Oil damper rubber node press-fitting equipment for rail transit vehicle

A technology of rail transit vehicles and oil pressure shock absorbers, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as poor adaptability and angle deviation, and achieve improved accuracy, convenient press-fitting work, and adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

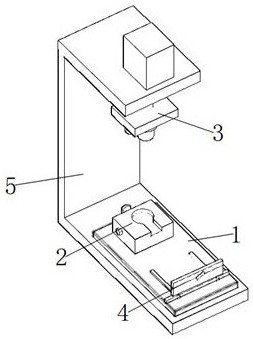

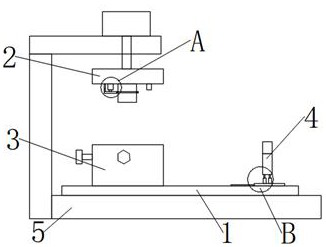

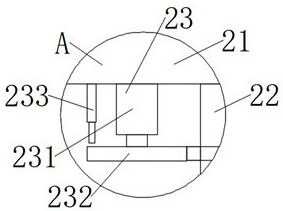

[0030] like Figure 1-7 As shown, the embodiment of the present invention provides an oil pressure shock absorber rubber node press-fitting device for a rail transit vehicle, including a mounting plate 1 for connecting with a punching machine 5, and the inside of the mounting plate 1 is provided with a mounting hole, and the mounting plate The upper surface of 1 is provided with a lower mounting frame 3, which is used to fix the position of the shock absorber 33 and adapt to the size of the shock absorber 33. The lower mounting frame 3 includes a placement frame 31 for placing the shock absorber 33, and the placement frame 31 The upper surface of the upper surface is provided with a placement groove 32, which is used to limit the shock absorber 33, so that the suspension ring of the shock absorber 33 is placed upwards, and the inside of the placement groove 32 is provided with a clamping part 34, which clamps the suspension ring of the shock absorber 33. , the clamping part 34...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com