Patents

Literature

38results about How to "Convenient pressing work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

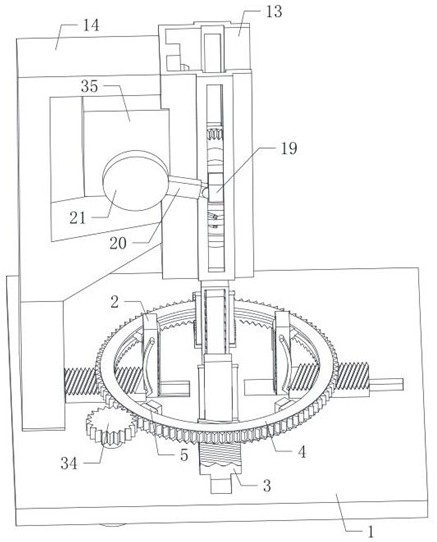

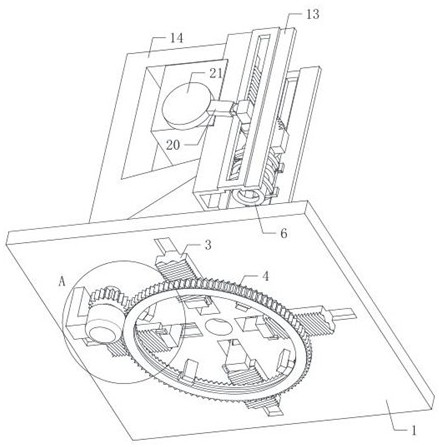

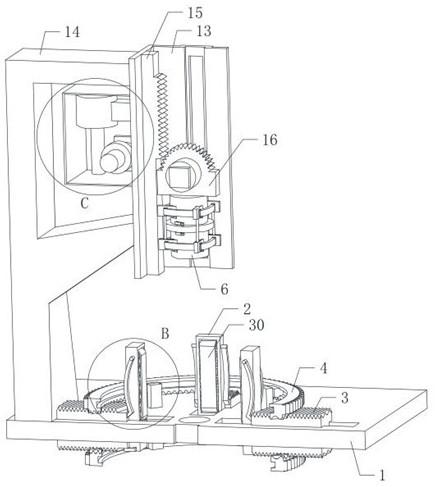

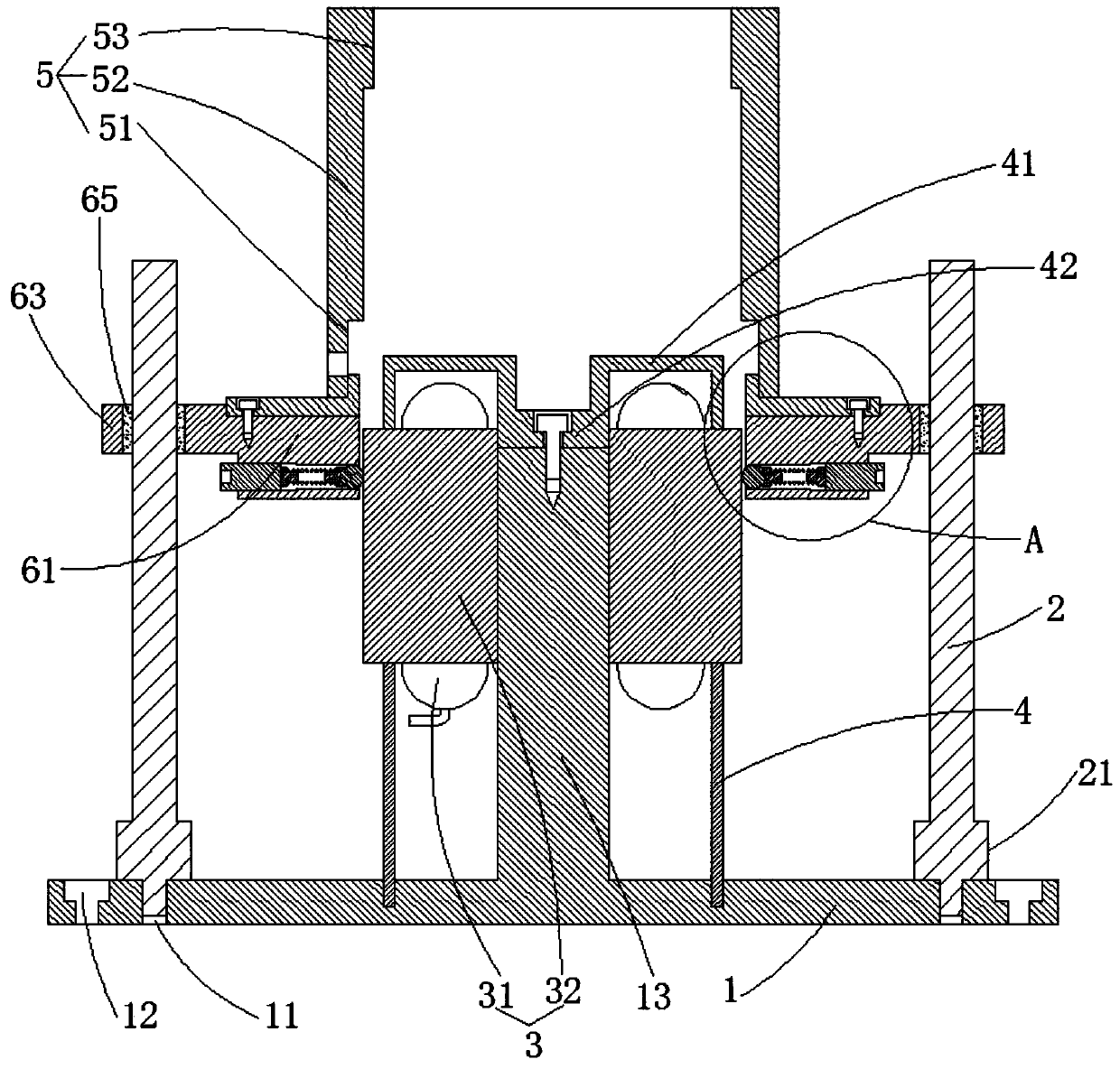

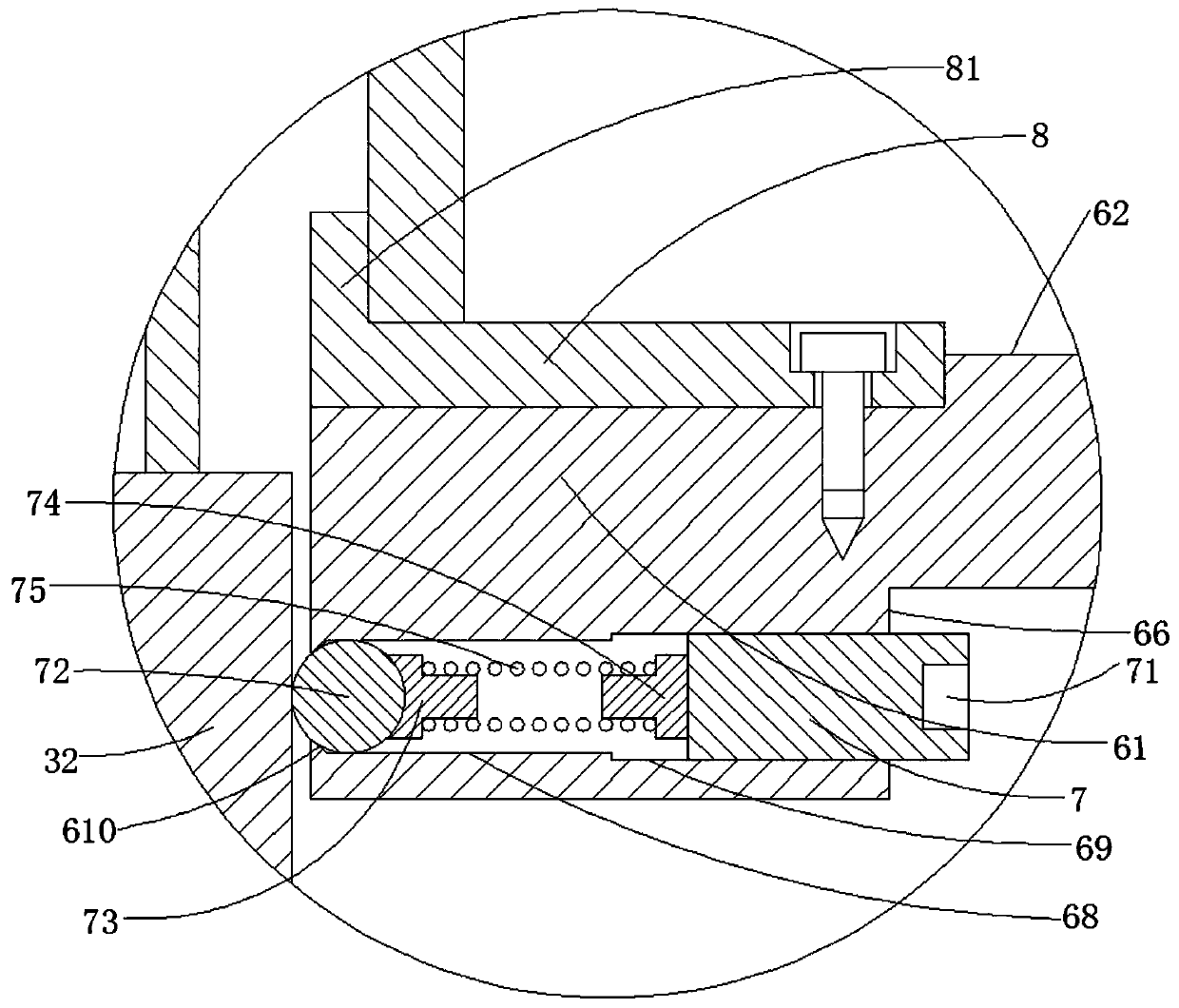

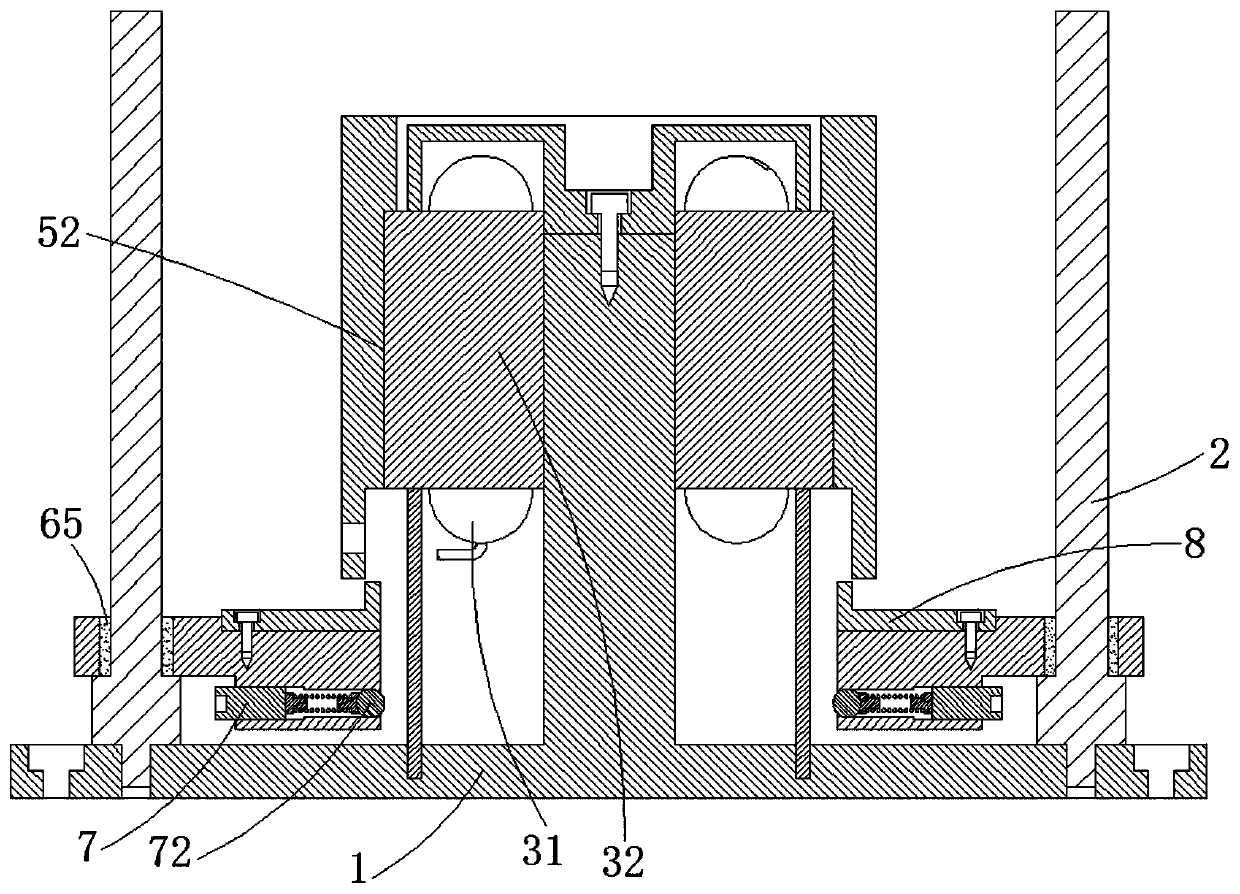

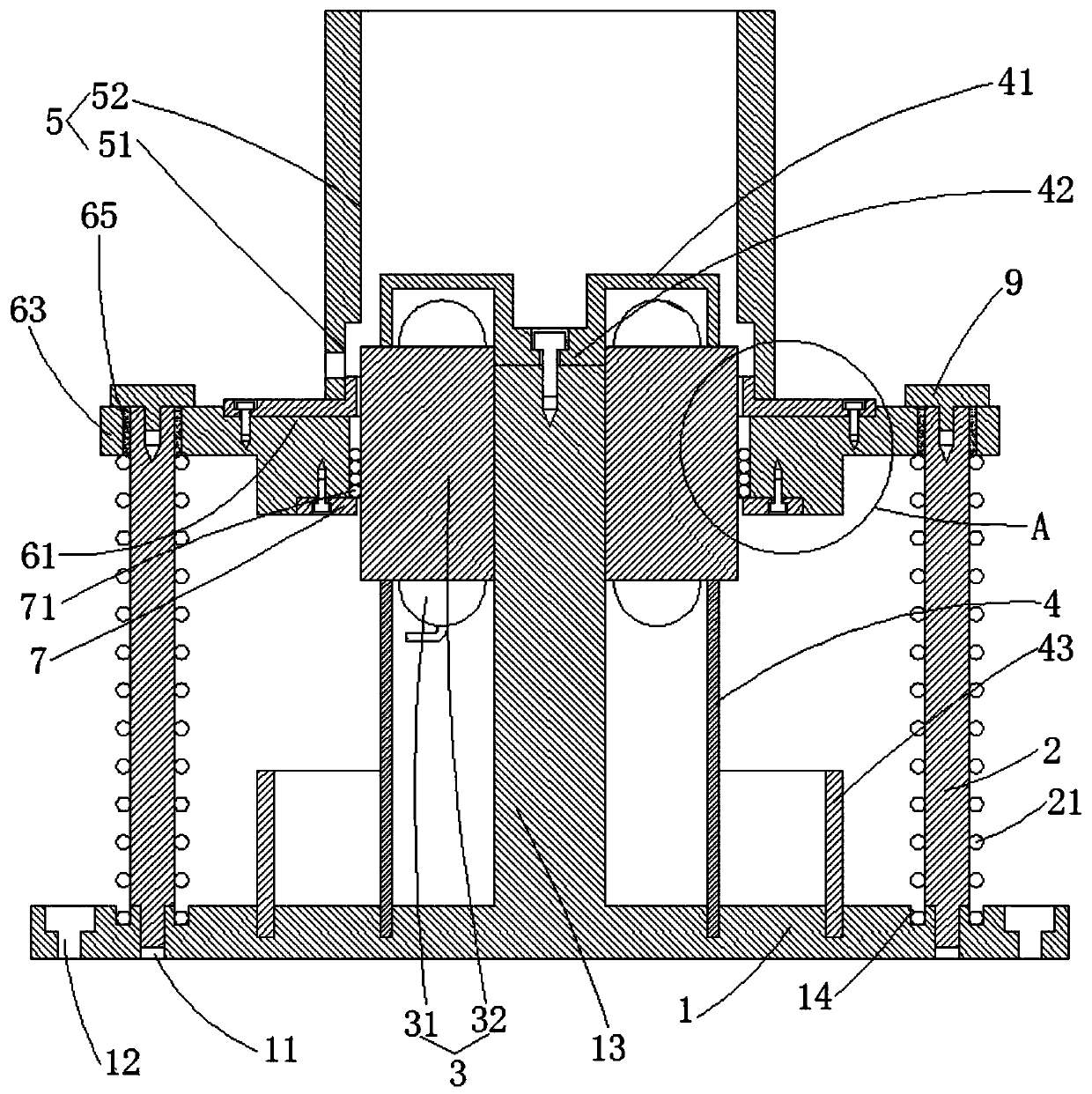

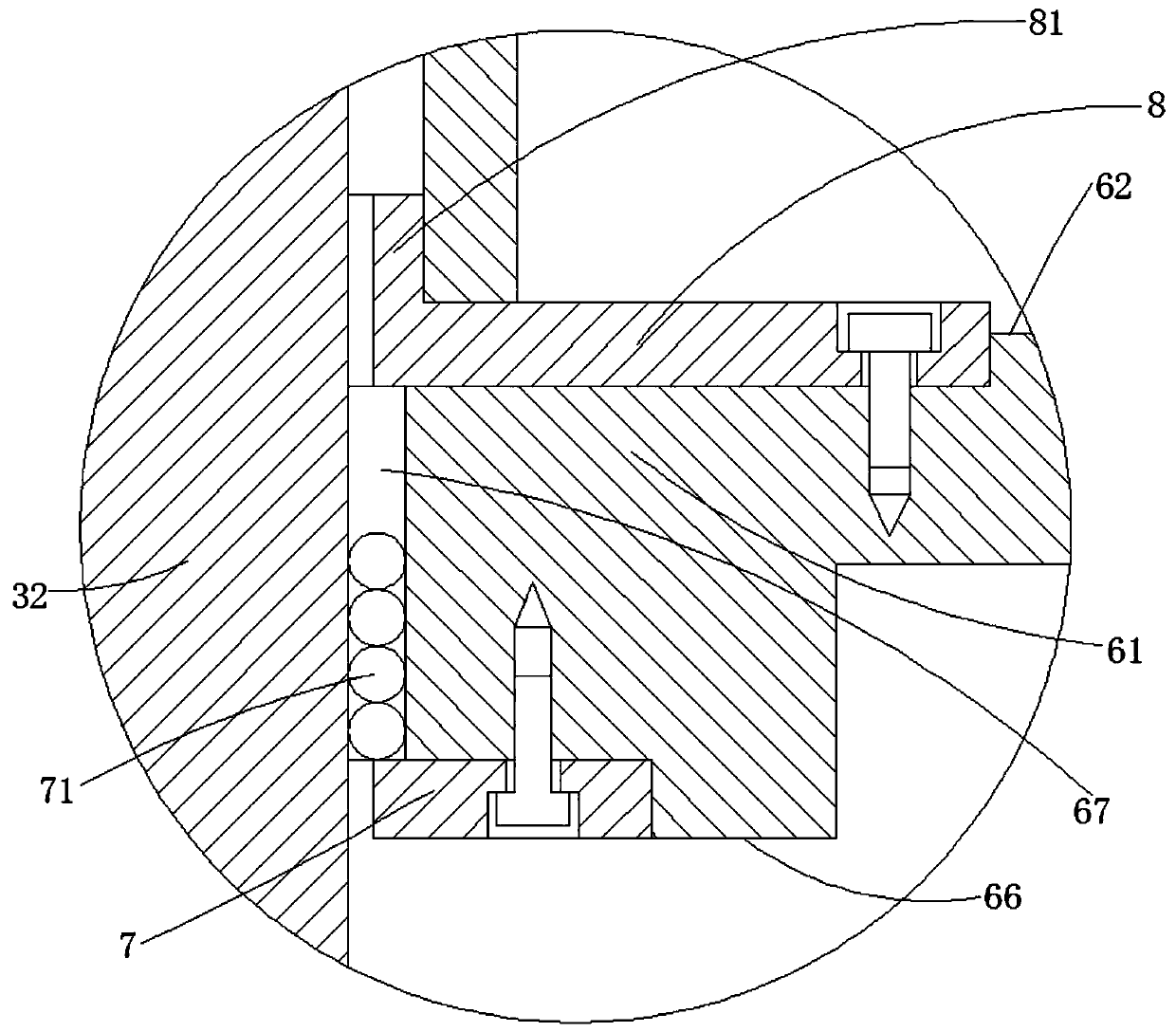

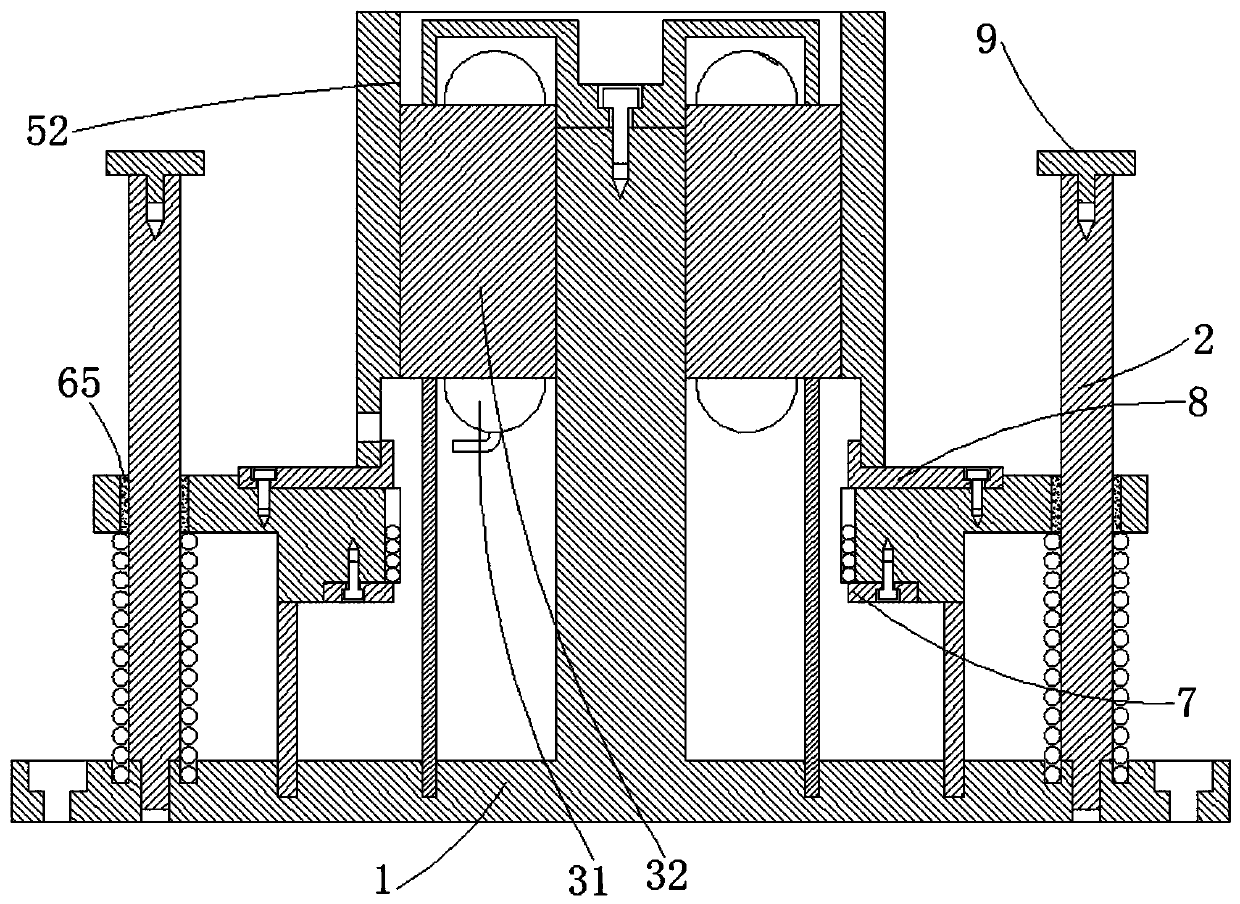

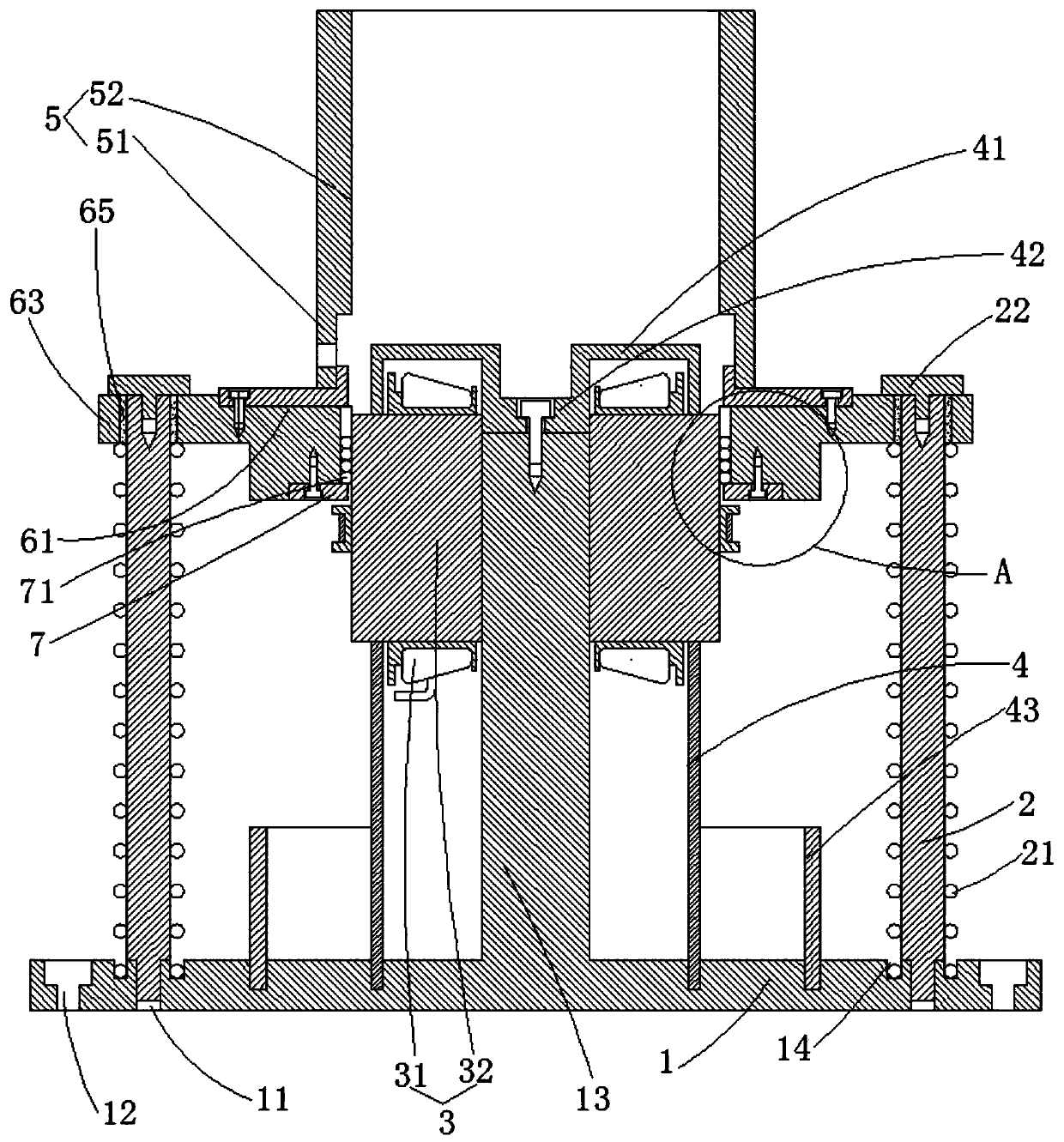

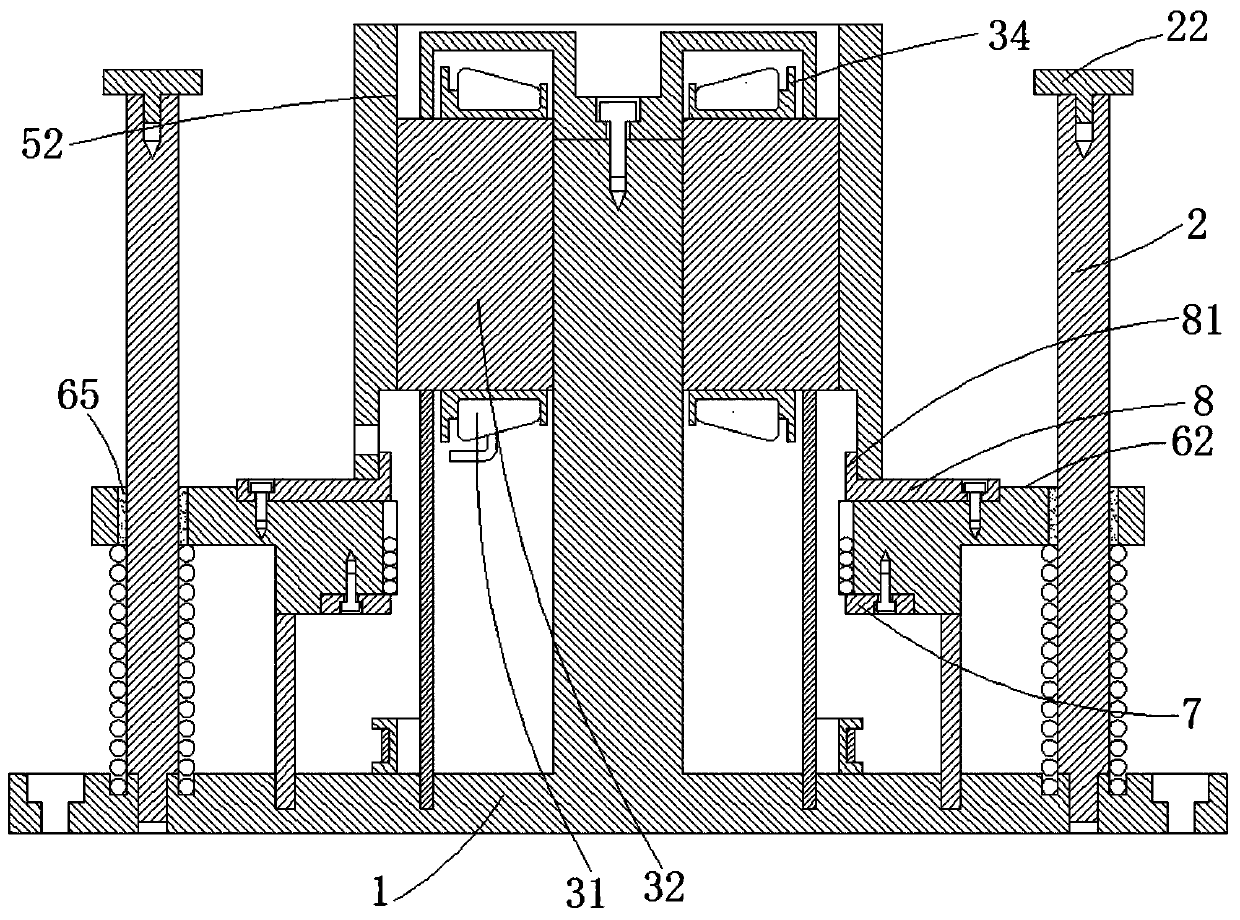

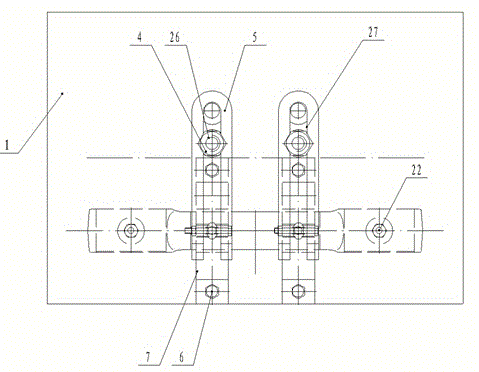

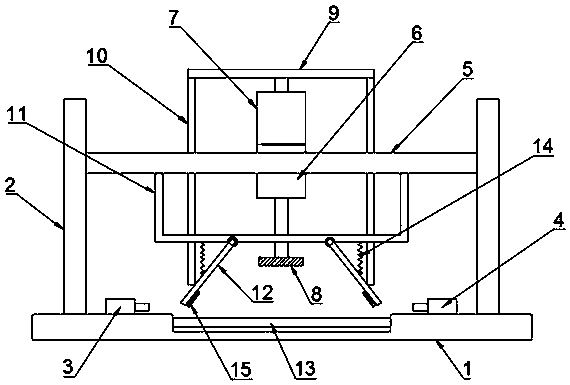

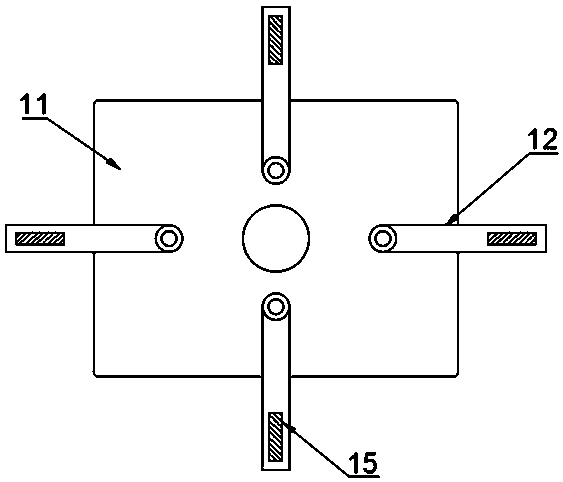

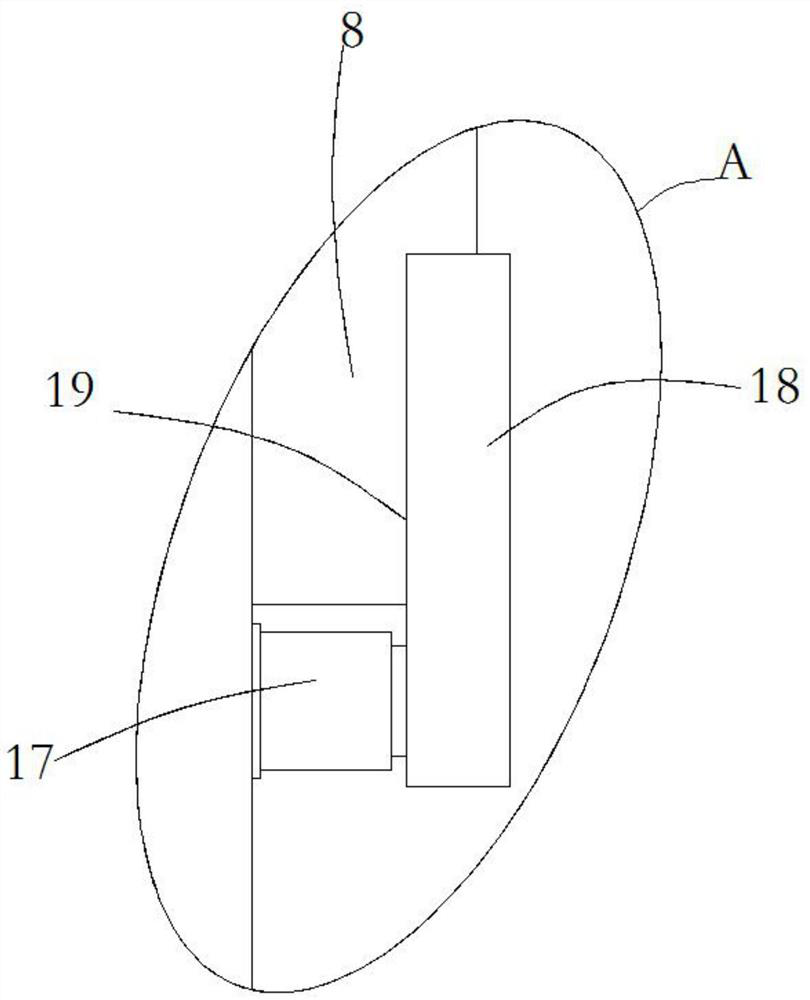

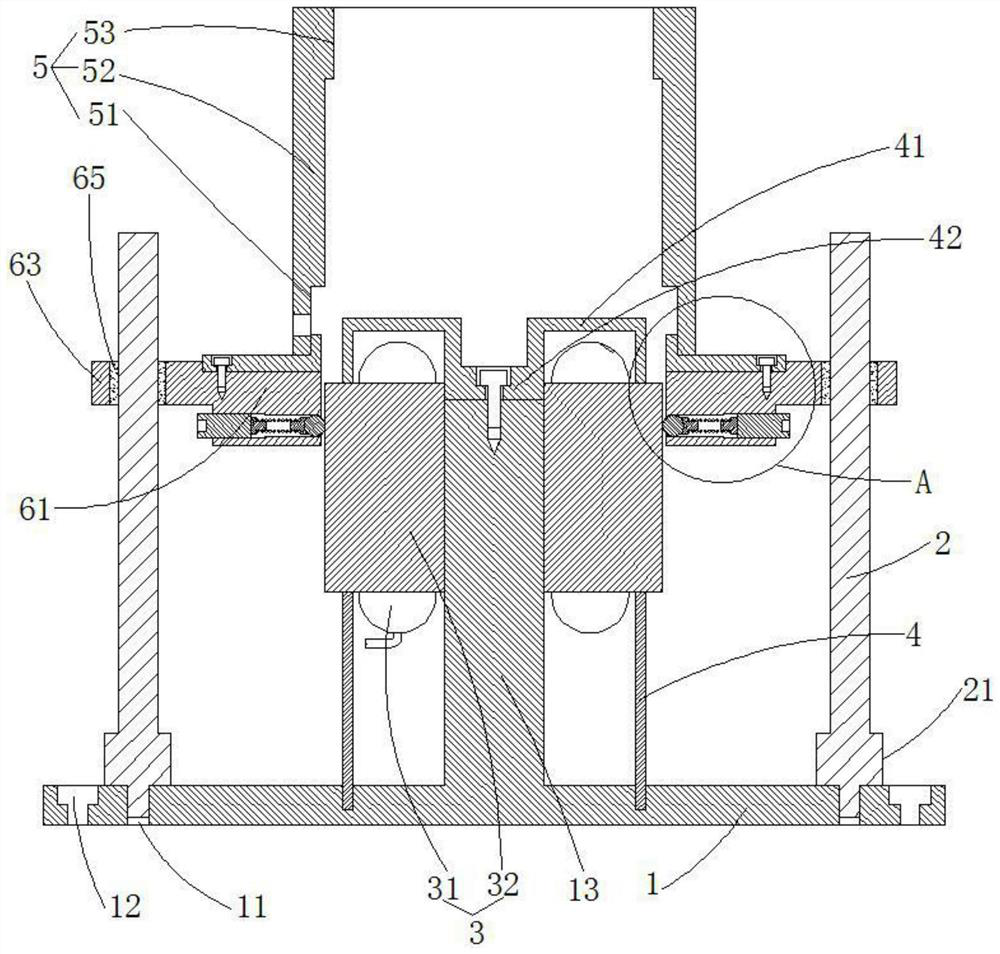

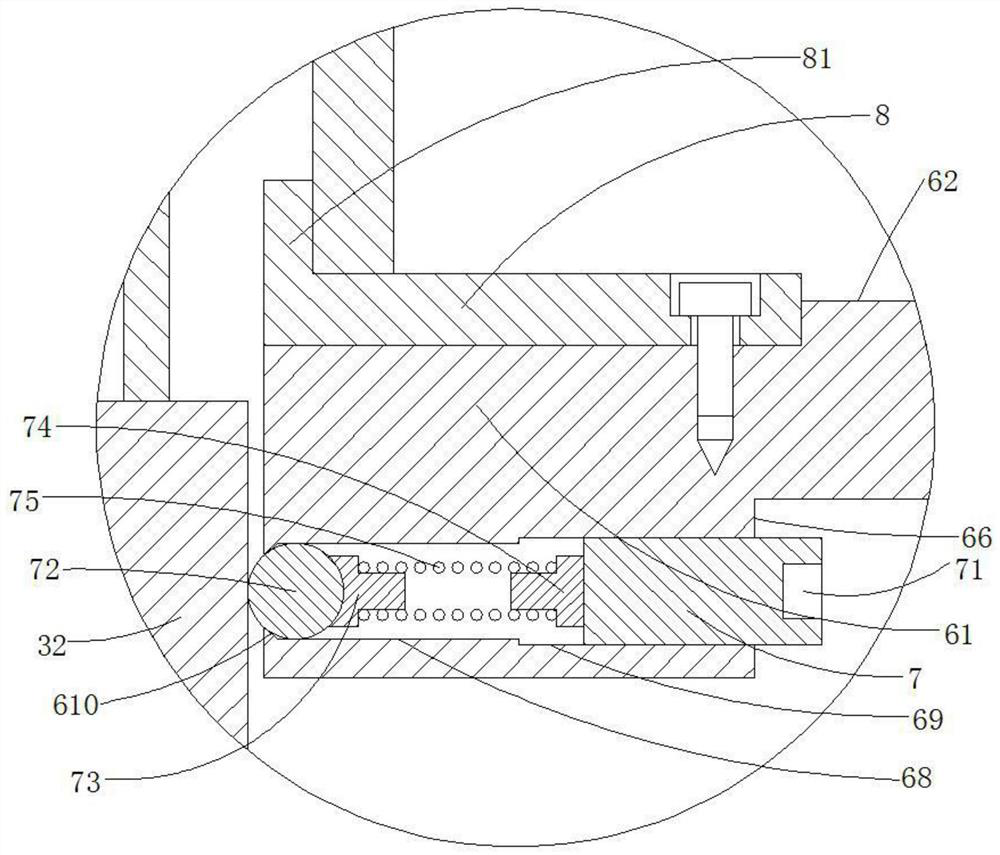

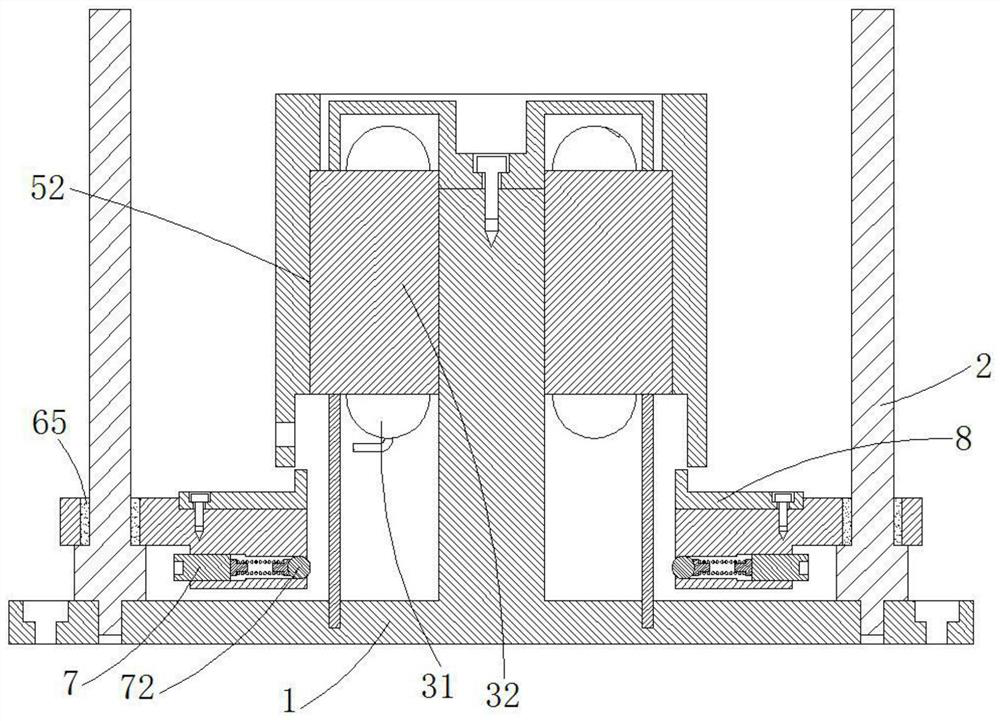

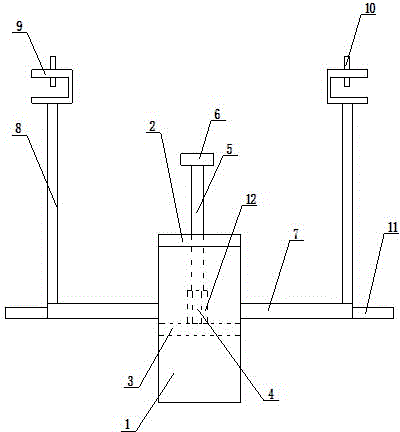

