Inverted cone led bracket step-by-step side push molding method

A technology of LED bracket and molding method, which is applied in the direction of molding tools, metal processing equipment, manufacturing tools, etc., to achieve the effects of avoiding interference wear and abnormal damage, high anti-aging light decay, and improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

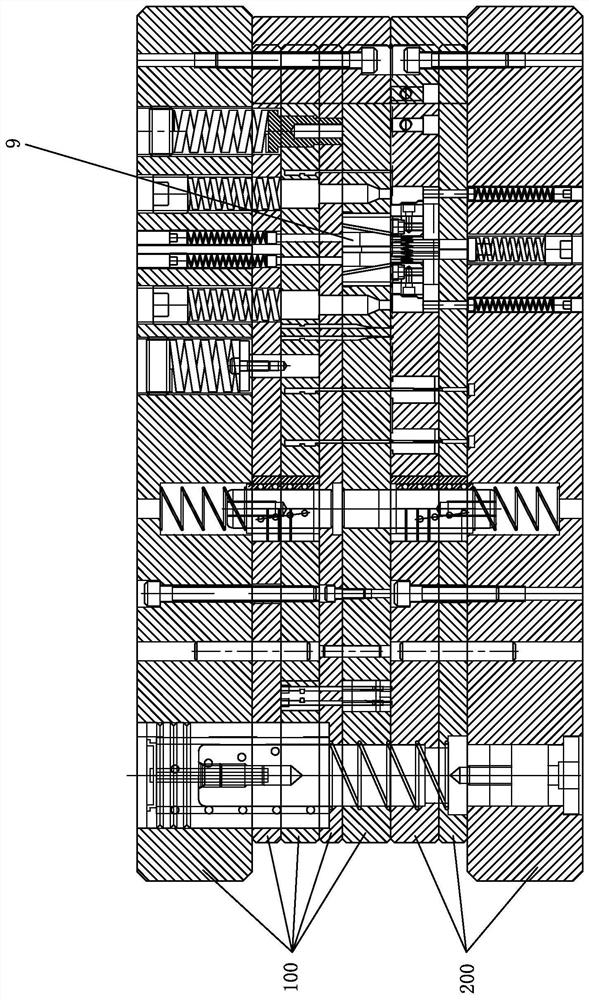

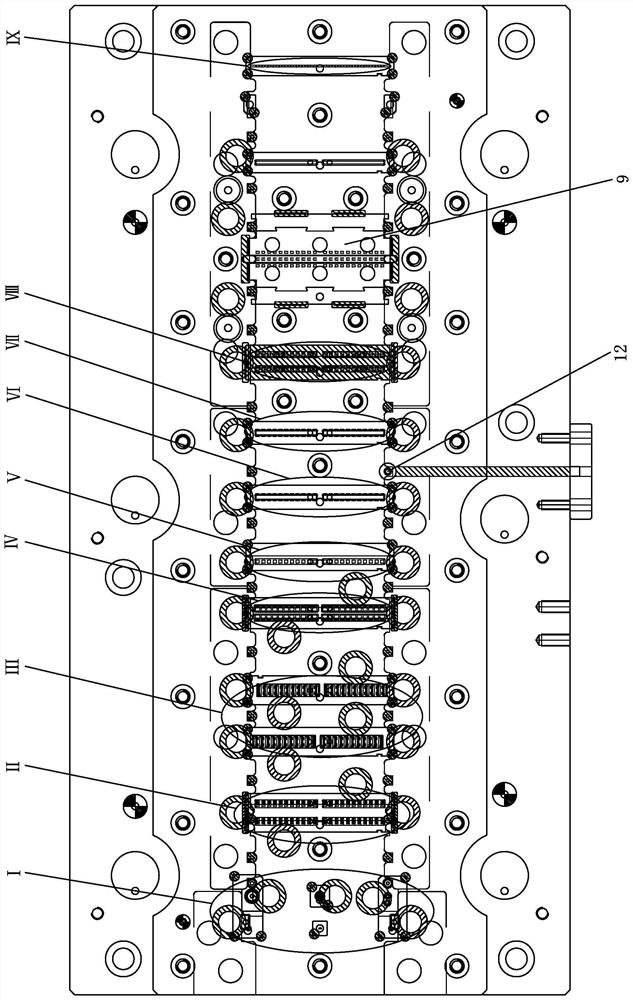

[0057] Such as Figure 1-23 As shown, the inverted cone LED bracket molding mold includes an upper die set 100 and a lower die set 200 that is compatible with the upper die set 100, and is located between the upper die set 100 and the lower die set 200 The inverted cone-type LED bracket pushes the molding structure step by step 9.

