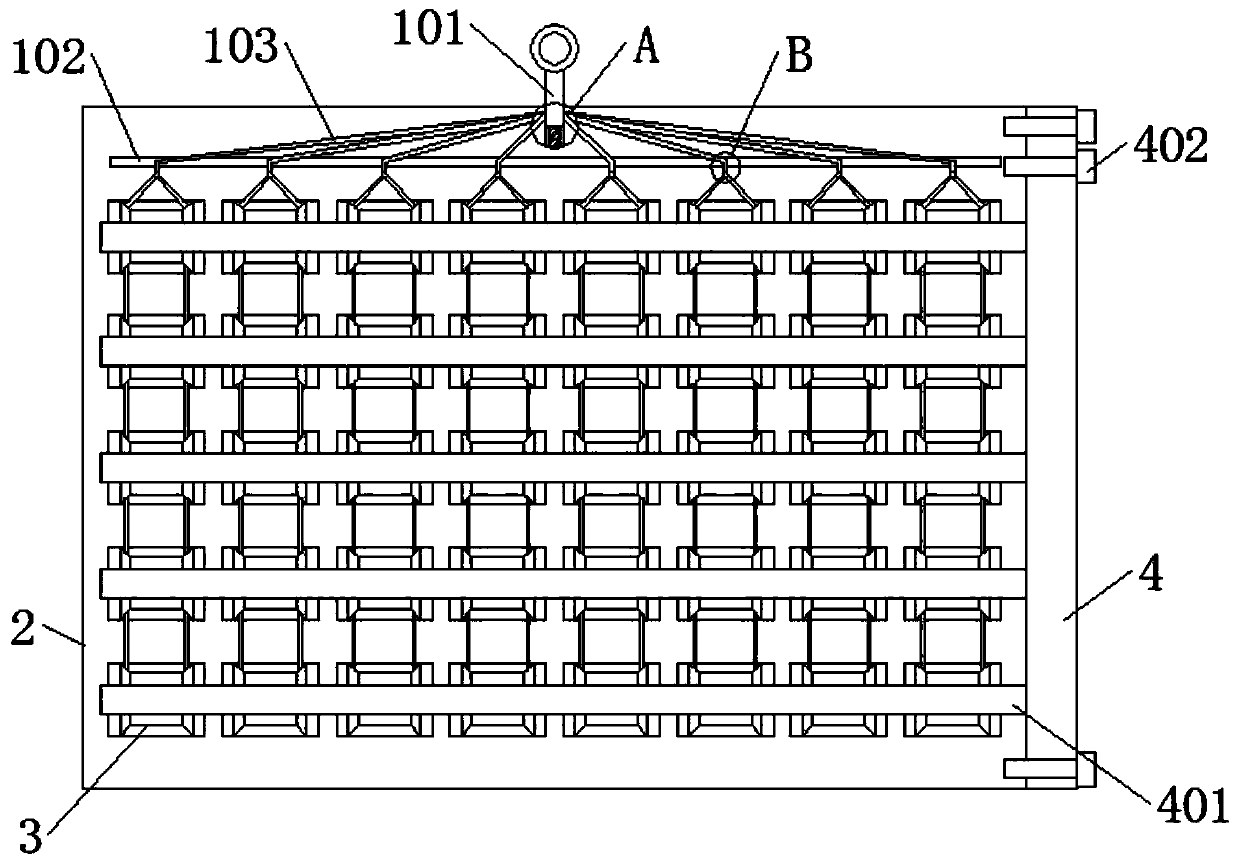

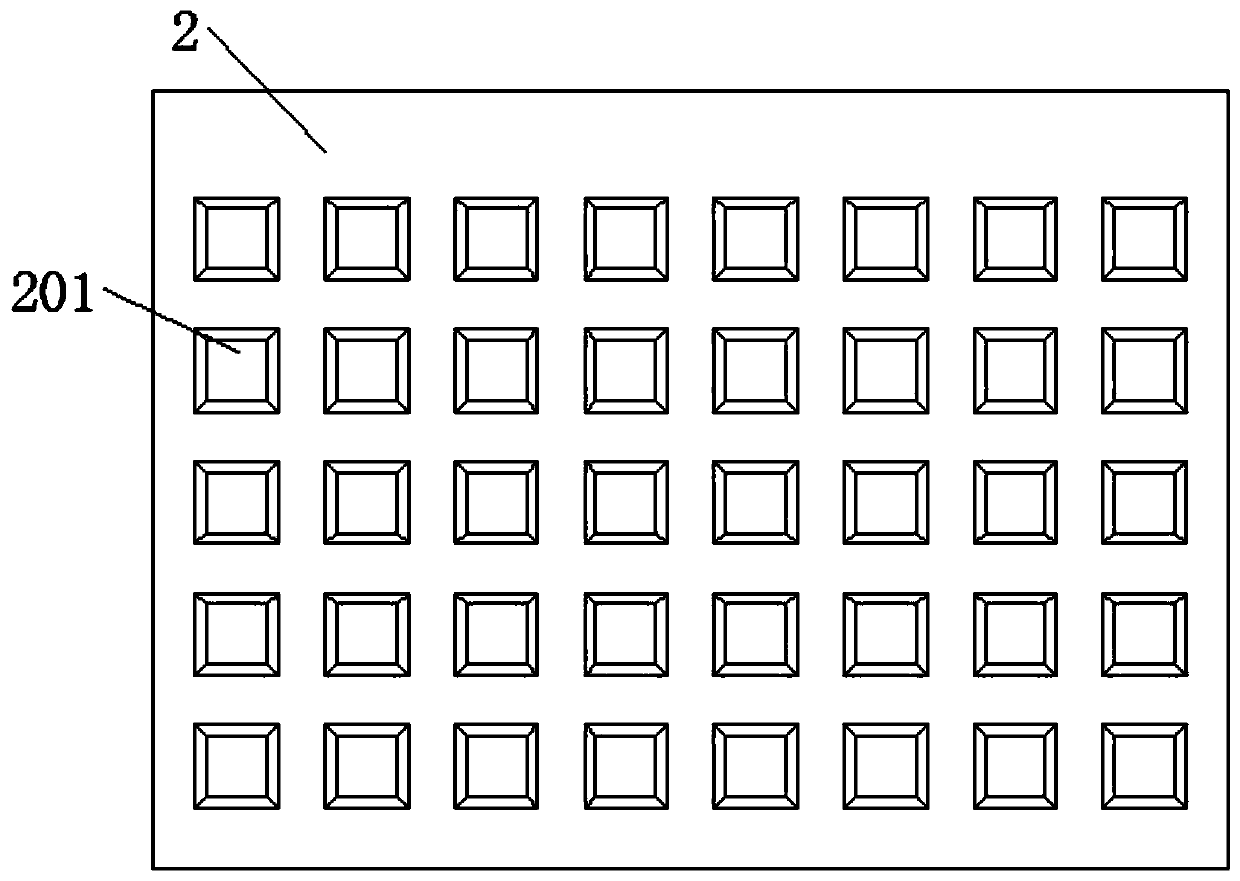

[0032] see figure 1 to attach Figure 9 , a grid hollow brick filling frame that fits centripetally and compactly, including: a formwork 1, an extruded cover 2, a pressing plate 201, a shaping groove 3 and a push plate 4, and an extruded cover 2 is arranged on the top of the formwork 1 , the bottom surface of the extrusion cover 2 is integrally provided with a pressure plate 201 , the middle part of the mold base 1 is embedded with a shaping groove 3 , and the right side of the mold base 1 is provided with a push plate 4 .

[0033] see figure 2 and Figure 7 , further, a drawstring 101 is provided in the middle part of the rear side of the formwork 1, a guide plate 102 is embedded in the middle part of the rear side of the formwork 1, and through holes are embedded in the left and right sides of the guide plate 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com