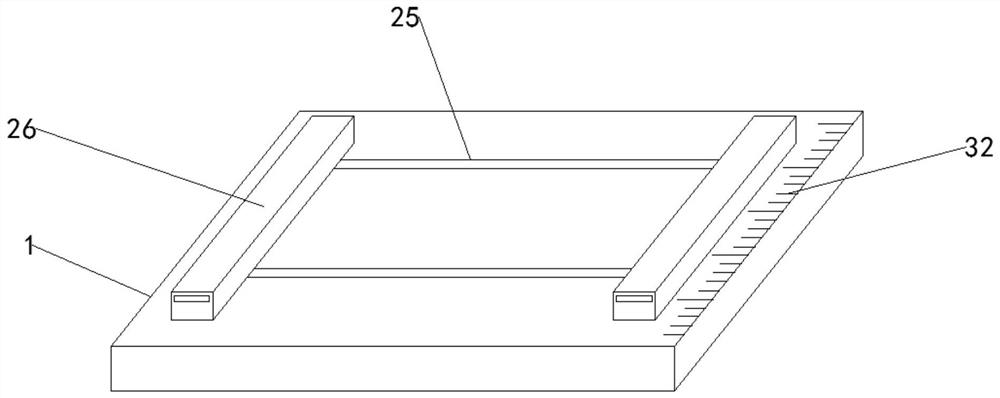

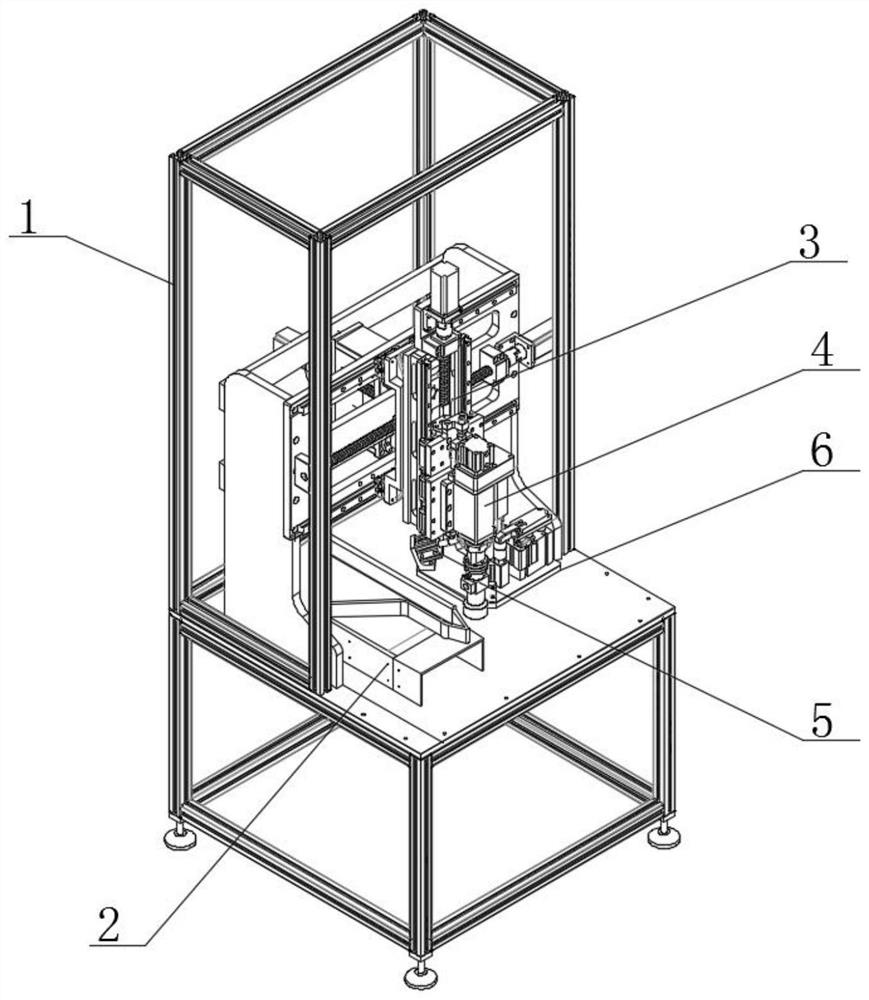

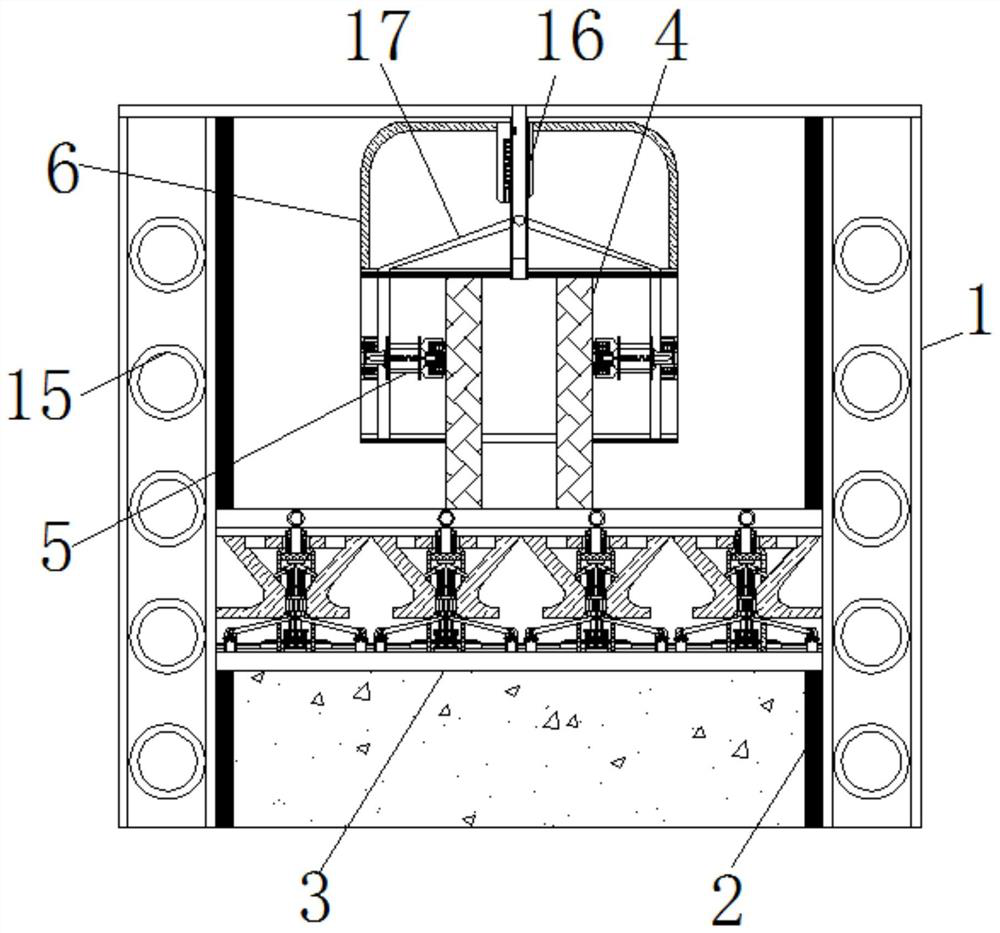

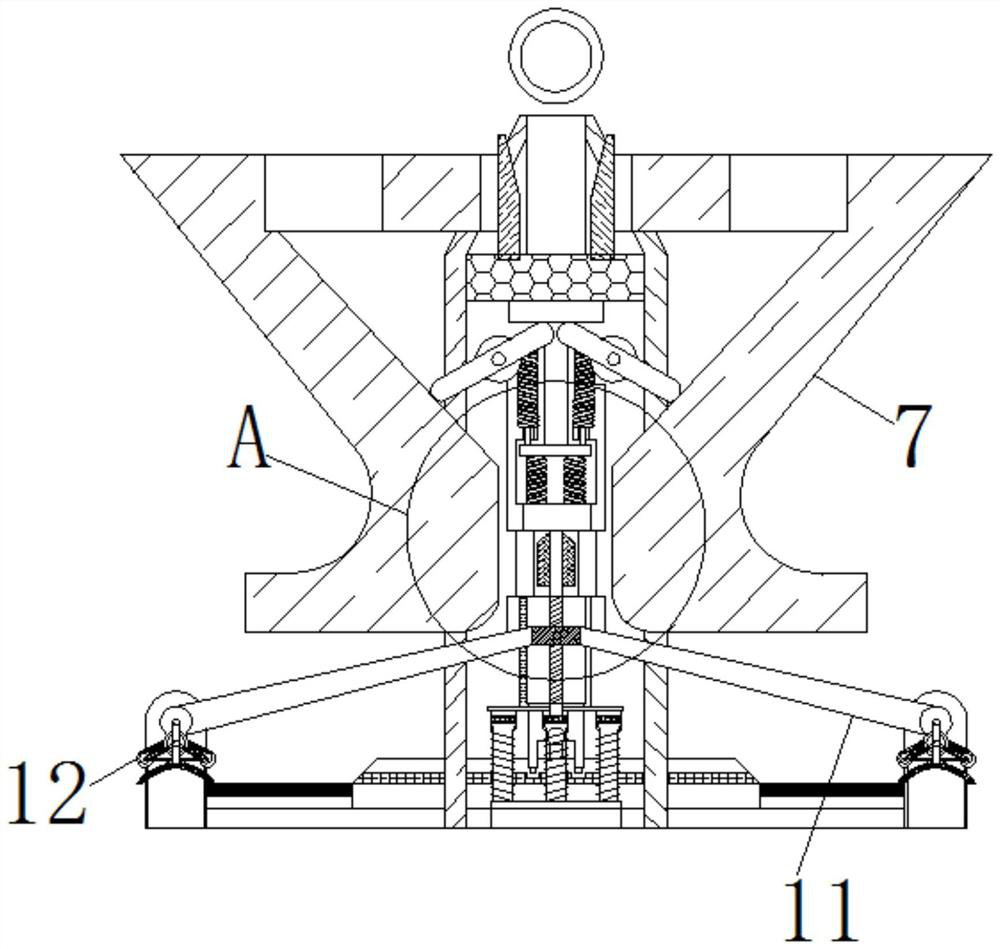

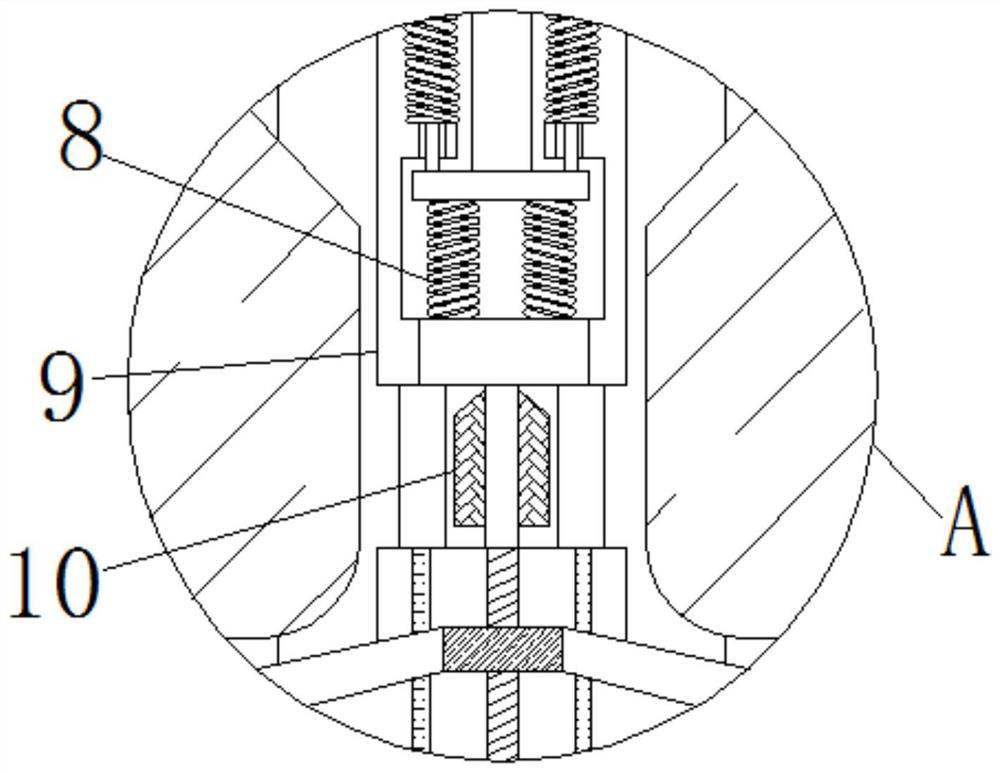

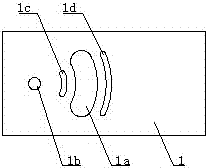

Three-phase asynchronous motor rotor mandrel press fitting device

ActiveCN114161116AImprove mobile stabilityHigh positioning accuracyWork holdersMetal working apparatusThree phase asynchronous motorElectric machine

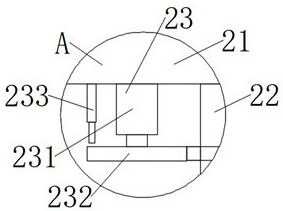

The invention relates to the technical field of motor press-fitting equipment, in particular to a three-phase asynchronous motor rotor mandrel press-fitting device which comprises a bottom plate, an auxiliary hole is formed in the middle of the bottom plate, and a plurality of through grooves are evenly formed in the bottom plate and distributed in an annular mode. The length direction of the through groove is along the radial direction of the process hole in the bottom plate; the multiple sets of clamping plates are kept in the vertical direction; the equipment can effectively improve the positioning precision of the iron core, the motor shaft and the iron core can be conveniently kept opposite in position, the situation that the motor shaft collides and damages the iron core when the distance deviation between the axis of the motor shaft and the axis of the iron core is large is avoided, parts are conveniently protected, the press-fitting precision of the equipment is improved, and the production efficiency is improved. And meanwhile, the iron core can be conveniently and synchronously fixed, the situation that the motor shaft cannot be normally pressed into the iron core due to sliding deviation of the iron core caused by stress during press fitting is avoided, the running stability of equipment is improved, and the practicability is improved.

