Screw compressor

a screw compressor and compressor body technology, applied in the direction of machines/engines, liquid fuel engines, positive displacement liquid engines, etc., can solve the problem that the oil level detection means disposed in the interior of the screw compressor cannot be utilized, and achieve the effect of preventing damage to the bearings, reducing viscosity, and avoiding oil shortages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

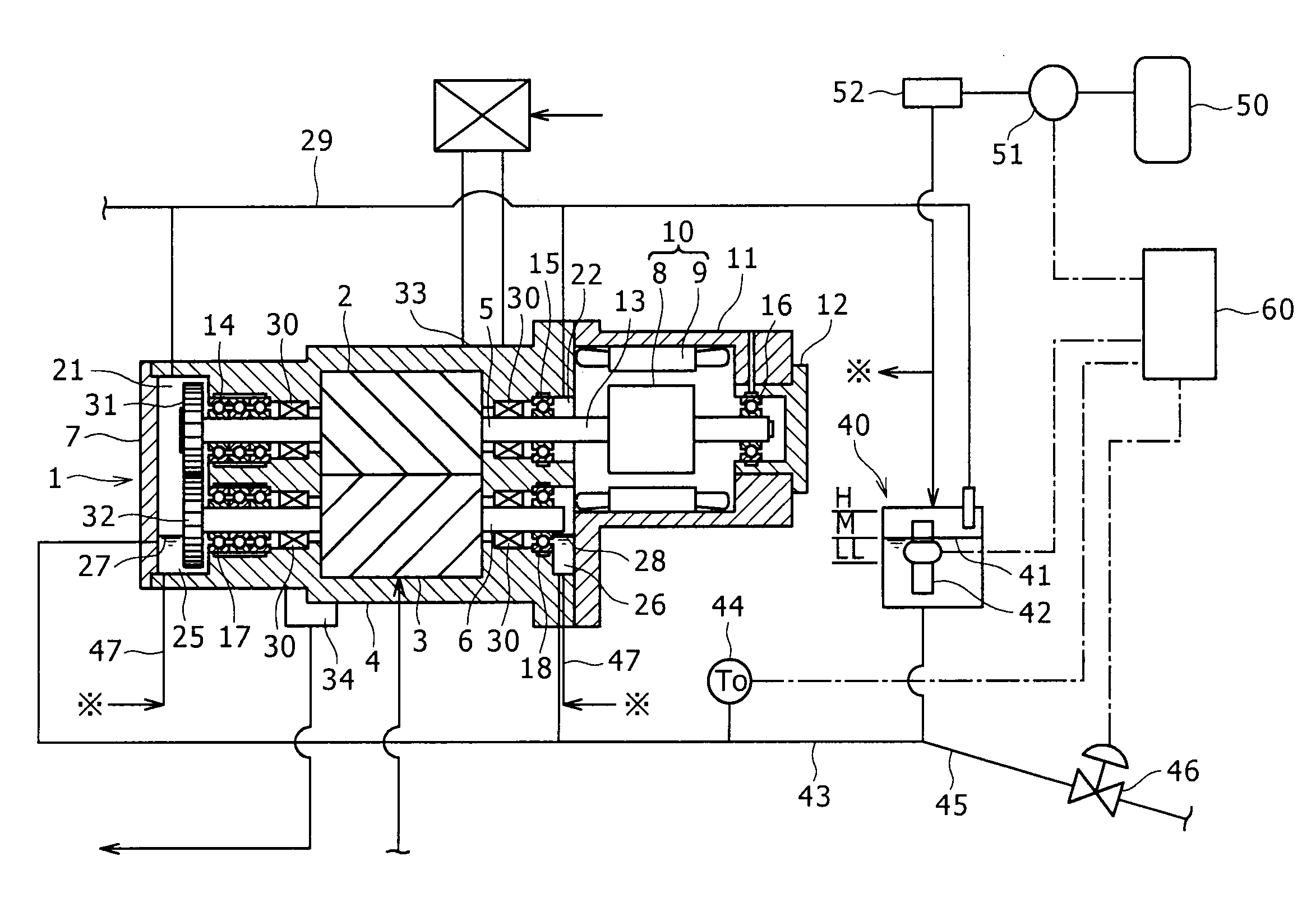

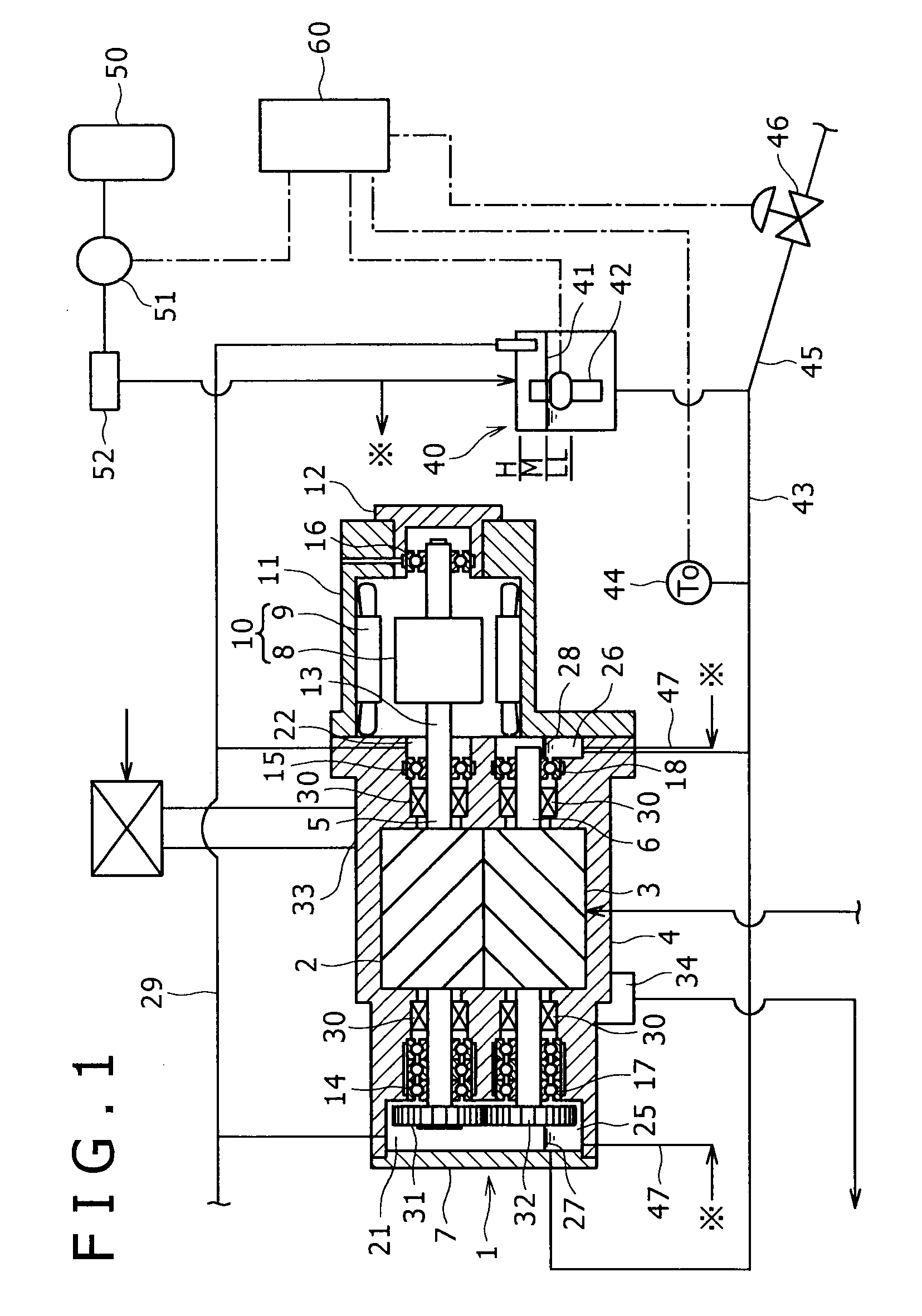

[0022]An embodiment of the present invention will be described below with reference to the accompanying drawings.

