Pressing fixture for traction rod of rail vehicle

A technology for pulling pull rods and rail vehicles, applied in the field of clamping fixtures, can solve problems such as monotonous structure of tooling and inability to be flexible, and achieve the effects of simple structure, reduced alignment work, and convenient clamping work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment, further clarifies the present invention, and this practical example is carried out under the premise of the technical solution of the present invention, understands that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention.

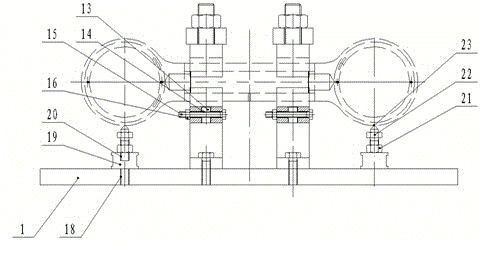

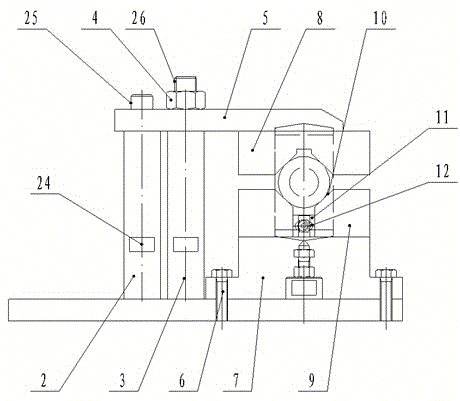

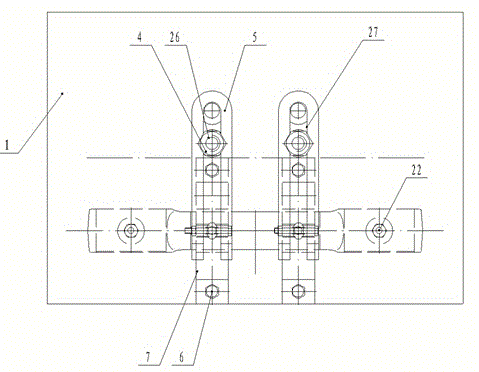

[0015] Such as Figure 1 to Figure 3 As shown, a compression fixture for rail vehicle traction rods includes a compression device, a movable compression device and a support device; the compression device is provided with a bottom plate 1, a support rod 2, a compression rod 3, a lock Tighten the nut 4 and the pressure plate 5, the top of the base plate 1 is provided with a support rod 2 and a compression rod 3, the support rod 2 and the compression rod 3 are connected to the base plate 1 through threads, a polished rod 25 is arranged above the support rod 2, and a light rod 25 is arranged above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com