Owner:山东瑞博电机有限公司

Processing method of particle board

InactiveCN106738180AEasy to demouldEven by forceFlat articlesDomestic articlesWood shavingsParticle board

The invention belongs to the technical field of artificial board production and particularly discloses a processing method of a particle board. The processing method comprises raw material preparation, screening, flaking, drying, storing, mixing, mould feeing, hot pressing and inspecting and storing, wherein in the step of hot pressing, a motor is started, a second rotation shaft rotates to generate down pressing force, a down-pressing block drives a hydraulic block to move downward together so as to push an up-pressing plate to move downward and down press a particle board and heating plates; meanwhile, the particle board is extruded between the heating plates to realize a pressing operation of the particle board; and after the pressing of the particle board, the motor is turned off, a flexible connector and a spring recover deformation to promote separation of the heating plates, and then the upper surface of the particle board is separated from the lower surface of the heating plate. The scheme provides a processing method of a particle board, wherein the pressing plate is under uniform stress, and the pressed particle board easily falls off and is not crushed.

Owner:重庆木园春木业有限公司

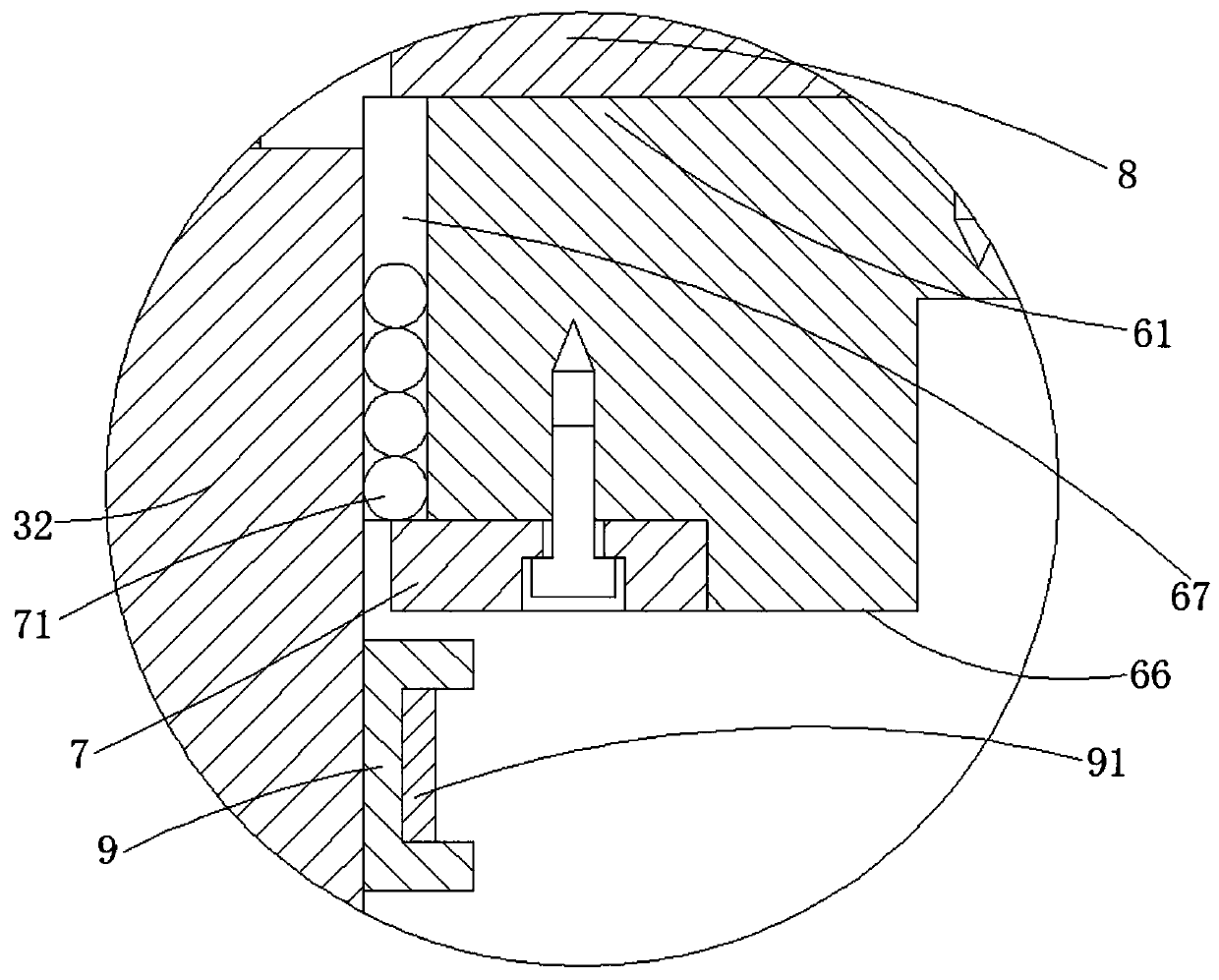

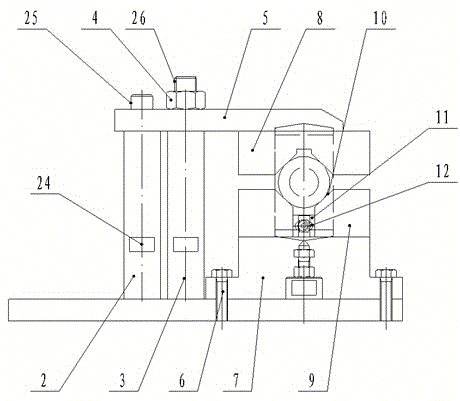

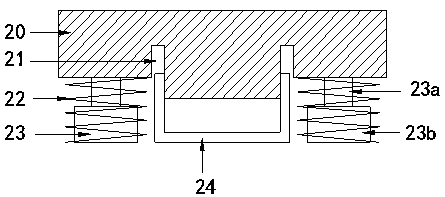

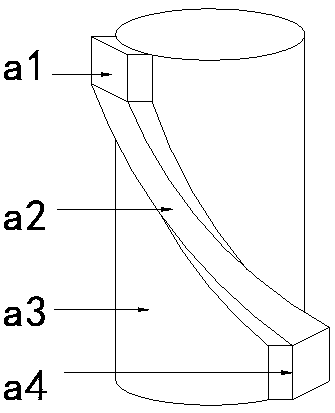

Assembling tool for shell and stator of direct drive motor

ActiveCN110571986AEasy to fixReliable concentric positioning accuracyManufacturing stator/rotor bodiesInterference fitDrive motor

The invention discloses an assembling tool for a shell and a stator of a direct drive motor. The assembling tool comprises a base, guide rods, a support ring and a guide ring. The upper end of the base is connected with the guide rods. A base boss is arranged in the center of the upper end face of the base. The support ring is installed on the upper end face of the base. A stator is attached to the outer wall of the base boss. The lower end face of the stator abuts against the support ring in an attached mode. The guide ring comprises a mounting table, and a mounting table lower bulge is formed on the lower end face of the mounting table. Lower bulge through holes penetrating through the inner and outer walls are formed in the mounting table lower bulge. The inner end of each lower bulge through hole abuts against a ball. The inner ends of the balls are exposed out of the lower bulge through holes and abut against the outer wall of the stator. A heat insulation ring is arranged on theupper end face of the mounting table, and the heat insulation ring abuts against the shell in an attached mode. The shell includes a second shell body matched with the stator. The shell is pressed downwards to drive the guide ring to be pressed downwards along with the guide rod so that the second shell body can be pressed into the outer wall of the stator in an interference fit manner. In the invention, the stator is fixed reliably and firmly, the temperature of the shell will not decrease rapidly, and the assembly of the shell and the stator is premise, reliable and efficient.

Owner:HENAN NORMAL UNIV

Convenient assembling auxiliary tool for casing and stator of direct-drive motor

ActiveCN110649770AEasy to fixReliable concentric positioning accuracyManufacturing stator/rotor bodiesInterference fitElectric machine

The invention discloses a convenient assembling auxiliary tool for a casing and a stator of a direct-drive motor. The convenient assembling auxiliary tool comprises a base, a guide rod, a supporting ring, a positioning ring and a guide ring. The upper end of the base is connected with the guide rod. A base boss is arranged at the upper end of the base. The supporting ring and the positioning ringare mounted at the upper end of the base. A stator is attached to the outer wall of the base boss. The lower end of the stator abuts against the supporting ring. The guide ring comprises a mounting table, arc-shaped through holes are uniformly distributed in the inner wall of the mounting table, and balls arranged up and down are attached into the arc-shaped through holes. A gland is installed onthe lower end face of the mounting table. The inner ends of the balls are exposed out of the arc-shaped through holes and abut against the outer wall of the stator. A heat insulation ring is arrangedat the upper end of the mounting table. The gland and the heat insulation ring limit the balls in the arc-shaped through holes between the gland and the heat insulation ring. The heat insulation ringabuts against the casing. The casing comprises a second shell, and the casing is pressed downwards to enable the second shell to be pressed into the stator in an interference fit mode. According to the invention, the stator is fixed reliably and firmly, the temperature of the casing cannot be reduced rapidly, and the casing and the stator are assembled accurately and reliably with high efficiency.

Owner:HENAN NORMAL UNIV

Apparatus for sticking and pressing surface sticker of liquor box

InactiveCN111645360AGlue evenly distributedEasy to applyBox making operationsPaper-makingAir bubbleWorkbench

The invention relates to the technical field of bonding of wine box cardboards and stickers, and discloses an apparatus for sticking and pressing a surface sticker of a liquor box. The apparatus comprises a worktable; the middle part of the worktable is provided with a conveying belt; the front and rear ends of the top of the worktable are each provided with a vertical plate; a top plate is installed at the tops of the two vertical plates; a glue containing box is fixedly installed at the top of the top plate; the bottom of the glue containing box communicates with a glue guide pipe; the bottom end of the glue lead pipe penetrates through and extends to the lower direction of the top plate; a fixed plate is fixedly installed at the bottom of the top plate; the fixed plate is provided witha glue feeding mechanism; a first cylinder is fixedly installed at the right end of the bottom of the top plate; a pressing plate is fixedly installed at an output shaft of the first cylinder; and a brush plate is fixedly installed at the bottom of the top plate through a vertical rod. The apparatus disclosed by the invention solves the problems that the existing manufacturing of a wine box and the bonding of a sticker and a paper box are both implemented manually, swelling and air bubbles are easily generated, the quality is not guaranteed, meanwhile the production efficiency is low, the amount of workers is high and the cost is relatively high.

Owner:泉州台商投资区源平信息技术有限公司

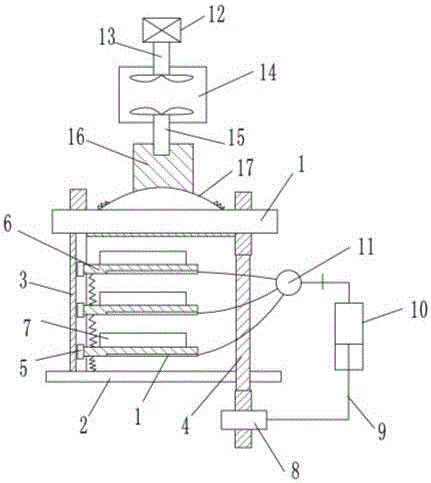

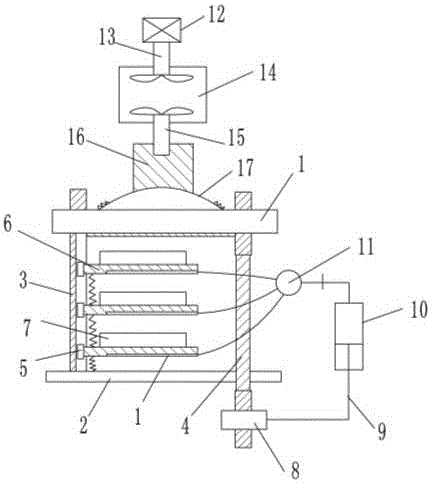

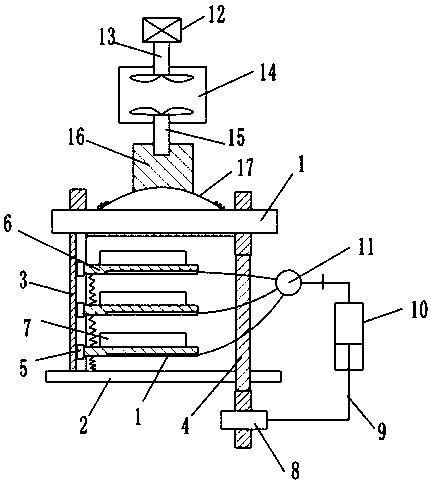

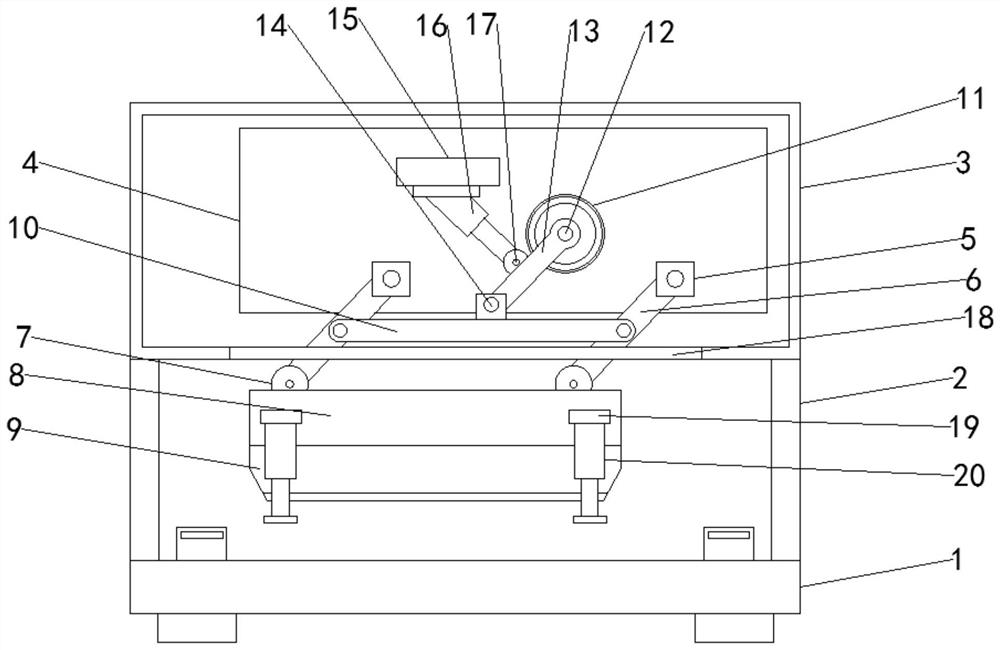

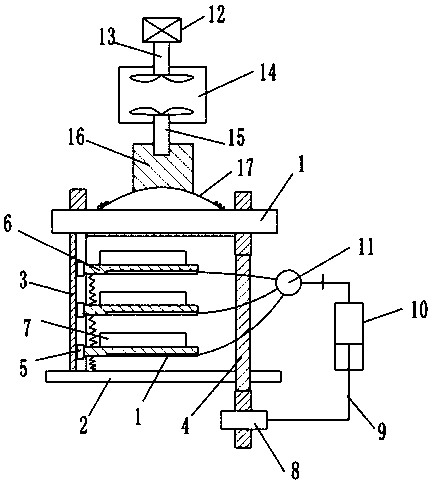

Hot press with demolding function

InactiveCN106827120AEven by forceConvenient pressing workPlywood pressesVeneer pressesMechanical engineeringWater tanks

The invention belongs to the field of presses, and particularly discloses a hot press with the demolding function. The hot press comprises an upper pressing plate and a fixing plate; the two ends of the upper pressing plate are connected with a first supporting frame and a second supporting frame in a sliding mode respectively; a plurality of sliding blocks are arranged in the first supporting frame; heating plates are arranged on the sliding blocks and are connected through springs; a motor is arranged above the upper pressing plate and is fixedly connected to a first rotating shaft, and the first rotating shaft is rotationally connected to a water tank; the water tank is rotationally connected to a second rotating shaft; a plurality of blades are arranged on the opposite ends of the first rotating shaft and the second rotating shaft; the second rotating shaft is fixedly connected to a lower pressing block; a hydraulic block is arranged at the bottom of the lower pressing block; a hollow cavity is formed in the hydraulic block; and the two ends of the hydraulic block are fixedly connected to the upper pressing plate through flexible connecting pieces. The invention provides the hot press with the demolding function. The hot press with the demolding function has the advantages that the upper pressing plate is stressed uniformly, and a plate is easy to demold and can be kept from being crushed.