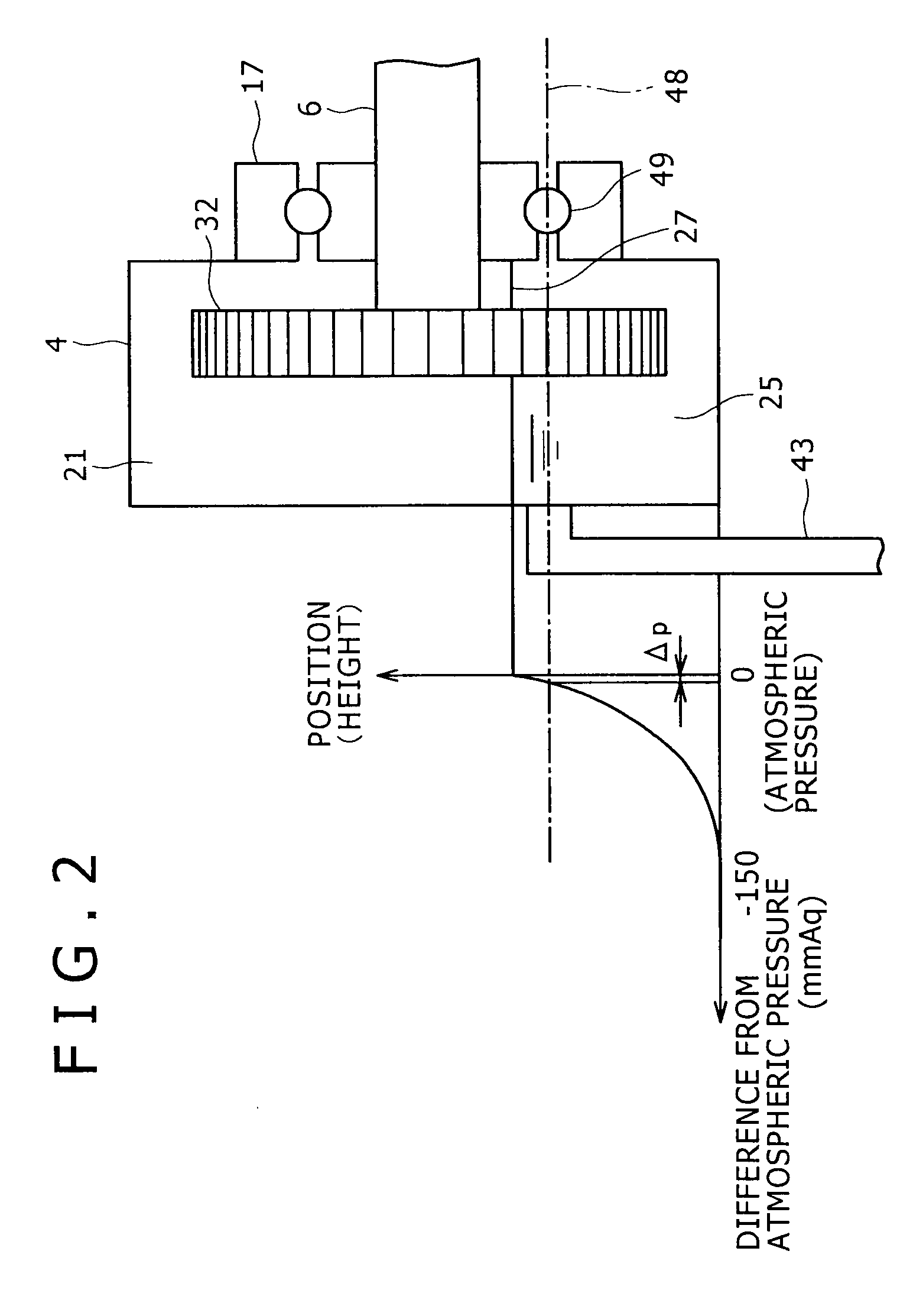

[0023]FIG. 1 illustrates a screw compressor 1 according to an embodiment of the present invention. The screw compressor 1 is a water lubrication type screw compressor wherein screw rotors 2 and 3 are cooled and lubricated with water. In the screw compressor 1, a pair of male rotor 2 and female rotor 3 meshing with each other are accommodated within a rotor casing 4. Rotor shafts 5 and 6 of the rotors 2 and 3 are disposed horizontally. One end of the rotor casing 4 is closed with a cover 7, while to an opposite end of the rotor casing 4 is mounted a motor casing 11 which accommodates a motor 10 composed of a rotor 8 and a stator 9. An end portion of the motor casing 11 is also closed with a cover 12. The rotor shaft 5 of the male rotor 2 and a motor shaft 13 of the motor 10 share an integrally-formed shaft (separate rotor shaft 5 and motor shaft 13 may be coupled together ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com