Patents

Literature

361 results about "Rotary-screw compressor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A rotary-screw compressor is a type of gas compressor, such as an air compressor, that uses a rotary-type positive-displacement mechanism. They are commonly used to replace piston compressors where large volumes of high-pressure air are needed, either for large industrial applications or to operate high-power air tools such as jackhammers and impact wrenches. For smaller rotor sizes the inherent leakage in the rotors becomes much more significant, becoming less practical than piston types for smaller volume air compressors.

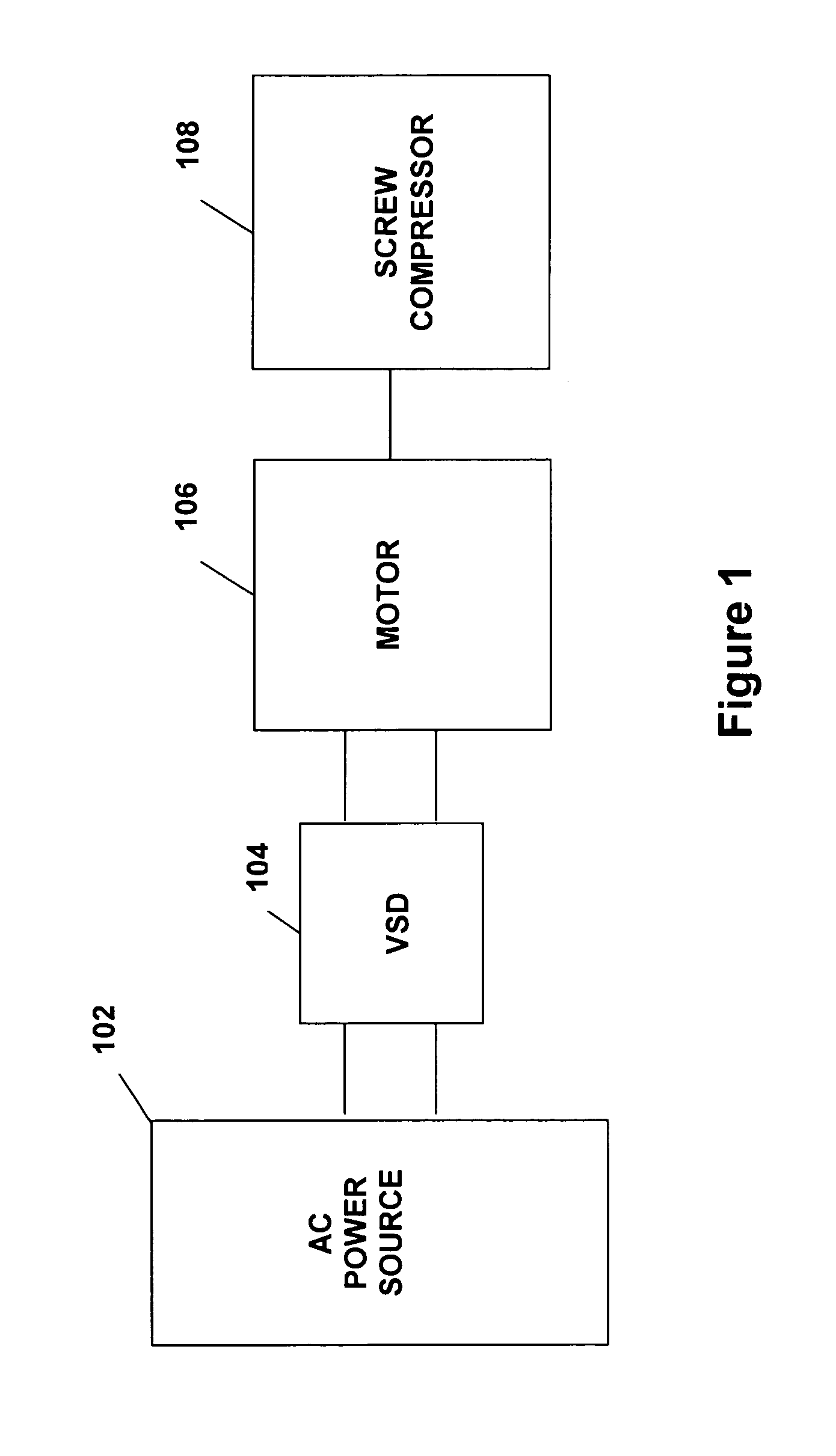

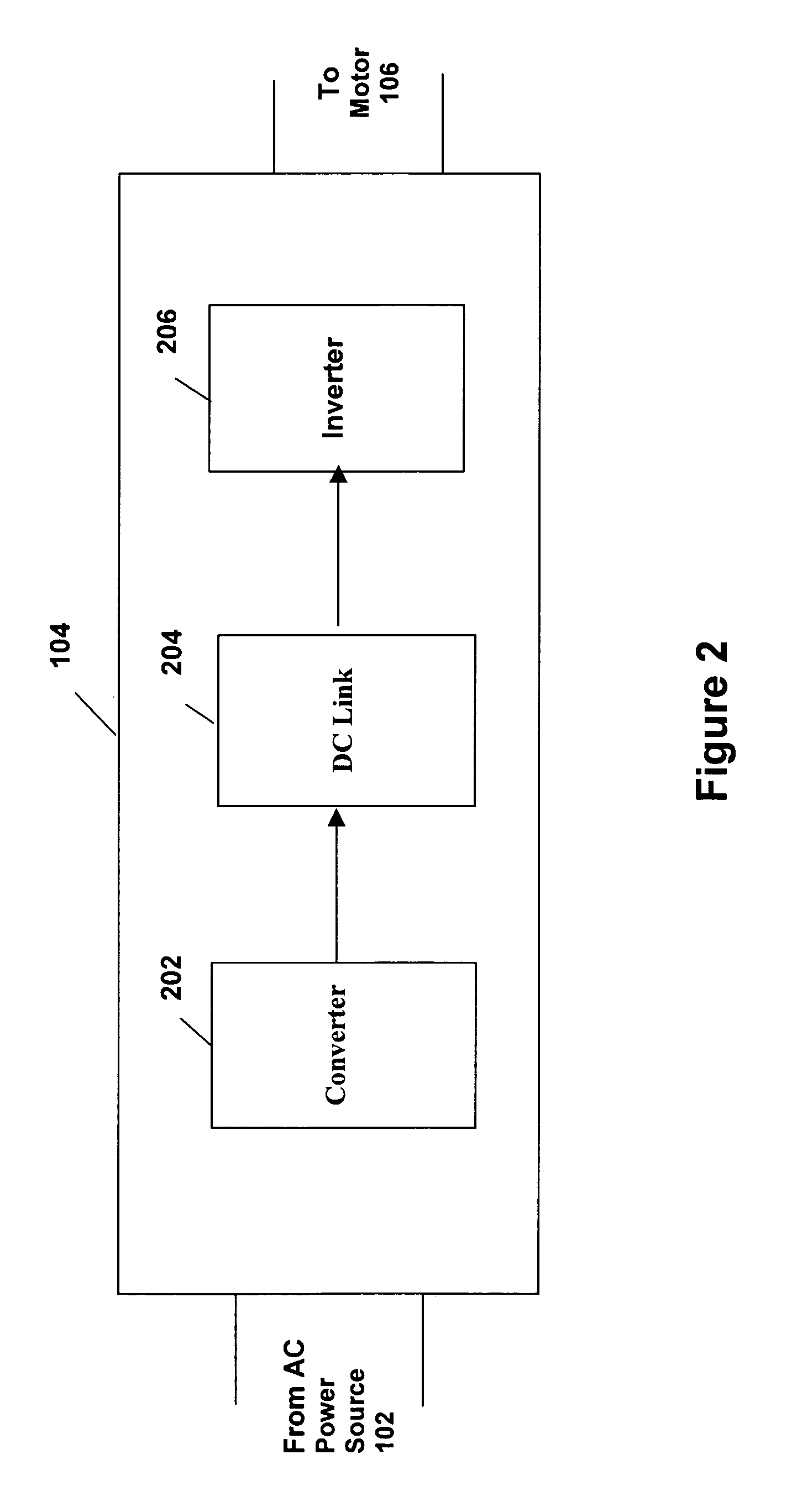

System and method for variable speed operation of a screw compressor

ActiveUS20050188708A1Efficient screw compressor operationReduce gas leakageAC motor controlRotary piston pumpsControl theoryOperating speed

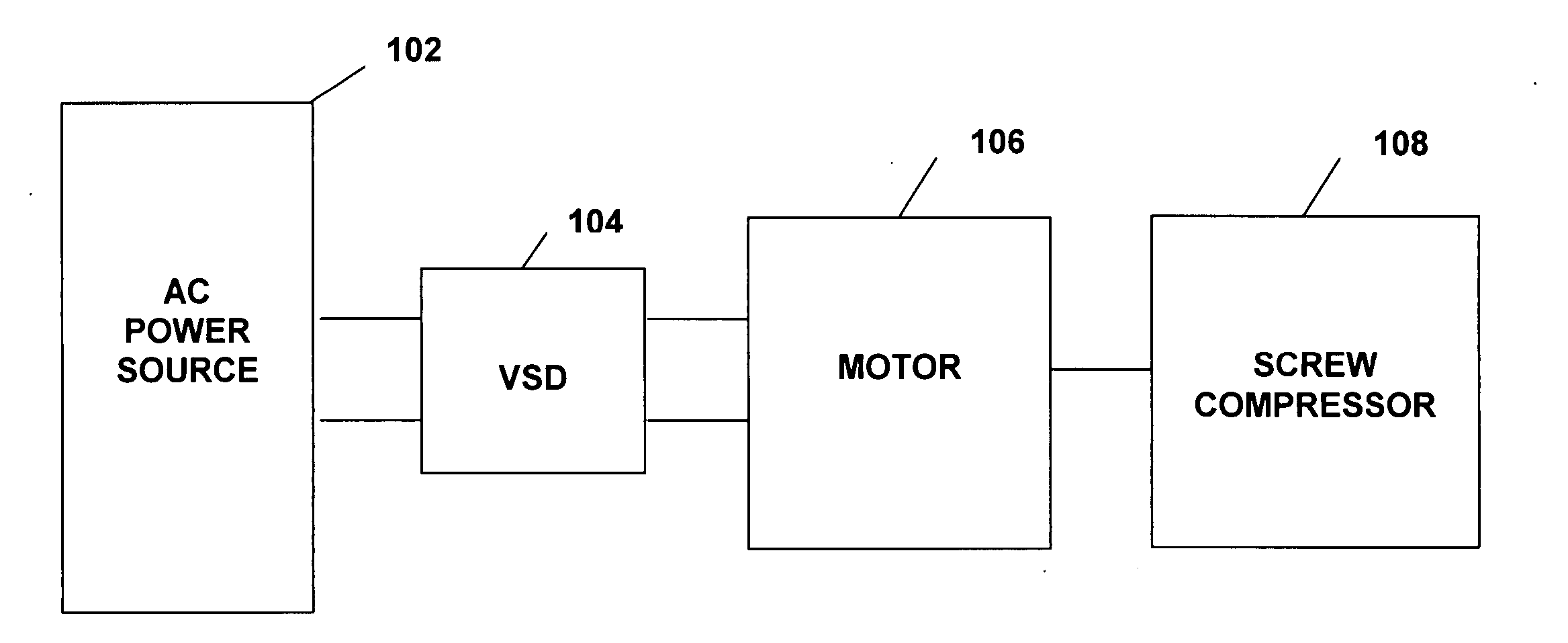

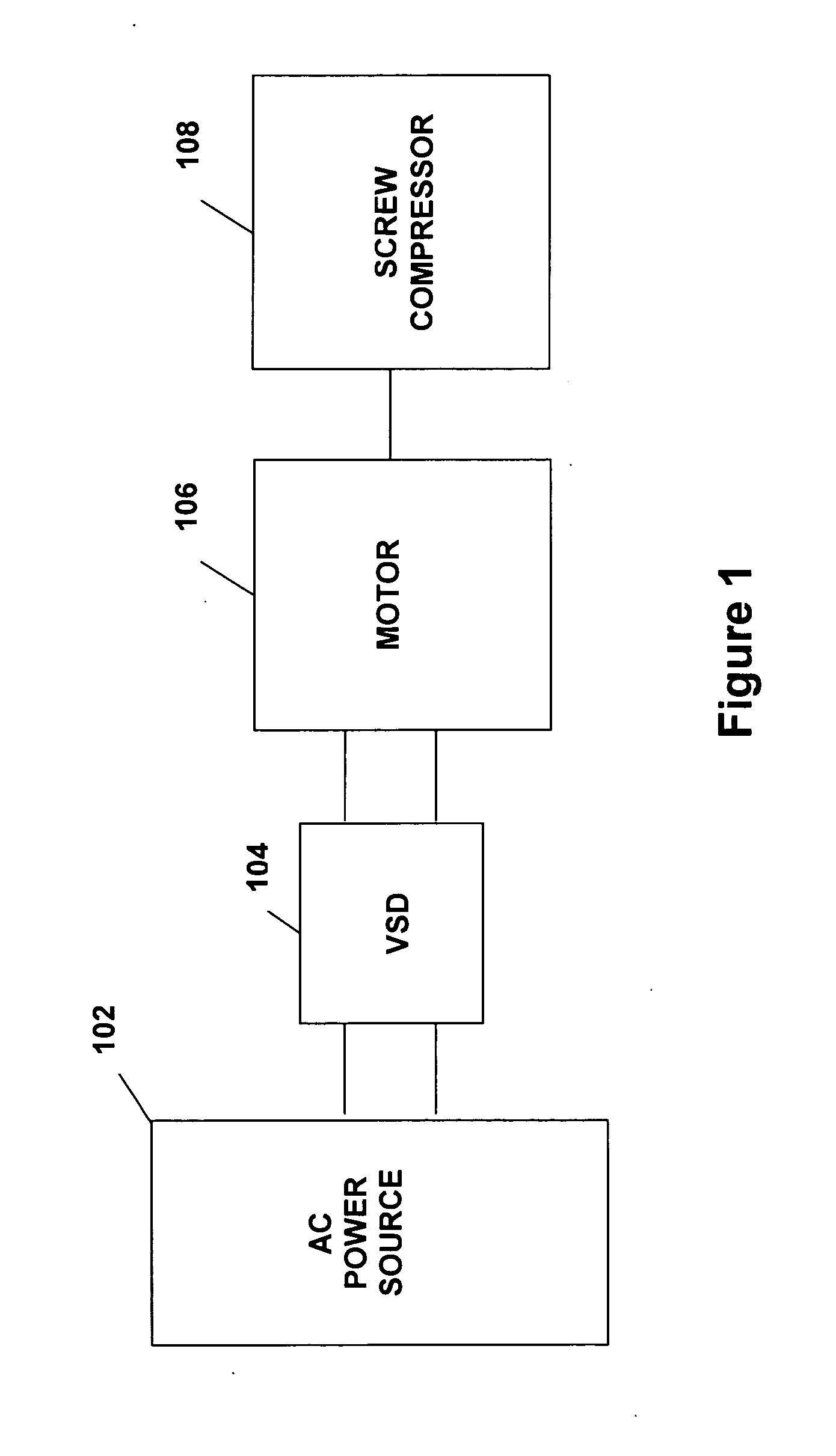

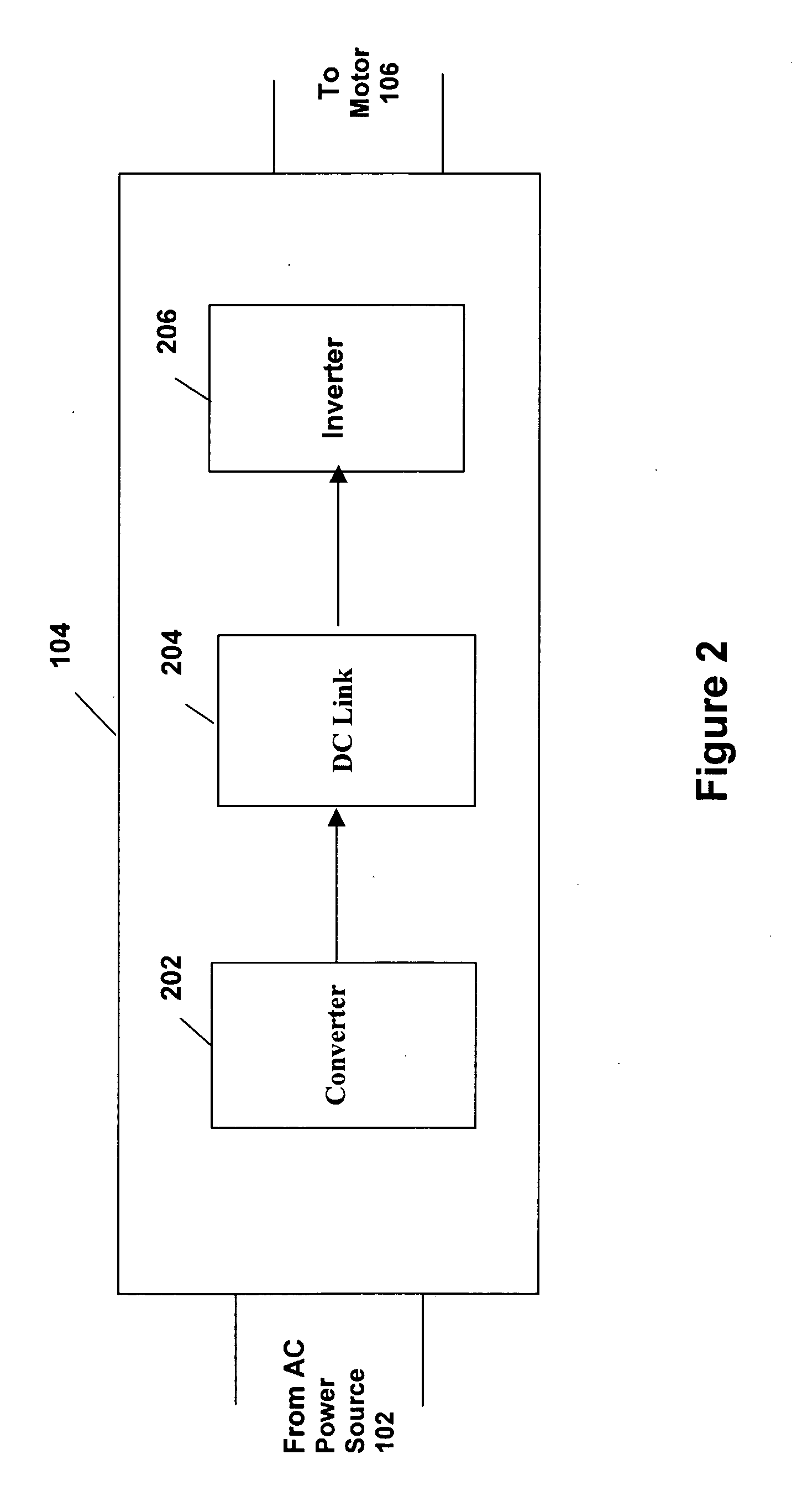

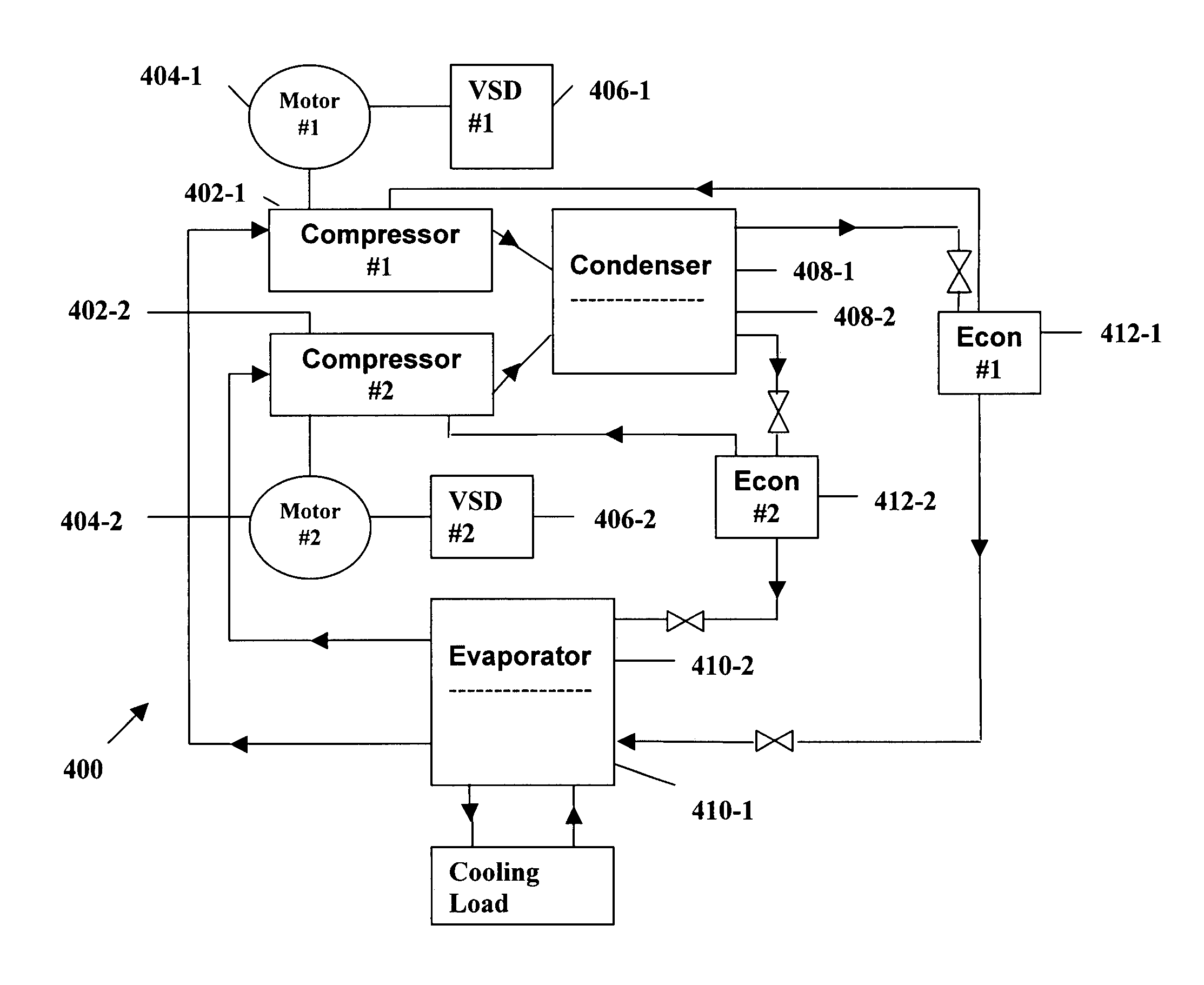

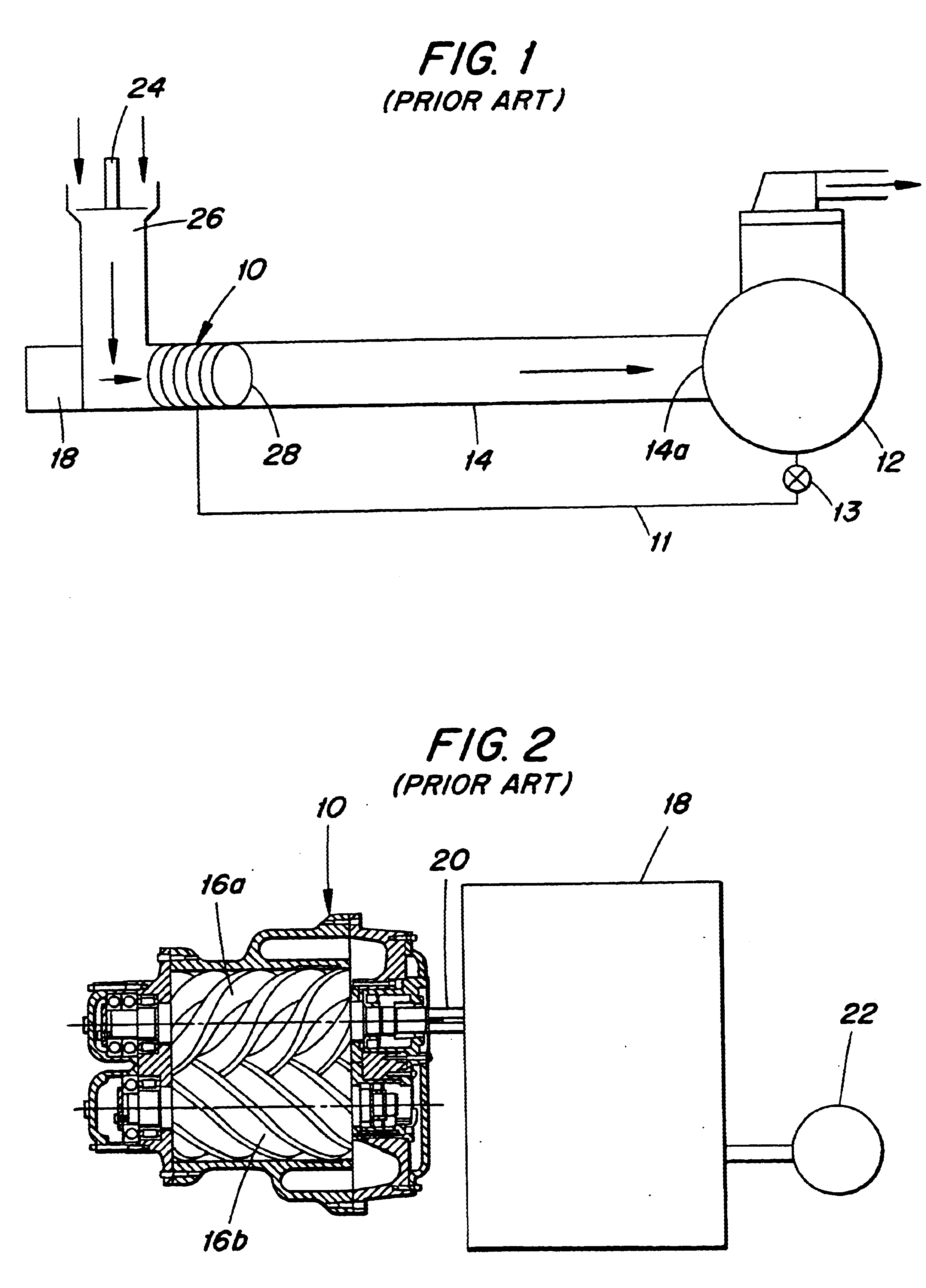

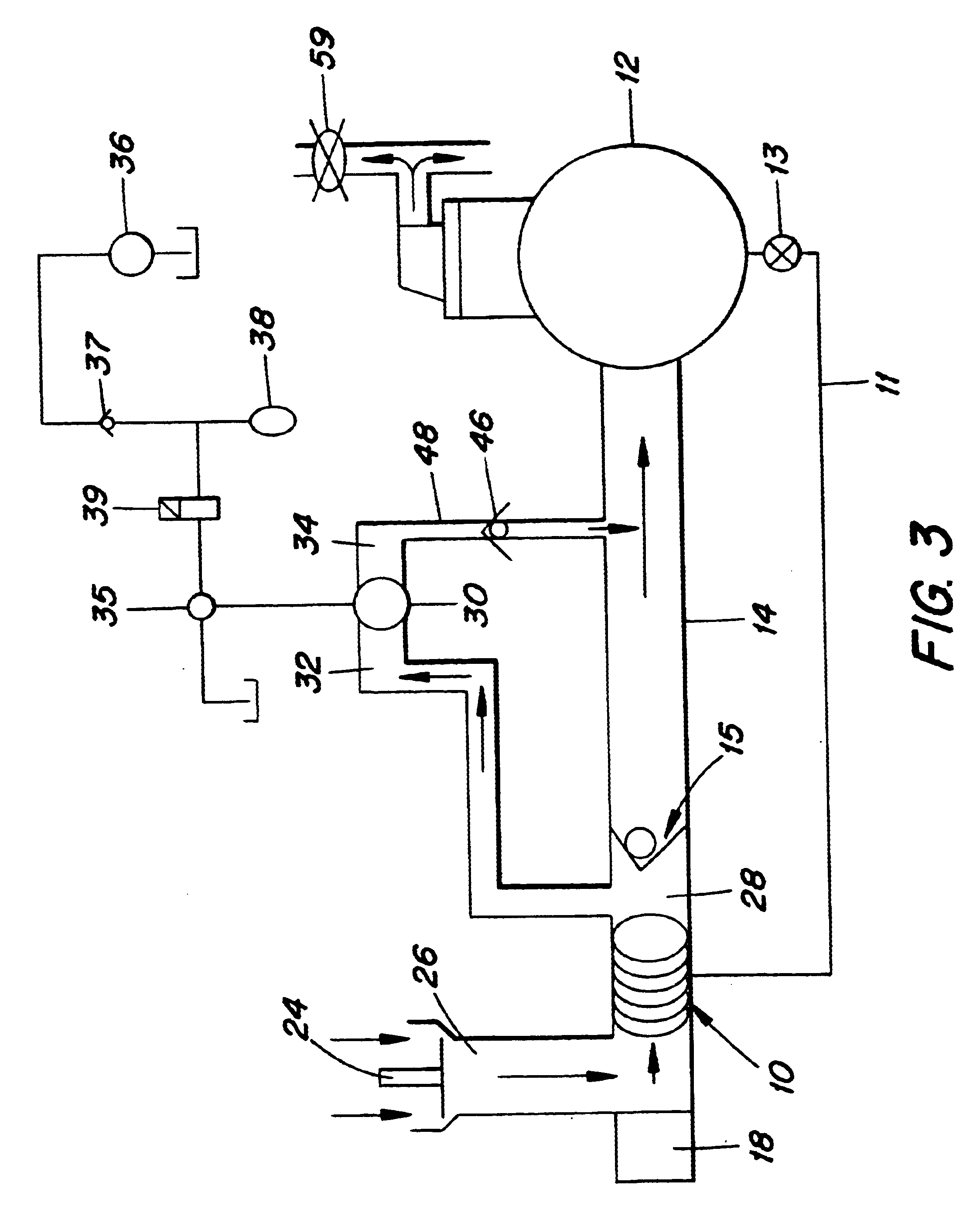

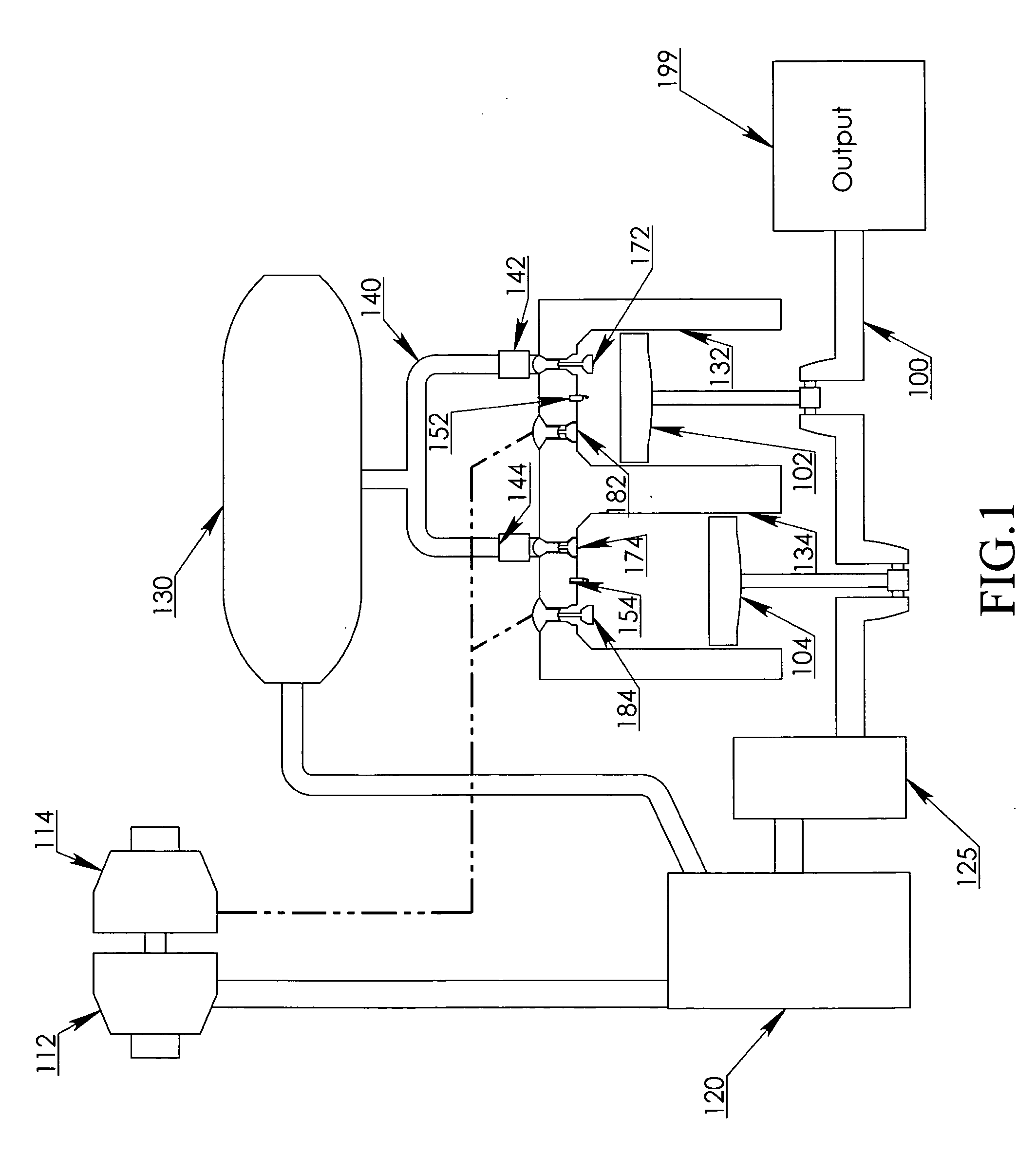

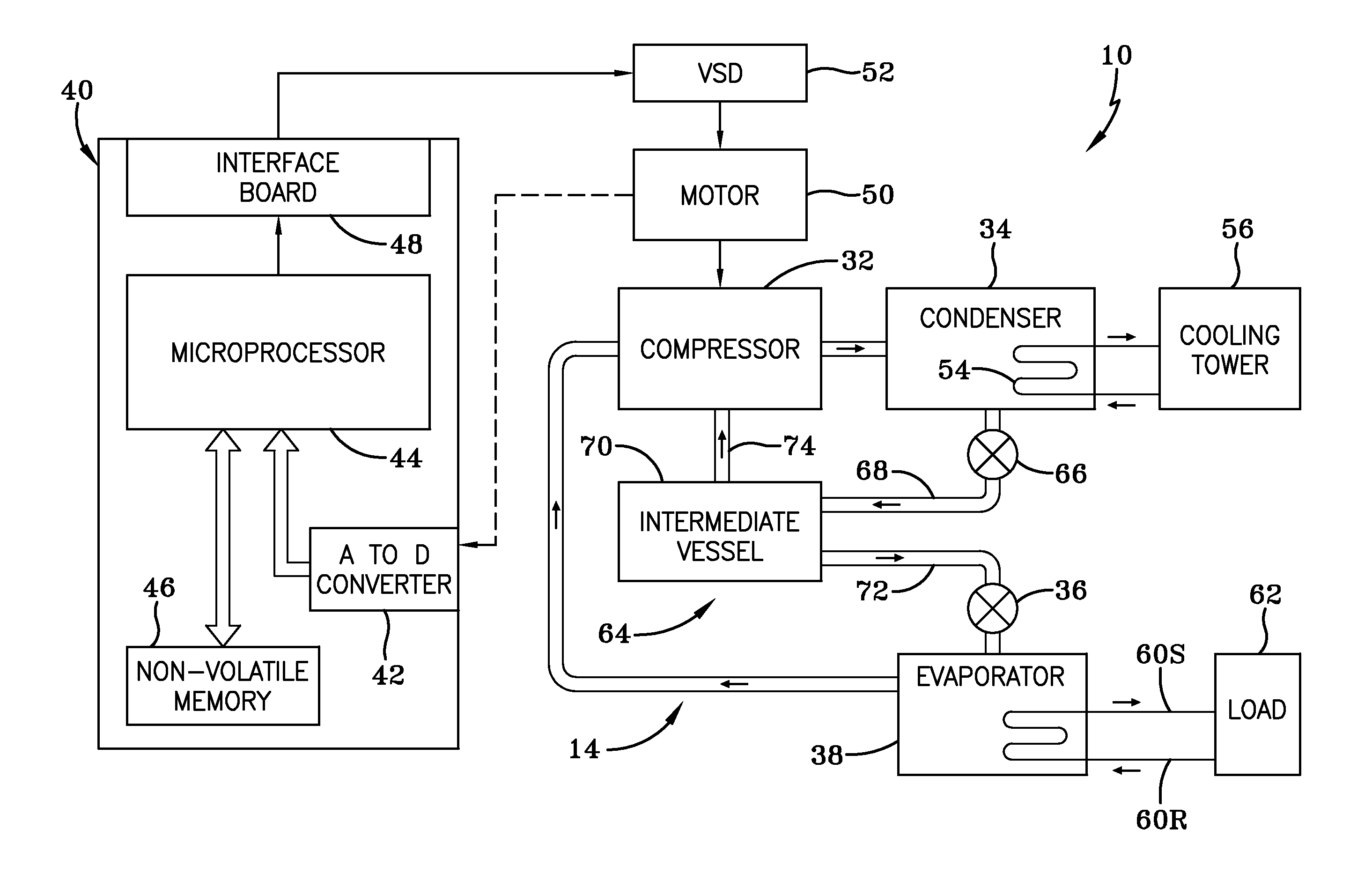

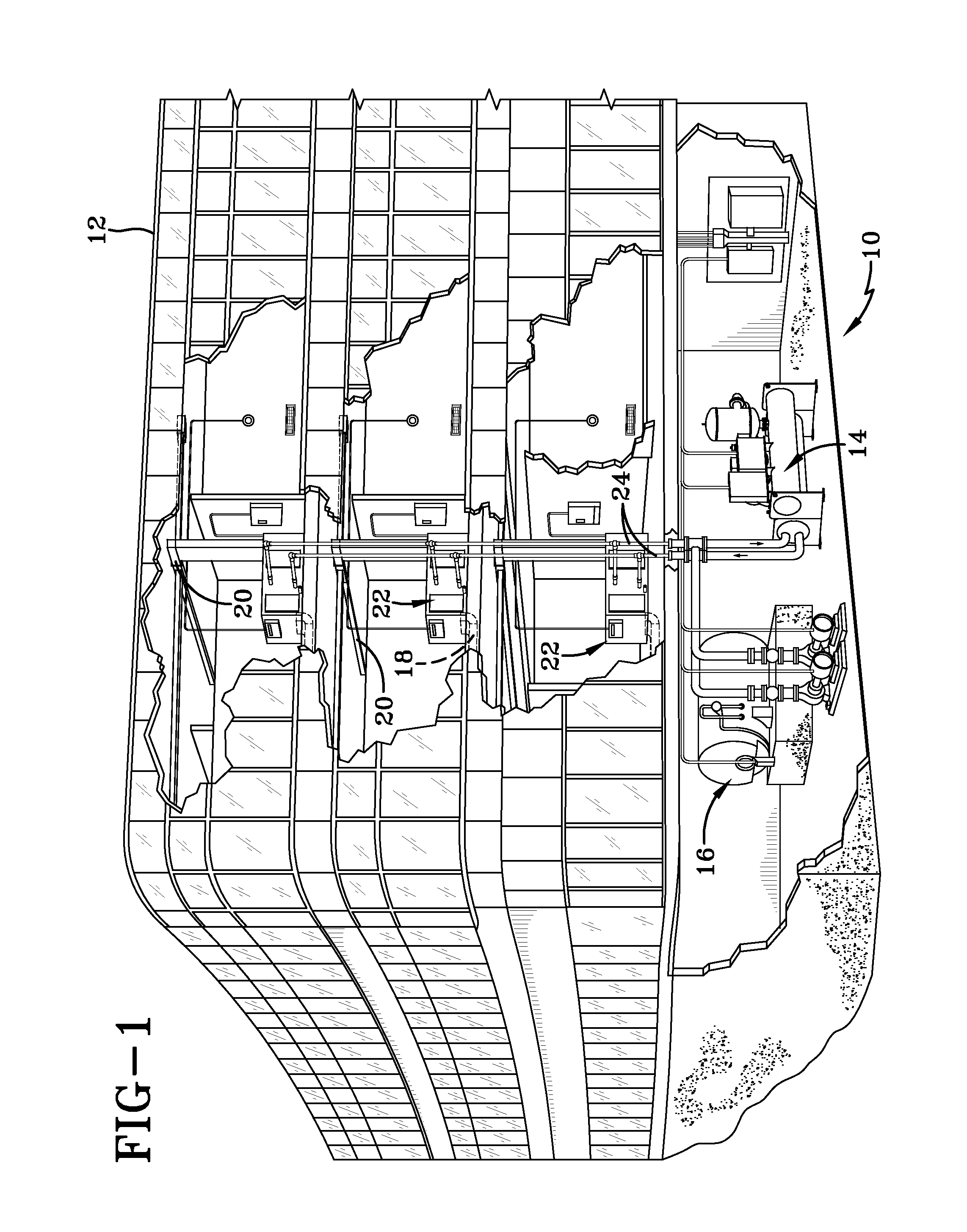

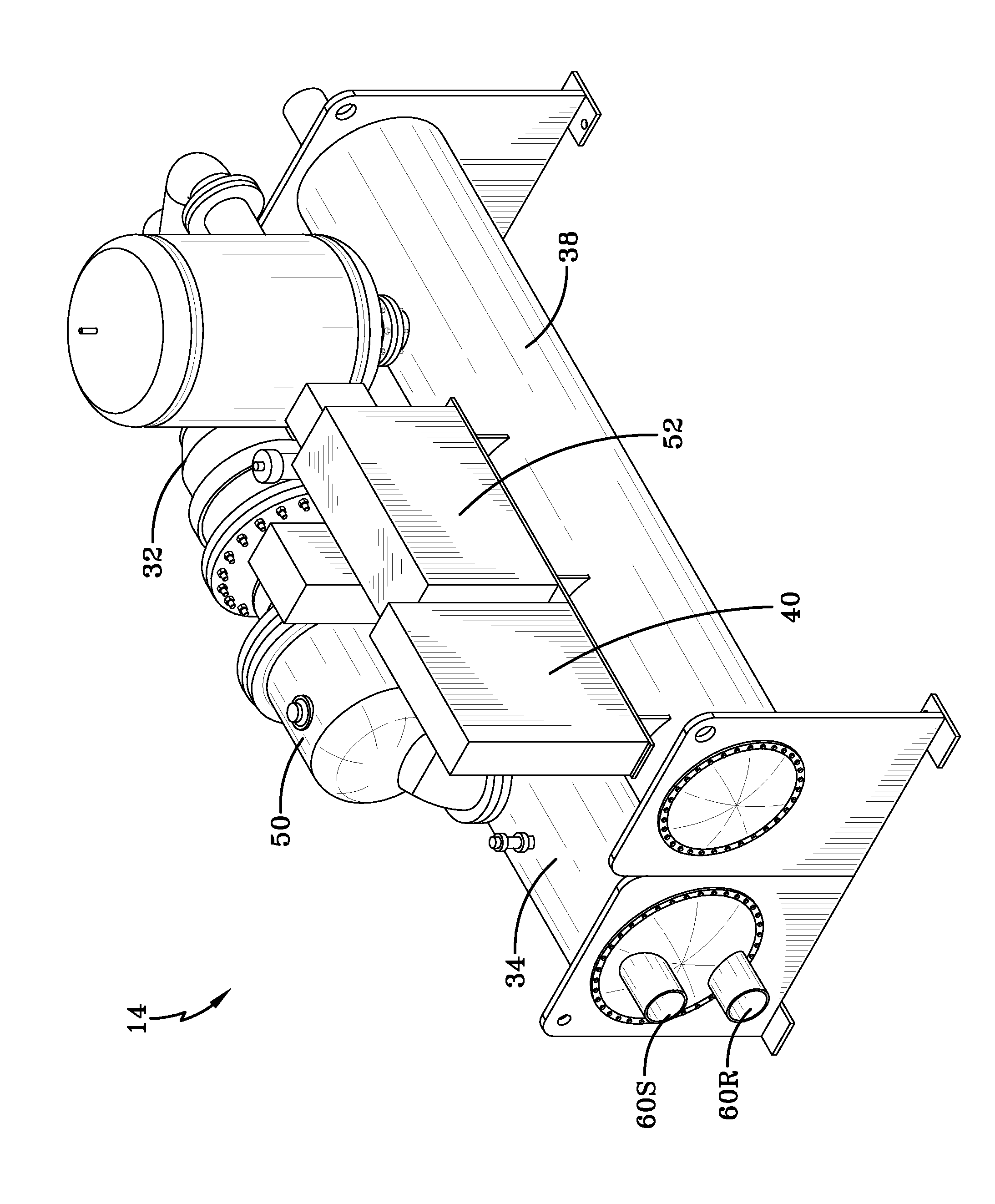

A system and method are provided for variable speed operation of a screw compressor to obtain increased capacity and efficiency. The screw compressor is connected to an induction motor driven by a variable speed drive, wherein the screw compressor has a variable output capacity that is dependent on the output speed of the motor. To obtain increased capacity and efficiency, the screw compressor is operated at a speed greater than the screw compressor's rated speed and does not include a slide valve. The maximum operating speed of the screw compressor, which speed is greater than the rated speed, is related to the maximum operating speed of the motor when operated at a voltage and frequency provided by the variable speed drive that is greater than the motor's rated voltage and frequency in a constant flux or constant volts / Hz mode.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