Owner:重庆木园春木业有限公司

Convenient assembling auxiliary tool for case and stator of servo motor

ActiveCN110545015AReliable positioning accuracyEasy to operateManufacturing stator/rotor bodiesStatorEngineering

Owner:HENAN NORMAL UNIV

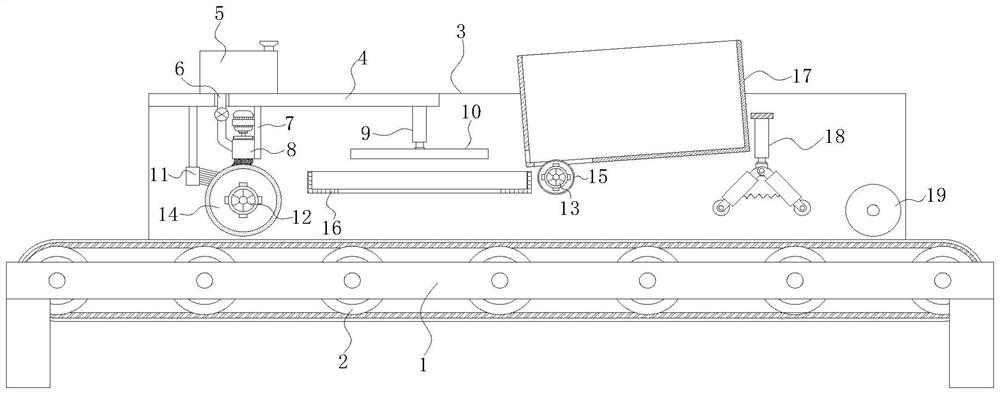

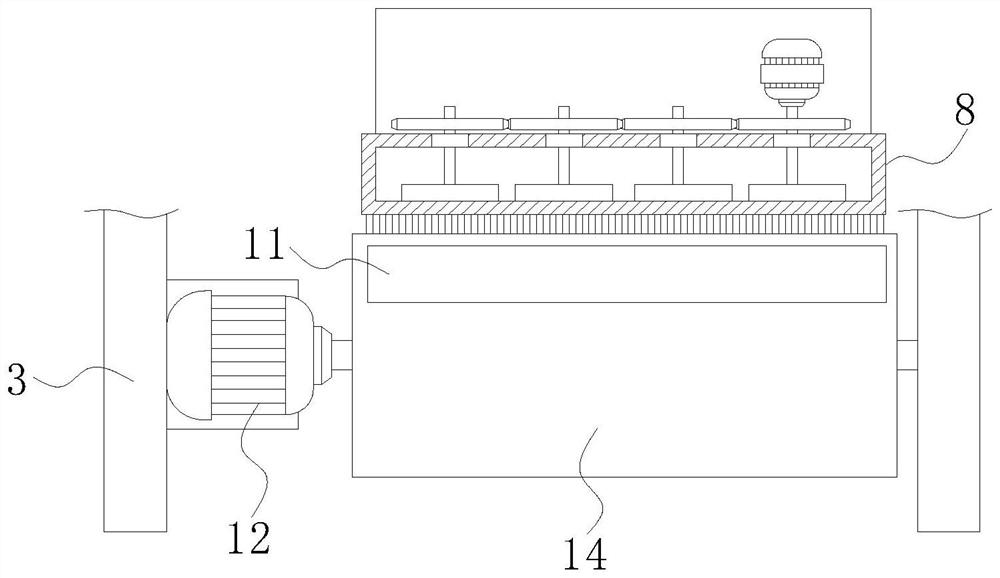

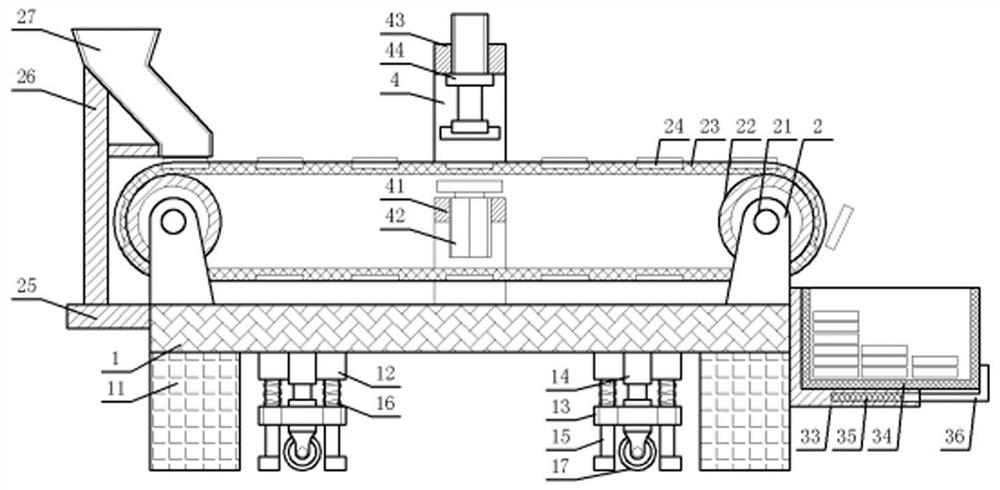

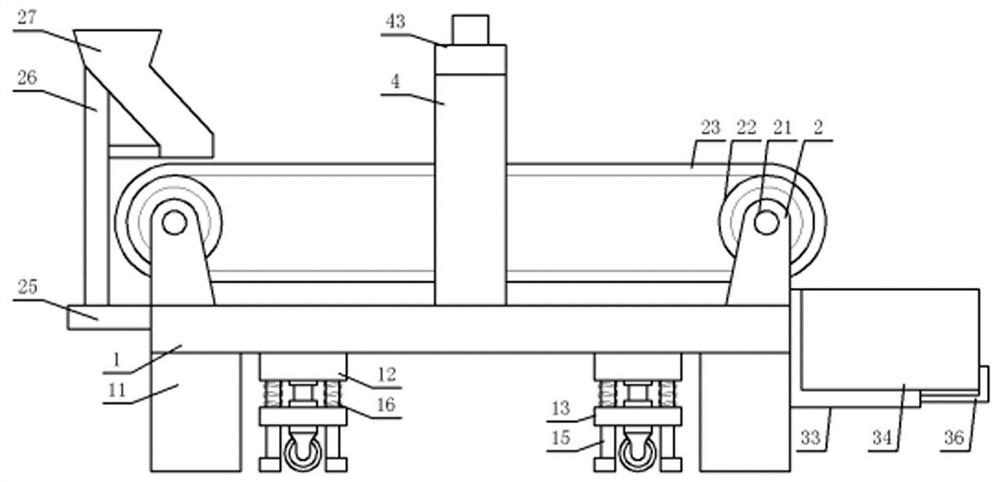

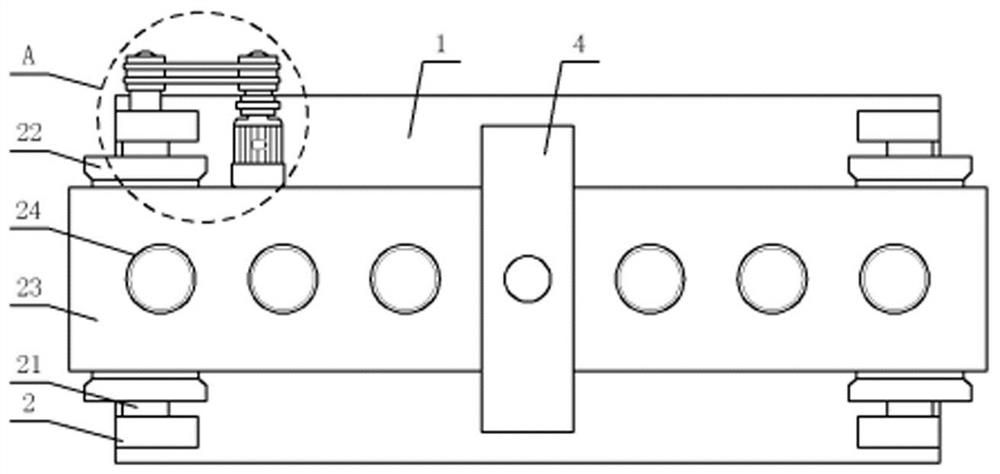

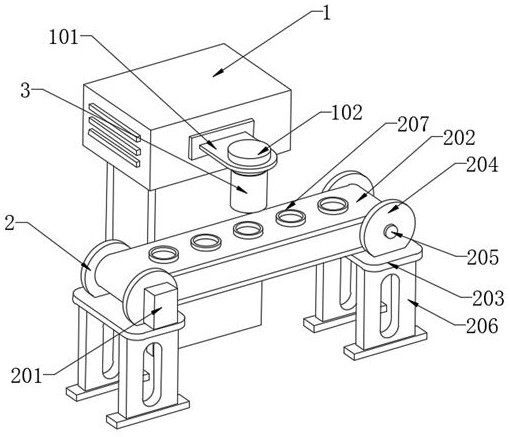

Merging equipment for semiconductor graphite production and processing and merging method thereof

The merging equipment comprises a bottom plate, supporting assemblies, a conveying belt, a feeding assembly, a discharging assembly and a pressing mechanism, the bottom is located on the inner side ofeach supporting base, the supporting assemblies are arranged on the bottom surface of the bottom plate, each roller shaft is sleeved with a roller, and the front end and the rear end of the conveyingbelt are sleeved with the corresponding rollers correspondingly; a feeding assembly is installed on the bottom plate and located at the front end of the transmission belt, and a discharging assemblyis installed on the bottom plate and located at the rear end of the transmission belt. A pair of vertical plates is longitudinally arranged on the top face of the bottom plate and located on the two sides of the middle of the transmission belt, and a pressing mechanism is installed between the two vertical plates. The invention further discloses a merging method of the merging equipment for semiconductor graphite production and processing. According to the equipment, the problem that graphite flake feeding time intervals are not uniform is solved, through cooperative use of all mechanism assemblies, tedious operation steps are simplified, pressing forming of graphite flakes is facilitated, the graphite flake machining and combining speed is increased, and the graphite flake machining and combining efficiency is improved.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

A kind of processing method of chipboard

InactiveCN106738180BEven by forceConvenient pressing workDomestic articlesFlat articlesWood shavingsParticle board

Owner:重庆木园春木业有限公司

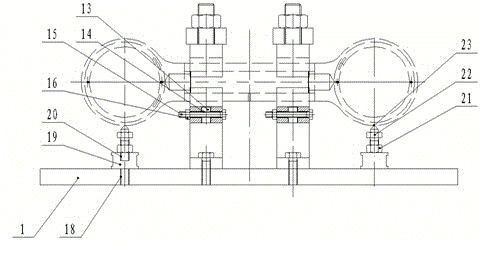

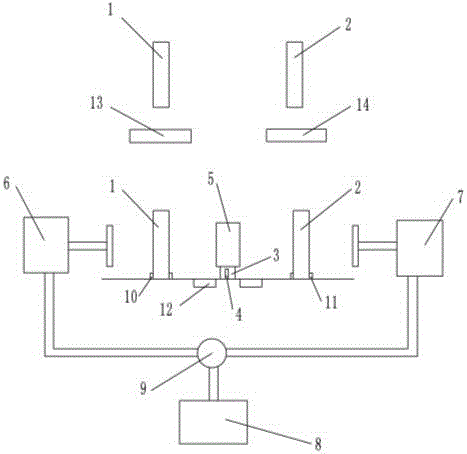

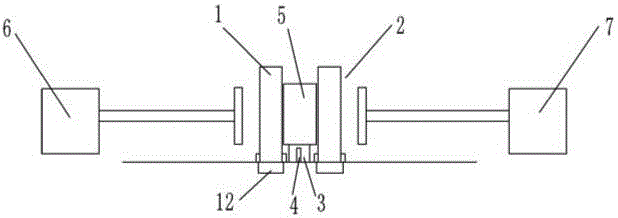

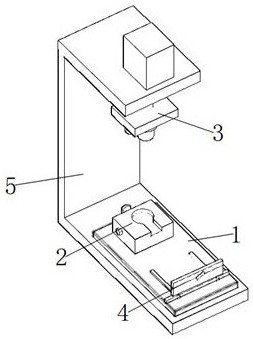

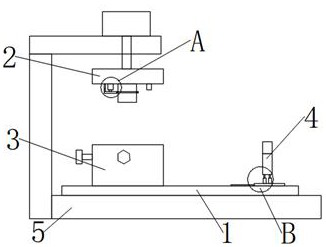

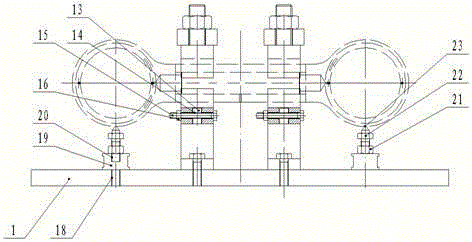

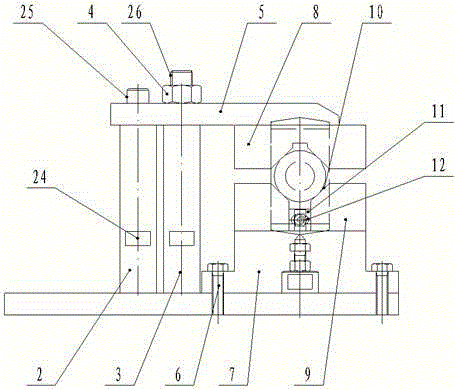

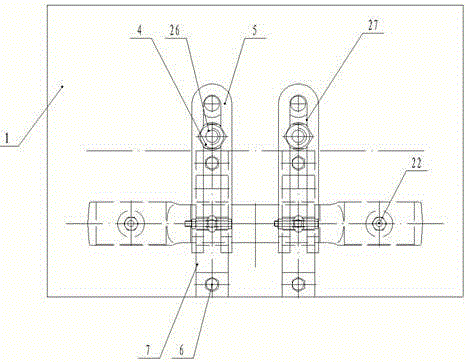

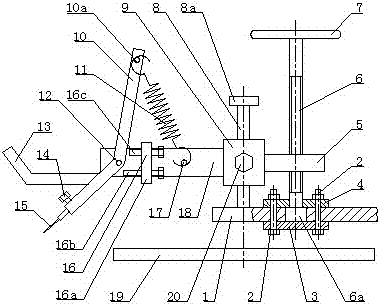

Pressing fixture for traction rod of rail vehicle

ActiveCN104084907ASimple structureConvenient pressing workWork holdersStructural engineeringMechanical engineering

The invention discloses a pressing fixture for a traction rod of a rail vehicle, which comprises a pressing device, a movable pressing device and a supporting device; a bottom plate, a supporting rod, a pressing rod, a locknut and a pressing plate are arranged on the pressing device; an upper V-shaped block, a lower V-shaped block, a lower supporting seat, a fixed bolt, a second locknut and an outer hexagon bolt are arranged on the movable pressing device; a supporting nut, a third locknut and a supporting bolt are arranged on the supporting device. The pressing fixture has the benefit that the structure is simple, the operation is convenient and practical, and the pressing fixture can be suitable for pressing any traction rod, has larger pressing force and can be automatically aligned through a step shaft and a first light hole, so that great convenience is brought to the pressing work, and much unnecessary alignment work in the previous work is greatly reduced.

Owner:CHUANLI ELECTRIC CO LTD

Press-fitting support of LED display screen built-in lamp tube press-mounting equipment

InactiveCN108705287AGuaranteed relativityPress work orderlyMetal working apparatusLED displayMaster controller

The invention discloses a press-fitting support of LED display screen built-in lamp tube press-mounting equipment. The press-fitting support comprises a workbench. A groove is formed in the upper sidewall of the workbench. A transmission mechanism is arranged in the groove. A transmission mechanism is arranged in the groove and comprises a conveying roller mounted in the groove. Two vertically-arranged supporting columns located on the two sides of the groove are fixedly connected to the upper side wall of the workbench. A mounting plate is fixedly connected between the two supporting columns. A mounting opening is formed on the mounting plate, and an air cylinder is mounted in the mounting opening. According to the press-fitting support, the conveying work of the conveying roller is controlled through connection of a through beam type photoelectric sensor and an external master controller, and the automation degree is high; through work of an electric telescopic rod, push rods move downwards to push limiting plates to be pushed inwards, an LED display screen located among the four limiting plates is pushed to move inwards, consistency of the position of a pressing block and the position of a lamp tube is guaranteed, and press-mounting work is facilitated; and manual operation is avoided, and convenience and practicality are achieved.

Owner:江苏君华光电科技有限公司

Hot press

InactiveCN106696015AHeating fastEven by forcePlywood pressesVeneer pressesHydraulic cylinderMechanical engineering

The invention belongs to the field of press equipment, and specifically discloses a hot press. The hot press comprises a first heating plate, a second heating plate and a working table, wherein a rail is arranged on the working table; the bottom of the working table is hinged with a movable plate; a first hydraulic cylinder and a second hydraulic cylinder are separately arranged at the two sides of the working table; each of the first hydraulic cylinder and the second hydraulic cylinder is equipped with a piston rod; a pushing plate is arranged on each piston rod; a first slide slot and a second slide slot are separately formed in the two sides of the rail; and a first high-frequency inducting heater and a second high-frequency inducting heater, which are opposite to the first slide slot and the second slide slot, are arranged above the first slide slot and the second slide slot. According to the scheme adopted by the invention, the invention provides the hot press which enables plate heating speed to be high and enables a plate to be not deformed.

