Hardware bathroom part forming mold and using method thereof

A technology for forming molds and hardware guards, which is applied in casting molding equipment, casting molds, cores, etc., can solve the problems of inconvenient demoulding treatment, general sealing of mold connection, etc., and achieve convenient demoulding work, good sealing, The effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

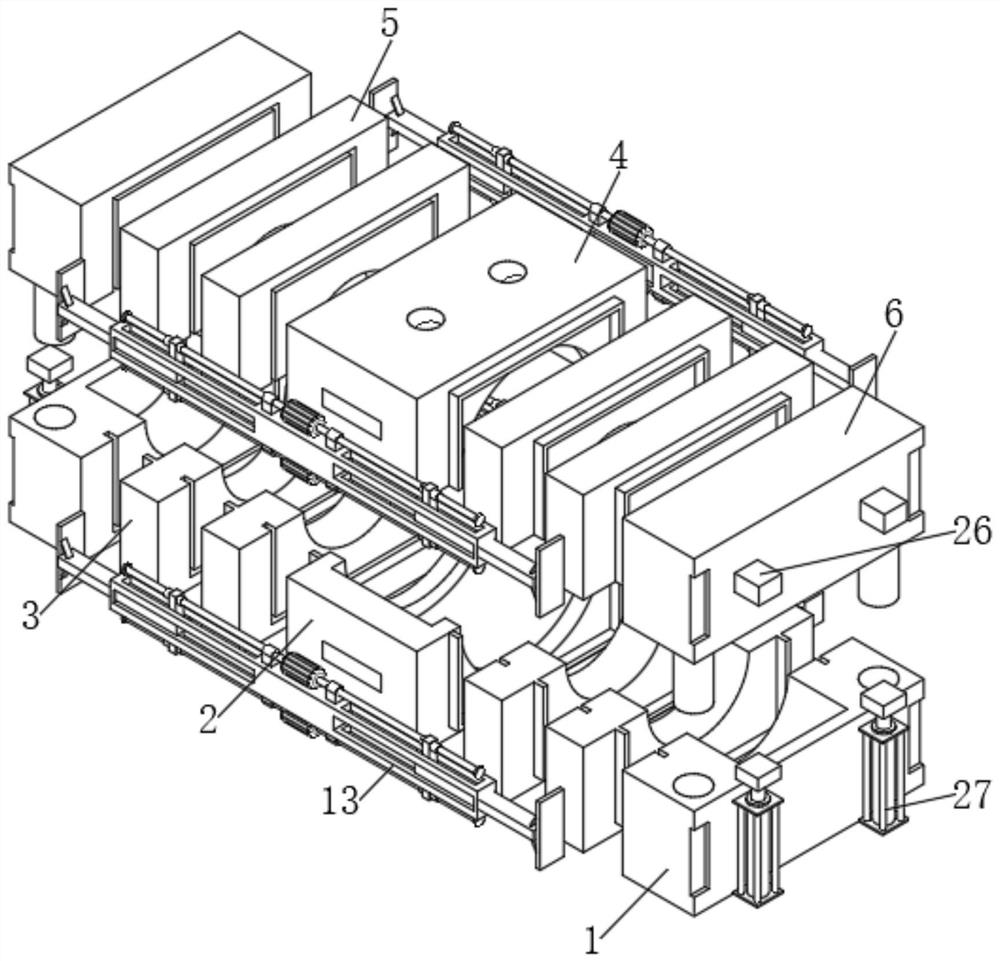

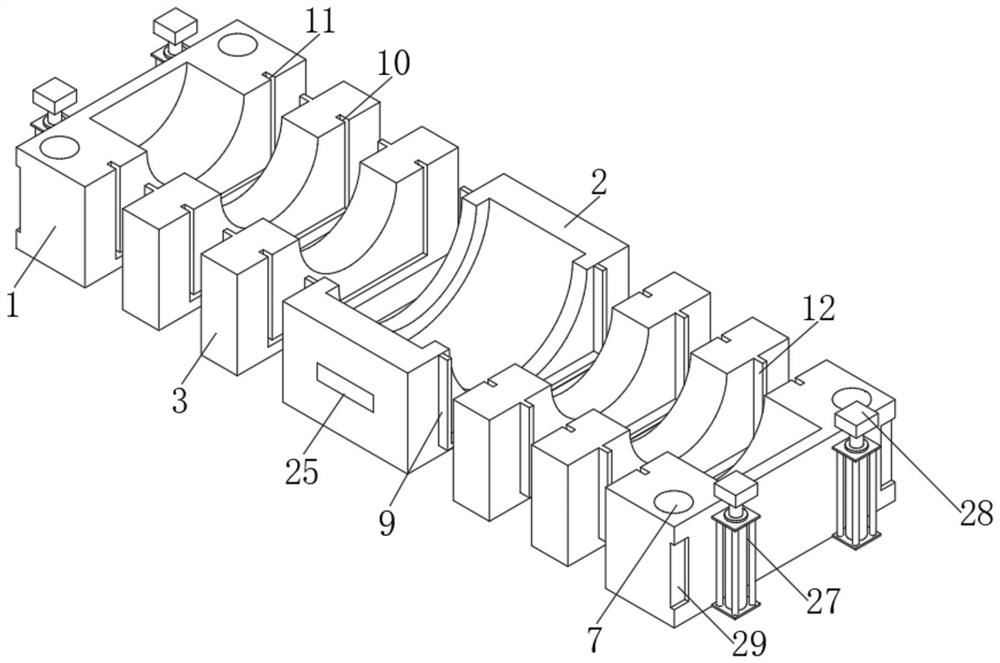

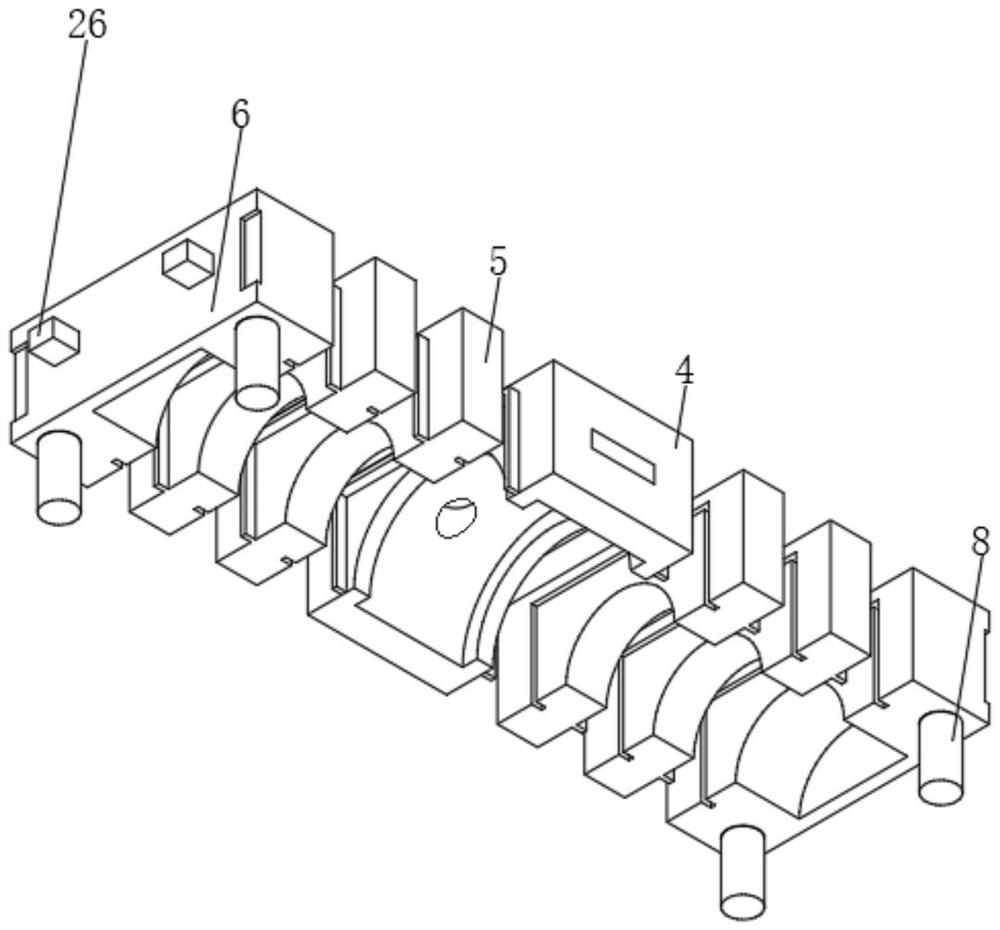

[0032] see Figure 1-5 , the present invention provides the following technical solutions: a mold for forming hardware and sanitary parts, including a lower end mold shell 1, a lower middle end mold shell 2, a lower shaft mold shell 3, an upper middle end mold shell 4, an upper shaft mold shell The shell 5 and the upper end mold shell 6, the upper end surface of the lower end mold shell 1 is provided with a docking socket 7, the lower end surface of the upper end mold shell 6 is fixedly connected with a docking insertion rod 8, and the lower middle end mold Both sides of the shell 2 and the upper and middle end formwork 4 are fixedly connected with first sealing inserts 9, and one side surface of the lower shaft formwork 3 and the upper shaft formwork 5 is provided with a first Sealing slot 10, one side surface of the lower end mold shell 1 and the upper end mold shell 6 are provided with a second sealing slot 11, the lower shaft mold shell 3 and the upper shaft mold shell 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com