System and method for variable speed operation of a screw compressor

ActiveUS7096681B2Guaranteed uptimeIncrease rotor speedAC motor controlRotary piston pumpsInduction motorEngineering

A system and method are provided for variable speed operation of a screw compressor to obtain increased capacity and efficiency. The screw compressor is connected to an induction motor driven by a variable speed drive, wherein the screw compressor has a variable output capacity that is dependent on the output speed of the motor. To obtain increased capacity and efficiency, the screw compressor is operated at a speed greater than the screw compressor's rated speed and does not include a slide valve. The maximum operating speed of the screw compressor, which speed is greater than the rated speed, is related to the maximum operating speed of the motor when operated at a voltage and frequency provided by the variable speed drive that is greater than the motor's rated voltage and frequency in a constant flux or constant volts / Hz mode.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

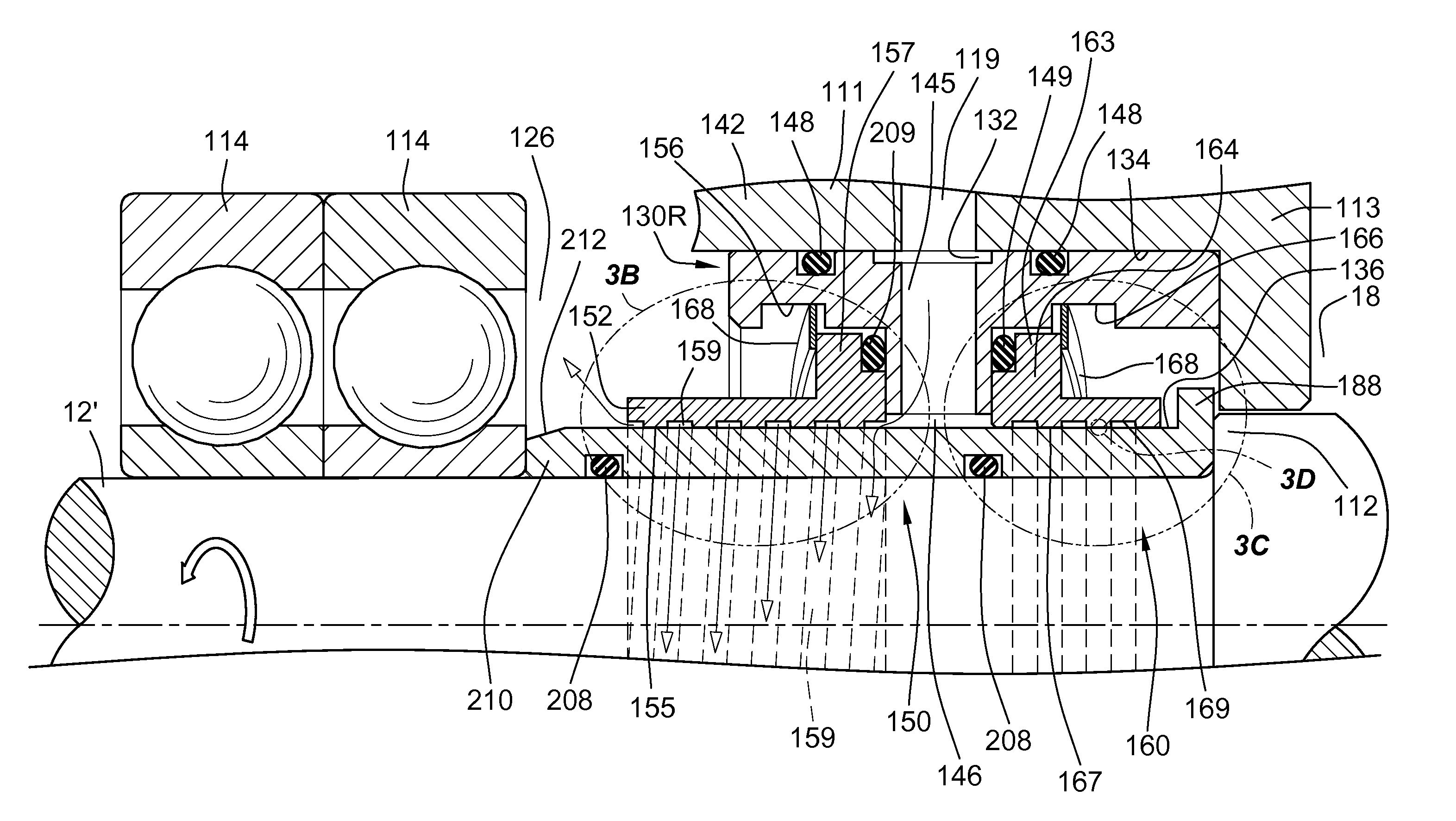

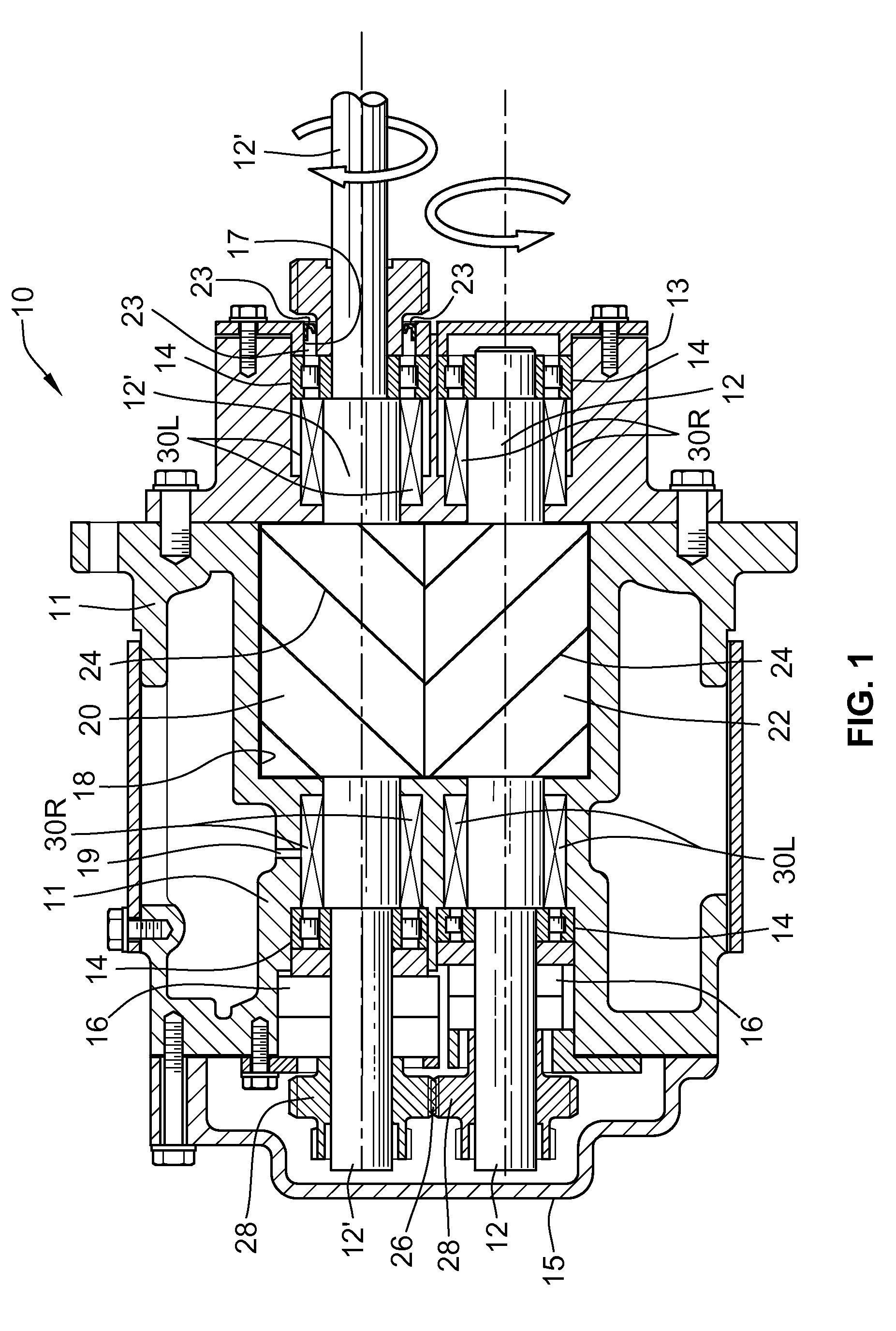

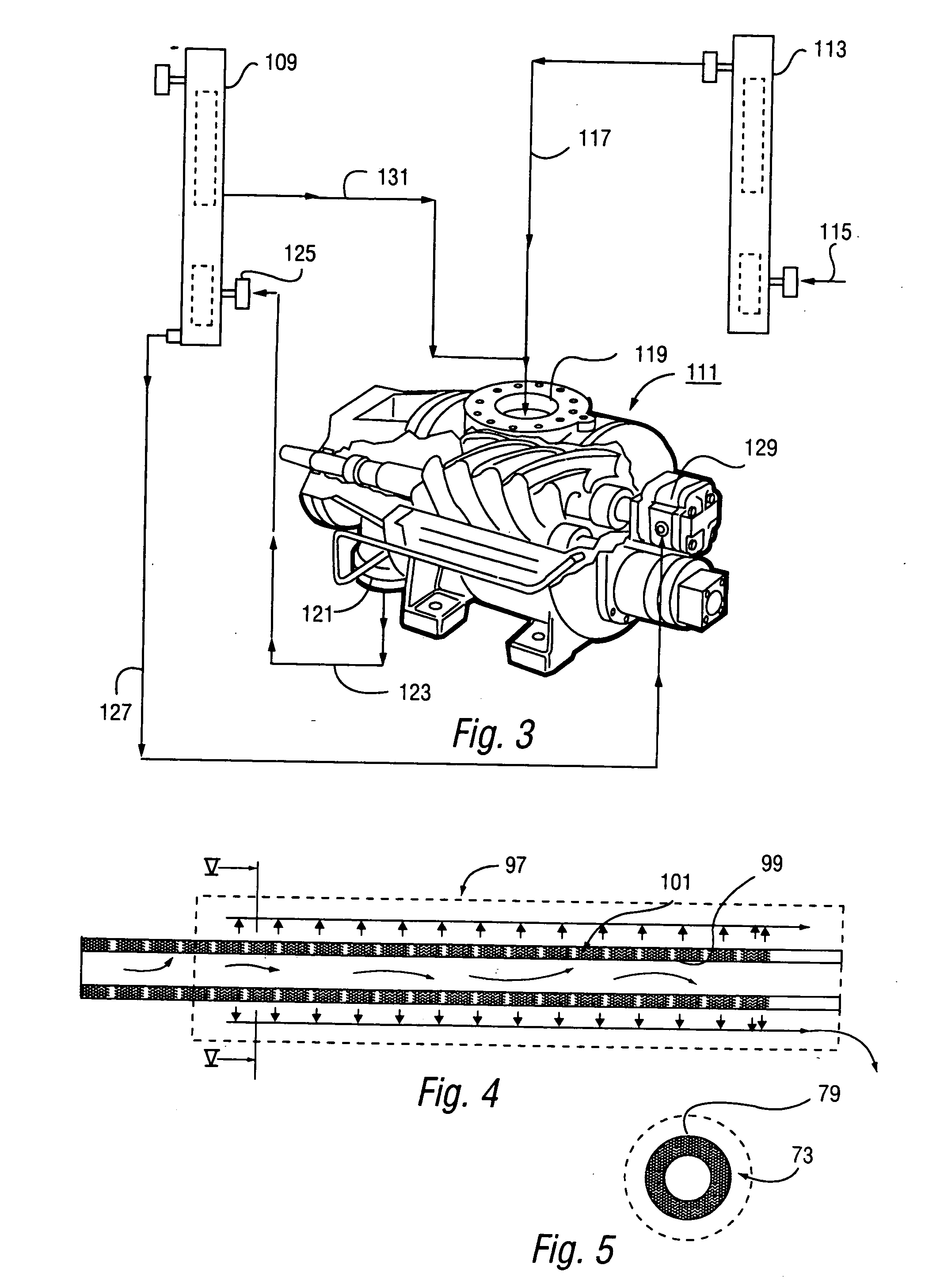

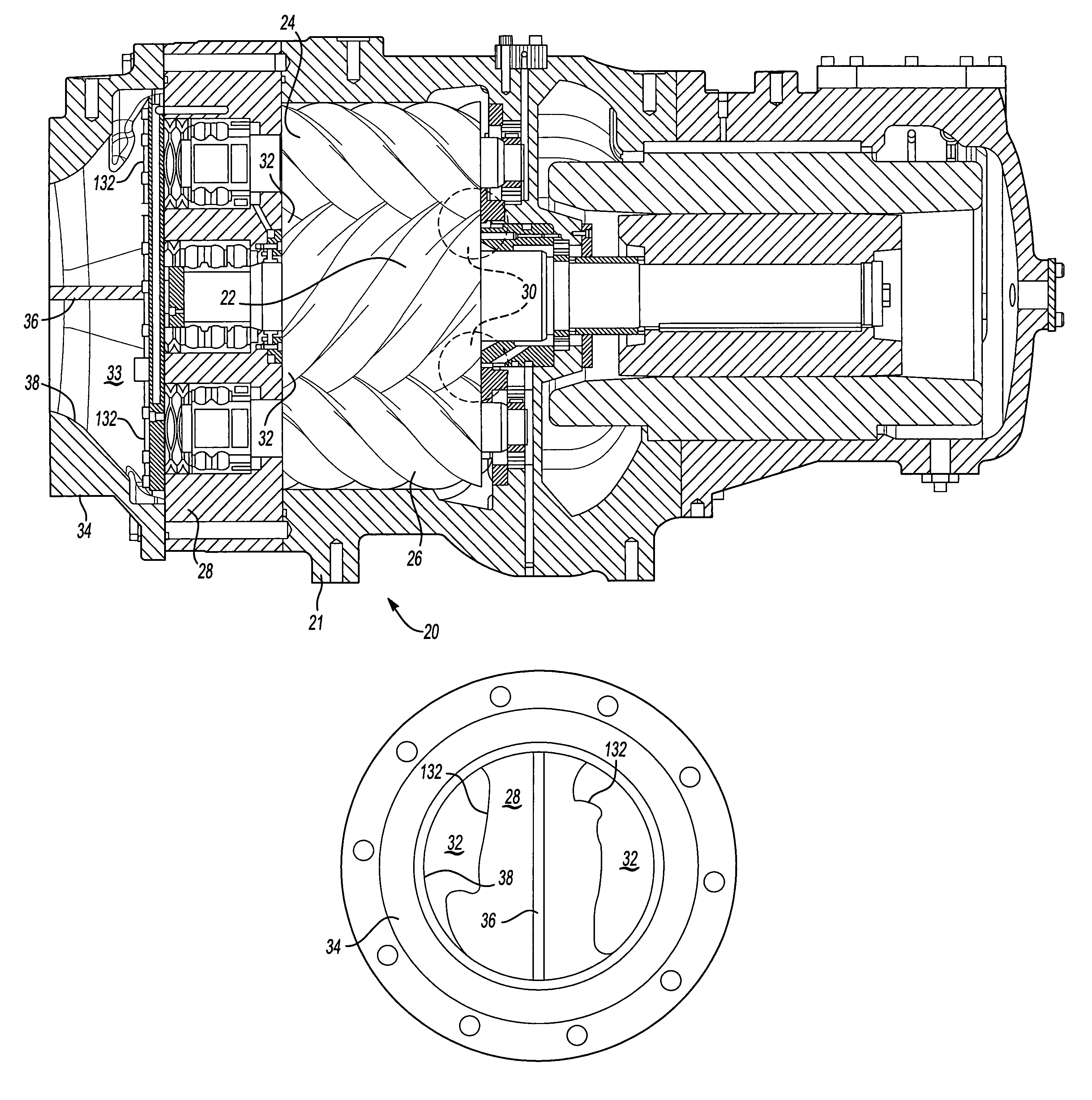

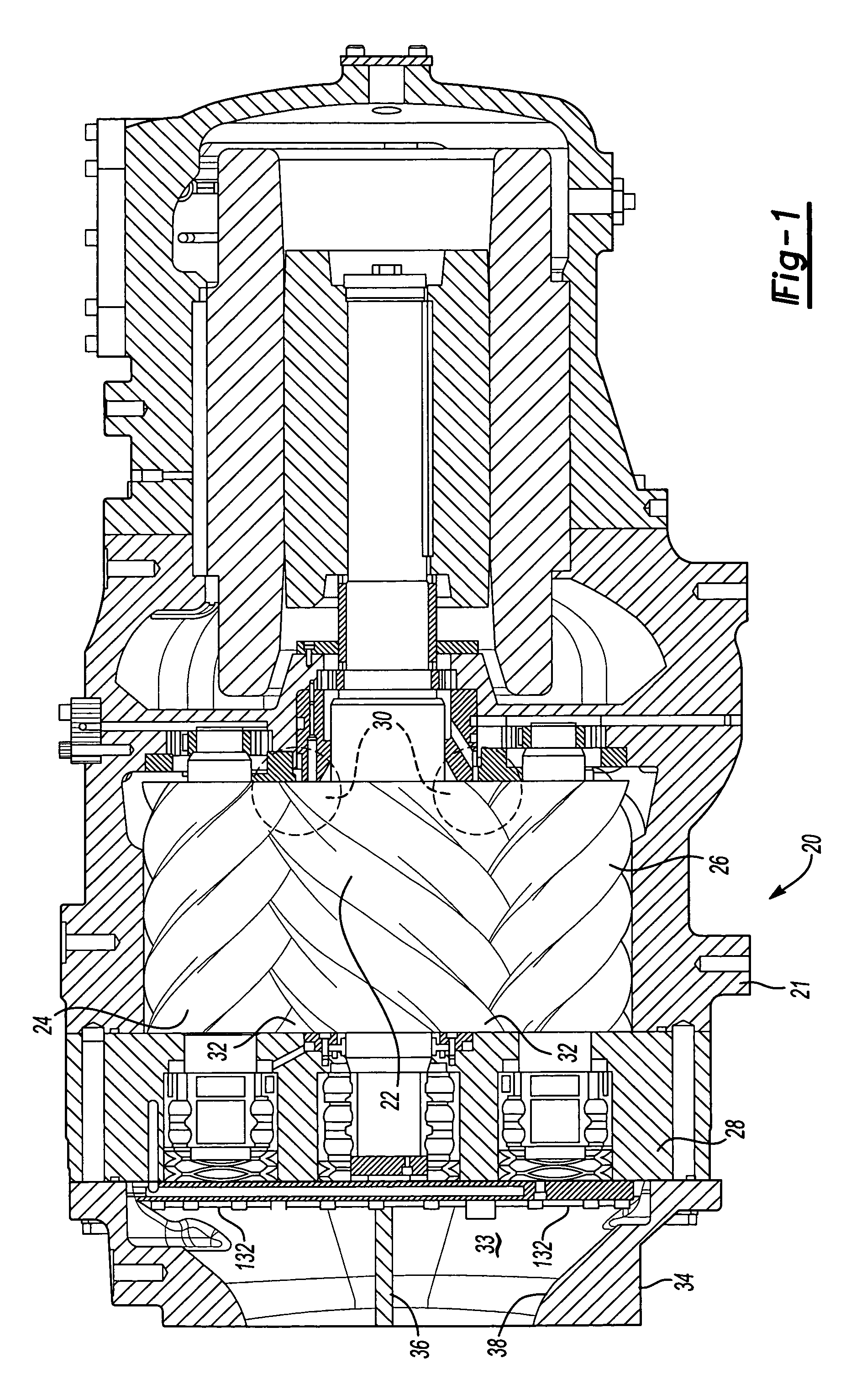

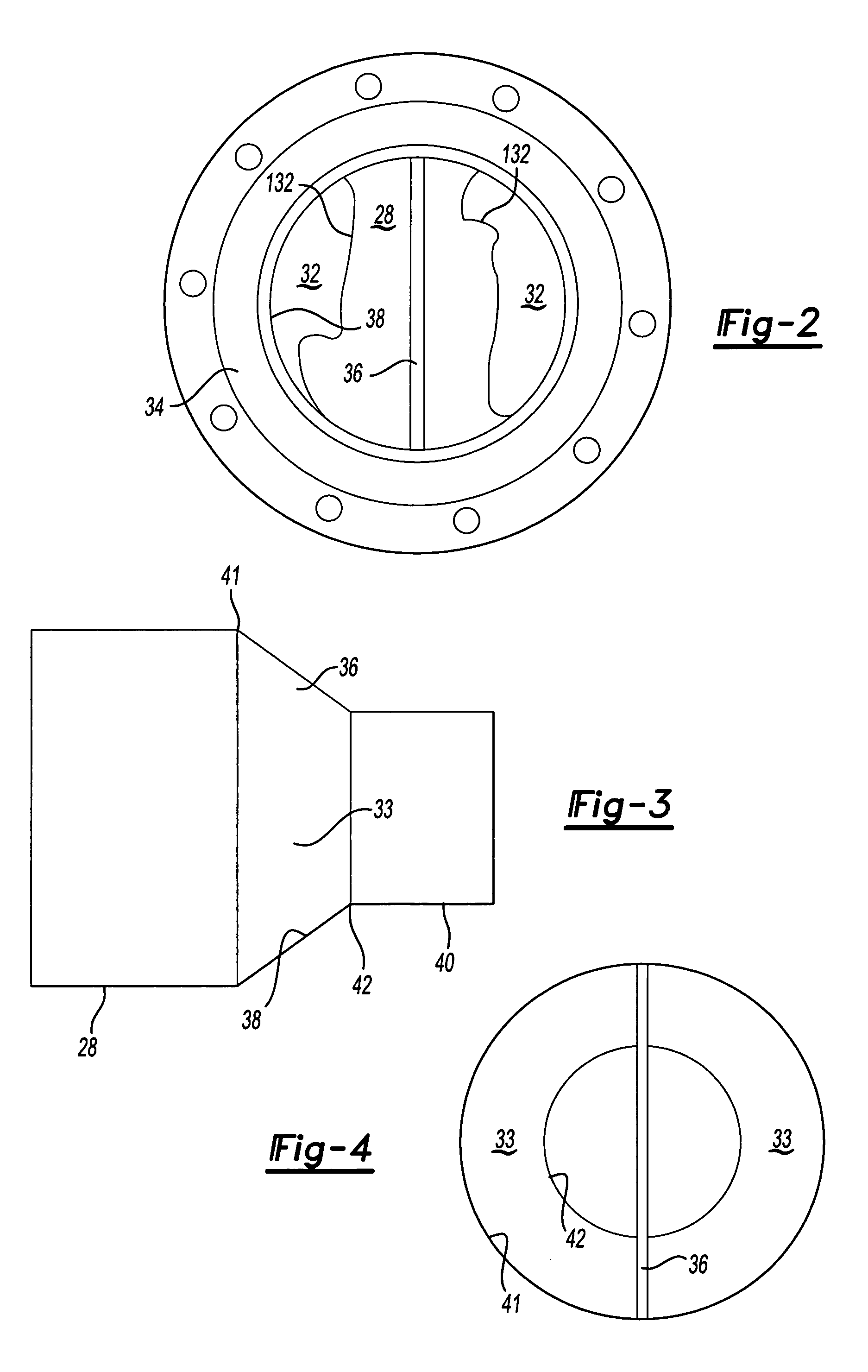

Seal for oil-free rotary displacement compressor

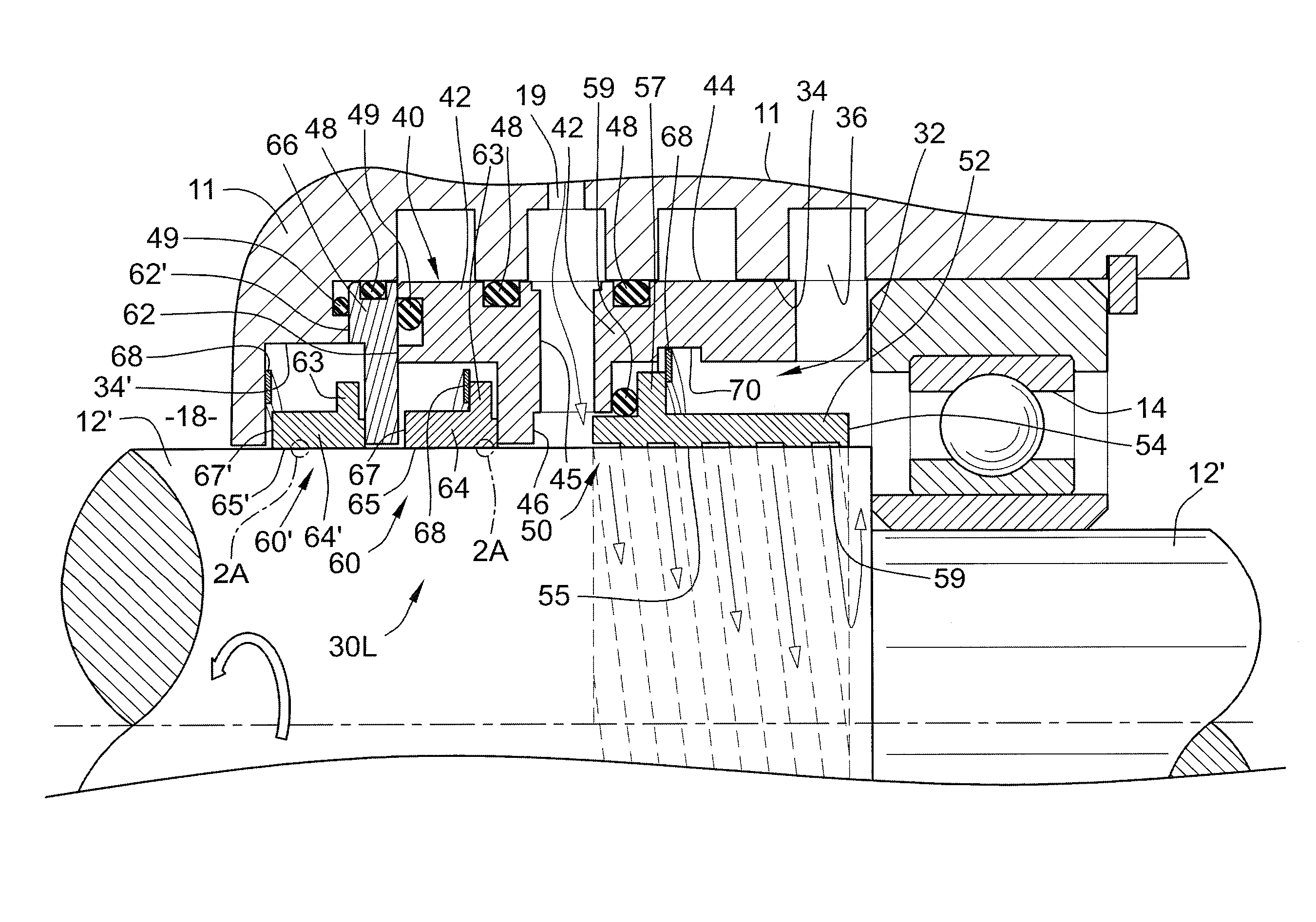

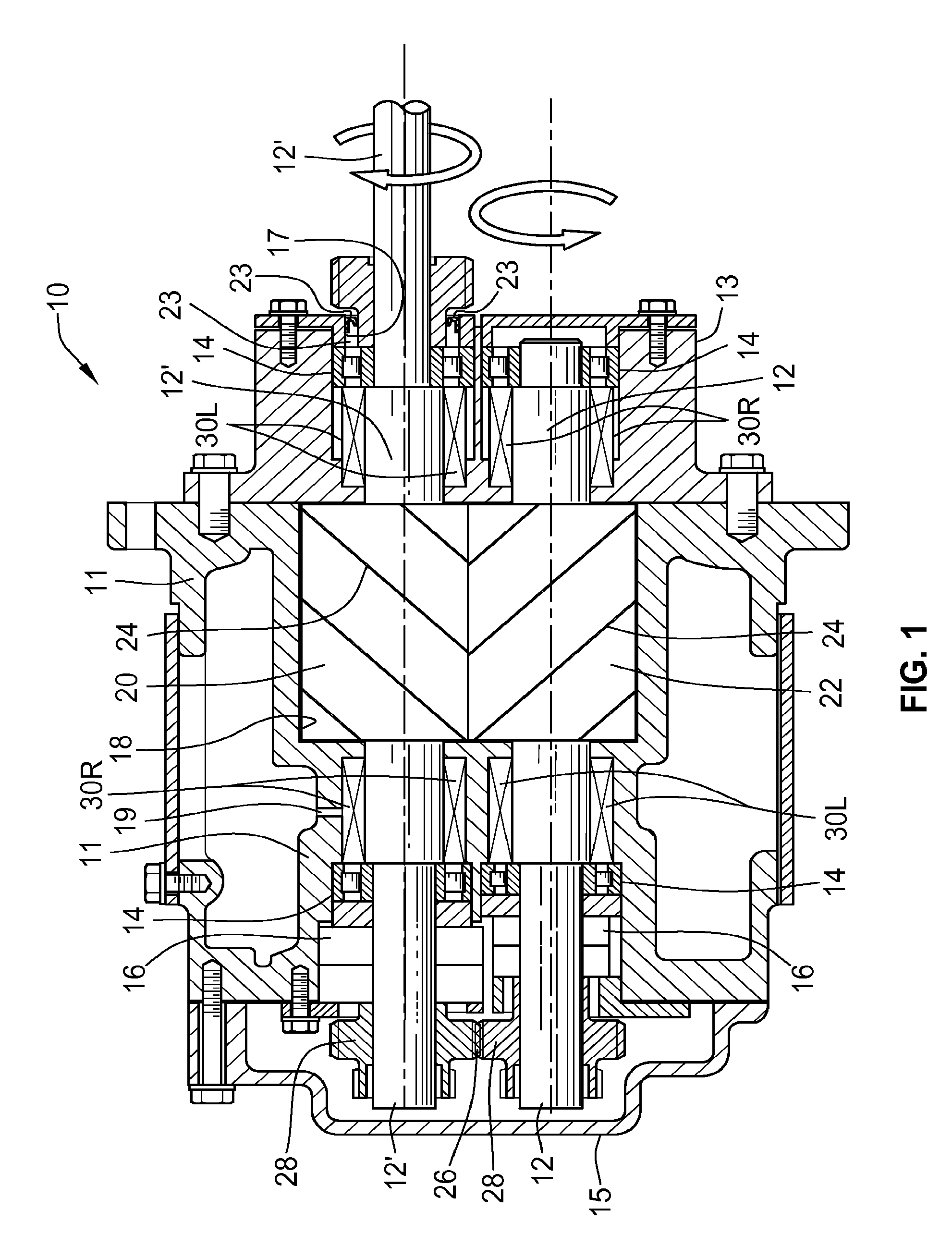

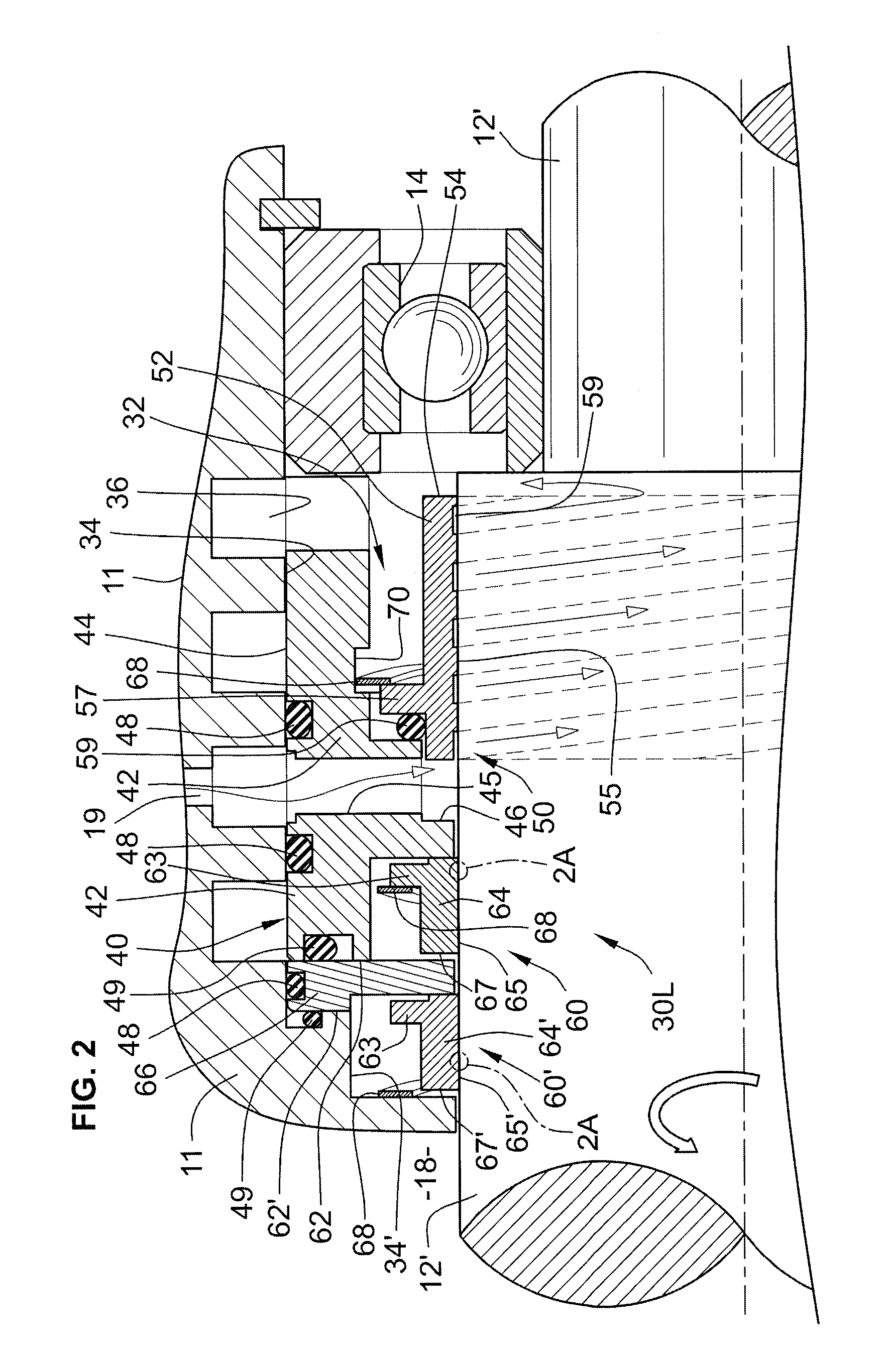

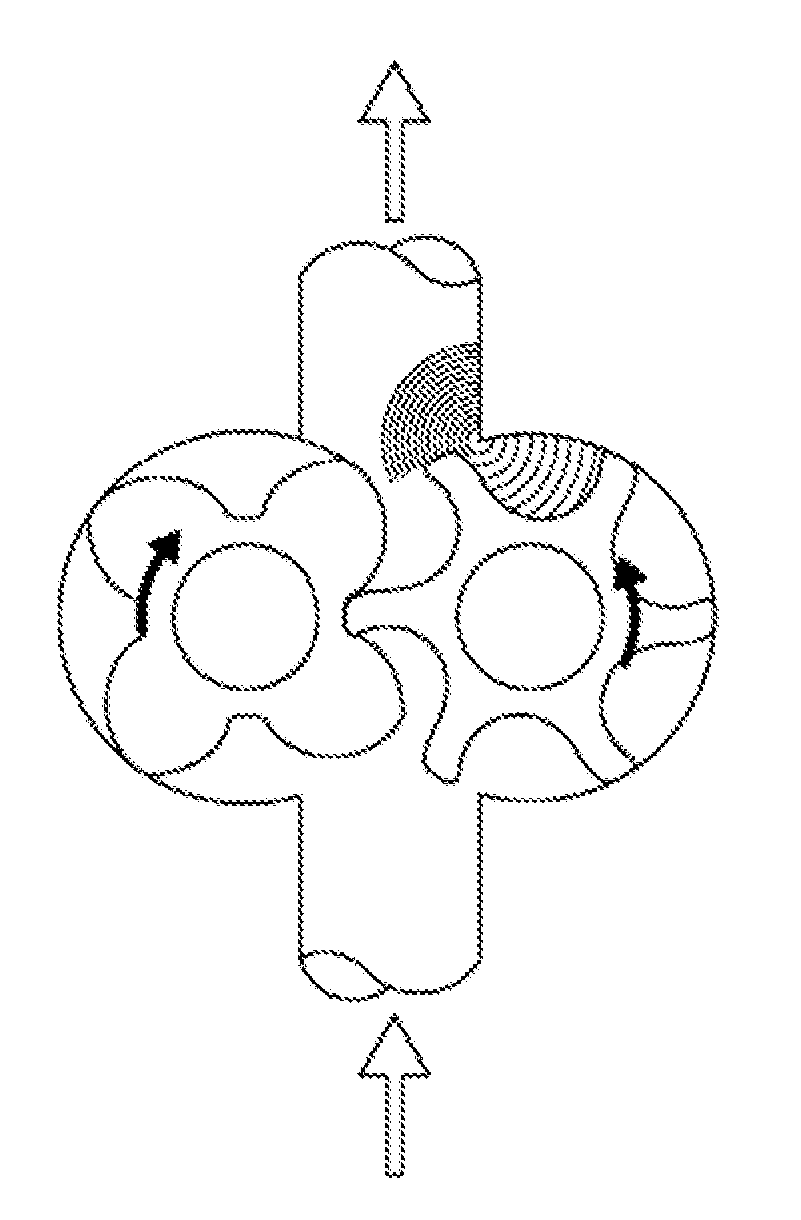

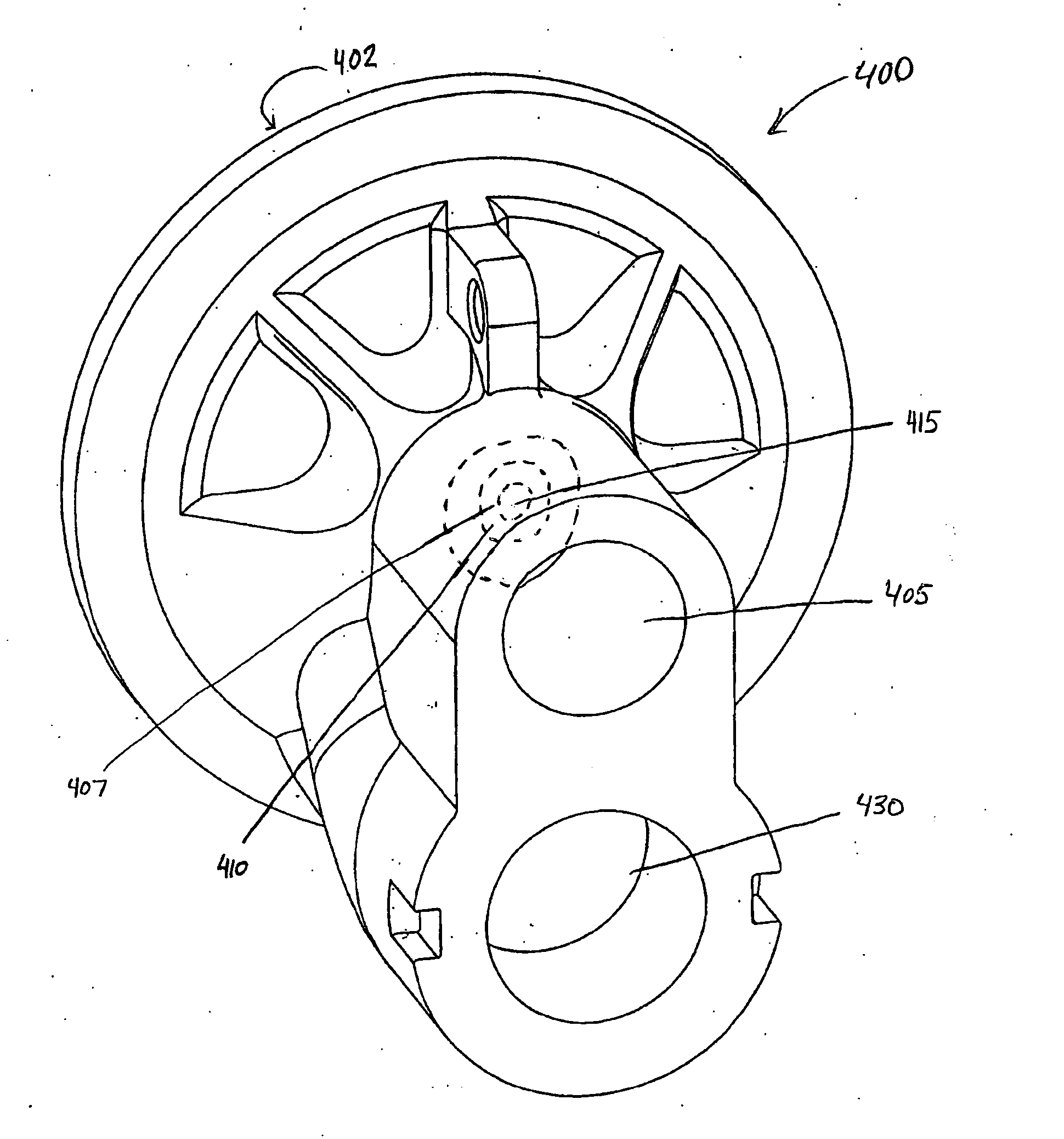

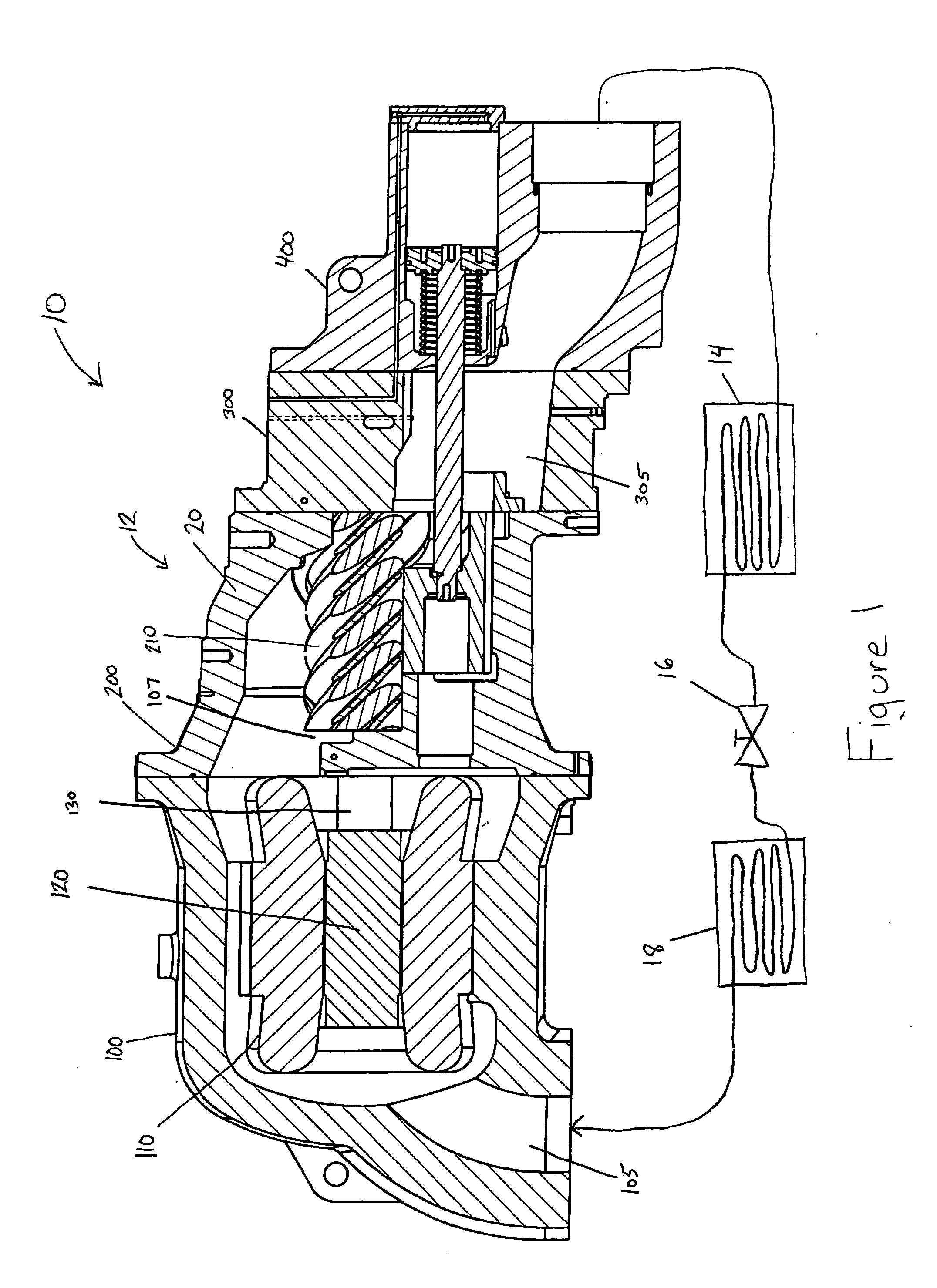

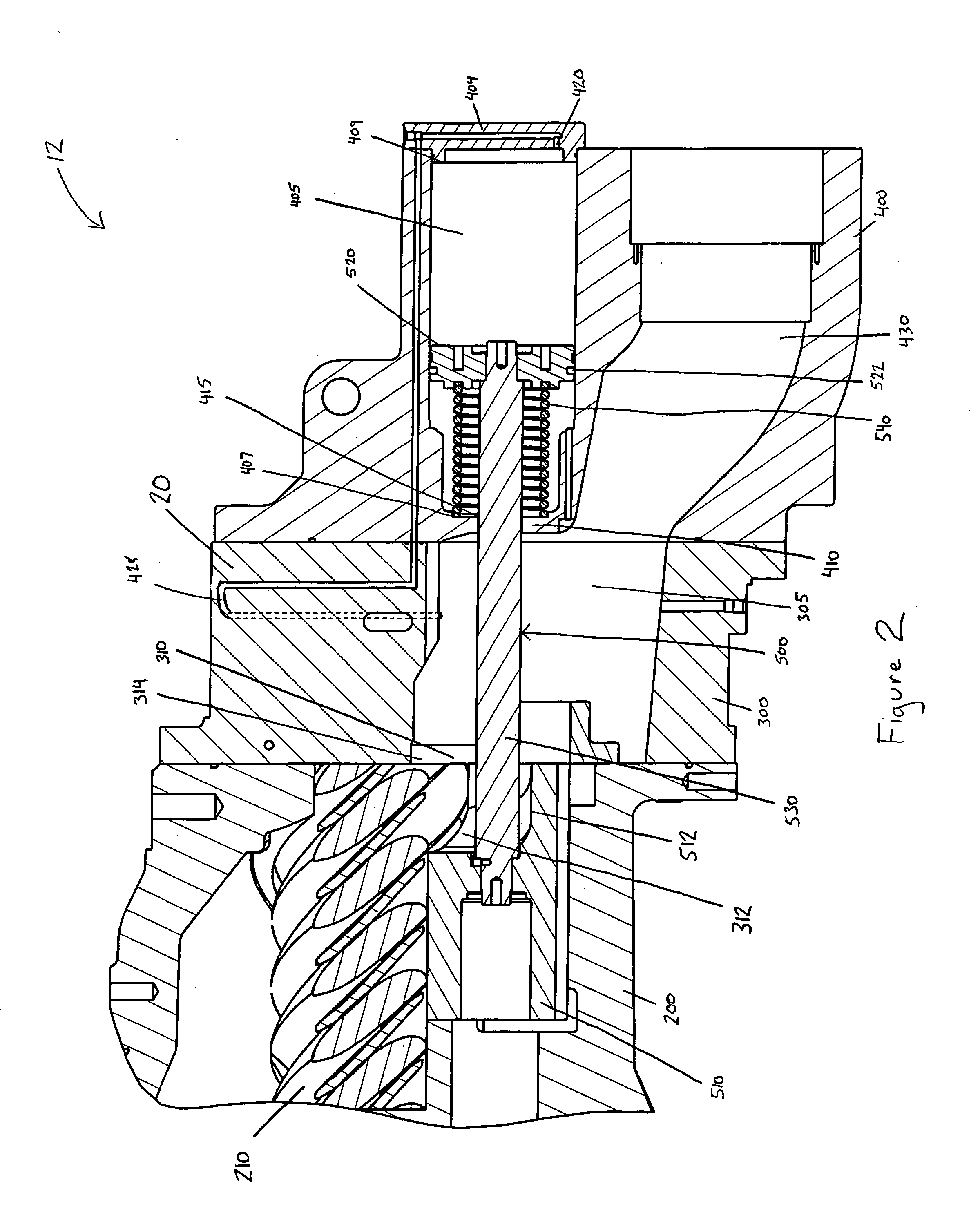

Non-contacting cartridge shaft seals prevent leakage loss of process gases in an “oil free” rotary screw compressor or blower, while simultaneously preventing ingress of lubricating oil to the pumping chamber, allowing the compressor / blower to generate process pressure differentials without oil contamination. A compact unitized seal cartridge assembly is provided in the end plates of the pump housing. One of the rotor shafts extends through an aperture in the end plate or housing, between the pumping chamber and oil-lubricated gear / bearing cases. Internal elements have the ability to self-align radially achieving essential