Owner:重庆木园春木业有限公司

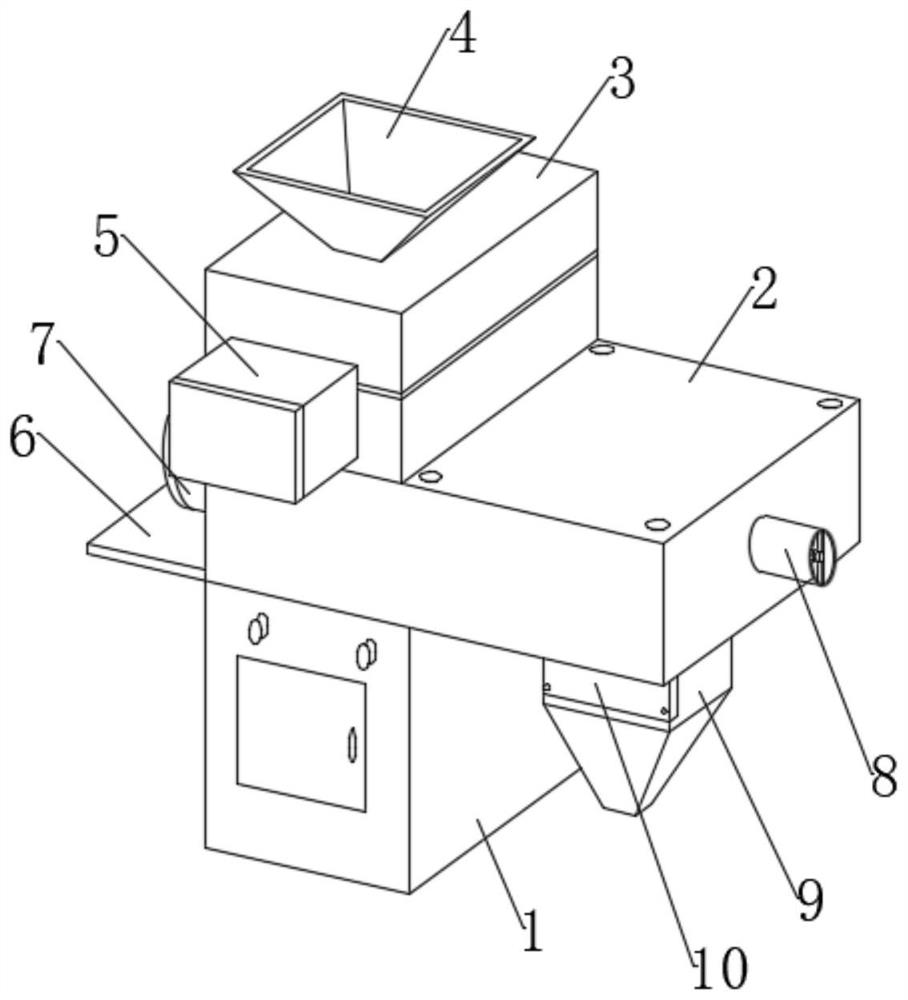

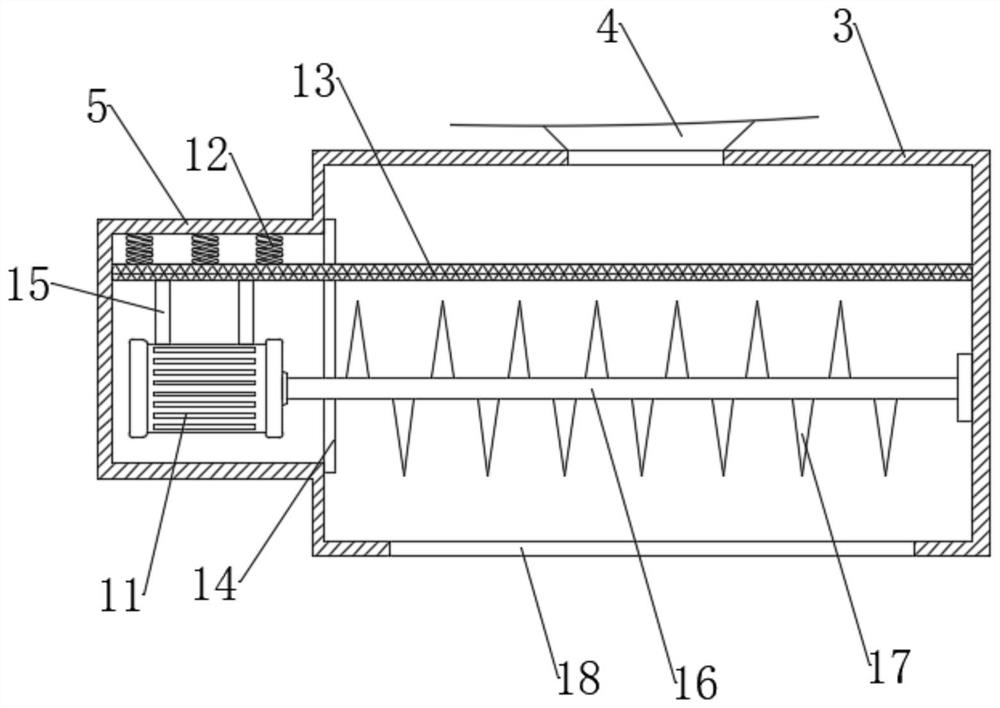

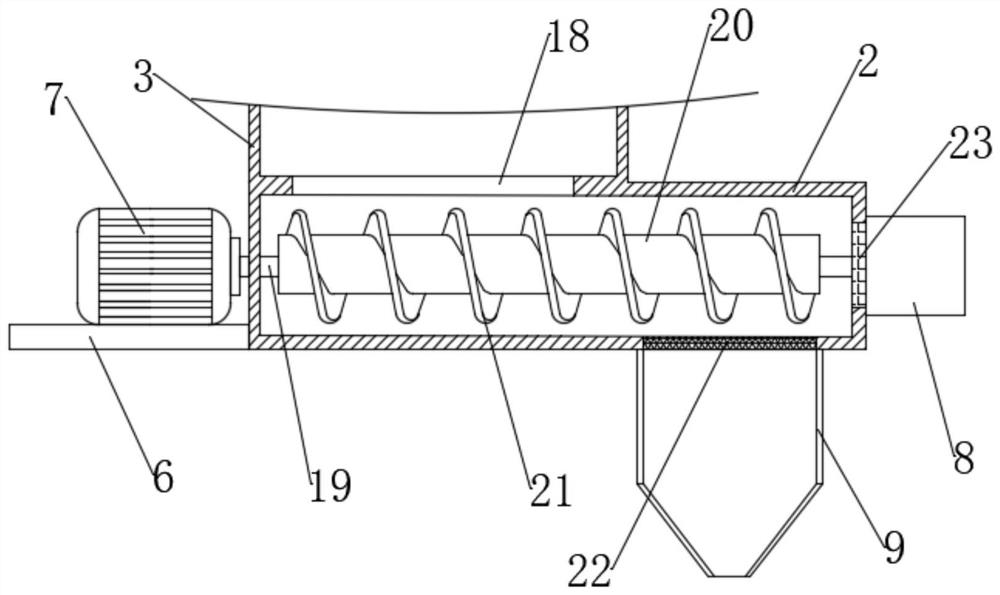

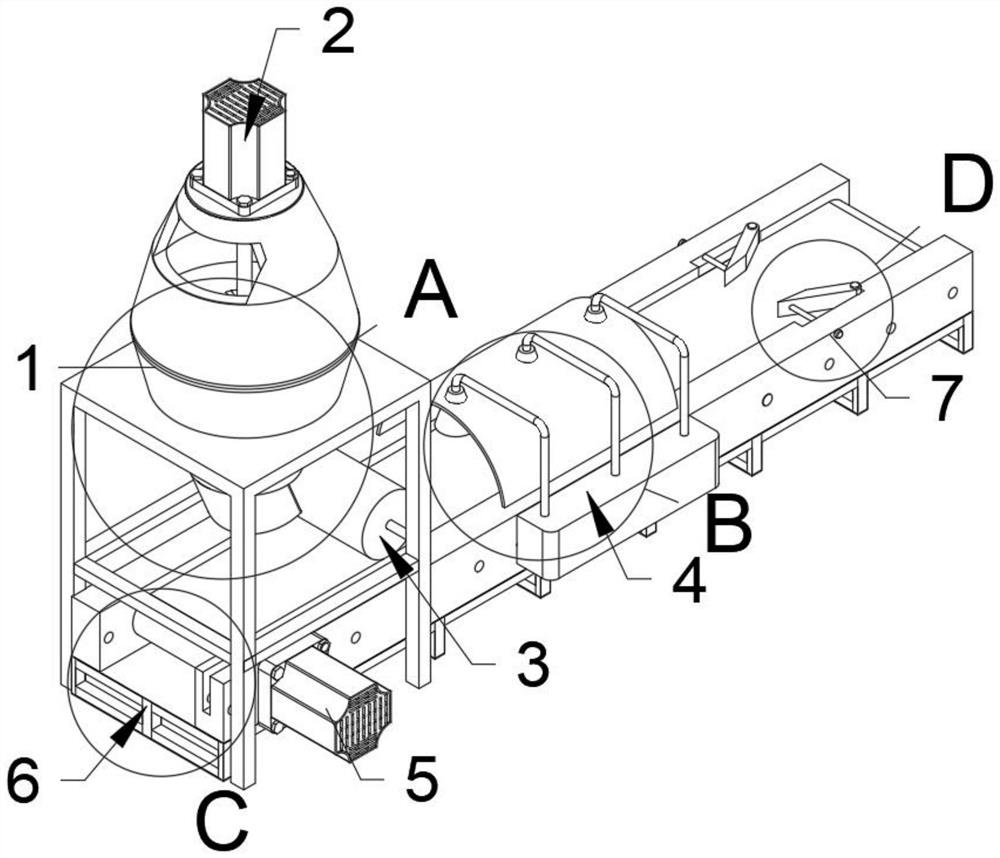

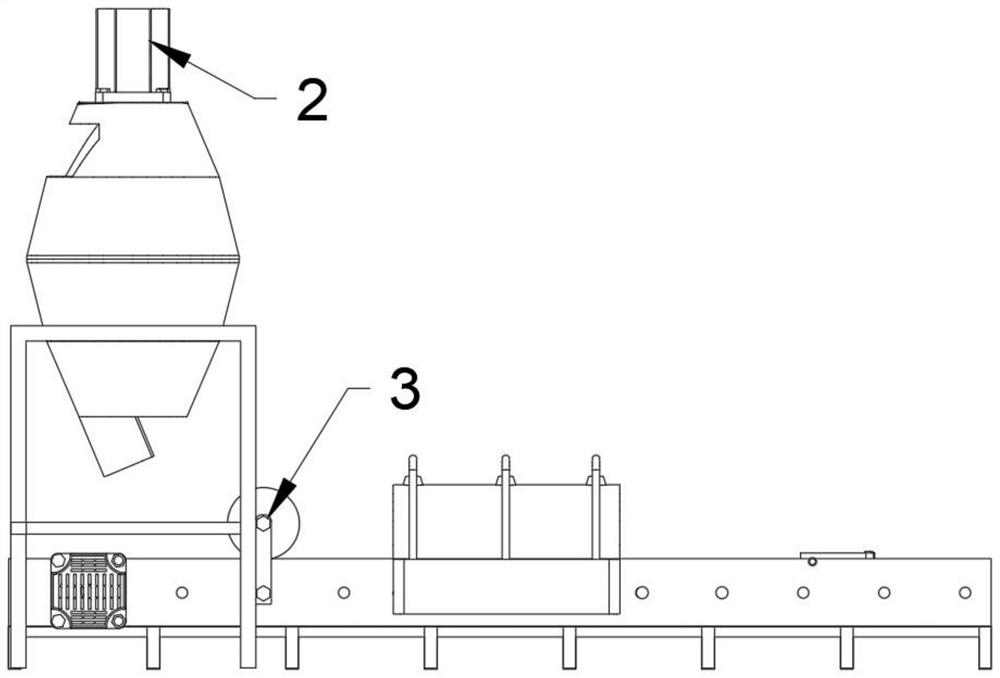

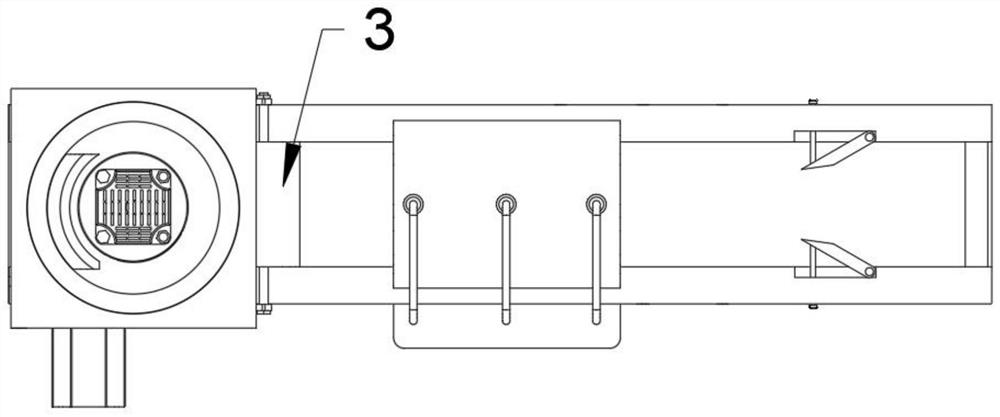

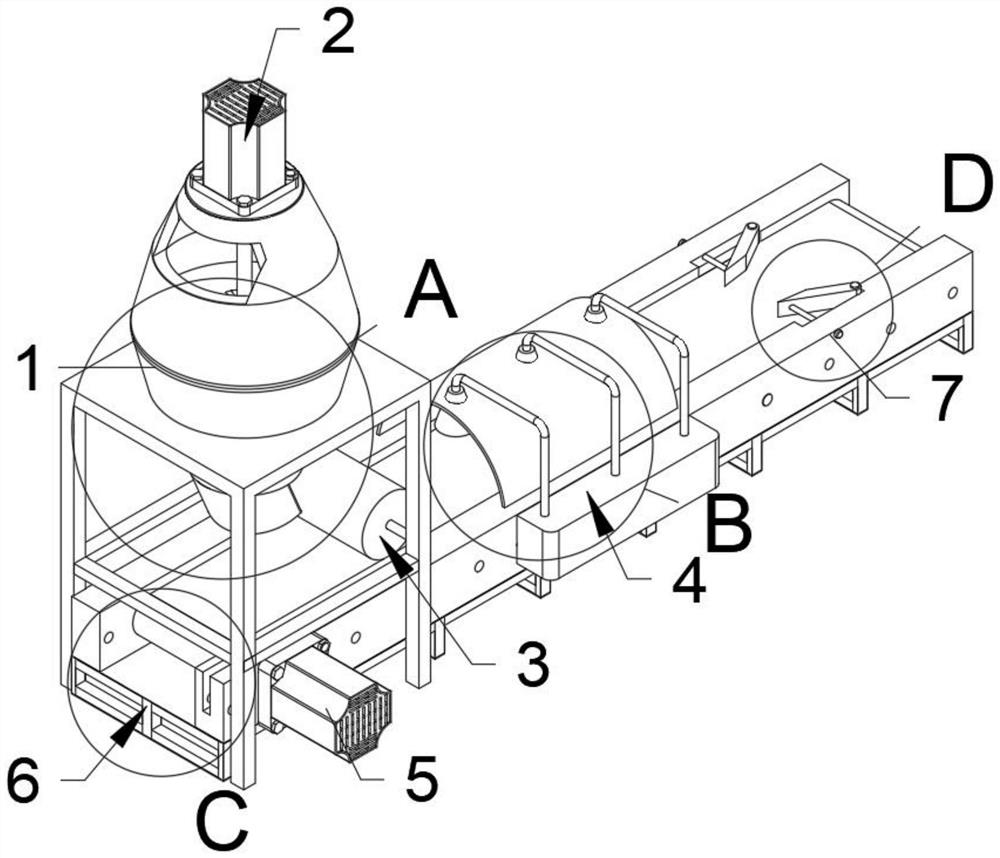

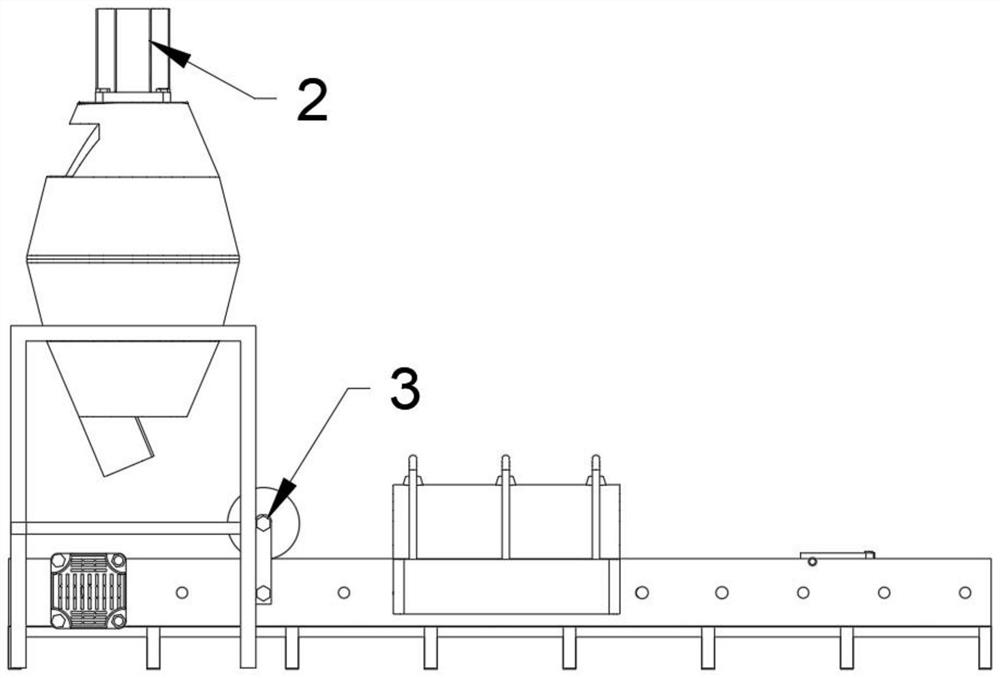

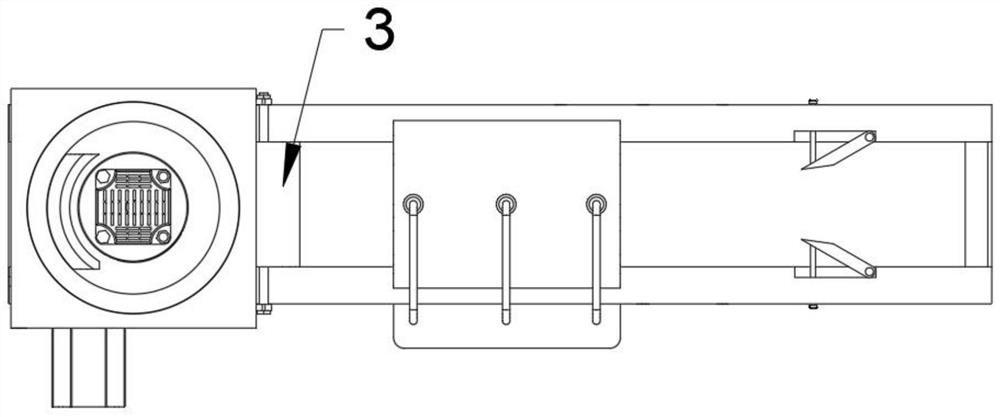

Rapeseed oil squeezing device

InactiveCN112743899AConvenient pressing workQuality improvementSievingScreeningConical tubeElectric machinery

The invention discloses a rapeseed oil squeezing device which comprises a control cabinet. A squeezing box is fixedly installed at the upper end of the control cabinet, a screening box is fixedly connected to the left portion of the upper end of the squeezing box, a feeding hopper is fixedly installed in the middle of the upper end of the screening box, a driving box is fixedly connected to the middle of the left end of the screening box, and a second motor is arranged in the driving box. A supporting plate is fixedly connected to the lower portion of the rear end of the squeezing box, a first motor is fixedly installed in the middle of the upper end of the supporting plate, a residue outlet pipe is fixedly connected to the middle of the front end of the squeezing box, and an oil outlet pipe is fixedly connected to the front portion of the lower end of the squeezing box and located in front of the control cabinet. The oil outlet pipe is of a conical pipe structure, a cleaning door is arranged on the upper portion of the left end of the oil outlet pipe, and a center shaft is arranged in the squeezing box. According to the rapeseed oil squeezing device, the rapeseed oil squeezing efficiency of the device can be greatly improved, the quality of finished oil is guaranteed, and the practicability is high.

