Ecological stone demolding equipment for building

A technology for ecological stone and construction, applied in the direction of unloading device, manufacturing tools, etc., can solve the problems of long time and energy, cumbersome and other problems, and achieve the effect of easy demoulding work and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

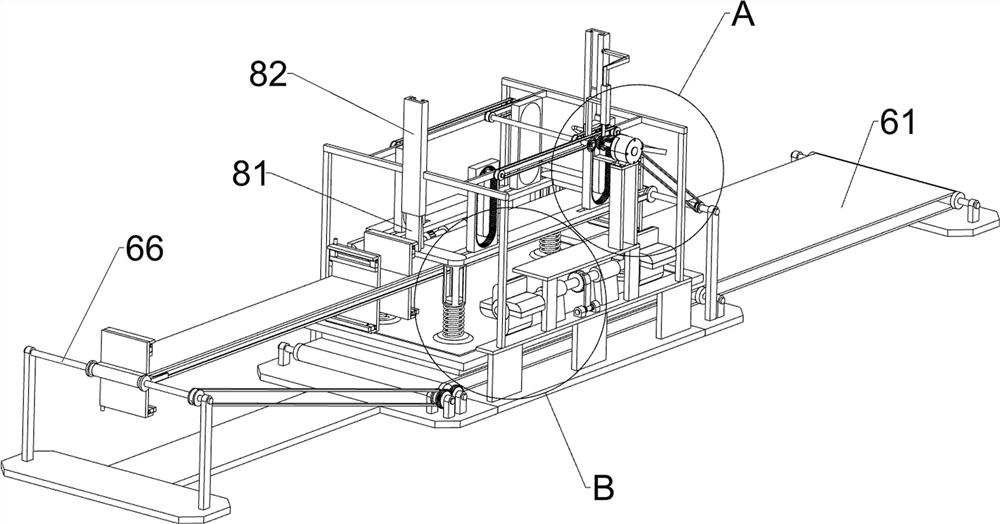

[0025] A kind of ecological stone demoulding equipment for building, such as Figure 1-8 As shown, it includes a base 1, a mounting frame 2, a demoulding mechanism 5 and a moving mechanism 6, the top of the base 1 is connected with a mounting frame 2, the mounting frame 2 is equipped with a demoulding mechanism 5, and the base 1 is equipped with a moving mechanism 6 , the moving mechanism 6 is connected with the demoulding mechanism 5 in transmission.