concentricity with shaft rotational axes. The rotor shafts or sleeves non-contact relationship during operation allow increased ranges of shaft rotational speeds. Air seal elements restrict flow of process air from the pumping or compression chamber, and oil seal elements with a directional spiral groove on the inside diameter prevent the leakage of lubricating oil to the process or atmosphere.

Owner:ERGOSEAL

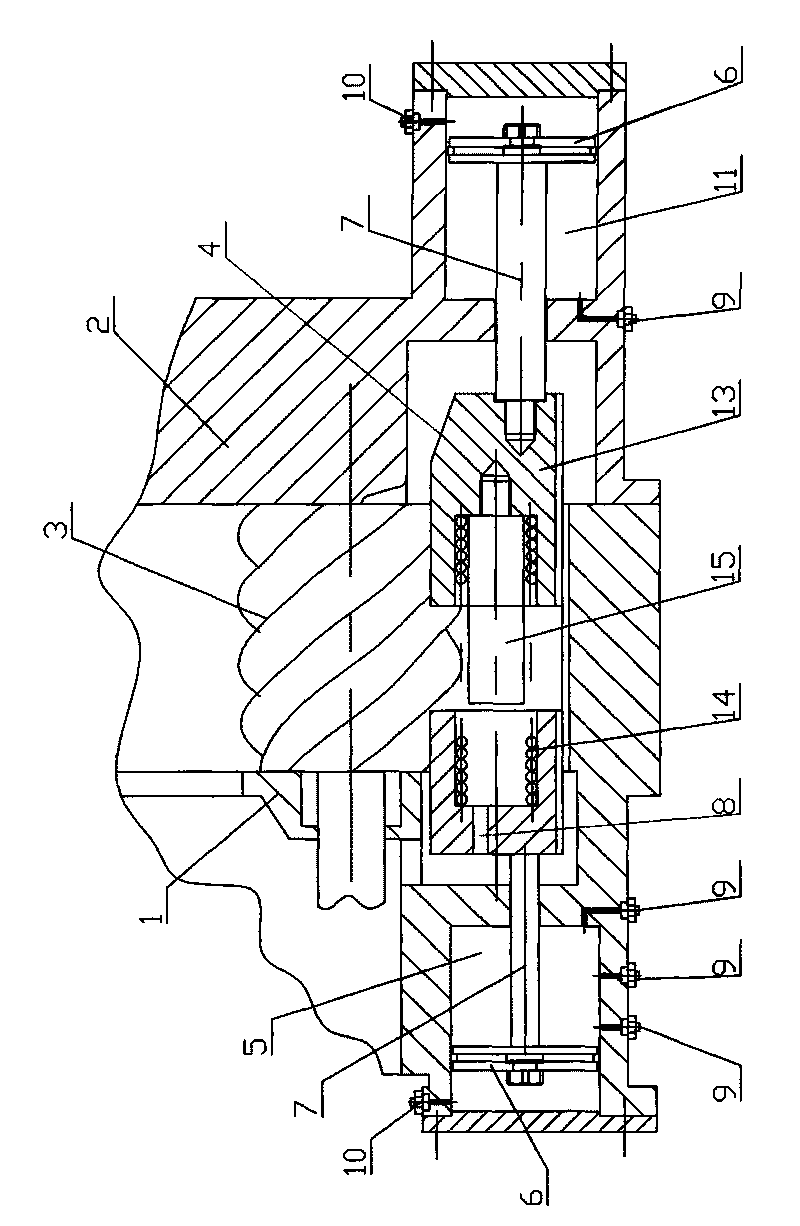

Screw-type compressor with adjustable interior volume specific ratio

ActiveCN101761479AAdaptableImprove energy savingRotary piston pumpsRotary piston liquid enginesEngineeringCylinder block

The invention discloses a screw-type compressor with adjustable interior volume specific ratio, comprising a compressor housing and an exhaust end housing, wherein a screw rotor is arranged between the compressor housing and the exhaust end housing; an air suction port is arranged on the compressor housing; an axial exhaust port and a radial exhaust port are arranged on the exhaust end housing; an actuating part is arranged at the radial exhaust port; the compressor housing or the exhaust end housing is also provided with a cylinder body in which a piston is arranged; an oil inlet side of the cylinder body is provided with an oil inlet; an oil outlet side of the cylinder body is provided with at least two oil outlets along the axial direction; one end of a piston rod is connected with the piston, and the other end thereof is connected with the actuating part; and the radial exhaust port is arranged on the actuating part. In the invention, the interior volume specific ratio of the screw-type compressor can be adjusted according to needs, and the screw-type compressor has strong adaptability and good energy saving effect.

Owner:GREE ELECTRIC APPLIANCES INC

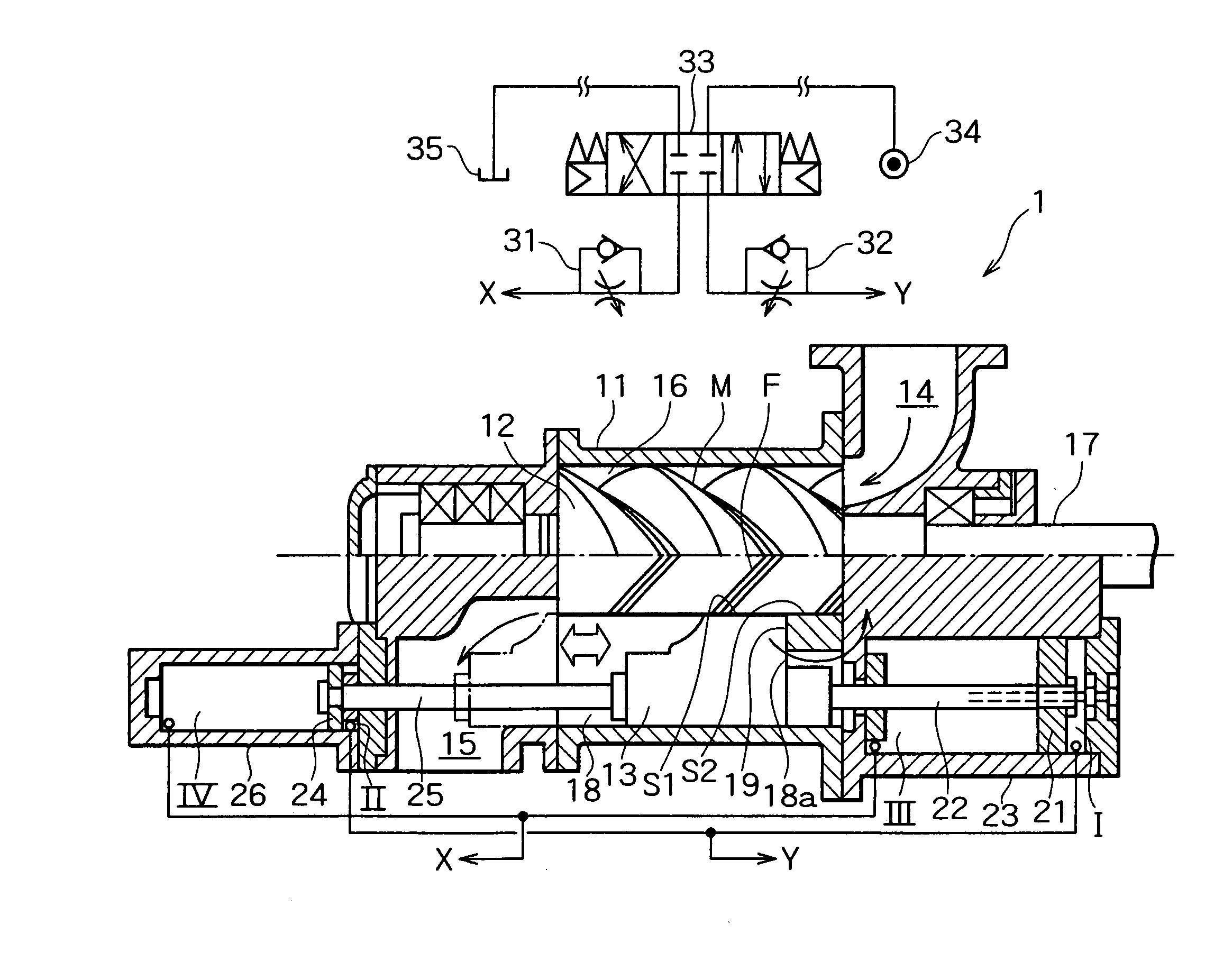

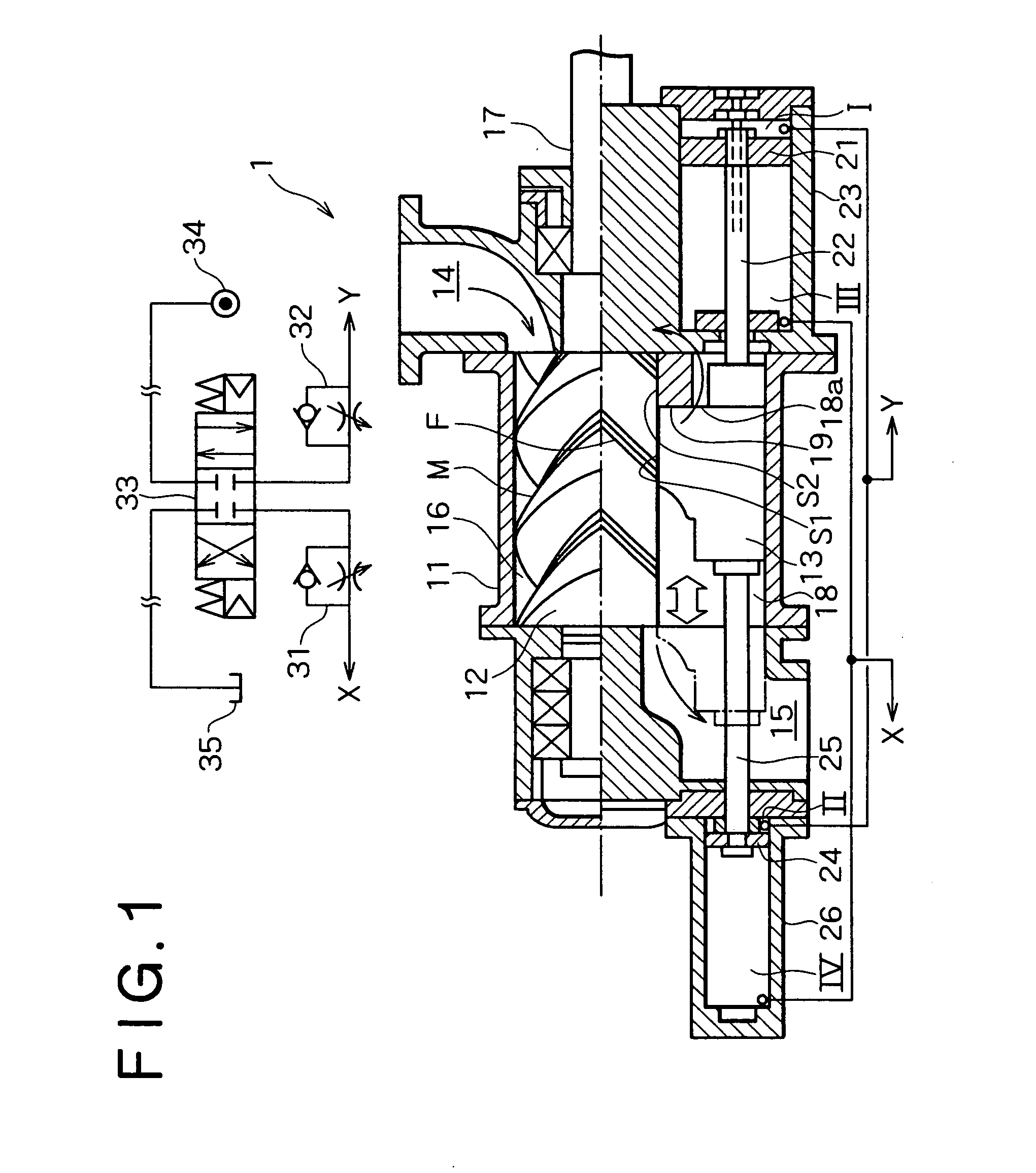

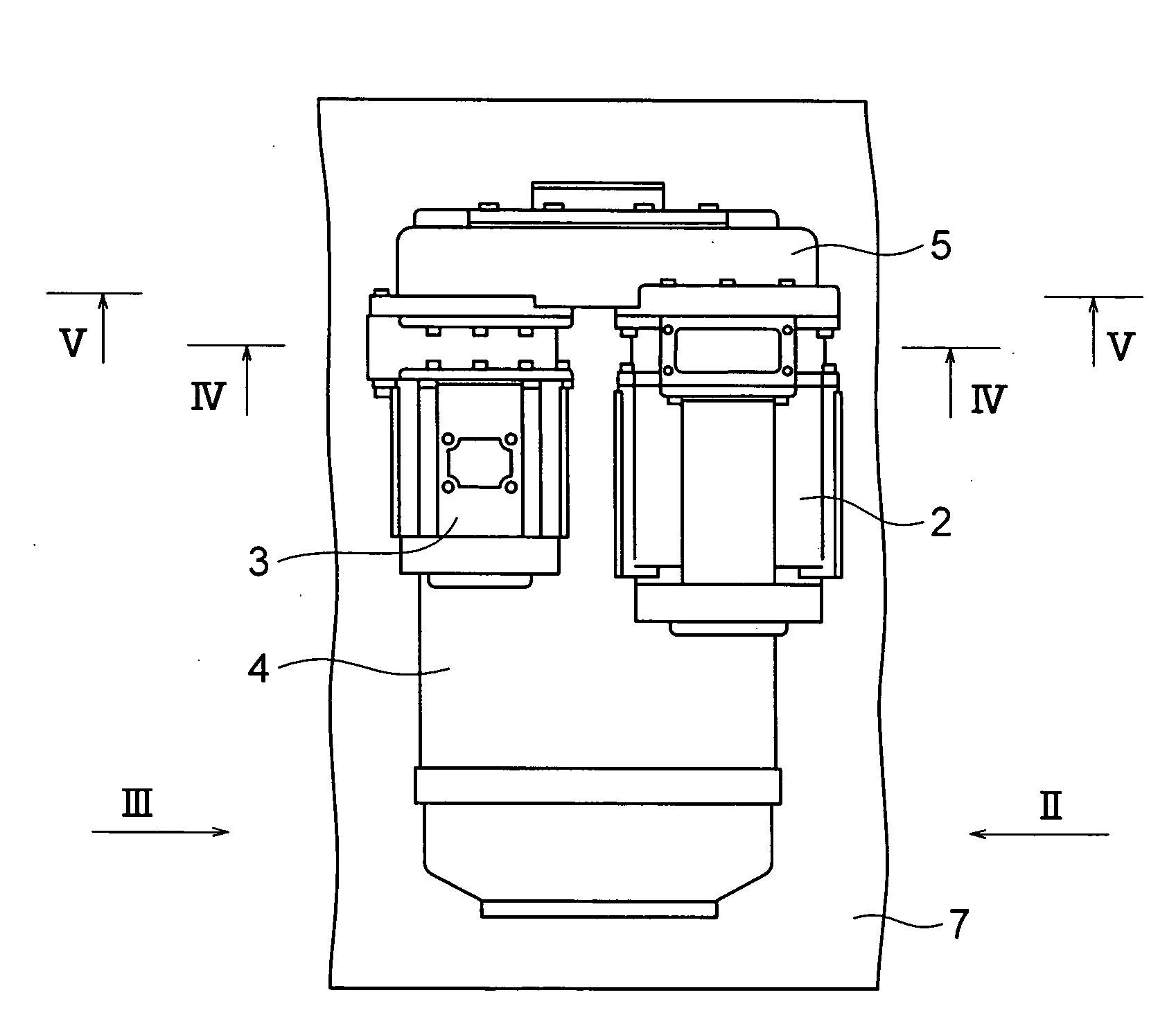

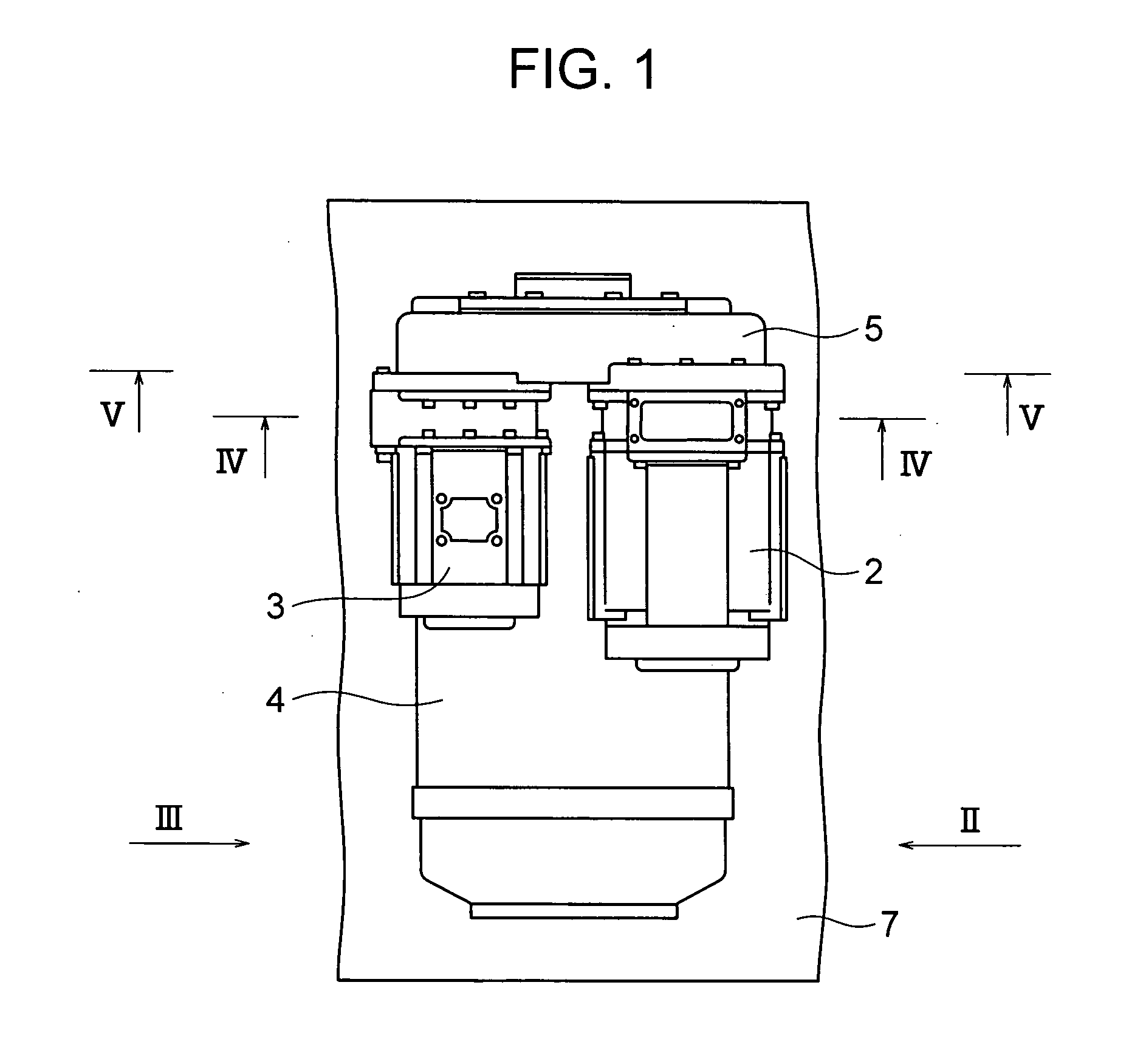

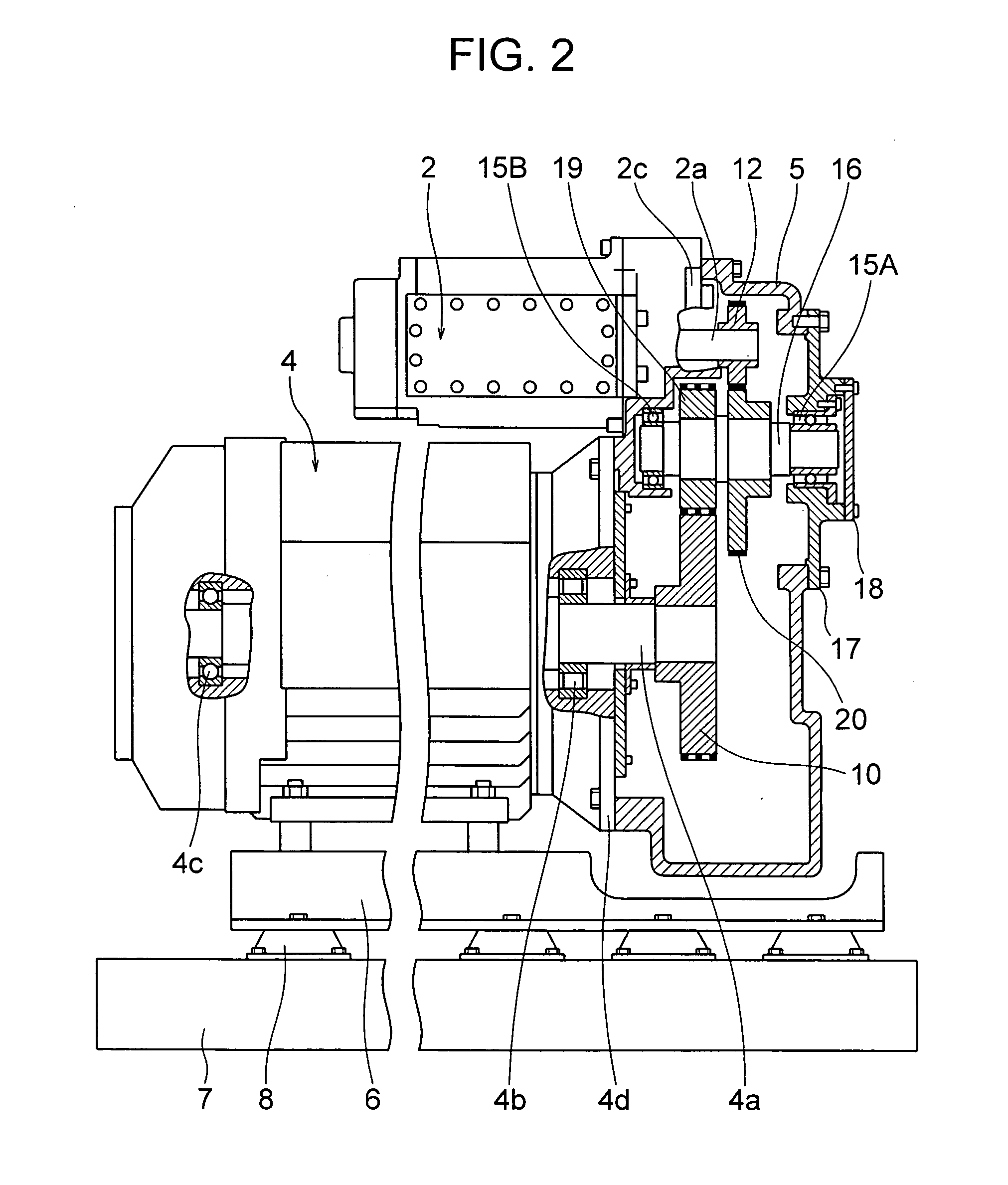

Screw compressor

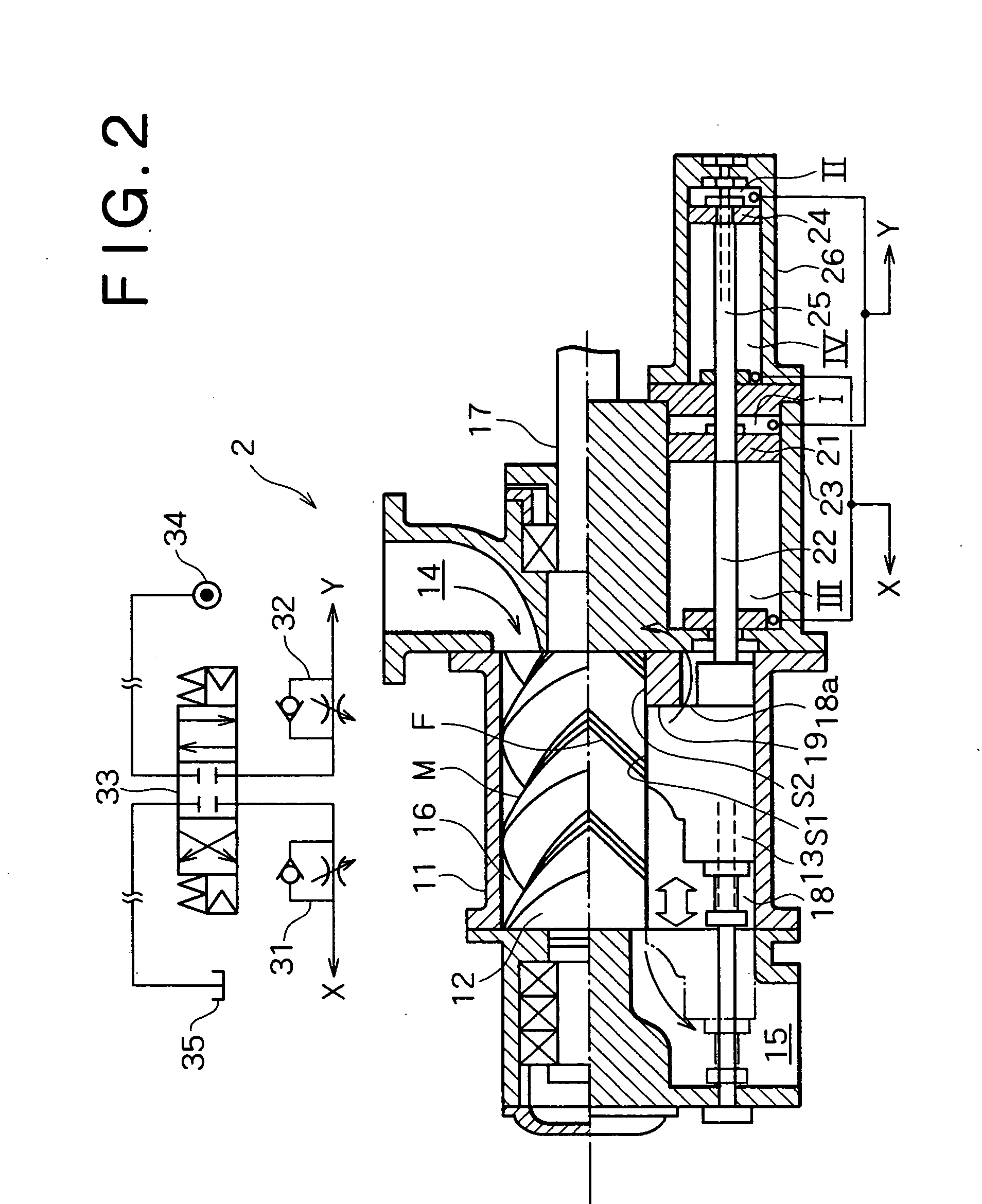

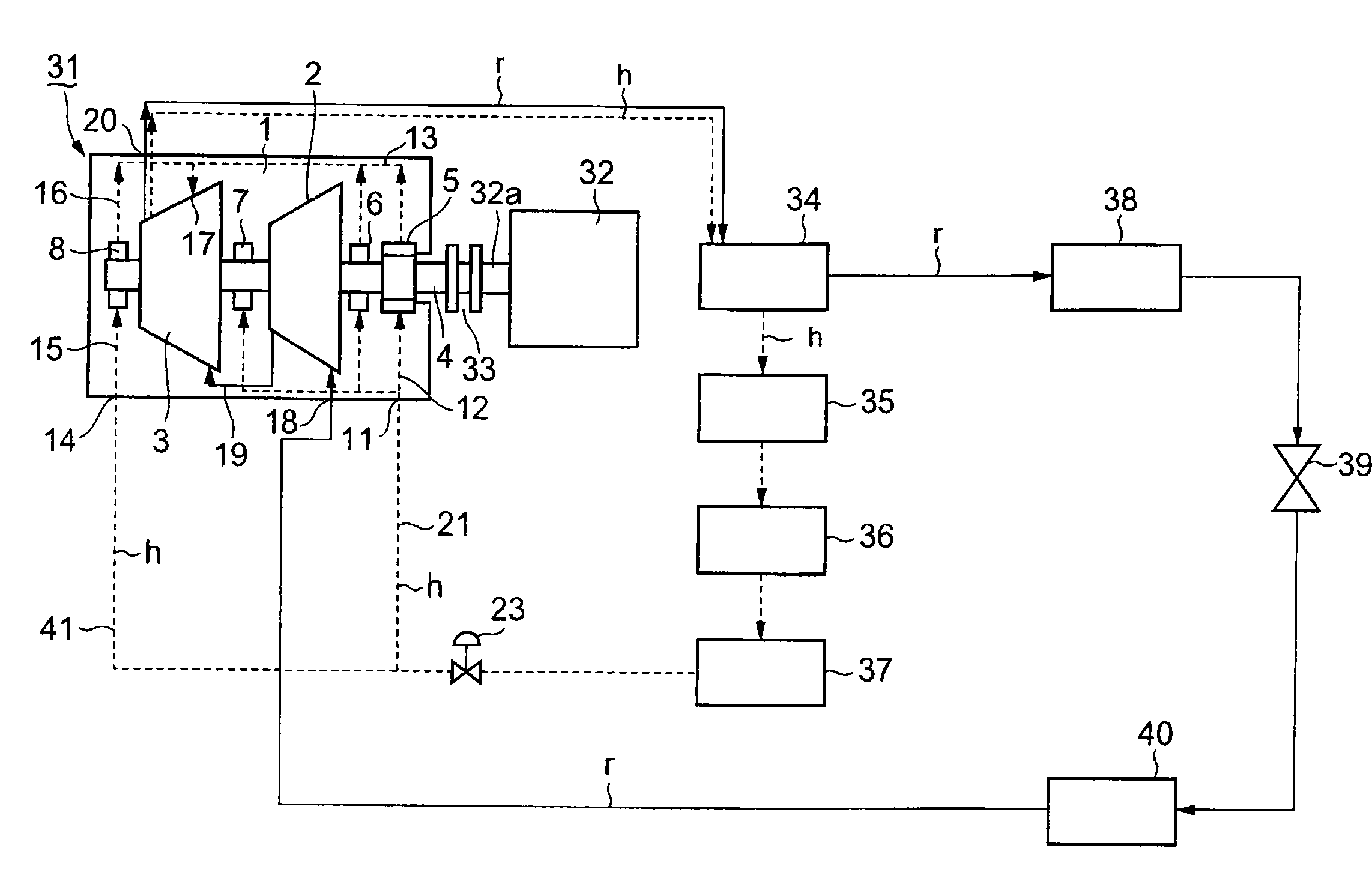

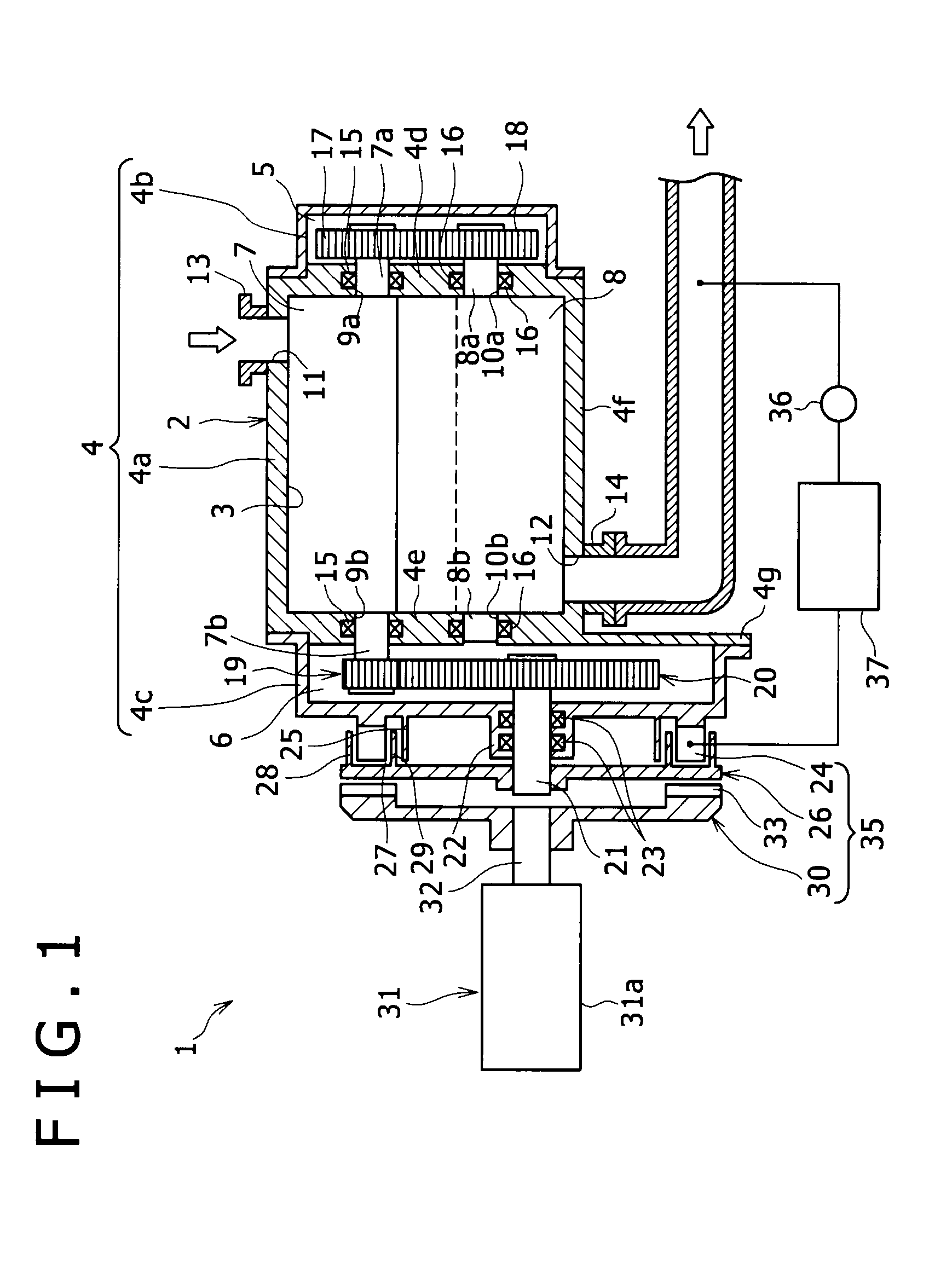

ActiveUS20060008375A1Easy to operateImprove responseOscillating piston enginesEngine of counter-engagement typeHydraulic cylinderSpool valve

