Convenient assembling auxiliary tool for casing and stator of direct-drive motor

An assembly-assisted, direct-drive motor technology, applied in electromechanical devices, manufacturing of motor generators, manufacturing of stator/rotor bodies, etc., can solve problems such as difficult alignment, unfavorable press fitting, and casing temperature drop. , to achieve the effect that the temperature will not drop rapidly, the press-fitting work is labor-saving and convenient, and the work efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

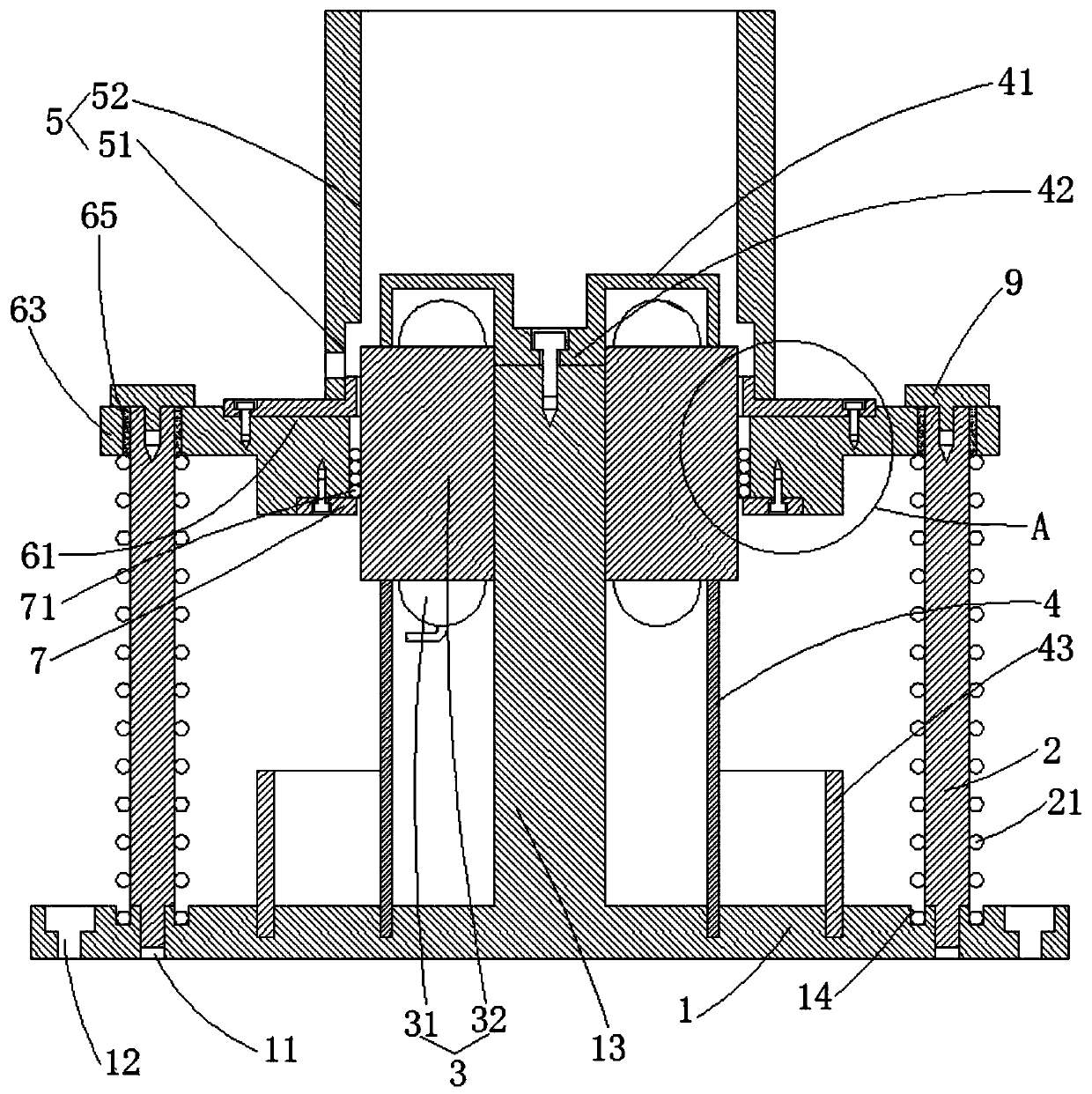

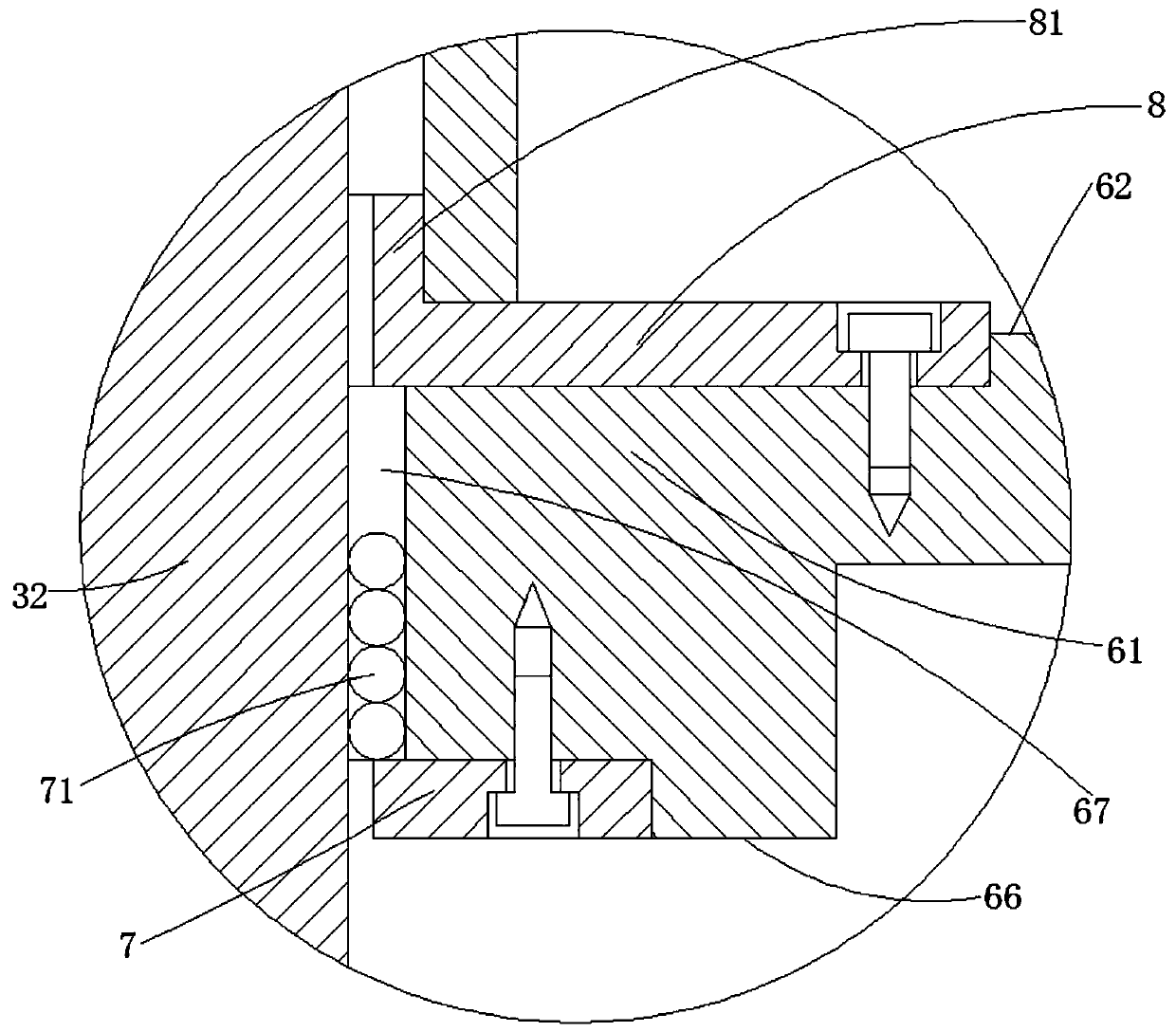

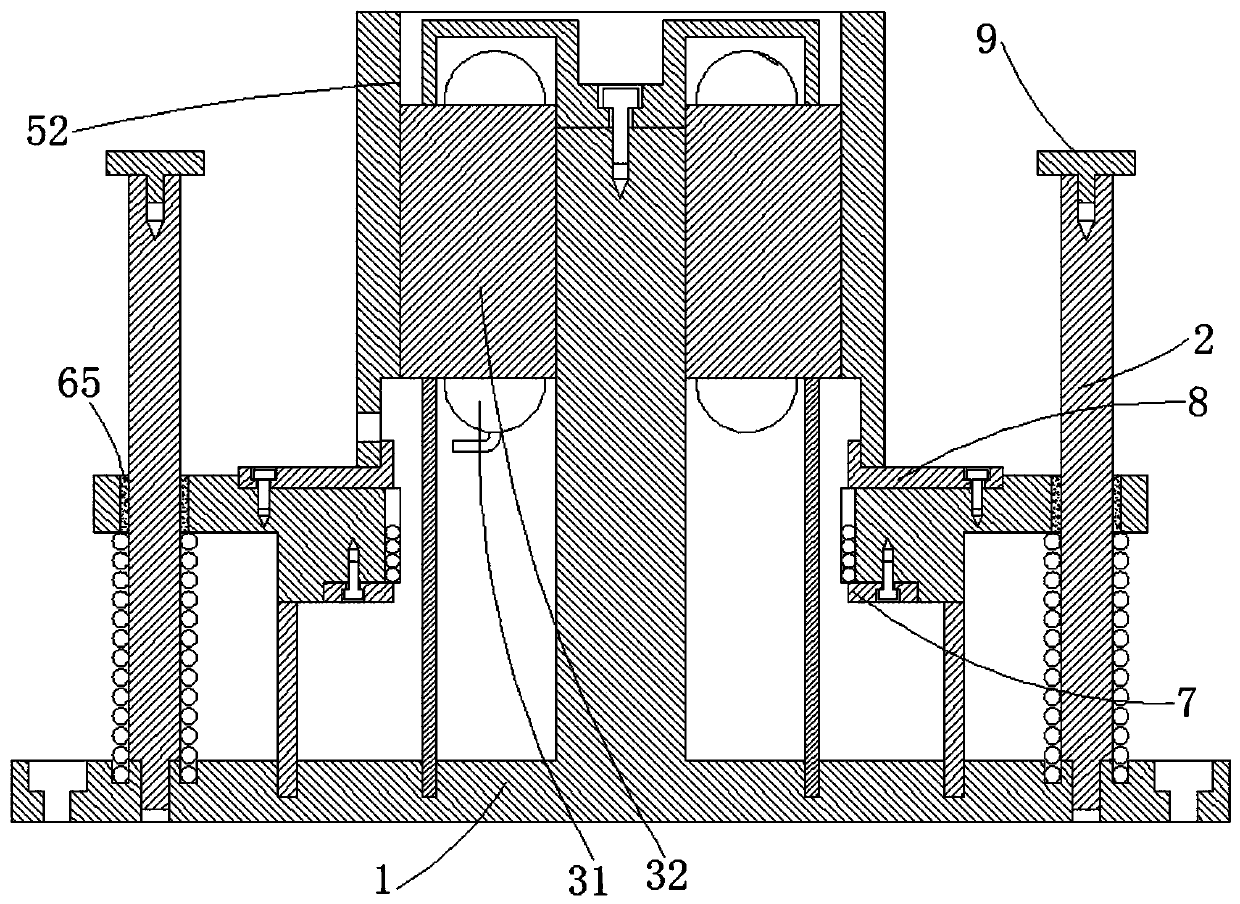

[0019] Such as Figure 1-Figure 6 As shown, a convenient assembly auxiliary tooling for the casing and stator of a direct drive motor includes a base 1, a guide rod 2, a support ring 4, a positioning ring 43 and a guide ring 6, and the upper end of the base 1 is symmetrically connected with a guide Rod 2, the base 1 is provided with a base screw hole 11, the bottom end of the guide rod 2 is a threaded section and the outer diameter of the threaded section is smaller than the outer diameter of the upper part of the guide rod 2, and the bottom end of the guide rod 2 is screwed into the screw hole of the base 11 until the upper end surface of the base 1 is attached to the step at the lower end of the guide rod 2 .

[0020] The base 1 is located on the periphery of the base screw hole 11 and is evenly distributed around the base mounting counterbore 12, and the base 1 can be installed and fixed by screwing screws in the base mounting counterbore 12.

[0021] The center of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com