Owner:湖南四通食品科技有限责任公司

Extracting and filtering device for radix sophorae flavescentis flavone production

Owner:SHAANXI UNDERSUN BIOMEDICAL TECH CO LTD

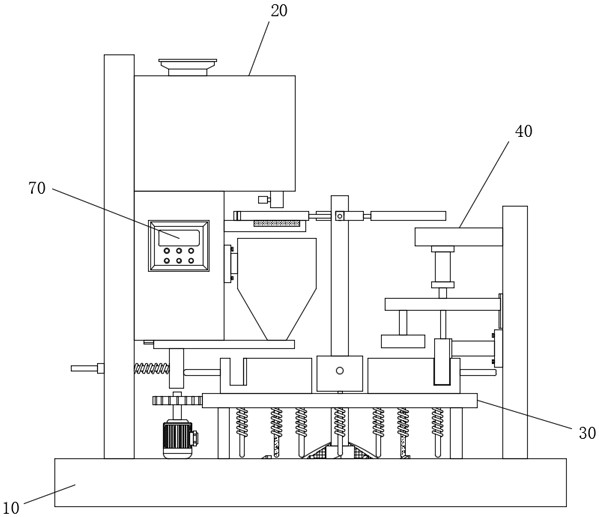

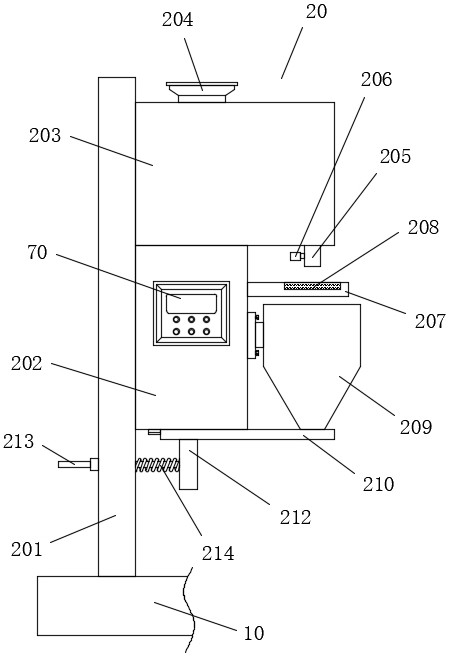

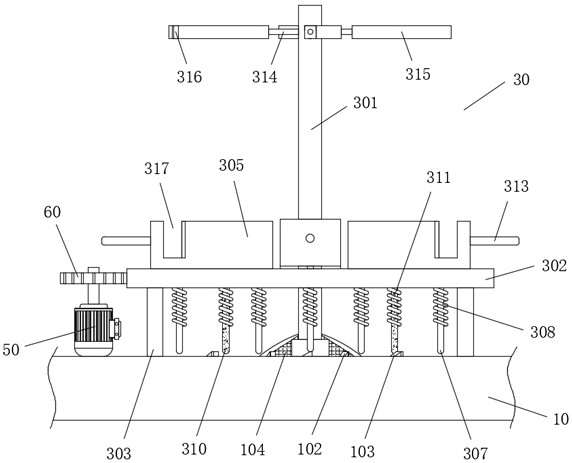

An intelligent packaging and weighing device for tea production and its use method

ActiveCN112895562BRealize the effect of automatic quantitative dischargeImprove stabilityWeighing apparatus for materials with special property/formWeighing auxillary devicesProcess engineeringTea leaf

The invention belongs to the technical field of tea production devices, in particular to an intelligent sub-packaging and weighing device for tea production, which includes a base, a discharge mechanism and a pressing mechanism are respectively provided on both sides of the top of the base, and a discharge mechanism and a pressing mechanism are located on the two sides of the top of the base. The feeding mechanism between the mechanisms, the discharge mechanism includes a first vertical plate fixedly connected to the top side of the base, the side of the first vertical plate close to the feeding mechanism is fixedly connected with a fixed seat, and the top of the fixed seat is fixedly connected with a storage The top of the material storage box is provided with a feeding port; it also discloses a method of use. In the present invention, the whole device has reasonable structure, few power sources, low energy consumption, simple and practical operation, convenient control, and strong overall linkage, from discharging, weighing, conveying, feeding, feeding to pressing and finally finished product discharging All the automatic operation is realized, and at the same time, the vibration effect can be realized during the feeding process, which improves the flatness of the tea leaves, and greatly improves the work efficiency and processing accuracy.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

Assembly tooling for casing and stator of a direct drive motor

ActiveCN110571986BEasy to fixReliable concentric positioning accuracyManufacturing stator/rotor bodiesInterference fitElectric machine

The invention discloses an assembling tool for a shell and a stator of a direct drive motor. The assembling tool comprises a base, guide rods, a support ring and a guide ring. The upper end of the base is connected with the guide rods. A base boss is arranged in the center of the upper end face of the base. The support ring is installed on the upper end face of the base. A stator is attached to the outer wall of the base boss. The lower end face of the stator abuts against the support ring in an attached mode. The guide ring comprises a mounting table, and a mounting table lower bulge is formed on the lower end face of the mounting table. Lower bulge through holes penetrating through the inner and outer walls are formed in the mounting table lower bulge. The inner end of each lower bulge through hole abuts against a ball. The inner ends of the balls are exposed out of the lower bulge through holes and abut against the outer wall of the stator. A heat insulation ring is arranged on theupper end face of the mounting table, and the heat insulation ring abuts against the shell in an attached mode. The shell includes a second shell body matched with the stator. The shell is pressed downwards to drive the guide ring to be pressed downwards along with the guide rod so that the second shell body can be pressed into the outer wall of the stator in an interference fit manner. In the invention, the stator is fixed reliably and firmly, the temperature of the shell will not decrease rapidly, and the assembly of the shell and the stator is premise, reliable and efficient.

Owner:HENAN NORMAL UNIV

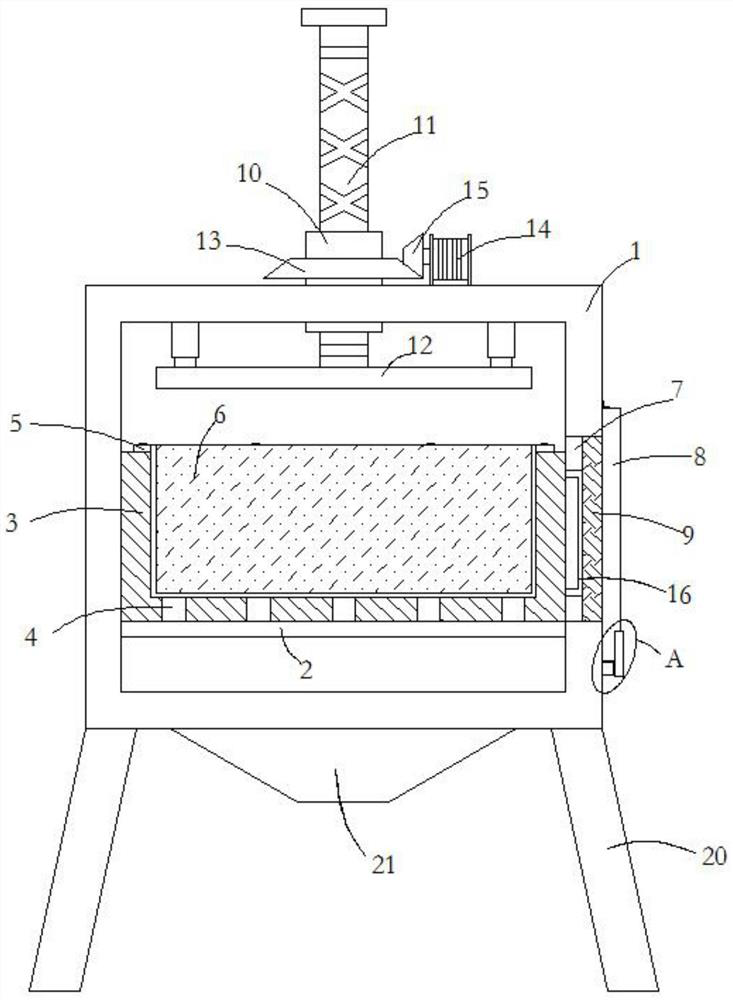

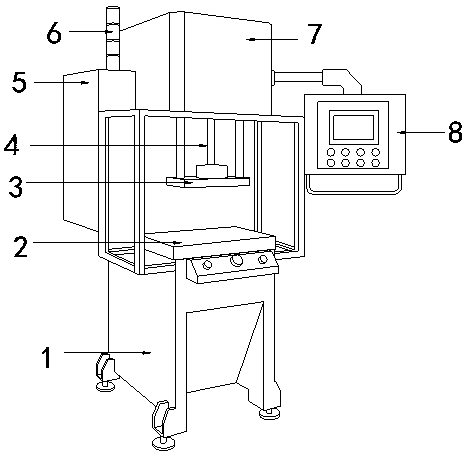

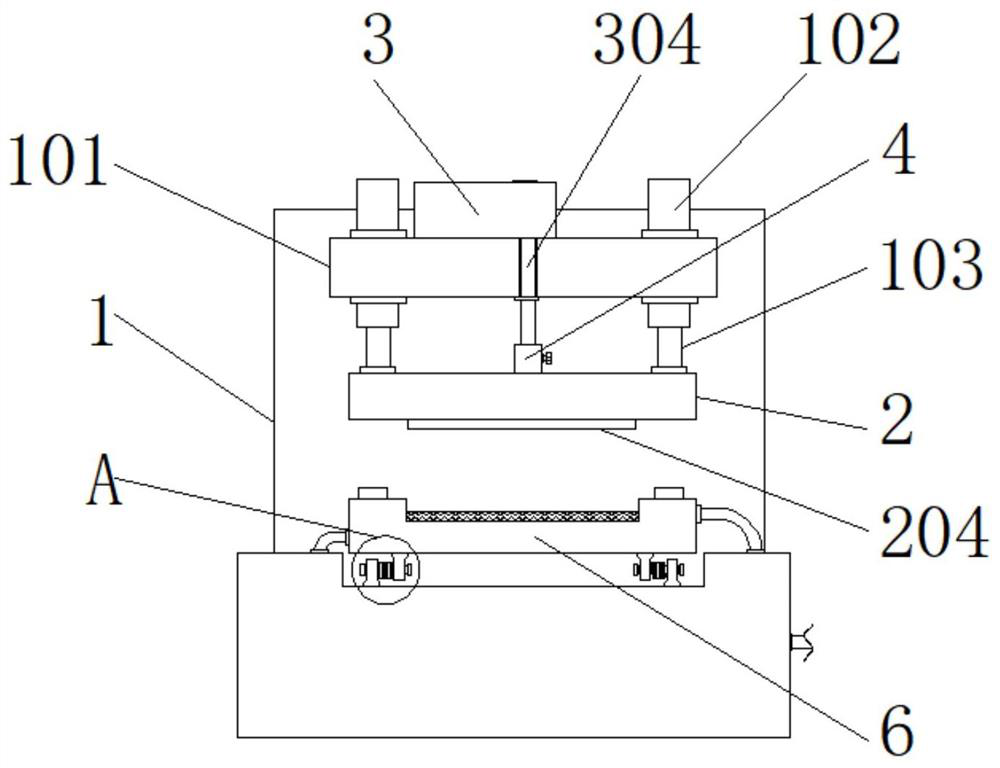

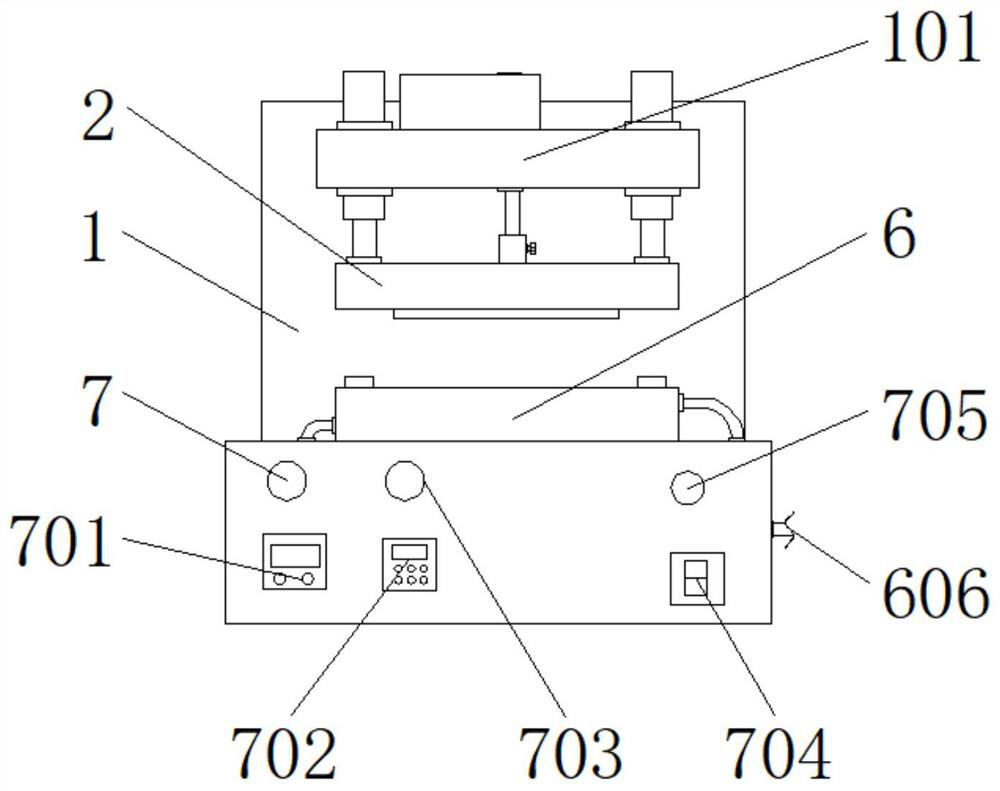

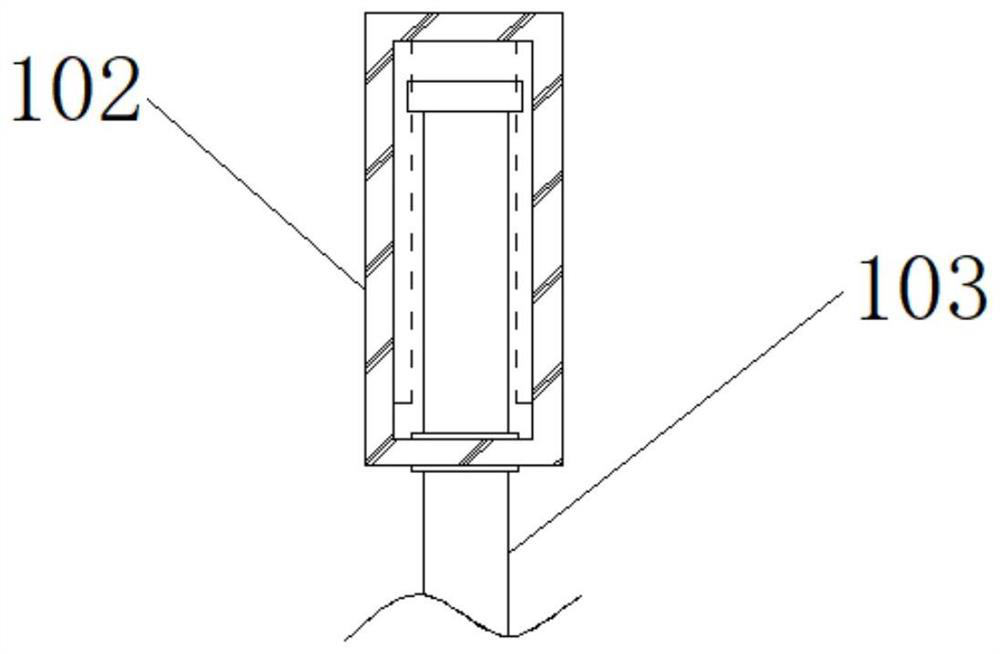

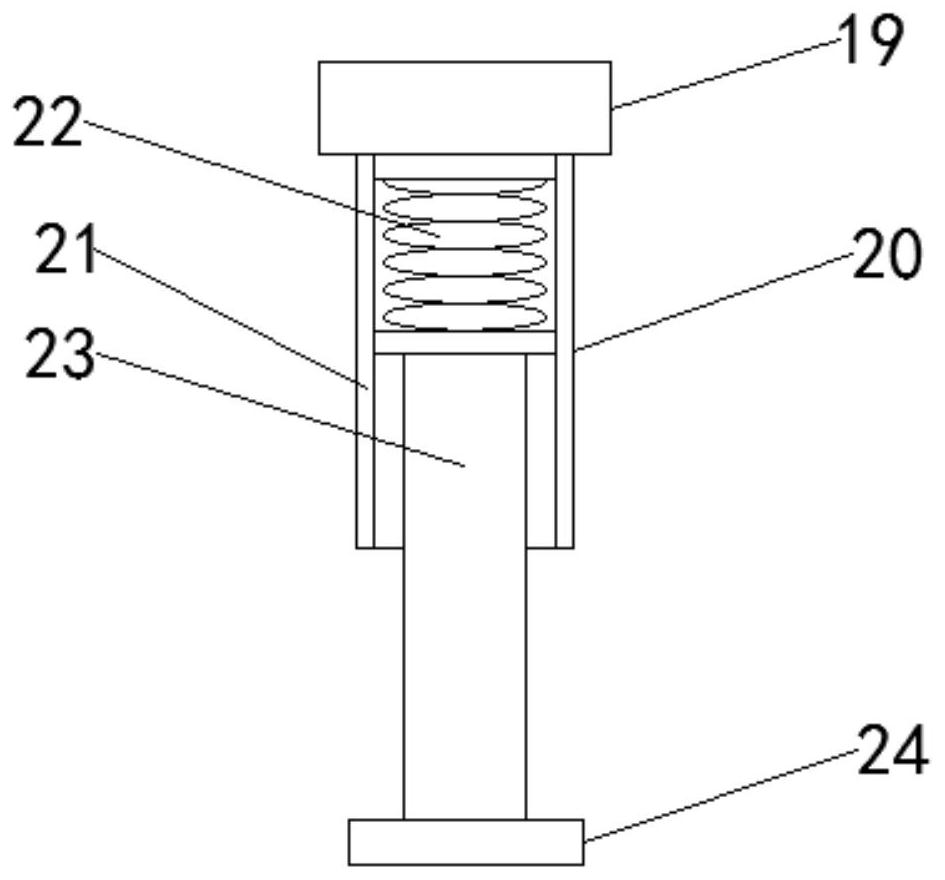

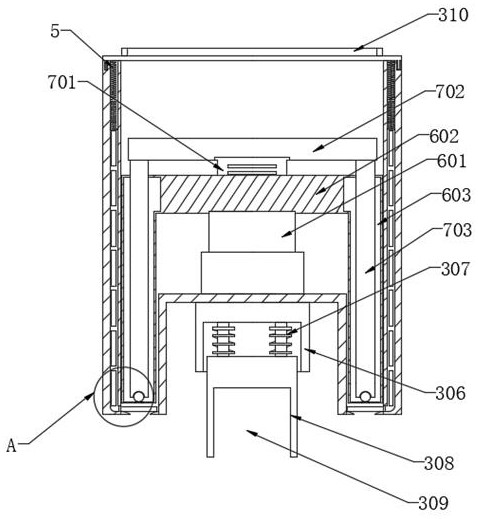

Pressing-fit machine for new material production

InactiveCN110900158AReduce reaction forceConvenient pressing workMetal working apparatusMachineNew materials

The invention discloses a pressing-fit machine for new material production. The pressing-fit machine for new material production structurally comprises a base, a bearing device, a pressing element, acylinder, an electric cabinet, an alarm, a working box and a controller, wherein the bearing device is installed on the base; the pressing element is arranged above the bearing device; the pressing element is connected with the working box through the cylinder; the controller is connected to the right side of the working box, and the left side of the working box is connected with the electric cabinet; the alarm is arranged above the electric cabinet; the bearing device comprises a bearing plate, a groove, jacking springs, buffer devices and a guide sleeve; an annular groove is formed in the bottom of the bearing plate; the groove is matched with the guide sleeve; the guide sleeve is fixed to the base; the buffer devices are arranged at the two sides of the guide sleeve separately; and thefour corners of the bearing plate are connected with the base through the jacking springs separately. The pressing-fit machine for new material production has the following beneficial effects: a vertical force can be converted to a horizontally-rotating force through the buffer devices, a vertically-pressing force is decomposed and converted, and the generation of a counter-acting force is reduced, so that the pressing-fit working is facilitated.

Owner:黄月运

Oil damper rubber node press-fitting equipment for rail transit vehicle

PendingCN114367803AAccurate confirmationHigh precisionMetal working apparatusRail transitShock absorber

The invention provides oil damper rubber node press-fitting equipment for a rail transit vehicle, and relates to the technical field of damper assembly. The oil damper rubber node press-fitting equipment for the rail transit vehicle comprises a mounting plate, a lower mounting frame is arranged on the upper surface of the mounting plate, an upper mounting frame is arranged above the lower mounting frame, and a positioning device is arranged on the upper surface of the mounting plate and located on the right side of the lower mounting frame. And the lower surface of the mounting plate is fixedly connected with a punching machine. By arranging the adjusting device in the upper mounting frame, the rotating angle can be accurately confirmed and cannot be changed in the press-fitting process, so that the press-fitting precision is improved, and a top plate is arranged in the positioning device to control the end part of the shock absorber, so that accidents cannot occur in the press-fitting process of the shock absorber, and the press-fitting precision is improved. And an adjusting device is arranged in the lower mounting frame, so that shock absorbers with different diameters can be pressed, and the adaptability is high.