A screw compressor according to the present invention includes a slide valve adapted to move forward and backward in parallel with the axis of a pair of screw rotors and also includes a plurality of hydraulic cylinders for moving the slide valve forward and backward, the plural hydraulic cylinders imparting, in synchronization with each other, a driving force to the slide valve in the same direction. With this configuration, it is possible to quicken an operation of the slide valve and improve the responsivity in volume control without increasing the diameters of pistons of the hydraulic cylinders for actuating the slide valve and without complicating equipment.

Owner:KOBE STEEL LTD

Seal for Oil-Free Rotary Displacement Compressor

ActiveUS20130075975A1Prevent leakageImprove sealingEngine sealsSealing arrangement for pumpsRotary-screw compressorRotational axis

Non-contacting cartridge shaft seals prevent leakage loss of process gases in an “oil free” rotary screw compressor or blower, while simultaneously preventing ingress of lubricating oil to the pumping chamber, allowing the compressor / blower to generate process pressure differentials without oil contamination. A compact unitized seal cartridge assembly is provided in the end plates of the pump housing. One of the rotor shafts extends through an aperture in the end plate or housing, between the pumping chamber and oil-lubricated gear / bearing cases. Internal elements have the ability to self-align radially achieving essential concentricity with shaft rotational axes. The rotor shafts or sleeves non-contact relationship during operation allow increased ranges of shaft rotational speeds. Air seal elements restrict flow of process air from the pumping or compression chamber, and oil seal elements with a directional spiral groove on the inside diameter prevent the leakage of lubricating oil to the process or atmosphere.

Owner:ERGOSEAL

Screw compressor

ActiveUS20060280626A1Reduce rotation speedLow costRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsElectric machineEngineering

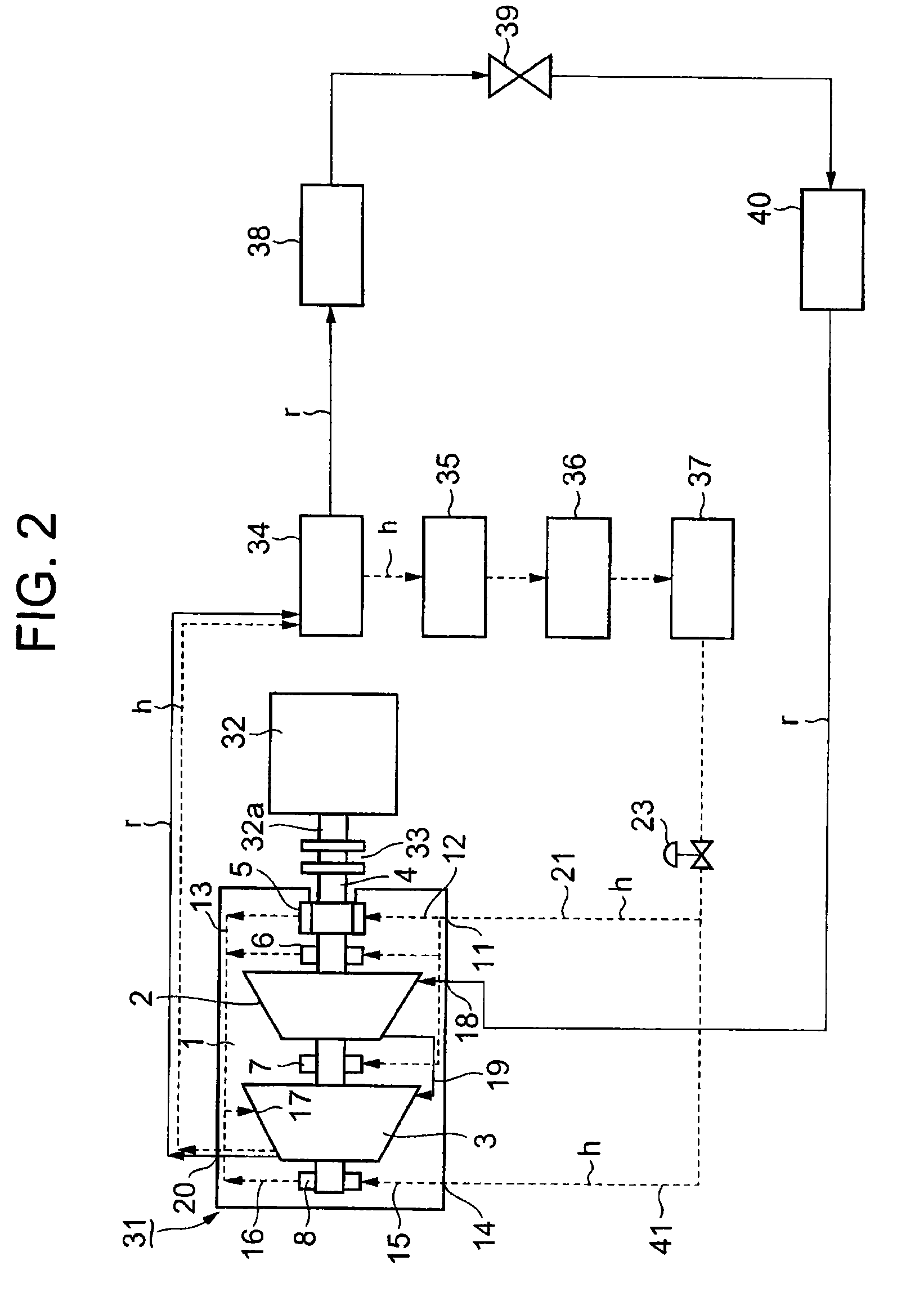

A screw compressor comprising: a low pressure stage compressor body; a high pressure stage compressor body that further compresses a compressed air compressed by the low pressure stage compressor body; pinion gears for example, respectively, provided on, for example, a male rotor of the low pressure stage compressor body and, for example, a male rotor of the high pressure stage compressor body; a motor; a bull gear for example, provided on a rotating shaft of the motor; and an intermediate shaft supported rotatably and provided with a pinion gear, which meshes with the bull gear, and a bull gear, which meshes with the pinion gears. Thereby, it is possible to make the motor relatively low in rotating speed while inhibiting the gears from being increased in diameter, thus enabling achieving reduction in cost.

Owner:HITACHI IND EQUIP SYST CO LTD

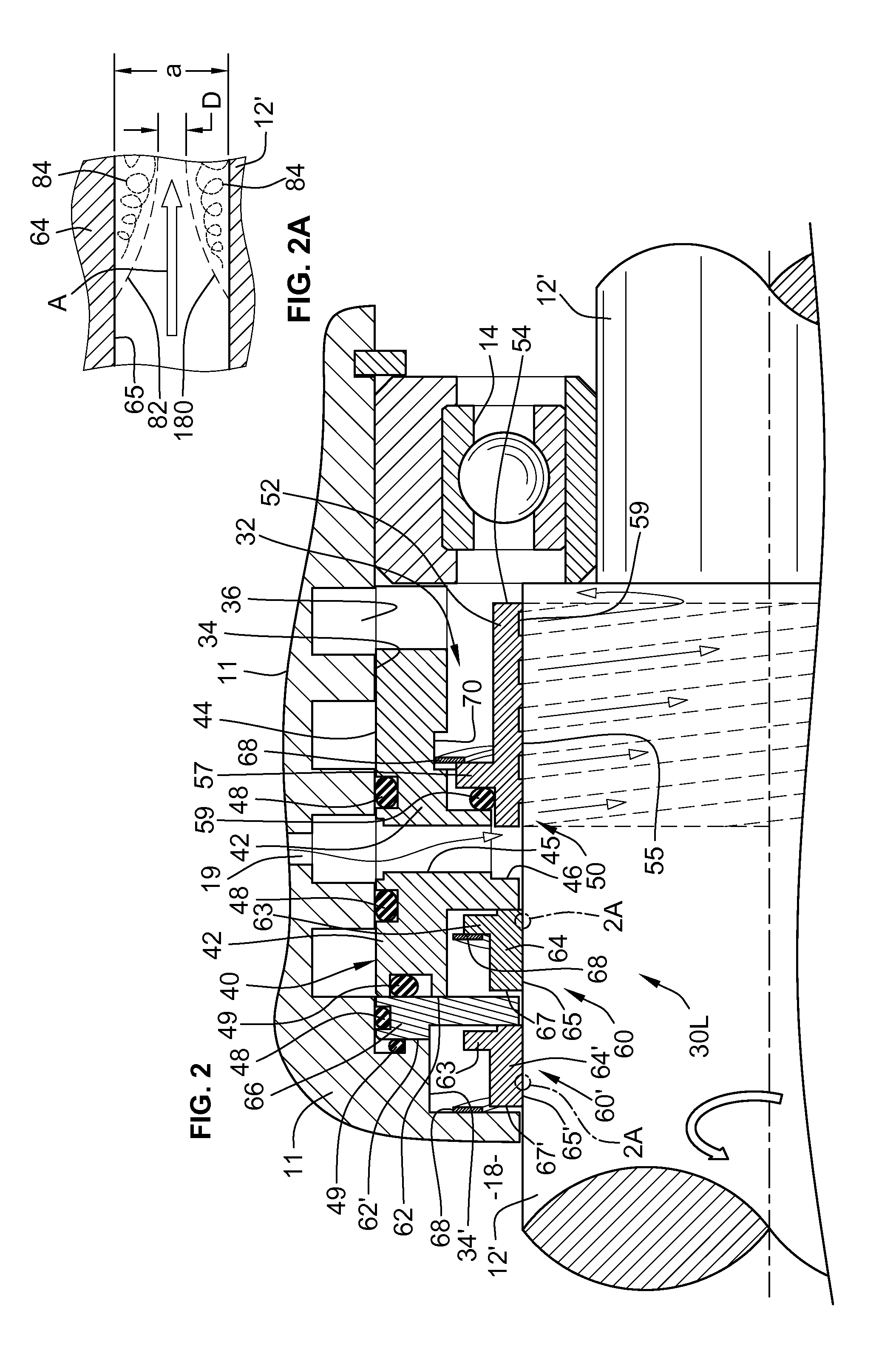

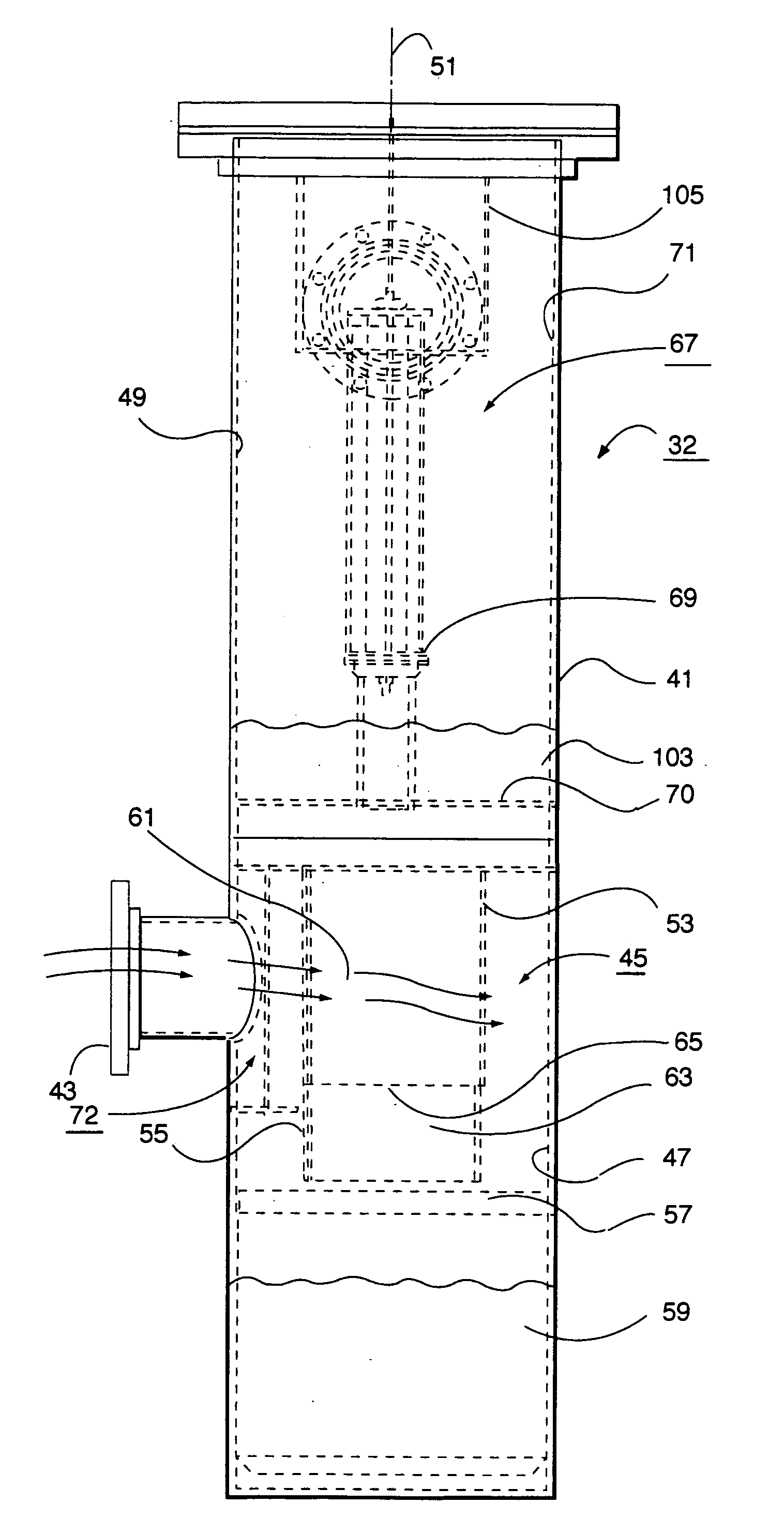

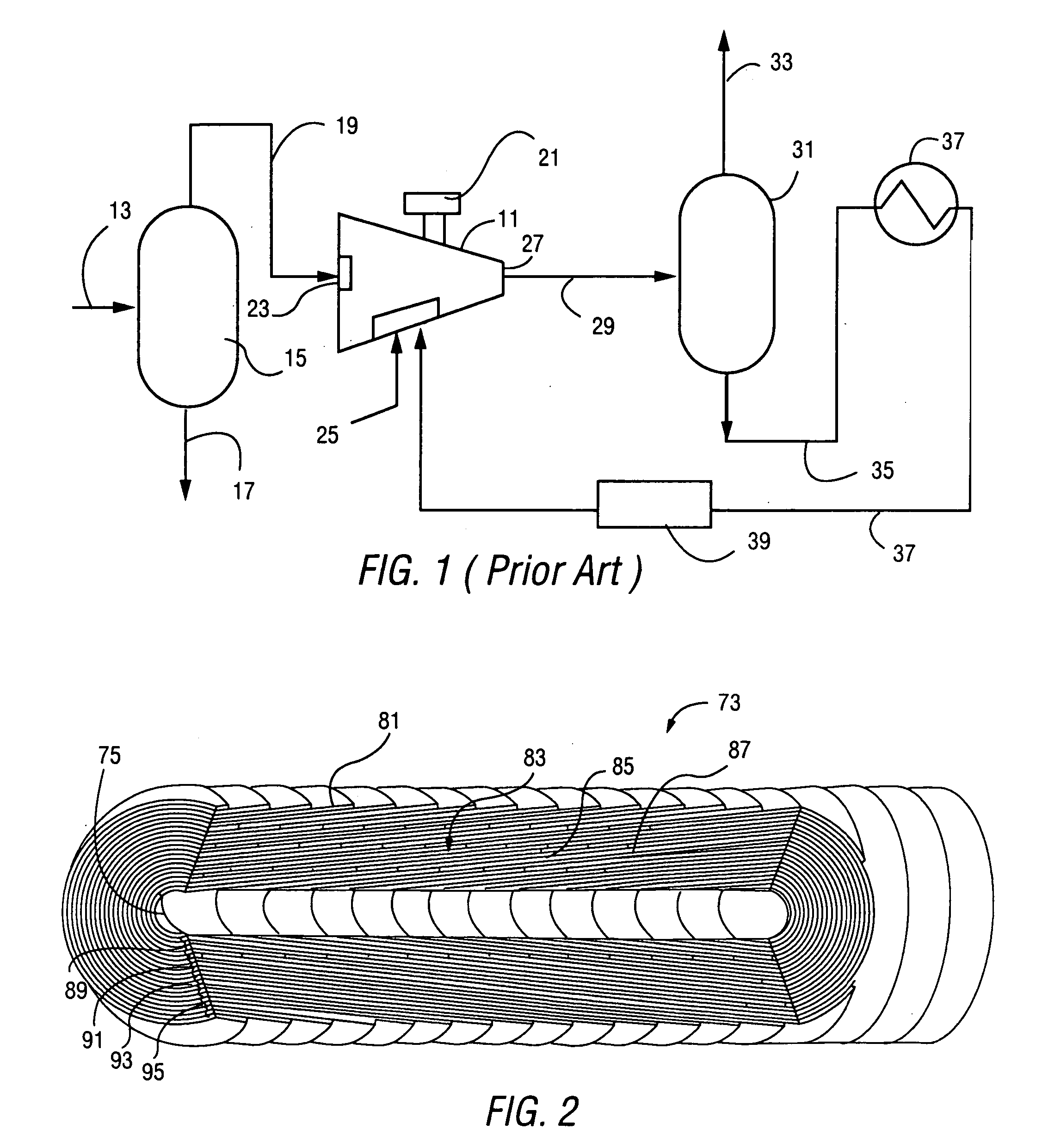

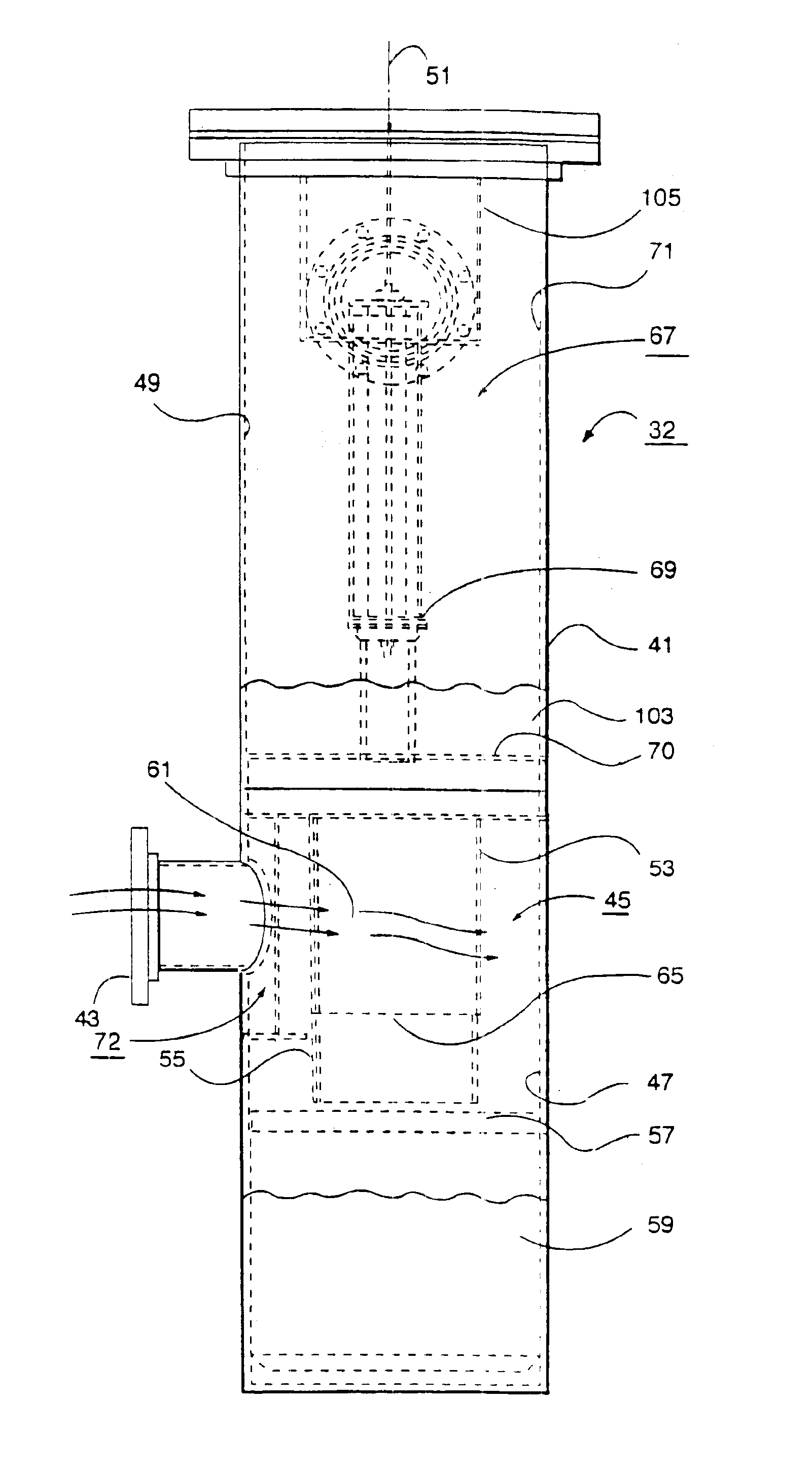

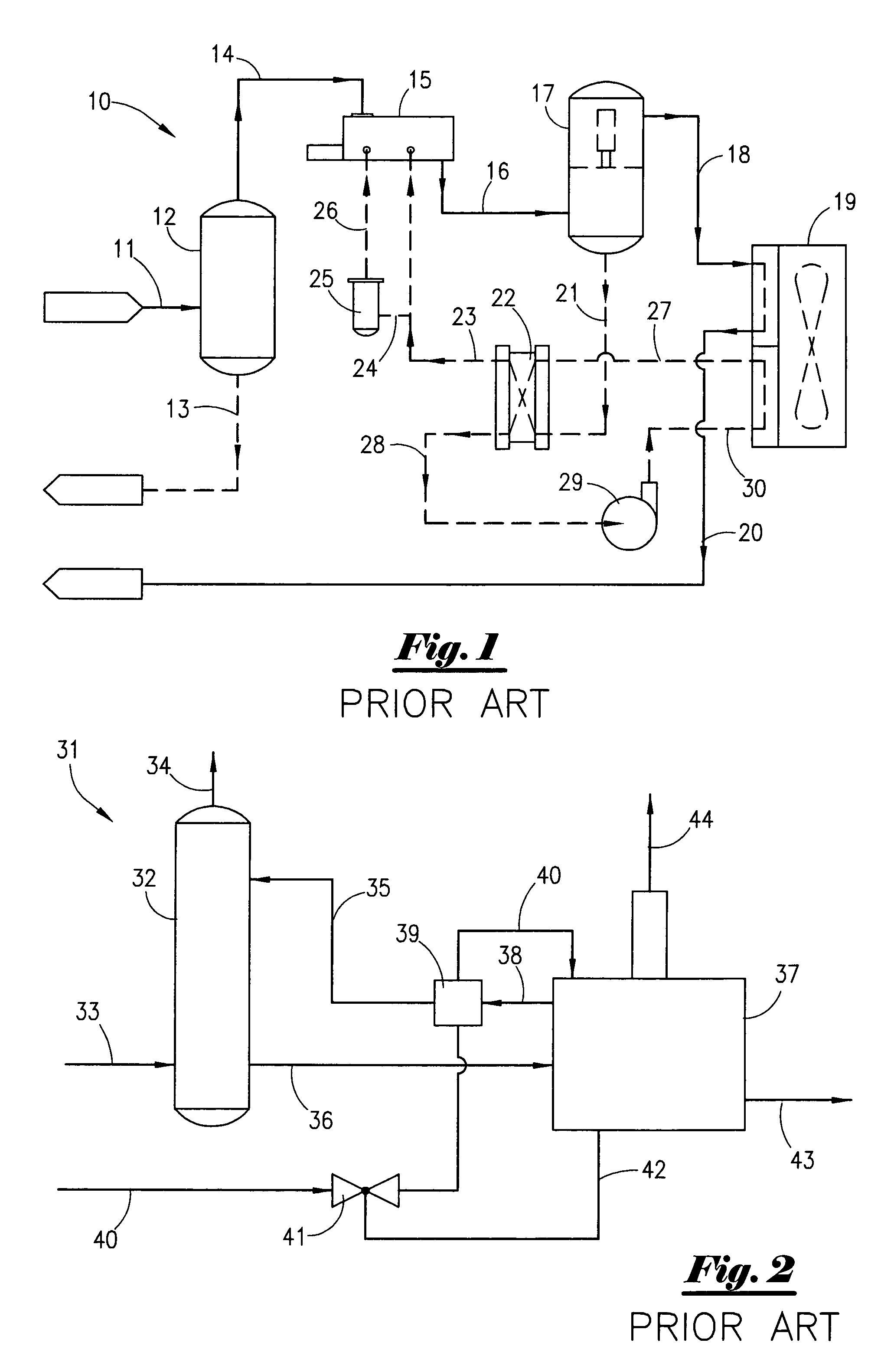

Filtration vessel and method for rotary gas compressor system

A filtration vessel is shown for use with a rotary screw compressor which receives a compressed liquid / gas mixture from the compressor. The vessel utilizes a first stage vortex knockout region to remove bulk liquids through a circular motion which imposes centrifugal forces on the gas and liquid mixture. A coalescer region located above the vortex knockout region receives the relatively lighter fluids and separates any remaining entrained liquids from the fluids. The discharge from the filtration unit is an essentially liquid free compressed gas. The liquid discharge, in the case of lube oil can be recirculated to the compressor for another cycle.

Owner:PARKER INTANGIBLES LLC

Screw compressor

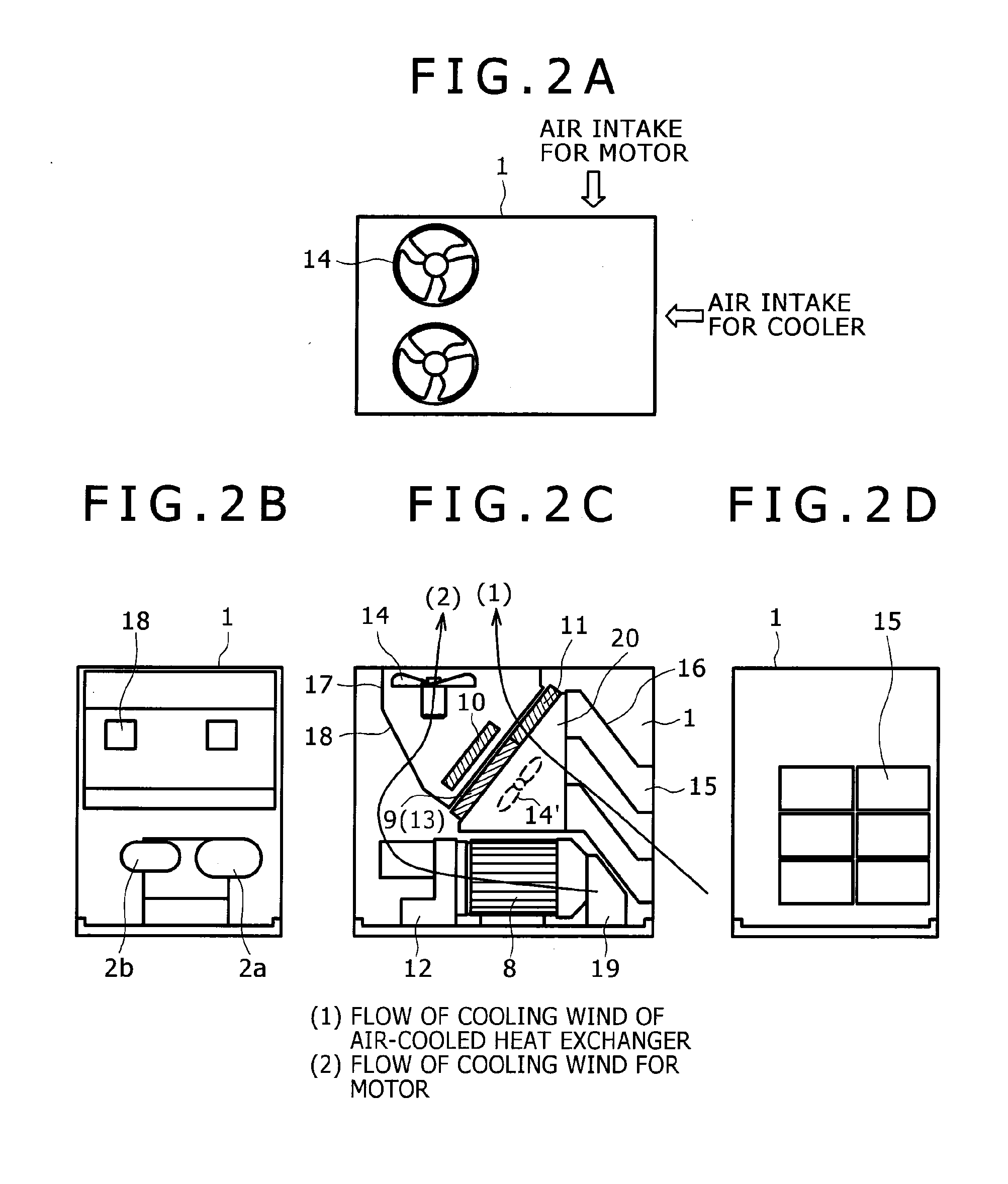

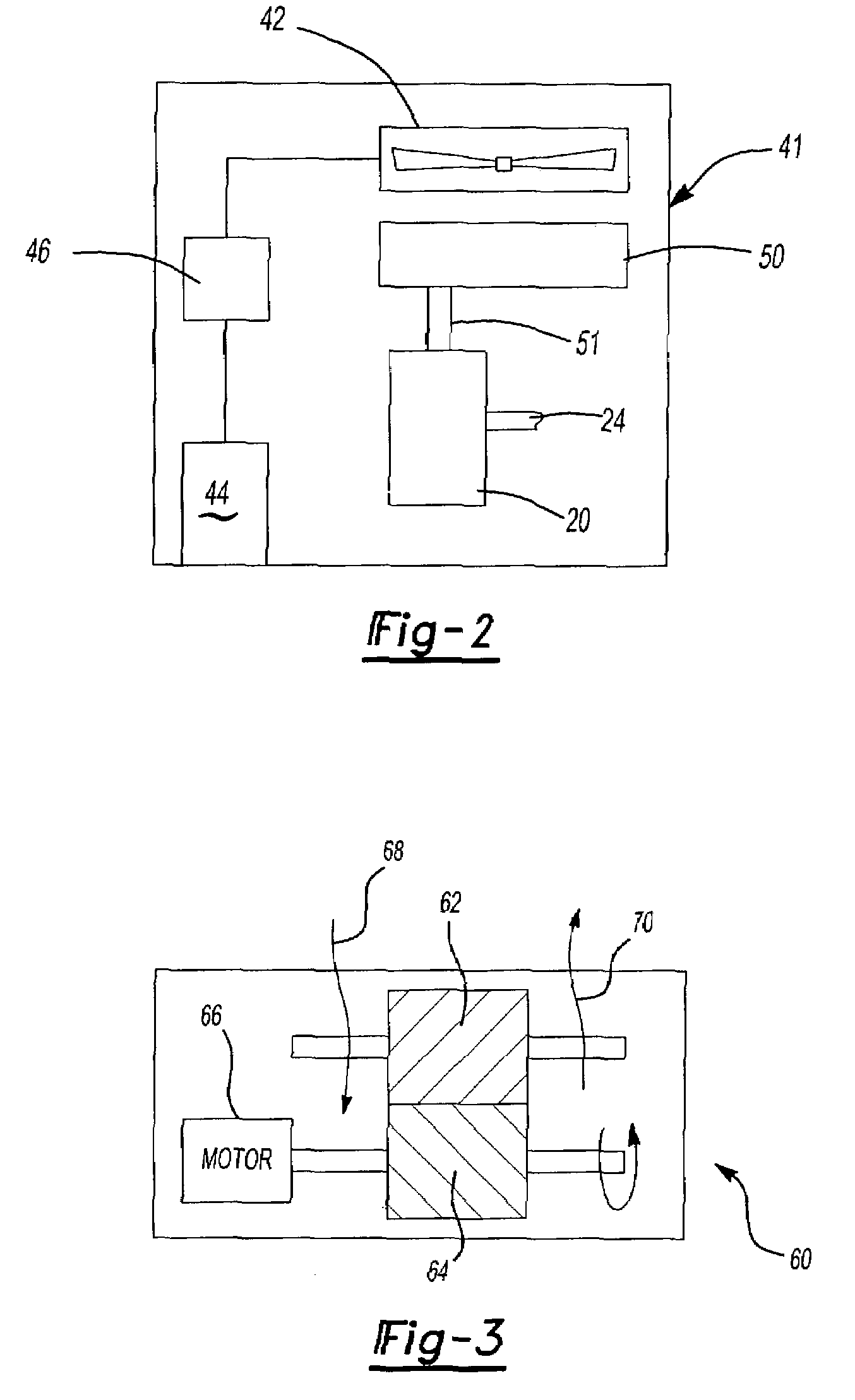

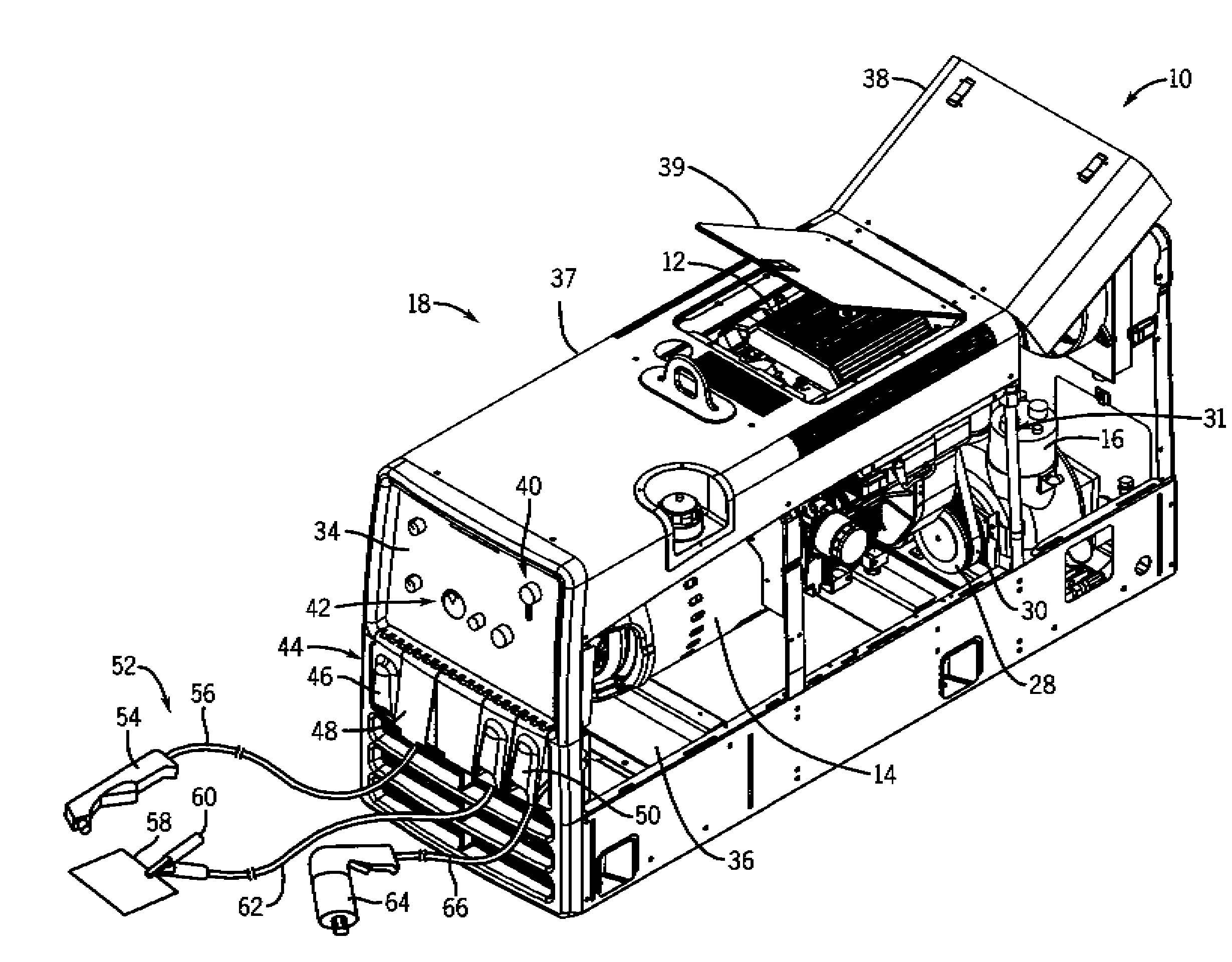

ActiveUS20100135840A1Large sound emitting areaReduce noiseRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsEngineeringMicro heat exchanger

A screw compressor comprising: a pair of male and female screw rotors; and an air-cooled heat exchanger, wherein the air-cooled heat exchanger is provided above a motor for driving the compressor body; wherein, with respect to a cooling wind for the air-cooled heat exchanger, the air-cooled heat exchanger is inclined to the upstream side; wherein the uppermost portion of a unit suction port for the air-cooled heat exchanger cooling winds is positioned below the uppermost portion of the air-cooled heat exchanger positioned at the uppermost portion; wherein the lowermost portion of the unit suction port for the air-cooled heat exchanger cooling wind is positioned below the lowermost portion of the air-cooled heat exchanger positioned at the lowermost portion; and wherein the cooling wind for the air-cooled heat exchanger is exhausted from a ceiling portion of the compressor unit. With this structure, it becomes possible to provide a compact screw compressor with less noise whose installation area can be reduced.