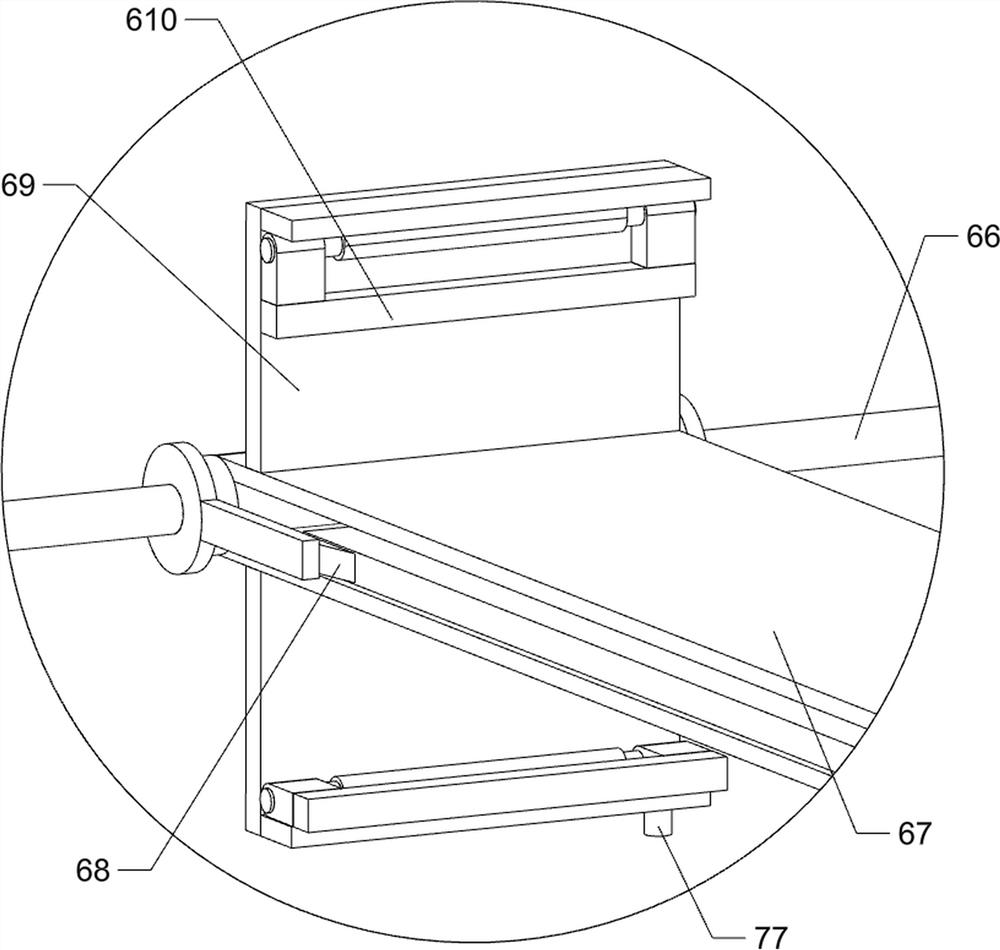

[0026] The stripping mechanism 5 includes a servo motor 51, a double-sided bevel gear 52, a first bevel gear 53, a first connecting shaft 54, a first transmission belt set 55, a second connecting shaft 56, a second transmission belt set 57, a first Gear 58, sliding lifting frame 59, ring rack 510, connecting frame 511, hollow frame 512, sliding rod 513, support spring 514, suction cup 515, first baffle plate 516, second baffle plate 517, first fixed ring sleeve 518 , fixed seat 519, movable limit plate 520, torsion spring 521,...

Embodiment 2

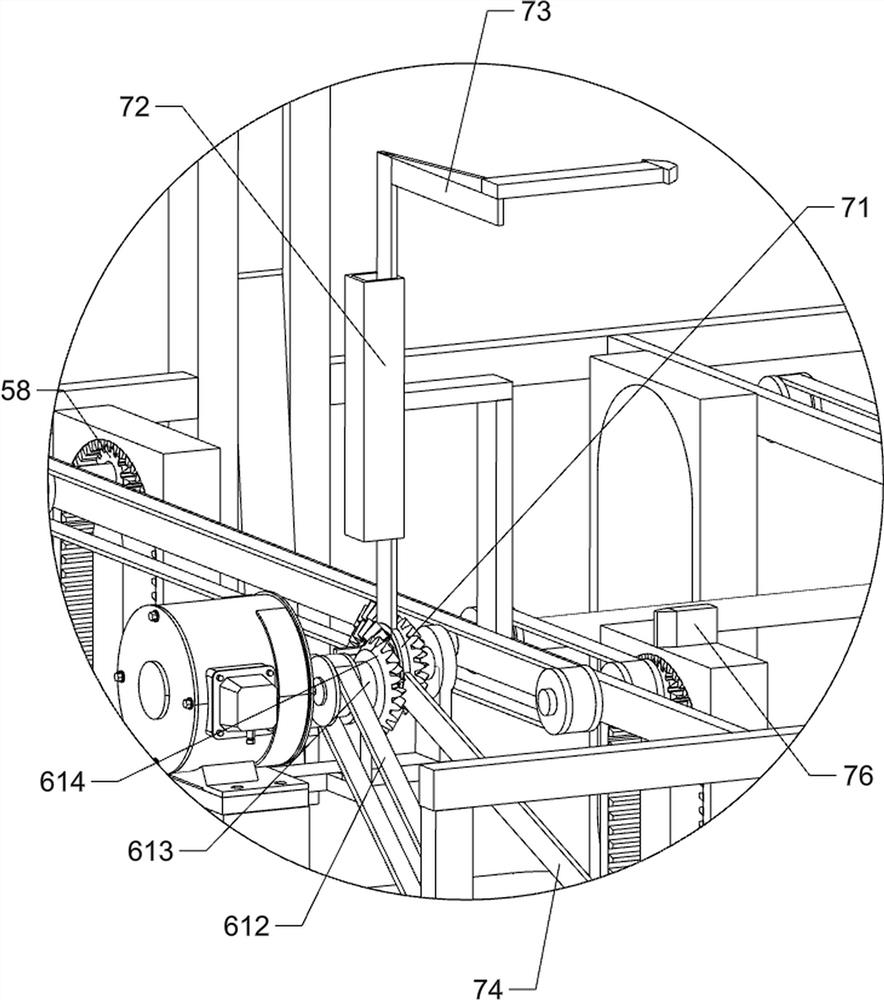

[0030] On the basis of Example 1, such as figure 1 , image 3 , Figure 6 and Figure 8 As shown, it also includes a power automatic switching mechanism 7, and the power automatic switching mechanism 7 includes a sliding collar 71, a fixed guide frame 72, a first push rod frame 73, a second push rod frame 74, a third fixed collar 75, Jack block 76 and ejector rod 77, the outer wall of double-sided bevel gear 52 is connected with sliding collar 71, and the front side of the top of installation frame 2 is connected with fixed guide frame 72, and the fixed guide frame 72 is slidingly connected with first push rod frame 73, The bottom of the first push rod frame 73 is connected with the top of the sliding collar 71, the right side of the sliding collar 71 is connected with the second push rod frame 74, the right side of the right rail frame 82 is connected with the third fixed collar 75, the second push The rod frame 74 is slidably connected in the third fixed collar 75, and th...

Embodiment 3

[0033] On the basis of Example 2, such as Figure 1-2 As shown, a reinforcement structure 8 is also included. The reinforcement structure 8 includes a slide block 81 and a guide rail frame 82. The left and right sides of the upper part of the installation frame 2 are connected with a guide rail frame 82, and the guide rail frame 82 is slidably connected with a slide block 81. The bottom of the slider 81 is connected to the top of the connecting frame 511 .

[0034] The connecting frame 511 can be guided by the guide rail frame 82 and the sliding block 81 to prevent the connecting frame 511 from shaking left and right when moving up and down, thereby facilitating demoulding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com