Owner:扬州华通橡塑有限公司

An environmentally friendly and sustainable recycling wood panel production equipment

ActiveCN111761681BTightly boundNeat edgesOther plywood/veneer working apparatusProfiling/shaping machinesPlant fibreElectric machinery

The invention provides an environment-friendly and sustainable recycling type wooden board production equipment, which relates to the technical field of wooden board production, and solves the problem that most of the existing board production machines use wood and other raw materials to manufacture furniture boards, but it is impossible to realize the recycling of waste paper. Or other waste containing plant fibers for renewable recycling, so it will cause a lot of waste of resources. When in use, the stirring motor in the stirring mechanism is started by connecting an external power supply, and the stirring motor connected to the output end of the stirring mechanism is used. The transmission shaft drives the stirring teeth to rotate quickly to achieve the rapid mixing and crushing of various fillings, so as to facilitate the subsequent pressing work. When the waste mixture passes through the leveling mechanism, the mixture will be squeezed by the rollers. Preliminary extrusion molding is carried out. This design can squeeze the moisture inside the mixture, so that the various mixtures can be combined more tightly, which can speed up the work efficiency.

Owner:日照益尔居木业股份有限公司

Pickled Chinese cabbage compaction device

The invention discloses a pickled Chinese cabbage compaction device. The pickled Chinese cabbage compaction device comprises a tank body and a tank cover matched with the tank body, wherein the a pressing plate is arranged in the tank body, and a pressing rod is connected to the top of the pressing plate through a spring; the top of the pressing rod penetrates through the tank cover to communicate with outside, and a rotating handle is arranged at the top of the pressing rod; support rods are symmetrically arranged on two side surfaces of the tank body, and a plurality of connecting rods are arranged on the support rods; clamps are connected to the other ends of the connecting rods, and fastening bolts are arranged on the clamps; connecting devices are arranged at one ends away from the tank body of the support rods. The pickled Chinese cabbage compaction device disclosed by the invention is short in making time, and free from limitation of regions.

Owner:果涛

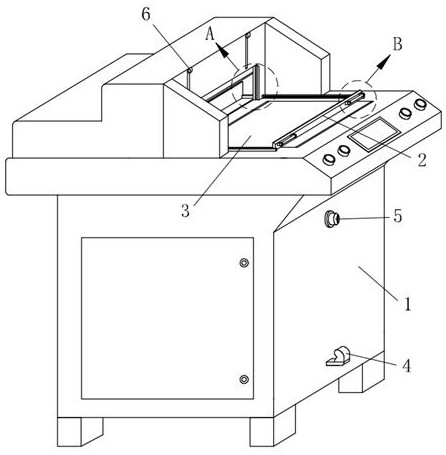

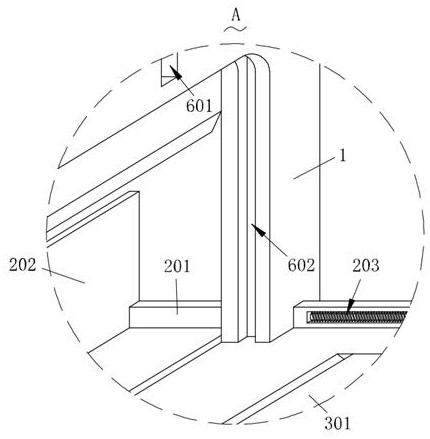

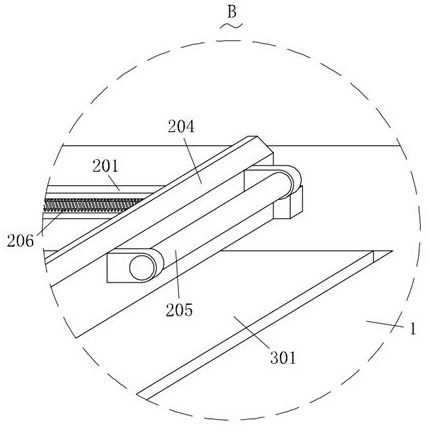

Auxiliary feeding and discharging device for English book binding, processing and shearing

The invention relates to the technical field of book binding and shearing, in particular to an auxiliary feeding and discharging device for English book binding, processing and shearing. The auxiliary feeding and discharging device for English book binding, processing and shearing comprises a paper cutting machine, wherein a pushing mechanism and a rotating mechanism are installed on the paper cutting machine; an abutting mechanism is installed in the paper cutting machine; a limiting mechanism is installed on the paper cutting machine; and a protection mechanism is installed on the paper cutting machine. Under the action of the pushing mechanism, book paper needing to be cut can be pushed into the paper cutting machine so as to be cut, books can be conveniently pulled out and discharged subsequently, operation is convenient, the paper flatness is better, and the paper cannot be dispersed; through cooperation of the abutting mechanism and the rotating mechanism, the paper placed on the rotating mechanism can be conveniently rotated, so that four sides of the paper can be pushed and cut; and under the action of the protection mechanism, a feeding port of the paper cutting machine can be closed and protected, so that the situation that sundries enter the paper cutting machine, and the paper cutting machine is damaged during working is prevented.

Owner:武汉商贸职业学院

Pressing and fixing machine processing equipment for storage chip

ActiveCN112820667AEasy to replaceConvenient pressing workSemiconductor/solid-state device manufacturingTransmission beltEngineering

The invention discloses a pressing and fixing machine processing equipment for storage chip. The pressing and fixing machine machining equipment comprises a pressing and fixing machine body, a servo motor and a vacuum pump, a fixing plate is fixedly installed on the pressing and fixing machine body, a sleeve rod is inserted into the fixing plate, a fixing rod is inserted into the sleeve rod, the bottom end of the fixing rod is fixedly connected to a jig plate, a sliding block is arranged in the jig plate, a connecting rod is fixedly connected to the sliding block, the bottom end of the connecting rod is fixedly connected to a fixing seat, the fixing seat is fixedly connected to the pressing plate, an equipment box is fixedly installed on the fixing plate, a servo motor is fixedly installed in the equipment box, and the servo motor is sleeved with a transmission belt. When the jig plate needs to move downwards, the equipment box starts to operate, the transmission belt rotates through operation of the equipment box, the fluted disc rotates through rotation of the transmission belt, the fluted disc rotates to drive the push rod to move downwards, and therefore the jig plate can conduct pressing work conveniently.

Owner:深圳市铨天科技有限公司

A clamping fixture for a rail vehicle traction rod

ActiveCN104084907BSimple structureConvenient pressing workWork holdersEngineeringIndustrial engineering

The invention discloses a pressing fixture for a traction rod of a rail vehicle, which comprises a pressing device, a movable pressing device and a supporting device; a bottom plate, a supporting rod, a pressing rod, a locknut and a pressing plate are arranged on the pressing device; an upper V-shaped block, a lower V-shaped block, a lower supporting seat, a fixed bolt, a second locknut and an outer hexagon bolt are arranged on the movable pressing device; a supporting nut, a third locknut and a supporting bolt are arranged on the supporting device. The pressing fixture has the benefit that the structure is simple, the operation is convenient and practical, and the pressing fixture can be suitable for pressing any traction rod, has larger pressing force and can be automatically aligned through a step shaft and a first light hole, so that great convenience is brought to the pressing work, and much unnecessary alignment work in the previous work is greatly reduced.

Owner:CHUANLI ELECTRIC CO LTD

Drawing cutting device for mechanical automation specialty

PendingCN112917522AImprove croppingImprove flatnessMetal working apparatusEngineeringMechanical engineering

The invention belongs to the technical field of cutting, and particularly relates to a drawing cutting device for mechanical automation specialty. The device comprises a cutting table, wherein supporting rods are fixedly connected to the four corners of the upper end face of the cutting table, a mounting box is fixedly connected to the upper end faces of the four supporting rods, and a mounting plate is fixedly connected to the back of the inner wall of the mounting box. A cutter holder at the bottom performs the same right lower movement, so that the cutter is driven to move downwards and move rightwards at the same time, a drawing at the upper end of the cutting table is obliquely cut, an air cylinder shrinks after cutting is completed, and the cutter can be driven to retract, so that compared with vertical tangent cutting, the flatness of the cutting face is improved, more labor is saved, and the drawing cutting effect is improved; and the device solves the problems that according to an existing drawing cutting device, generally used drawing cutting devices are all in a vertically-downward straight cutting mode, and when a plurality of drawings are cut at the same time, power needed by the cutter is large, meanwhile, the cutting face is uneven, the cutting effect is poor, the drawings cannot be well fixed, and the cutting effect is affected due to displacement of the drawings in the cutting process.

Owner:JIUQUAN VOCATIONAL & TECHN COLLEGE

A kind of environment-friendly and sustainable recycling wood plank production method

ActiveCN111645162BTightly boundNeat edgesDomestic articlesFlat articlesPlant fibrePulp and paper industry

The invention provides an environment-friendly and sustainable circular wood board production method, which is realized by a wood board production equipment equipped with a feeding mechanism, a stirring mechanism, a leveling mechanism, a glue spraying mechanism, a driving mechanism, a supporting mechanism, and an edge trimming mechanism Production of wooden panels. The present invention solves the problem that the existing board production methods mostly use wood and other raw materials to manufacture furniture boards, but it is impossible to realize the reproducible recycling of waste paper or other wastes containing plant fibers, so it will not only cause A lot of resources are wasted and it will also cause certain pollution to the environment.

Owner:广东中泰家具集团有限公司

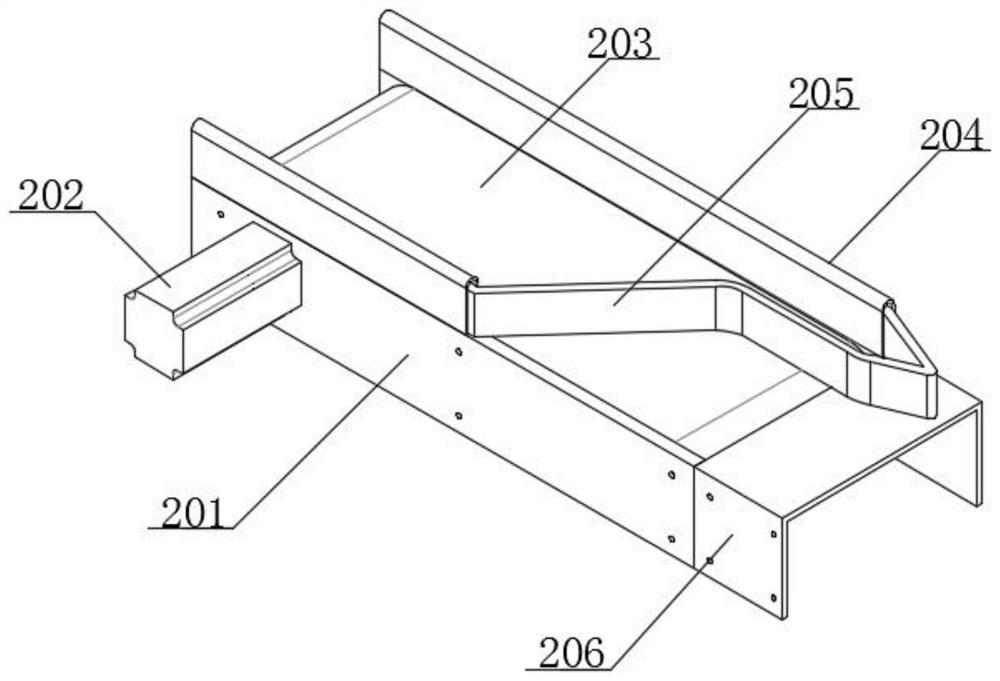

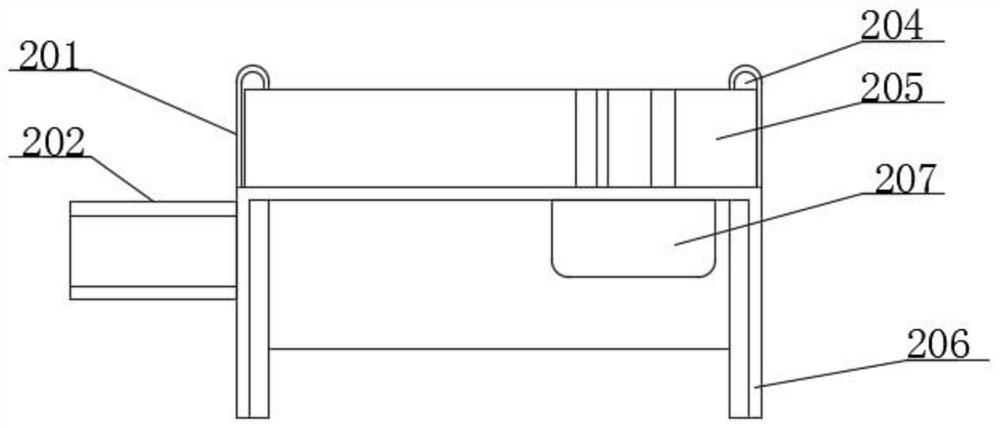

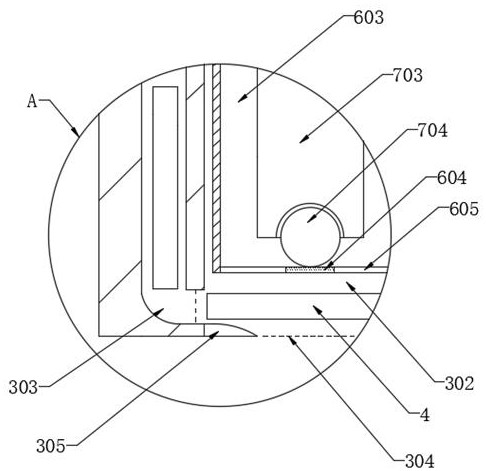

Automatic press-fitting device for piston

InactiveCN113319553AOrderly rowsConvenience for follow-up workMetal working apparatusEngine lubricationElectric machineryPiston

The invention discloses an automatic press-fitting device for a piston. The automatic press-fitting device for the piston comprises an equipment body, a positioning device, a pressing device, a grabbing device, an oiling device and a tensioning device, wherein the positioning device is arranged on the surface of the equipment body; the pressing device is arranged above the positioning device; the grabbing device is arranged at the front end of the pressing device; the oiling device is arranged on the lower part of the grabbing device; the tensioning device is arranged on one side of the oiling device; a transmission motor is arranged on one side of the positioning device; a positioning plate is arranged at one end of the transmission motor; a conveying belt is arranged on the inner side of the positioning plate; a side supporting plate is arranged above the conveying belt; a baffle is arranged on one side of the side supporting plate; a material table is arranged at the lower end of the baffle; and an infrared sensor is arranged at the bottom of the material table. The automatic press-fitting device for the piston provided by the invention has the advantages of being accurate in positioning, firm in grabbing, capable of improving production efficiency, even in oil coating, capable of improving the expansion stability and high in automation degree.

Owner:河南明卓智能科技有限公司

Heat press machine with demoulding function

InactiveCN106827120BEven by forceConvenient pressing workPlywood pressesVeneer pressesElectric machineryEngineering

The invention belongs to the field of presses, and particularly discloses a hot press with the demolding function. The hot press comprises an upper pressing plate and a fixing plate; the two ends of the upper pressing plate are connected with a first supporting frame and a second supporting frame in a sliding mode respectively; a plurality of sliding blocks are arranged in the first supporting frame; heating plates are arranged on the sliding blocks and are connected through springs; a motor is arranged above the upper pressing plate and is fixedly connected to a first rotating shaft, and the first rotating shaft is rotationally connected to a water tank; the water tank is rotationally connected to a second rotating shaft; a plurality of blades are arranged on the opposite ends of the first rotating shaft and the second rotating shaft; the second rotating shaft is fixedly connected to a lower pressing block; a hydraulic block is arranged at the bottom of the lower pressing block; a hollow cavity is formed in the hydraulic block; and the two ends of the hydraulic block are fixedly connected to the upper pressing plate through flexible connecting pieces. The invention provides the hot press with the demolding function. The hot press with the demolding function has the advantages that the upper pressing plate is stressed uniformly, and a plate is easy to demold and can be kept from being crushed.

Owner:重庆木园春木业有限公司

Environment-friendly soybean oil multi-time squeezing and filtering treatment device

InactiveCN112375615AReduce contentImprove oil yieldFatty-oils/fats productionOil and greaseEngineering

The invention relates to the technical field of soybean oil squeezing, and discloses an environment-friendly soybean oil multi-time squeezing and filtering treatment device. The device comprises a shell, sliding rails are arranged on the two side walls of the interior of the shell, a sliding plate is slidably connected to the surfaces of the sliding rails, push rods are movably connected to the surface of the sliding plate, adjusting rods are movably connected to the surfaces of the push rods, a telescopic plate is movably connected to the upper ends of the push rods, supporting frames are fixedly connected into the sliding plate, spring rods are movably connected into the supporting frames, blocking blocks is movably connected to the surfaces of the spring rods, oil outlet holes are formed in the sliding plate and located in the backs of the blocking blocks, and movable rods are movably connected to the lower ends of the spring rods. The sliding plate can discharge oil liquid locatedon the upper portion of the sliding plate from an oil discharge pipe. Due to the fact that the opening sizes of the oil outlet holes are small, the oil liquid is squeezed out under the action of pressure. Because the flowing speeds of liquid and solid are different under the same pressure, the effect of anti-gravity separation of oil and fat to reduce the oil residue content is achieved.

Owner:温州芷唇贸易有限公司

Swing lever press cloth handle

The invention discloses an oscillating rod type cloth-pressing handle which comprises a cloth-pressing handle and a round needle disk, and is characterized by further comprising a machine frame, two bolts, a lower pressing plate, an upper pressing plate, a connecting plate, a screw rod, a hand wheel, a sliding rod, a sliding base, an oscillating rod, an extension spring, a rotating shaft, an operating rod, a cloth-pressing handle pressing screw, a limiting device, a seat plate pin, a seat plate and a sliding seat locking screw, wherein the limiting device comprises a limiting seat, a lower limiting screw and an upper limiting screw; the limiting seat is welded on the seat plate; the upper limiting screw and the lower limiting screw are connected and arranged to the upper part and the lower part of the limiting seat respectively through threads; the machine frame is provided with a big waist-shaped hole, a sliding rod hole, a short waist-shaped hole and a long waist-shaped hole; a limiting block is arranged at the lower end of the screw rod. The oscillating rod type cloth-pressing handle is novel in structure, labor-saving in operation, high in production efficiency, excellent in pressing effect and long in service life.

Owner:DAYE XINGYUN ELECTROMECHANICAL TECH RES INST

Installation device for rotary oil seal

ActiveCN113579693BPrevent crushingImprove the pressing effectMetal working apparatusProcess engineeringAssembly line

The invention relates to the technical field of rotary oil seals, and discloses an installation device for a rotary oil seal, which includes a workbench, a transport assembly and a pressure head assembly. Below the component, a mounting plate is fixedly connected to the workbench, and the first telescopic electric cylinder is connected through the mounting plate. The lower part of the first telescopic electric cylinder is fixedly connected with the pressure head assembly. The body is provided with a feeding assembly and an extrusion assembly. The first shell is fixed with an annular extrusion chamber and a feeding chamber. The feeding assembly is movable on the top of the feeding chamber. The feeding chamber is equipped with multiple rotary oil seals. The feeding chamber The bottom is connected with the bottom of the extrusion chamber, and the invention can carry out batch press-fitting of the rotary oil seal on the factory assembly line, the press-fit is stable, the sealing performance is strong, and the rotary oil seal will not rebound.

Owner:YANTAI RUNFUXIANG OIL SEAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com