Owner:HITACHI IND EQUIP SYST CO LTD

Compressor discharge chamber with baffle plate

InactiveUS6976833B2Positive displacement pump componentsOscillating piston enginesCompressed fluidEngineering

Owner:CARRIER CORP

Filtration vessel and method for rotary gas compressor system

InactiveUS6858067B2Easy to separateCombination devicesDispersed particle filtrationLighter fuelFiltration

A filtration vessel is shown for use with a rotary screw compressor which receives a compressed liquid / gas mixture from the compressor. The vessel utilizes a first stage vortex knockout region to remove bulk liquids through a circular motion which imposes centrifugal forces on the gas and liquid mixture. A coalescer region located above the vortex knockout region receives the relatively lighter fluids and separates any remaining entrained liquids from the fluids. The discharge from the filtration unit is an essentially liquid free compressed gas. The liquid discharge, in the case of lube oil can be recirculated to the compressor for another cycle.

Owner:PARKER INTANGIBLES LLC

Methods and apparatus for unloading a screw compressor

InactiveUS6860730B2Improve startupOscillating piston enginesSealing arrangement for pumpsAir volumeStart up

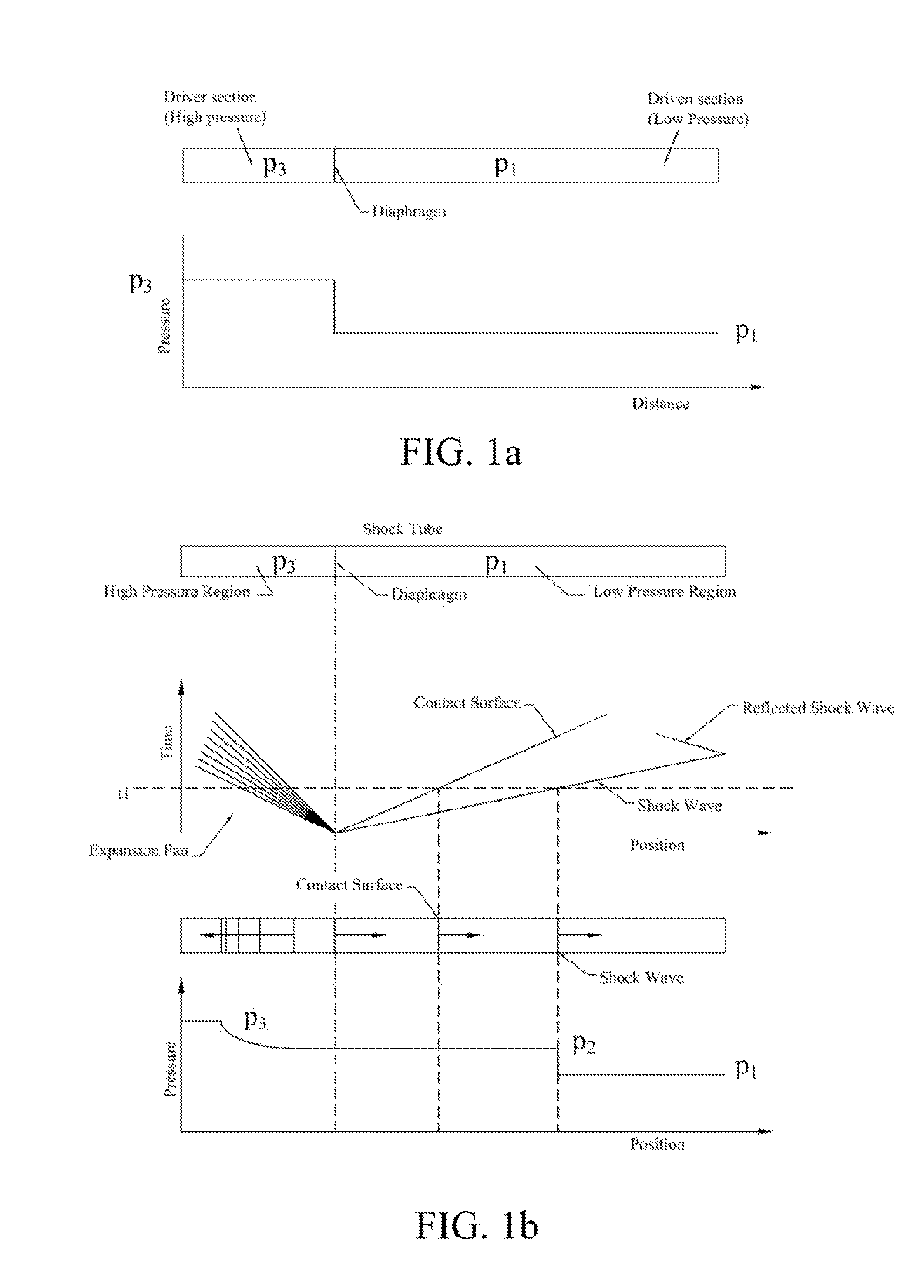

A screw compressor is connected to a motor to be driven by the motor even during periods of low compressed air consumption. During such periods, the screw compressor is at least partially unloaded to make it easier and less costly to drive the compressor. The unloading is performed by removing air from the compressor. Preferably, that is done by communicating the air inlet of a small capacity vacuum device with the air outlet of the screw compressor. Suction from the vacuum device is transmitted to the air outlet of the screw compressor to suck air out of the screw compressor to reduce the engine horsepower needed to rotate the screw compressor. The vacuum device can also be used to boost the air volume and / or the air pressure. The system can be used in a drilling rig which drills holes in the ground. The screw compressor can be unloaded during start up of the motor by briefly driving the vacuum device by pressurized liquid from a pre-pressurized hydraulic accumulator.

Owner:DRILTECH MISSION

Screw compressor with a shunt pulsation trap

ActiveUS20120171069A1Reducing gas pulsationSimple structurePositive displacement pump componentsOscillating piston enginesInjection portOff design

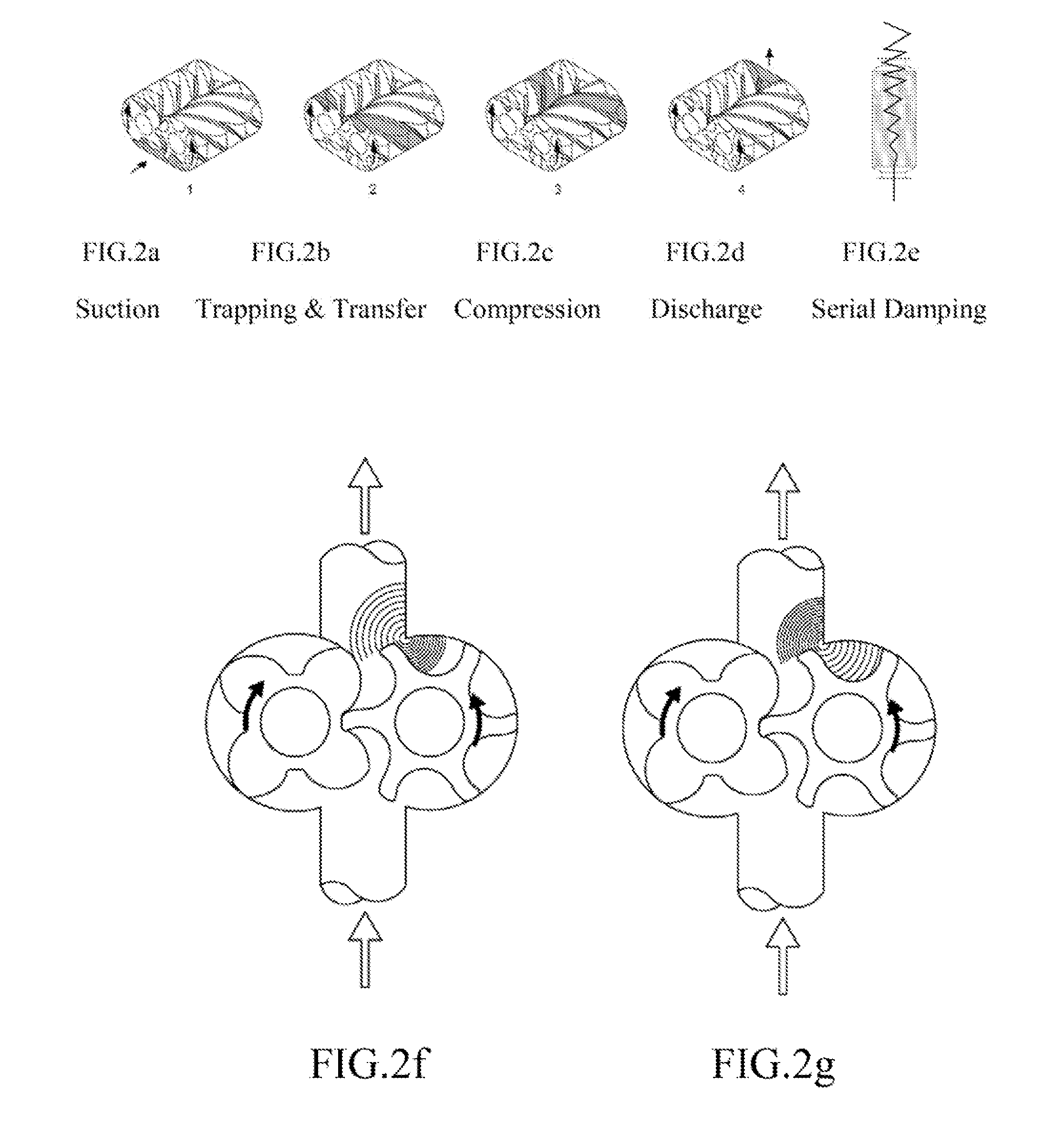

A shunt pulsation trap for a screw compressor reduces gas pulsation, NVH and improves off-design efficiency without using a traditional serial pulsation dampener and a sliding valve. Generally, a screw compressor with the shunt pulsation trap has a pair of multi-helical-lobe rotors housed in a compressor chamber for propelling gas flow from a suction port to a discharge port of the compressor chamber with internal compression. The shunt pulsation trap comprises an inner casing as an integral part of the compressor chamber, and an outer casing oversized surrounding the inner casing, therein housed various gas pulsation dampening means or gas pulsation energy recovery means or gas pulsation containment means, at least one injection port (trap inlet) branching off from the compressor chamber into the pulsation trap chamber and a feedback region (trap outlet) communicating with the compressor outlet.

Owner:HI BAR BLOWERS

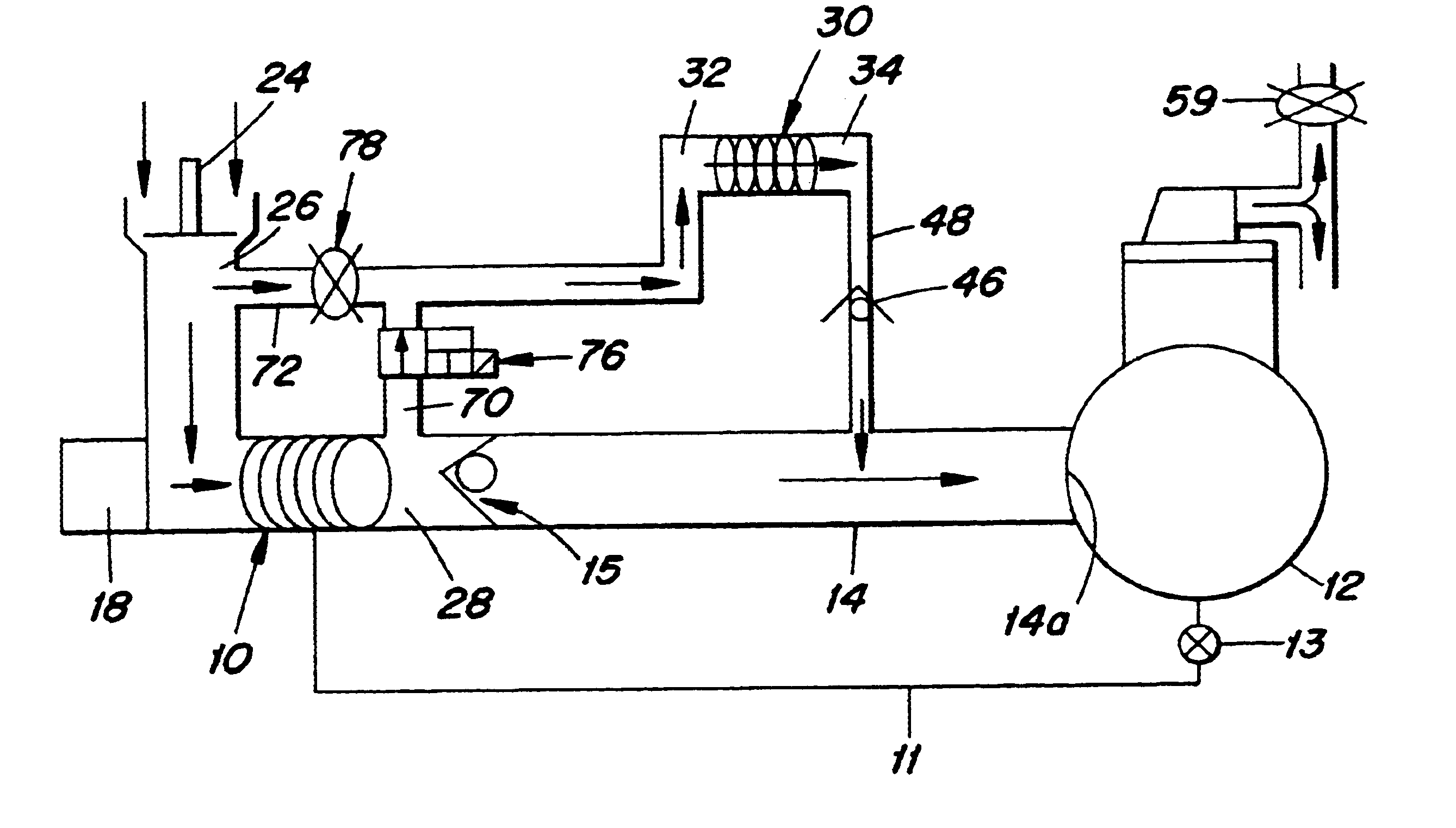

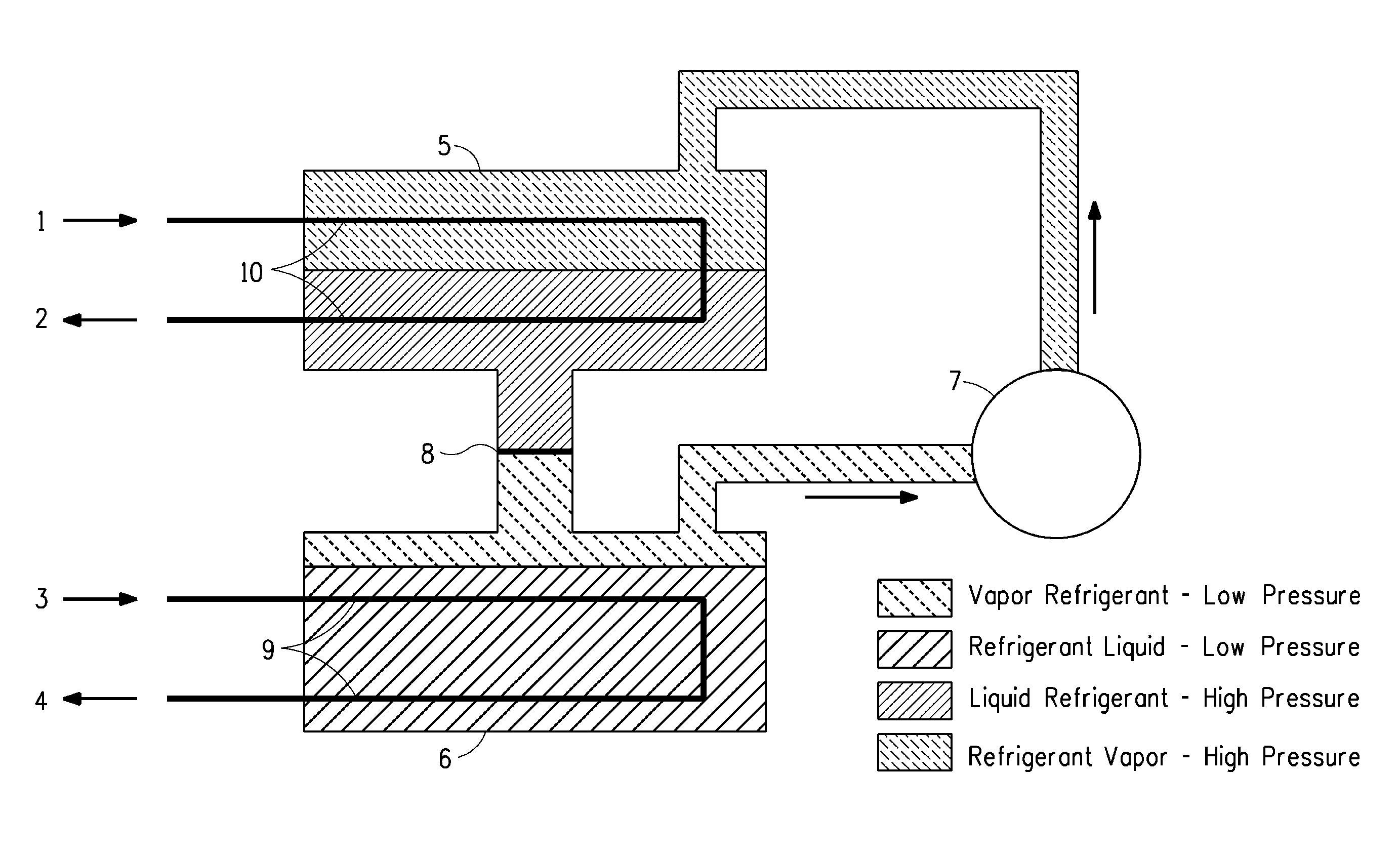

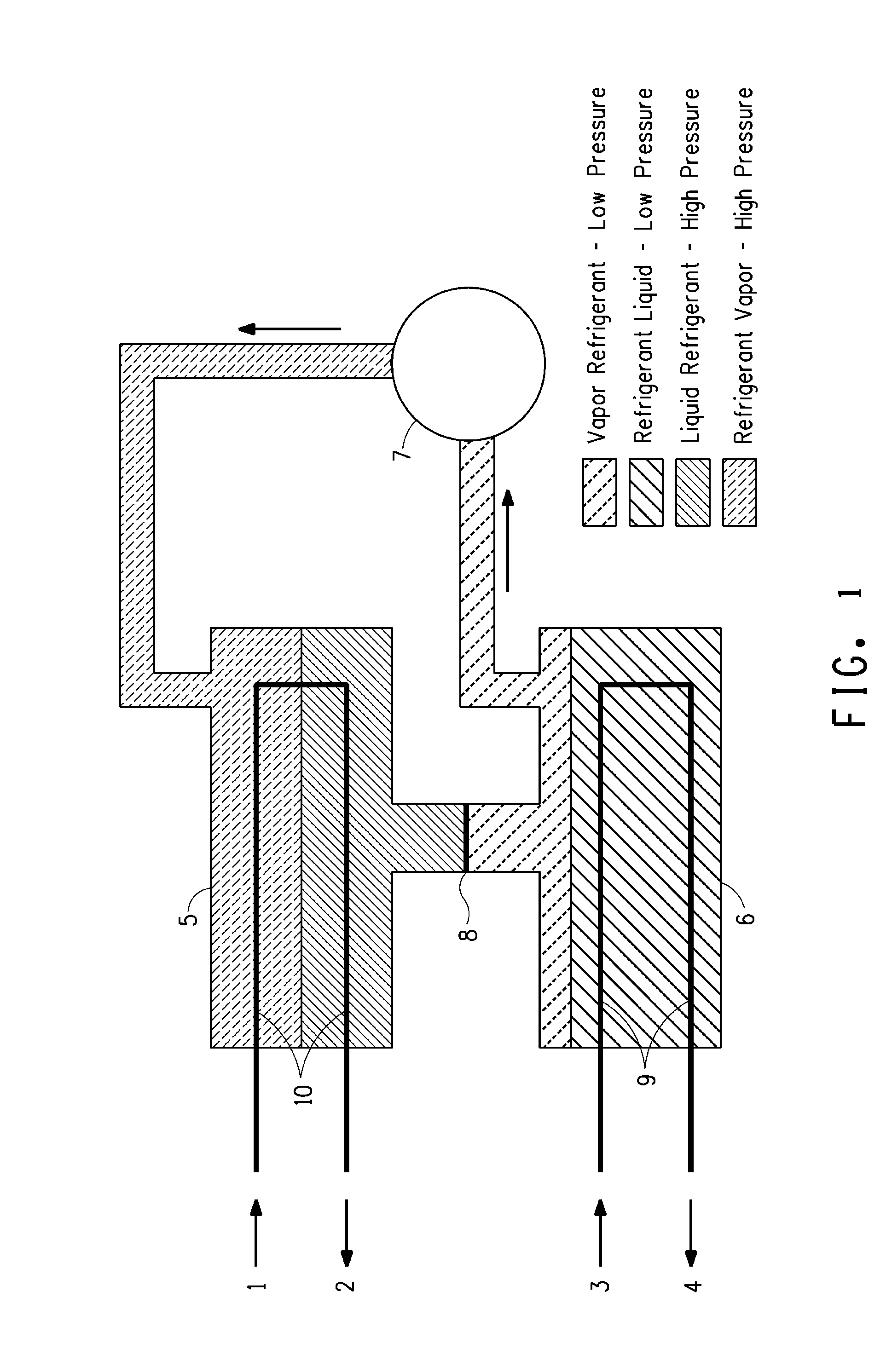

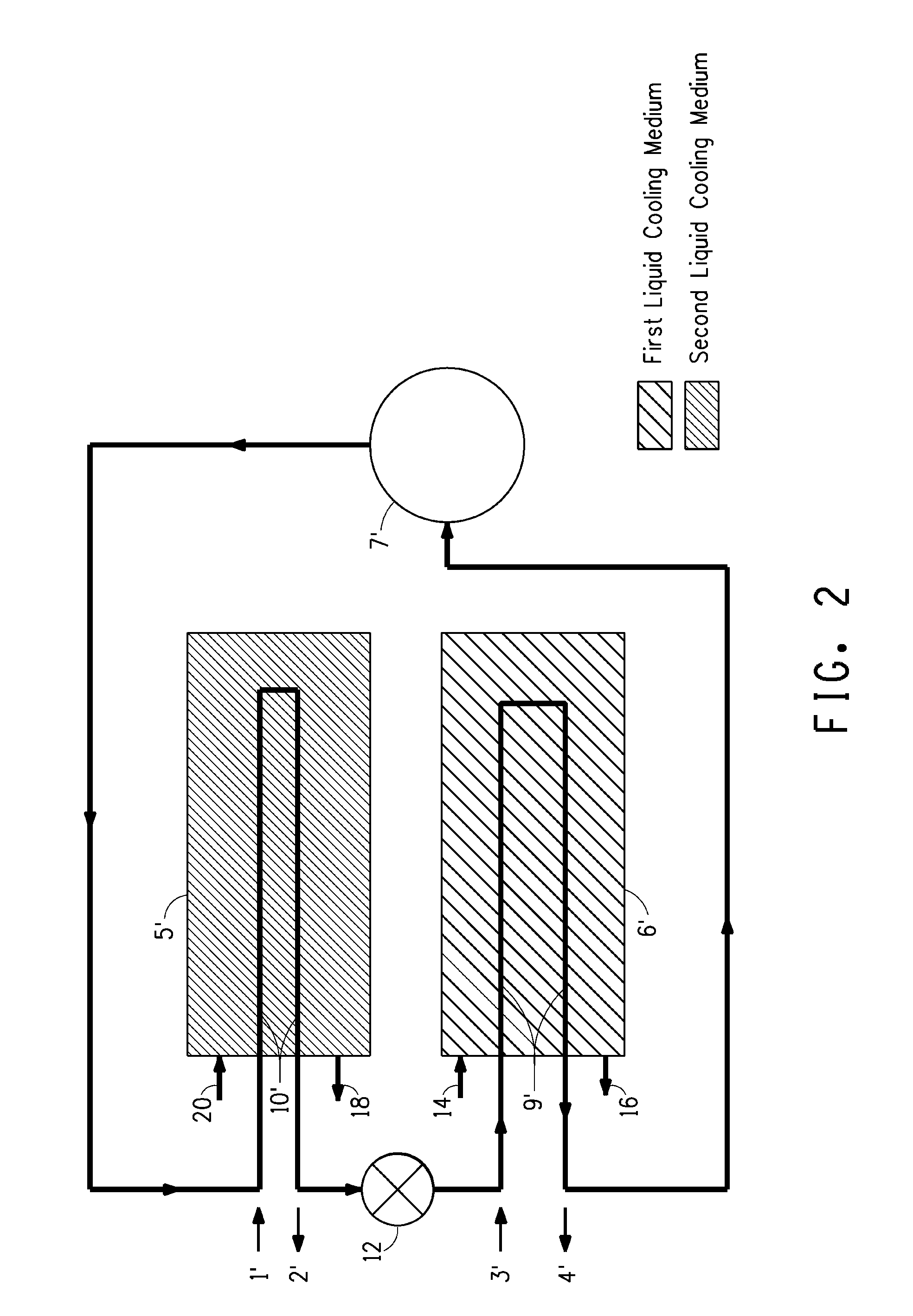

Chiller apparatus containing trans-1,1,1,4,4,4-hexafluoro-2-butene and methods of producing cooling therein

ActiveUS20120159976A1Improve energy efficiencyReasonable cooling capacitySolidificationLiquefactionButeneEngineering

Disclosed herein is a chiller apparatus containing refrigerant characterized by said refrigerant being HFO-1336mzz that is trans isomer or primarily trans isomer. These chillers may be flooded evaporators or direct expansion evaporators, which utilize either centrifugal or screw compressors. Also disclosed herein are methods for producing cooling comprising evaporating trans-HFO-1336mzz in an evaporator in the vicinity of a body to be cooled, thereby producing cooling. Also disclosed herein is a method for replacing HFC-236fa or CFC-114 refrigerant in a chiller apparatus, said method comprising providing HFO-1336mzz to said chiller apparatus in place of the replaced refrigerant; wherein said HFO-1336mzz is trans isomer or primarily trans isomer.

Owner:THE CHEMOURS CO FC LLC

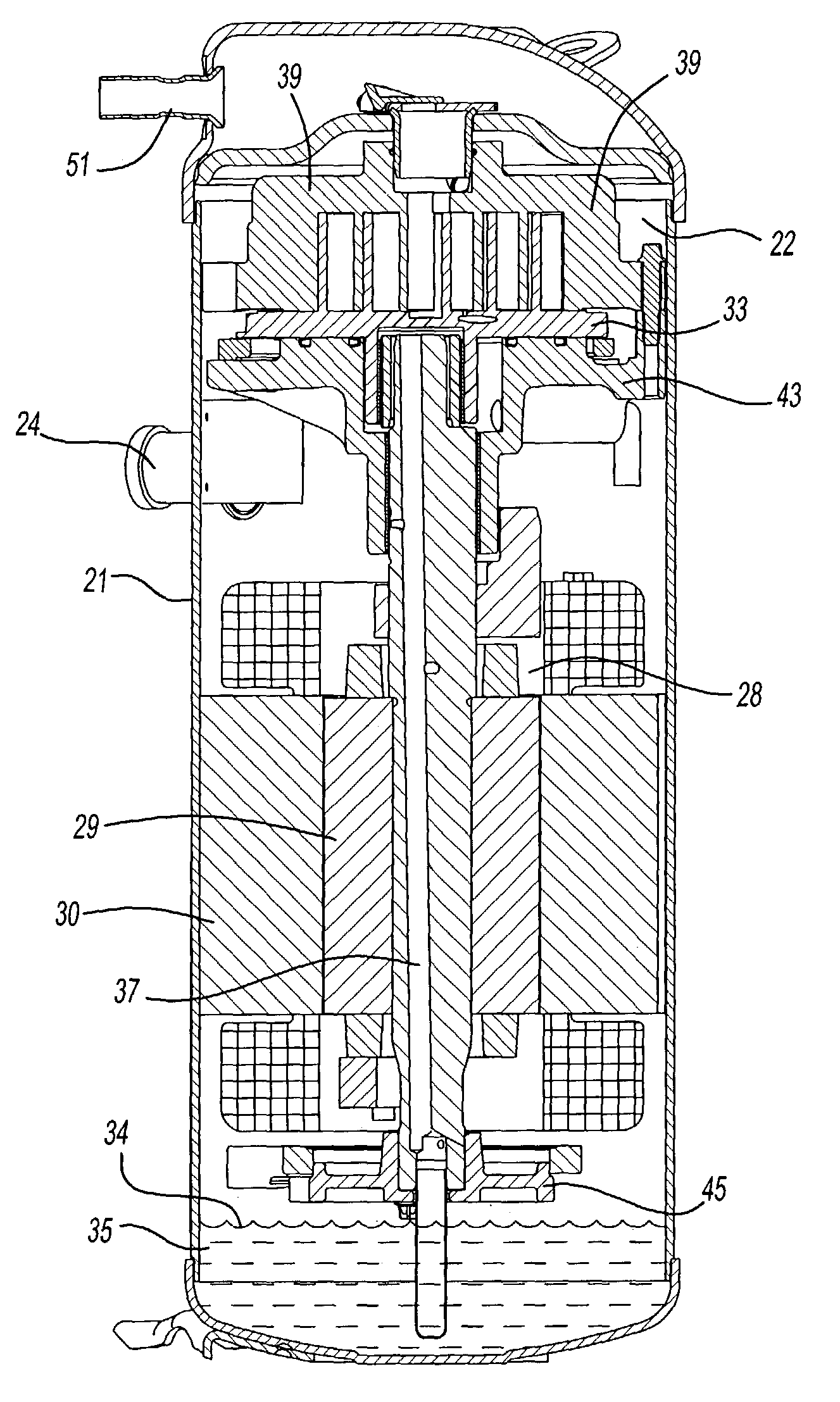

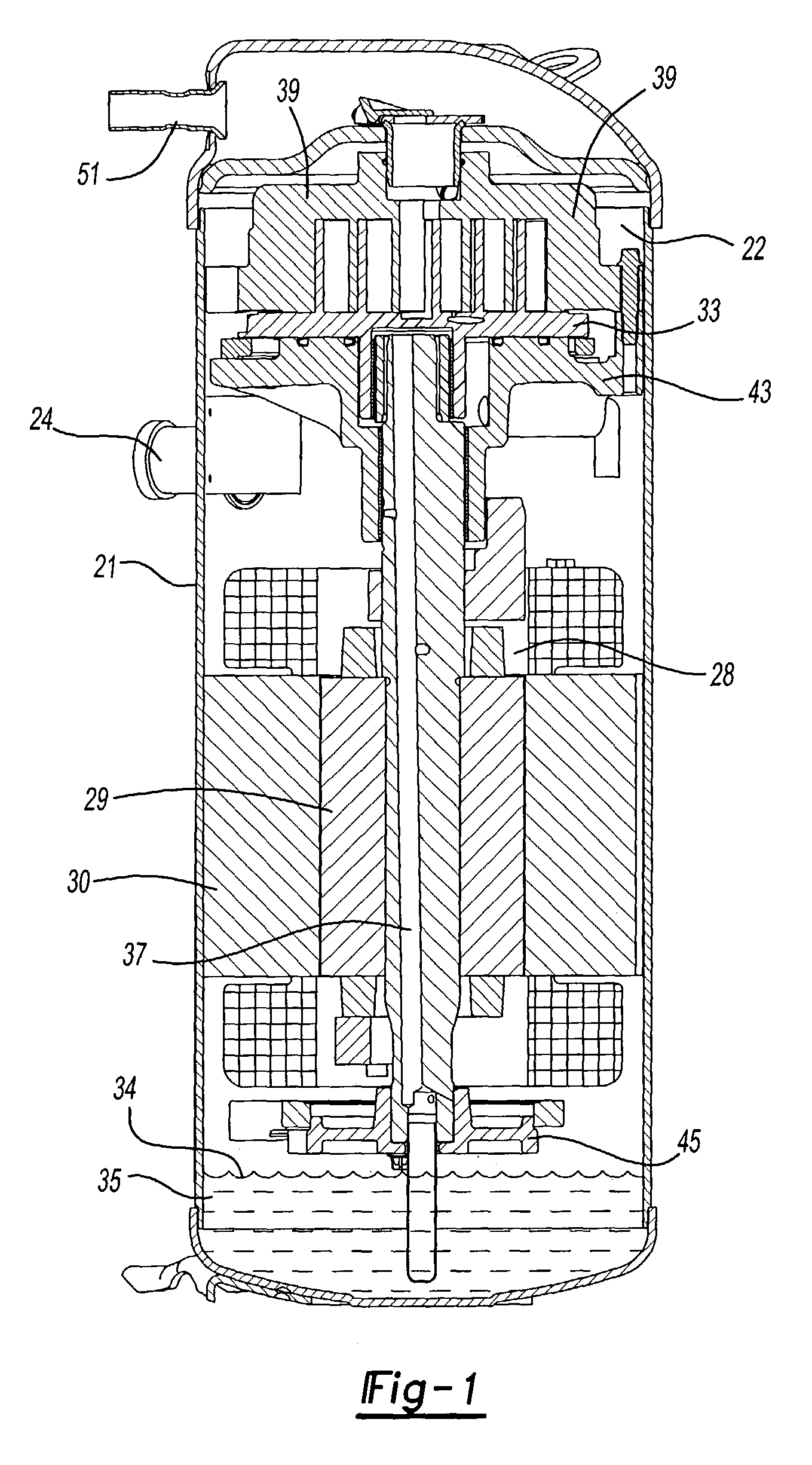

Short reverse rotation of compressor at startup

InactiveUS7290990B2Rotary/oscillating piston combinations for elastic fluidsFlexible member pumpsEngineeringBrief periods

In a method of operating a scroll or screw compressor at startup, the compressor is rotated in reverse for a brief period of time. The compressor is of a type that does not compress liquid when rotated in reverse. The purpose is to boil off the liquid refrigerant from the oil by heating and agitating the mixture of oil and refrigerant in the oil sump. This results in much more benign forward start as no refrigerant is drawn into the scroll compressor pump and the amount of oil pumped out of the compressor on start up is minimized. Also, the viscosity of oil is increased and lubrication of the bearings is improved. After a short period of time reverse rotation is stopped and the compressor can begin to be driven in the forward direction.

Owner:CARRIER CORP

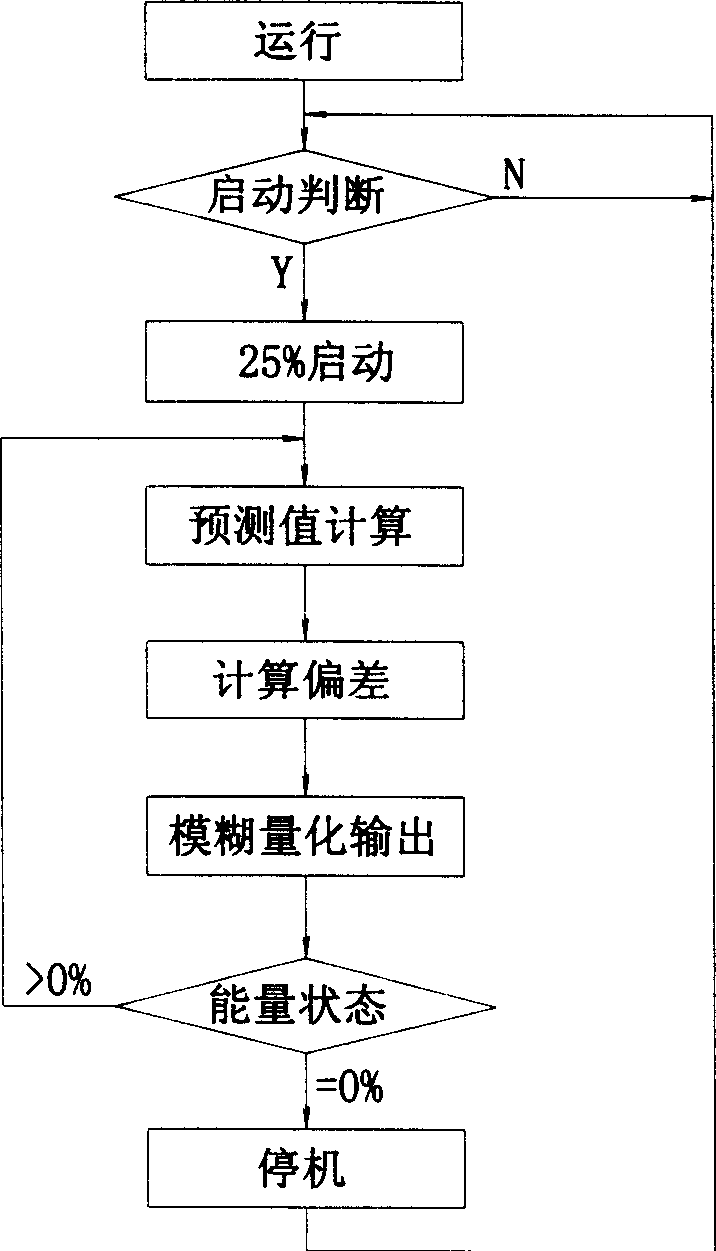

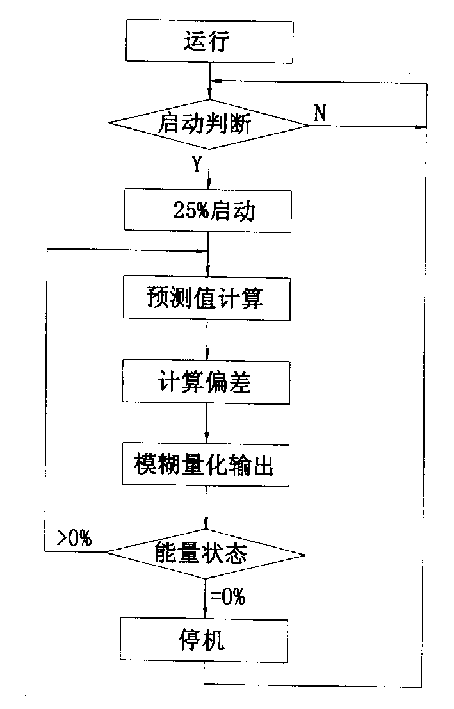

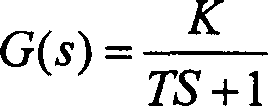

Fuzzy control method of screw refrygerating compressor energy

InactiveCN1534259AEasy to controlRealize fuzzy control functionRefrigeration safety arrangementControl tableRotary-screw compressor

A fuzzy control method for the energy of screw-type refrigerating compressor is disclosed. As the energy of compressor is regulated according to the temp of return water or discharged water and the temp variation rate is considered, an one-dimension fuzzy control table is used to quickly and precisely control the temp of heat medium (water) according to variation of heat load.