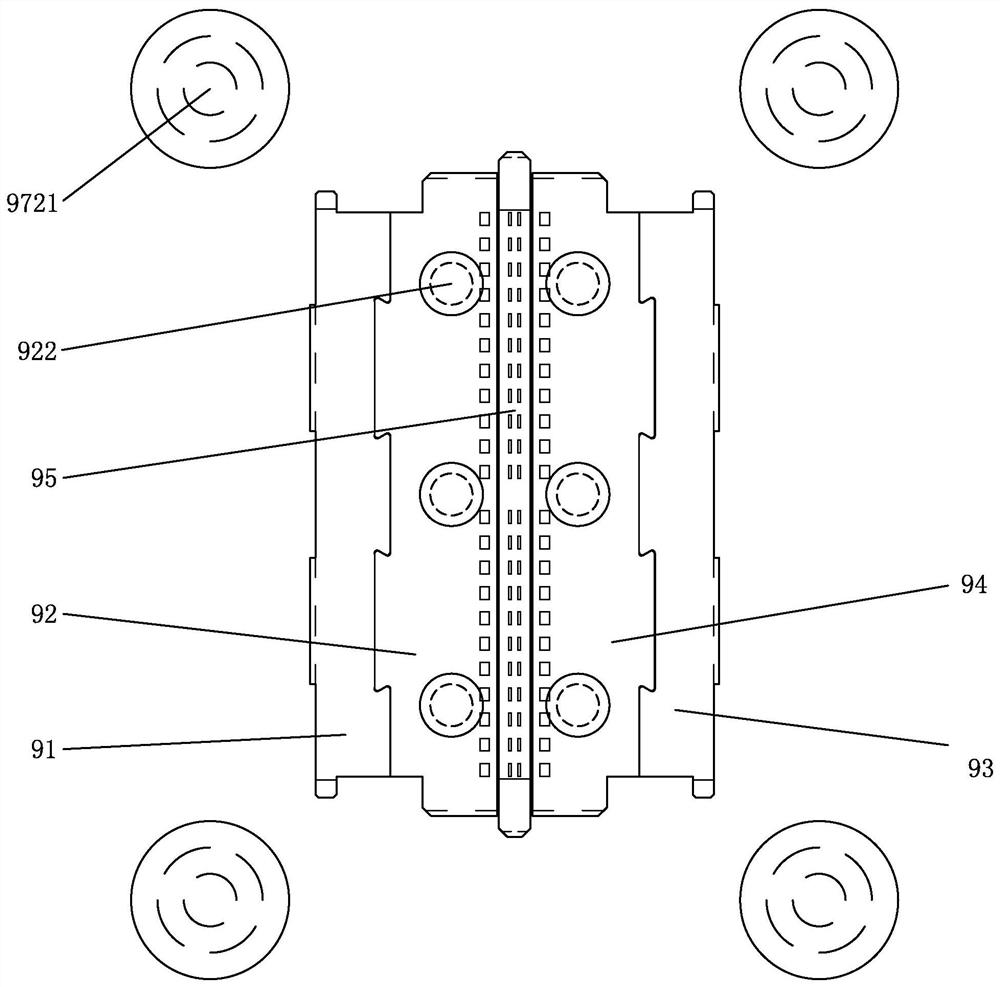

[0058] Specifically, the inverted cone-type LED bracket is pushed side by step, including an upper left slider seat 91, an upper left lower pressure group 92, an upper right slider seat 93, an upper right lower pressure group 94, an upper middle limit group 95. Lower middle upper top group 96. Left pushing group 97. Right pushing group 98. The upper left slider seat 91 is disposed on the upper die set 100 . The upper left lower pressing group 92 is arranged on the right side of the upper left slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com