Owner:上海百富勤空调设备有限公司

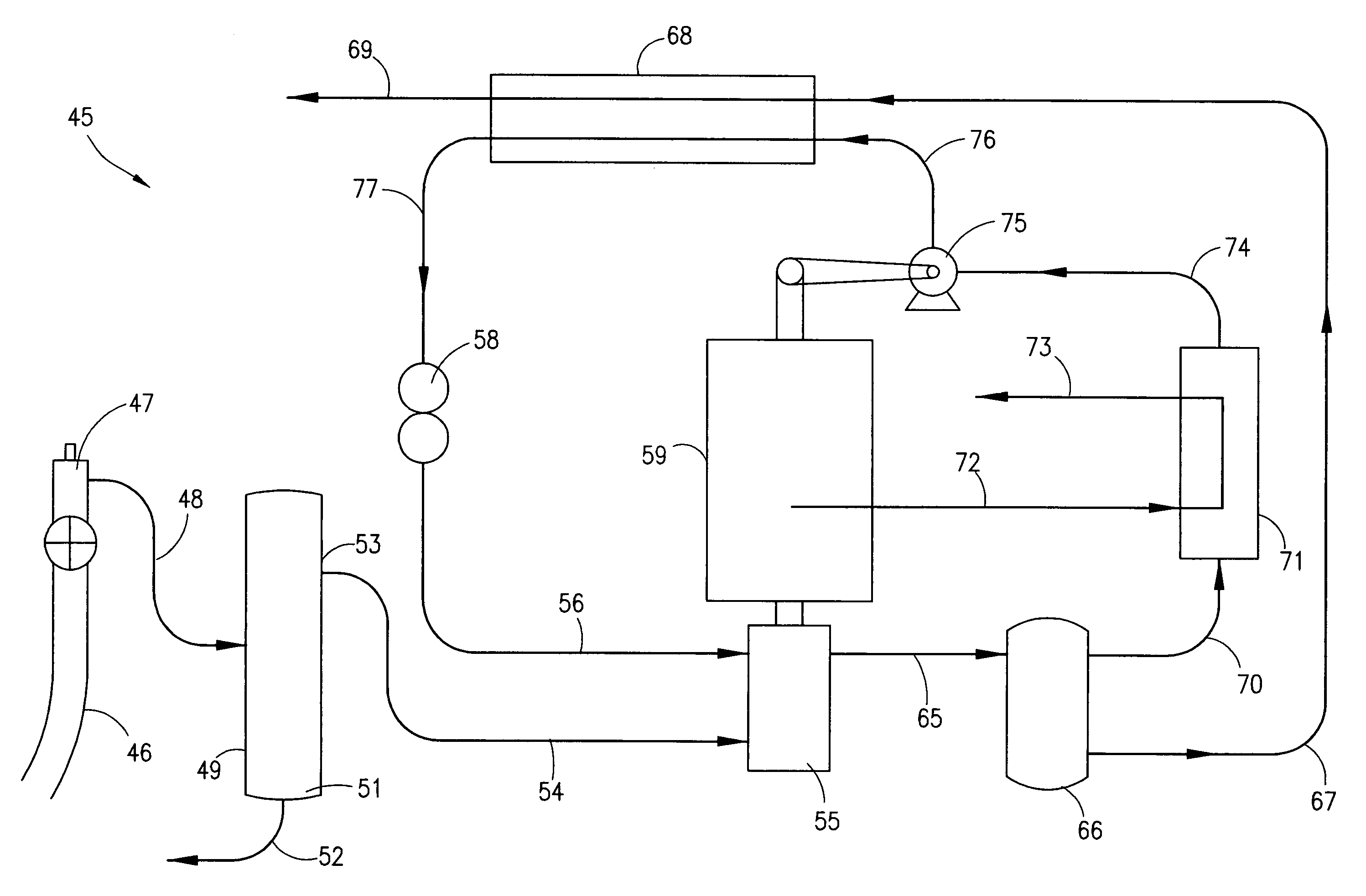

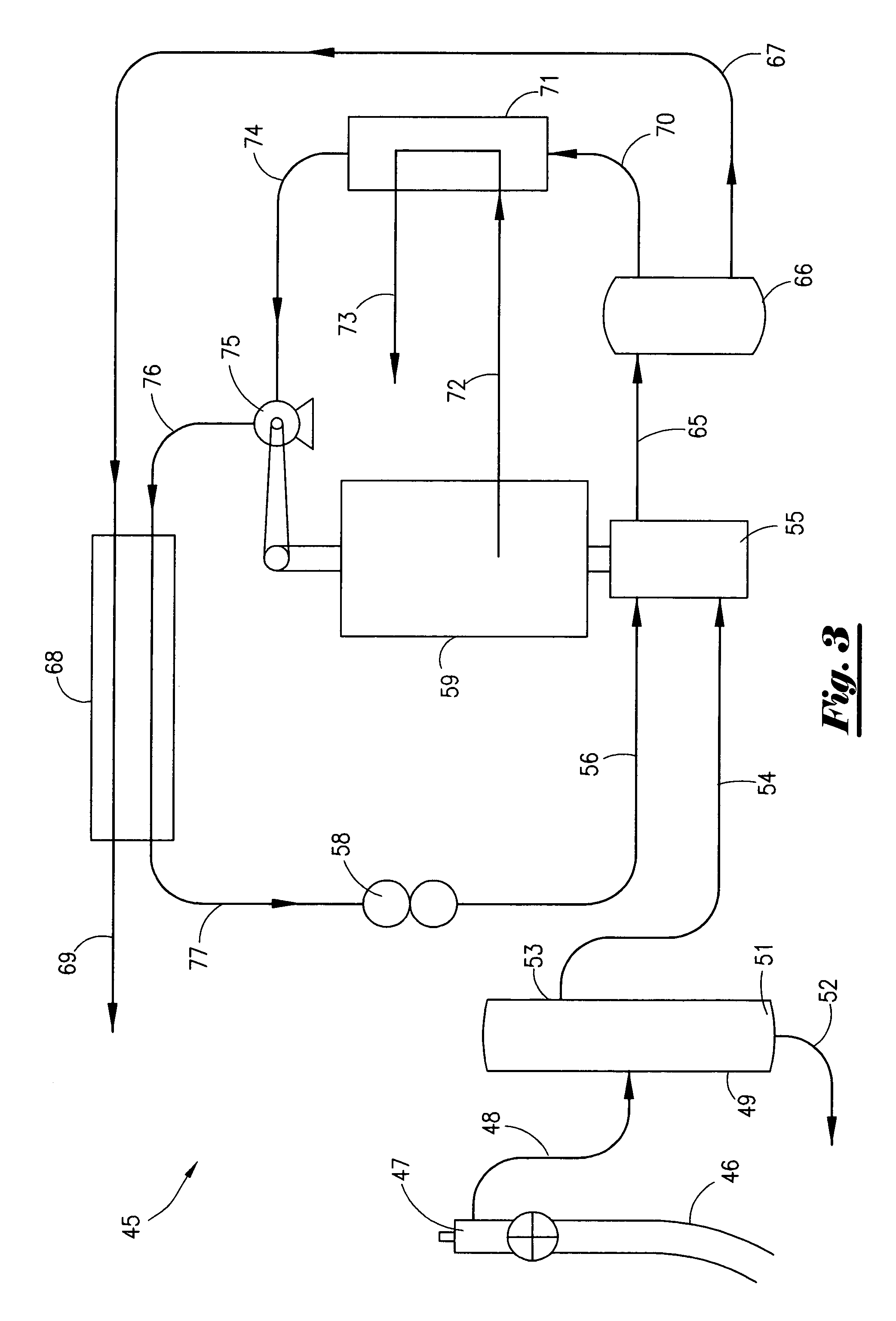

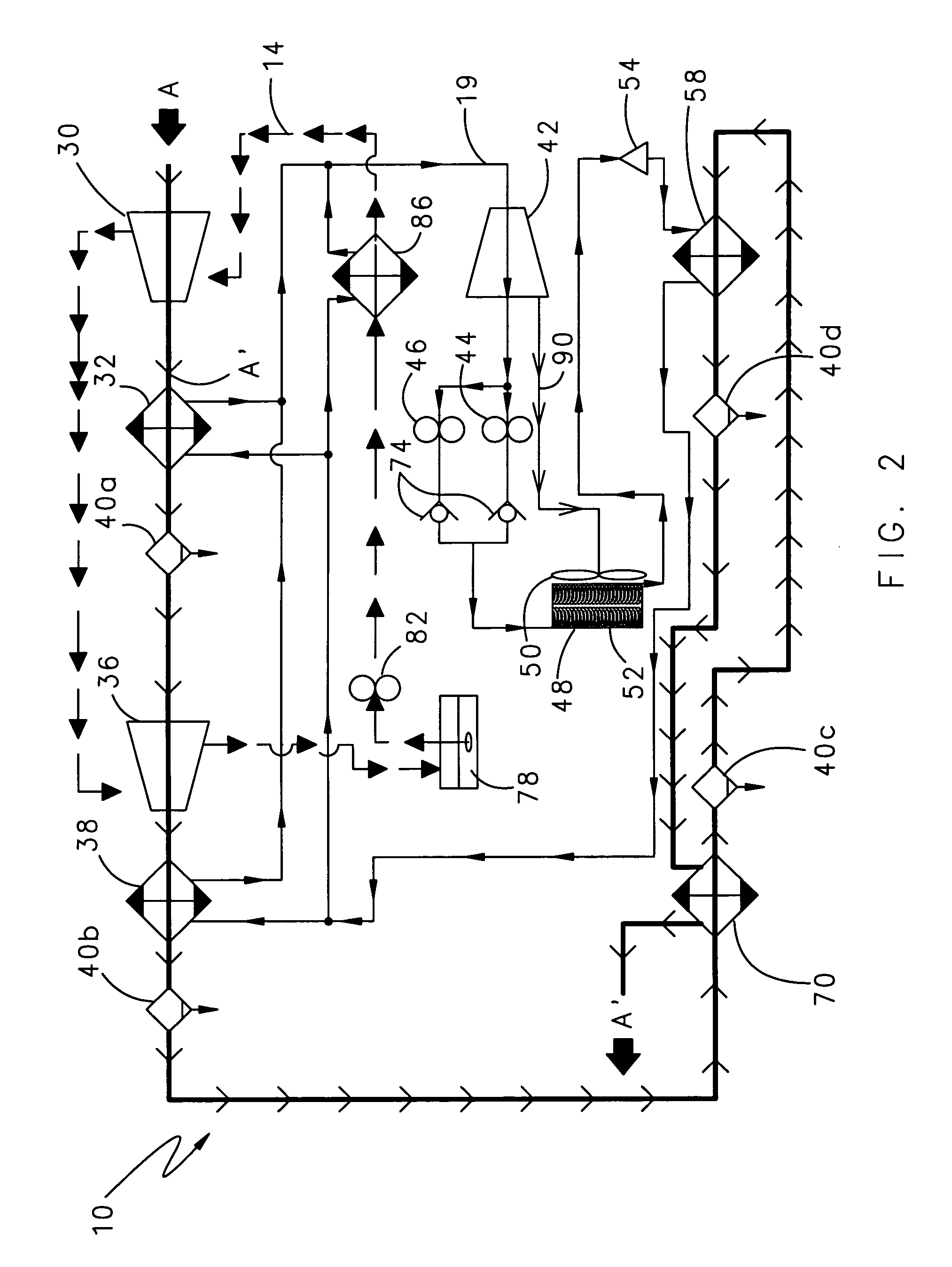

Method and system for compressing and dehydrating wet natural gas produced from low-pressure wells

InactiveUS6955705B1Improve efficiencyEliminating certain dehydration equipmentAircraft power plantsLiquid degasificationProcess engineeringDehydration

Method and system for compressing and dehydrating wet natural gas produced from a low-pressure well using a rotary screw compressor. A dehydrating agent is combined with wet natural gas within a rotary screw compressor. Operation of the rotary screw compressor causes compression and dehydration of the wet natural gas to produce a compressed dry natural gas. Engine exhaust produced by the engine which powers the rotary screw compressor may be used to remove water absorbed by the dehydrating agent and thereby recover the dehydrating agent for re-circulation in the system.

Owner:RDC RES

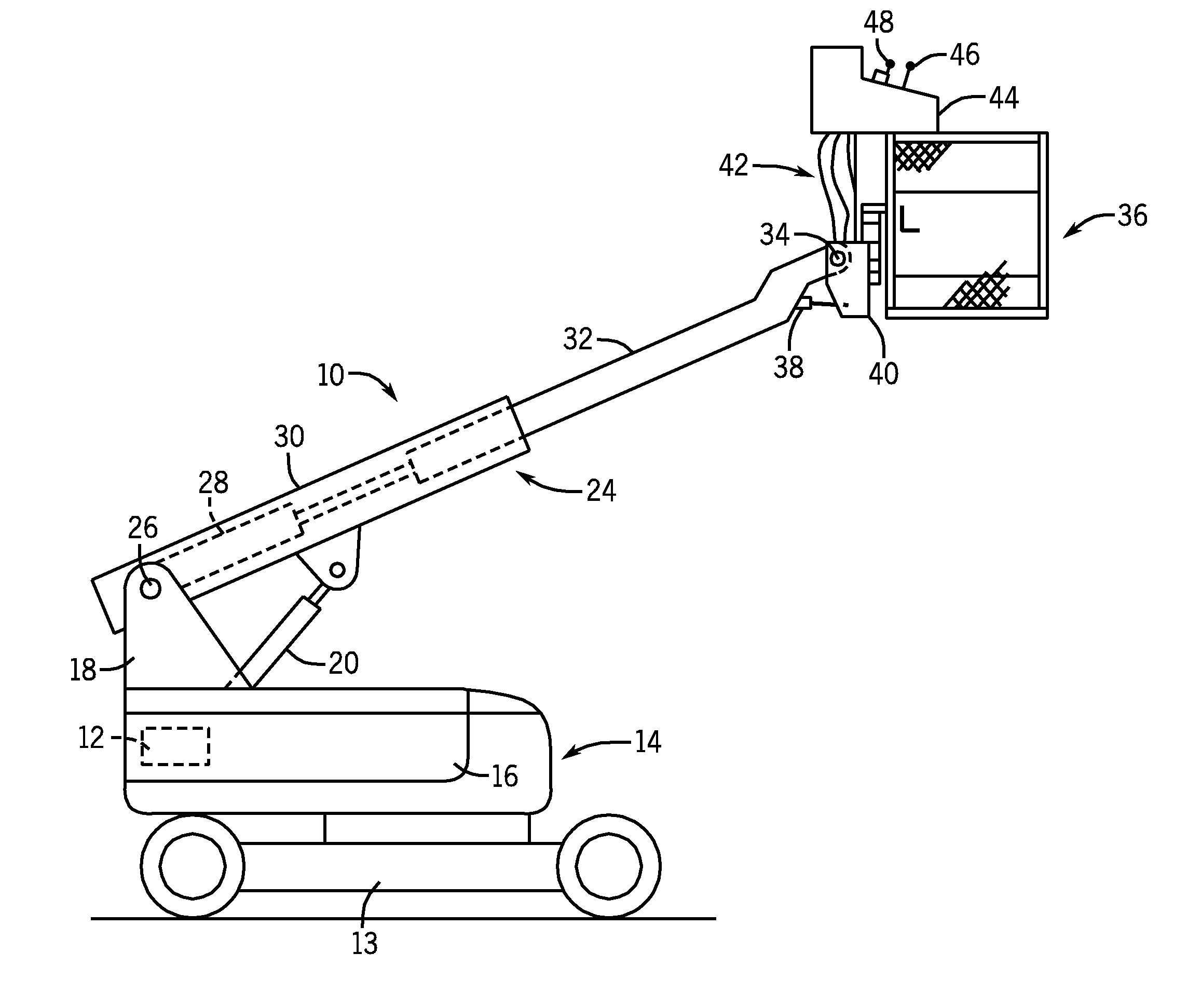

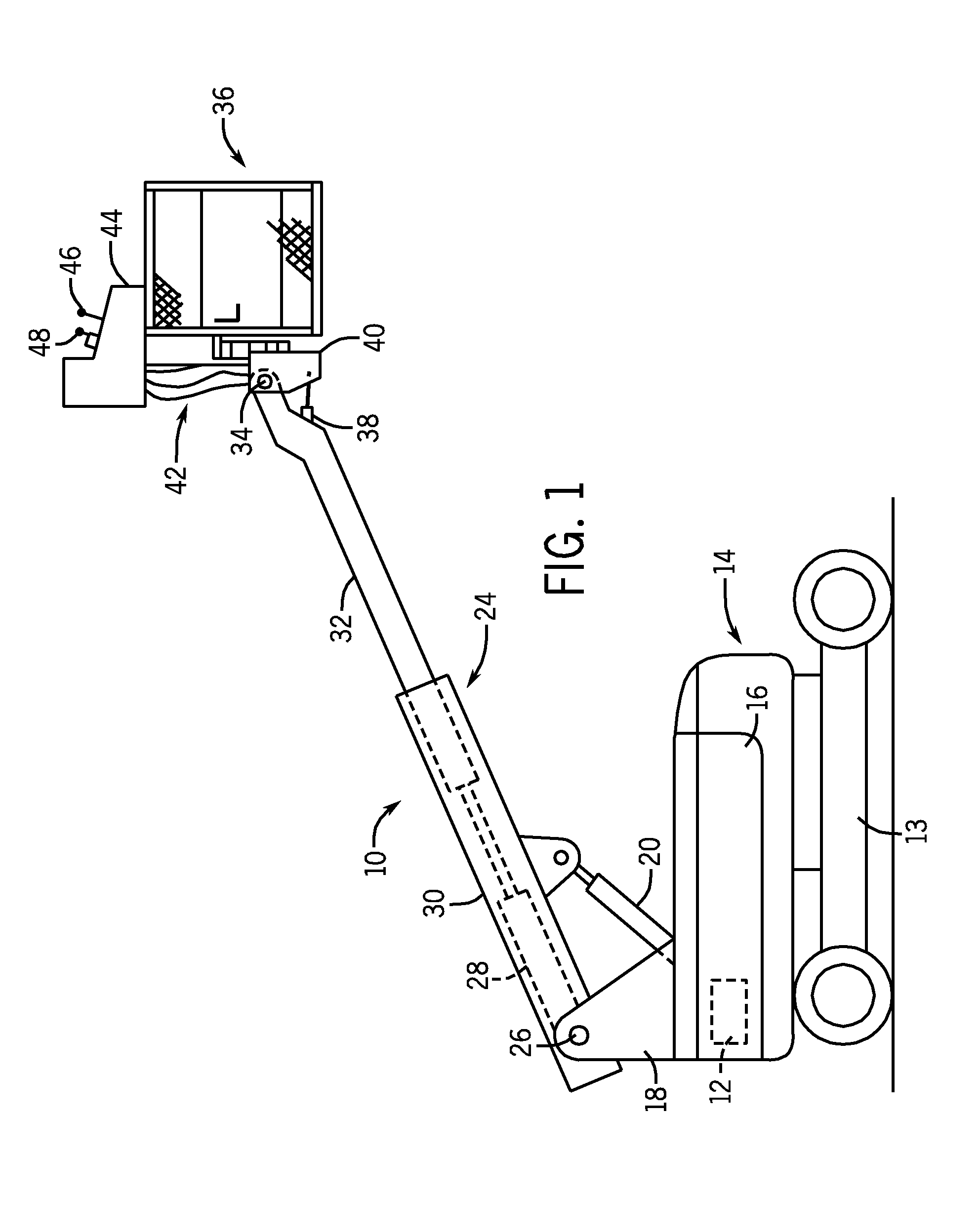

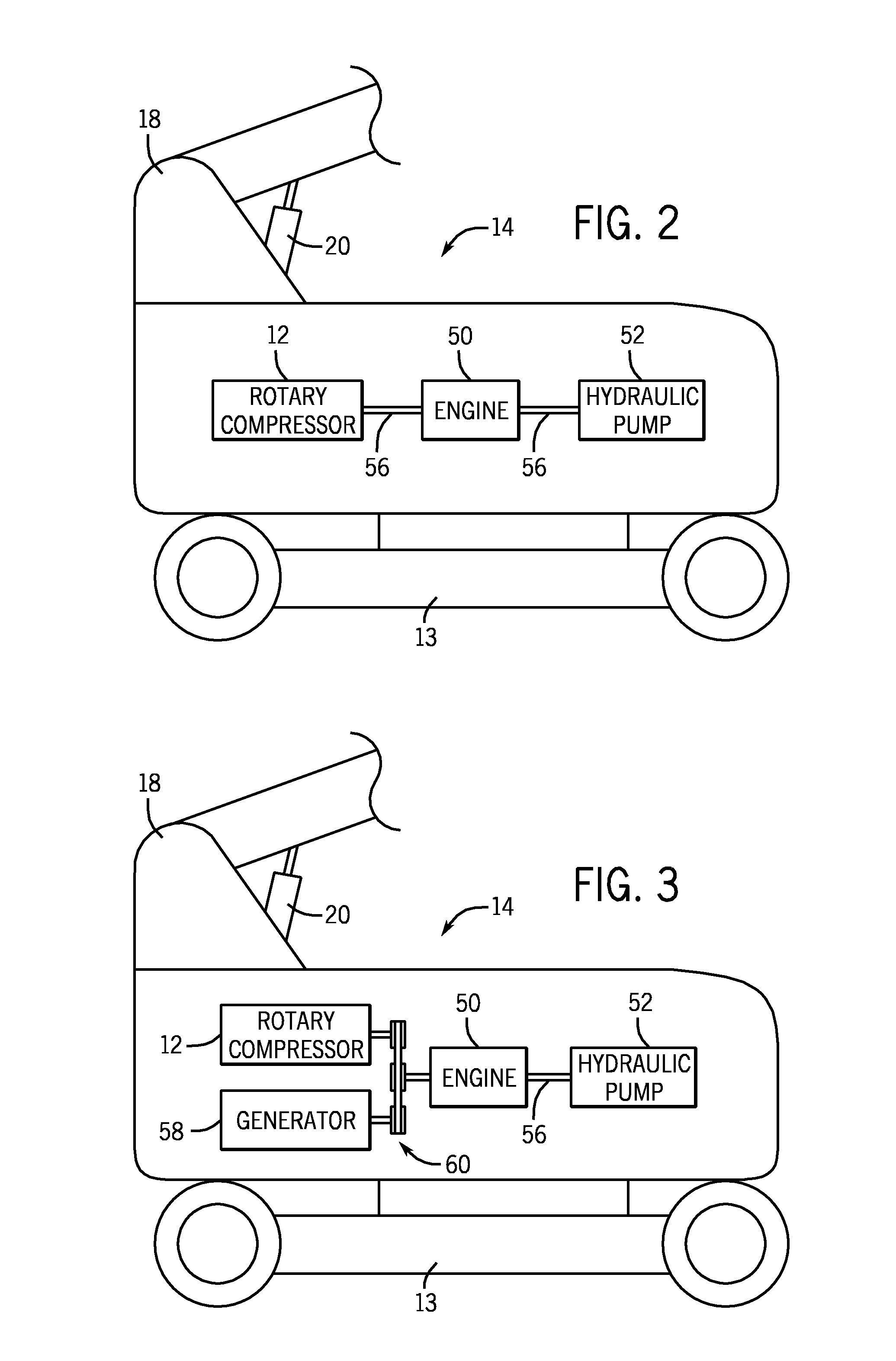

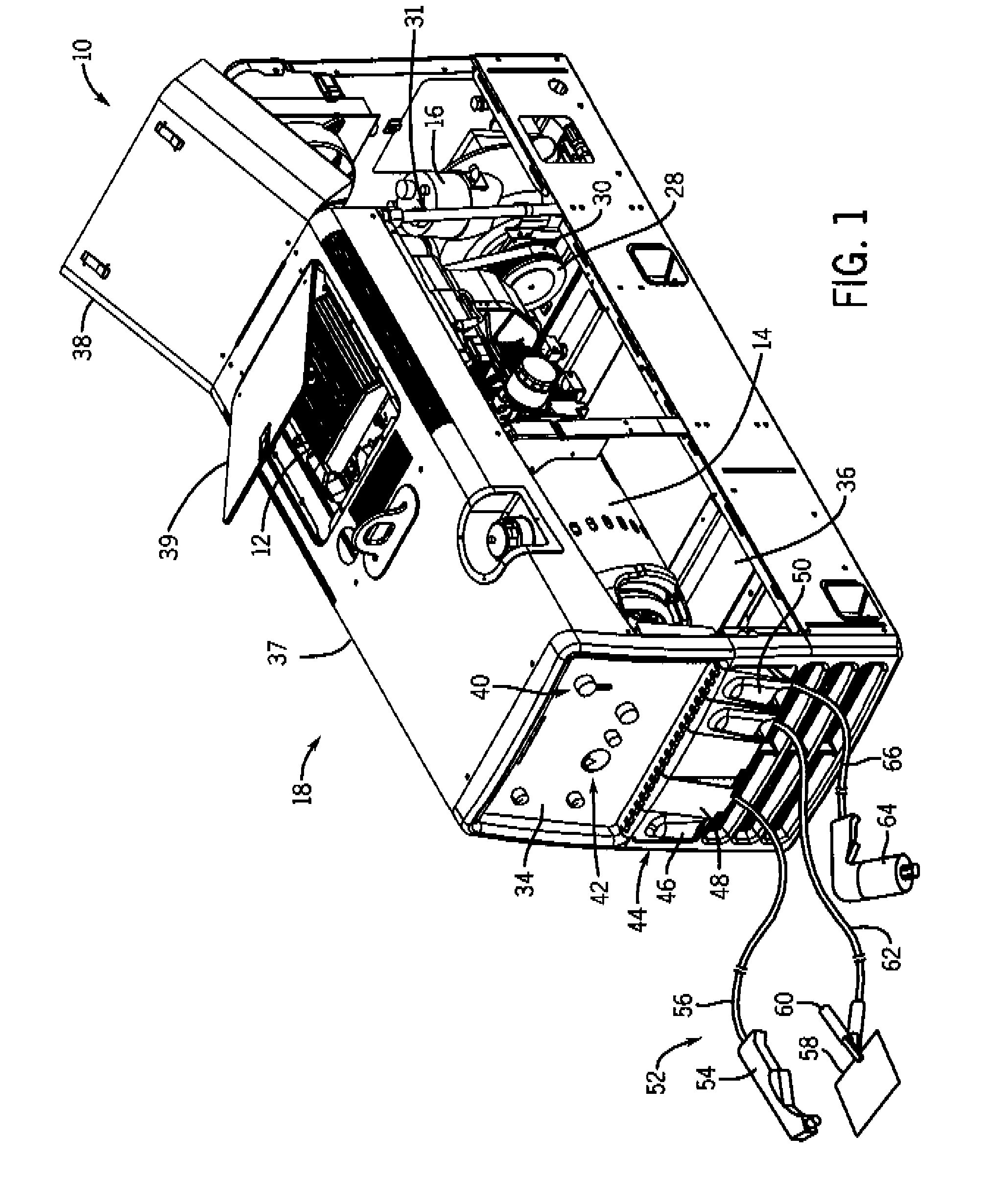

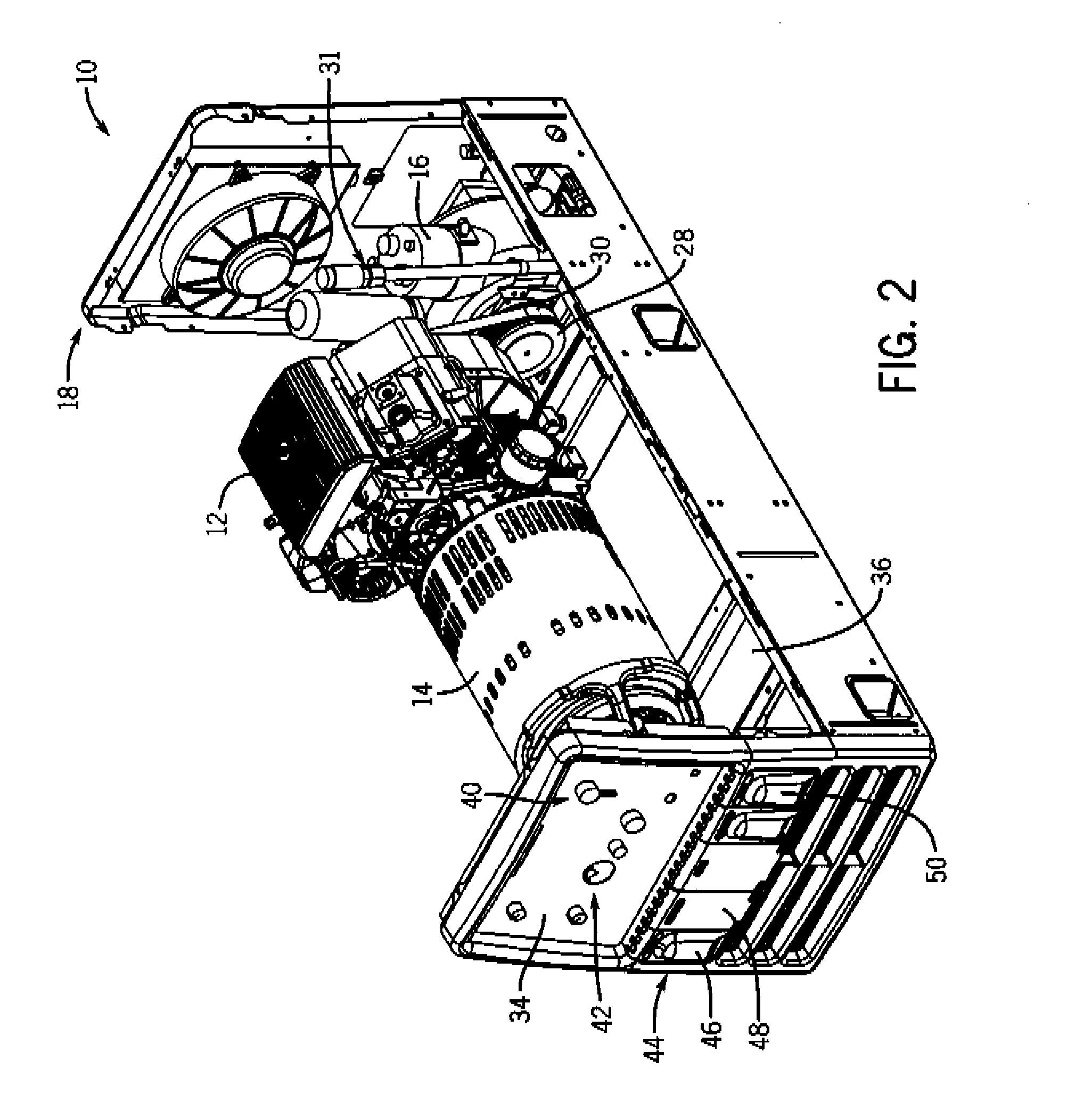

Aerial Work Platform with Compact Air Compressor

An aerial work platform, in one embodiment, includes a platform, including a hydraulic lift, and a base unit. The base unit includes a combustion engine and a hydraulic pump driven by the combustion engine. The hydraulic pump may be configured to drive the hydraulic lift. The base unit may also include a rotary screw type compressor, belt-driven by the combustion engine.

Owner:ILLINOIS TOOL WORKS INC

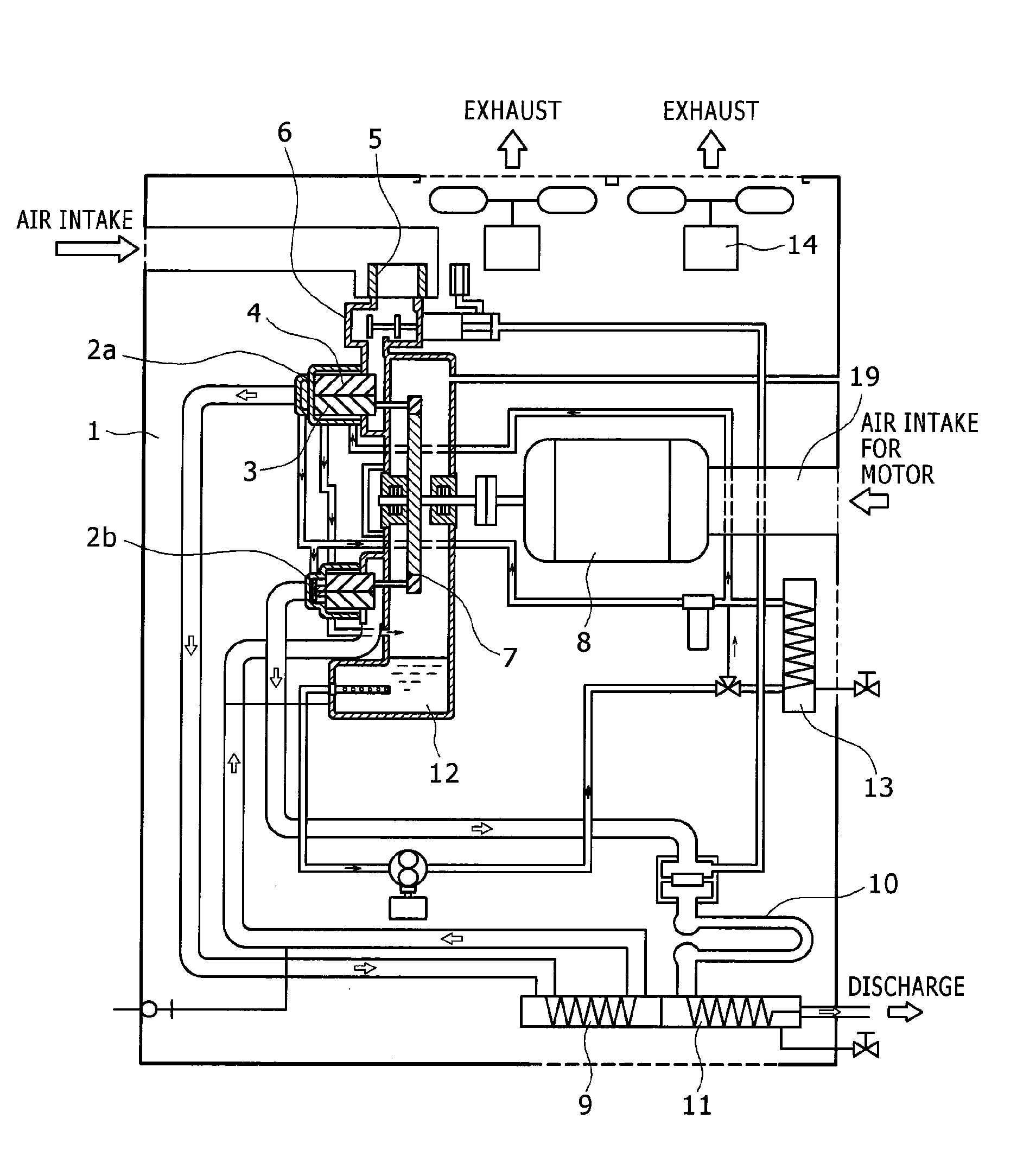

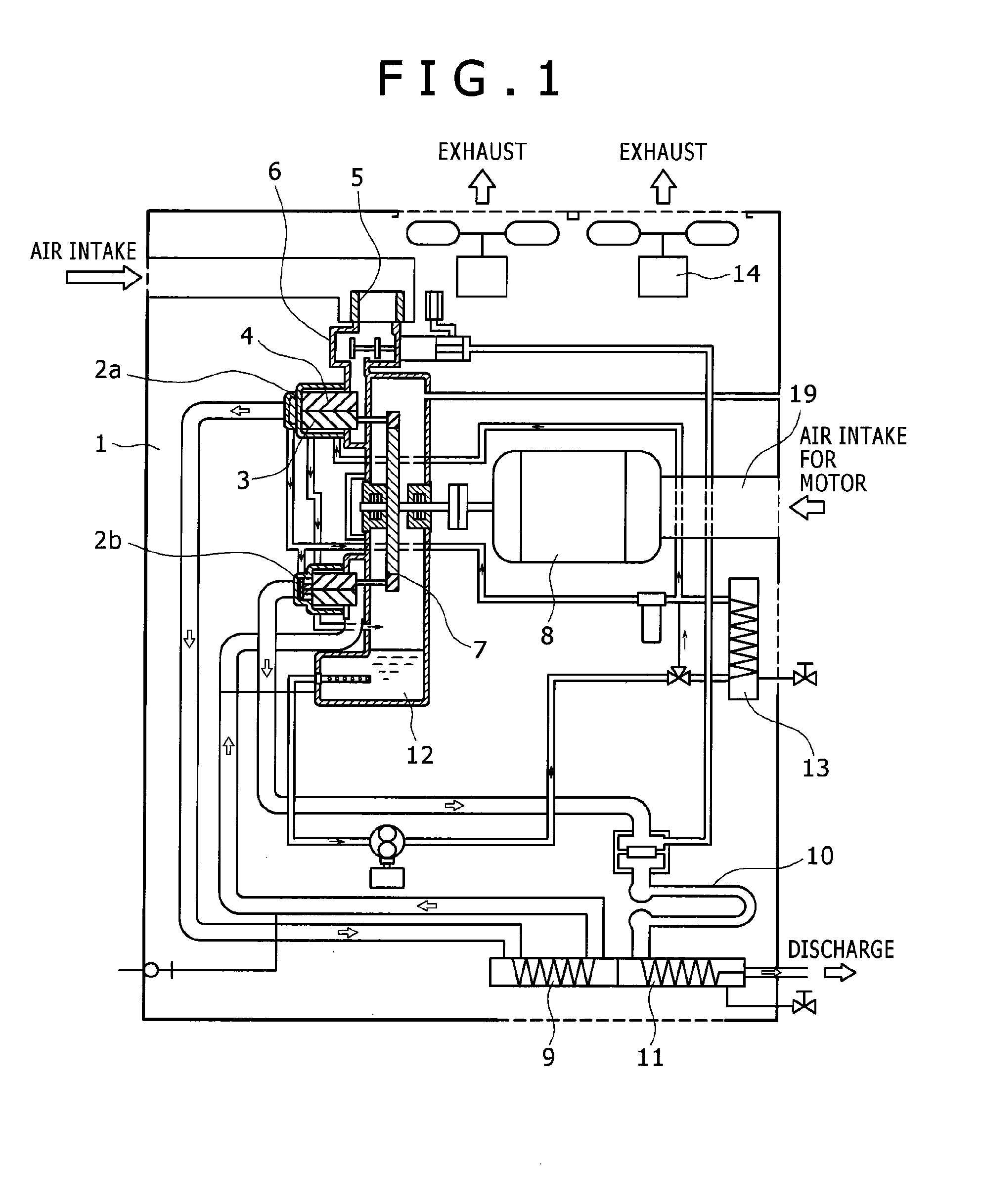

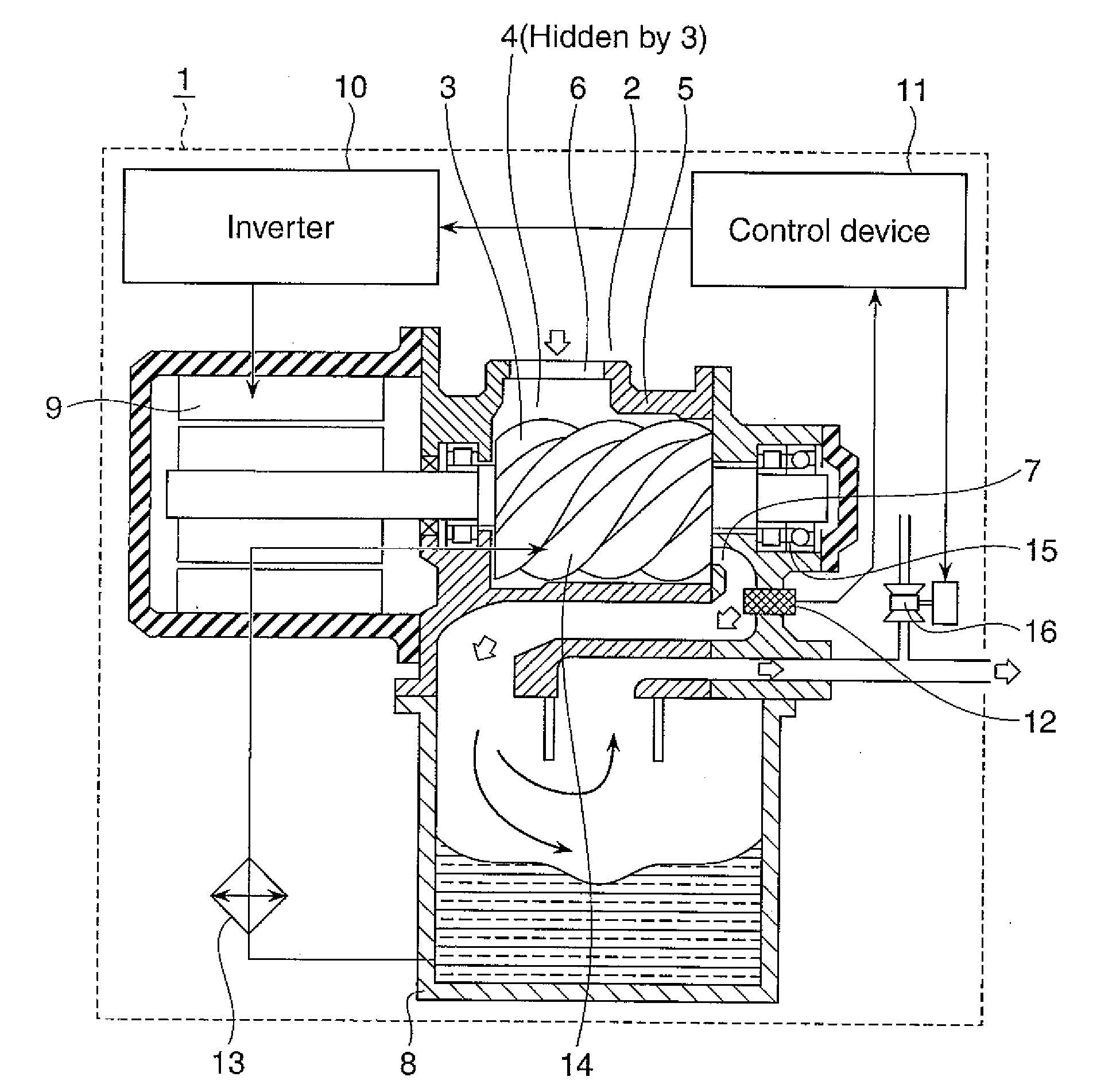

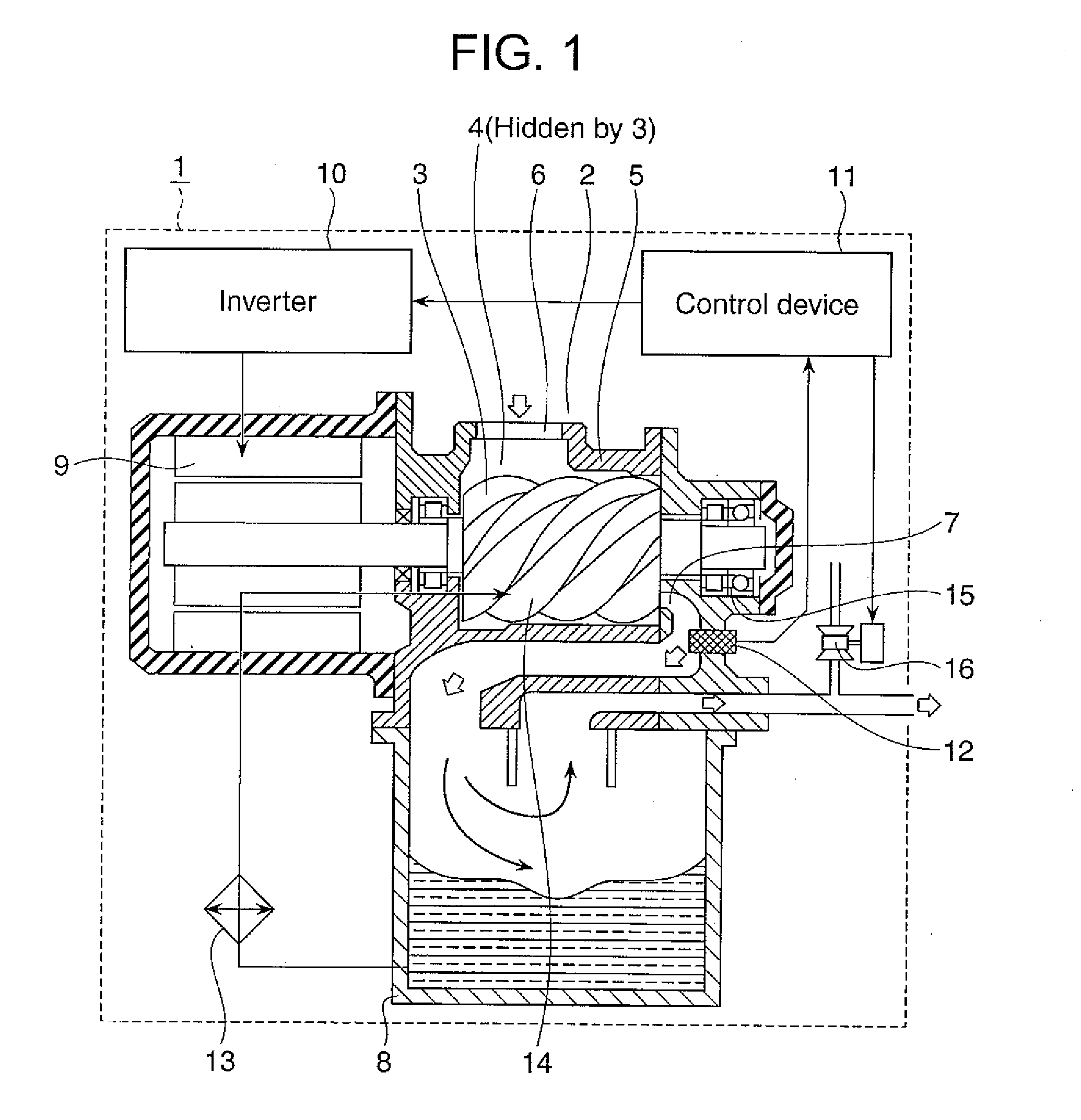

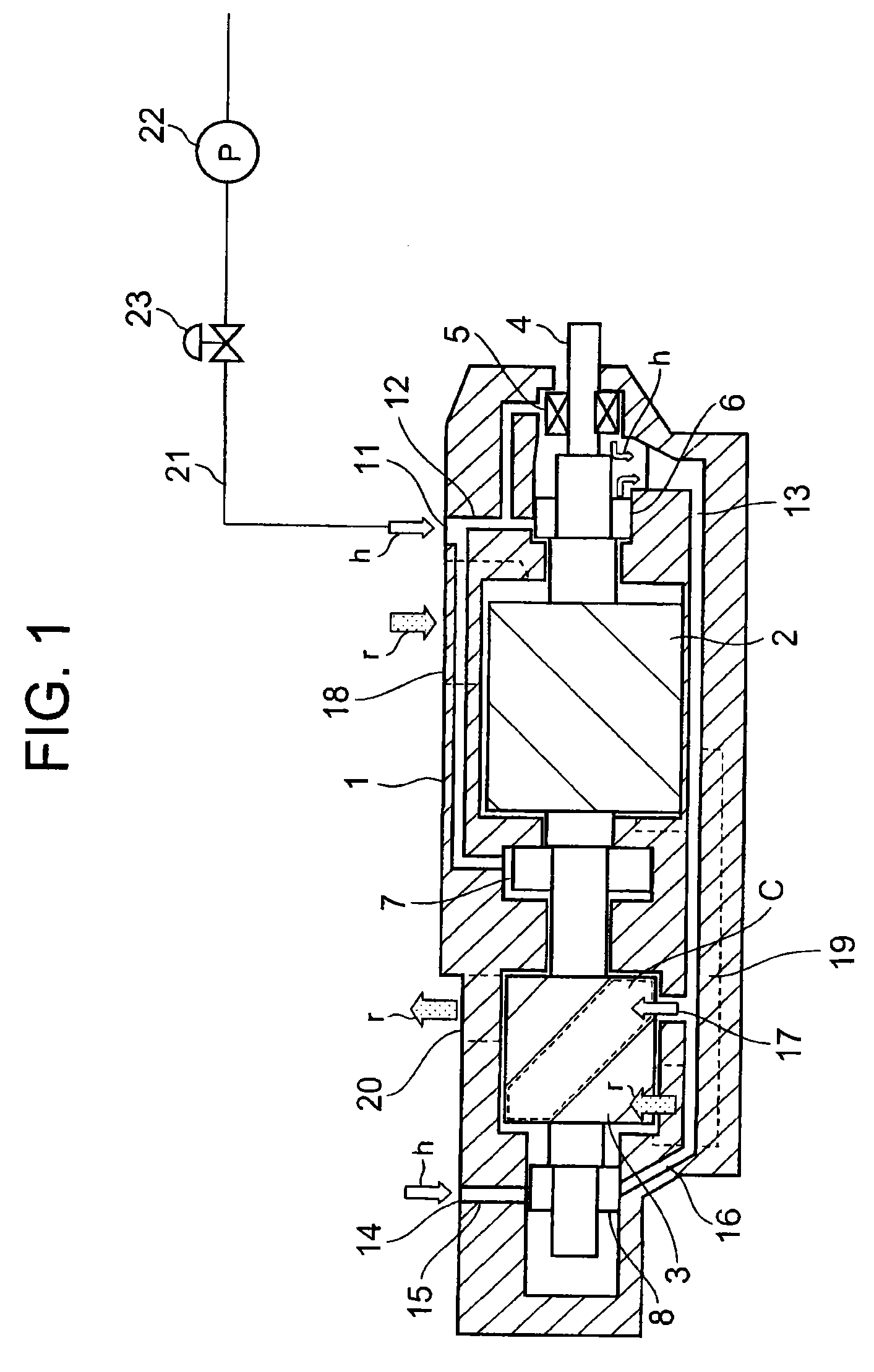

Oil-flooded screw compressor, motor drive system, and motor control device

ActiveUS20100028165A1Smooth startReduce weightDC motor speed/torque controlEmergency protective circuit arrangementsMotor driveMotor control

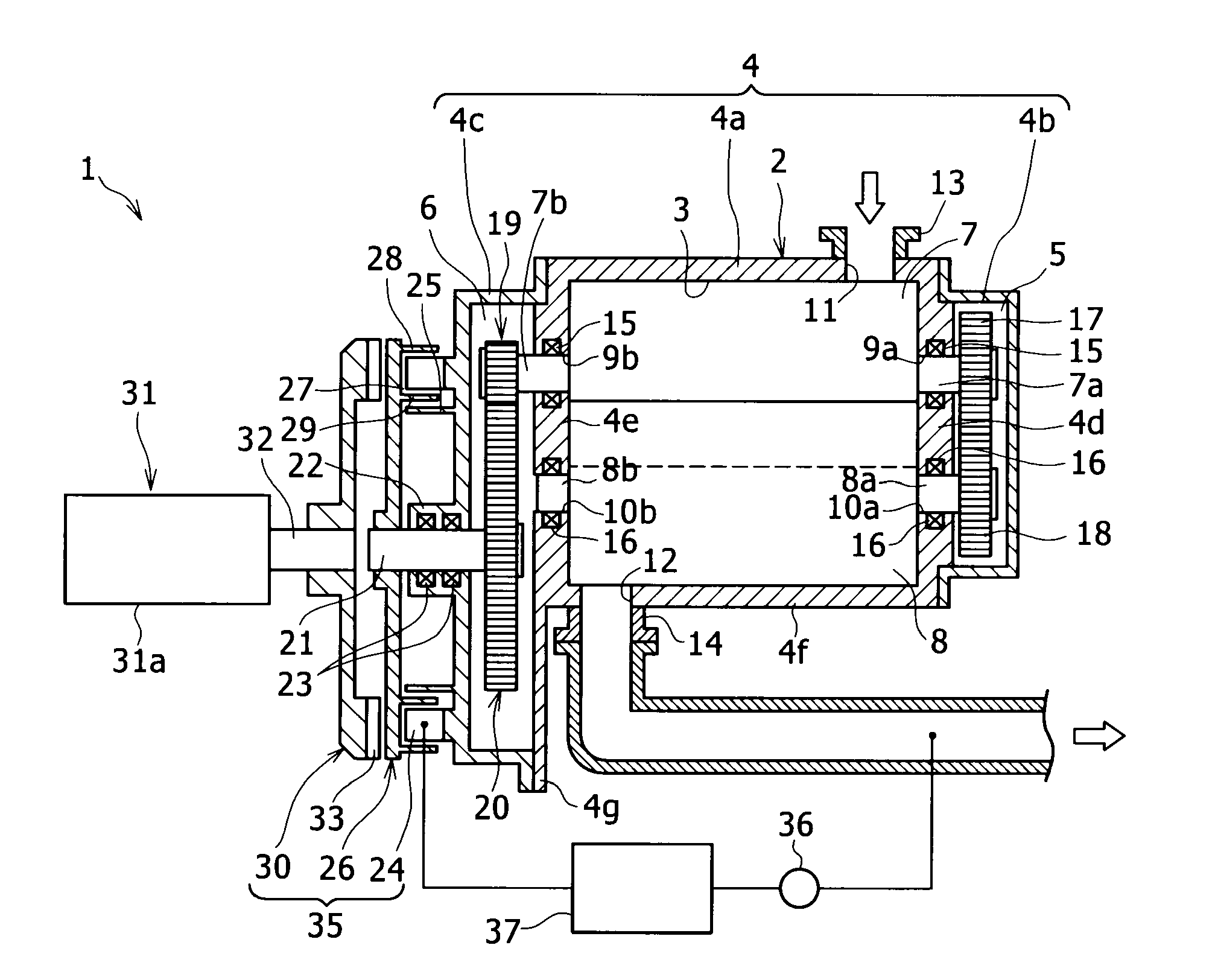

When an oil-flooded screw compressor is started up in a cold environment after a long halt, start-up torque increases due to the increased viscosity of the oil that has long stayed inside the working chambers of the compressor. This has necessitated drive means with a larger capacity than that required for normal operation.An oil-flooded screw compressor according to the invention comprises: a casing; a pair of rotors each having screw-thread-shaped groove and being housed in the casing; an electric motor for rotationally driving the pair of rotors; a control device for controlling the electric motor; an oil feeding mechanism for feeding oil into working chambers formed by being enclosed by the casing and the pair of rotors in which teeth thereof are meshed to each other; and an oil separating mechanism for separating the oil from compressed gas discharged from the working chambers. The oil-flooded screw compressor drives the pair of rotors at a rotational speed which is low enough not to increase torque for a short amount of time after start-up and accelerates the pair of rotors up to a normal-operation rotational speed after oil discharge. Alternatively, the oil-flooded screw compressor rotates the pair of rotors for a short amount of time after the remaining compressed gas is discharged after a halt, thereby allowing the oil accumulated inside the working chambers to be discharged and ensuring smooth start-up after the halt.

Owner:HITACHI IND EQUIP SYST CO LTD

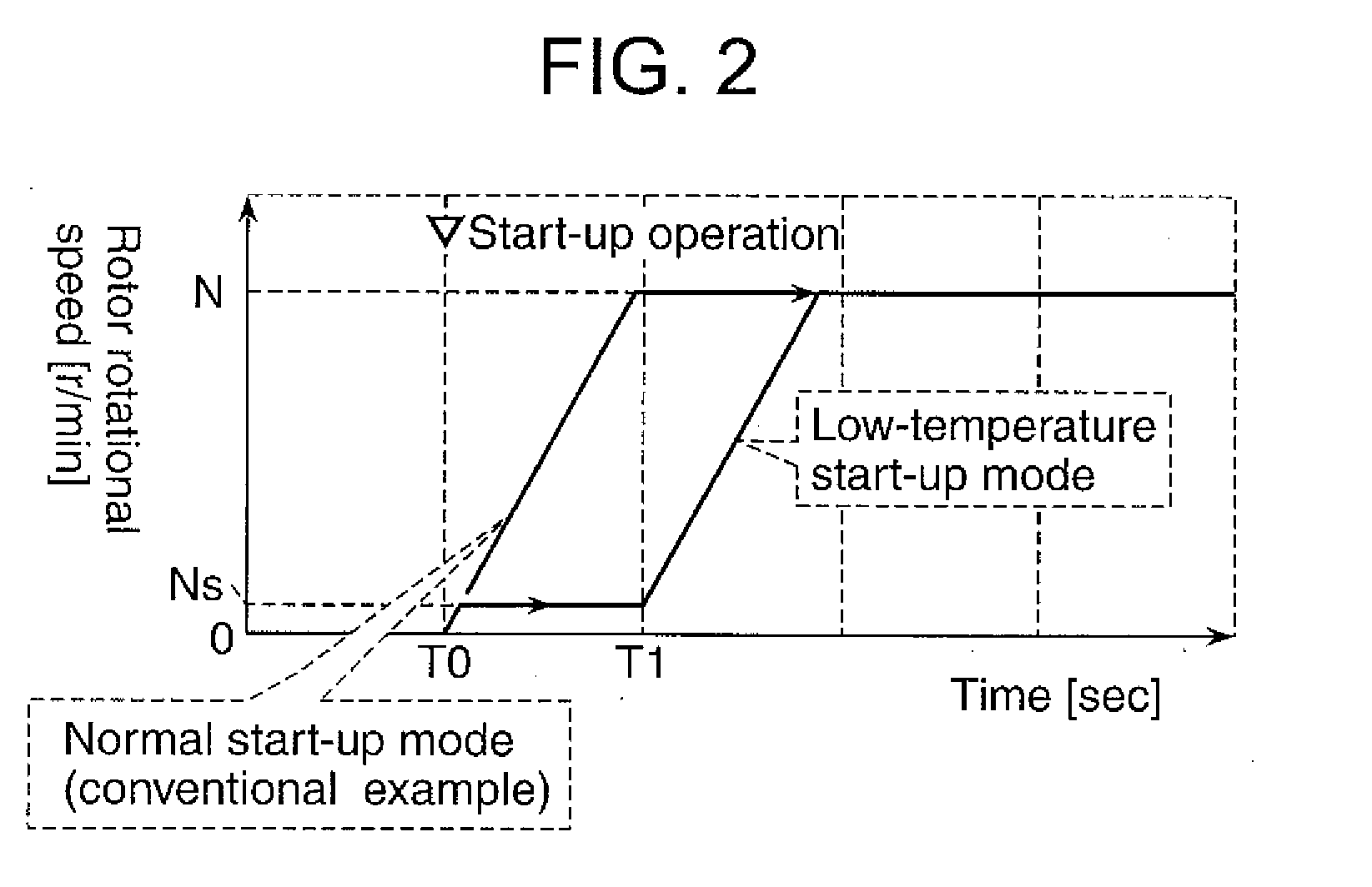

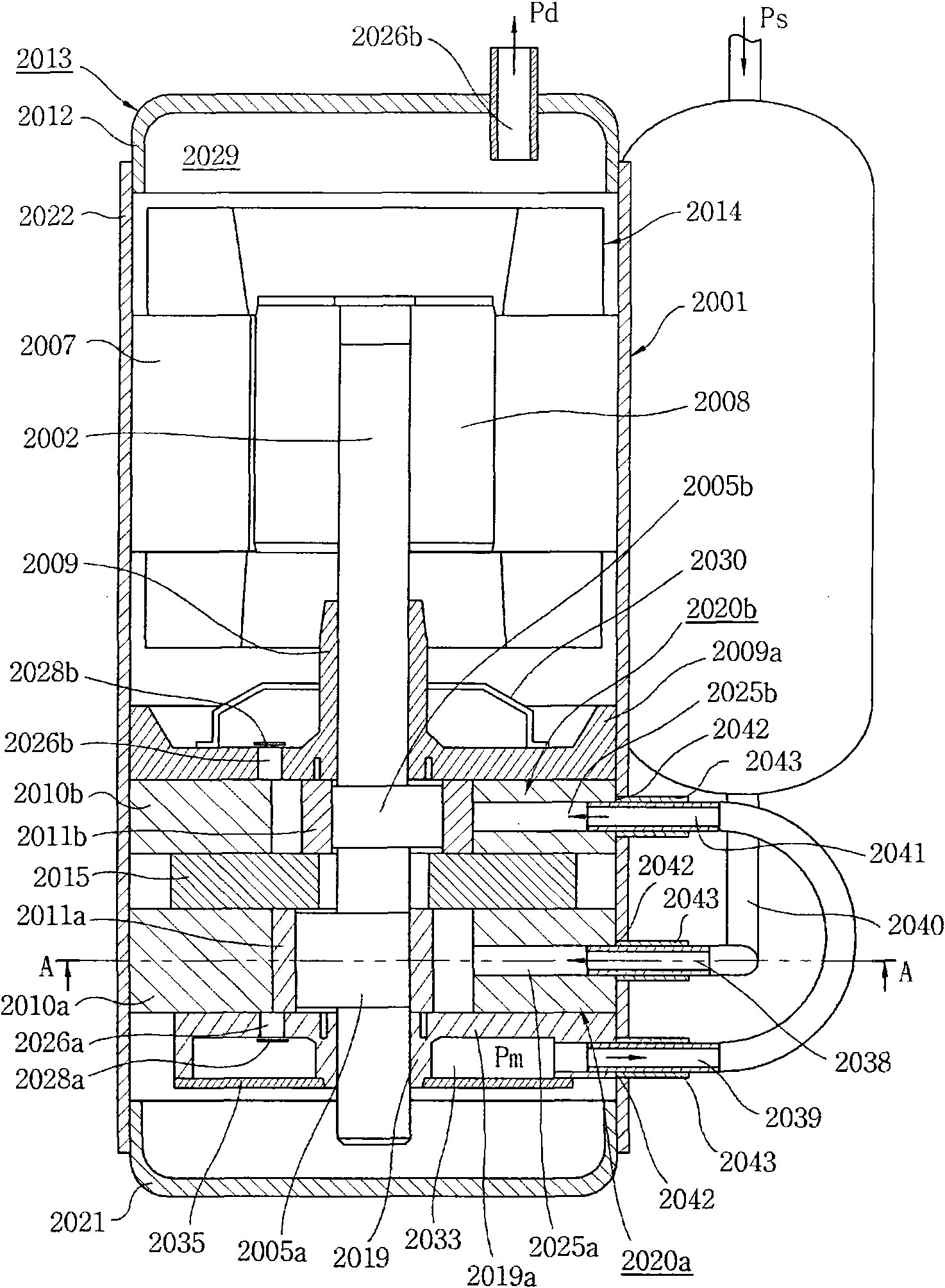

Rotary compressor

InactiveCN101684814AIncrease credibilityEasy to recycleRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsMotor oilAutomotive engineering

The invention relates to a rotary compressor which comprises a sealed container, an electric motor, a rotating shaft, a lower compression combination, an upper compression combination and an engine oil separating plate, wherein the sealed container is provided with an inflow pipe and a discharge pipe and stores engine oil at the bottom; the electric motor is arranged in the sealed container near the discharge pipe and generates rotary force; the rotating shaft supplies the engine oil and transmits rotary force generated by the electric motor; the lower compression combination is positioned inthe sealed container and compresses refrigerant when the rotating shaft rotates; the upper compression combination is positioned at the upper side of the lower compression combination and compresses the refrigerant when the rotating shaft rotates; and the engine oil separating plate is arranged between the electric motor and the upper compression combination, crushes the refrigerant discharged bythe upper compression combination before the refrigerant flows through the electric motor and separates the refrigerant and the engine oil. Because the engine oil and the refrigerant are separated andrecovered by the engine oil separating plate before the refrigerant flows through the electric motor, the engine oil and the refrigerant are prevented from flowing out of the sealed container together; because the engine oil is rapidly recovered, both the compression performance and the operating reliability of the compressor are improved.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

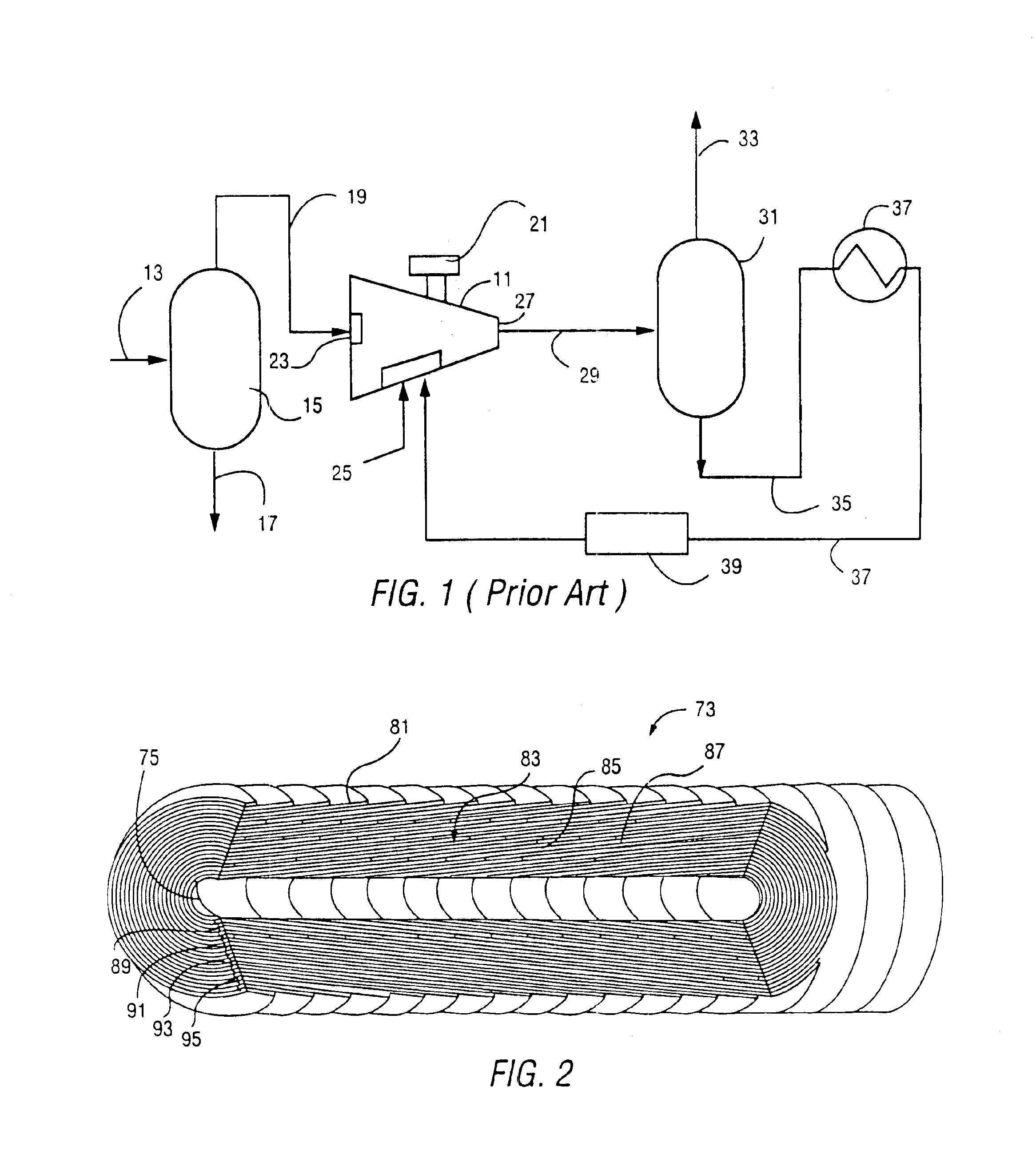

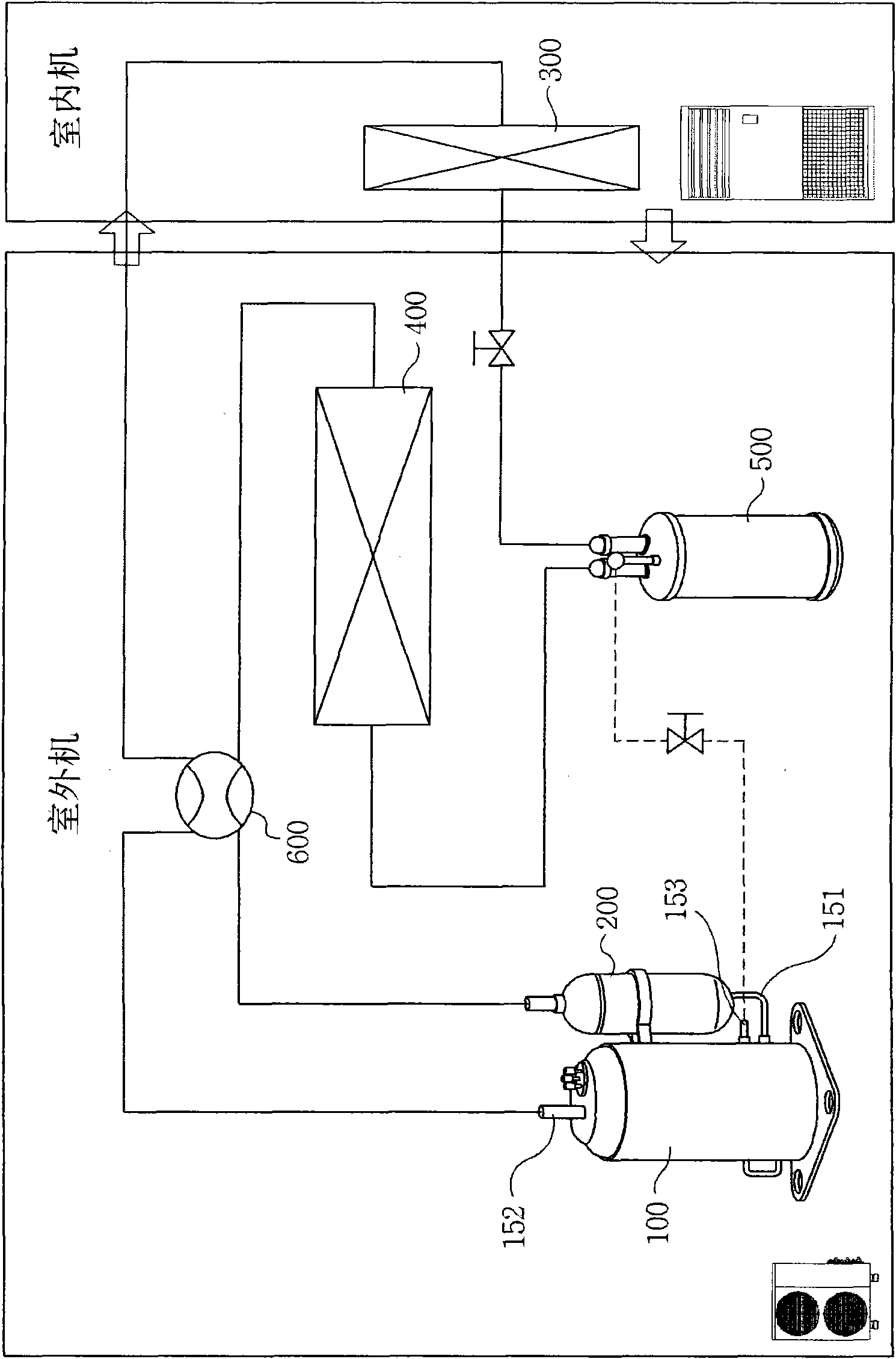

Oil supply method of two-stage screw compressor, two-stage screw compressor applying the method, and method of operating refrigerating machine having the compressor

InactiveUS20080152524A1Improve volumetric efficiencyImprove compression efficiencyRotary/oscillating piston combinations for elastic fluidsOscillating piston enginesEngineeringHigh pressure

A method of supplying lubrication oil to a two-stage screw compressor is disclosed in which a low-pressure stage screw compressor and a high-pressure stage screw compressor are integrally constructed. A compression space is formed by a male rotor and a female rotor, and operation gas is fed for compression to the compression space. The method prevents degradation of volumetric efficiency caused by return of lubrication oil, coming from a bearing and a shaft sealing device, to the low-pressure stage screw compressor, and as a result, refrigeration capacity is improved and the amount of the lubrication oil is reduced.

Owner:MAYEKAWA MFG CO LTD

Screw compressor acoustic resonance reduction

InactiveUS20060165543A1Reduce the possibilityReduce wearOscillating piston enginesEngine of counter-engagement typeSpool valveNoise barrier

A screw compressor for acoustic resonance reduction and refrigeration systems including the screw compressor are disclosed. The screw compressor has an acoustic barrier integral with the compressor housing for use with a slide valve assembly that includes a piston connected to a slide valve. A shaft connecting the slide valve and the piston passes through an aperture in the barrier with the piston and the slide valve disposed on opposite sides of the barrier. The acoustic barrier protects the piston from discharge pulses of compressed fluid exiting the rotors of the screw compressor, thus attenuating acoustic resonance, reducing compressor noise and premature wear of the slide valve assembly and compressor housing.

Owner:YORK INT

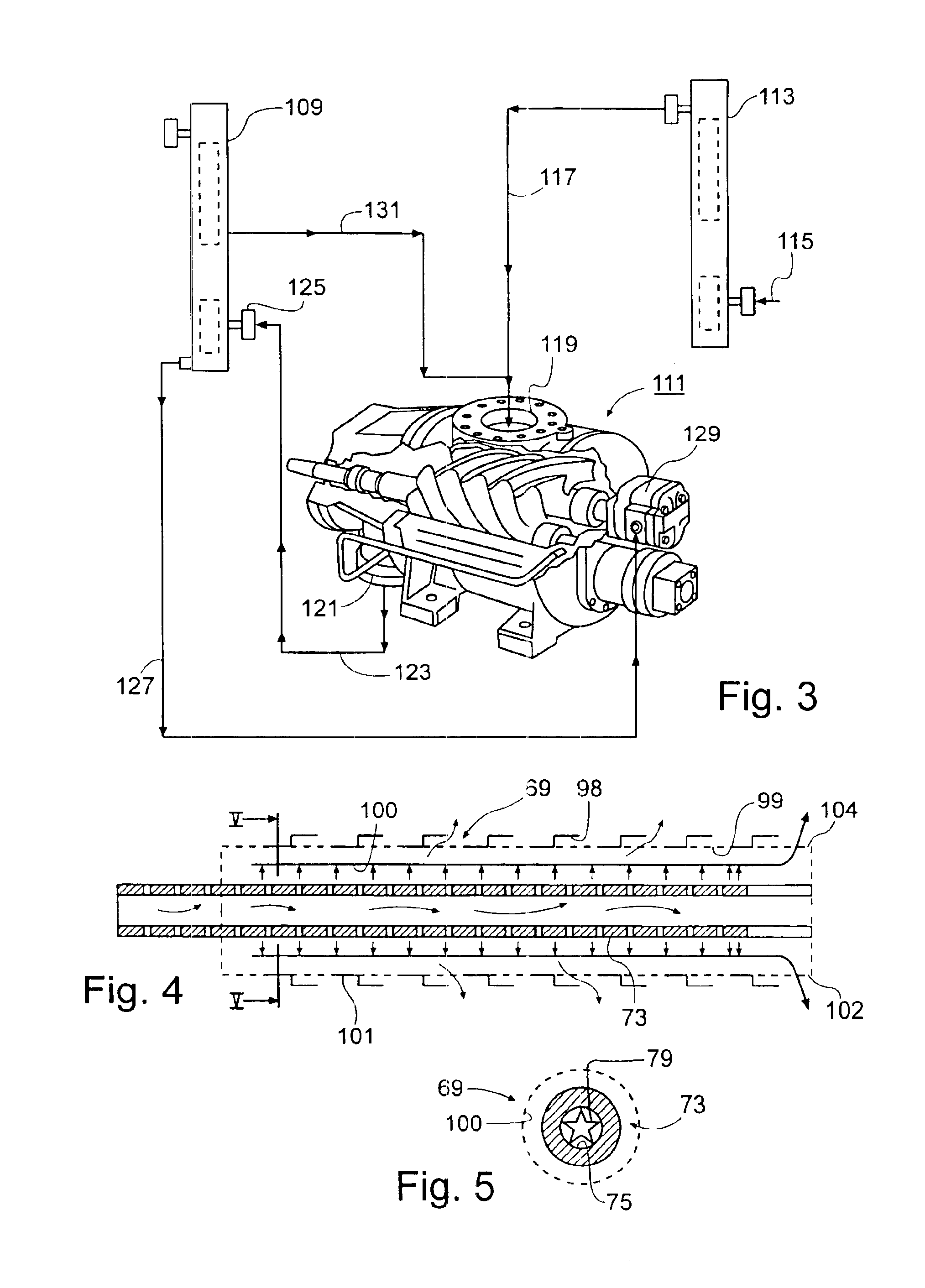

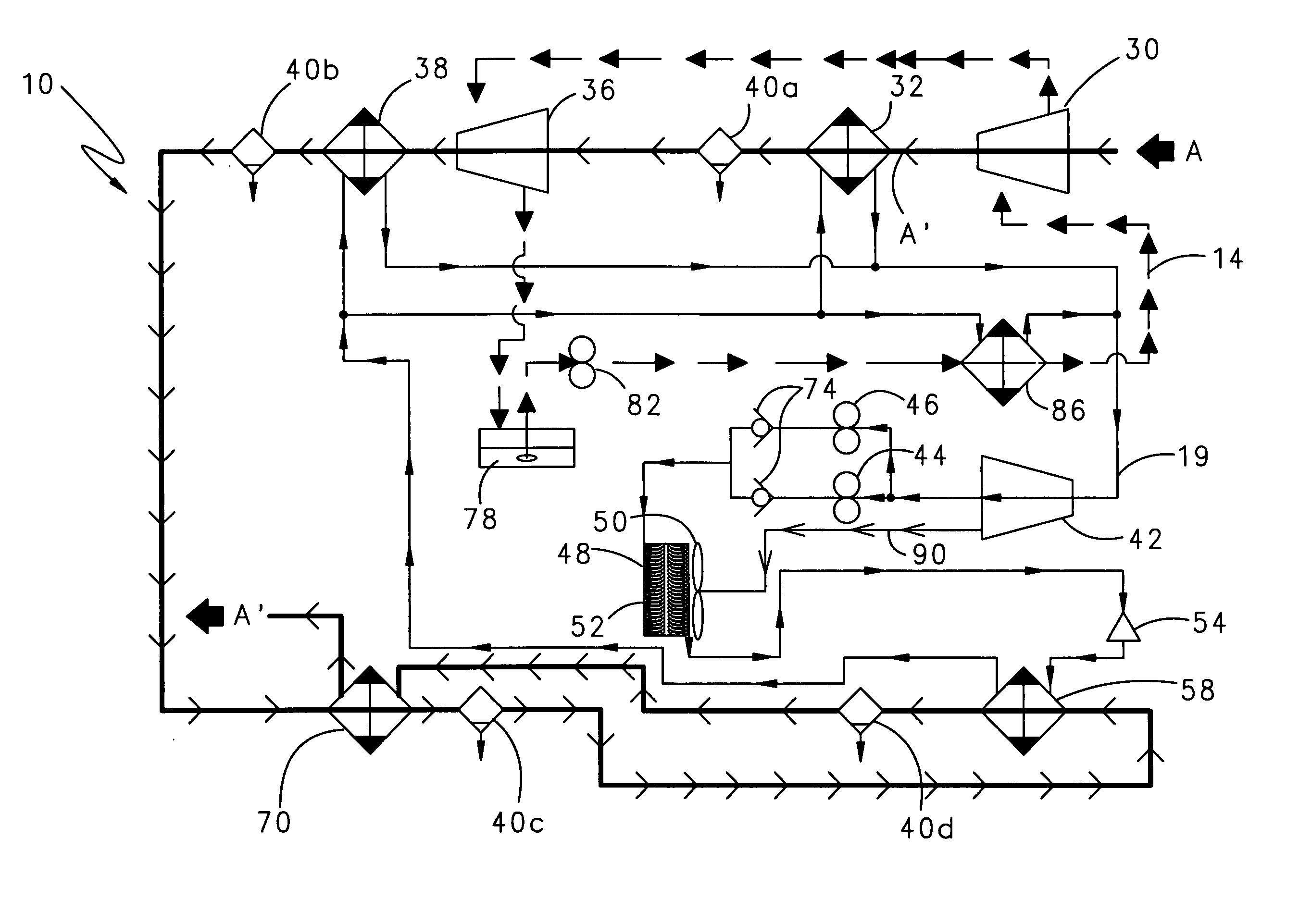

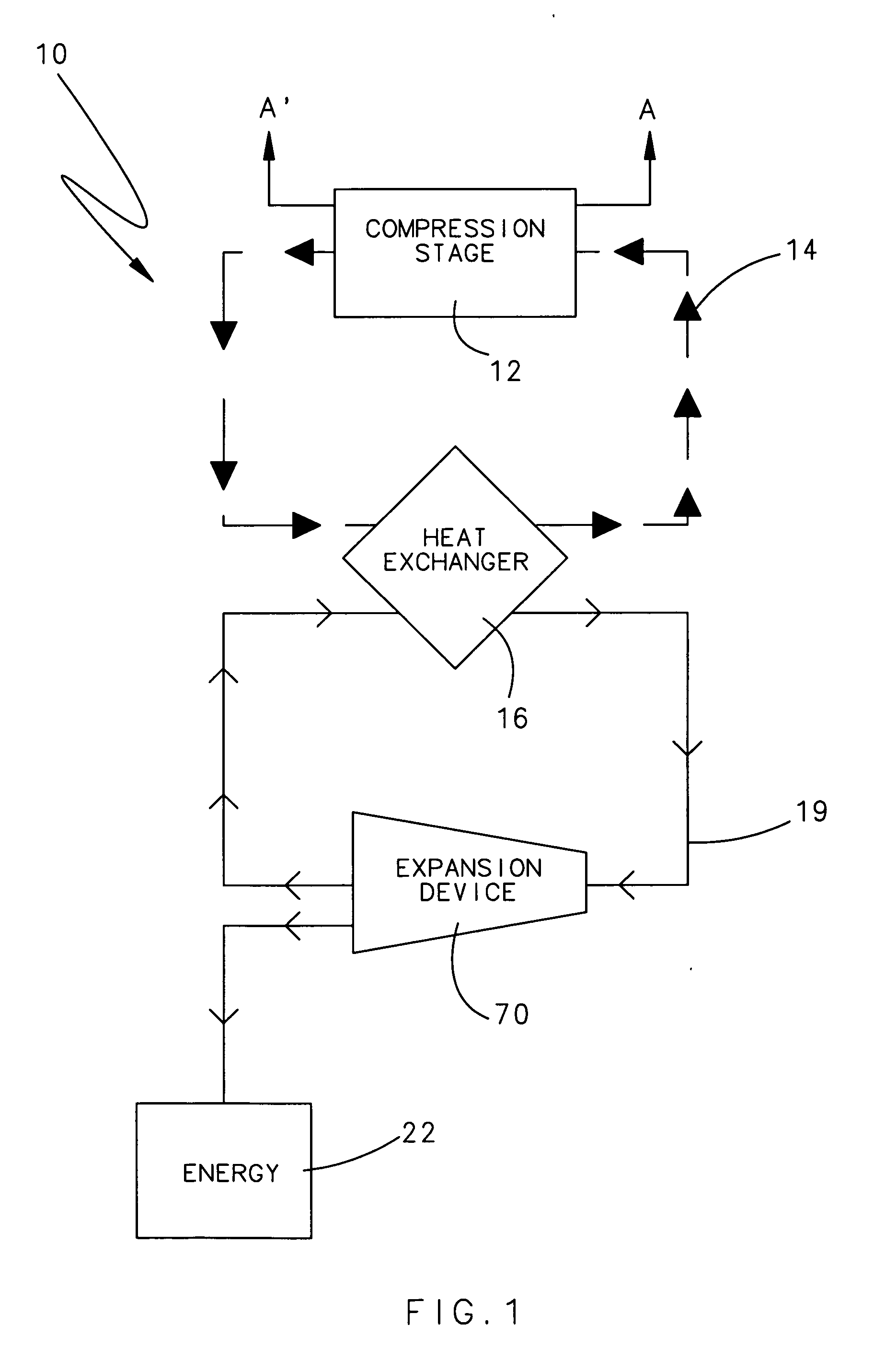

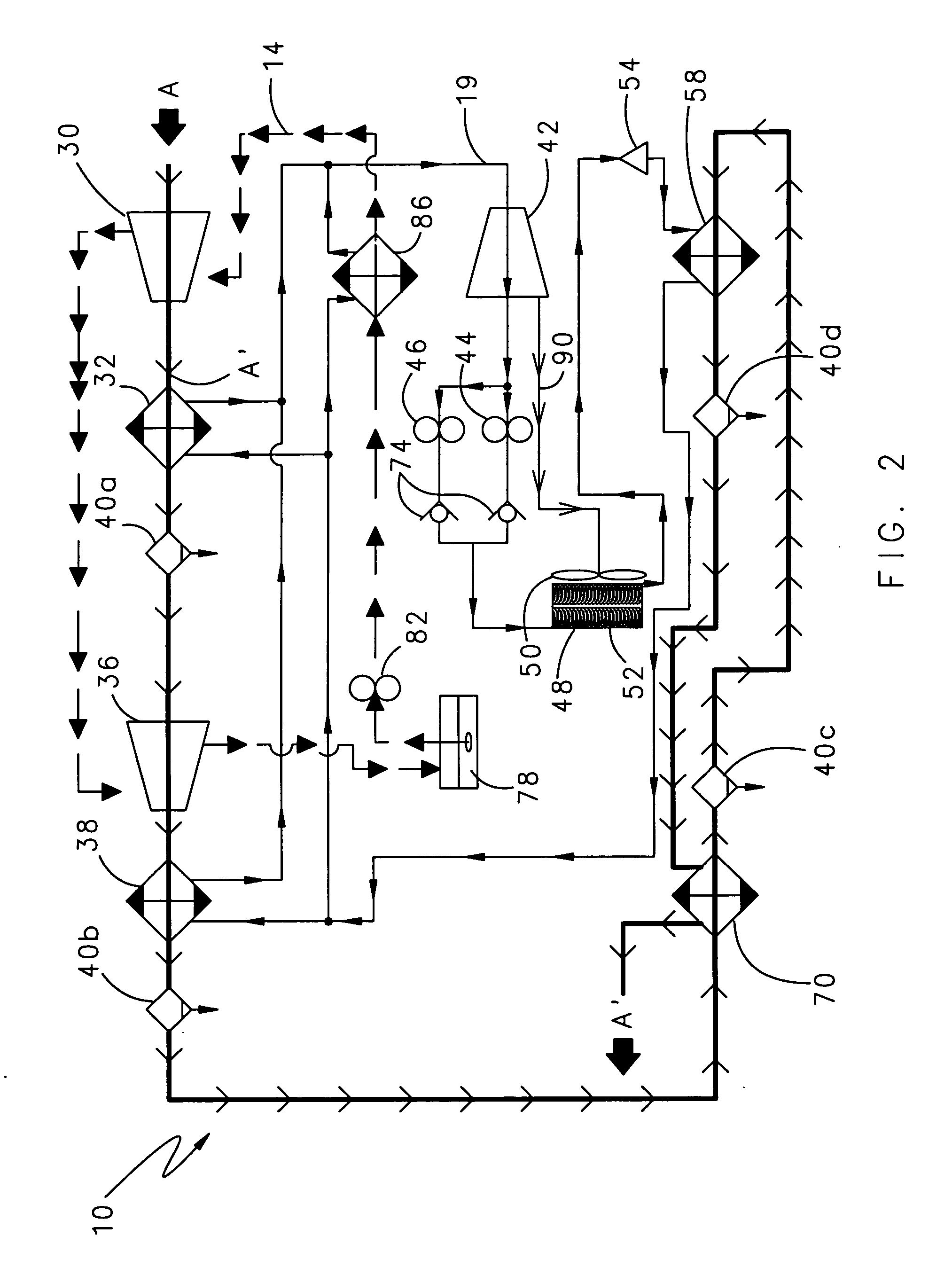

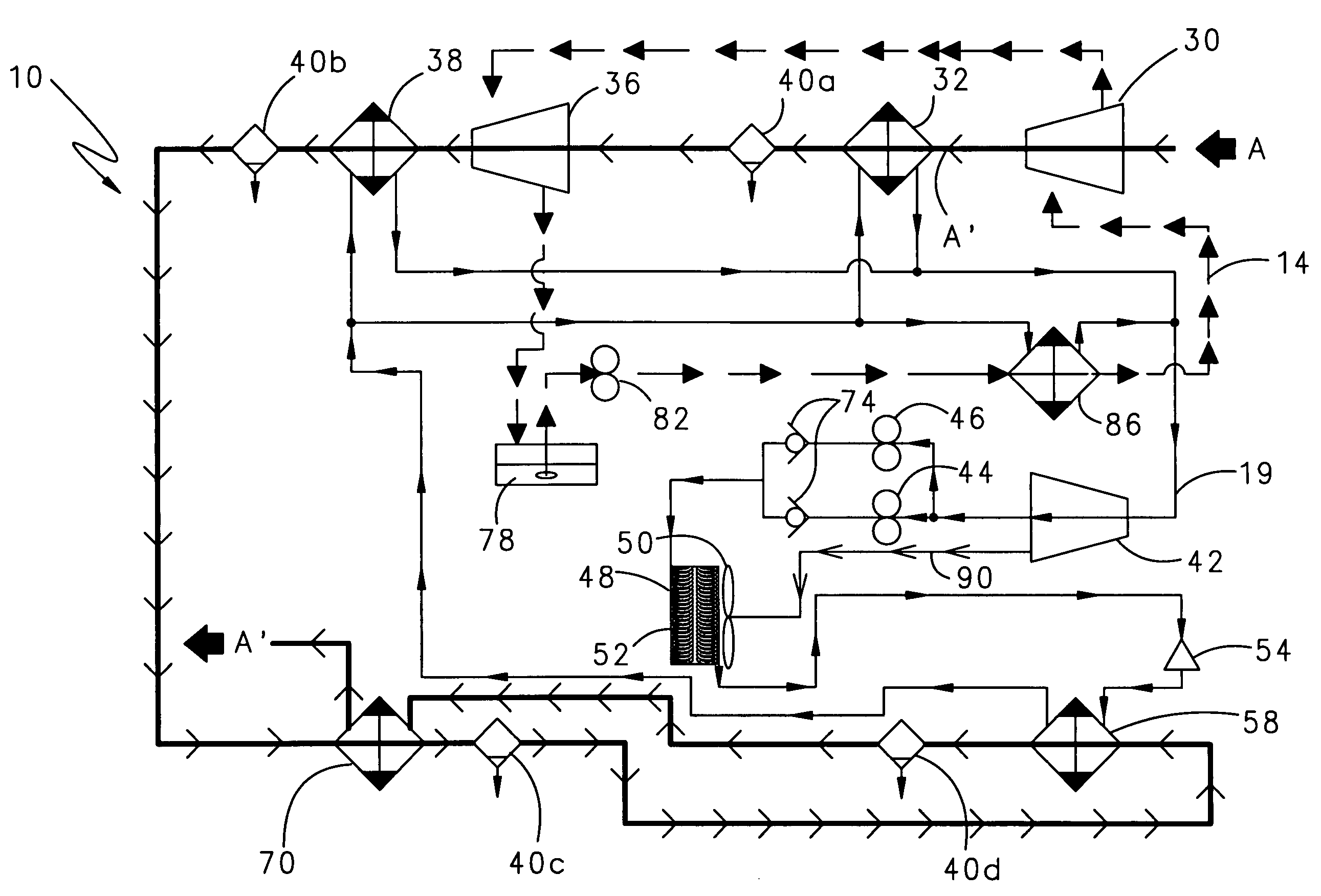

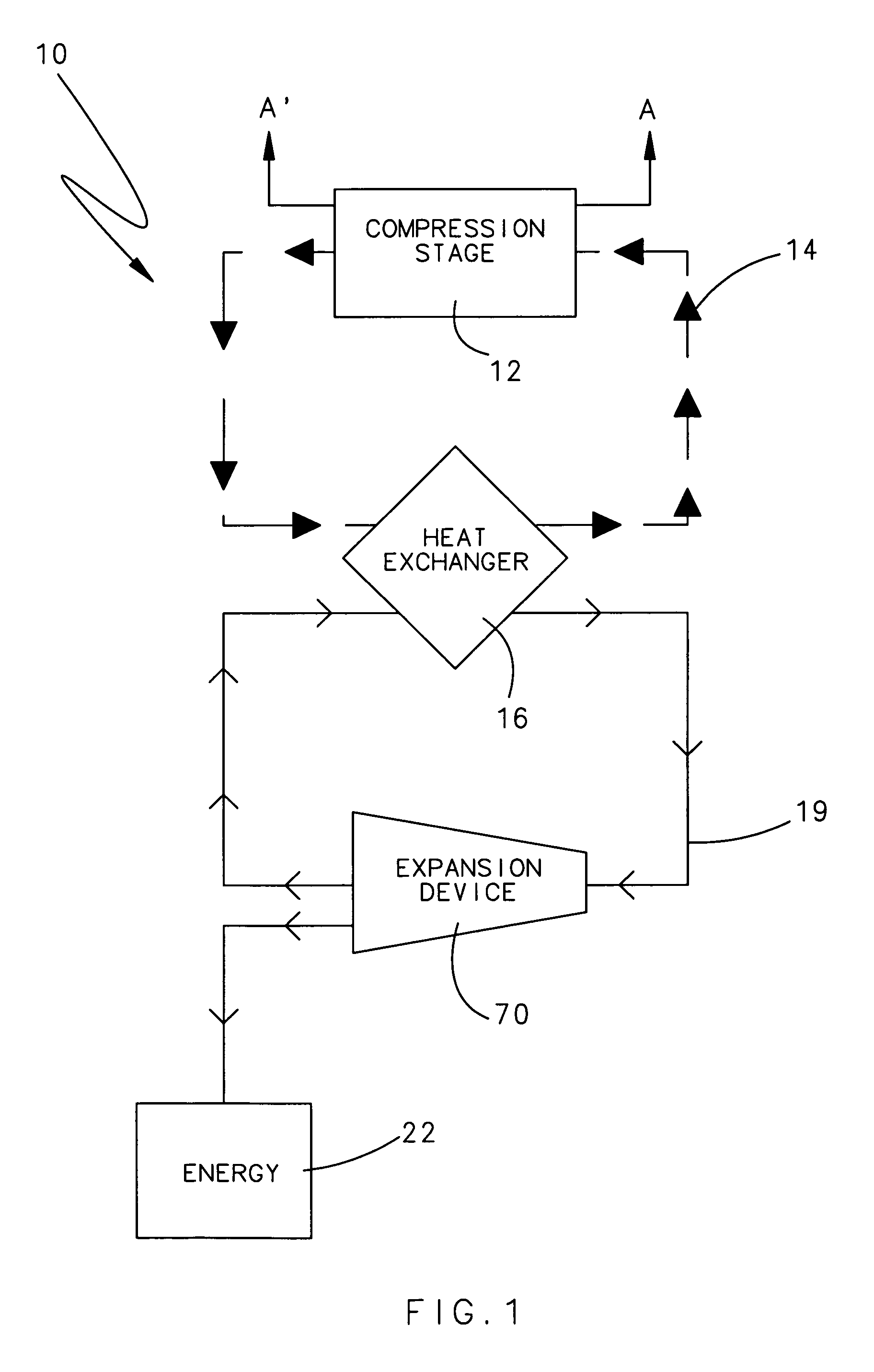

Cooling system for a rotary screw compressor

InactiveUS20070074535A1Compression machines with non-reversible cycleCompression machines using turbinesEngineeringRefrigerant

A compressor system has a compression stage, a coolant circuit and a refrigerant circuit. The compression stage compresses ambient air and generates compressed air and heat. A coolant removes heat from the compression stage and the heat is transferred from the coolant to a refrigerant. A refrigerant expansion device is incorporated into the refrigerant circuit. The expansion device expands the pressurized refrigerant utilizing a rotary expander. Energy generated during refrigerant expansion is captured and used to drive components of the cooling system.

Owner:SULLAIR CORP

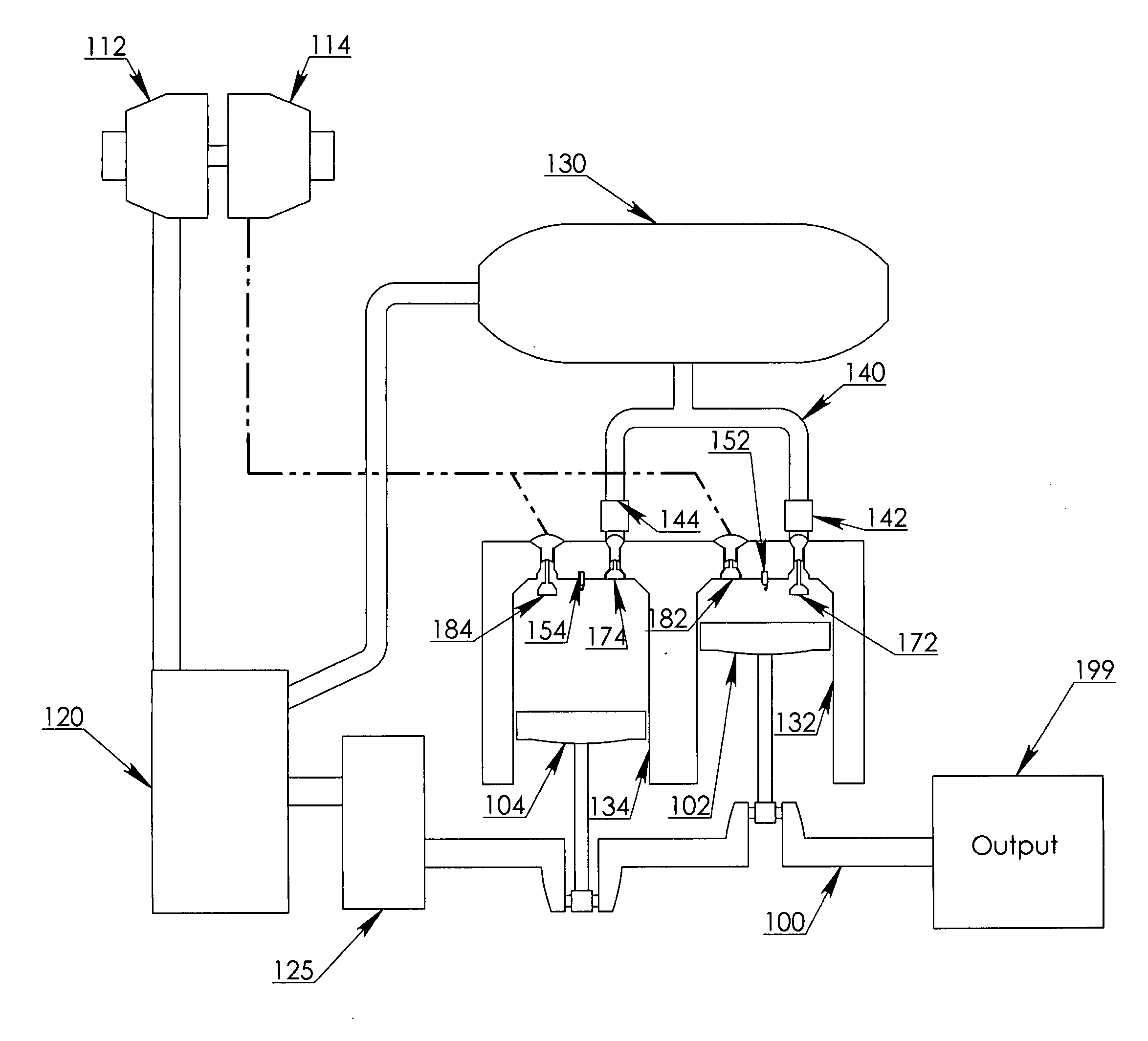

Controlled-compression direct-power-cycle engine

InactiveUS20120090580A1Improve efficiencyAvoid low lightElectrical controlInternal combustion piston enginesCombustion chamberPower cycle

The present invention provides a controlled-compression direct-power-cycle engine for performing the direct-power-cycle, wherein the air is compressed with three compression processes and cooled to a controlled temperature before ignition, the engine power output is controlled by both the compressor-transmission and the servo-intake-valve; the three compression processes are the initial-compression-process, the intermediate-compression-process, the final-compression-process, wherein, the initial-compression-process is performed by the turbocharger, the intermediate-compressor-process is performed by a screw type compressor, a rotary type compressor, or a scroll type intermediate-compressor, the final-compression-process is performed by the pistons of the combustion chambers; said intermediate-compressor is coupled to the compressor-transmission for adjusting the compression-capacity according to the instruction signals from the engine control unit, which computes the required compression-capacity by the user's power demand and the pressure in the cooling tank; said final-compression-process adjusts the actual-pressure-ratio with the actuation-time of the servo-intake-valve; said servo-intake-valve is opened for 5-60 degree of crankshaft rotation and is shut at a point between 90 degree BTC and 10 degree BTC according to instruction signals from the engine control unit; wherein the compressor-transmission is set to provide a higher airflow and said servo-intake-valve is shut at an earlier crankshaft reference angle to increase the actual-pressure-ratio of the final-compression-process for operating the direct-power-cycle at a high power output, whereas the compressor-transmission is set to provide a lower airflow and said servo-intake-valve is shut at a later crankshaft reference angle to decrease the actual-pressure-ratio of the final-compression-process for operating the direct-power-cycle at a lower power output.

Owner:HU LUNG TAN

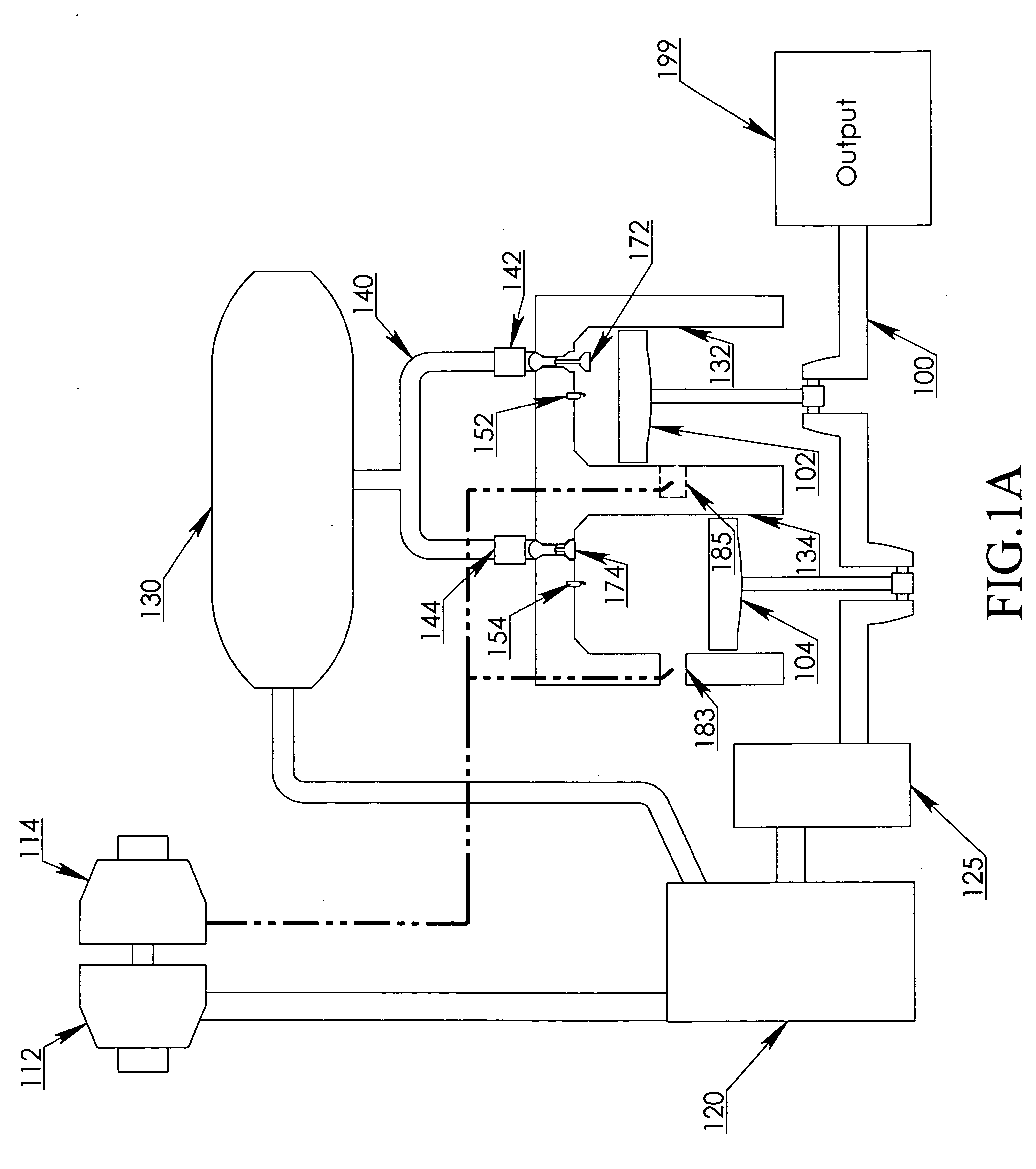

Method for the production of a workpiece and grinding machine

ActiveCN101637878ACheap manufacturingShort processing timeEdge grinding machinesAbrasion apparatusEngineeringMachining process

The invention relates to a method for the production of a rotor of a rotary screw compressor (1) with a cylindrical basic shape, which has a helical profile (2) at its outer circumference, wherein the method comprises the steps of: a) Pre-processing of the workpiece (1) by bringing in the profile (2), wherein the profile (2) has a stock compared with the finished shape, b) Pre-grinding of the profile (2) by a rough-machining process in a grinding machine, wherein a part of the stock is removed and c) Finish-grinding of the profile (2) by a finish-machining process in the grinding machine, wherein the remainder of the stock is removed and the finished shape of the profile (2) is produced. To improve the efficiency of the production especially of rotors of rotary screw compressors and ensure a high quality of the production the invention is characterized in that the pre-grinding and / or the finish-grinding is carried out with a grinding worm (3) by a continuous generative grinding process.

Owner:KAPP GMBH & CO KG WERKZ MASCHFAB

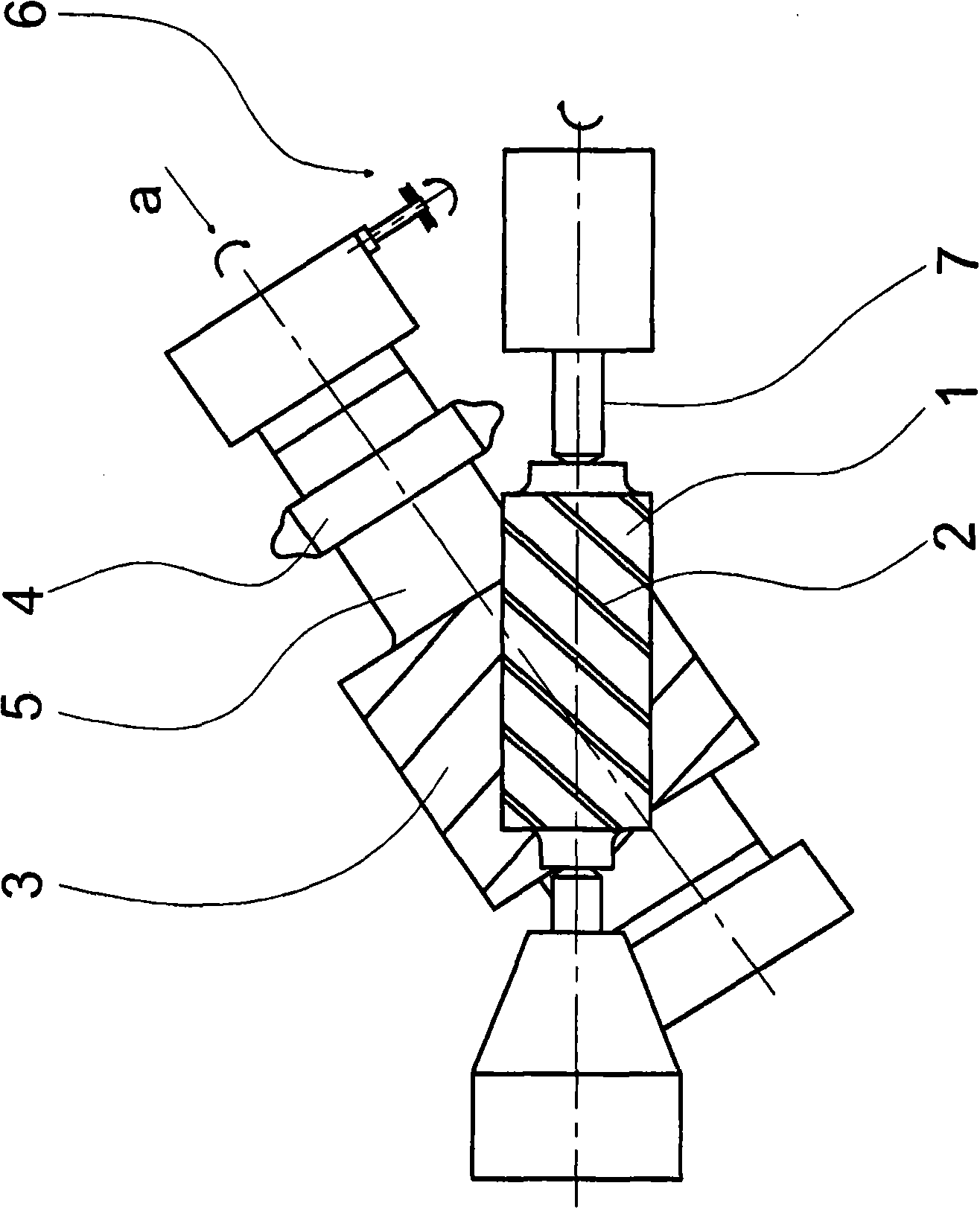

Portable Generator and Air Compressor Mounting Arrangement

A system, in one embodiment, may include a chassis, an engine coupled to the chassis, a generator coupled to the engine, and a rotary screw compressor coupled to the chassis independent from the engine. The engine may be configured to drive both the generator and the rotary screw compressor. A method, according to another embodiment, may include isolating a rotary air compressor from an engine and a generator in a common chassis. The isolating may include separately mounting the rotary air compressor and the engine with a resilient or distance adjustable connection in between. The isolating also may include resiliently mounting the engine, or the rotary air compressor, or both.

Owner:ILLINOIS TOOL WORKS INC

Cooling system for a rotary screw compressor

InactiveUS7334428B2Compression machines with non-reversible cycleCompression machines using turbinesEngineeringRefrigerant

A compressor system has a compression stage, a coolant circuit and a refrigerant circuit. The compression stage compresses ambient air and generates compressed air and heat. A coolant removes heat from the compression stage and the heat is transferred from the coolant to a refrigerant. A refrigerant expansion device is incorporated into the refrigerant circuit. The expansion device expands the pressurized refrigerant utilizing a rotary expander. Energy generated during refrigerant expansion is captured and used to drive components of the cooling system.

Owner:SULLAIR CORP

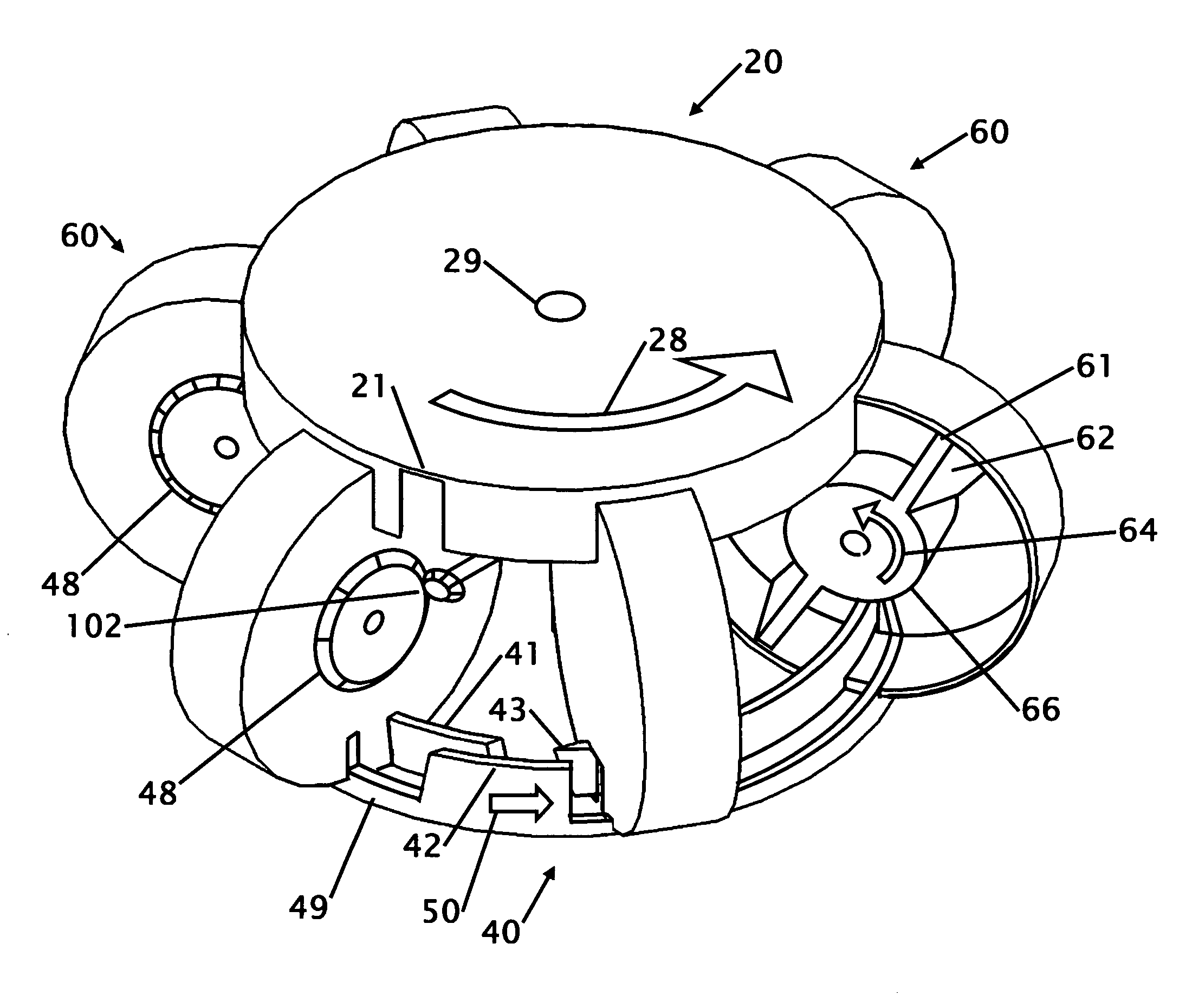

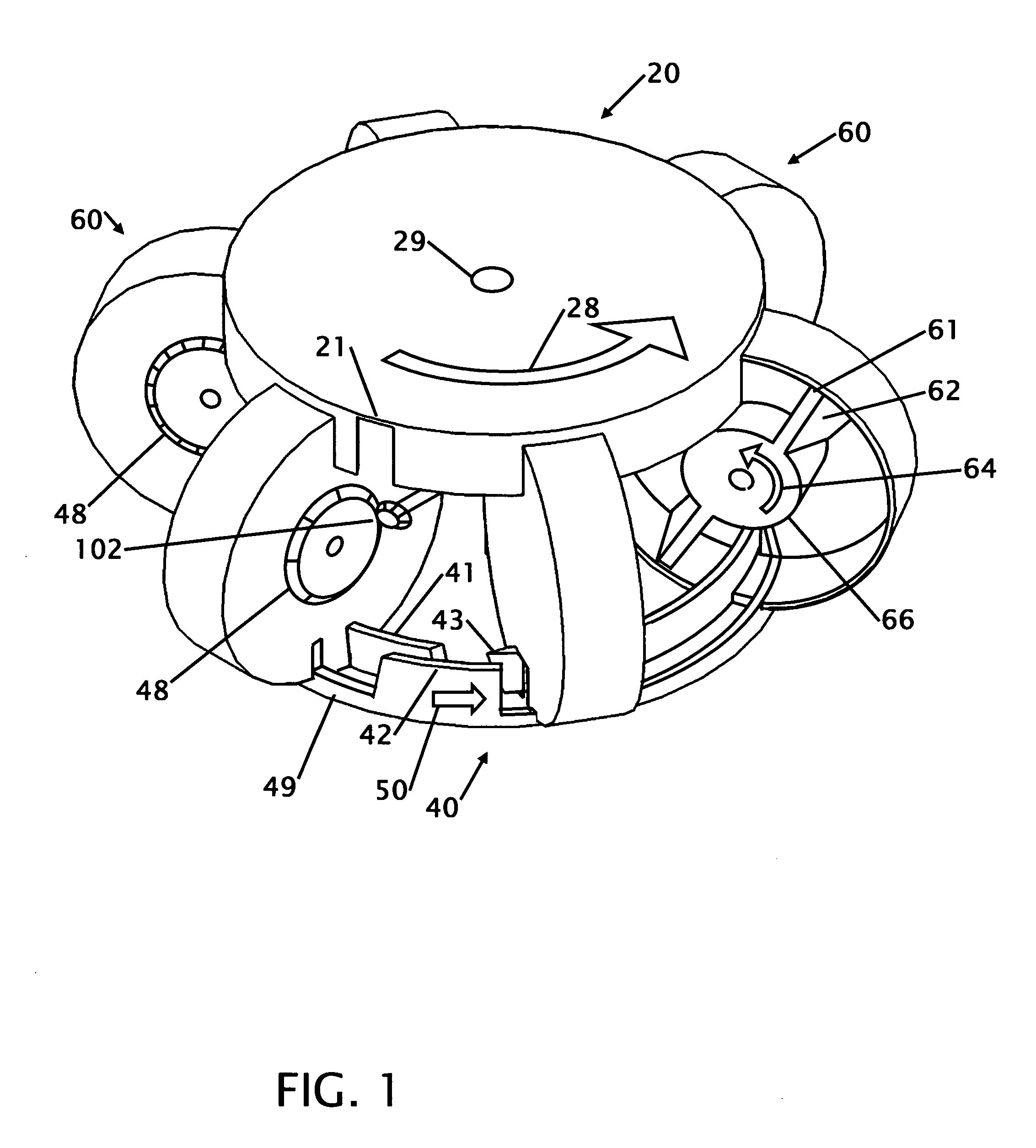

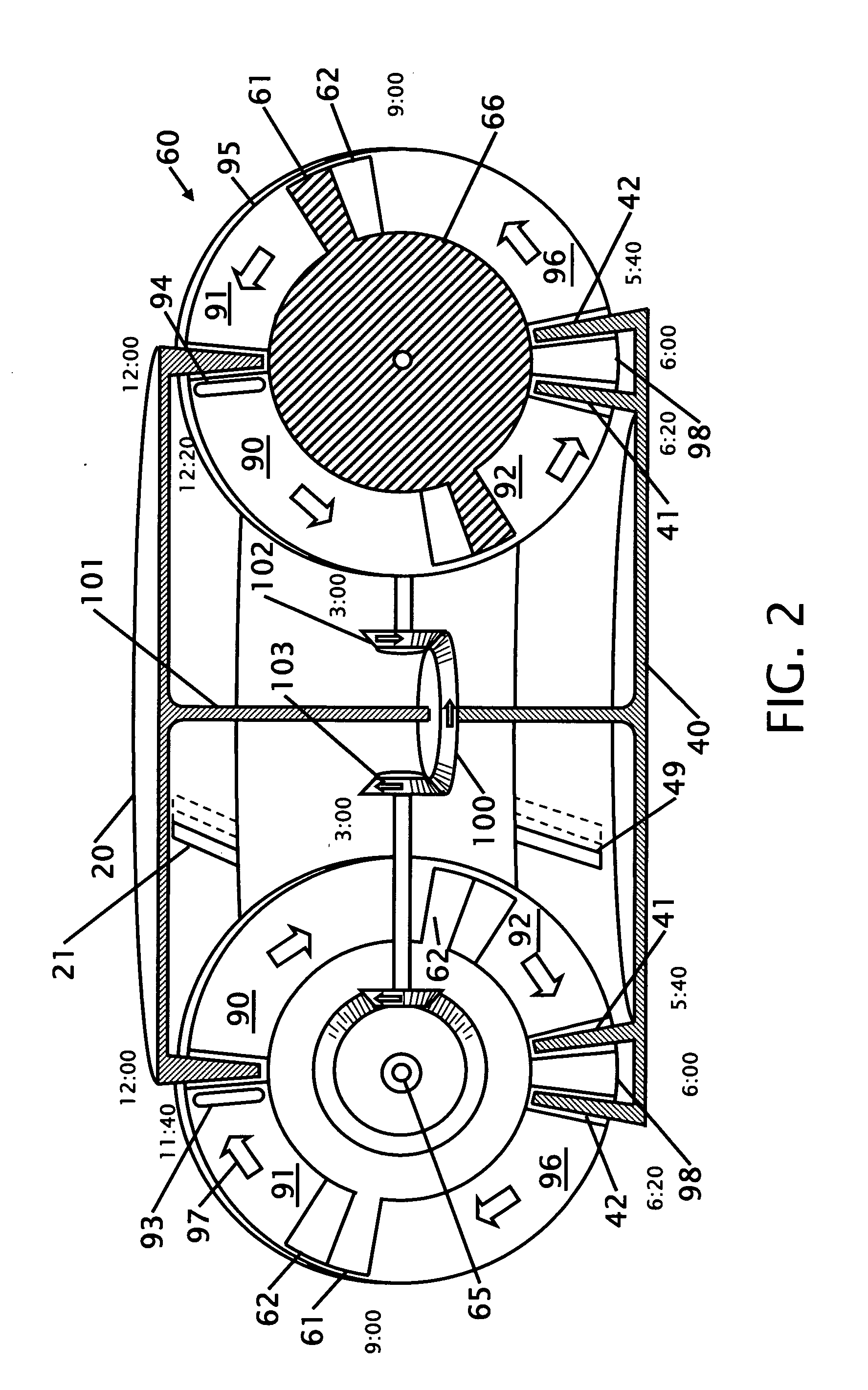

Rotary internal combustion engine and rotary compressor

InactiveUS20080202466A1Eliminate stressEliminate vibrationInternal combustion piston enginesOscillating piston enginesExternal combustion engineInternal combustion engine

The rotary internal combustion engine is a rotary internal combustion engine that uses the unique combination of multiple rotors on a vertical axis with piston vanes, which are intersected by horizontally oriented valve rings so that rotating rotors intersect gaps on the rotating valve rings, thus creating the intake compression and power and exhaust cycles on this internal combustion engine. The unique design allows the motor to operation as either a motor or pump. High volume of compressed air virtually eliminates the need for a storage tank. These engines are an elegant solution that fulfills the century long quest for quiet, clean, highly efficient rotary power. When available, the demand for the benefits of rotary piston power in air, surface, and marine applications, will be immediate and rewarding.

Owner:WEBSTER RICHARD COLMAN

Compressor with a bypass port

ActiveUS20120027632A1Improve energy efficiencyPerformanceRotary piston pumpsRotary piston liquid enginesMechanical engineeringRotary-screw compressor

A system is provided for adjusting the volume ratio of a screw compressor. The system can use a port in a rotor cylinder to bypass vapor from the compression chamber to the discharge passage of the compressor. A valve can be used to open or close the port to obtain different volume ratios in the compressor.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

Screw compressor

ActiveUS20120156079A1Reduce power lossReduce power consumptionOscillating piston enginesEngine of counter-engagement typeDischarge pressureControl theory

A screw compressor including a driving machine having an output shaft coupled to an input shaft of a compressor main body; a clutch mechanism between the output shaft of the driving machine and the input shaft of the compressor main body; a pressure sensor installed in a discharge channel; and a controller that controls the switching of the clutch mechanism between an engaged state and a disengaged state based on a discharge pressure value detected by the pressure sensor is disclosed. When the discharge pressure value becomes higher than an unload set value that is predetermined, the controller controls the clutch mechanism to be switched to the disengaged state. According to the above screw compressor, power losses are reduced even when the supply of compressed gas is hardly required.

Owner:KOBELCO COMPRESSORS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com